2.1. Fundamentals and Past Studies

Anisotropy is an outstanding characteristic of composite materials and leads, in a more general case, to the elastic constitutive relationship given by Equation (1), observing the minor and major symmetries existing for the 4th order stiffness tensor [

5]:

And according to Voigt or Engineering notation, the above relationship is rewritten as follows [

5]:

Based on the analysis of symmetry planes for levels of anisotropy less accentuated than that explicit by Equations (1) and (2), it can be demonstrated that in orthotropic composites, for example, the stiffness tensor depends only on nine independent constants, that is [

5]:

From the previous mathematical descriptions, the stiffness tensor for an orthotropic laminated composite can be represented as a function of the elastic constants for the homogenized material, which form each component of the stiffness tensor in Equation (3) [

6]:

in which,

[

6].

For a stress field that depends only on the spatial variables contained in a plane, i.e.,:

with,

the plane state stress field acting on a lamina can be expressed as [

5,

6]:

Considering orthotropy and in relation to the principal directions of the material, Equation (5) reduces to [

5,

6]:

The linear transformation of the base through the product of the rotation tensor by the stress tensor in the original base and, consequently, by the product of the resulting matrix by the transpose rotation tensor, can be expressed by Equation (7) [

5,

6]:

where,

then:

With the angle ϕ being positive (counterclockwise), neverthless, conventionally in studying laminates it is defined

to indicate the orientation of the lamina in relation to the principal axes of the laminate and in a complementary way the parameters are also defined

. Therefore, it is written [

5,

6]:

and

According to Shenoi and Wellicome [

6], the transformation of the components of the stiffness matrix with respect to the symmetry axes of an orthotropic lamina (

is expressed by:

and

Within the domain of geometric linearity, the strains in a lamina are described by [

5,

6]:

where,

is the strain in the midplane of the lamina [

5,

6].

Second the classical theory of plates and shells, the internal forces acting in an xy plane are given by [

5,

6]:

whose dimensions are force/length, and [

5,

6]:

where the appropriate dimensions are torque/length [

5,

6].

Physical modeling of classical laminated plate theory considers the following hypotheses below [

5,

6]:

There is a plane state of stress in each lamina.

There is no slipping between any two laminae.

The laminae remain cohesive.

A line of material perpendicular to the midplane remains this way in relation to it in the deformed configuration.

In this way, the laminate deforms according to matrix Equation (14). Strains are assumed to vary continuously throughout the laminate and in-plane stresses change linearly across the laminate. According to these hypotheses, the calculations begin with the linear variation of the strain distribution in a plane and the constitutive relationship of the k

th lamina referring to the principal directions of the lamina is expressed by [

5,

6]:’

Concerning the principal directions of the laminated composite, it can be written [

5,

6]:

The stiffness tensor in Equation (22) is expressed by the set of equations from (23) to (28) [

5,

6]:

The strain vector

of the k

th lamina as a function of the z coordinate is given by [

5,

6]:

where z is the coordinate of the midplane of the k

th lamina

Then:

It is observed that in the case of a laminated composite with

, the matrices

and

are equal. Due to the stresses in the plane showing a discontinuity at interfaces, the sum of the integrals of separate laminae must be used [

5,

6].

Contracting the Equation (26), it can be written [

5,

6]:

Matrices A and B are defined in the following ways [

5,

6]:

Due to the matrices

are symmetric ones, matrices A and B are also symmetric, thus,

. By analogy, for the torque equation, it can be expressed as [

5,

6]:

with i and j

{1,2,6}

Observing the existing symmetry for the matrix D (

, in contract form, can be written the following matrix equation [

5,

6]:

It should be noted that matrix A has a force/length dimension, matrix B has a force dimension and D has a force x length dimension. The matrix A determines the stiffness in the midplane of the lamina under the influence of tension, compression and shear. The

elements are called laminate planar stiffnesses. They are independent of the lamina packing sequence and the term

is a weighting factor for the lamina thickness. Matrix B is responsible for the coupling effects between in-plane stresses and curvatures, between bending and twisting moments, and between strains that occur in the plane. This is called coupling matrix and the elements

are the coupling stiffnesses and depend on the stacking sequence. D is a matriz that determines the stiffness of the laminate in a perpendicular direction under the influence of bending and torsional moments, while the elements

are the so-called flexural stiffnesses of the laminate and also depend on the lamina assemblage sequence [

6].

To the rotations of the coordinate system around an axis normal to the laminate midplane, the same transformation matrix T (here with respect to ϕ > 0) can be used. This linear transformation exhibit the fact of the laminate’s stiffnesses are function of analysis orientation [

6].

The compliance tensors represented by matrices [a], [b] and [d] are given for the following Equations (41) to (43) below [

6]:

Due to the assembly anisotropy of the laminate, there are several couplings between stresses and strains that are absent in an isotropic material. Most of these coupling effects, especially those resulting from matrix [B], are undesirable and should be avoided, except for very specific cases. To demonstrate these effects, it is simpler to analyze some elements of matrix [b]. Well, the existence of the element

leads to the curvature

caused by an axial force

and a moment

to cause a strain

. These coupling effects can be verified between other elements of the matrix [b] and respective components of forces and moments [

6].

In order to avoid these coupling effects, it is sufficient to make [b] = 0 or [B] = 0. From the analysis of Equation (34) it can be noted that a symmetrical laminate in relation to the midplane, i. e., with the same number of layers (same configuration) above and below that plane, will not present the coupling effects caused by matrix [B] [

6].

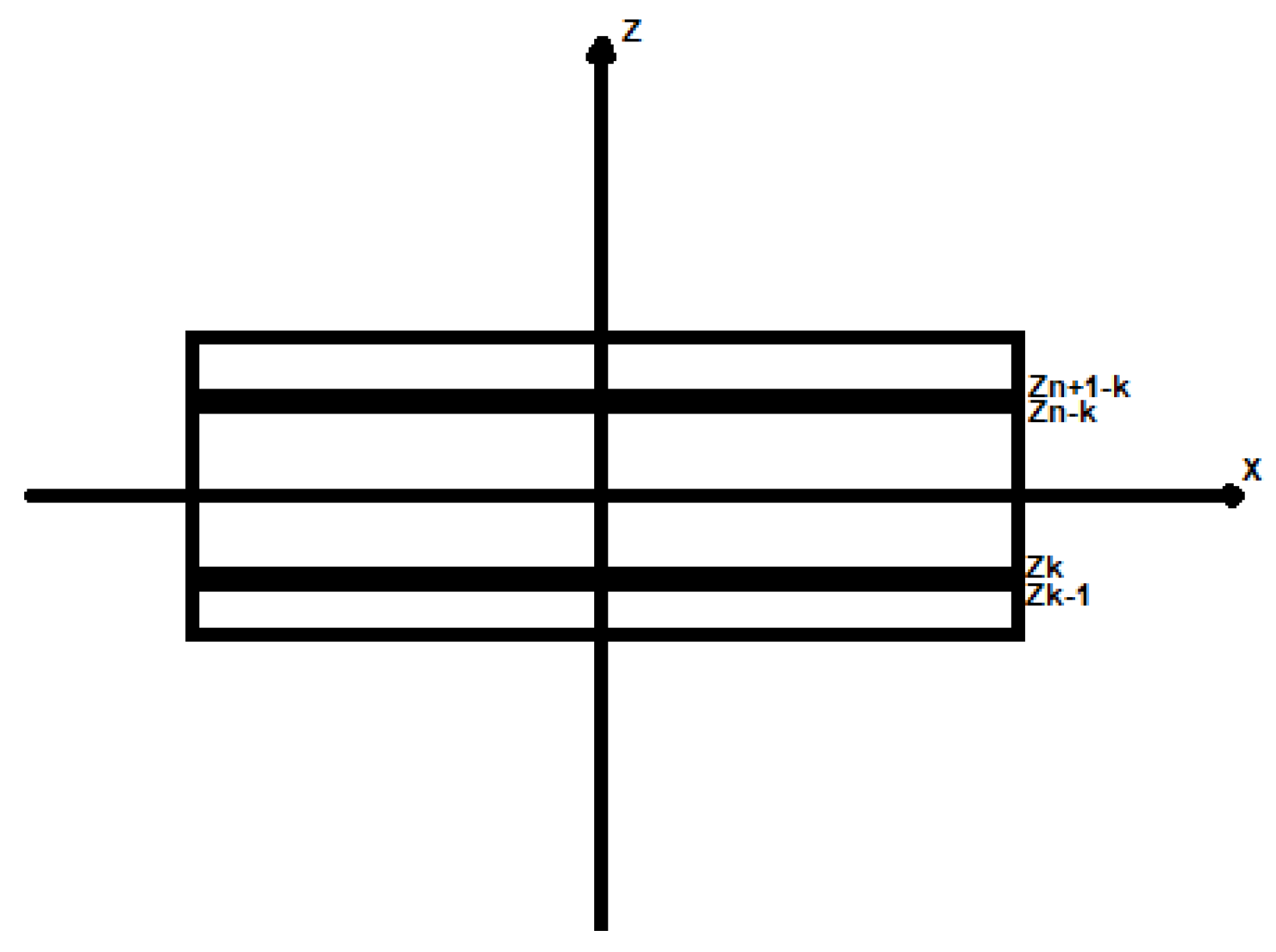

Figure 2.

Schematic representation of a possible symmetry between

layers [

6].

Figure 2.

Schematic representation of a possible symmetry between

layers [

6].

From

Figure 1 it can be seen that the k

th lamina is symmetrical, in relation to the midplane, to the (n+1-k)

th lamina. Both laminae of each pair are identical and have the same orientation, as follows [

6]:

But,

, in other words, the symmetric contributions in relation to the midplane cancel each other out [

6].

In addition to the laminated composite concepts mentioned above, it can also be structured with orthotropy in relation to the in-plane stiffness matrix, [A], that is, to constitute the material in such a way to obtain the elements

with respect to the principal directions of the multiphase material [

6].

The Equation (33) shows that orthotropy in relation to the planar stiffness of the laminate can be created using pairs of identical laminae and when one of them has an orientation

, the symmetrical one must have an orientation

. In this condition, the contributions of each lamina in the pair to

and

cancel each other out, given that:

. There are no requirements regarding the packing sequence of these laminae. Therefore, it is easy to make a combination so that there is orthotropy in relation to planar stiffness with symmetry to the midplane [

6].

Layers with 0°/90° orientation do not generate the terms

, and they can be included to angle ply laminates, i.e., those with

in a layer and

in another, without disrupting its orthotropy characteristic. Laminates with a 0°/90° orientation are called cross ply laminates, which are always orthotropic in relation to the matrix [A] [

6].

As regards matrix [D], it is also possible to obtain the orthotropy, which means, in summary, to have

. From Equation (36), it is noted that this characteristic of [D] is contradictory to that of [B], because to be achieved it, the laminate needs to be antisymmetric in relation to the midplane, however, for practical issues, the consideration of not coupling made to the matrix [B] is indispensable [

6].

According to the works of Jones [

7] and Daniel and Ishai [

8], macroscopic theories of failure in composites have been proposed as extensions and/or adaptations of theories for isotropic materials in the sense of considering the characteristic of anisotropy and strength of the composites.

First of all, strength to failure of a simple isolated lamina is discussed, for which the theories can be subdivided according to [

8]:

Non-interactive or limit theories (direct comparisons between stresses and strains in a lamina with the respective limits for each that field, for example, the theory of maximum stress and strain).

Interactive theories (where interactions between stress components are considered, for example, Tsai-Hill and Tsai-Wu)

Failure-mode-based or partially interactive theories (in which separate criteria are used for fiber, matrix and interface, for example, those of Hashin-Rotem and Puck).

Due to the synthesis aspect of this research, it adresses only the last two groups of theories mentioned above, considering that they present more sophisticated models than non-interactive theories. Firstly, the theoretical macroscopic failure model for an orthotropic Tsai-Hill lamina is described, which is based on the Von Mises maximum distortion energy criterion, thus, can be written [

8]:

In which each F (1, 2 and 6, respectively) represents the ultimate strength to longitudinal, transverse and shear stresses in-plane of the lamina, while the stresses indicated in the numerator are the respective ones acting. The Equation (45) does not differentiate tensile strength from compressive strength, only making a distinction for the appropriate values according to the signs in

and

[

8].

The limitations of the Tsai-Hill criterion are associated with the fact that it is based on a physical model in which the set of hypotheses includes the homogeneity and ductility of the material, however, it is known that most composites have marked characteristics of heterogeneity and brittleness [

8].

The Tsai-Wu criterion is based on the concept of strength tensors, which is more general for failures in composites and gives rise to strength predictions in general stress states. More specifically, Tsai and Wu suggested the so-called polynomial theory of modified tensors, where the existence of a failure surface in the stress space is assumed. Therefore, the mathematical model of the criterion can be expressed by [

8]:

In which,

and

are the respective second and fourth order strength tensors whose components can be mathematically obtained from algebraic expressions that include the strengths related to the appropriate acting stresses [

8]. For a plane stress state it can be expanded in following form [

8]:

As can be seen, both the Tsai-Hill and Tsai-Wu criteria do not consider the relationship between the kinds of acting loads and failures in the constituents of the composite, in other words, in the fiber and in the interfibers regions (matrix + interface) [

8]. As the ultimate tensile strength for other axis, except the longitudinal of the fibers, are experimentally distinct for ductile and brittle matrices in a unidirectional composite, Hashin and Rotem noted that failure in a lamina can be conditioned on a non-single criterion, as can be seen in Equation (48), for example:

where, consecutively, Equation (48) defines a double criterion regarding failure for the fiber and for the interfiber region, with the lamina being subjected to a plane stress state. Regarding strengths

, for linear behavior until failure, the ultimate strength is used, whereas in cases of non-linearity the proportional limit can be used [

8].

Puck’s theory can be seen in a detailed way in the next section, but like the Hashin-Rotem theory, it also considers non-linear aspects of stress-strain relationships and also distinguishes fiber and interfibers, neverthless, because it is more complex and requires additional parameters related to the material without proven advantages, the Hashin-Rotem theory ends up being preferred in many cases [

8,54].

Daniel and Ishai [

8] also describe about failure criteria for fabric-reinforced composites. The authors state that the failure in these composites depends on the type of the weave, in addition to the fiber and matrix properties. In case of tensile loading along the plane of the laminae (acting in the two preferential axes) a non-linear behavior is presented due to the nucleation of micro cracks in the matrix, a mechanism that precedes the ultimate tensile strength.

Failure criteria discussed in this research can be used to analyzelysis in fabric-reinforced composites as long as they are properly modified. With this remark, the Tsai-Hill criterion, for example, can be presented with the following mathematical modeling [

8]:

Just as a complement to the previous discussion on failure criteria for structural composites, reference is also made to the works of Robinson et al. [

9], Hilton et al. [

10], and the classic paper of Tsai and Wu [

11], where is proposed a general theory of strength for anisotropic materials.

Also in the way to establish mathematical models as parameters for evaluating macro failures in structural composites, the context of buckling is analyzed, which constitutes a relevant failure mechanism in structural components. In this sense, Ventsel and Krauthammer [

12] present an interesting macromechanical modeling about buckling of orthotropic circular cylindrical shells, which can be useful for laminated composite structures with this directional characteristic after having their effective properties and, consequently, homogenization defined. To this end, these authors are based on the Donnell-Mushtari-Vlasov theory (DMV theory) of thin shells in order to determine the governing equations for that kind of shell subjected to uniform axial compression loading

. In this context, the authors have obtained [

12]:

where,

are the bi-harmonic operators associated respectively with the bending and extension stiffnesses, and the distortion stiffness of the cylindrical shell. R is the radius of curvature of the circular base,

is the stress function and w is the displacement function in the z direction (with x and y belonging to surface of the problem) [

12].

Using the Galerkin method and assuming that the critical load corresponds to the axisymmetric instability mode with only circumferential bulges, can be written the following solutions for the displacement function and critical load, consecutively [

12]:

where,

is the so-called small parameter (ratio between the deflection w

0 at a reference point of the middle surface and the thickness of the structure),

is the longitudinal half-wave length caused by the instability and,

, are components associated with the bending and axial stiffnesses, in this case [

12].

In a study conducted by Jeong et al. [

13], a macroscopic dynamic analysis of a laminated composite is carried out based on the Euler-Bernoulli plate and beam theories, taking into account the anisotropy of the material. In summary, after investigating the dynamic characteristics of an epoxy/carbon fiber composite experimentally, the authors conclude that the proposed macromechanical modeling has been able to predict those to a satisfactory approximation.

Fundamental dynamic macromechanical aspects for laminated composites are explored by Aydin et al. [

14]. From this published chapter it is possible to highlight the modeling presented for the transverse vibration of an orthotropic laminated plate of dimensions (a x b) upon which, applying the force balance, can be written [

14]:

where,

is the displacement in the transverse direction z and the terms indicated by D are constants obtained from the integration of stiffness terms and

is the mass per unit area of the laminate [

14]

From Equation (54) the natural frequencies can be computed and the respective vibration modes of the plate are expressed by [

14]:

In which m and n are the indices related to each vibration mode and

[

14].

Concerning the damping of dynamic loads in polymer laminated composites, the authors in [

14] comment that although the main energy dissipation mechanism appears to be viscoelastic, other processes such as: thermoelastic, Coulomb friction, cracks and delaminations are also forms of energy dissipation in this kind of composites.

One multiscale analysis was proposed by Ladeveze and Dantec [

15] in order to predict the mechanical behavior at the level of an elementary composite lamina and its effects on the entire laminate. These researchers used damage mechanics to describe microcracks in the matrix and the separation between fiber and continous phase, to this end, they developed a plasticity modeling in which the distinctions between tension and compression, as well as the directions of the fibers are considered. To prove the model’s ability to account for the aforementioned characteristics and effects on the mechanical behavior of the multiphase material, the authors of the study [

15] compared theoretical results with those obtained from tensile and compression tests.

Especially in the last two decades, modeling procedures proposing integration between the micro and macromechanical scales of analysis for composites have had significant growth, as can be seen below by describing some researches. Initially, stands out the study of Aboudi and Williams [

16], in which the modeling aims to predict the response of multiphase composites whose constituents are hygrothermoelastic. In special cases which polymer continous phase are composed of thermoset resins, as epoxy and polyester, the effects of temperature and moisture variations may be relevant and must be computed to the strain analyzes and properties degradation studies related to the laminated composites [

16,40].

One of the distinguishing features of the study [

16] is the suggested geometric modeling, in which the multiphase laminated composite is formed from several inclusions immersed in a matrix. Other hypotheses assumed are: the plane containing the fibers (x

2x

3) has dimensions much larger than the thickness H in the direction of the x

1 axis, the composite has a periodic structure in the x

2x

3 plane and variable in x

1.

Then, the construction of the geometric model use a generic unit cell composed of eight subcells identified by local variables (α, β, γ), with the dimensions of the subcells fixed at x

2x

3 (h

1, h

2 and l

1, l

2) and variables from one generic cell to another along x

1 (d

1(p), d

2(p)), where the index p refers to the cell number and is associated with the dimensions of the subcells in this direction. As p remains constant in the x

2x

3 plane, two other indexes q and r have been introduced to identify a generic cell in these directions as well, so each cell is indicated by (p, q, r) [

16]. When containing M generic cells in the x

1 direction, the thickness H of the laminate is determined by:

Micro-macromechanical modeling has been formulated to satisfy governing equations for a monolithic hygrothermoelastic material in each subcell, as well as fulfill interface conditions and satisfy appropriate boundary conditions [

16]. For analysis, the researchers base their model on the approximation of the displacement, temperature and moisture concentration fields in each subcell (of any cell) to the corresponding fields in the center of the subcells and a quadratic expansion in the local coordinates (x

1(α), x

2(β), x

3(γ)) of the same [

16], in summary, for the displacements, temperature and moisture concentration can be written:

where,

are the displacements in the centers of the subcells,

,

and

are all the micro variables that must be obtained for the subcells of the coupling of the governing equations of the hygrothermoelastic material with the interface and boundary conditions [

16].

In Equation (61),

is the approximation for the temperature field in a given subcell,

is the temperature at the center of the subcell (average temperature for the subcell),

are unknowns to be determined from the governing equations in the subcells, so as well as continuity and boundary conditions [

16].

The Equation (62) provides the deviation in relation to C

0 (moisture concentration distribution in a given subcell

),

is the concentration in the center of the subcell,

are unknowns to be determined from the governing equations in the subcells, as well as the boundary and continuity conditions [

16].

Subsequently, the authors carry out volume analyzes for the equilibrium, energy and diffusion in order to write the coupled governing equations for the hygrothermoelastic multiphase composite in all its M generic cells [

16], which in contracted form are expressed by:

where, A is the matrix that represents the stiffness tensor that contains geometric information and the hygrothermoelastic properties of the materials that constitute all the subcells in the M cells of the composite,

contains

(includes the far field strain rates

, [

16]) unknowns which represent the rates of micro variables present and G is the so-called force vector, which contains information on the hygrothermoelastic boundary conditions applied and, even, the values of the micro variables in the current iteration t, given that the system of equations is solved incrementally [

16].

In terms of the development of micro-macromechanical models, i.e., modeling that starts from considerations involving each phase (such as the paper [

16]), to establish the influences of these components on the constitutive relation of the composites as a whole and, in this way, describe their physical behaviors with a better accuracy. In sequence, it is also done an extension on the study Toledo et al. [

17], where a micro-macromechanical approach for laminated composites is also proposed.

The authorss in [

17] provide a constitutive modeling for the components of the composite expressed as follows:

In which,

is the stress tensor, C is the elastic stiffness tensor,

is the strain tensor for the elastic regime,

is the strain tensor and

is the strain tensor in the inelastic regime [

17].

Assuming behaviors in parallel (all constituents have the same strain) and in series (all constituents of the composite are subjected to the same stresses) when a simple composite is analyzed with respect to its principal directions, the researchers in [

17] define the tensor ε* (containing strain components related to the directions of parallel behavior and stress components corresponding to the directions of behavior in series) and the tensor σ* (containing stress components related to the directions of parallel behavior and respective strain components corresponding to the directions of behavior in series) for the rearrangement of the analysis.

To express this proposed rearrangement, the following fourth order tensors are defined [

17]:

In which,

it is a threshold function with the variable p

rs assuming the following values [

17]:

In summary, this function is conditionally defined according to the physical behavior of that specific constituent of the composite.

Therefore, the stress and strain components are rearranged as tha set of equations below [

17]:

And combining Equation (64) with the equations in (67), the secant constitutive relation can be described by [

17]:

in which,

[

17].

Finally, Toledo et al. [

17] describe the constitutive model for a simple composite, in which the principal directions and the tensors

are coincident for all constituents, then:

, where c indicates an arbitrary constituent material. Additionally, considering that the inelastic strains of the composite in the directions in which the material works in series are given by the sum of the inelastic strains of the constituents weighted by the volume fraction of each one, we have in the secant equation of the composite (likewise to 68):

In which the authors consider

as the volume fraction of a generic constituent [

17]. Thomason’s analysis [

18] sought to determine micromechanical parameters, shear strength at the interface, fiber orientation factor and stresses in the fiber at failure of the composite by macromechanical tests on the composite. Next, it’s highlighted the use of data obtained experimentally by the researcher in the Kelly-Tyson method in order to predict the ultimate tensile strength, among other characteristics, considering a polymer composite reinforced with discrete fibers aligned in the direction of loading. Conclusively, this work shows that the macromechanical model used agrees, to a good approximation, with predictions made using other modeling.

Drago and Pindera [

19] carried out a micro-macromechanical research where effective elastic constants for two types of unidirectional composites are analyzed and compared using the finite element method with three sets of boundary conditions. The study is based on the concepts of periodic microstructural structure for heterogeneous materials (representative unit cell) and statistically homogeneous or macroscopically homogeneous materials at an appropriate scale (RVE - representative volume element). The numerical analysis of unit cells with increasing numbers of inclusions in square arrays quantified the convergence of the apparent engineering moduli generated under homogeneous boundary conditions in relation to the values obtained under periodic boundary conditions.

2.2. Advances and Recent Researches

In recent studies involving macromechanical modeling for laminated composites, can be initially mentioned the Korkeai et al. [

20] research, which proposes a modeling for the buckling of an elliptical laminated composite shell subjected to axial compression and shear loading, whose solution is obtained numerically using the finite strip method. The elliptical cylinder of elastic laminated composite has N laminae, where the position of each point of the cylindrical shell is indicated in the local coordinate system (x, θ, z), with

and the mathematical model used in [

20] to describe the macromechanics of this laminated structure is presented as follows:

where, [N] is the force/length vector for membrane loading, [M] is the vector of bending and twisting moments per unit length, [Q] is the vector containing the shear components along of thickness,

are the membrane, flexo-membrane and flexural stiffness tensors, respectively, as already seen at the beginning of the previous section. From the conclusions described by the authors, the fact of the arrangement of laminae (0, 90, 90, 0)s presented a higher critical load than the unidirectional modes (0)8 and (90)8 and (0,90)2s stands out [

20].

Still within this context of buckling analyzes of cylindrical shells made of laminated composites, Li et al. [

21] developed a research with the purpose of predicting failure due to instability in multiphase shells subjected to the submarine environment.

According to the authors of the sudy [

21], the analytical solutions obtained for the critical pressure, based on the equilibrium equations of bending stresses state in the elastic regime, have been validated by comparison with experimental data. As a differential for the research, the authors propose the consideration of geometric imperfections generated during the loading process. This is done by correcting the stiffness coefficients of the analytical model. According to the final conclusion, the determined analytical solutions can provide a practical and efficient way for the critical pressure evaluation of buckling within the considered project scenarios [

21]

At the scale of the laminae, Aoki et al. [

22] proposed a mesoscale modeling based on continuum damage mechanics, loading and unloading tests, as well as simulation to evaluate the effects of layer thicknesses on the evolution of damage in laminated carbon fiber composite. Based on the concept of elastic strain energy of damaged materials, the authors describe the constitutive relation given by the matrix equation below:

Where,

are called damage variables described as:

In which,

are the so-called thermodynamic forces in the fiber direction, their critical value and the equivalent,

the parameters are coupling parameters and

are material parameters,

is the accumulated diffuse damage before crack nucleation,

is the damage variable for transverse cracks,

is the rate of energy released due to the emergence of a new transverse crack and redistribution of diffuse damage along the lamina thickness,

is the degraded fracture toughness, ρ is the crack density (can be obtained by equality between the energy rate released and fracture toughness degraded). The way to calculate these variables, as well as the model for plastic strains can also be seen in [

22].

Aoki et al. [

22] confirmed through experiments that discrete damages (transverse cracks) are dependent on the layer thickness, neverthless, the evolution of damage in the lamina compliance tensor caused mainly by diffuse damage is independent of it. The mesoscale simulation combining finite elements and the proposed model revealed its limitation in accurately predicting delamination effects occurring in experiments with thin-layer composites [

22].

Ud Din et al. [

23] use a plane stress version of Puck’s failure theory as an indicator of the initiation of interlaminar meso-damage in order to predict the mechanical behavior of laminated polymer matrix composites. As described in [

23], the first sources of nonlinearities are the irreversible strains observed in softer polymer matrices and, subsequently, there is the damage accumulation (micro voids, cracks, decohesion between fibers and matrices, among others). These authors also mention the fact that most models based on continuum damage mechanics do not consider inelasticity caused by microdamage (

), only that due to irreversible strains in the matrix (

). Therefore, the total strain vector can be represented by [

23,54]:

Considering the previous conceptual observations, it is developed in [

23] a coupled anisotropic damage/plasticity modeling for the material. In damage mechanics, conceptually, all microdamage/void is homogenized over the continuum and an updated and less resistant version of the material is considered. In this continuum, unless cracks and microdamage occur, the equations of the analyzed physical fields are smooth and also continuous [

23], then, the effective stress vector,

, is written over a reduced effective area (due to microdamages and voids) as a function of the Cauchy stress vector, σ, and the so-called damage effect tensor, M(d) according to Equation (77).

where,

and

are, as already indicated in this work, the damage variables in the principal directions of the material and in-plane shear, constitute state variables that increase proportional to the applied load and due to the irreversibility of the damage. The upper indexes T and C distinguish tensile and compressive interactions, respectively [

23,54].

Consecutively, the authors described in [

23] the version of Puck’s theory for plane stress states, the damage progression criterion and the phenomenological plastic model. According to Puck’s conditions, there are two criteria for fiber failure in tension and compression (f

E,FFT, f

E,FFC) and three failure modes associated with mesoscopic transverse cracks along the thickness of a lamina (IFF initiation), which come from both the coalescence of microcracks in the matrix and the separation between fibers and matrices at the interfaces. The set of Equations (79)–(83) expresses these failure exposure factors, f

E [

23]:

In which,

the slope points quantify the increase in strength to fracture due to friction in transverse compression,

are due to stregnth in the direction of the fibers, transversal to them and shear in the plane,

it is a stress intensification factor associated with the distinct effects of modulus of elasticity of fiber and matrix, mode A is under transverse tension, mode B is under transverse compression and mode C is under transverse compression of higher magnitude [

23].

The researchers of [

23] formulate the state variables based on Puck’s theory to develop the damage evolution criteria as described below:

where,

are the rates of energy released and Lc is the so-called length of the characteristic element and depends on the size of the mesh that is used to discretize the domain and numerically solve the problem [

23].

To the plasticity modeling is used in [

23] the model given by Equation (87), which couples this inelastic phenomenon to Puck’s theory:

where

is the yield limit as a function of the accumulated equivalent plastic strain, a is a coupling parameter between transverse and in-plane shear plasticity,

and

are the coefficient and exponent of the hardening law, respectively [

23]. After incremental numerical modeling, the researchers from [

23] implement the models using computational tools and compare the theoretical results obtained with data previously available in the specific literature, verifying a good congruence between them.

In a recent study, Fuga and Donadon [

24] suggested a novel model for predicting progressive damage in laminated composites considering structural behaviors under static loading and fatigue. The static modeling carried out is based on orthotropic constitutive relations coupled to stiffness tensor degradation laws, see Equation (88) below:

Accordingo with the authors of the research [

24], an elasto-plastic constitutive behavior is exhibited by composites subjected to shear loads, which can be modeled through a shear modulus as a function of shear strain (

. In the approach in question, the researchers consider Mode II of fracture (in-plane shear) is insignificant, then,

and it can be assumed that the stress-strain relation of the material is linear for shear [

24].

Considering that the released rate of critical strain energy of the material is given by the area under the tension-separation curve for a given failure mode and the infinitesimal strain tensor, the relationship between the damage variables, d

ii, and the normal strains associated with the current maximum opening displacements, damage initiation and failure have been determined in [

24].

The hypotheses that cracks propagate only following the opening mode, that the direction of crack propagation can be determined independently from the behaviors in directions 1 and 2 of the lamina plane and that the evolution of crack length is governed by the given Paris law by Equation (89) are adopted in modeling damage in continuum under fatigue mechanism [

24].

After writing the crack lengths a

ii as a function of the fatigue and static damage variables

and

, respectively, and the lengths of the continuum, L

jj, the authors obtain [

24].

In which, N is the number of fatigue cycles, m

ii, C

ii, G

cii are the parameters of the Paris law in the appropriate directions, R is the ratio between the maximum and minimum loads,

is the released rate of strain energy in each direction. Based on the comparison of theoretical results obtained with experimental data from post-implementation literature, the authors believe that these models (static and fatigue) bring improvements to damage predictions in laminated composites subjected to these two structural stress mechanisms [

24].

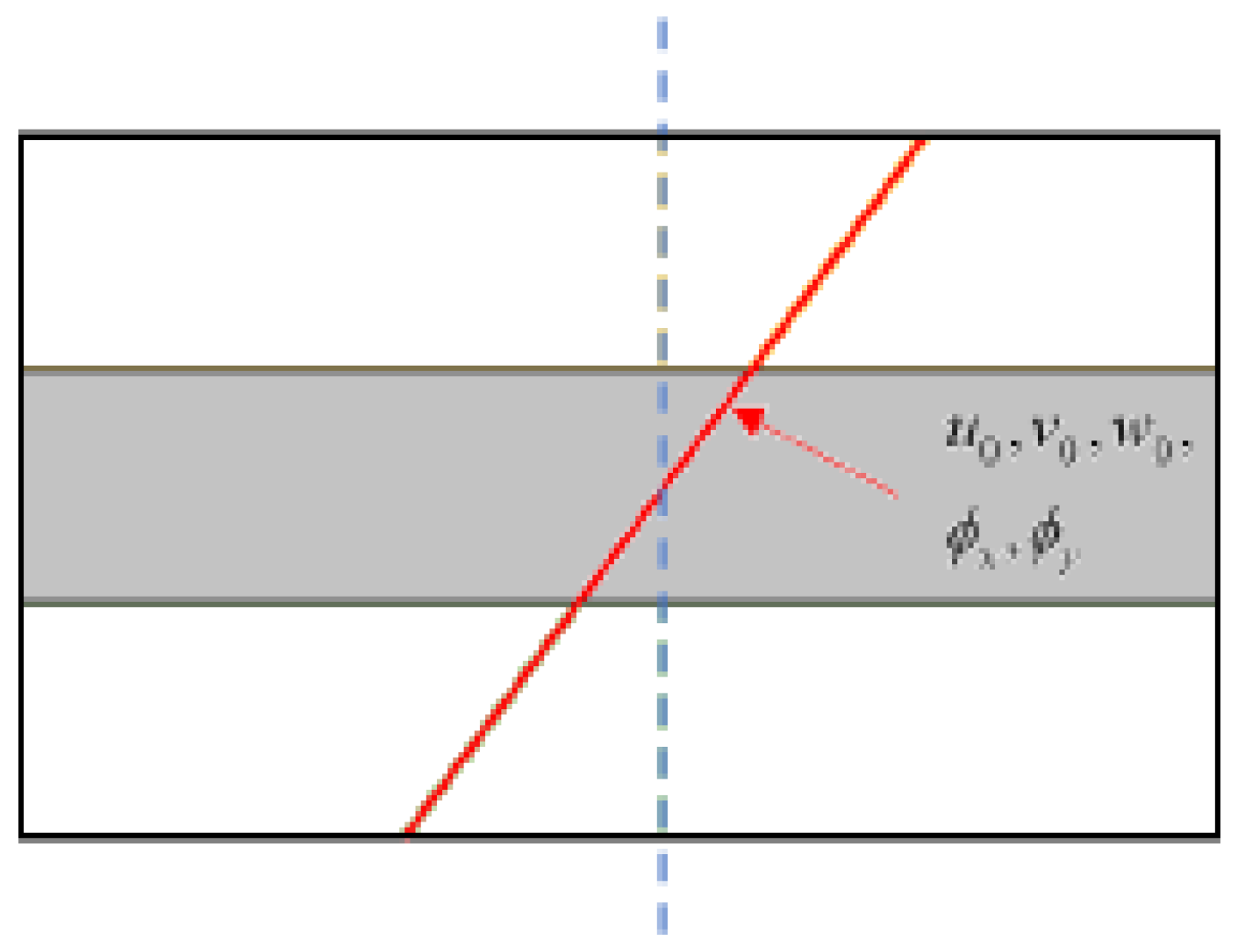

An overview of the so-called layerwise theories is provided by Liew et al. [

25]. In this research, a comparison is made with the theory of three-dimensional elasticity and the equivalent single-layer theories. Such theories have been highlighted in the modeling and numerical solution of plates and shells made of laminated composites in recent decades. Three-dimensional analyzes based on elasticity theory consider the composite structure without any special layered configuration are highly computationally expensive [

25].

The equivalent single layer (ESL) theories constituted by classical laminate theory, first-order and higher-order shear deformation theories reduce a three-dimensional problem to two-dimensional form and it is precisely this basic simplification that does not make them able of satisfying the fields of continuous displacements required and defined by parts (zig-zag continuity), in addition to not representing transverse stress fields with a good approximation [

25].

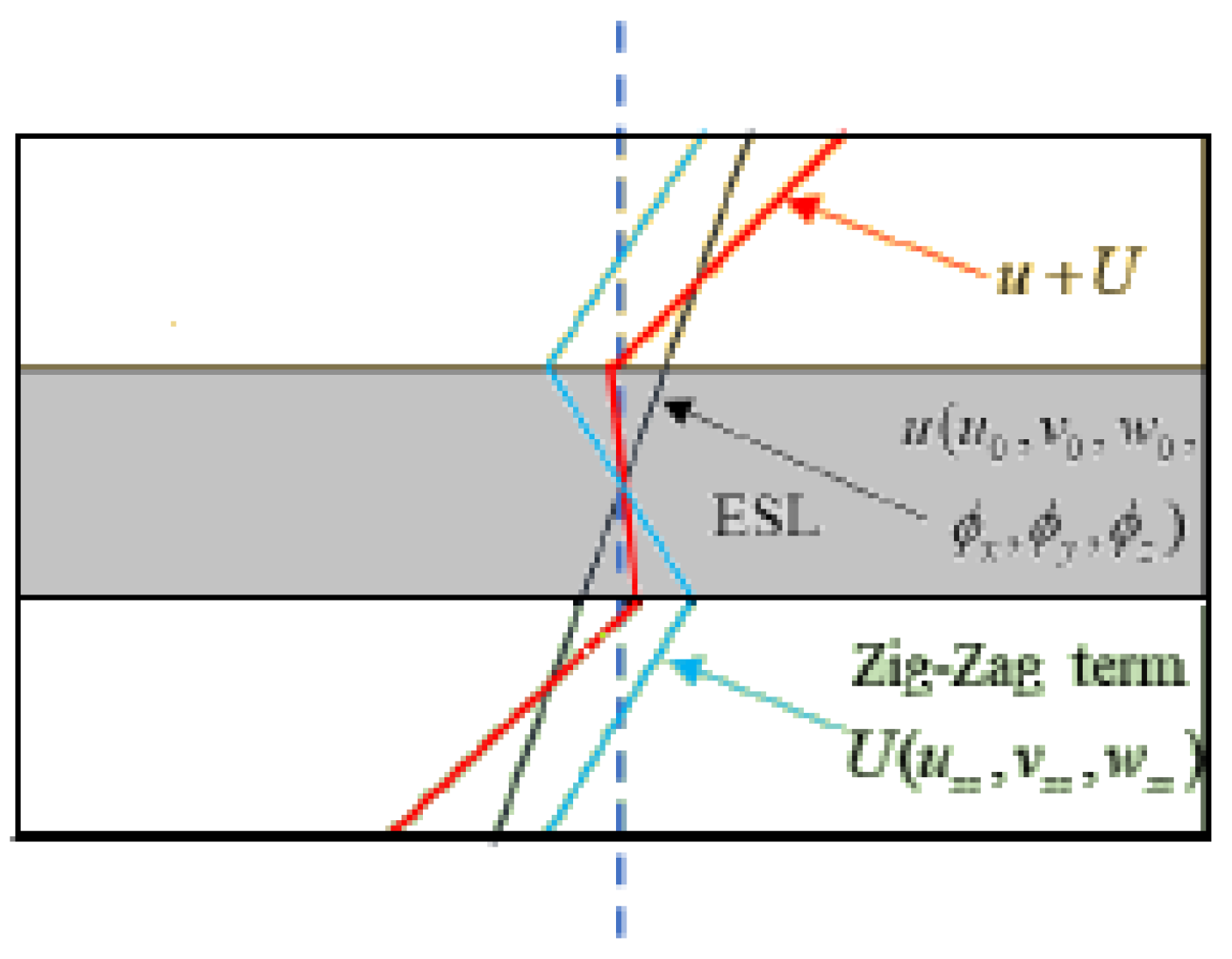

In order to overcome the aforementioned limitations, more refined theories such as zig-zag and layerwise theories have been proposed. The fundamental idea behind zig-zag theories is the consideration of the displacement field being a superposition of a first-order, second-order or higher order global field with a local zig-zag function. However, transverse stress fields cannot be accurately obtained through the direct solution of the constitutive equations [

25].

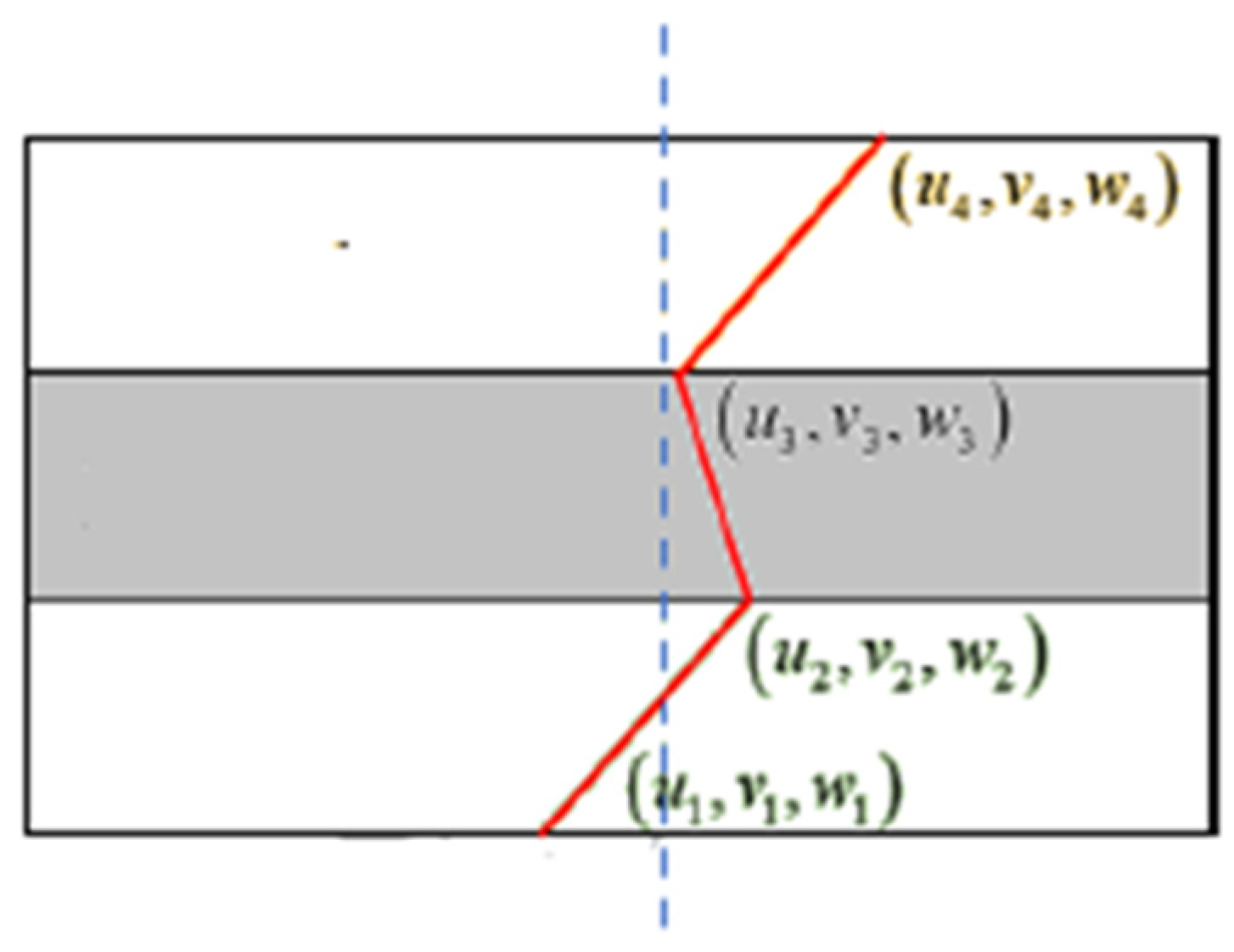

According to research [

25], layerwise theories can be classified in two ways: those based only on displacement variables and those called mixed, with displacement and transverse stress variables. The first group considers independent displacement fields in each layer and imposes compatibility conditions on the interfaces among layers. The second form of modeling works by satisfying displacement fields and interlayer transverse stresses using the variational principle. For comparative purposes, illustrations of displacement field modeling through equivalent single layer theories, zig-zag theories and, finally, layerwise theories were adapted from [

25], such representations can be seen in Figure 3, Figure 4 and Figure 5 below.

Figure 3.

Graphical representation of the modeling of displacement fields by the equivalent single layer theory [

25].

Figure 3.

Graphical representation of the modeling of displacement fields by the equivalent single layer theory [

25].

Figure 4.

Graphical representation of the modeling of displacement fields by the zig-zag theory [

25].

Figure 4.

Graphical representation of the modeling of displacement fields by the zig-zag theory [

25].

Figure 5.

Graphical representation of the modeling of displacement fields by layerwise theory [

25].

Figure 5.

Graphical representation of the modeling of displacement fields by layerwise theory [

25].

In the search for improving computational mechanical analyzes on laminates, the study [

26] works with a three-dimensional modeling for rectangular plates subjected to generic boundary conditions based on the strong sampling surfaces formulation (SaS formulation) and the extended differential quadrature method (EDQ). The first approach consists of choosing, within the n layers, I

n (

sampling surfaces parallel to the middle surface of the laminate and located at the so-called Chebyshev polynomial nodes. The coordinates of the sampling surfaces of the n layers can be expressed as [

26]:

In which,

and

are the coordinates of the interfaces

and

, respectively, in is the index that identifies any quantity in relation to the sampling surfaces of the n layers and varies from 1 to I

n. In this formulation, the total number of sampling surfaces is given by:

[

26].

The fields of displacement, strain, stress and the constitutive relation of the sampling surfaces are determined by [

26]:

The continuity of the proposal modeling done in [

26] is based on the extended differential quadrature method, which is used by employing the Chebyshev-Gauss-Lobatto mesh in a rectangular domain [

26] to solve numerically, through interpolations based on Lagrange polynomial functions, the boundary value problem originated from Equations (93)–(96). Therefore, the authors of the research [

26] were able to conclude that such techniques used in numerical modeling facilitate their computational implementation, given that they use only first-order derivatives in the balance equations.

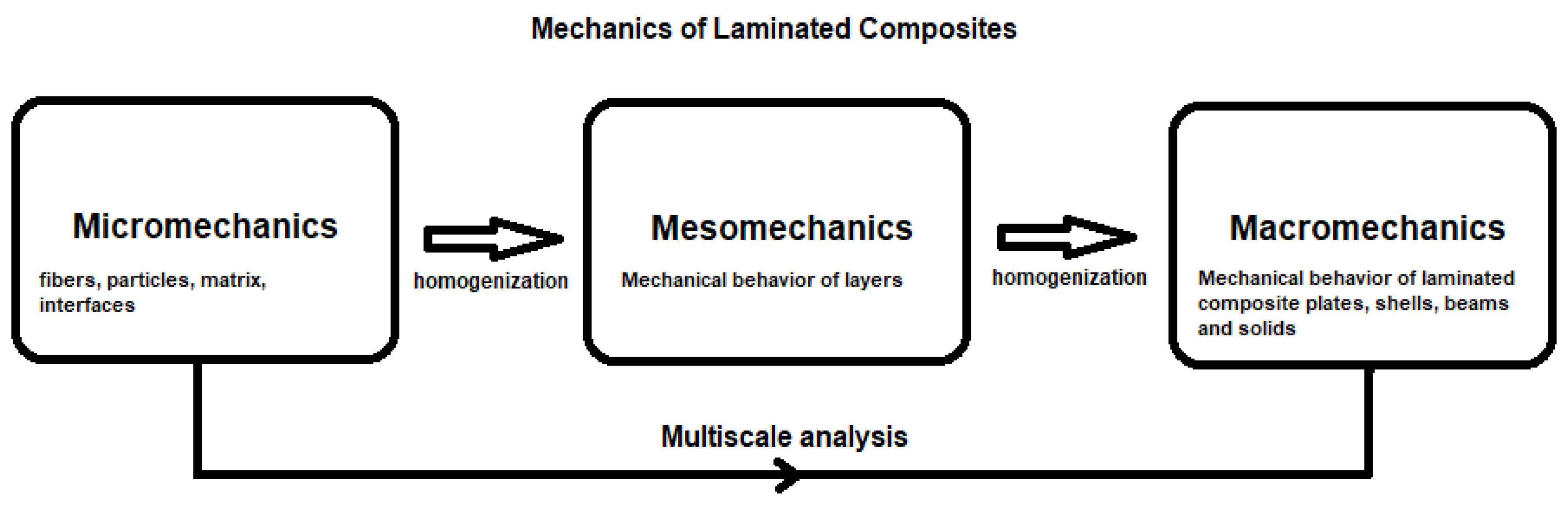

Concerning the multiscale analyses, some recent studies propose micro-macromechanical modeling to describe structural behaviors related to laminated composites. In [

27], researchers develop creep modeling in polymer matrix composites using a nonlinear viscoelastic constitutive model (Sawant model) based on the Shapery integral (Equation (97)), in order to examine the effects of stress and temperature on the time-dependent behavior that these materials present.

In which, in a more general case, the compliance tensor is a function of time, stress and temperature, then [

27]:

Substituting (98) into (97), can be written:

After adding nonlinear parameters to Equation (99), the authors of the research [

27] present the algorithms used to study creep in isotropic and orthotropic materials, in which the components of the compliance tensors are determined incrementally and iteratively through the model of the Prony’s series [

27].

Based on this, a micromechanical approach assuming the concept of a representative volume element (RVE), with a viscoelastic matrix and elastic unidirectional fibers with angles of 0° and 90° in relation to the loading, was shown to be able of determining the creep behavior of the composite with good approximation in relation to experimental data used. However, as this micro-analytical method is not suitable for various fiber orientations, a macromechanical experimental approach (considering 0°, 45° and 90° fiber orientations at different stress levels and temperatures) and a numerical approach assuming multidirectional laminates were conducted. Therefore, it was concluded that for low stress levels (linear viscoelastic behavior) the results of the experiment and numerical macromechanical modeling in glass fiber/vinylester laminates have good congruence, being slightly distinct as the stress levels rise and the non-linear parameters become more significant [

27].

A theoretical interesting study is the multiscale analysis of research [

28], which sought to improve low-velocity composite impact performance using shape memory alloy inclusions. The effective properties for the laminate are determined analytically by the VSPKc micromechanical model. The stresses that indicate the relevant strength to the evaluation of the damage caused by the impact can be calculated analytically using [

28]:

where,

is the critical expansion energy density of the matrix,

is the interface strength,

, are polynomial functions of the volume fraction of fibers defined in [

28].

Hence, the authors of this research carry out three different macromechanical numerical analyzes are developed in ANSYS, two of them with inclusions of shape memory alloys (included in parallel and in series with the upper layers of the composite), finally, the authors’ conclusion about a 63% reduction in average damage obtained with the addition

of shape memory alloy in series in the

glass fiber reinforced polymer composite [

28].

A micro-macromechanical modeling for creep was proposed in [

29], in which a stress analysis model was developed on a global scale, a study of long-term creep for the pure resin and a stress analysis at a micromechanical scale in order to extend the behavior to the resin creep to the laminate, updating the constitutive relations in each layer of the laminate.

The macroscopic stress analysis was carried out using finite elements in ABAQUS based on values of effective elastic constants determined from micromechanical models such as the rule of mixture, the semi-empirical Halpin-Tsai and Chamis models. Regarding the analysis of stresses at the micromechanical level, the authors of [

29] worked with two approaches: one to evaluate the degradation of the elastic creep constants and the other accounting for the elastic and creep strains separately, in both modeling the rule of the mixture was used. In conclusive words, the research [

29] found a satisfactory correspondence among the results of the suggested theoretical modeling and those was experimentally verified during long-term creep tests with polymer laminated composite pipes.

Li et al. [

30] developed a multiscale analysis based on Reddy’s layerwise theory to discretize the macroscopic model of a laminated composite plate. At the mesoscopic scale, three-dimensional finite elements were used in the numerical analysis in order to stabilize it and, finally, micromechanical modeling was carried out based on the concept of unit cells (RUC) made up of fibers and matrix. The authors were able to conclude, at the end of the research, that the proposed modeling (after being used even in analyzes with fabric-reinforced laminates) is promising in comparison with direct simulation and other methods of homogenization of the structural composite domain [

30].

Alazwari and Rao [

31] published an interesting recent study on micro- macromechanical modeling of laminated composites in the presence of uncertainty. According to these authors, fundamental parameters of this group of materials, such as the properties of the constituent phases, layer thicknesses, fiber orientation in each layer, as well as the loads requested by these structures have a certain level of variability and, consequently, the mechanical behavior of the material also have this characteristic. The uncertainty methods used in [

31] were: the probabilistic approach, interval analysis and the universal grey system theory.

Briefly, the probabilistic approach considers each basic variable in the composite to be random, whose mean and standard deviation values are known., then, the response of each quantity is calculated within the lower and upper limits (μ - 3σ, μ + 3σ), respectively [

31]. Lower and upper limits are also used in interval analysis, neverthless, in order to prevent computational calculations with these intervals from violating physical laws, a truncation parameter necessary for the maximum allowable variation is specified, which is determined from understanding the nature of the issue [

31].

Additionally, a text space is opened here for an explanation arising from the complementary study [

32], in which a grey system is defined as one whose information is only partially known, in other words, the variable values of the system are not completely unknown (black box systems) and not fully known (white systems), i. e., there are uncertainties associated with all information. Therefore, this theory defines the so-called grey numbers, which are uncertain values within a continuous set, and can be expressed as follows [

32]:

where, t represents information limited to the appropriate continuous range.

When developing analyzes simulating composites with different layer orientations in study [

31], Alazwari and Rao have concluded that mathematical operations considering the concept of grey numbers were able to predict the uncertainties of the analyzed systems within realistic ranges for the stress responses in the laminae with good accuracy and lower computational cost than the probabilistic approach (widely used in this context of composites) and that interval analysis, the latter being less economical, with large ranges of values and lower reliability to model uncertainty in the macromechanics of laminated composites.

Still within the modeling that considers the variables of laminated composites as random, Gholami et al. [

33] worked on a micro-macromechanical analysis aimed at the stochastic prediction of fatigue life for these multiphase materials. Initially, a deterministic modeling is carried out, coupling the continuum damage mechanics to the Bridging micromechanical model.

The elasto-plastic aproximmation of [

33] uses three variables associated with damage to fibers, matrix and fiber/matrix. After calibrating the parameters of the proposed model using experimental data, it was implemented in ABAQUS through a subroutine, with numerical results confirming that modeling plastic strains makes fatigue life prediction more accurate, especially with regard to fatigue low cycle. As for the stochastic model, the random variables considered were: the volume fraction of fibers, critical damage parameters and the mechanical properties of materials, both of which are assumed to have a normal distribution. The probabilistic approach with mean and standard deviation was used to describe the mechanical behavior of the material and through Monte Carlo simulation, the authors obtained the results of this stochastic process. Finally, a statistical analysis showed that the mean fatigue life obtained theoretically is close to the experimental one [

33].