Submitted:

01 April 2024

Posted:

01 April 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Preparation of Tellurium Flakes

2.2. Preparation of Tellurium Devices to Be Tested

2.3. Plasma Treatment of Tellurium Flakes

3. Results and Discussion

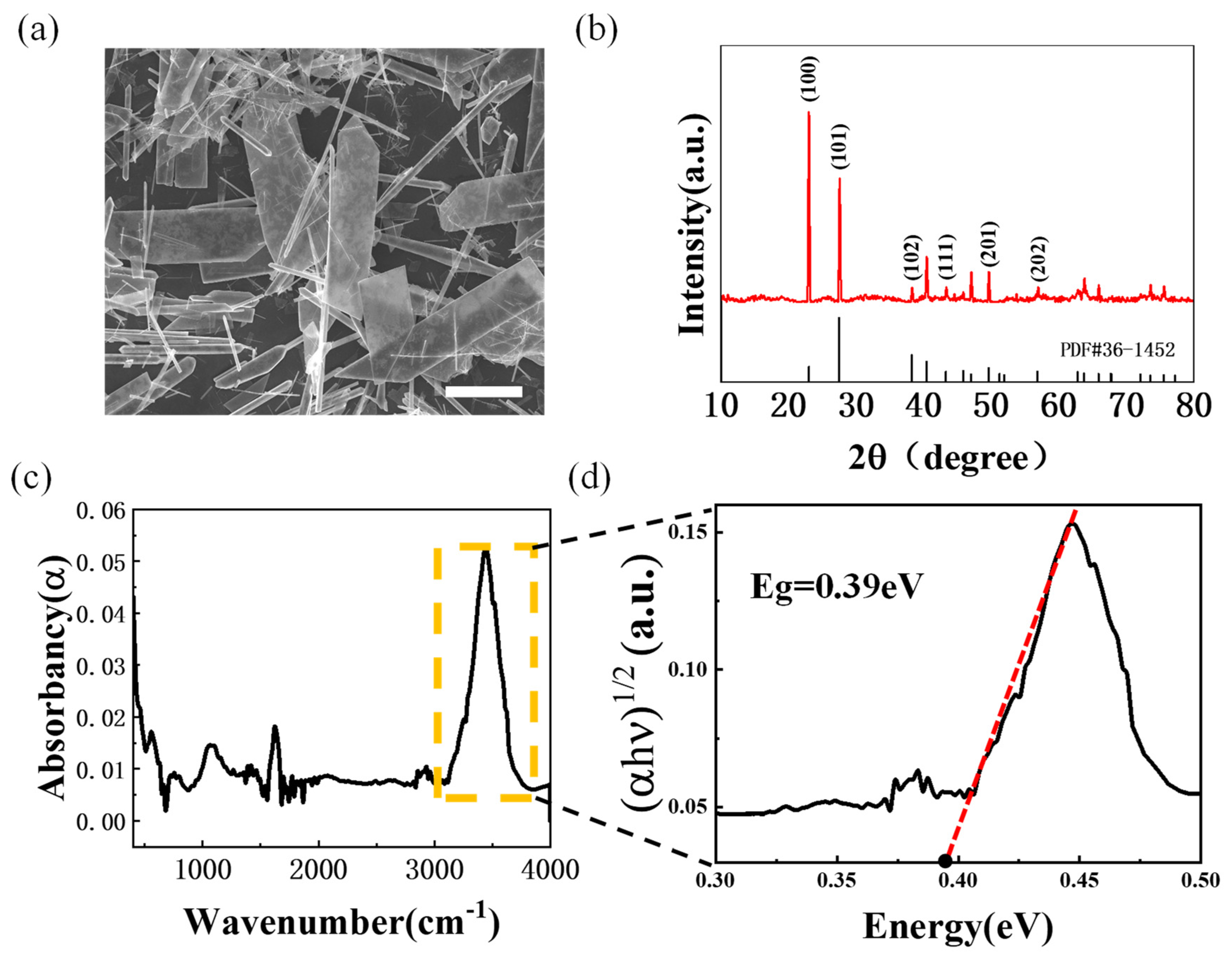

3.1. Crystal Morphology and Band Gap Characterization for the Pristine Tellurium Flakes

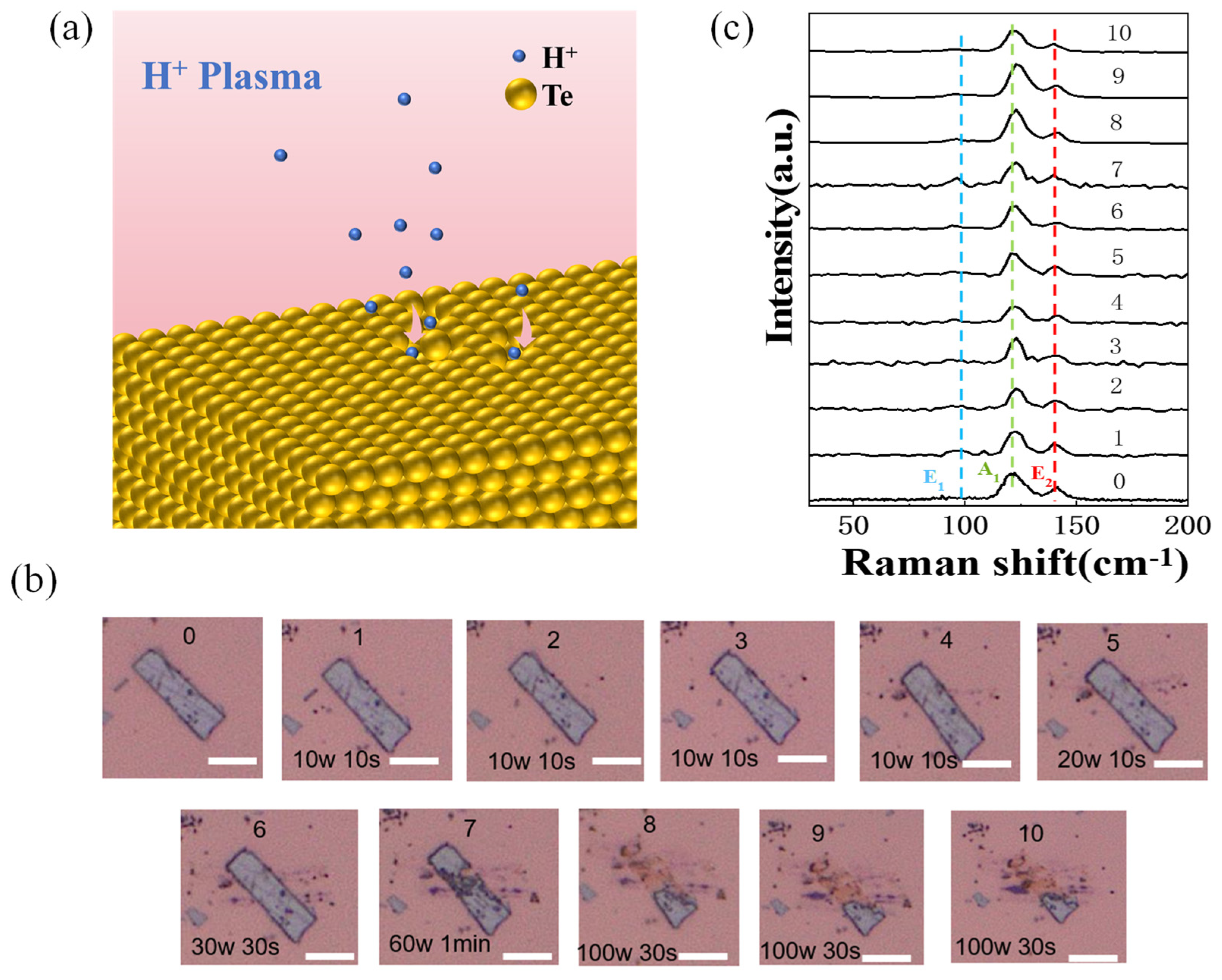

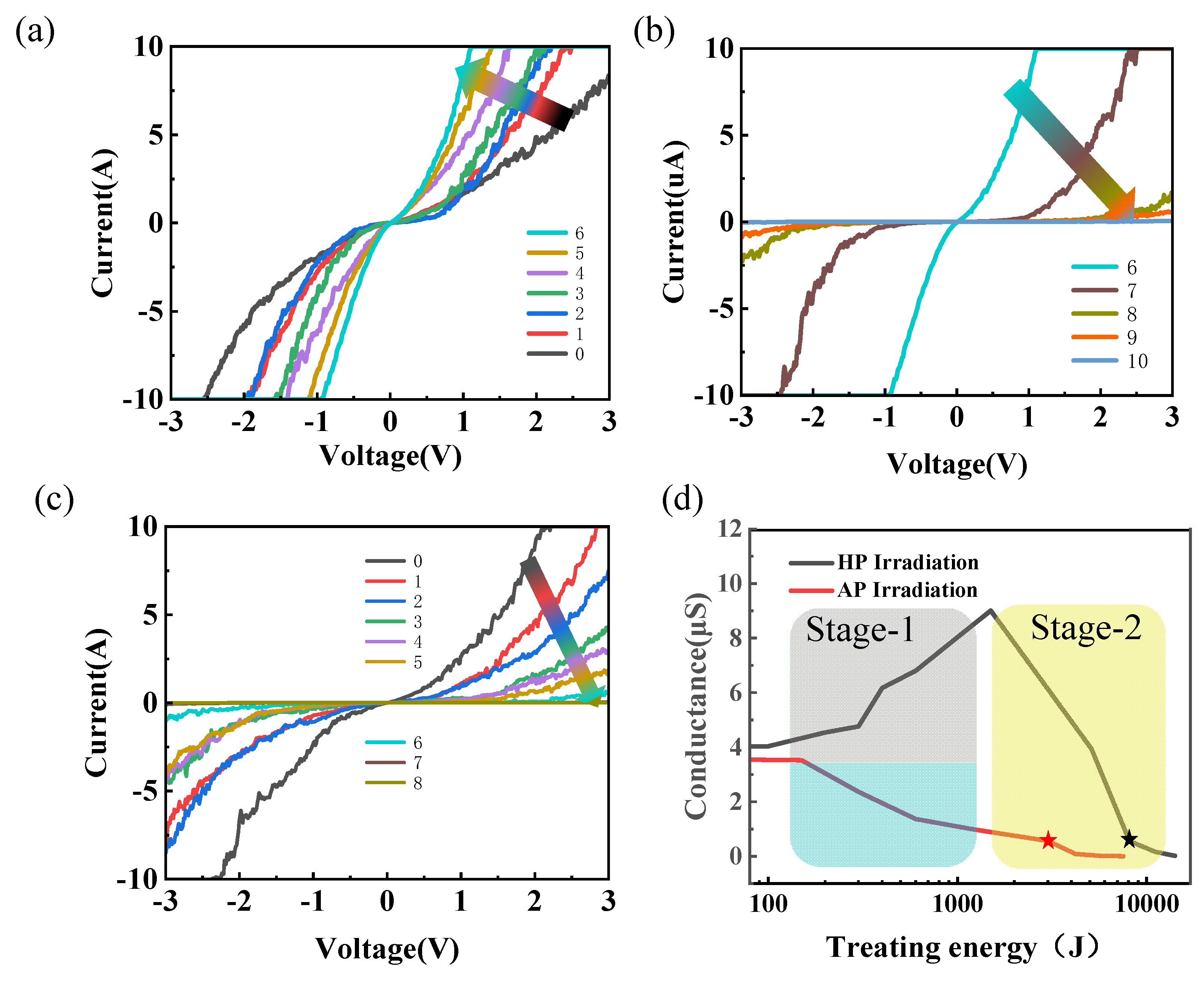

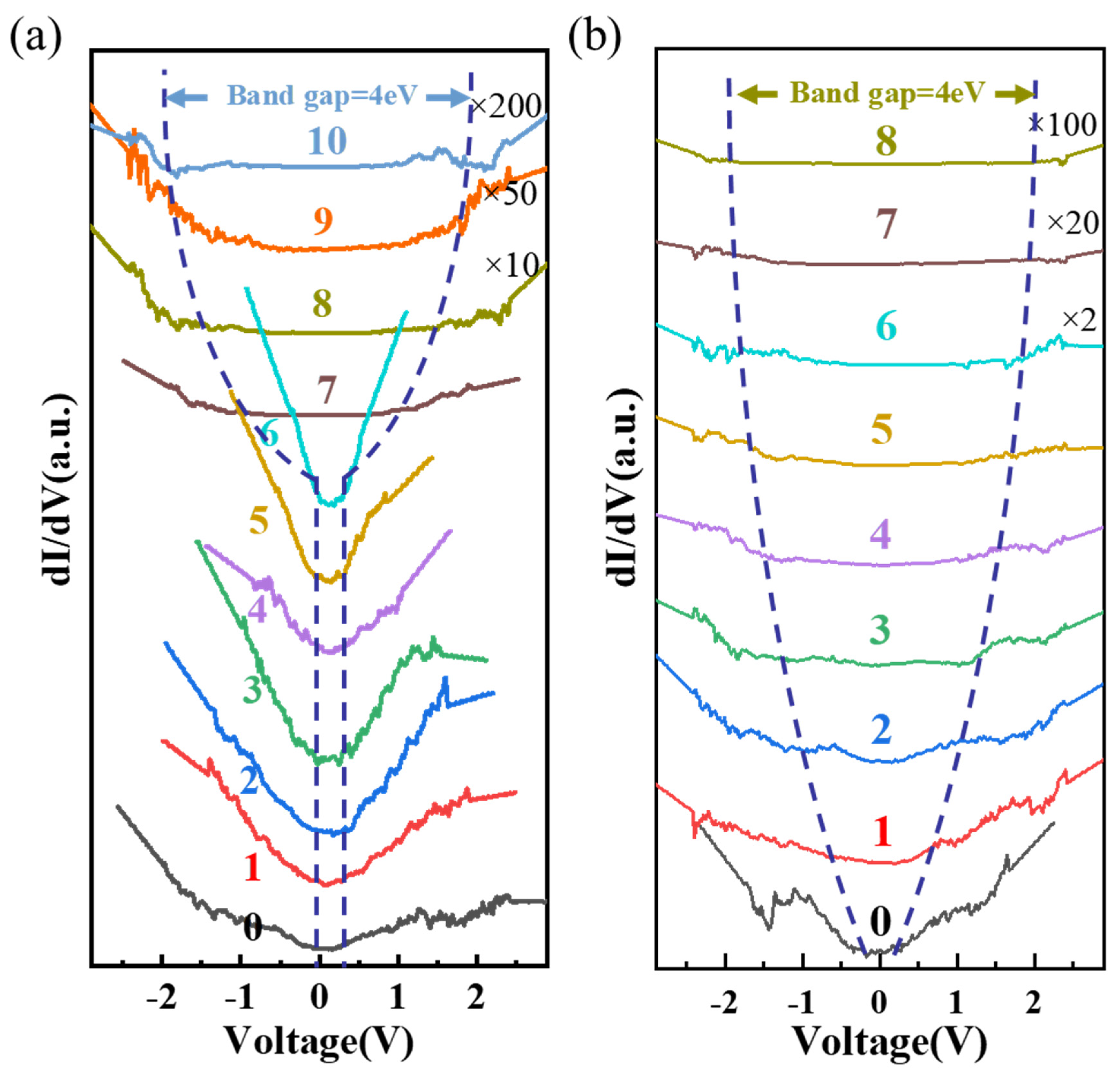

3.2. Study on the Evolutions of the Structure and Electronic Properties of Tellurium Crystal Flake under Plasma Treatment

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sattar, T. Current Review on Synthesis, Composites and Multifunctional Properties of Graphene. Top. Curr. Chem. 2019, 377, 45. [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666-669. [CrossRef]

- Li, Q.Y.; Alfrey, A.; Hu, J.Q.; Lydick, N.; Paik, E.; Liu, B.; Sun, H.P.; Lu, Y.; Wang, R.Y.; Forrest, S.; et al. Macroscopic transition metal dichalcogenides monolayers with uniformly high optical quality (vol 14, 1837, 2023). Nat. Commun. 2023, 14, 1. [CrossRef]

- Bonera, E.; Molle, A. Emerging Two-Dimensional Materials: Inspiring Nanotechnologies for Smart Energy Management. Nanomaterials 2023, 13, 2. [CrossRef]

- Molas, M.R. Excitons and Phonons in Two-Dimensional Materials: From Fundamental to Applications. Nanomaterials 2023, 13, 3. [CrossRef]

- Cao, R.; Fan, S.D.; Yin, P.; Ma, C.Y.; Zeng, Y.H.; Wang, H.D.; Khan, K.; Wageh, S.; Al-Ghamd, A.A.; Tareen, A.K.; et al. Mid-Infrared Optoelectronic Devices Based on Two-Dimensional Materials beyond Graphene: Status and Trends. Nanomaterials 2022, 12, 53. [CrossRef]

- Zhou, C.J.; Wang, X.S.; Raju, S.; Lin, Z.Y.; Villaroman, D.; Huang, B.L.; Chan, H.L.W.; Chan, M.S.; Chai, Y. Low voltage and high ON/OFF ratio field-effect transistors based on CVD MoS2 and ultra high-k gate dielectric PZT. Nanoscale 2015, 7, 8695-8700. [CrossRef]

- Yan, Z.H.; Yang, H.; Yang, Z.; Ji, C.G.; Zhang, G.Y.; Tu, Y.S.; Du, G.Y.; Cai, S.H.; Lin, S.H. Emerging Two-Dimensional Tellurene and Tellurides for Broadband Photodetectors. Small 2022, 18, 27. [CrossRef]

- Wu, W.Z.; Qiu, G.; Wang, Y.X.; Wang, R.X.; Ye, P.D. Tellurene: Its physical properties, scalable nanomanufacturing, and device applications. Chem. Soc. Rev. 2018, 47, 7203-7212. [CrossRef]

- Wang, Y.X.; Qiu, G.; Wang, R.X.; Huang, S.Y.; Wang, Q.X.; Liu, Y.Y.; Du, Y.C.; Goddard, W.A.; Kim, M.J.; Xu, X.F.; et al. Field-effect transistors made from solution-grown two-dimensional tellurene. Nature Electronics 2018, 1, 228-236. [CrossRef]

- Lozovoy, K.A.; Izhnin, II; Kokhanenko, A.P.; Dirko, V.V.; Vinarskiy, V.P.; Voitsekhovskii, A.V.; Fitsych, O.I.; Akimenko, N.Y. Single-Element 2D Materials beyond Graphene: Methods of Epitaxial Synthesis. Nanomaterials 2022, 12, 21. [CrossRef]

- Zhu, Z.; Cai, C.; Niu, C.; Wang, C.; Sun, Q.; Han, X.; Guo, Z.; Jia, Y. Tellurene-a monolayer of tellurium from first-principles prediction. Arxiv 2016, arXiv:1605.03253. [CrossRef]

- Zhang, X.; Jiang, J.Z.; Suleiman, A.A.; Jin, B.; Hu, X.Z.; Zhou, X.; Zhai, T.Y. Hydrogen-Assisted Growth of Ultrathin Te Flakes with Giant Gate-Dependent Photoresponse. Adv. Funct. Mater. 2019, 29, 9. [CrossRef]

- Wang, C.; Xu, C.; Guo, X.Y.; Zhang, N.; Yan, J.M.; Chen, J.W.; Yu, W.; Qin, J.K.; Zhu, Y.; Li, L.J.; et al. Alloy-buffer-controlled van der Waals epitaxial growth of aligned tellurene. Nano Res. 2022, 15, 5712-5718. [CrossRef]

- Yan, J.H.; Zhang, X.Y.; Pan, Y.Y.; Li, J.Z.; Shi, B.W.; Liu, S.Q.; Yang, J.; Song, Z.G.; Zhang, H.; Ye, M.; et al. Monolayer tellurene-metal contacts. J. Mater. Chem. C 2018, 6, 6153-6163. [CrossRef]

- Shi, Z.; Cao, R.; Khan, K.; Tareen, A.K.; Liu, X.S.; Liang, W.Y.; Zhang, Y.; Ma, C.Y.; Guo, Z.N.; Luo, X.L.; et al. Two-Dimensional Tellurium: Progress, Challenges, and Prospects. Nano-Micro Lett. 2020, 12, 34. [CrossRef]

- Amani, M.; Tan, C.L.; Zhang, G.; Zhao, C.S.; Bullock, J.; Song, X.H.; Kim, H.; Shrestha, V.R.; Gao, Y.; Crozier, K.B.; et al. Solution-Synthesized High-Mobility Tellurium Nanoflakes for Short-Wave Infrared Photodetectors. ACS Nano 2018, 12, 7253-7263. [CrossRef]

- Xie, Z.J.; Xing, C.Y.; Huang, W.C.; Fan, T.J.; Li, Z.J.; Zhao, J.L.; Xiang, Y.J.; Guo, Z.N.; Li, J.Q.; Yang, Z.G.; et al. Ultrathin 2D Nonlayered Tellurium Nanosheets: Facile Liquid-Phase Exfoliation, Characterization, and Photoresponse with High Performance and Enhanced Stability. Adv. Funct. Mater. 2018, 28, 11. [CrossRef]

- Deckoff-Jones, S.; Wang, Y.X.; Lin, H.T.; Wu, W.Z.; Hu, J.J. Tellurene: A Multifunctional Material for Midinfrared Optoelectronics. ACS Photonics 2019, 6, 1632-1638. [CrossRef]

- Lee, T.I.; Lee, S.; Lee, E.; Sohn, S.; Lee, Y.; Lee, S.; Moon, G.; Kim, D.; Kim, Y.S.; Myoung, J.M.; et al. High-Power Density Piezoelectric Energy Harvesting Using Radially Strained Ultrathin Trigonal Tellurium Nanowire Assembly. Adv. Mater. 2013, 25, 2920-2925. [CrossRef]

- Wang, Y.X.; Wang, R.X.; Wan, S.H.; Wang, Q.X.; Kim, M.J.; Ding, D.; Wu, W.Z. Scalable nanomanufacturing and assembly of chiral-chain piezoelectric tellurium nanowires for wearable self-powered cardiovascular monitoring. Nano Futures 2019, 3, 9. [CrossRef]

- Yang, D.D.; Qiu, W.; Chen, X.J.; Liu, L.; Lai, Y.J.; Meng, Z.H.; Song, J.P.; Liu, Y.F.; Liu, X.Y.; Zhan, D. Achieving High-Performance Surface-Enhanced Raman Scattering through One-Step Thermal Treatment of Bulk MoS2. J. Phys. Chem. C 2018, 122, 14467-14473. [CrossRef]

- Sun, L.F.; Hu, H.L.; Zhan, D.; Yan, J.X.; Liu, L.; Teguh, J.S.; Yeow, E.K.L.; Lee, P.S.; Shen, Z.X. Plasma Modified MoS2 Nanofl akes for Surface Enhanced Raman Scattering. Small 2014, 10, 1090-1095. [CrossRef]

- Morales-Masis, M.; Ding, L.; Dauzou, F.; Jeangros, Q.; Hessler-Wyser, A.; Nicolay, S.; Ballif, C. Hydrogen plasma treatment for improved conductivity in amorphous aluminum doped zinc tin oxide thin films. APL Mater. 2014, 2, 7. [CrossRef]

- Li, R.R.; Taniguchi, T.; Watanabe, K.; Xue, J.M. Detecting band profiles of devices with conductive atomic force microscopy. Rev. Sci. Instrum. 2020, 91, 6. [CrossRef]

- Gong, Y.; Li, H.K.; Jiao, C.; Xu, Q.C.; Xu, X.Y.; Zhang, X.M.; Liu, Y.F.; Dai, Z.Y.; Liu, X.Y.; Chen, W.; et al. Effective hydrogenation of g-C3N4 for enhanced photocatalytic performance revealed by molecular structure dynamics. Appl. Catal. B-Environ. 2019, 250, 63-70. [CrossRef]

- Pankove, J.I. Optical Processes in Semiconductors; Dover Publications: New York, 1971.

- Marini, C.; Chermisi, D.; Lavagnini, M.; Di Castro, D.; Petrillo, C.; Degiorgi, L.; Scandolo, S.; Postorino, P. High-pressure phases of crystalline tellurium: A combined Raman and ab initio study. Phys. Rev. B 2012, 86, 5. [CrossRef]

- Shahzad, F.; Qamar, A.; Nabi, G. Significant enhancement in field emission and photoluminescence properties of vertically aligned tellurium nanorods by plasma treatment. Opt. Mater. 2022, 126, 9. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).