1. Introduction

A monolithic blisk is a critical component of an aircraft engine (aero engine). In contrast to the traditional fan design, in which multiple removable blades are assembled on an individual disk, the design of a blisk entails integrating the blades of the blisk with the disk. This design can reduce weight, improve stability during high-speed revolutions, and improve the performance of engines. Moreover, the design obviates the necessity of assembling the blades and the disk during the production process, which improves manufacturing efficiency. Blisks can be manufactured using various methods; the most common method involves machining from solid material by using machine tools. However, because a blisk has a complex geometry and requires high temperatures and durability, it must have excellent mechanical properties. The requirements for material selection, processing environment, and precision in the manufacturing process are strict. Blisks are usually made from difficult-to-cut materials such as titanium and nickel-based alloys and require the use of multiaxis machine tools and complex toolpath planning by using suitable tools and cutting parameters.

Inconel 718 has been used frequently in blisk materials because of its superior mechanical properties. However, the machinability of Inconel 718 is relatively low owing to its extreme performance. This thermal-resistant alloy exhibits high strength and tends to exhibit strain hardening even at high temperatures, resulting in high cutting forces and extreme temperatures during machining. Traditional carbide tools wear quickly during machining, especially uncoated tungsten carbide inserts employed under dry conditions [

1]. Research has focused on improving the machining efficiency of Inconel 718 through the use of tool coatings, use of coolants, and optimization of cutting parameters [

2]. Liquid coolants, also known as cutting fluids, are used to cool the tool and workpiece by removing the heat generated during machining. Pereira et al. proposed the use of external MQL lubrication (CryoMQL) with CO2 as an internal coolant for the cryogenic cooling of Inconel 718 during milling [

3]. This ambient cooling method was demonstrated to engender increased tool life [

4]. Kursuncu et al. conducted cryogenic heat treatment on cemented carbide tools to increase their wear resistance and thus improve their cutting performance [

5].

Scholars have extensively discussed the effect of cutting conditions, including the tool material and geometry, feed rates, and radial depth of cuts, on tool life [

6]. Different cutting methods with various cutting parameters and machining strategies have been proposed for controlling tool wear [

7]. Moreover, a study introduced a laser preheating–assisted system and ultrasonically assisted system for optimizing cutting parameters and improving cutting performance [

8]. The computer-aided engineering (CAE) software was also used to predict the deformations and stresses of the spindle and cutting tools under external loads to evaluate the rationality of cutting conditions [

9,

10].

The first step of blisk machining entails rough milling, followed by the establishment of a boundary contour on the free surface of the blade [

11] and then the control of the tool axis and cutting path to remove the groove material [

12]. Traditional flank mills or barrel cutters are often used for machining [

13]. In rough machining, efficiency is essential. Studies have presented a plunge milling strategy or four-axis cycloid path for material removal to improve efficiency [

14,

15]. Although most studies on blisk machining have discussed roughing processes [

16], the blisk must be finished ultimately to achieve the required tolerance limits. A high-quality surfacbladenish and predictable, long tool life are critical considerations in blisk milling. Selecting the optimal machining parameters to obtain the desired surface quality and tool life is the most critical task in blisk finishing.

The aim of the present study was to optimize parameters for the finish machining of Inconel 718 alloy monolithic blisk blades. AlTiN-coated ball cone mills were used to machine the surfaces of the blades at a constant depth. The study also investigated the effects of two manipulated cutting parameters: cutting speed and feed per tooth. Cutting force signals during the machining process were collected using a sensory tool holder, and tool wear was observed under a digital microscope. The relationship between cutting conditions and machining efficiency was analyzed. The study results can serve as a reference in the optimization of parameters for the finish machining of blisk blades.

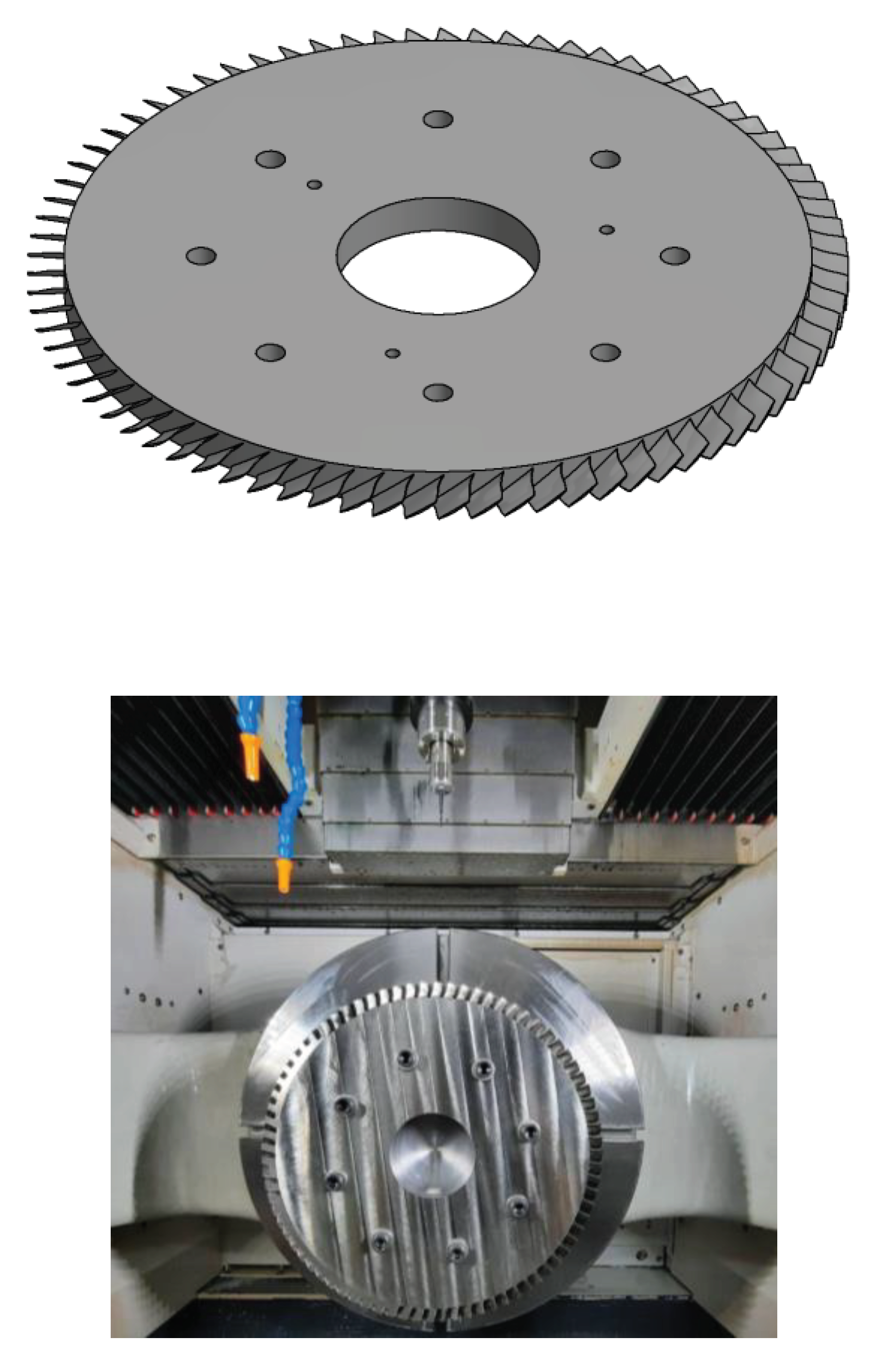

2. Machining of Blisk Blades

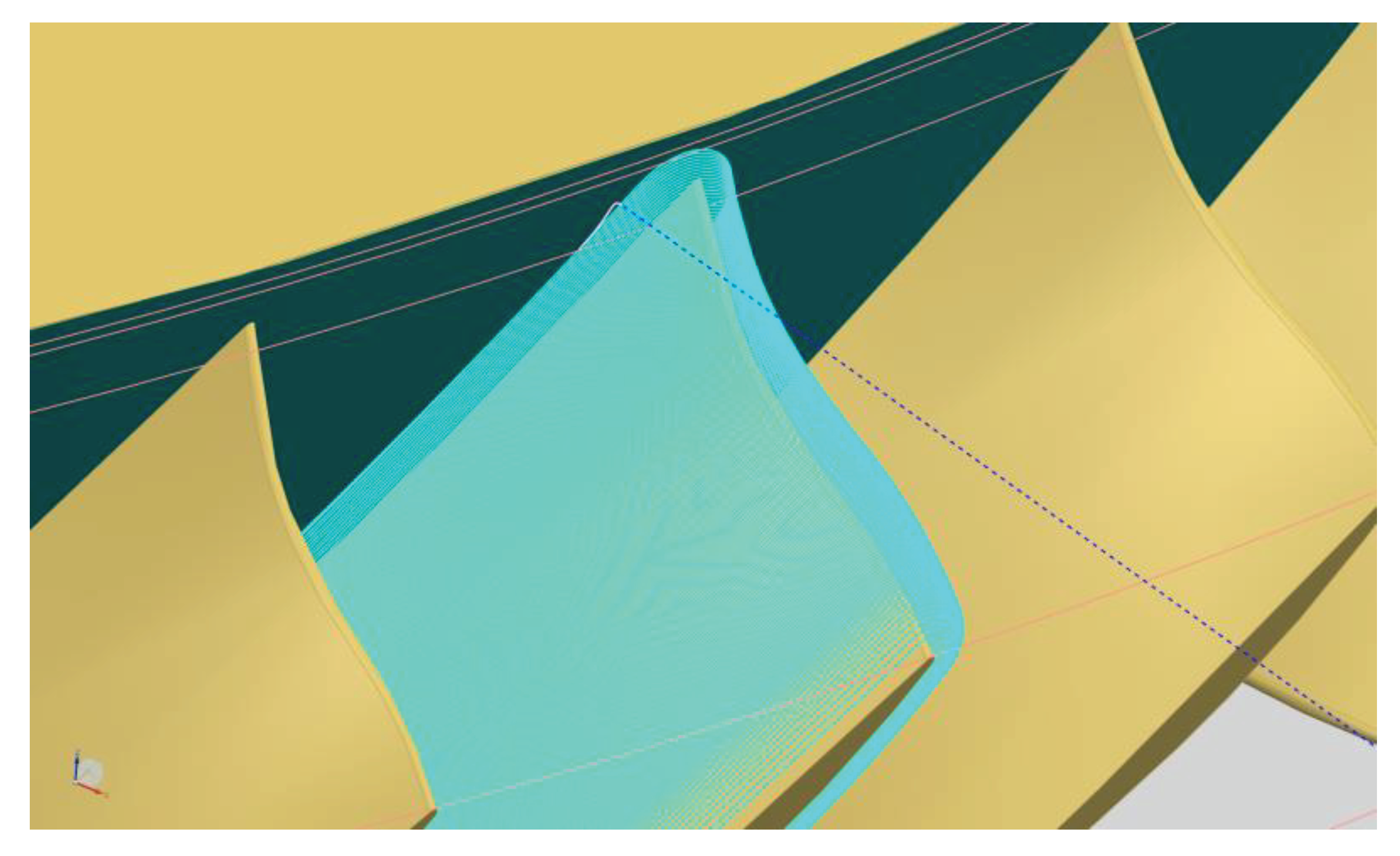

Figure 1 depicts a computer-aided design (CAD) model and solid model of a typical monolithic blisk. A nickel-based alloy was subjected to rough machining and grooving processes to produce the blisk; subsequently, the finishing path of the blade was planned according to the shape of the machined blisk by using the impeller module in NX software, as illustrated in

Figure 2. The driving method was blade finishing milling. In the multi-axis machining of NX, in order to better control the inclination angle of the tool axis, we can set the lead angle and tilt angle according to the direction of the tool path. Previous studies disclosed that when the inclination angle is 25° in machining, the workpiece will have better surface roughness [

17]. After selecting the blade surface, we set the tilt angle of the tool to 0.2° and set the minimum lead angle to −30°. A negative lead angle value indicates that the tool is tilted backward relative to the tool path direction. The tool axis was automatically determined by the NX program. After the toolpath was completed, VERICUT—a virtual cutting program—was used for verification to avoid the interference in the toolpath and prevent collisions.

Figure 3 presents the relationship between the tool axis and the blade surface in VERICUT.

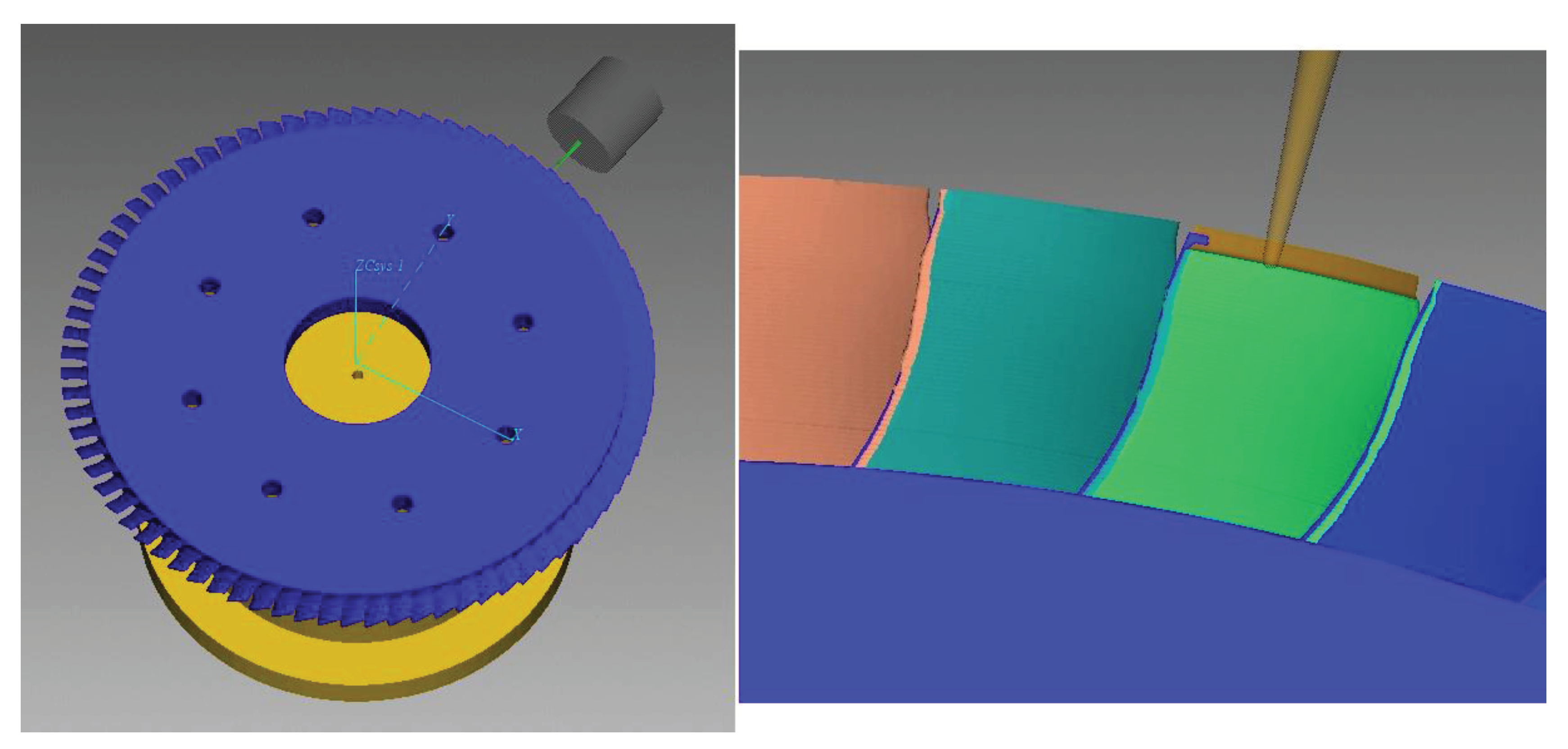

2.1. Blisk Machining Parameters

The outer diameter of the blisk was 364 mm, the outer diameter of the hub was 331.5 mm, the length of the blade was 16.25 mm, the thinnest part of the blade was approximately 0.23 mm, the thickest part of the blade was approximately 1.59 mm, the groove width was approximately 6.46 mm, and the number of blades was 78. The primary dimensions are presented in

Figure 4.

2.2. Material

Inconel 718 has high strength and oxidation/corrosion resistance at elevated temperatures, rendering it suitable for high kinetic–energy and corrosion-resistant environments in the aerospace industry. Inconel 718 is primarily composed of nickel and chromium. Nickel can improve heat resistance and corrosion resistance, and chromium can improve oxidation resistance and sulfur resistance.

Table 1 lists the mechanical properties of Inconel 718, which were provided by the material supplier Xitron Innovation [

18].

2.3. Experimental Equipment

2.3.1. Machine Tool

The milling machine was a five-axis machining center CT-630 (Tongtai, Kaohsiung, Taiwan) equipped with a Siemens 840Dsl CNC controller.

2.3.2. Cutting Tools

The material of a cutting tool considerably influences the machining of Inconel 718 alloy blisks. The tool must have high thermal hardness, good ductility, high wear resistance, and high impact resistance. In this study, a tapered ball-nose end mill (Jen Wu Cheng Shun Turning Tools, Kaohsiung, Taiwan) was used for machining, as displayed in

Figure 5. Several studies on the machining of nickel-base alloys had showed that TiAlN coated tools have better tool life in high speed milling than other coatings, such as TiN and TiCN [

19]. Therefore, this study used TiAlN-coated. The specifications of the tool are presented in

Table 2 [

20].

2.3.3. Sensory Tool Holder

A sensory tool holder (pro-micron, Kaufbeuren, Germany) was used to measure cutting force signals [

21]. The sensory tool holder collected the axial cutting force, cutting torque, and x–y bending moment during the finish machining of the blisk blades and wirelessly sent the collected data to a computer. Because the tool axis was set to side milling during the cutting process, the bending moment was selected as the primary observation parameter. Polar diagrams of the bending moment in the x–y direction were used to observe the force in real time [

22]. The specifications of the sensory tool holder are presented in

Table 3.

2.3.4. Digital Microscope

A digital microscope (VHX900F, Keyence, Osaka, Japan) with depth-of-field synthesis and multiple illumination functions was used to examine the milling cutters during the experiments. The microscope was used to examine the wear of the cutting edge and the side edge after machining. The magnification of the microscope ranges from 20× to 1000×; we set the magnification to 100× to examine the tools.

3. Finish Machining Strategy and Method

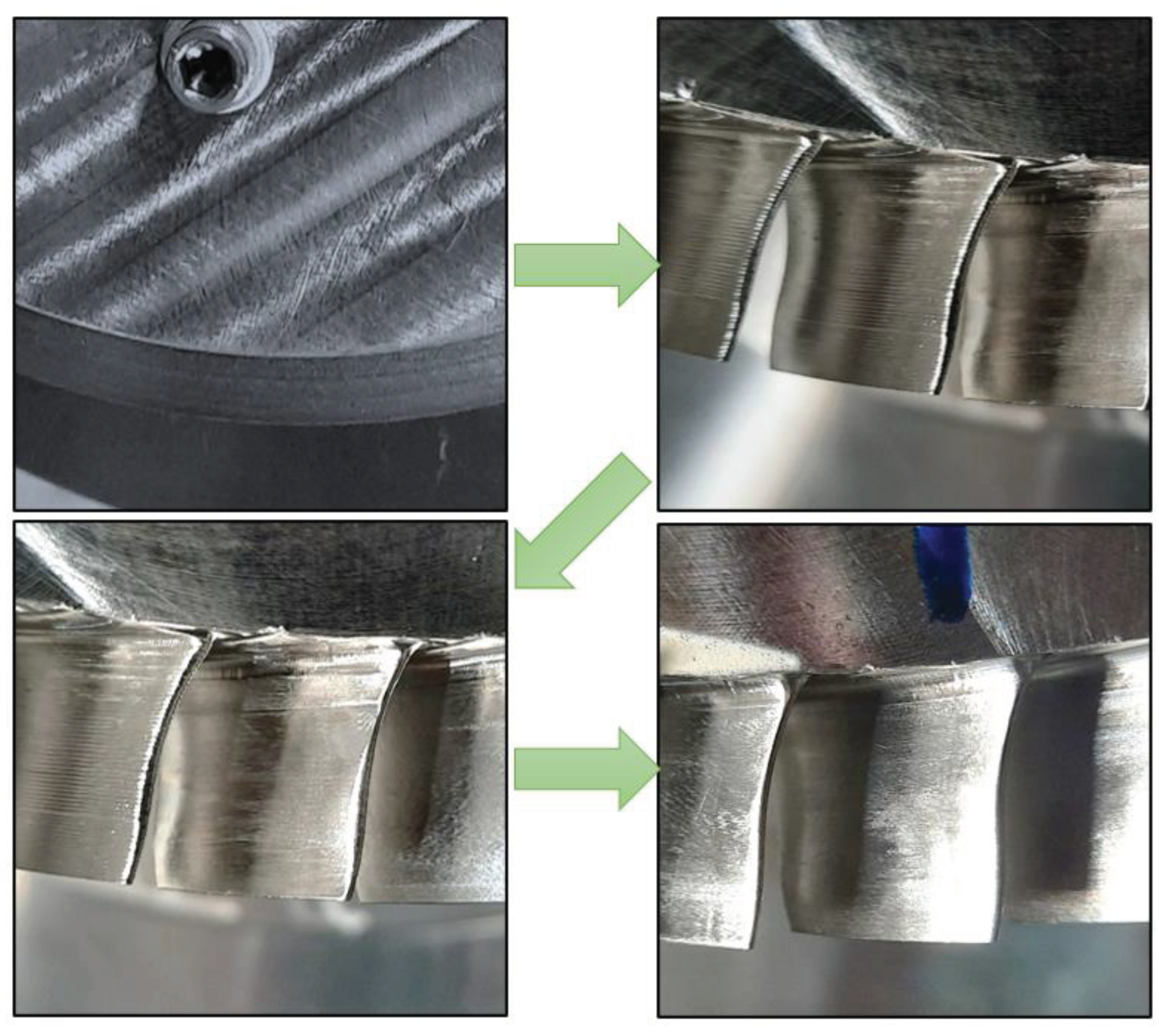

The machining strategy first involved rough machining on the blank and grooving using a torus milling cutter with D5R0.5. The thickest part of the blade was machined to a thickness of 2.18 mm. To ensure the surface quality, a ball-end mill with R2.0 was used for semifinish machining. Processed the thickest part of the blade to 1.78 mm with the machining allowance set to 0.1 mm. Finally, the tapered ball-nose end mill was used for finishing to the required dimensions 1.59 mm. The machining process is displayed in

Figure 6. During the machining process, we set different parameters for the cutting speed and feed per tooth to observe the cutting bending moment and tool wear.

3.1. Cutting Speed

3.1.1. Processing Conditions and Parameters

It was reported that feed has no significant effect on carbide cutter milling Inconel 718 [

17]. Nevertheless, cutting speed Vc is related closely to cutting force and tool wear. An appropriate range of cutting speed for side milling has been proposed in the literature. Hence, in our experiments, the depth of cut Ap and feed per tooth Fz were fixed, and different cutting speeds were set (ranging from 26 to 96 m/min). The effective cutting speed Ve during the cutting process is very important. It is calculated based on the effective diameter De, as shown in

Figure 7 [

23].

Where Dc is the ball nose diameter. φ is the inclination angle of the tool. Because the lead angle is set to -30° in the NX program, the maximum tool inclination angle is 30°. The maximum effective diameter De can be calculated to be 2.115mm. When the cutting depth is tiny, the effective cutting speed is much lower than the setting speed, and the tool cutting conditions will be lower than its application range. Therefore, this study recalculated the effective cutting speed Ve.

Thus, eight experiments were performed. The effective cutting speeds after recalculation were listed in

Table 4. Each experiment was a complete process in which a new tool was used for blade cutting. In Experiment 7, the cutting speed was originally set to 86 m/min, and the spindle speed was set to 9125 RPM, which resonated with the machine. Therefore, the cutting speed was increased to 91 m/min in this experiment. Under the fixed feed per tooth, an increase in the cutting speed also engendered an increase in feed, which reduced the time required for processing.

3.1.2. Cutting Signal Capture and Analysis

During the machining process, cutting force signals were captured by the sensory tool holder. Because the toolpath involved side milling using a side rake, the tool was mainly subjected to lateral forces. The bending moment was thus used as the basis for evaluating the cutting condition. The toolpath progressed from the periphery of the blade to the hub on a layer-by-layer basis along the blade surface, as illustrated in

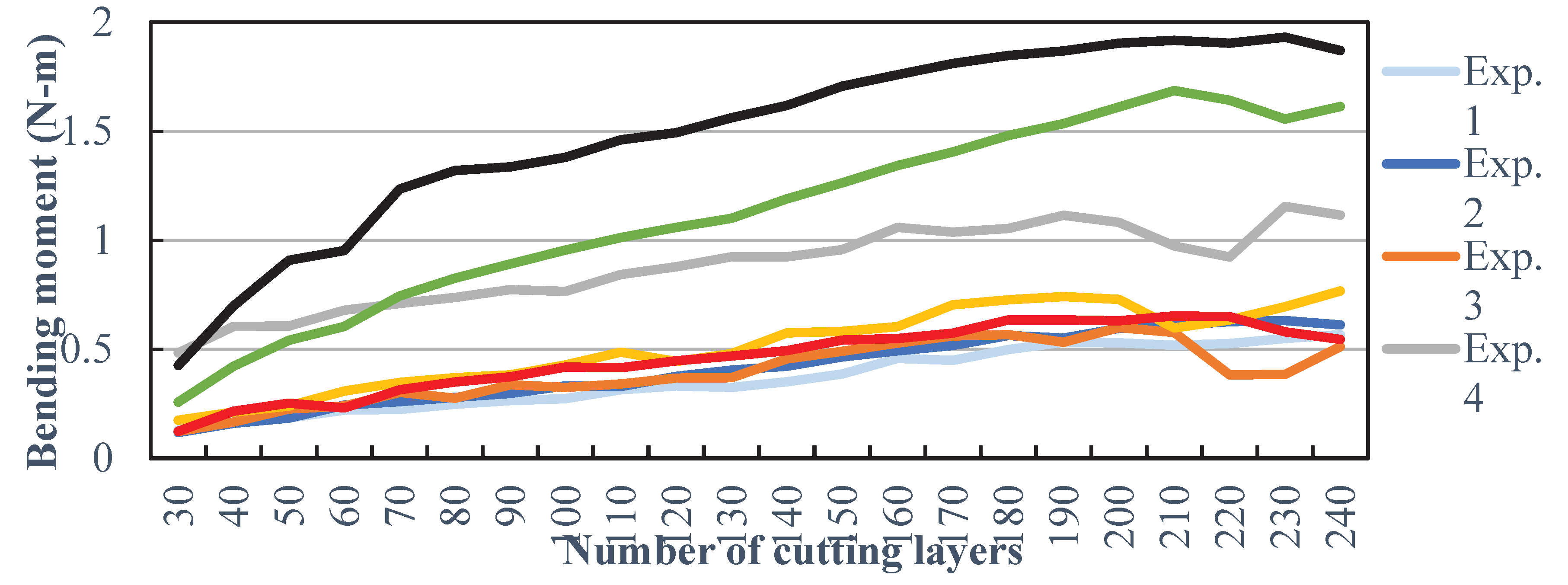

Figure 2. The bending moment signals captured in each experiment were recorded on the basis of the cutting layer, as shown in

Figure 8. The bending moments recorded in Experiments 4, 7, and 8 increased, and those captured in the other experiments remained relatively stable.

3.1.3. Tool Wear and Cutting Moment

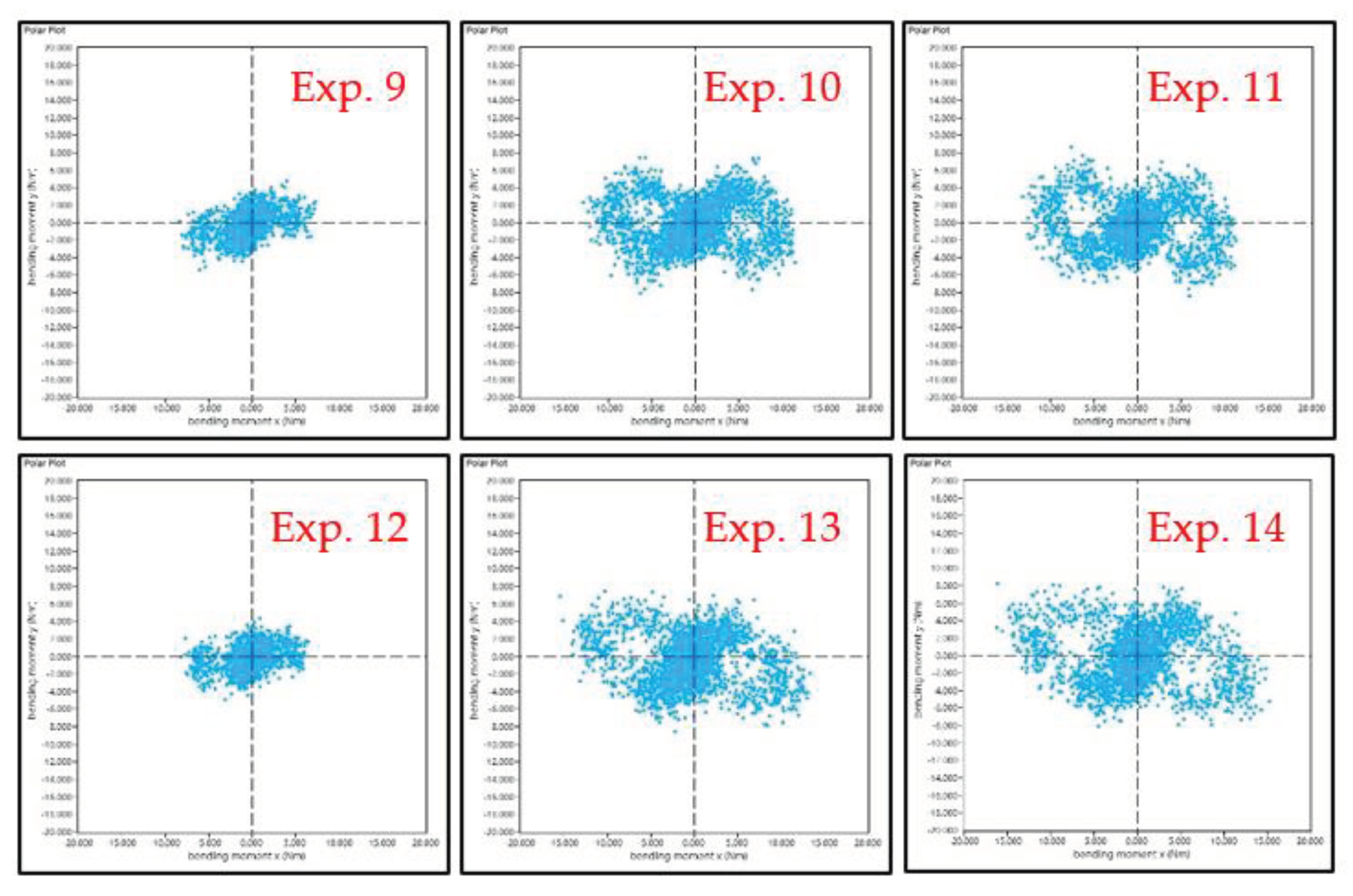

The captured bending moment signals during processing in the x direction and y direction were plotted on the x- and y-axes, respectively, and a polar diagram of the bending moment signals was generated, as displayed in

Figure 9. The size and distribution of the plots on the polar diagram were examined to determine the cutting force and damage to the tool die. According to the distribution of the plots, Experiments 1–3 exhibited the most concentrated and uniform distributions, indicating that the force in the cutting process was average and stable. The graphs of Experiments 7 and 8 were relatively scattered and revealed that the cutting edge was 2. The data revealed that the bending moment increased. Tool wear was observed under a digital microscope with a magnification of 100×, as depicted in

Figure 10. Because of the setting of the tool axis (

Figure 3), the contact area between the tool and the blade was on the side cutting edge of the front end of the tool. The most severe wear occurred on the flank of the side edge. The tool flank in Experiments 4, 7, and 8 demonstrated severe wear, which corresponded to an increase in bending moment (

Figure 7).

3.2. Feed Per Tooth

3.2.1. Processing Conditions and Parameters

According to the experimental results regarding cutting speeds, we also considered tool wear and machining efficiency. Cutting speeds of 66 and 76 m/min were selected as the reference, and the feed per tooth was adjusted. The machining parameters were determined and are presented in

Table 5. A new tool was used for each experiment.

3.2.2. Cutting Signal Capture and Analysis

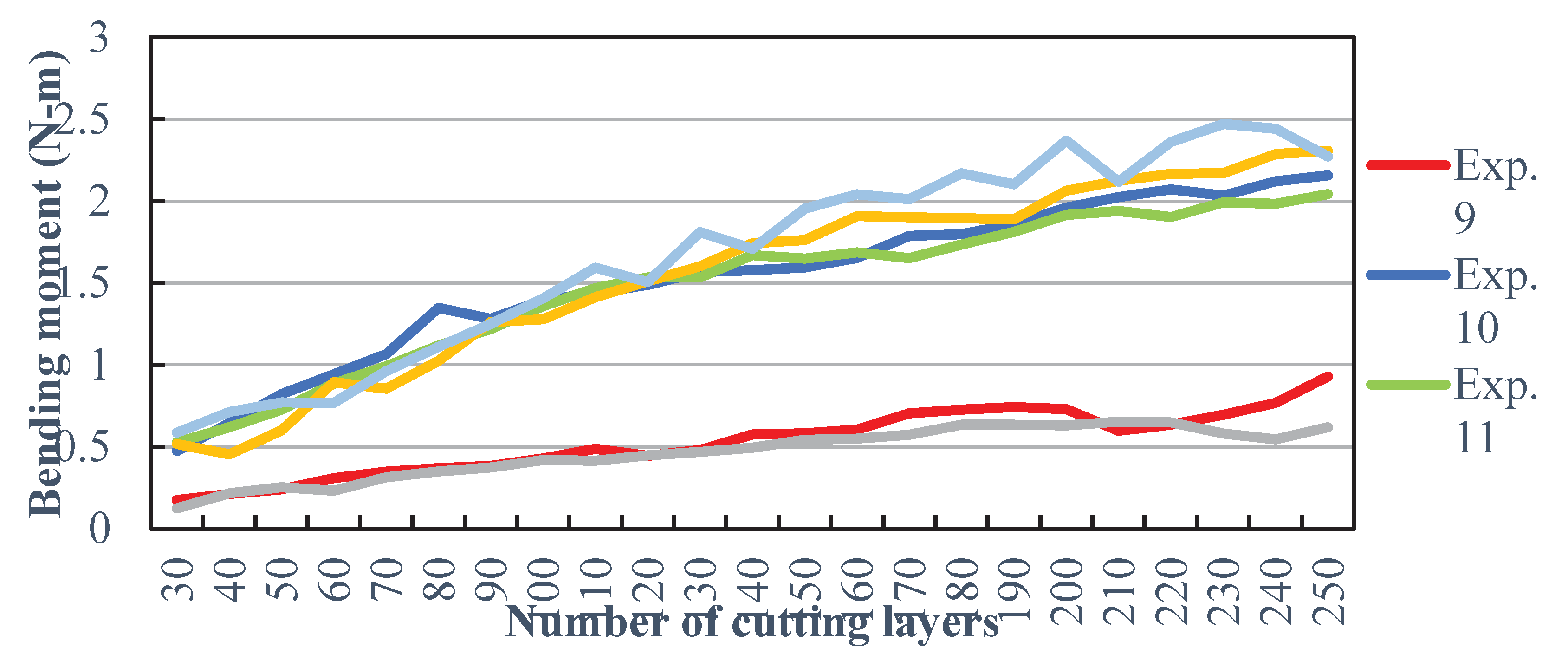

As presented in

Figure 11, Experiments 9 and 12 yielded lower bending moment curves than did the other experiments. When the feed per tooth was set to 0.05 mm, less cutting force was observed. The cutting forces at a feed per tooth of 0.1 and 0.075 mm were similar.

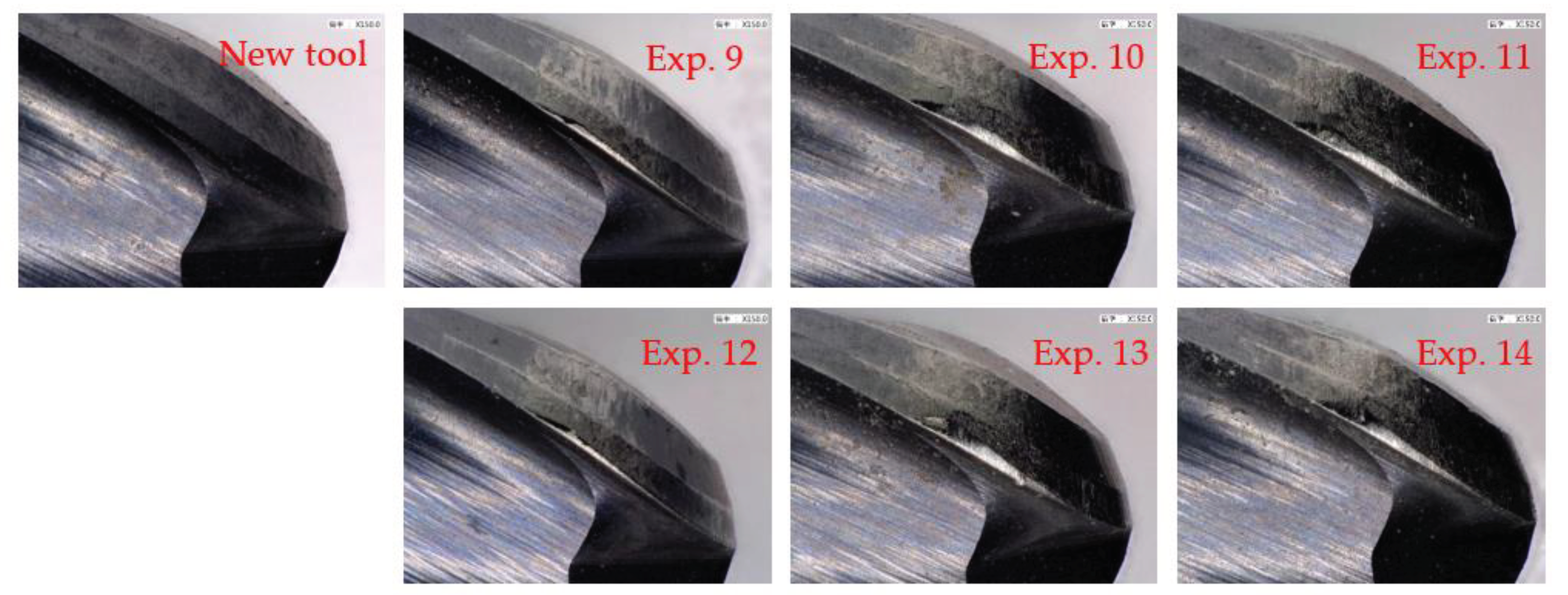

3.2.3. Tool Wear and Cutting Moment

According to the polar diagram of the bending moment, the distributions observed for Experiments 9 and 12 were more concentrated than those observed for the other experiments (

Figure 12). The other diagrams revealed a relatively large cutting force, and the tool may break at dense points. The tool exhibited various degrees of wear under magnification, as illustrated in

Figure 13. Experiments 9 and 12 yielded relatively low wear, which may be due to their small bending moment.

4. Tool Life Test

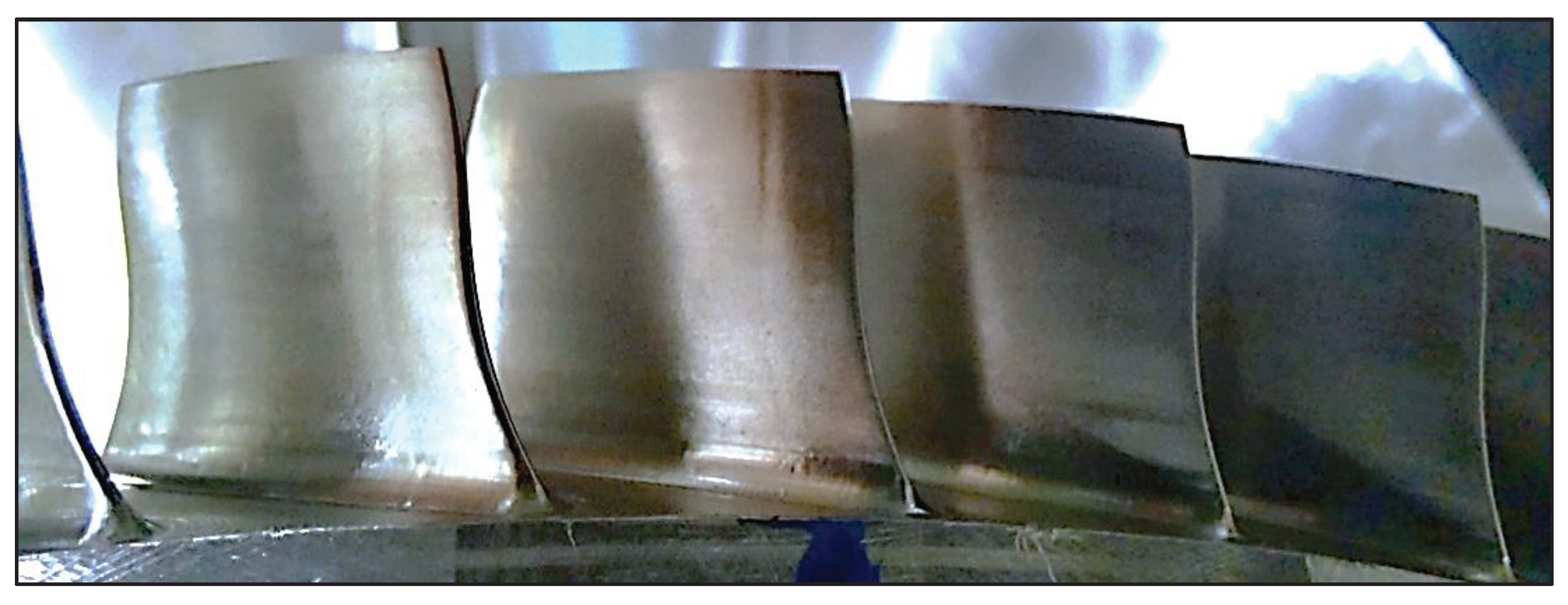

Through basic cutting experiments, we determined the relationship between cutting parameters, bending moments, and tool wear. The experimental results could be used to evaluate machining efficiency and surface roughness requirements. For mechanical efficiency considerations, this study expected the blade surface roughness to reach a satin finish, which means the roughness requirement is RZ6.3. We measured the finished surface roughness, as shown in

Figure 14. According to the measurement results, we explored reasonable machining parameters that could be used to test the tool life.

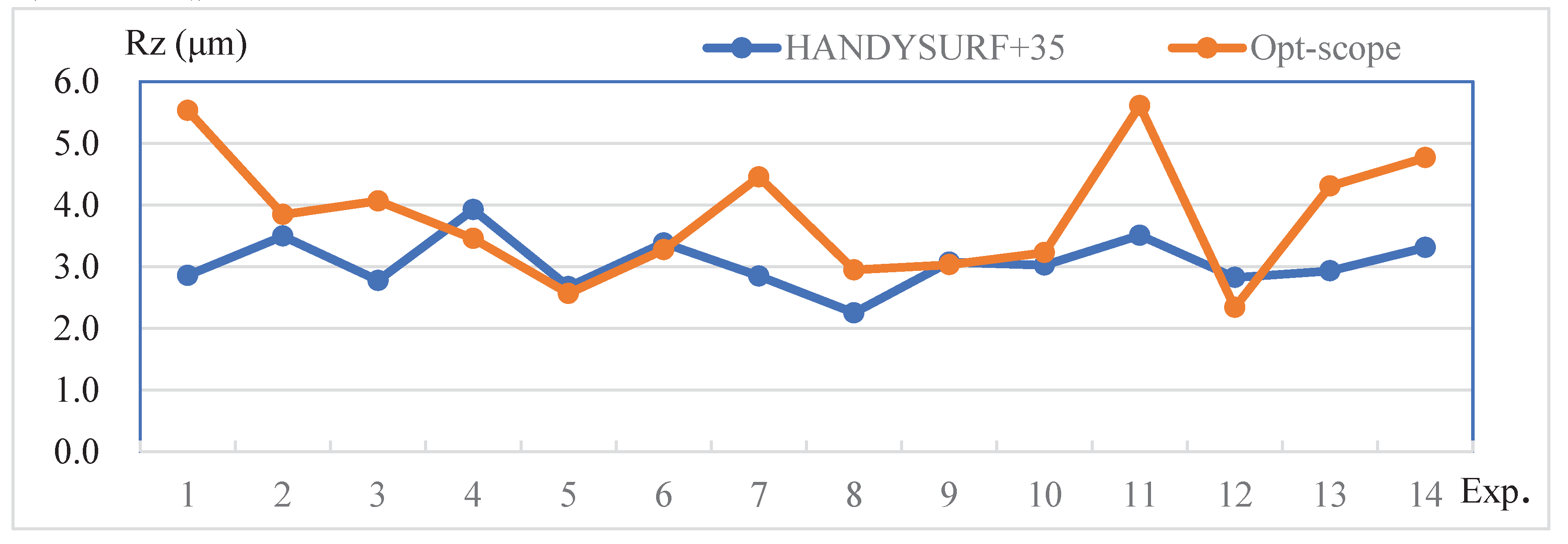

4.1. Assessment of Surface Roughness

Currently, two methods are widely used in the aerospace industry to measure surface roughness: contact and noncontact. We used the noncontact method by portable surface texture measuring instrument for online measurement during processing. The instrument was HANDYSURF+35 (TOKYO SEIMITSU, Tokyo, Japan) and its resolution can reach 0.0007μm. Each blade was measured three times to get the average. Non-contact 3D white light interferometer microscope Opt-scope (TOKYO SEIMITSU, Tokyo, Japan) with a high vertical resolution of 0.01nm was used for offline measurement. We compared the results of the two measurement methods, as shown in

Figure 15. The results revealed that all processing results in Experiments 1–14 fulfilled the roughness requirements.

4.2. Repetitive Experiments

The basic cutting experiments revealed optimal machining parameters yielding small and stable cutting forces, which helped improve the surface quality of the blade. However, considering processing efficiency, one can adjust the machining parameters within an acceptable surface quality to shorten the machining time. We selected the parameters of Experiment 11 and performed repeated experiments by using the same tool 12 times (

Table 6) for tool life assessment.

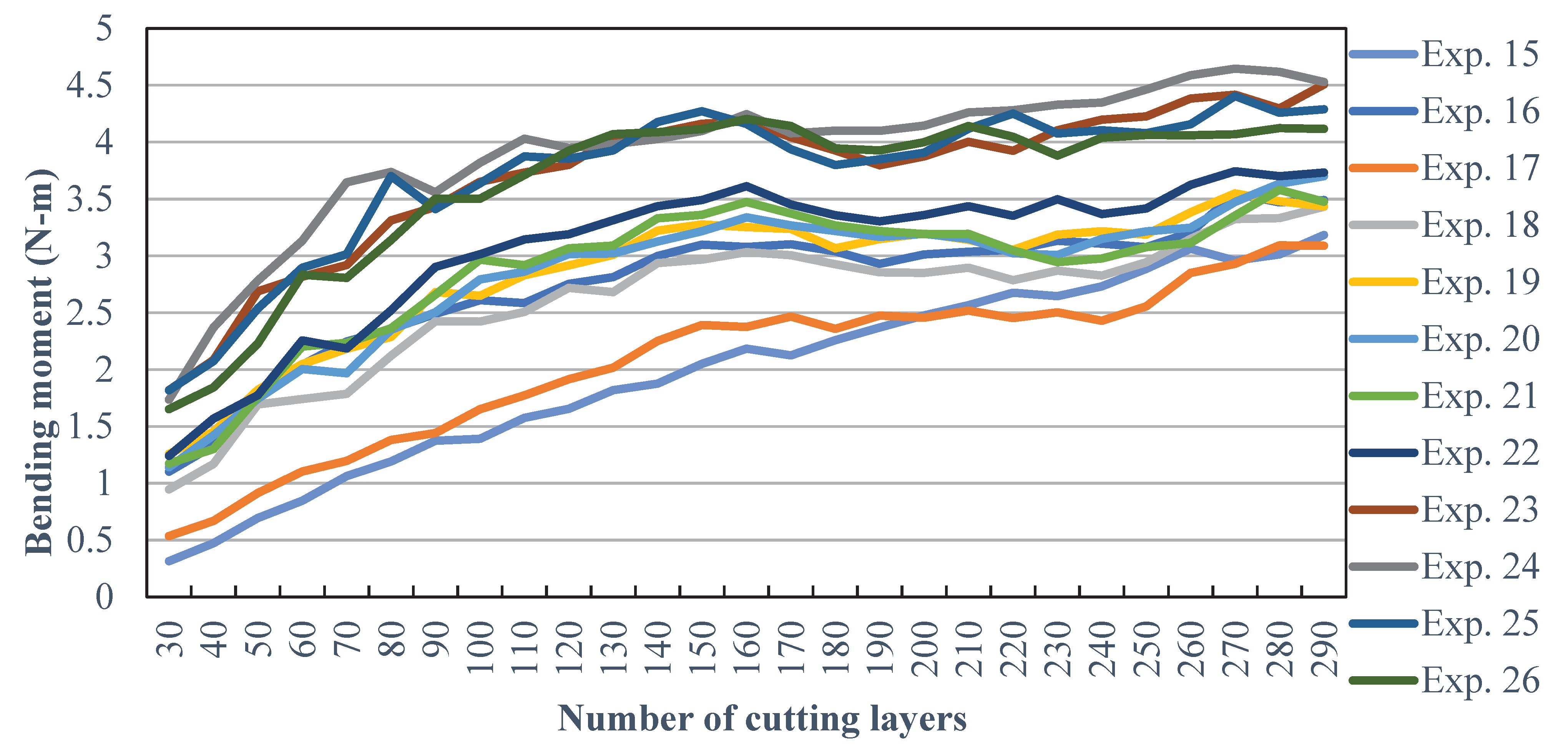

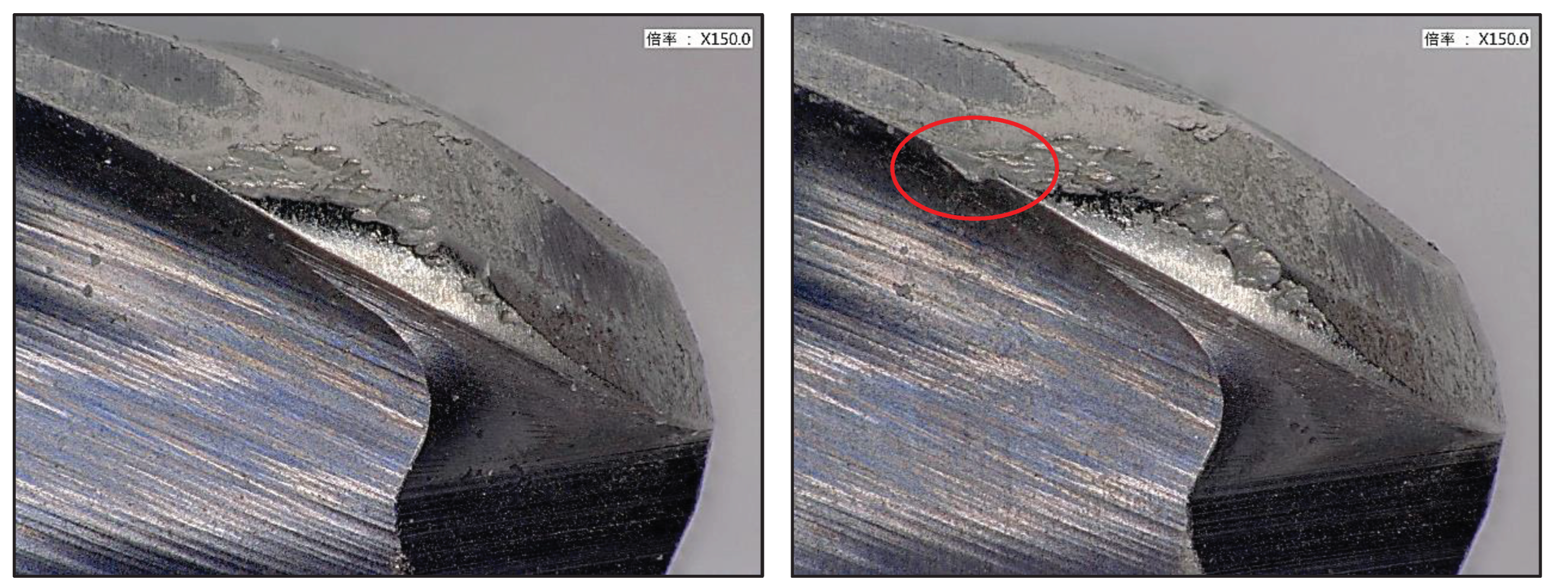

4.3. Bending Moment and Tool Wear

The cutting force increased steadily as the experiment progressed, as shown in

Figure 16. The bending moment demonstrated a step jump after Experiment 23. We assessed magnified images of the tool and detected a crack on the flank of the tool after Experiment 23 (

Figure 17); this crack was indicated by the increase in bending moment. On the basis of the evaluation results, we determined that the tool life was approximately 8 blades under the selected surface quality and efficiency parameters.

5. Conclusions

In this study, we conducted basic cutting and tool life experiments to analyze cutting conditions in blisk finishing processes. Force signals collected by a sensory tool holder directly indicated the cutting forces, and the influence of machining parameters on the cutting forces was nonlinear; this could thus help us select efficient parameters. The bending moment diagram also accurately indicated tool wear, which could help us estimate the time required to change the tool. On the basis of our findings, we drew the following conclusions:

(1) A cutting speed between 66 and 76 m/min (effective cutting speed between 46 and 53 m/min) can provide a relatively low cutting force, which can short the machining time and maintain surface quality.

(2) A feed per tooth of 0.05 mm can provide a relatively low cutting force, and a feed per tooth of 0.075 and 0.1 mm can provide relatively high cutting forces with similar values.

(3) A cutting speed of 66 mm/min (effective cutting speed of 46 m/min) and feed per tooth of 0.1 mm can provide the most stable cutting force and the highest processing efficiency.

(4) Under the aforementioned conditions, a tapered ball-nose end mill can process a total of 8 blades.

Author Contributions

Conceptualization, M.-H.T. and J.-N.L.; methodology, M.-H.T.; software, T.-L.H. and D.-K.H.; validation, T.-H.C.; formal analysis, M.-H.T.; investigation, T.-H.C.; resources, J.-N.L.; data curation, D.-K.H.; writing—original draft preparation, D.-K.H.; writing—review and editing, M.-H.T.; supervision, T.-H.C.; project administration, M.-H.T.; funding acquisition, J.-N.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

This manuscript was edited by Wallace Academic Editing.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Alauddin, M.; El Baradie, M.; Hashmi, M. Tool-life testing in the end milling of Inconel 718. J. Am. Acad. Dermatol. 1995, 55, 321–330. [Google Scholar] [CrossRef]

- Kuo, C.; Su, S.; Chen, S. Tool life and surface integrity when milling inconel 718 with coated cemented carbide tools. J. Chin. Inst. Eng. 2010, 33, 915–922. [Google Scholar] [CrossRef]

- Pereira, O.; Urbikain, G.; Rodríguez, A.; Fernández-Valdivielso, A.; Calleja, A.; Ayesta, I.; De Lacalle, L.L. Internal cryolubrication approach for Inconel 718 milling. Procedia Manuf. 2017, 13, 89–93. [Google Scholar] [CrossRef]

- Pereira, O.; Celaya, A.; Urbikaín, G.; Rodríguez, A.; Fernández-Valdivielso, A.; de Lacalle, L.N.L. CO2 cryogenic milling of Inconel 718: cutting forces and tool wear. J. Mater. Res. Technol. 2020, 9, 8459–8468. [Google Scholar] [CrossRef]

- Kurşuncu, B.; Çay, V.V. Effect of deep cryogenic treatment on cutting performance in Inconel 718 milling. IENSC 2019, 948–953. [Google Scholar]

- Krain, H.; Sharman, A.; Ridgway, K. Optimisation of tool life and productivity when end milling Inconel 718TM. J. Am. Acad. Dermatol. 2007, 189, 153–161. [Google Scholar] [CrossRef]

- Szablewski, P.; Dobrowolski, T.; Chwalczuk, T. Optimization of Inconel 718 milling strategies. Mechanik 2019, 92, 824–826. [Google Scholar] [CrossRef]

- Lin, S.Y.; Yang, B.H. Experimental Study of Cutting Performance for Inconel 718 Milling by Various Assisted Machining Techniques. Solid State Phenom. 2019, 294, 129–134. [Google Scholar] [CrossRef]

- Hong, C.C.; Chang, C.L.; Ou, N.R.; Lin, C.Y. CAE Analysis of Primary Shaft Systems in Great Five-Axis Turning-Milling Complex CNC Machine. Proc. eng. technol. innov. 2019, 12, 01–08. [Google Scholar]

- Hong, C.C.; Chang, C.L.; Huang, C.C.; Yang, C.C.; Lin, C.Y. CAE Analysis of Secondary Shaft Systems in Great Five-axis Turning-Milling Complex CNC Machine. Adv. technol. innov. 2017, 3, 43–50. [Google Scholar]

- Hu, C.G.; Zhang, D.H.; Ren, J.X.; Yang, L. Research on the 5-axis Machining of Blisk. Mater. Sci. Forum 2006, 532-533, 612–615. [Google Scholar] [CrossRef]

- Huang, J.C.; Liu, X.L.; Yue, C.X.; Cheng, Y.N.; Zhang, H. Tool Path Planning of 5-Axis Finishing Milling Machining for Closed Blisk. Mater. Sci. Forum 2012, 723, 153–158. [Google Scholar] [CrossRef]

- Lu, Y.A.; Ding, Y.; Wang, C.; Zhu, L. Tool path generation for five-axis machining of blisks with barrel cutters. Int. J. Prod. Res. 2018, 57, 1300–1314. [Google Scholar] [CrossRef]

- Shan, C.W.; Zhang, D.H.; Ren, J.X.; Hu, C.G. Research on the Plunge Milling Techniques for Open Blisks. Mater. Sci. Forum 2006, 532–533, 193–196.

- Luo, M.; Hah, C.; Hafeez, H.M. Four-axis trochoidal toolpath planning for rough milling of aero-engine blisks. Chin. J. Aeronaut. 2018, 32, 2009–2016. [Google Scholar] [CrossRef]

- Chen, T.H.; Lee, J.N.; Tsai, M.H.; Shie, M.J.; Lin, C.Y. Optimization of milling parameters based on five-axis machining for centrifugal impeller with titanium alloy. J. Physics: Conf. Ser. 2022, 2345. [Google Scholar] [CrossRef]

- Liao, Y.; Lin, H.; Wang, J. Behaviors of end milling Inconel 718 superalloy by cemented carbide tools. J. Am. Acad. Dermatol. 2008, 201, 460–465. [Google Scholar] [CrossRef]

- Xitron Innovation, Co. Ltd. https://www.ixitron.com/ (accessed 22). 20 October.

- Sharman, A.; Dewes, R.C.; Aspinwall, D.K. Tool life when high speed ball nose end milling Inconel 718™. J. Am. Acad. Dermatol. 2001, 118, 29–35. [Google Scholar] [CrossRef]

- Jen Wu Cheng Shun Turning Tool, CO. LTD. http://www.jsk-tools.com.tw/ (accessed 22). 20 October.

- Lu, Z.; Wang, M.; Dai, W. Machined Surface Quality Monitoring Using a Wireless Sensory Tool Holder in the Machining Process. Sensors 2019, 19, 1847. [Google Scholar] [CrossRef] [PubMed]

- Tsai, M.-H.; Lee, J.-N.; Shie, M.-J.; Deng, M.-H. Intelligent Performance Prediction of Flank Milling of Ti6Al4V Using Sensory Tool Holder. Sensors Mater. 2022, 34, 3241. [Google Scholar] [CrossRef]

- Daymi, A.; Boujelbene, M.; Linares, J.M.; Bayraktar, E.; Amara, A. Influence of workpiece inclination angle on the surface roughness in ball end milling of the titanium alloy Ti-6Al-4V. J. Achiev. Mater. Manuf. Eng. 2009, 35, 79–86. [Google Scholar]

Figure 1.

CAD Model and Solid Model of Monolithic Blisk.

Figure 1.

CAD Model and Solid Model of Monolithic Blisk.

Figure 2.

Blade Finishing Tool Path on NX.

Figure 2.

Blade Finishing Tool Path on NX.

Figure 3.

Tool Axis in VERICUT.

Figure 3.

Tool Axis in VERICUT.

Figure 4.

Dimensions of Monolithic Blisk (unit: mm).

Figure 4.

Dimensions of Monolithic Blisk (unit: mm).

Figure 5.

Tapered Ball Nose End Mill.

Figure 5.

Tapered Ball Nose End Mill.

Figure 6.

Blank → Roughing → Semi-Finishing → Finishing.

Figure 6.

Blank → Roughing → Semi-Finishing → Finishing.

Figure 7.

The effective cutting speed Ve for inclined milling.

Figure 7.

The effective cutting speed Ve for inclined milling.

Figure 8.

Bending Moments at Different Cutting Speeds.

Figure 8.

Bending Moments at Different Cutting Speeds.

Figure 9.

Bending Moment in Polar Coordinates at Different Cutting Speeds.

Figure 10.

This is a figure. Schemes follow the same formatting.

Figure 10.

This is a figure. Schemes follow the same formatting.

Figure 11.

Bending Moments at Different Feeds Per Tooth.

Figure 11.

Bending Moments at Different Feeds Per Tooth.

Figure 12.

Polar Coordinates of Bending Moment at Different Feeds Per Tooth.

Figure 12.

Polar Coordinates of Bending Moment at Different Feeds Per Tooth.

Figure 13.

Flank Wear at Different Feeds Per Tooth.

Figure 13.

Flank Wear at Different Feeds Per Tooth.

Figure 14.

Finished Blade Surface.

Figure 14.

Finished Blade Surface.

Figure 15.

Surface roughness measurement results.

Figure 15.

Surface roughness measurement results.

Figure 16.

Bending Moments in Repeated Experiments.

Figure 16.

Bending Moments in Repeated Experiments.

Figure 17.

Flank Wear After Experiments 22 (Left) and 23 (Right).

Figure 17.

Flank Wear After Experiments 22 (Left) and 23 (Right).

Table 1.

Mechanical Properties of Inconel 718.

Table 1.

Mechanical Properties of Inconel 718.

| Property |

Values |

| Density (g/cm3) |

8.19 |

| Poisson's Ratio |

0.29 |

| Young's Modulus (GPa) |

200 |

| Ultimate Stress (MPa) |

860 |

| Yield Stress (MPa) |

551 |

| Elongation (%) |

51.7 |

| Hardness (HRB) |

97.7 |

| Thermal Conductivity (W/m.K) |

11.2 |

Table 2.

Specification of Tapered Ball Nose End Mill.

Table 2.

Specification of Tapered Ball Nose End Mill.

| Property/Composition |

Values |

Shank Diameter (mm)

Tool Nose Ridus (mm)

Over length (mm)

Cutting length (mm)

Single Side Angel (degree)

Flutes

Material

Coating |

6

1.5

75

20

3

2

Tungsten Carbide

AlTiN |

Table 3.

Specification of Sensory Tool Holder.

Table 3.

Specification of Sensory Tool Holder.

| Property |

Values |

Measuring frequency (Hz)

Maximum allowable speed (rpm)

Operating temperature (℃)

Collet size

Spindle taper

Total length (mm) |

2500

18000

0–50

ER20

BBT-40

155 |

Table 4.

Machining parameters I.

Table 4.

Machining parameters I.

| |

Cutting Speed

Vc (m/min) |

Effective Cutting Speed

Ve (m/min) |

Feed per Tooth

Fz (mm/tooth) |

Depth of Cut

Ap (mm) |

Time

(min:sec) |

| Exp. 1 |

26 |

19.33 |

0.05 |

0.05 |

56:25 |

| Exp. 2 |

36 |

25.38 |

0.05 |

0.05 |

40:53 |

| Exp. 3 |

46 |

32.43 |

0.05 |

0.05 |

32:08 |

| Exp. 4 |

56 |

39.48 |

0.05 |

0.05 |

26:26 |

| Exp. 5 |

66 |

46.53 |

0.05 |

0.05 |

22:30 |

| Exp. 6 |

76 |

53.59 |

0.05 |

0.05 |

19:43 |

| Exp. 7 |

91 |

64.16 |

0.05 |

0.05 |

16:48 |

| Exp. 8 |

96 |

67.69 |

0.05 |

0.05 |

16:06 |

Table 5.

Machining parameters II.

Table 5.

Machining parameters II.

| |

Cutting Speed

Vc (m/min) |

Effective Cutting Speed

Ve (m/min) |

Feed per Tooth

Fz (mm/tooth) |

Depth of Cut

Ap (mm) |

Time

(min:sec) |

| Exp. 9 |

66 |

46.53 |

0.05 |

0.05 |

22:30 |

| Exp. 10 |

66 |

46.53 |

0.075 |

0.05 |

16:36 |

| Exp. 11 |

66 |

46.53 |

0.1 |

0.05 |

13:02 |

| Exp. 12 |

76 |

53.59 |

0.05 |

0.05 |

19:43 |

| Exp. 13 |

76 |

53.59 |

0.075 |

0.05 |

14:09 |

| Exp. 14 |

76 |

53.59 |

0.1 |

0.05 |

12:14 |

Table 6.

Machining parameters III.

Table 6.

Machining parameters III.

| |

Cutting Speed

Vc (m/min) |

Effective Cutting Speed

Ve (m/min) |

Feed per Tooth

Fz (mm/tooth) |

Depth of Cut

Ap (mm) |

Time

(min:sec) |

| Exp. 15~26 |

66 |

46.53 |

0.1 |

0.05 |

13:02 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).