This section presents the results of all the characterization series carried out on Sikadur and Loctite adhesives. All the data collected during the tensile and aging tests are analyzed in detail, providing valuable information on the performance of these adhesives. In addition, the focus will be made on comparisons between the two adhesives in order to determine their relative suitability for specific marine applications. The implications of these results for the industry and potential areas of research are also be discussed.

3.1. Adhesives Behavior before Aging

This section examines the initial mechanical behavior of Sikadur and Loctite adhesives before they are subjected to the aging process. The results of tensile tests carried out on adhesive samples prior to aging are presented and analyzed in detail.

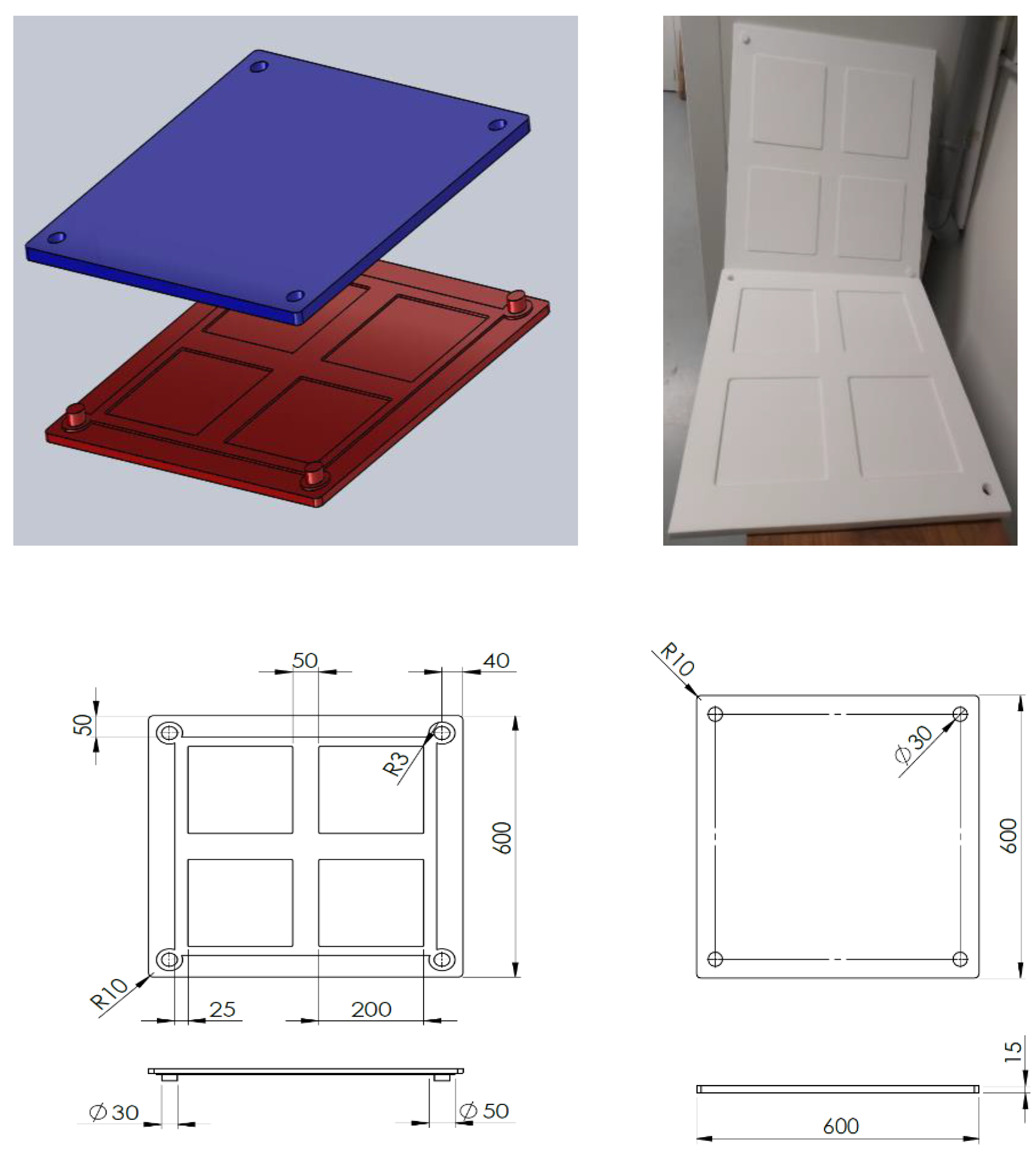

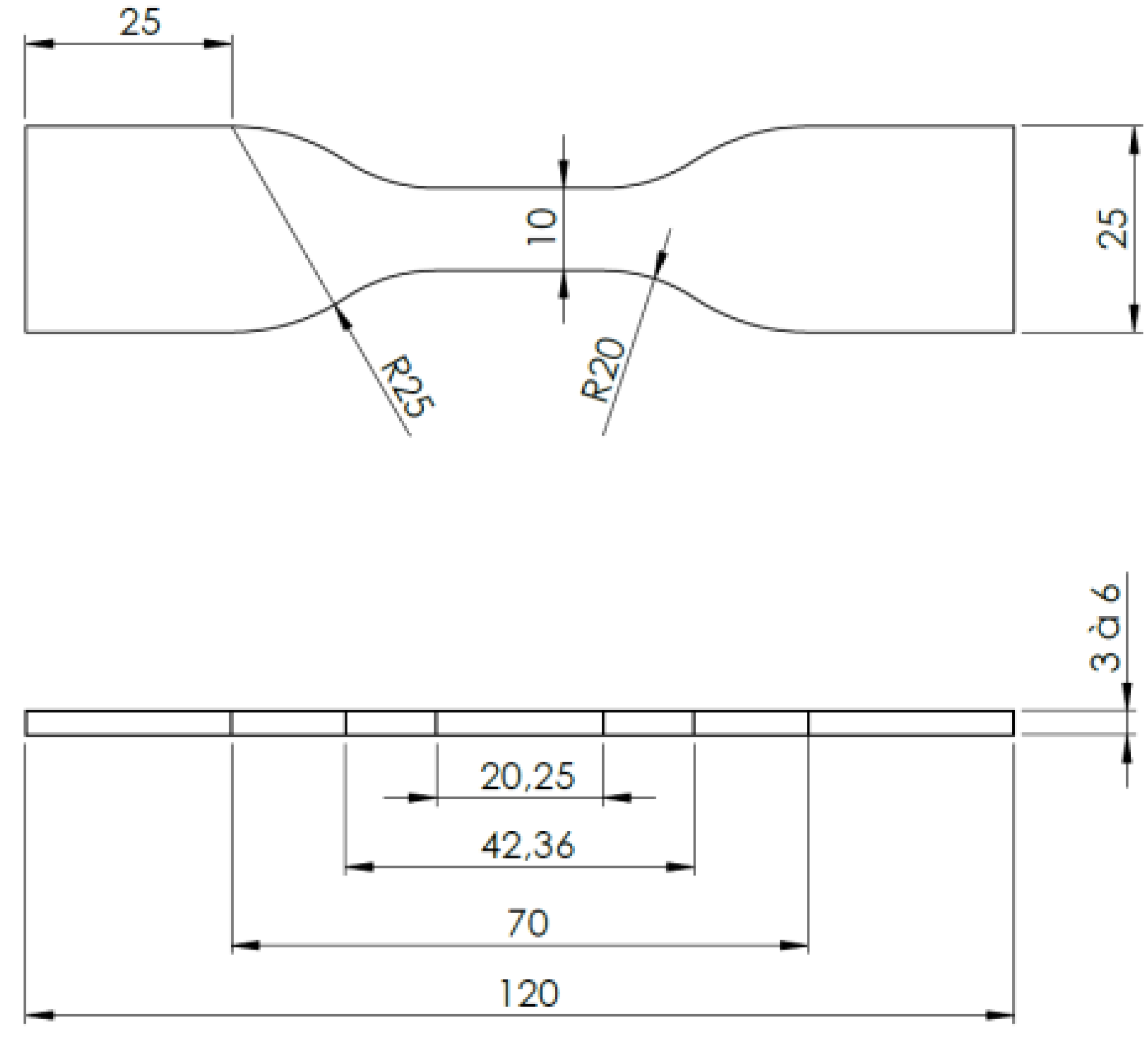

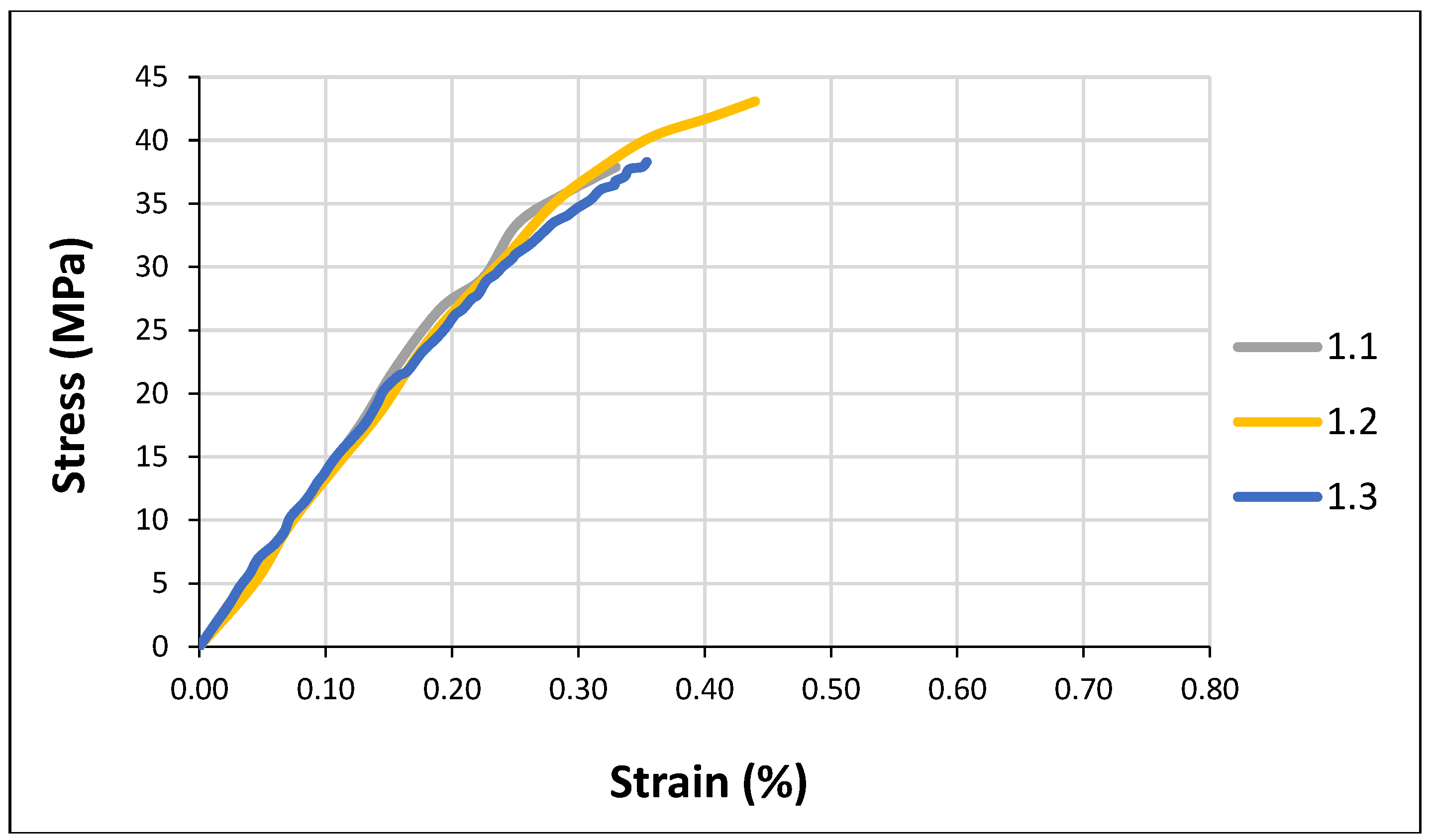

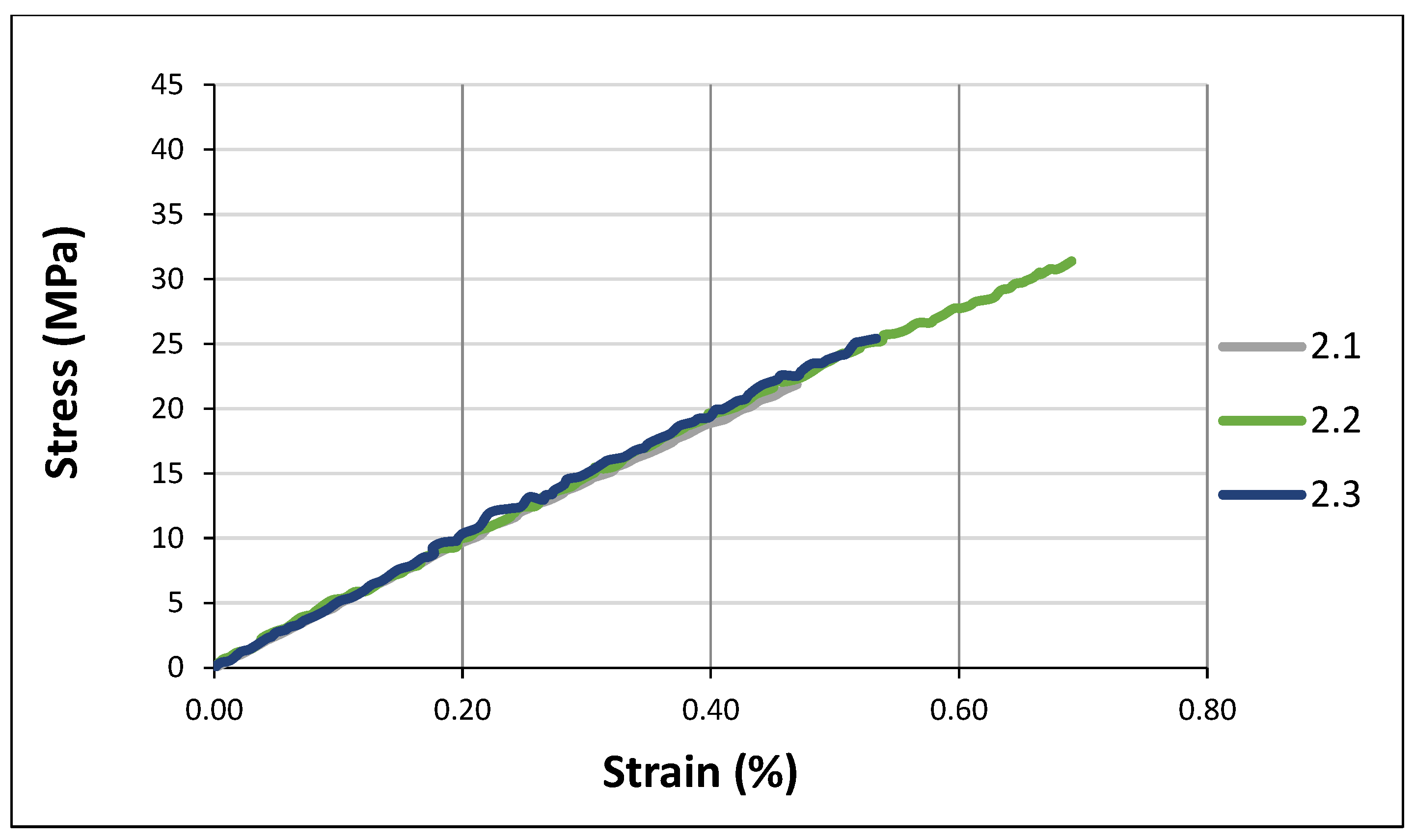

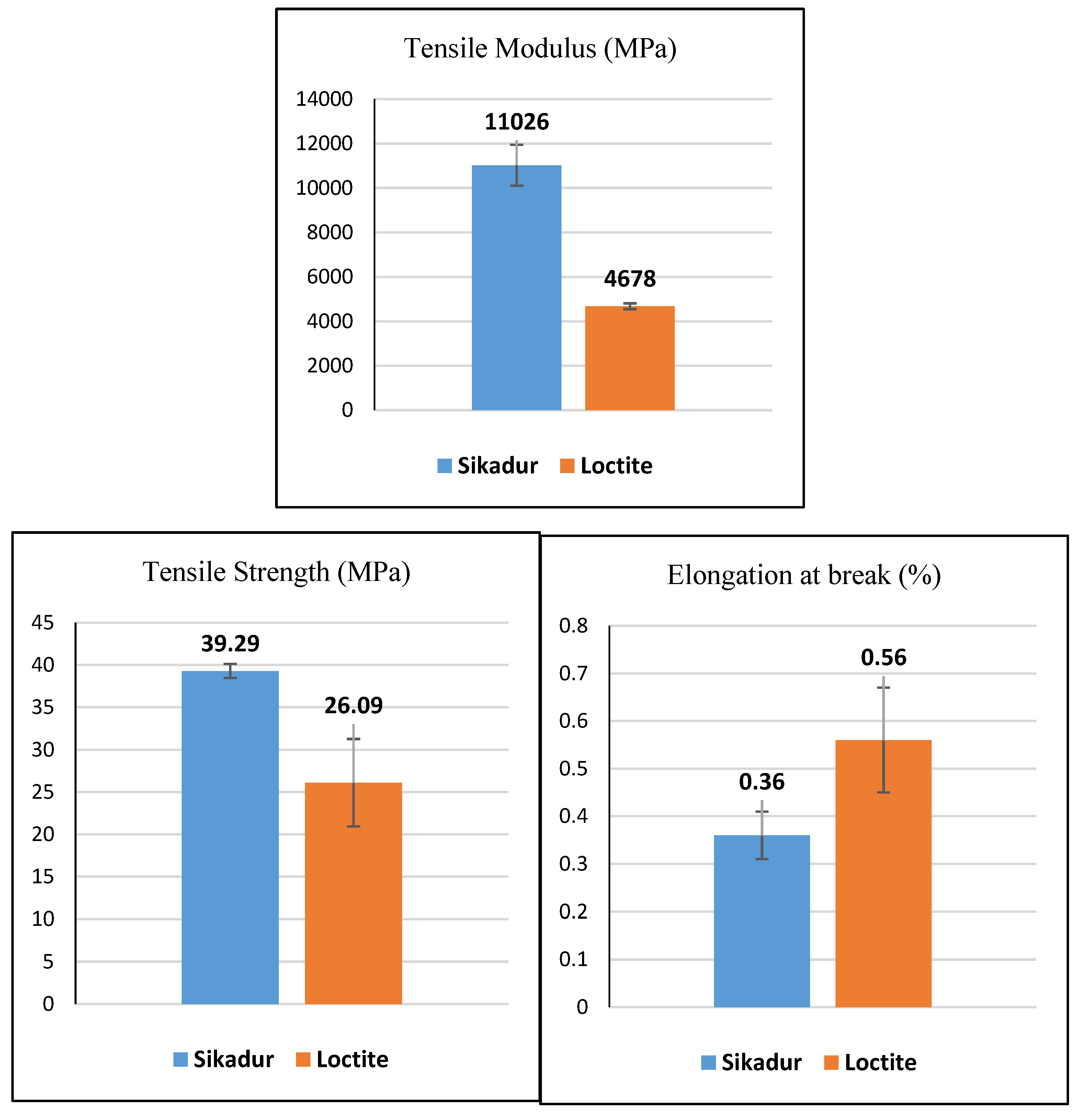

Figure 6 and

Figure 7 illustrate the tensile behavior of the adhesive samples under various conditions, focusing on the stresses recorded at the point of failure. Superimposed stress-strain curves for unaged Sikadur specimens are shown in

Figure 6.

As can be seen from

Figure 6 and

Figure 7, all the tensile curves show similar trends. This suggests a consistent mechanical behavior under different conditions. In fact, the results show that all the adhesives exhibit elastic behavior with a slight non-linearity observed up to brittle fracture. The assumed elastic character and the non-linearity of the elastic response could be interpreted as a discrete viscoplastic component.

The experimental tensile properties, extracted from

Figure 6 and

Figure 7, are summarized in the histograms (

Figure 8), including standard deviations for a better understanding.

Specifically, for the Sikadur adhesive, the average failure stress is 39.29 ± 0.84 MPa, and the elastic strain limit is 0.36 ± 0.05%. On the other hand, for the Loctite adhesive, the average ultimate stress reached 26.06 ± 5.17 MPa, with an elastic deformation limit of 0.56 ± 0.11%. These results are very close to the values quoted by the manufacturer.

Previous studies, such as those by Andersen et al [

1] and Gao et al [

9], have highlighted the importance of understanding the performance of adhesives in industrial applications. In addition, Chen et al [

5] have investigated the effect of moisture absorption on the mechanical performance of structural adhesive bonds, providing insights that may contribute to the interpretation of the behaviors observed in this study.

These initial mechanical characteristics are used as a reference to evaluate the effect of the aging process on the adhesive materials, following the methodology used in the studies by O'Connor et al [

18] and Williams et al [

19]. This comparative approach provides a better understanding of the performance of Sikadur and Loctite adhesives, and provides information to optimize material selection and maintenance practices in an industrial context.

3.2. Water Sorption Kinetics

This section focuses on the behavior of the two adhesives under aging conditions.

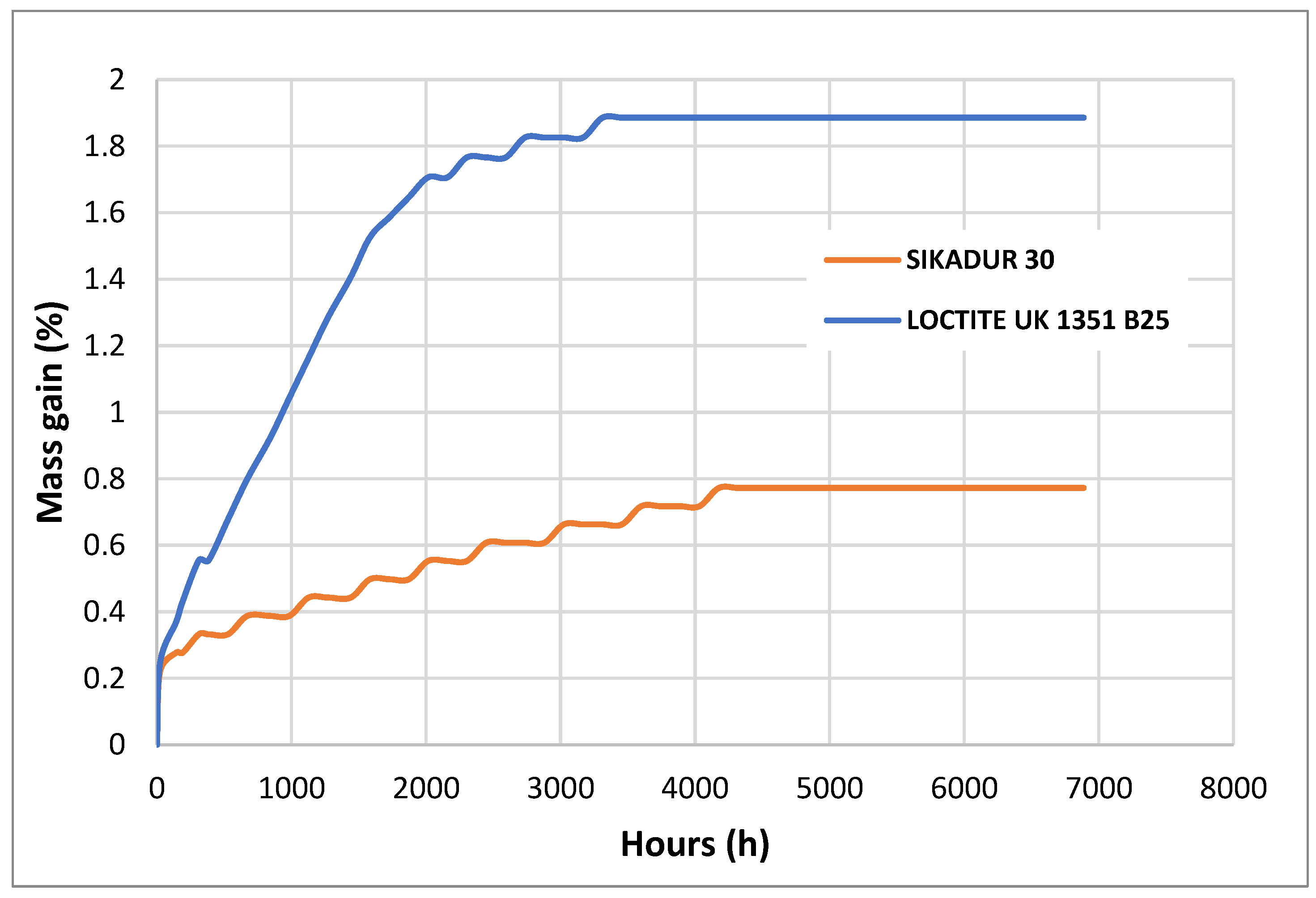

Figure 9 shows the mass uptake (in %) of both adhesives as a function of aging time in the specified environment and temperature. Simulations derived from the absorption model introduced by Bruneaux [

4] are superimposed on the experimental results. It is important to note that this model characterizes the absorption of water from the material as a process governed by the superposition of two mechanisms: i) firstly, the Fickian diffusion of water molecules through the free volume of the lattice. ii) secondly, the reorganization (or relaxation) of the macromolecular chains under the stresses of swelling. This allows the material to absorb more water than Fick's law alone predicts. This mechanism has been termed viscoelastic diffusion by Berens et al [

22].

The general shape of the mass evolution curves indicates the existence of two apparent regimes in the sorption kinetics:

In the short term and in the early stages, the kinetics of water absorption are very fast. In particular, the Loctite adhesive shows a significant absorption rate in the initial phase and it appears to have a higher free volume occupied by water. This initial phase therefore corresponds mainly to the filling of the free volume by the diffusion of water molecules, which is a thermally activated mechanism [

7,

23].

In the long term (over longer periods), the increase in water uptake is slow but continuous. No equilibrium is reached, but the evolution becomes asymptotic. This behavior cannot be explained by classical diffusion phenomena and would indicate either the presence of irreversible phenomena within the material or an internal reorganization of the macromolecular structure (chain relaxation) under the effect of swelling stresses [

4,

22]. Whatever the exact origin of the phenomenon, the observed effect appears to be the long-term non-saturation of the adhesive material.

According to

Figure 9, the comparison of the sorption kinetics for the two adhesives immersed in distilled water at 22°C shows that the initial water uptake is faster for Loctite adhesive. This could be related to a larger free volume accessible to water molecules by diffusion. In the long-term, however, the asymptotic plateau appears to be less pronounced for Loctite than for Sikadur. This result seems to be related to the extraction of the plasticizer during aging time.

From a quantitative point of view, if we look at the slope of the curve between 1000 and 30000h, we find a slope value of 6.5*10-4 (mass per hour) for Loctite adhesive and a slope value of 2.5*10-4 (mass per hour) for Sikadur adhesive. This means that Loctite adhesive has much faster absorption kinetics and it absorbs water at a slightly faster rate than Sikadur adhesive.

Figure 9 also shows an asymptotic plateau, which indicates the point at which water absorption slows down and the material appears to have absorbed as much water as it can under the specific conditions. For Sikadur, this plateau appears to be reached at around 2016 hours, whereas for Loctite it appears to be reached at around 2736 hours.

Similarly,

Figure 9 clearly shows the maximum absorption rates for the two adhesive samples. In fact, the Sikadur adhesive reaches a plateau or equilibrium value at around 0.7%, while for the Loctite adhesive this plateau is reached at around 1.8% by mass.

In addition, by expressing the changes in mass as a percentage of the initial mass of the samples, we can compare the relative performance of the materials in terms of water absorption. For example, after 2880 hours, Sikadur had absorbed approximately 60.77% of its initial mass, while Loctite had absorbed approximately 182.59% of its initial mass.

Finally, taking into account all the results obtained in this section, it can be concluded that there are important implications for the long-term durability and performance of adhesive materials in environments where water absorption is a critical factor.

3.3. Adhesives Behavior after Thermal and Hygrothermal Aging (after 46 Days)

As mentioned above, in the dynamic and demanding environment of offshore wind turbines, adhesives play a vital role in ensuring the structural integrity and longevity of critical joints. However, as these installations are subject to a wide range of environmental stressors, including temperature fluctuations and exposure to moisture, the durability of adhesives is of paramount importance. Understanding how adhesives react to prolonged exposure to these conditions is essential to ensure their reliability and performance over time.

In this section, we look at the behavior of adhesives after periods of thermal and hygrothermal aging. This study provides information on how the two adhesives adapt to the challenges of aging. By subjecting these adhesives to accelerated aging, we aim to identify any changes in their mechanical properties and structural integrity, and more importantly to predict their long-term behavior.

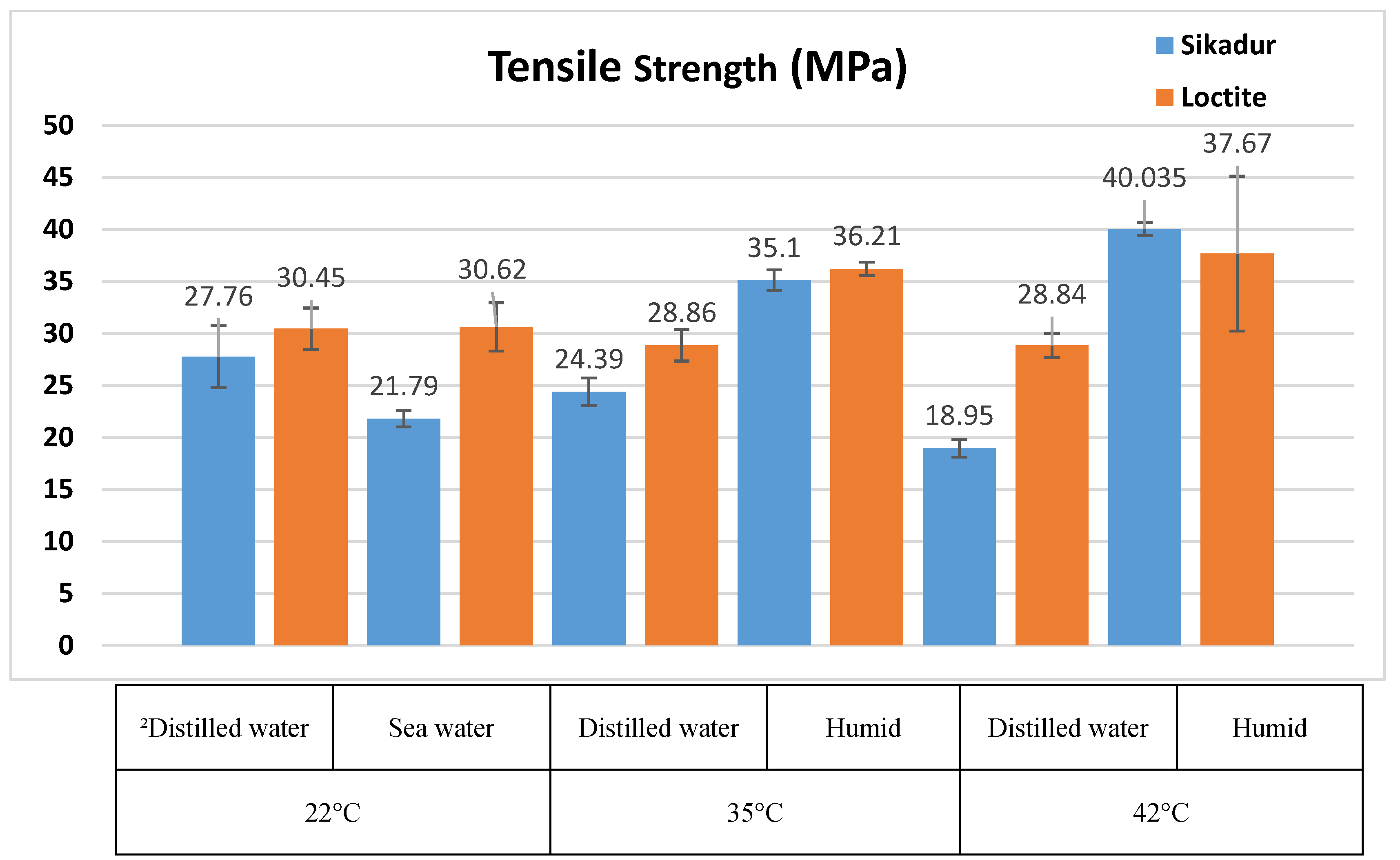

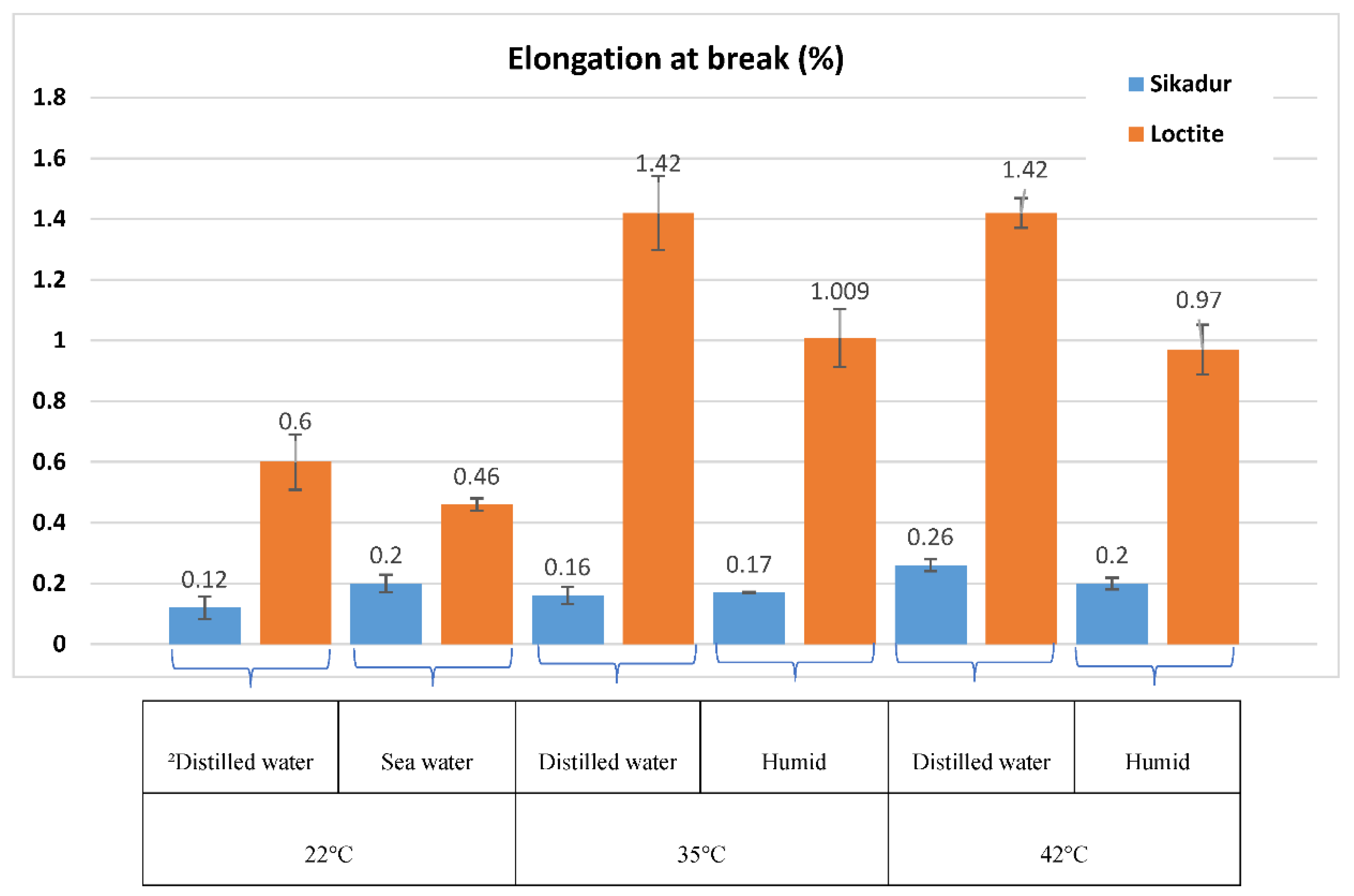

The histograms in

Figure 10,

Figure 11 and

Figure 12 show the tensile behavior of two adhesives aged at different temperatures and in different environments.

This section focuses on the effect of aging temperature and environment on the tensile behavior of the adhesives studied, as published in many papers on marine adhesives [

6,

10,

13,

24]. For this purpose, the adhesive samples were exposed to different conditions - humidity, distilled water and seawater - coupled with different temperatures (22°C, 35°C and 42°C) for 46 days. The main results obtained are shown in

Figure 10,

Figure 11 and

Figure 12. The initial parameters, consistent with the initial pre-aging tests, were used, and each temperature condition was evaluated with three samples, in accordance with established standards [

8,

15,

25].

With respect to the temperature range maintained, various changes in the behavior of the adhesives studied were observed, as previously reported in the literature [

3,

14]. From

Figure 10, it can be seem that in a humid environment, Sikadur showed a 9% decrease in yield stress at 35°C, while at 42°C it showed a 3% increase. The same tendency was observed for Loctite adhesive, with a 22% increase in stress at 35°C and a 25% increase at 42 °C. These variations highlight the role of recrystallisation in modifying the stiffness of the polymer matrix [

10,

16].

A comparison of the parameters in distilled water at different temperatures revealed some interesting information. For the Sikadur adhesive, the stress decreased by 12% between 22 and 35°C and by 31% between 22 and 42°C. On the other hand, Loctite adhesive showed an almost stable decrease of 5% between 22 and 35°C and remained constant between 22 and 35°C and remained constant between 22 and 42°C. These comparative observations are consistent with those reported in published work on the effect of temperature on the mechanical properties of adhesives [

7,

17].

In the case of Sikadur adhesive, the main observations correlate well with thermomechanical principles [

16,

26]. An increase in temperature resulted in an increase in deformation (

Figure 12), indicating the increased ductility of the material under elevated thermal conditions. Sikadur adhesive exhibited its highest tensile strength (40.035 MPa) at 35°C in a humid environment, highlighting its suitability for demanding conditions [

1].

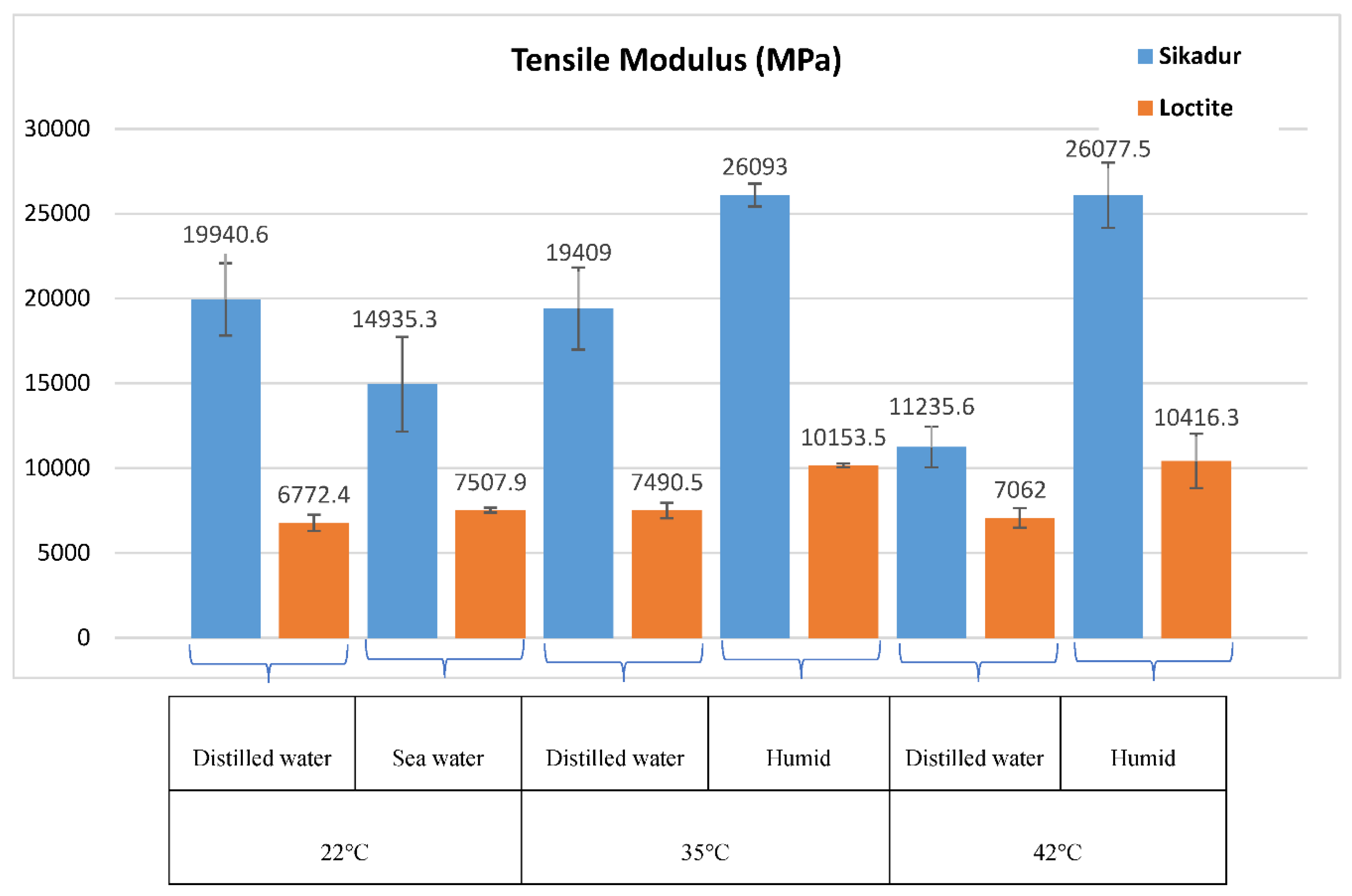

In terms of material stiffness,

Figure 11 shows that the tensile modulus of the material reaches its maximum at 35°C (26093 MPa), indicating that the material effectively maintains its stiffness. The superior performance in distilled water compared to seawater is consistent with Refs [

11,

27]. It also appears that the presence of moisture improves the performance, particularly at higher temperatures, suggesting a beneficial interaction with moisture. A similar trend was also observed for Loctite adhesive. In fact, as the temperature increases, the material deformation (ductility) becomes more important, which is the case for Sikadur. Loctite adhesive reached its maximum tensile strength (37.67 MPa) at 42°C in a humid environment, indicating remarkable strength, particularly at elevated temperatures. The tensile modulus reached its maximum at 35°C (10153.5 MPa), demonstrating excellent stiffness.

It should be noted that when seawater is combined with the positive influence of humidity on performance, the behavior of Sikadur is well illustrated.

In terms of comparative evaluation, both Loctite and Sikadur adhesives showed excellent mechanical properties under various conditions, confirming the findings of recent work in similar areas of research [

6,

28,

29].

3.4. Adhesives Behavior at Longer Periods

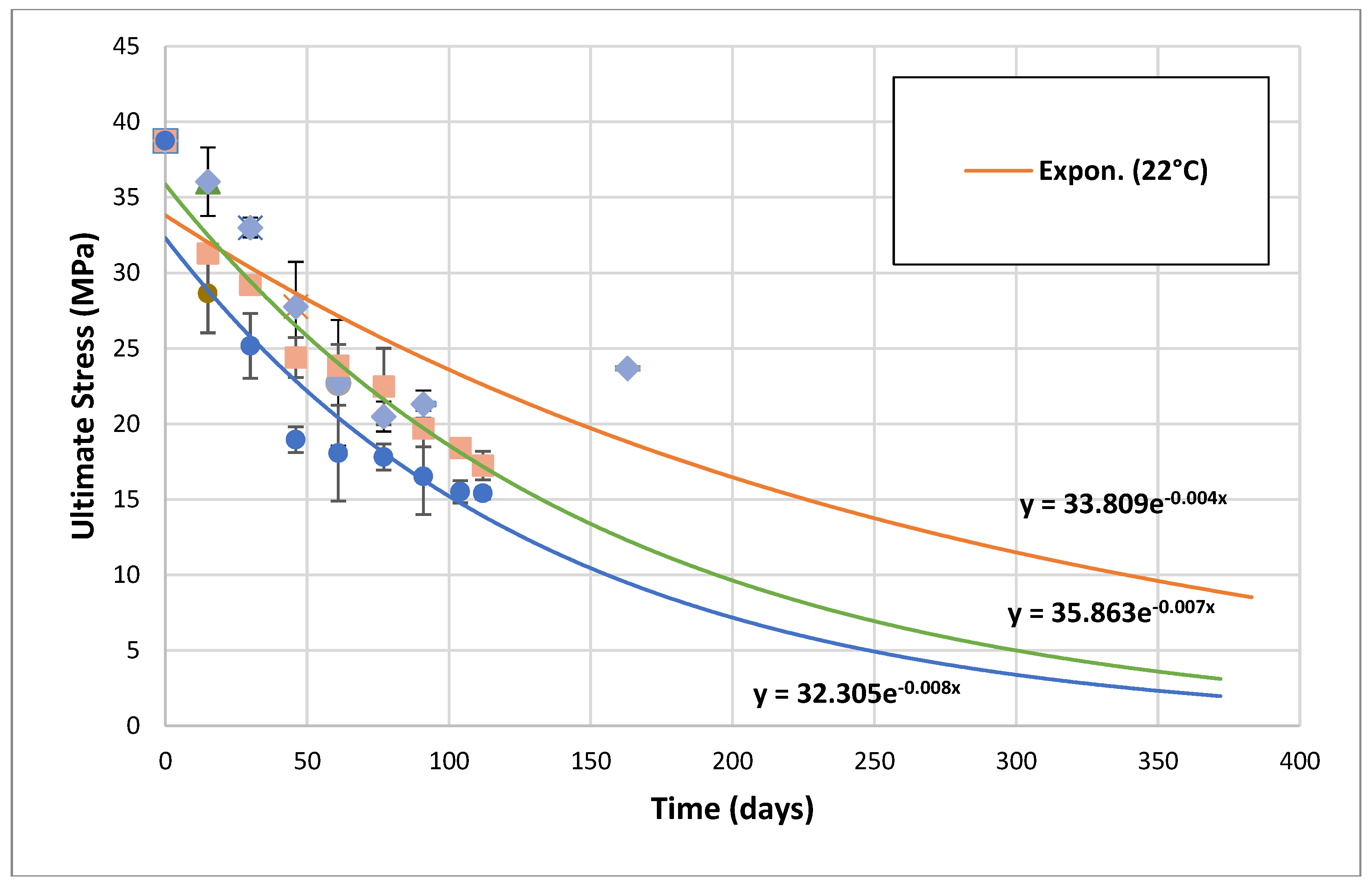

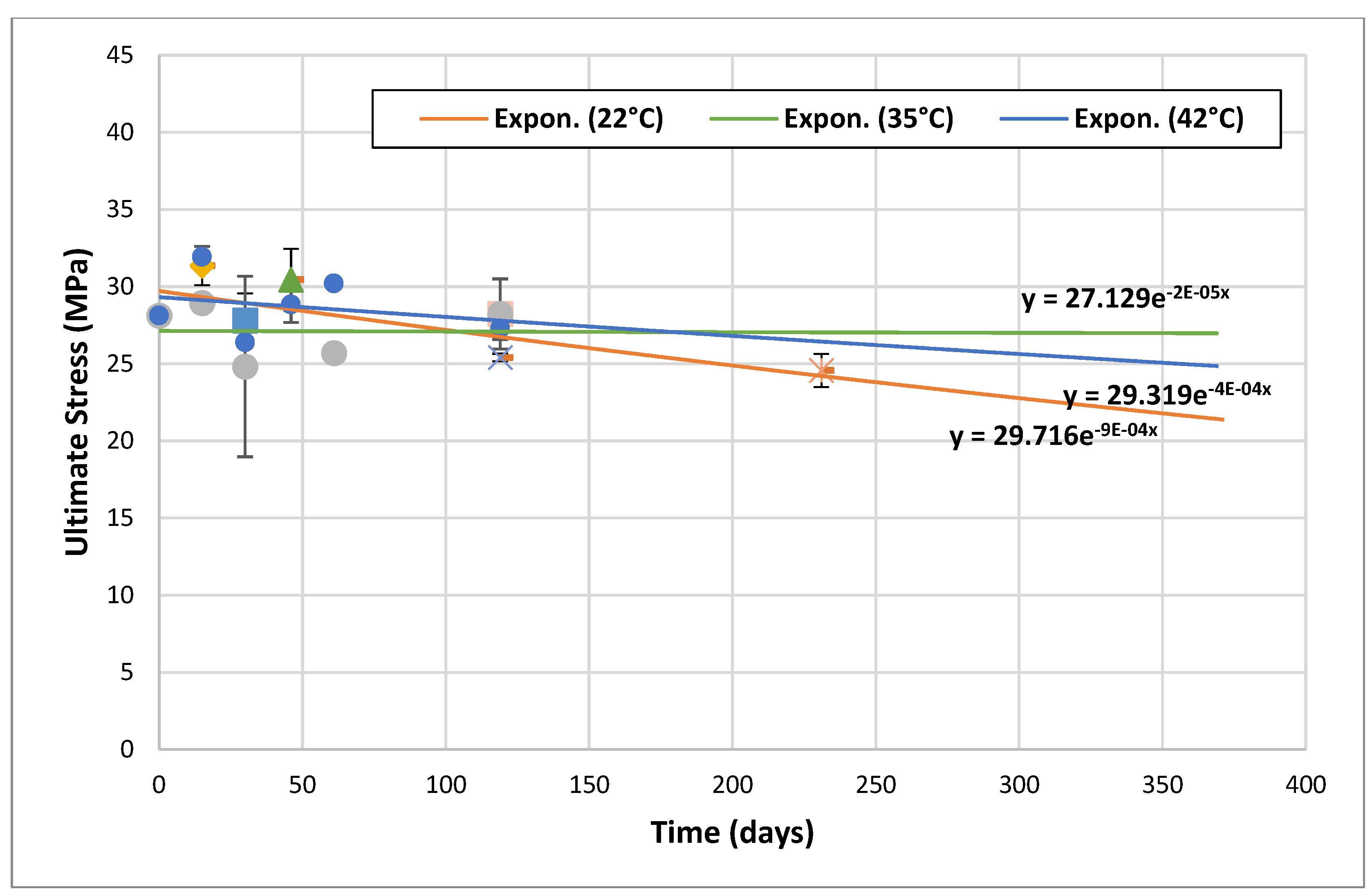

According to previous published work [

9,

30], the comparison between the two adhesives should consider all aspects in order to make the right decisions. For this purpose, in this section, the variation of the Ultimate Tensile Strength (UTS) for both adhesives at different aging times and at different temperatures (22, 35 and 42°C) has been followed. Then, in a second phase, this section deals with the detailed description of the evolution of the mechanical behavior of the two adhesives, especially at longer aging times. The results obtained are shown in

Figure 13 and

Figure 14 for Sikadur and Loctite adhesives, respectively.

As can be seen in

Figure 13 and

Figure 14, the study of the mechanical properties of aged Sikadur (up to 163 days) and Loctite (up to 231 days) shows a clear trend towards a progressive decrease in Ultimate Tensile Strength (UTS) with the exposure time. Such a trend can take the form of an exponential function, as follows:

where,

represents the ultimate stress,

is the aging time,

and

are parameters. It is important to note here that our observations are in good agreement with other published work on the aging of adhesives used in marine environments [

12,

19,

31].

For Sikadur adhesive exposed in distilled water at 22°C, the UTS decreased from an initial value of 38.75 MPa to 23.67 MPa after 163 days. A similar trend was observed for exposure at 35°C and 42°C. This progressive degradation is consistent with the expected effects of aging. This also highlights the importance of regular maintenance for adhesive materials during their service life [

18,

20].

Loctite adhesive also shows a similar aging behavior. In fact, at 22°C, the UTS Loctite adhesive decreased from 28.12 MPa to 24.56 MPa after 231 days. Similar trends were observed at 35°C and 42°C, indicating the evolution of the mechanical properties of the adhesive material over time [

32,

33,

34].

Based on

Figure 13 and

Figure 14, all parameters describing the aging behavior of the two adhesives were extracted and then summarized in

Table 3.

Comparing Sikadur and Loctite, it appears that Loctite generally retains a higher tensile strength under similar conditions, indicating potential resistance to the effects of aging. However, both adhesives show significant changes in UTS over time. In fact, both Sikadur and Loctite adhesives undergo some degree of degradation over time. Furthermore, this degradation is more pronounced at elevated temperatures which accelerate the aging process [

2,

25].

The exponential trends also highlight the need for a better understanding of the aging behavior of adhesives [

20,

35]. This fact underlines the essential role of regular evaluation and maintenance in order to ensure the long-term reliability of adhesives [

17,

20,

30].

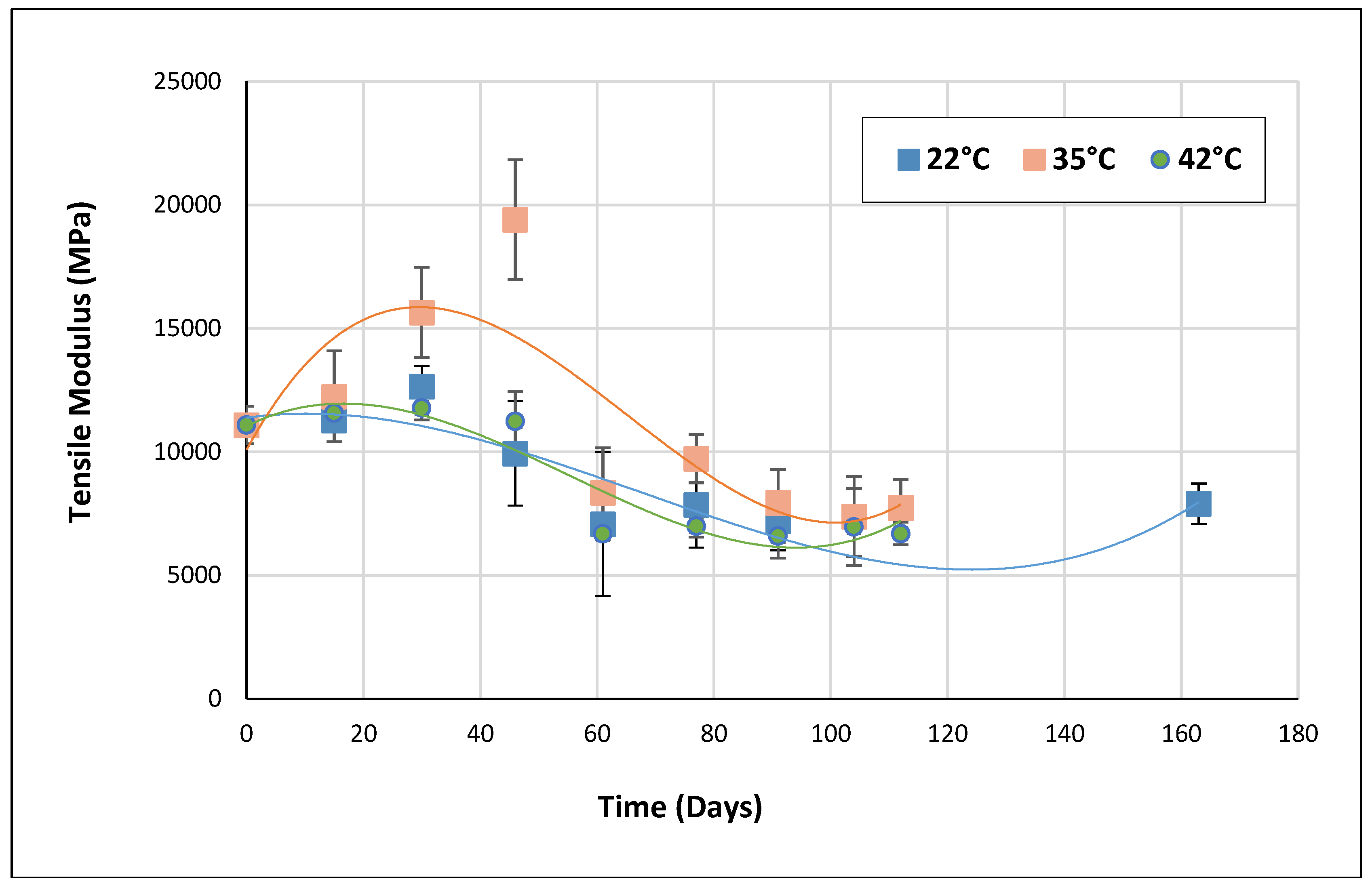

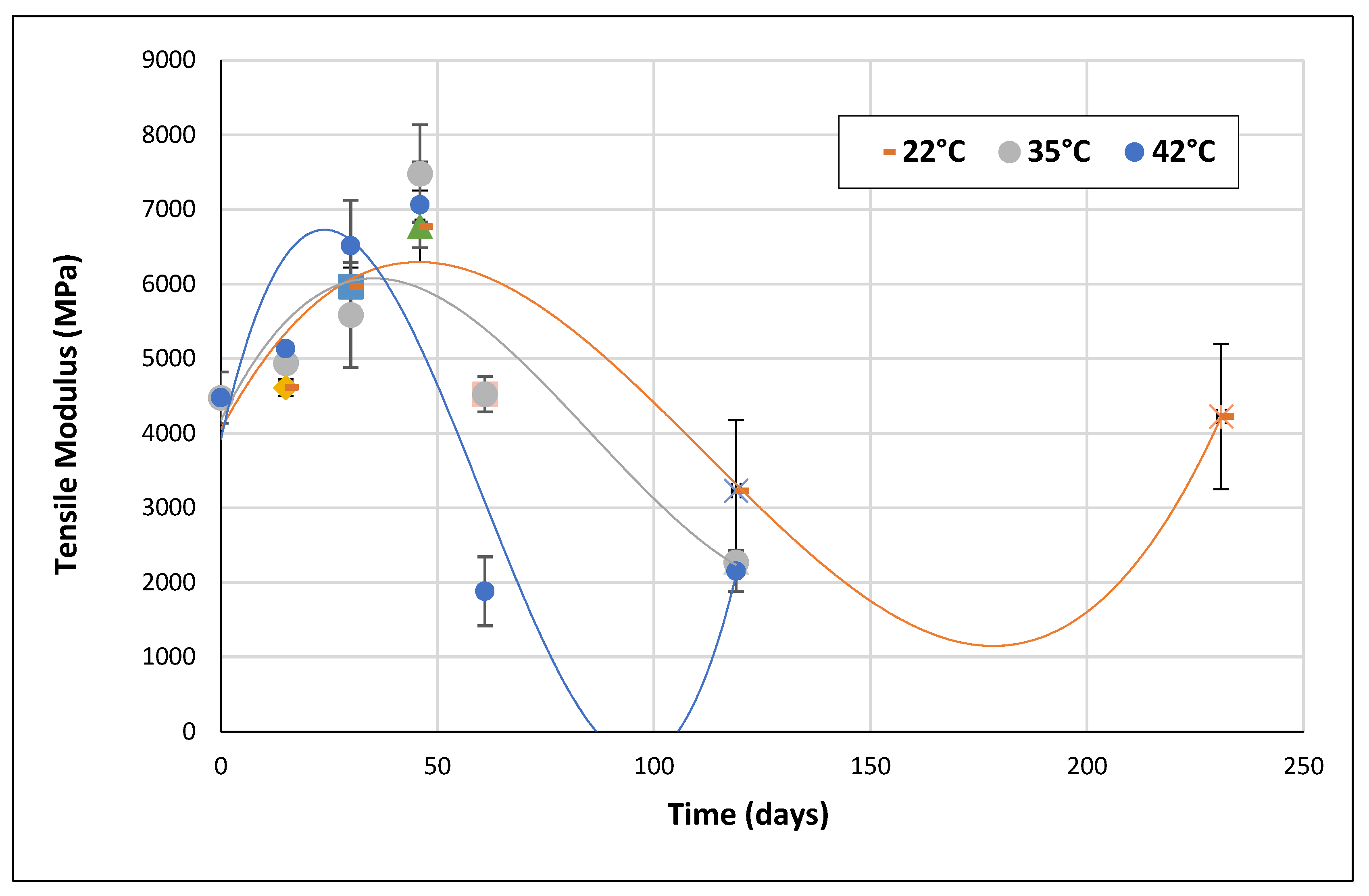

On the other hand, in addition to the tensile strength, the stiffness of the aged materials is also evaluated during aging period. The evolution of the tensile modulus over time for Sikadur and Loctite adhesives is shown in

Figure 15 and

Figure 16, respectively.

From

Figure 15 and

Figure 16, it can be seen that for both Sikadur and Loctite adhesives, the variation in tensile modulus over time shows several trends.

Firstly, for the Sikadur adhesive exposed at 22°C, an initial increase in tensile modulus was observed during the first 30 days of aging, followed by a gradual decrease up to 77 days. Thereafter the tensile modulus appears to stabilize. This trend may indicate an initial phase of aging during which chemical bonds are strengthened, followed by a possible gradual deterioration of mechanical properties.

At 35°C, there is a significant increase in tensile modulus during the first 30 days of aging, suggesting a more rapid response at higher temperatures. However, after this period, there is a significant decrease in modulus, which could indicate an early deterioration of mechanical properties at elevated temperatures.

For samples exposed at 42°C, a progressive decrease in tensile modulus was observed throughout the aging process. This again confirms the continuous degradation of mechanical properties with increasing temperature.

In the case of Loctite adhesive, an initial increase in tensile modulus was observed during the first 30 days (at 22°C), followed by a gradual decrease. This suggests a period of initial cure followed by subsequent degradation. At 35°C, an initial increase is observed, but this is followed by a marked decrease, indicating an early degradation of mechanical properties at higher temperatures. Finally, at 42°C, a similar trend of gradual decrease in tensile modulus is observed, suggesting continuous degradation at elevated temperatures.

In general, when comparing the performance of Sikadur and Loctite adhesives, Loctite appears to be more resistant to the mechanical degradation at higher temperatures. In fact, Loctite adhesive maintains relatively higher tensile moduli than Sikadur adhesive under the same conditions.

However, it is important to note that adhesive performance can be influenced by a variety of factors, including chemical composition, molecular structure and environmental conditions. Further analysis would therefore be required to fully understand the results obtained.

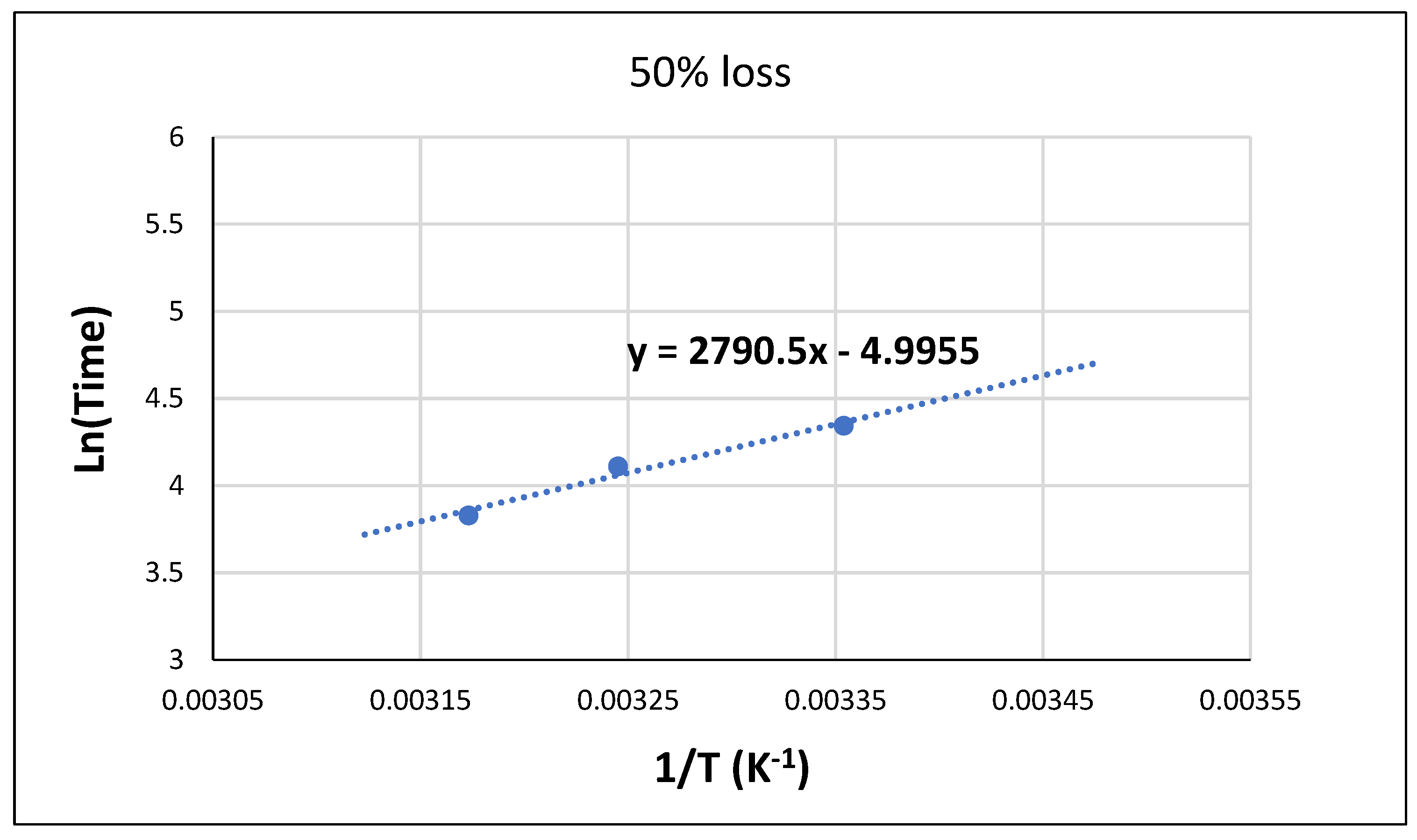

The following section focuses on the limitations of Arrhenius' law in the case of the two adhesives when exposed to an aging environment. To do this, the logarithm of the aging times (t) is plotted against the reciprocal of the temperature (1/T) in

Figure 17 and

Figure 18.

As can be seen in

Figure 17, the aging of Sikadur adhesive shows a remarkable validation of Arrhenius' law, which shows a linear relationship between the logarithm of time (in days) and the reciprocal of the absolute temperature (in Kelvin), Eq.3 :

Where, is the aging time, is the activation energy, is the perfect gas constant, is the absolute temperature, is the pre-exponential factor.

The result obtained are consistent with recent studies on adhesives used in marine environments [

11,

14,

24]. In particular, the linear correlation between Ln(time) and 1/T (

Figure 17) indicates that the aging process of Sikadur adhesive follows Arrhenius kinetics [

34]. This result provides a mathematical model for predicting the behavior of the adhesive over time under different temperature conditions.

In addition, the curve obtained in

Figure 17 also shows a 50% loss of properties, which represents a significant reduction in the mechanical performance of the adhesive [

26]. This can give an indication of the lifetime of the material and its ability to resist.

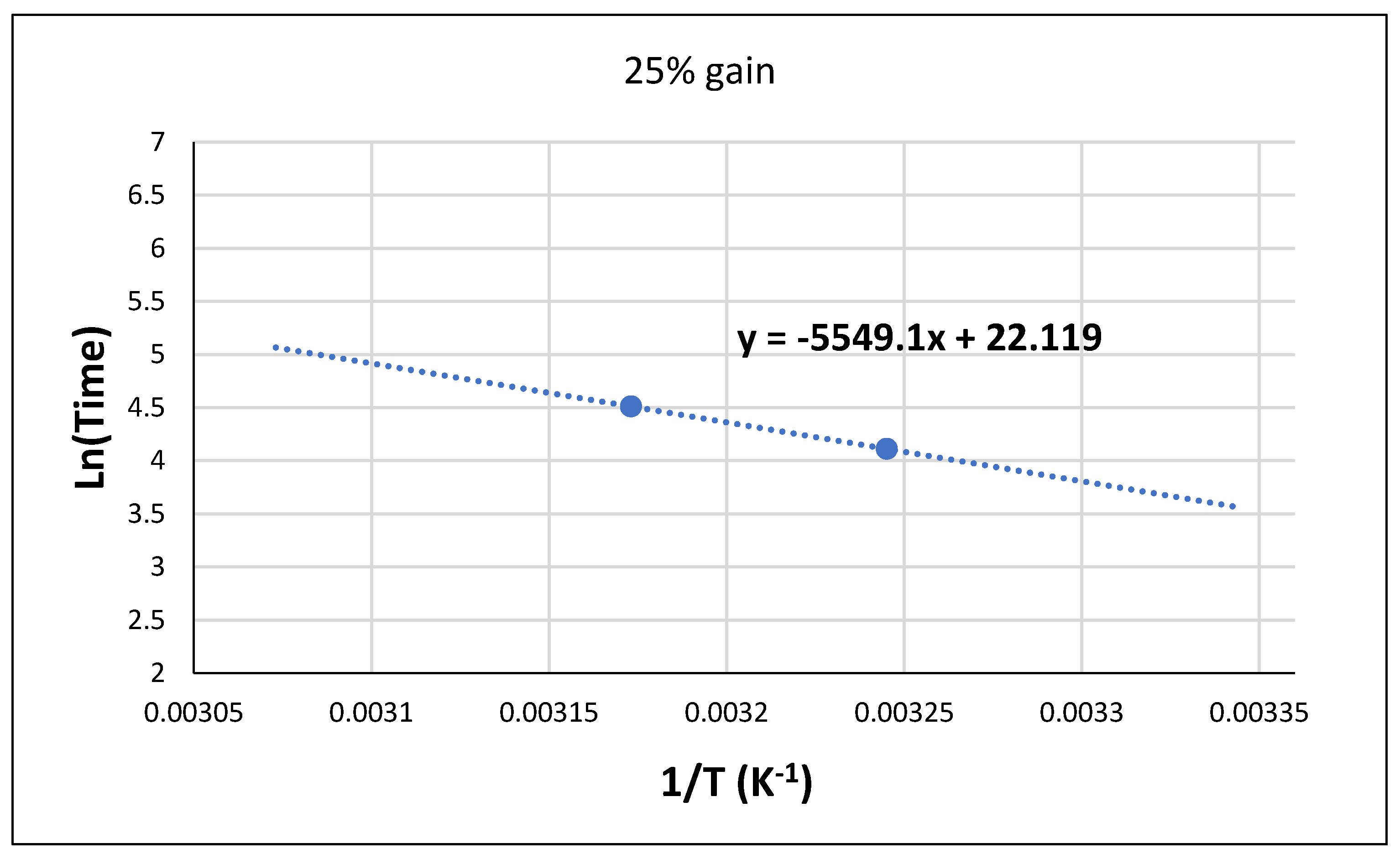

On the other hand, the curve obtained in

Figure 18 shows an increase in the mechanical performance of the adhesive as the wet temperature increases. In fact, at higher temperatures, the chemical reactions responsible for polymerization and curing of the adhesive can take place more rapidly. This makes it possible to improve its structure and mechanical properties.

However, it is important to note that this interpretation is based on an empirical relationship and that other factors, such as water, humidity and the composition of the environment, may also influence the mechanical performance of the adhesive materials.

By applying the Arrhenius law (Eq.3) and using the data provided, we can estimate the long-term behavior of the Sikadur adhesive under these specific conditions. In fact, by extrapolating the Ln(days) values for additional values of (1/T), we can potentially predict the evolution of the aging time in these environments.

However, it should be noted that long-term extrapolation may be subjected to uncertainties and limitations. Indeed, the extrapolation is based on limited experimental data and on the assumption of continuity of the observed behavior in the available data. In addition, other environmental and aging factors could potentially affect adhesive performance over time. As a result, long-term projections may be subject to potential variation.