1. Introduction

Currently, because of the development of the chemical industry and available technological capabilities, products made from polymer materials are represented in many sectors of consumer goods: construction, automotive industry, electronics, medicine [

1]. These can be polymer membranes for various purposes [

2,

3], solid-state lithium-metal batteries [

4], dielectric materials [

5], packaging [

6,

7], anti-corrosion coatings [

8], construction materials [

9,

10,

11].

The strength, lightness, and other properties of plastic have allowed it to establish a significant presence in the everyday life of modern people. One of the most common types of plastic is polyvinyl chloride (PVC), which is used in practically all spheres of human activity [

12,

13,

14,

15,

16,

17,

18]. Plasticized polyvinyl chloride (PVC-P) is one of the most used materials for the manufacture of various products [

19,

20,

21,

22,

23,

24]. The material is made soft and elastic due to the addition of up to 50 wt.% plasticizers. However, in the highly plasticized PVC the process of plasticizer migration occurs while using products made from such a material [

25,

26,

27], which is also an important aspect to study.

Recently, one of the significant disadvantages of PVC-based products, which poses an environmental threat, is its long “life span”. PVC-based materials do not biodegrade, and the issue of PVC waste disposal is quite acute [

28,

29,

30,

31,

32,

33]. Waste disposal by burning is also not a solution to this problem due to the release of pollutions generated into the atmosphere that are harmful for the environment and humans [

34,

35,

36,

37,

38]. Thus, it is necessary to consider alternative ways to produce materials and prevent the accumulation of polymers in the environment, for example, the creation of composites containing biopolymers and/or plant fillers.

The fabrication of polymer or filled PVC-based composites using biofillers with acceptable performance characteristics makes it possible to improve the environmental situation in the world [

39,

40,

41,

42,

43]. Fillers do not change the PVC particles themselves but can penetrate between the elements of the polymer structure leading to a change in the volume of external voids between them. This is due to the effectiveness of each supplement, its structure and polarity. However, it should be noted that fillers also result in a denser packing of PVC powder due to the interaction between the PVC particle and the additive. As a result, an interparticle interaction is reduced [

44]. One of the well-known types of PVC-based composites are wood-polymer or plant-filled composites, which except PVC and filler may contain additional components to control the properties of the final product [

45,

46,

47,

48,

49,

50].

The aim of this work was to obtain plant-filled polymer composites based on highly plasticized polyvinyl chloride filled with various types of plant fillers and to study their properties depending on the nature of the filler.

2. Materials and Methods

2.1. Polymer Compositions

The objects of study were polymer films based on an industrial composition of highly plasticized PVC (Klöckner Pentaplast Rus Ltd), containing various plant fillers with a concentration of 0 ÷ 40 wt.%. The industrial composition of highly plasticized PVC (Klöckner Pentaplast Rus Ltd) contains suspension polyvinyl chloride with the Fickentcher constant (Kf) equal to 67 plasticized and dioctyl terephthalate. Dioctyltin bis(2-ethylhexyl thioglycolate) with a concentration of 1 wt.% as a thermal stabilizer in the industrial PVC composition, glycerol ether as an internal lubricant of 0.5 wt.%, and oxidized polyethylene wax as an external lubricant of 0.1 wt.% were used.

Spruce flour (SF), lignin-free birch flour (BF) and rice husk (RH) were chosen as plant fillers. The choice of these fillers was because they have different strength characteristics and resinous substance content. The compositions of the films obtained presented in

Table 1.

2.2. Polymer Films Fabrication Method

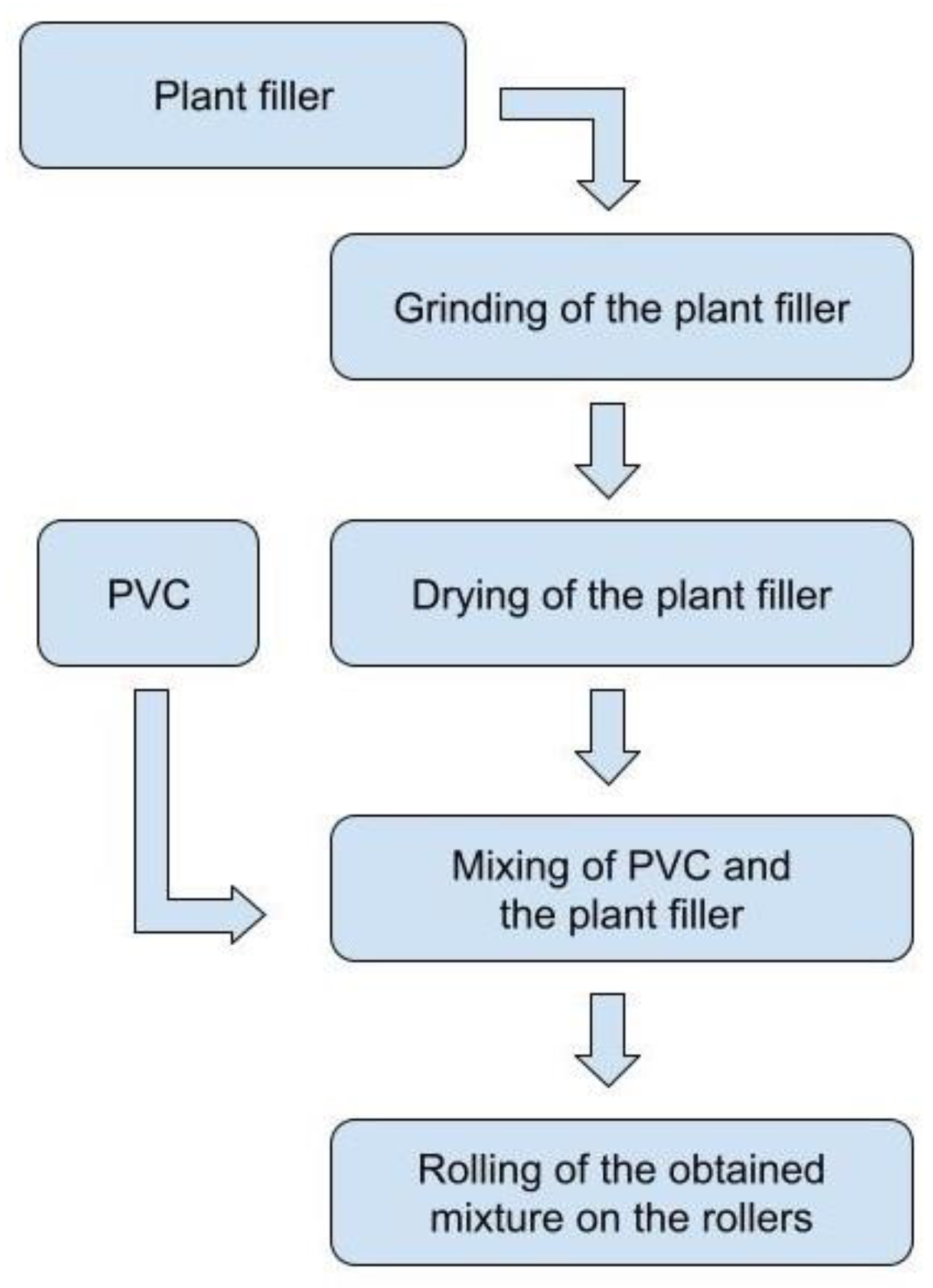

Plant-filled polymer composites were obtained with different ratios of components. Plant filler (PF) was ground previously for five minutes using a Brabender roller mill (Germany) to obtain a powder with a dispersion of 0.2 ÷ 2 mm and dried up to 3% of humidity. The components (PVC composition and PF) were mixed for three minutes using a HENSCHEL high-speed mixer (Germany) until a homogeneous mixture was obtained. The resulting mixture was fed to laboratory rollers Schwabenthan Maschinenfabrik Berlin (Germany) type Polymix 150U heated to a temperature of 175 °C to obtain a melt. The melt was rolled at the speed of 24 rpm for two minutes to obtain polymer composite films with a thickness of 500±5 microns. The technological scheme is shown in

Figure 1.

2.3. Investigation Methods

Structural, thermal, and mechanical properties of composite film samples were investigated using different methods. Optical microscopy was carried out using an Olympus STM6 optical measuring microscope using the transmission method. The chemical structure of the samples was studied by Fourier transform infrared spectroscopy. The IR spectra of the samples were recorded on a Bruker Tensor 37 FTIR spectrometer using a Pike MIRacle ATR (attenuated total internal reflection) attachment with a diamond coated ZnSe crystal. The spectra were recorded in the range of 4000-600 cm-1 with a resolution of 2 cm-1 and averaging over 32 spectra.

The thermal properties of the obtained samples were studied on a differential scanning calorimeter DSC 204 F1 Phoenix (Netsch, Germany), operating at a heating rate of 10 °C/min in the range from -30 °C to 175 °C. After an equilibration phase at 25 °C, the samples were first heated, after that cooled to -30 °C, and then heated again to a temperature of 250 °C. Nitrogen was used as the purge gas at a flow rate of 50 mL/min. The weight of the film samples used for DSC measurements varied from 5.5 to 8.5 mg. The samples were placed in aluminum crucibles with a pierced lid. To determine the glass transition temperature Tg the data from the second heating curve were analyzed.

Thermogravimetric analysis was used to study the thermal stability of the samples. All samples were measured using a Libra 209 F1 thermogravimetric analyzer (Netzsch, Germany) with a scanning speed of 10 °C/min under a nitrogen atmosphere in the temperature range 25–900 °C. Nitrogen was supplied at a flow rate of 50 ml/min.

Mechanical testing was carried out at a tensile strain rate of 180 mm/min using an Instron 5966 (USA) electromechanical testing machine equipped with a strain gauge (10 kN load capacity) and a pneumatic gripping system. Signal processing was performed using Bluehill 3 software. The loading speed was 25 mm/min when determining strength and permanent elongation.

3. Results and Discussion

3.1. Optical Measurments

While fabrication plant-filled polymer materials, it is especially important to achieve uniform distribution of the filler inside the polymer matrix. An uneven distribution negatively affects the performance characteristics of the materials causing anisotropy of properties and high defectiveness of samples, because of which the formation of products of various configurations from such samples is impossible.

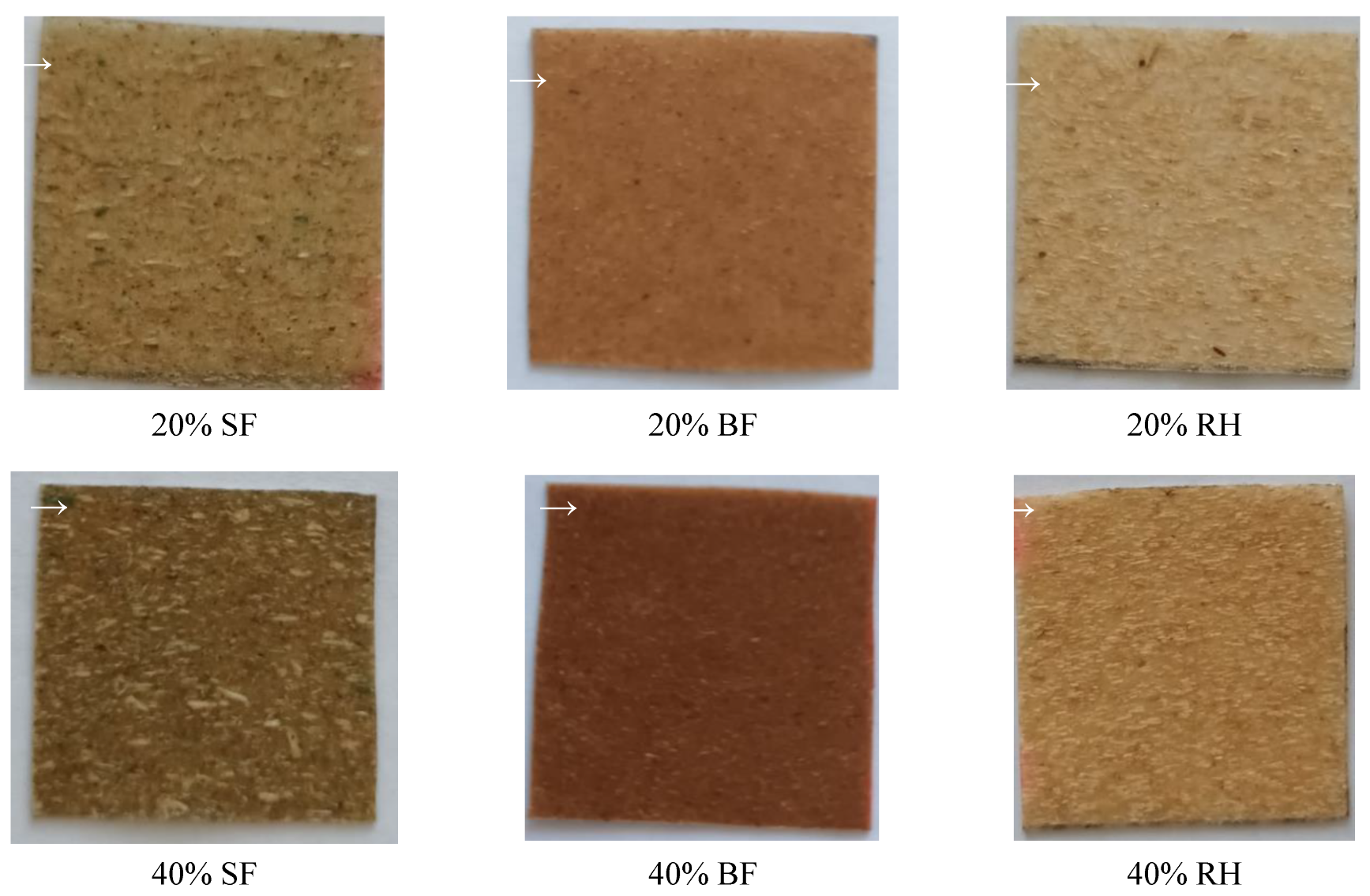

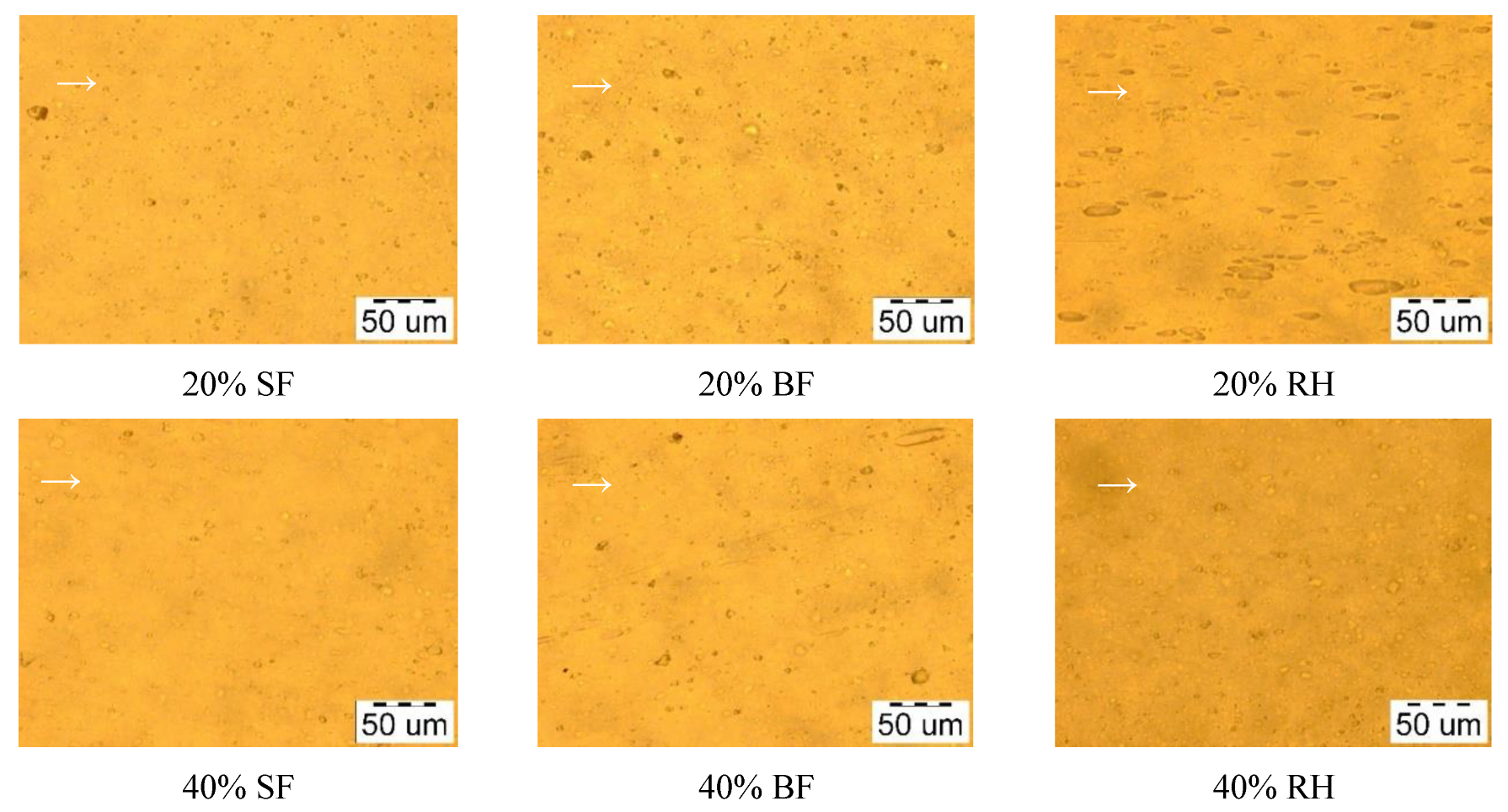

Images of plant-filled polymer films based on highly plasticized PVC taken in reflected and transmitted light modes are presented in

Figure 2 and

Figure 3, respectively. As can be seen from figures, with the selected technological parameters, it is possible to obtain films with a uniform distribution of dispersed plant filler in the polymer matrix. It can also be noted that the particles of plant filler are oriented in one direction, along the rolling axis. There are one more feature of films that all fillers have gave their own color to the samples.

3.2. IR Spectroscopy

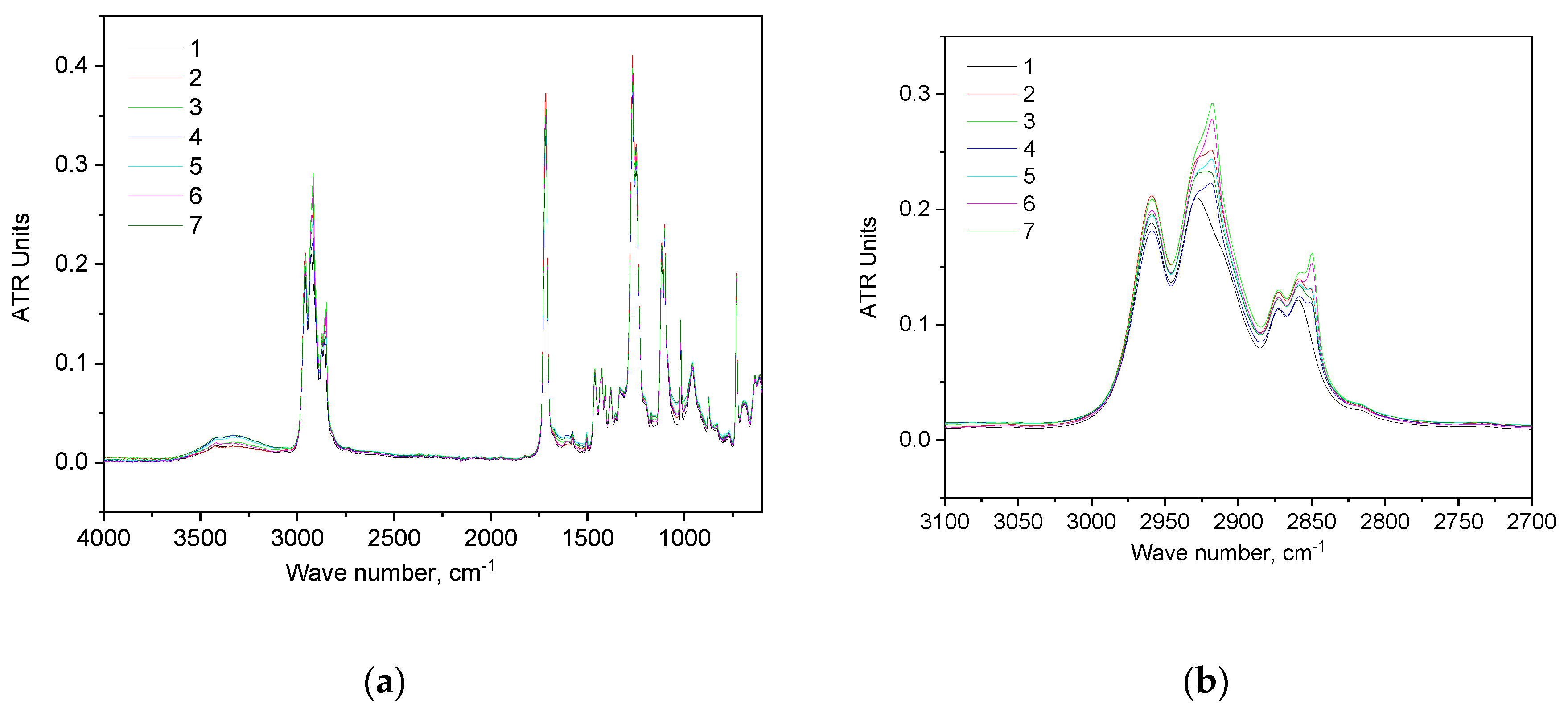

IR spectroscopy data for plant-filled polymer films based on highly plasticized PVC are presented in

Figure 4. As can be seen from the data obtained, a peak with a wave number of 752 cm

-1 corresponding to vibrations of the C-Cl bond is identified in the IR spectra of all samples. This peak is characteristic of PVC. In the wavenumber range of 2950-2900 cm

-1, there are peaks corresponding to the components of the plant filler.

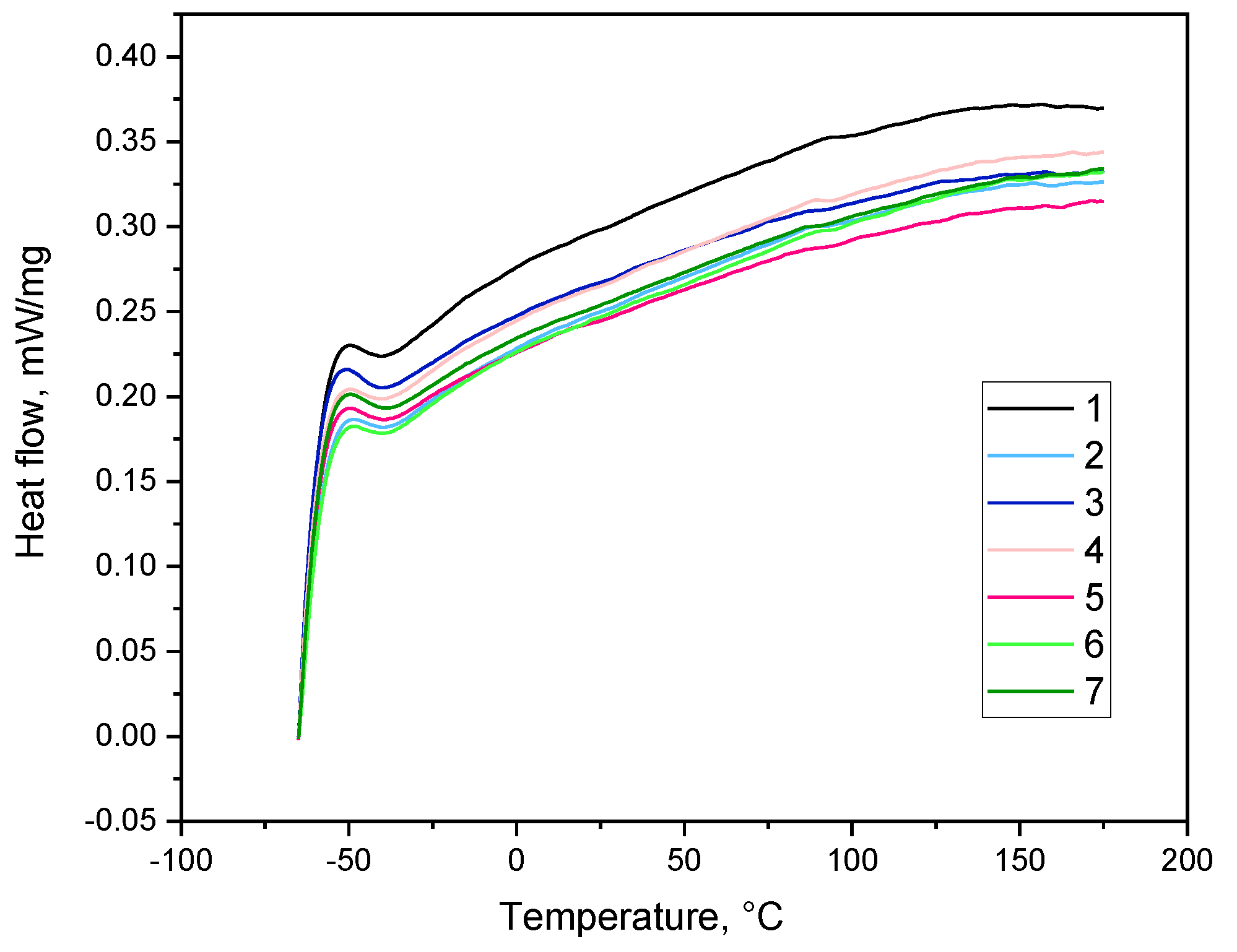

3.3. Thermal Properties

Since plant raw materials are sensitive to heat treatment and are characterized by flammability and poor thermal stability, the study of the thermal characteristics of the composites obtained in the work is important to determine the conditions of applicability of such polymeric materials. Thermograms were carried out by differential scanning calorimetry (

Figure 5). All DSC curves show the absence of a glass transition temperature for PVC. That is primarily due to the presence of a high-molecular plasticizer in the composition of the composites which is dioctyl terephthalate with a glass transition temperature of minus 67 ºC.

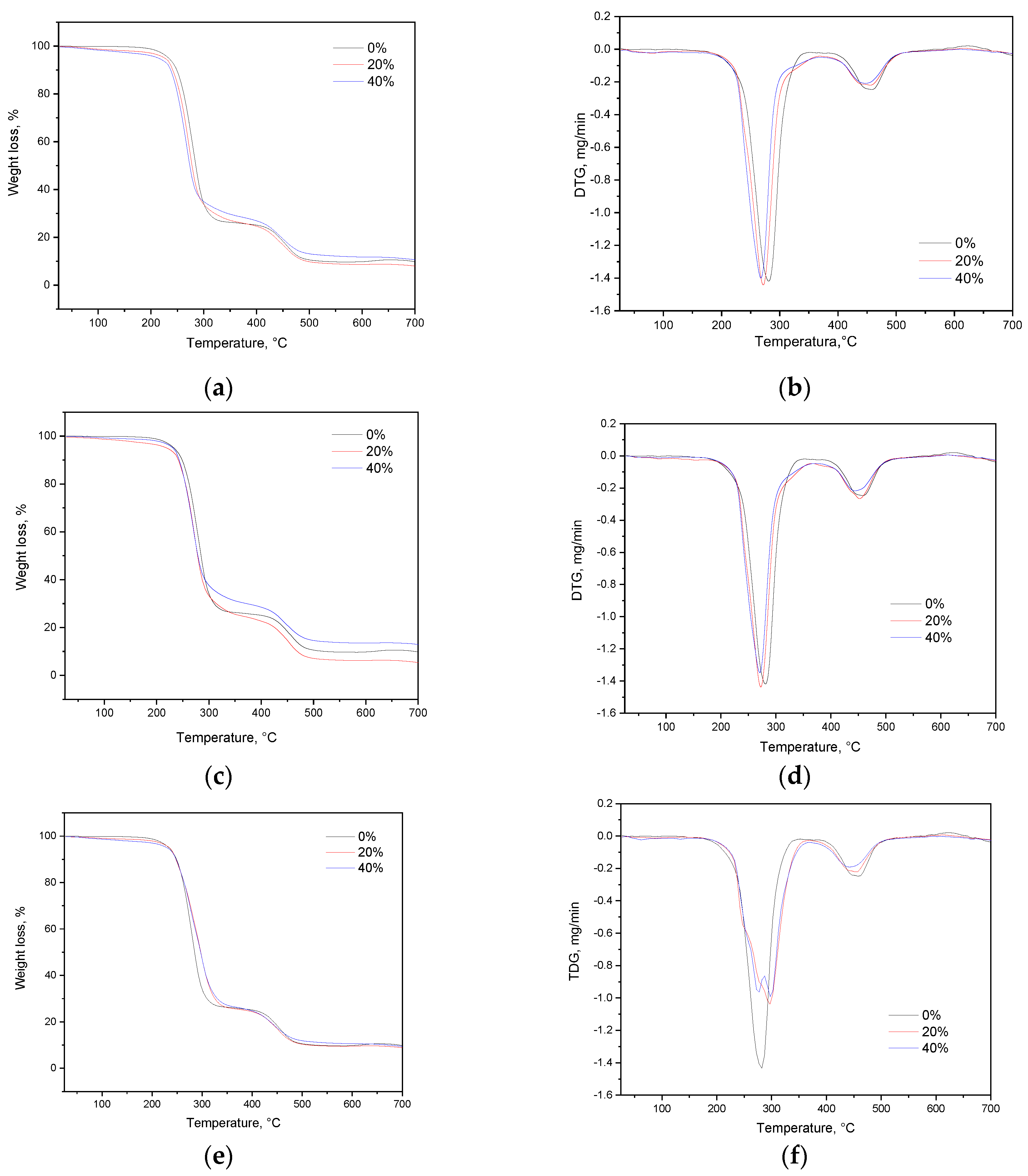

Plant-filled polymer films based on highly plasticized PVC were investigated by thermogravimetric analysis under argon atmosphere to understand their thermal behavior. Thermograms of the studied polymer composite films are shown in

Figure 6.

Typically, two stages of degradation are observed in PVC: the first stage occurred at 250–350°C is the destructive processes of PVC associated with the dehydrochlorination reaction and the removal of some volatile small molecules of saturated and unsaturated aliphatic or aromatic hydrocarbons [

51]. The second stage occurred in the temperature range of 350–500 °C includes the formation and volatilization of intramolecular cyclization products [

51,

52].

Table 2 show the characterized temperature values for decomposition stages of samples. As can be seen from the presented data in

Figure 6 and in

Table 2, plant-filled polymer films based on highly plasticized PVC are also characterized mostly by a two-stage destruction process. The adding of birch and spruce flour as filler in the polymer composition leads to a slight decrease in the initial decomposition temperature (T

d) of the material by 10–15 °C. In a case of adding of RH filler in the initial polymer mixture, the increase of the maximal temperature of decomposition in the first stage is observed, probably, due to the RH thermal behavior in the range of 250–350°C has the differ maximum of temperature (~303°C [

53]) in comparison with PVC (~280°C). For all composite samples the widening of thermal ranges for both stages of decomposition can be noted. Moreover, after 550°C the mass remained stable and the residual ash corresponded to 8-10 % for SF-filled, to 5.6-13% BF-filled, and to 8.9-10% polymer films of the total weight which was measured.

3.4. Mechanical Properties

As a result of testing the studied samples (5 samples of each composition) of plant-filled polymer films based on highly plasticized PVC under tension, data on tensile strength and breaking elongations were obtained. To avoid large scatters in the results for samples with plant fillers due to their anisotropy, stretching was carried out along the fiber orientation corresponding to the direction of rolling.

Statistical processing consisted of checking the data for errors. The conclusion about the presence of an error was made based on calculating the value of Student's t-test at the points most different from the average of the series of measurements, and comparing it with the table, which, with the number of measurements being 5 and a degree of reliability of 0.9, is equal to 1.79. Errors were excluded from the series. The test results of the obtained samples are presented in the

Table 3.

A common picture is observed for all types of plant filler: adding the filler in the composite led to decreasing of the strength properties of the material, since filler particles filled the intermolecular space violating the integrity and bonds of the polymer fibers. The more filler, the denser the structure of the material, which means less space is left for PVC molecules to straighten. As a result, the material becomes less flexible, and the value of breaking elongation decreases. Comparing the characteristics of composites with various fillers it can be noted that the most preferable filler is BF (20%). This may be due to the high content of binding and reinforcing components in wood fillers, for example, cellulose and lignin. Thus, increasing the proportion of plant filler to improve the environmental friendliness of materials is limited by decreasing strength characteristics and flexibility.

3.5. Water Absorption Test

Studying the stability of composite materials based on polymer materials filled with a hydrophilic filler, such as plant fibers, is an important part of the research, since water absorption can lead to negative phenomena, such as a decrease in strength, deformation of the product until its complete destruction, oxidation, etc. The reason for these phenomena, most often, is both the heterogeneity of the distribution of filler particles in the composite and poor compatibility between the original components of the film [

54]. So, in this work to study the effect of water on the resulting plant-filled polymer films based on highly plasticized PVC with various plant additives was performed.

Table 4 presents data on the degree of swelling of some samples of the obtained plant-filled polymer films based on highly plasticized PVC in water at a temperature of 25 ° C for 24 hours and 7 days according to the standard technique [

55].

As can be seen from the table, the higher the content of hydrophilic filler, the higher the degree of swelling of the filled polymer films. The samples containing birch flour as a plant filler have the maximum degree of swelling. The degree of swelling of samples with BF (40%) at a temperature of 25 ⁰C does not exceed 0.13 g/g.

4. Conclusions

In this work, the properties of PVC-based composite materials with proportions of different types of fillers up to 40% were analyzed. Increasing the proportion of plant filler to improve the environmental friendliness of materials somewhat reduces the strength characteristics and reduces the flexibility of the samples. However, by pre-treating the plant filler, for example by removing lignin, these limitations can be overcome.

The relatively low glass transition temperature (below – 65 ºС) for samples with plant filler allows them to be used at low temperatures. Also, due to their limited hydrophobicity, these samples cannot be used in conditions of constant contact with water, but they can withstand repeated short-term exposure to water without loss of performance characteristics.

Thus, plant-filled polymer composites based on PVC can be used on an equal basis with unfilled PVC plastic compound, since the decrease in performance characteristics (mechanical, thermal) is not critical. Due to the addition of plant filler to the composites, these materials cannot be used in areas where transparency is required but can be used in construction and other areas where there are no such requirements.

Author Contributions

Conceptualization – Mayya Uspenskaya; methodology – Mayya Uspenskaya, Evgeniia Samuilova; validation – Evgeniia Samuilova, Alina Ponomareva, Vera Sitnikova; formal analysis – Vera Sitnikova, Anton Zhilenkov; investigation data curation – Evgeniia Samuilova; writing—original draft preparation – Evgeniia Samuilova, Alina Ponomareva; writing—review and editing – Evgeniia Samuilova, Alina Ponomareva; visualization – Evgeniia Samuilova, Alina Ponomareva; supervision – Mayya Uspenskaya, Olga Kichigina. All authors have read and agreed to the published version of the manuscript.

Funding

The research is partially funded by the Ministry of Science and Higher Education of the Russian Federation as part of the World-class Research Center program: Advanced Digital Technologies (contract No. 075-15-2022-312 dated 20 April 2022).

Institutional Review Board Statement

Not applicable.

Acknowledgments

The authors acknowledge Evgeny Belukhichev for assistance in the fabrication of the samples and Alexander Podshivalov for taking a part in the investigation of mechanical characteristics of the samples.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Islam, A.; Mobarak, H.; Rimon, I.H.; Al Mahmud, Z.; Ghosh, J.; Ahmed, M.S.; Hossain, N. Additive manufacturing in polymer research: Advances, synthesis, and applications. Polym. Test. 2024, 132, 108364. [Google Scholar] [CrossRef]

- Karki, S.; Hazarika, G.; Yadav, D.; Ingole, P.G. Polymeric membranes for industrial applications: Recent progress, challenges and perspectives. Desalination 2024, 573, 117200. [Google Scholar] [CrossRef]

- Konjarla, A.; Sreekanth, T.; Mallikarjun, A.; Mettu, M.R.; Reddy, M.J. Membrane formation of PVC and PVDF-HFP polymer blend. Materials Today: Proceedings 2023, 92, 561–564. [Google Scholar] [CrossRef]

- Kang, J.; Deng, N. Cheng, B.; Kang, W. Progress in the application of polymer fibers in solid electrolytes for lithium metal batteries. J. Energy Chem. 2024, 92, 26–42. [Google Scholar] [CrossRef]

- Islam, Z.; Fu, Y.; Deb, H.; Hasan, K.; Dong, Y.; Shi, S. Polymer-based low dielectric constant and loss materials for high-speed communication network: Dielectric constants and challenges. Eur. Polym. J. 2023, 200, 112543. [Google Scholar] [CrossRef]

- De Santis, F.; Boragno, L.; Jeremic, D.; Albunia, A.R. Trimodal polyethylene polymer design for more sustainable packaging applications. Polymer. 2024, 295, 126740. [Google Scholar] [CrossRef]

- Huang, H.; Ren, P.; Zhong, G.; Olah, A.; Li, Z.; Baer, E.; Zhu, L. // Promising strategies and new opportunities for high barrier polymer packaging films. Prog. Polym. Sci.. 2023, 144, 101722. [Google Scholar] [CrossRef]

- Dua, S.; Arora, N.; Prakashaiah, B.G.; Saxena, R.C.; Ganguly, S.K.; Senthilkumar, T. Conjugated polymer-based composites for anti-corrosion applications. Prog. Org. Coat. 2024, 188, 108231. [Google Scholar] [CrossRef]

- Frigione, M.; Lettieri, M.; Sarcinella, A.; Barroso de Aguiar, J. Sustainable polymer-based Phase Change Materials for energy efficiency in buildings and their application in aerial lime mortars. Constr Build Mater. 2020, 231, 117149. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, Z.; Li, Q.; Wang, K.; Jiang, D.; Hou, P.; Huang, Y.; Zhao, P. // Insights on the role of particulate filler on the polymer-modified cement-based coating and its application. J. Build. Eng. 2023, 76, 107395. [Google Scholar] [CrossRef]

- Abdulla, N.A. A state-of art-review of materials, methods, and applications of PVC-FRP-confined concrete. Constr Build Mater. 2023, 363, 129719. [Google Scholar] [CrossRef]

- Kobayashi, S. Encyclopedia of Polymeric Nanomaterials., 1st ed.; Shiro Kobayashi, Klaus Mullen, Ed.; Publisher: Berlin: Springer-Verlag Berlin Heidelberg, Germany, 2015; p. 2617. [Google Scholar] [CrossRef]

- Wypych, G. Handbook of polymers; ChemTech Publishing: Toronto, ON, Canada; New York, NY, USA, 2012; p. 696. [Google Scholar] [CrossRef]

- Mijangos, C.; Calafel, I.; Santamaría, A. Poly(vinyl chloride), a historical polymer still evolving. Polymer, 2023; 266, 125610. [Google Scholar] [CrossRef]

- Alshammari, A.H.; Alshammari, M.; Ibrahim, M.; Alshammari, K.; Taha, A.M. M. Processing polymer film nanocomposites of polyvinyl chloride – Polyvinylpyrrolidone and MoO3 for optoelectronic applications. Optics & Laser Technology. 2024, 168, 109833. [Google Scholar] [CrossRef]

- Sonia, D. ’ Malagavelli, V.; Balguri, P.K. Strength Assessment of PVC Pipes Filled with Geo-Polymer Concrete asS lender Column. Materials Today: Proceedings. 2022, 62, 3001–3005. [Google Scholar] [CrossRef]

- Silva, T.I.B.; Moreira, F.T.C.; Truta, L.A.A.N.A.; Sales, M.G.T. Novel optical PVC probes for on-site detection/determination of fluoroquinolones in a solid/liquid interface: Application to the determination of Norfloxacin in aquaculture water. Biosens. Bioelectron. 2012, 36, 199–206. [Google Scholar] [CrossRef]

- Mohammed, S.J.; Hawaiz, F.E.; Aziz, S.B.; Al-Jaf, S.H. // Organic soluble nitrogen-doped carbon dots (ONCDs) to reduce the optical band gap of PVC polymer: Breakthrough in polymer composites with improved optical properties. Opt. Mater. 2024, 149, 115014. [Google Scholar] [CrossRef]

- Li, Y.; Feng, X.; Zhu, L.; Zhang, Z.; Guo, M.; Li, Y.; Minoru Hashimoto, M. High performance fiber-constrained plasticized PVC gel actuators for soft robotics. Sens. Actuators B Chem. 2023, 393, 134177. [Google Scholar] [CrossRef]

- Lang, J.; Stanhope, B.E. Benzoate plasticizer for flexible PVC injection moulded toy applications. Plastics, Additives and Compounding. 2001, 39, 30–33. [Google Scholar] [CrossRef]

- Simon, M.A.; Kusy, R.P. Plasticizer-level study of poly(viny1 chloride) ion-selective membranes J. Biomed. Mater. Res. 1996, 30, 313–320. [Google Scholar] [CrossRef]

- Jiaa, P.; Mab, Y.; Song, F.; Hua, Y.; Zhang, C.; Zhoua, Y. Toxic phthalate-free and highly plasticized polyvinyl chloride materials from non-timber forest resources in plantation. React Funct Polym. 2019, 144, 104363. [Google Scholar] [CrossRef]

- Pannico, M.; Musto, P. Migration of plasticizers from flexible PVC: Monitoring the concentration profiles by confocal Raman microspectroscopy. Polymer. 2024, 294, 126731. [Google Scholar] [CrossRef]

- Zhang, Y.; Qian, L.; Qu, L.; Wang, J.; Qiu, Y.; Xi, W.; Ma, Y. // Bismuth trioxide replaced diantimony trioxide to obtain polyvinyl chloride leather with high flame retardancy and low flame propagation rate React. Funct. Polym. 2024, 197, 105864. [Google Scholar] [CrossRef]

- Bajagain, R.; Panthi, G.; Park, J.; Moon, J.; Kwon, J.; Kim, D.Y.; Kwon, J.; Hong, Y. Enhanced migration of plasticizers from polyvinyl chloride consumer products through artificial sebum. Sci. Total Environ. 2023, 874, 162412. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.Y.; Sochichiu, S.; Kwon, J.-H. Effects of time, temperature, and sebum layer on migration rate of plasticizers in polyvinyl chloride products. Chemosphere. 2022, 308, 136478. [Google Scholar] [CrossRef] [PubMed]

- Gulizia, A.M.; Philippa, B.; Zacharuk, J.; Motti, C.A.; Vamvounis, G. Plasticiser leaching from polyvinyl chloride microplastics and the implications for environmental risk assessment. Mar. Pollut. Bull. 2023, 195, 115392. [Google Scholar] [CrossRef] [PubMed]

- Cardarelli, F. Polymers and Elastomers. In Materials Handbook, 3rd ed.; Publisher: Springer Cham, USA, 2018; pp. 1013–1092. [Google Scholar] [CrossRef]

- Khalid, A.R.; Shah, T.; Asad, M.; Ali, A.; Samee, E.; Adnan, F.; Bhatti, M.F.; Marhan, S.; Kammann, C.I.; Haider, G. // Biochar alleviated the toxic effects of PVC microplastic in a soil-plant system by upregulating soil enzyme activities and microbial abundance. Environ. Pollut. 2023, 332, 1218100. [Google Scholar] [CrossRef]

- Kang, J.; Kim, J.Y.; Sung, S.; Lee, Y.; Gu, S.; Choi, J.-W.; Yoo, C.-J.; Suh, D.J.; Choi, J.; Ha, J.-M. Chemical upcycling of PVC-containing plastic wastes by thermal degradation and catalysis in a chlorine-rich environment. Environ. Pollut. 2024, 342, 123074. [Google Scholar] [CrossRef] [PubMed]

- Ghosal, K.; Ghosh, S. Biodegradable polymers from lignocellulosic biomass and synthetic plastic waste: An emerging alternative for biomedical applications. Mater. Sci. Eng. R Rep. 2023, 156, 100761. [Google Scholar] [CrossRef]

- Lu, L.; Li, W.; Cheng, Y.; Liu, M. Chemical recycling technologies for PVC waste and PVC-containing plastic waste: A review. Waste Manage. 2023, 166, 245–258. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, Q.; Xu, F.; Wang, Z. Formation and evolution of PVC waste-derived hydrochar. J. Anal. Appl. Pyrolysis. 2023, 175, 106211. [Google Scholar] [CrossRef]

- Meng, J.; Xu, B.; Liu, F.; Li, W.; Sy, N.; Zhou, X.; Yan, B. Effects of chemical and natural ageing on the release of potentially toxic metal additives in commercial PVC microplastics. Chemosphere 2021, 283, 131274. [Google Scholar] [CrossRef] [PubMed]

- Lu, L.; Li, W.; Cheng, Y.; Liu, M. Chemical recycling technologies for PVC waste and PVC-containing plastic waste: A review. Waste Manage. 2023, 166, 242–258. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Jiang, S.; Li, Y.; Su, J.; Shangguan, J.; Zhan, M.; Wang, Y.; Su, X.; Li, J.; Zhang, G. The impact of three related emission industries on regional atmospheric chlorinated paraffins pollution Environ. Pollut. 2023, 316, 120564. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Bai, Z.; Zhang, T.; Jia, Y.; Hou, Y.; Chen, J.; Guo, Z.; Kong, L.; Bai, J.; Li, W. Comparative study on pyrolysis behaviors and chlorine release of pure PVC polymer and commercial PVC plastics. Fuel. 2023, 340, 127555. [Google Scholar] [CrossRef]

- Czégény, Z.; Jakab, E.; Bozi, J.; Blazsó, M. // Pyrolysis of wood–PVC mixtures. Formation of chloromethane from lignocellulosic materials in the presence of PVC. J Anal Appl Pyrolysis. 2015, 113, 123–132. [Google Scholar] [CrossRef]

- Altaee, N.; El-Hiti, G.A.; Fahdil, A.; Sudesh, K.; Yousif, E. Biodegradation of different formulations of polyhydroxybutyrate films in soil. Springerplus. 2016, 5, 762–12. [Google Scholar] [CrossRef]

- Kushwah, B.S.; Singh Kushwah, A.V.; Singh, V. Towards understanding polyhydroxyalkanoates and their use. J. Polym. Res. 2016, 23, 153–4. [Google Scholar] [CrossRef]

- Sharma, S.D.; Sowntharya, L.; Kar, K.K. Polymer-Based Composite Structures: Processing and Applications. In Composite Materials, 1st ed.; Kar. K., Publisher: Springer-Verlag Berlin Heidelberg, Germany, 2017; pp. 1–36. [Google Scholar] [CrossRef]

- Ratanawilai, T.; Taneerat, K. Alternative polymeric matrices for wood-plastic composites: Effects on mechanical properties and resistance to natural weathering. Constr Build Mater. 2017, 172, 349–357. [Google Scholar] [CrossRef]

- Kuyyakanont, A.; Iwata, M. Study of different degradation effects in UV-sensitive polymers using xenon lamp and deuterium lamp to simulate UV irradiation in space environment. Nucl Instrum Methods Phys Res B. 2024, 549, 165267. [Google Scholar] [CrossRef]

- Subramanian, N. Update on Troubleshooting the PVC Extrusion Process, Publisher: Smithers Rapra Technology, UK, 2011; 164 р.

- Yang, A.; Zhang, R.; Xu, Z.; Liu, T.; Fang, Y.; Wang, W.; Xu, M.; Song, Y.; Wang, Q. Preparation of situ microfiber-reinforced co-extruded high-filled wood-plastic composite with excellent mechanical, creep resistance, and water resistance properties. Constr Build Mater. 2024, 415, 135002. [Google Scholar] [CrossRef]

- Qi, Z.; Cai, H.; Ren, F.; Liu, L.; Yang, K.; Han, X. In-situ lignin regeneration strategy to improve the interfacial combination, mechanical properties and stabilities of wood-plastic composites. Compos. Sci. Technol. 2024, 246, 110366. [Google Scholar] [CrossRef]

- Yang, R.; Fang, Y.; Zhu, J.; Ren, G.; Lin, B.; Wang, F.; Ou, R.; Wang, Q.; Song, Y. Fabrication ZnO functionalized nano-montmorillonite for enhancing the fire-safety and mechanical properties of wood flour/poly (vinyl chloride) composites. Constr Build Mater 2024, 420, 135522. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Panchal, H.; Shanmugan, S.; Muthuramalingam, T.; El-Kassas, A.M.; Ramesh, B. Recent progresses in wood-plastic composites: Pre-processing treatments, manufacturing techniques, recyclability and eco-friendly assessment. Clean. Eng. Technol. 2022, 8, 100450. [Google Scholar] [CrossRef]

- Petchwattana, N.; Covavisaruch, S. Effects of Rice Hull Particle Size and Content on the Mechanical Properties and Visual Appearance of Wood Plastic Composites Prepared from Poly(vinyl chloride). J. Bionic. Eng. 2013, 10, 110–117. [Google Scholar] [CrossRef]

- Bai, X.; Wang, Q.; Sui, S.; Zhang, C. The effects of wood-flour on combustion and thermal degradation behaviors of PVC in wood-flour/poly(vinyl chloride) composites. J. Anal. Appl. Pyrolysis. 2011, 91, 34–39. [Google Scholar] [CrossRef]

- Jia, P.; Wang, R.; Hu, L.; Zhang, Meng & Zhou, Y. Self-Plasticization of PVC via click reaction of a monooctyl phthalate derivative. Polish. J. Chem. Technol. 2017, 19, 16–19. [Google Scholar] [CrossRef]

- Wilkie, C.; Summers, J.; Daniels, C. Polyvinylchloride. Publisher: Professiya, Russia, 2007; 728 p. (In Russian)

- Hincapie Rojas, D.F.; Pineda Gómez, P.; Rivera, A.R. Production and characterization of silica nanoparticles from rice husk. Adv Mater Lett. 2019, 10, 67–73. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, K.; Chen, D.; Zhang, Y.; Zhang, Xi.; Yang, Z. Effect of alkali treatment on water absorption deterioration and mechanism of wheat straw/PVC composites. Polym Test. 2024, 131, 108348. [Google Scholar] [CrossRef]

- ISO 62:2008. Plastics - Determination of water absorption. – 2008. – 15 p.

Figure 1.

Scheme for the fabrication of plant-filled polymer films based on highly plasticized PVC.

Figure 1.

Scheme for the fabrication of plant-filled polymer films based on highly plasticized PVC.

Figure 2.

Images of plant-filled polymer films based on highly plasticized PVC taken in the reflected light mode (sample size of 30x30 mm). The arrow indicates the predominant orientation direction of the filler.

Figure 2.

Images of plant-filled polymer films based on highly plasticized PVC taken in the reflected light mode (sample size of 30x30 mm). The arrow indicates the predominant orientation direction of the filler.

Figure 3.

Images of plant-filled polymer films based on highly plasticized PVC taken in the transmitted light mode (sample size of 30x30 mm). The arrow indicates the predominant orientation direction of the filler.

Figure 3.

Images of plant-filled polymer films based on highly plasticized PVC taken in the transmitted light mode (sample size of 30x30 mm). The arrow indicates the predominant orientation direction of the filler.

Figure 4.

Averaged IR spectra of plant-filled polymer films based on highly plasticized PVC: (a) full spectra range and (b) the of characterized peaks of plant fillers, where 1 - unfilled PVC, 2 - 80/20-SF, 3 - 60/40-SF, 4 - 80/20-BF, 5 - 60/40-BF, 6 - 80/20-RH, 7 – 60/40-RH.

Figure 4.

Averaged IR spectra of plant-filled polymer films based on highly plasticized PVC: (a) full spectra range and (b) the of characterized peaks of plant fillers, where 1 - unfilled PVC, 2 - 80/20-SF, 3 - 60/40-SF, 4 - 80/20-BF, 5 - 60/40-BF, 6 - 80/20-RH, 7 – 60/40-RH.

Figure 5.

DSC of plant-filled polymer films based on highly plasticized PVC: 1 - PVC, 2 - 80/20-SF, 3 - 60/40-SF, 4 - 80/20-BF, 5 - 60/40-BF, 6 - 80/20-RH, 7 – 60/40-RH.

Figure 5.

DSC of plant-filled polymer films based on highly plasticized PVC: 1 - PVC, 2 - 80/20-SF, 3 - 60/40-SF, 4 - 80/20-BF, 5 - 60/40-BF, 6 - 80/20-RH, 7 – 60/40-RH.

Figure 6.

TGA and DTG curves of plant-filled polymer films based on highly plasticized PVC: (a) and (b) – with addition of SF, (c) and (d) – with addition of BF, (e) and (f) – with addition of RH.

Figure 6.

TGA and DTG curves of plant-filled polymer films based on highly plasticized PVC: (a) and (b) – with addition of SF, (c) and (d) – with addition of BF, (e) and (f) – with addition of RH.

Table 1.

Compositions of the studied plant-filled polymer films based on highly plasticized PVC.

Table 1.

Compositions of the studied plant-filled polymer films based on highly plasticized PVC.

Composition of samples

PVC/plant filler

|

Component, wt.% |

| PVC composition |

Plant filler |

| Spruce flour |

Birch flour |

Rice husk |

| PVC |

100 |

- |

- |

- |

| 80/20-SF |

80 |

20 |

- |

- |

| 60/40-SF |

60 |

40 |

- |

- |

| 80/20-BF |

80 |

- |

20 |

- |

| 60/40-BF |

60 |

- |

40 |

- |

| 80/20-RH |

80 |

- |

- |

20 |

| 60/40-RH |

60 |

- |

- |

40 |

Table 2.

Results of thermogravimetric analysis of plant-filled polymer films based on highly plasticized PVC.

Table 2.

Results of thermogravimetric analysis of plant-filled polymer films based on highly plasticized PVC.

| Sample |

Temperature value at mass loss during the decomposition (°C) |

| Тmax of 1st stage |

1st stage range |

Тmax of 2nd stage |

2nd stage range |

| PVC |

282 |

246 – 347 |

462 |

425 – 558 |

| 80/20-SF |

273 |

240 – 368 |

458 |

418 – 557 |

| 60/40-SF |

267 |

235 – 362 |

447 |

416 – 562 |

| 80/20-BF |

272 |

244 – 366 |

452 |

424 – 567 |

| 60/40-BF |

269 |

242 – 372 |

444 |

415 – 563 |

| 80/20-RH |

297 |

246 – 369 |

454 |

414 – 568 |

| 60/40-RH |

297 |

244 – 367 |

443 |

414 – 565 |

Table 3.

Mechanical characteristics of plant-filled polymer films based on highly plasticized PVC.

Table 3.

Mechanical characteristics of plant-filled polymer films based on highly plasticized PVC.

| Sample |

Tensile strength, MPa |

Relative elongation at break,% |

| PVC |

18.0±1.0 |

427.4±29.3 |

| 80/20-SF |

7.4±0.4 |

124.7±28.2 |

| 60/40-SF |

5.1±0.2 |

62.4±7.6 |

| 80/20-BF |

8.7±0.2 |

140.0±12.5 |

| 60/40-BF |

5.9±0.3 |

131.8±11.1 |

| 80/20-RH |

6.9±0.8 |

126.9±20.4 |

| 60/40-RH |

6.2±0.2 |

81.6±11.1 |

Table 4.

This is a table. Tables should be placed in the main text near to the first time they are cited.

Table 4.

This is a table. Tables should be placed in the main text near to the first time they are cited.

| Sample |

Swelling degree, g/g |

| after 24 hours |

after 7 days |

| 80/20- SF |

0.043±0.018 |

0.060±0.009 |

| 60/40- SF |

0.113±0.007 |

0.119±0.006 |

| 60/40- BF |

0.107±0.015 |

0.126±0.017 |

| 60/40-RH |

0.112±0.011 |

0.121±0.007 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).