1. Introduction

Precision agriculture (PA) emerged of an urgent need of transformation and upgrading of traditional agriculture and was driven by emerging technologies. Its purpose is to address shortcomings and deficiencies of traditional agriculture, which have resulted in excessive environmental pollution in the context of changing international situations and frequent natural disasters [1]. The PA concept has revolutionized agriculture over the last decades. Its aim is to increase farm profits and reduce environmental impacts by adjusting production inputs to specified levels, adjusted to the needs of each area of a field [2]. This technological incorporation has permeated all levels of agriculture and is present in practically all crops and production systems [3].

PA using spatial data of plant status and soil characteristics can be described as an integration of techniques and equipment to predict the crop’s requirements and supply those needs at the right time and place. This optimizes fertilizer-use efficacy and increases both crop quality and productivity [4]. Field information collection, data management, decision-making, and execution are the four key components of precision fertilization [1].

PA cycle can be summarized in three main phases: (i) surveying soil and crop spatial variability; (ii) processing data and defining differentiated management zones; (iii) making decisions and implementing differentiated soil, crop and production system management [5]. In this generic structure, variable rate application (VRA) represents the closing of the cycle and is a technology commonly used for different agricultural inputs such as seeds, fertilizers, irrigation water and tillage based on required needs of different management zones in the agricultural fields [6]. This is a popular technique that optimizes and matches the inputs to the condition of the growing crops [7]. According to Grisso et al. [8], not every farm or field will reap a measurable economic benefit from VRA, but these technologies offer opportunities for growers to increase both the production and environmental efficiencies of crop production and should be carefully evaluated at the field-scale, in experiments that compare variable-rate vs uniform application.

The two VRA systems currently available in the market for agriculture input applications are map-based variable rate technology (VRT with post-processing control) and sensor-based VRT (with real-time control) systems [4]. The choice between these systems depends primarily on the type of application required, but also on the investment policy and the level of technical know-how [6]. The capacity to employ numerous sources of information, the availability of application systems for most agricultural inputs, and the time interval between input sampling and application that helps improve system accuracy, are the main benefits of the map-based system (site-specific application via prescription maps). On the other hand, the most significant benefits of sensor-based systems (via on-the-go sensor´s feedback) include the possibility to alter the rate at which agricultural inputs are applied without first mapping the area or gathering field data and the opportunity to apply agricultural inputs immediately after measurement without any delay [8]. However, map-based methods can be considered as the most common approached to VRT, due to insufficient accuracy of the sensors used for real-time soil and crop mapping [9].

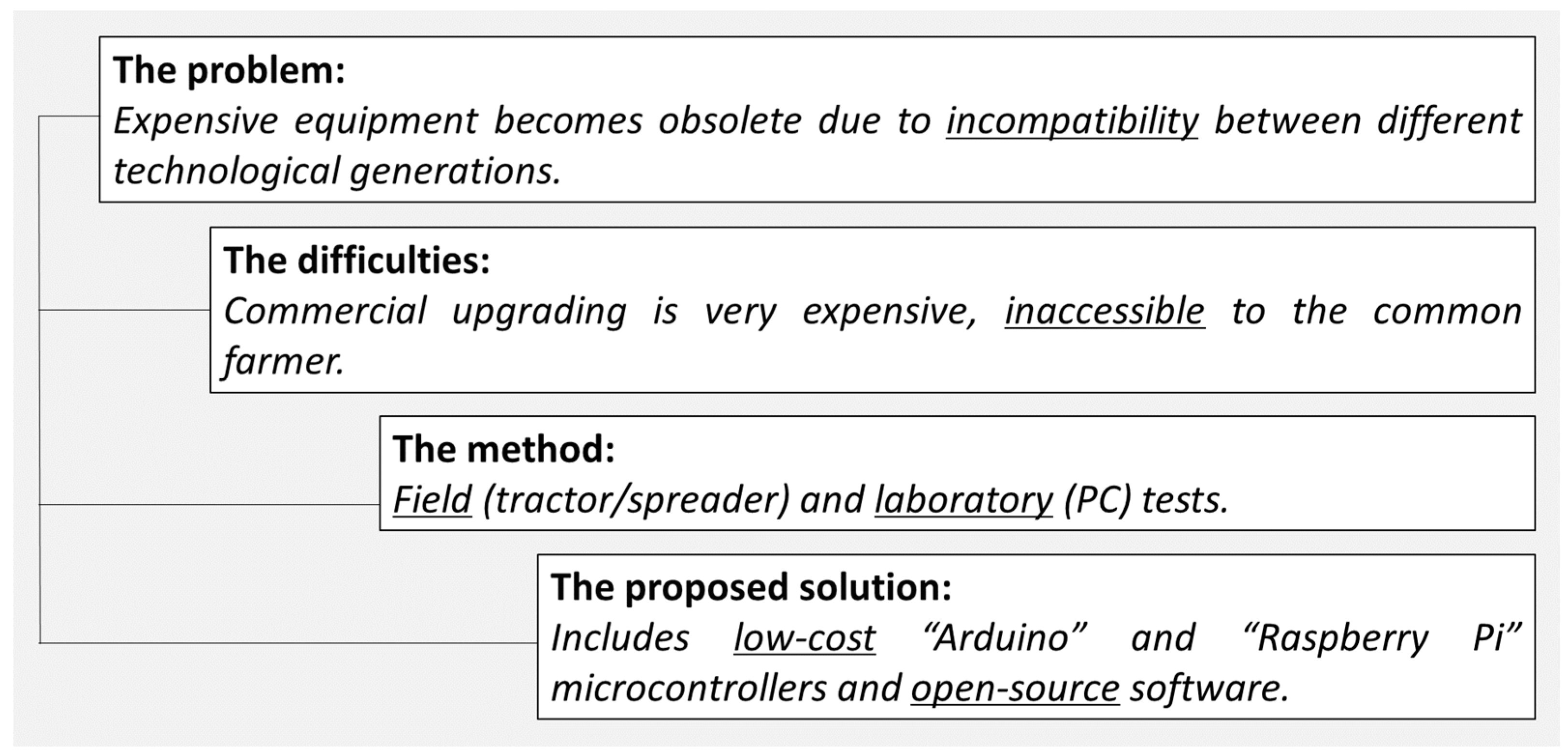

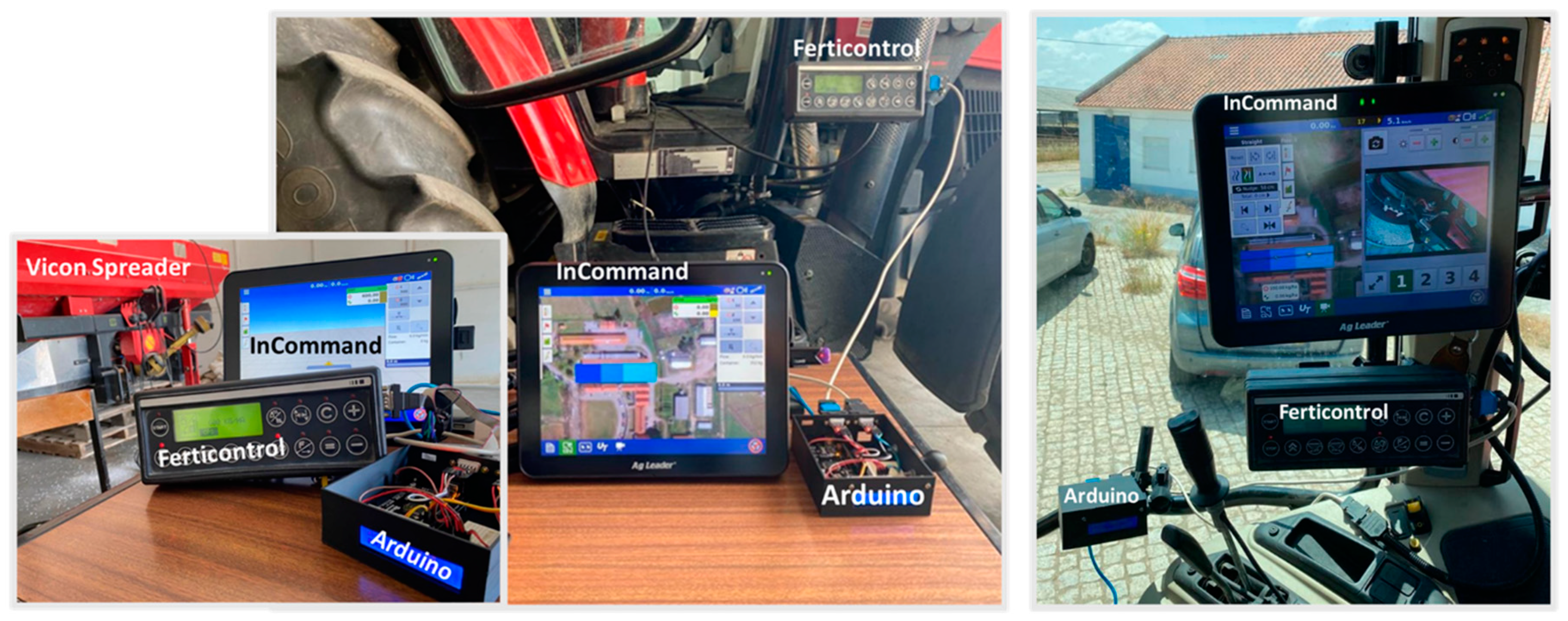

Given the speed of the developments of mechatronics and information technology, with the continuous launch of technological innovations in a highly competitive market such as agricultural machinery, equipment quickly become obsolete, especially due to the evolution of the communication protocols between hardware and software (between spreaders, seeders, sprayers, for example, and monitoring and control systems). Therefore, the adaption and update of control systems that maintain or provide the possibility of operating in VRT represents a challenge of great interest that has been taken on by several research teams, as shown in the list of studies presented in

Table 1.

Based on the above-mentioned techniques and technologies, numerous types of control systems for VRA of granular fertilizers have been created, tested, and put into practice by many researchers to assess their efficiency and the accuracy at different working conditions. Some works fall into sensor-based approaches [2,20,22,24], while a very important number follow the map-based approach [10–19,21,23] (

Table 1).

Table 1 also summarize three important characteristics of these systems: the controller or microcontroller type, the sensors used for monitoring the output fertilizer rate and the actuators type used as control drives. The low-cost solutions (technological update, which is the case of upgrading of this Vicon RS-EDW spreader) are particularly important for small farmers, who cannot continuously make large investments in new technologies. Low-income farmers are the most susceptible to negative changes in the environment. Providing these farmers with the right tools to mitigate adversity and to gain greater control of the production process could unlock their potential and support rural communities to meet the increasing global food demand [20]. The significance of VRA is underscored by both its economic and environmental implications [6]. This upgrade to VRT, the basis of VRA concept, when compared with uniform application, offers a sustainable, efficient, and cost-effective solution for fertilizer application [4]. Precision application of agricultural inputs strives to optimize crop profitability and sustainability by increasing yield and improving input efficiency while concurrently decreasing spatial and temporal variability and diminishing adverse environmental effects [8].

Many types of fertilizer ejectors are used in variable rate fertilization devices, including the outer grooved wheel type, centrifugal type, vibrating type, and star wheel type [1], although the centrifugal disc spreader is by far the most common applicator for granule fertilizer in Europe [7]. This spreader type uses the rotating disk at the bottom to scatter fertilizer particles under the action of centrifugal force [1]. The implementation of VRT technology is based on regulating the distributor opening, regulating the speed of the fluted cylinder shaft, or both (double-variable fertilization device, speed and opening).

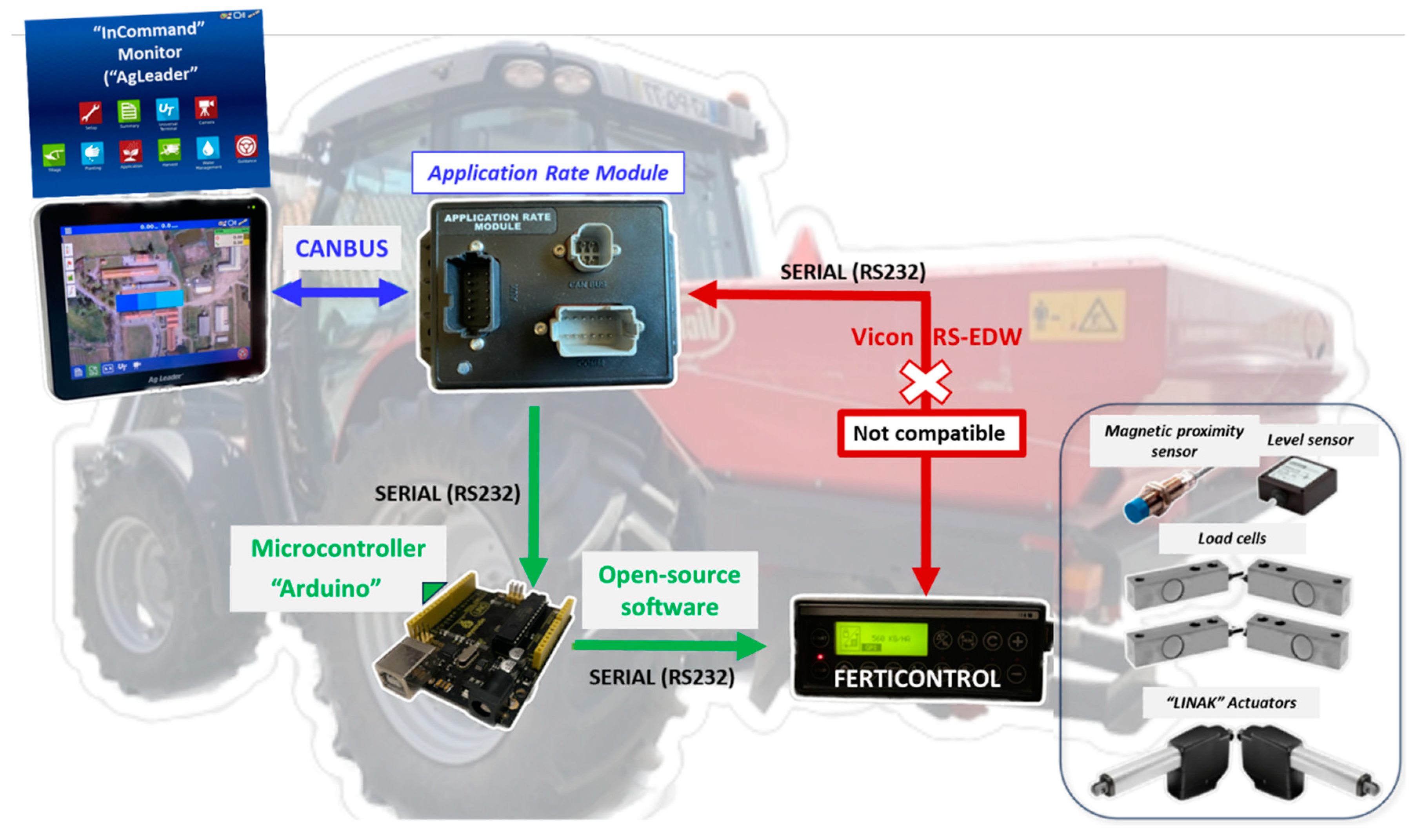

In this study a centrifugal two-disc spreader Vicon RS-EDW with two electric linear actuators (regulation the opening) was used. Despite this Vicon spreader still being functional and equipped with sensors, actuators, and electronic processing units, it has become obsolete in terms of communication, incompatible with new monitoring and control systems based in the “Isobus” protocol.

Figure 1 schematically shows the structure of this article, from the scientific problem posed to the proposed solution. The aim of is work is to present a low-cost solution that would allow updating the control system (“Ferticontrol”) of a “Vicon RS-EDW” spreader for VRA, making it compatible with the “InCommand” system from “Ag Leader”.

2. Materials and Methods

2.1. Characteristics of Vicon RS-EDW Spreader

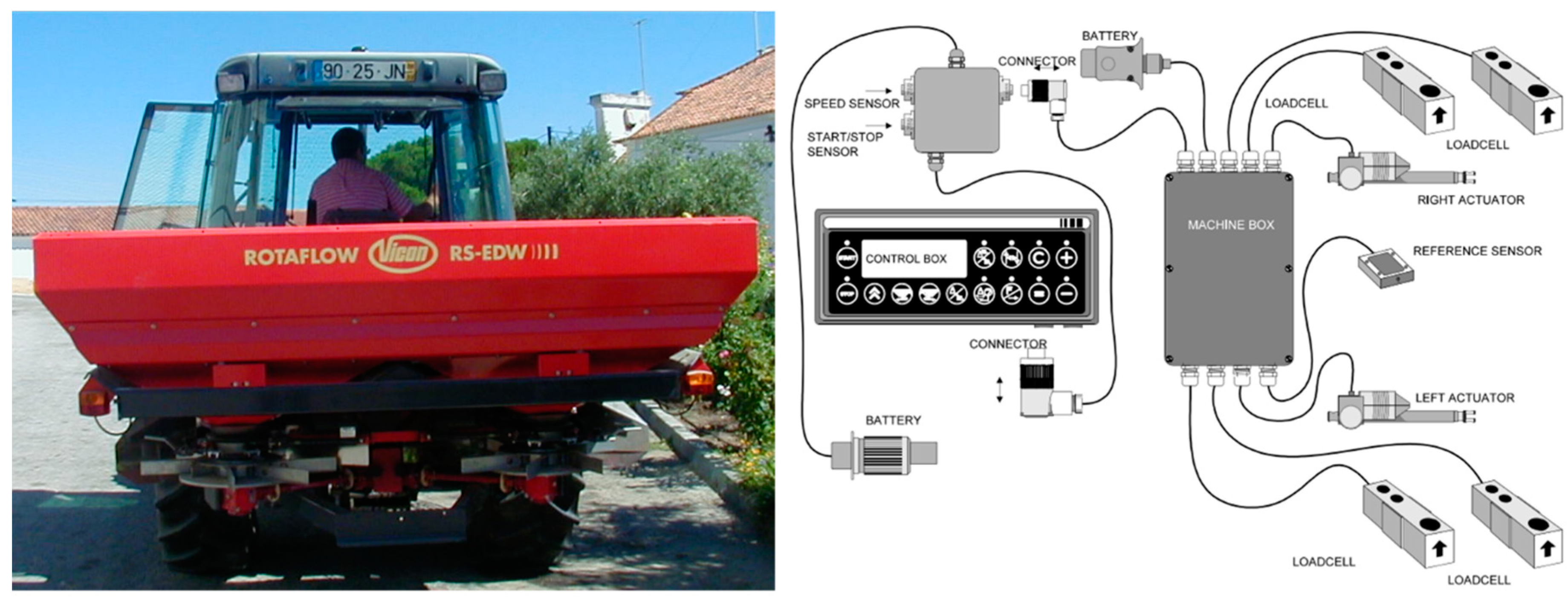

In this work, a “Vicon Rotaflow RS-EDW” spreader was used, with a “Ferticontrol” controller. This spreader, acquired in 2003 (

Figure 2), can be used to apply fertilizers or seeds, with variable rates (R, in kg/ha). The equipment receives mechanical power through the tractor's power take-off (at a standard speed of 540 rpm), which transmits rotation to a gearbox, where it is possible to regulate a combination of gears, with different transmission ratios, making it possible to adjust the rotation speed of the two centrifugal distribution discs. The combination of the disc rotation speed, the adjustment of the fertilizer's drop point on the disc and the characteristics of the fertilizer (density and granulometry) allow the working width adjustment (L, in m). The working width is an instruction data inserted by the operator in the monitoring and control system (“Ferticontrol”).

The “Vicon RS-EDW” spreader is equipped with electronic sensors at the base of the hopper (four load cells and a reference sensor), which allow accurate and regular weighing of the amount of fertilizer present in the hopper (every half second). This therefore provides a measurement of the flow of fertilizer being applied (Q, in kg h

-1). This information is transmitted to a microprocessor, which also receives information on the tractor's forward speed (v, in km h

-1; this can be provided by a radar, or a magnetic proximity sensor placed in the tractor transmission). With this information, the microprocessor calculates the work capacity (Ct, in ha h

-1; equation 1) and the rate of fertilizer application (R, in kg ha

-1; equation 2).

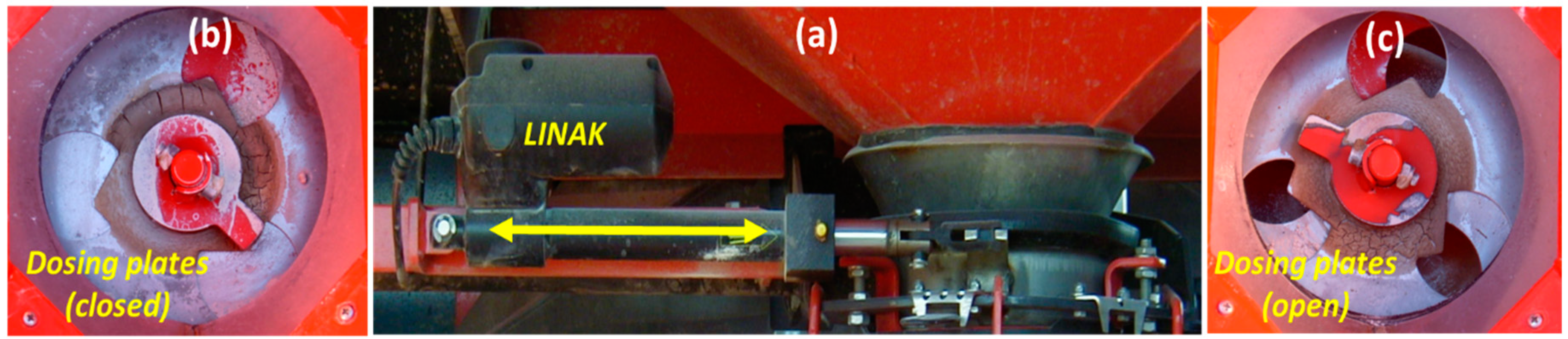

The spreader also has two linear electric actuators (“LINAK”, model “3031PO”;

Figure 3(a)) that make it possible to adjust, continuously, the position of three fertilizer dosing plates located at the bottom of the hopper, between the closed,

Figure 3(b) and open

Figure 3(c)) positions, therefore adjusting the flow rate. When the microprocessor receives instructions on the rate of fertilizer to be applied, it compares this instruction with the value measured from load cells in the field. Whenever there is no correspondence between the programmed and applied rate, the microprocessor gives instructions to the electrical actuators to adjust the opening of the dosing plates and, in this way, guarantees compliance with the programmed density.

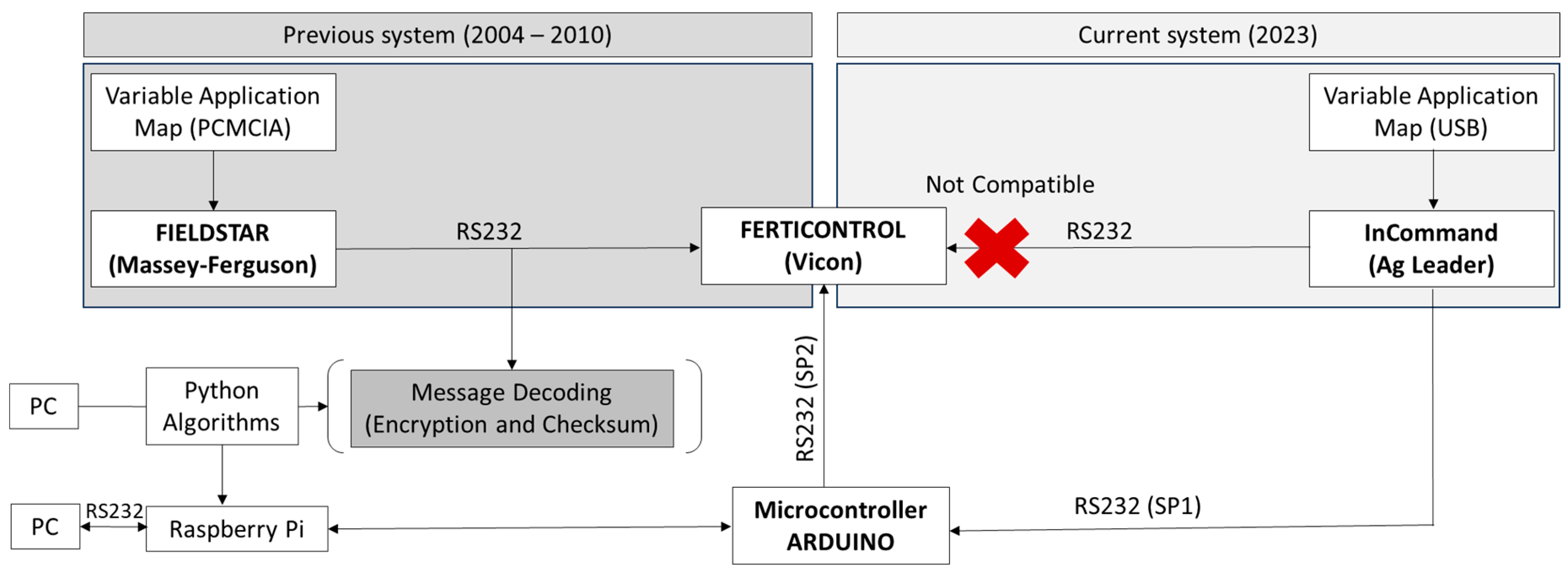

2.2. Previous VRT Control System of Vicon RS-EDW Spreader

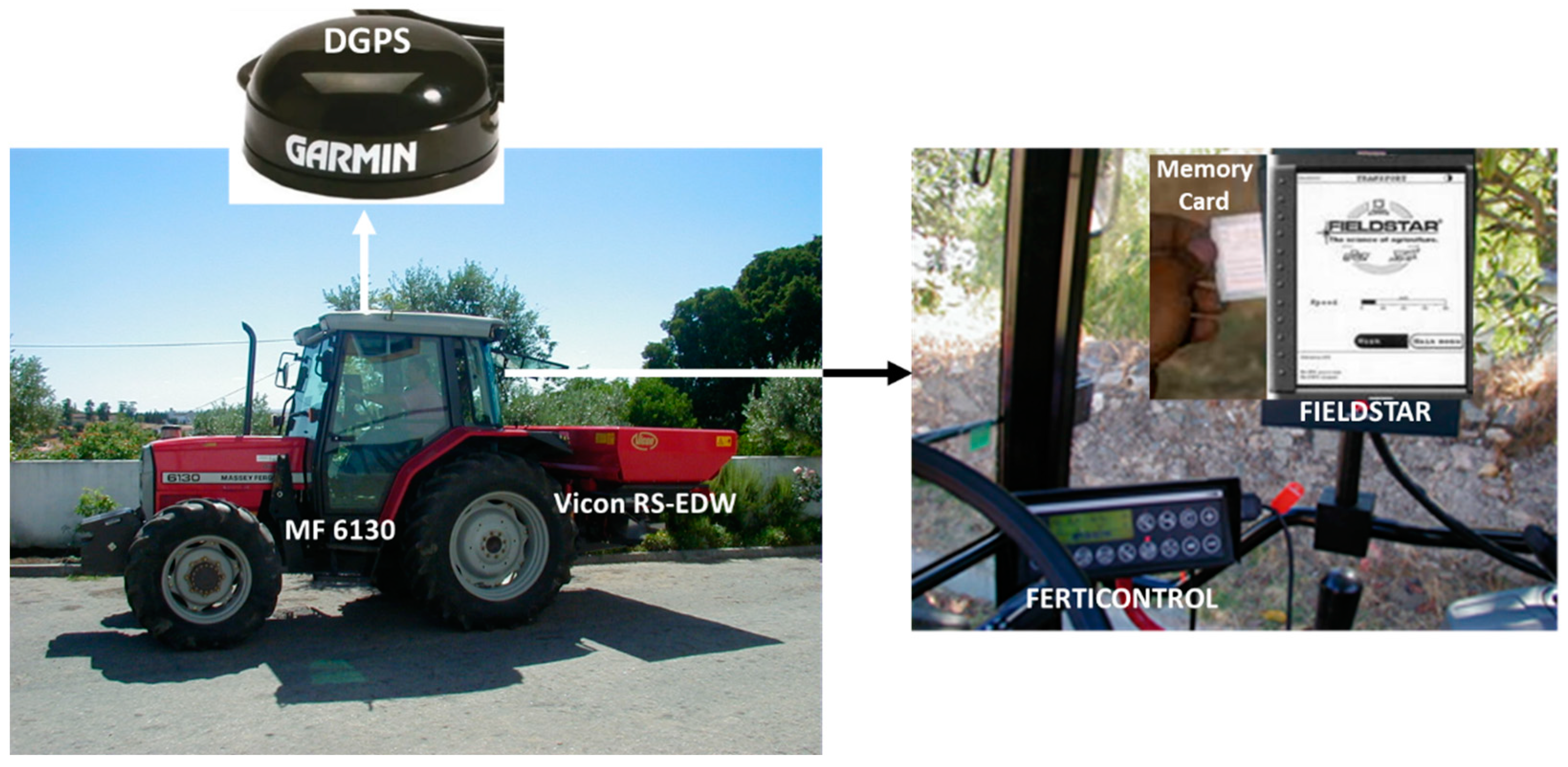

For this spreader to operate in VRT mode, a system is required that, receiving georeferenced information via GNSS (Global Navigation Satellite System) receiver, which functions as an interface with the “Ferticontrol” console. Between 2004-2010 the spreader was used with a “Massey-Ferguson” (MF) agricultural tractor, model 6130. A partnership was established with MF that allowed the use of its “Fiedstar” system and a GNSS antenna for this purpose, “Garmin 16” (

Figure 4).

The data transfer (prescription map) was loaded via a PCMCIA memory card. After 20 years, this system stopped receiving updates and support from the manufacturer, becoming an obsolete system. Its programming and map analysis software ran on “Windows XP”, which was also no longer supported as of 2014. Furthermore, data transfer between the computer and the “Fieldstar” system was carried out through the “PCMCIA” memory card, with the brand’s own data format (MF), thus making system maintenance and data transfer difficult.

2.3. Poposed System of Vicon RS-EDW Spreader Control as VRT

To try to resolve this issue, while maintaining the functionality of the spreader in VRT mode, an “InCommand 1200” (IC) monitor (launched in 2015 by “Ag Leader”) was purchased from the “AAMS Ibérica” as a monitor for controling tasks in PA. This controller is compatible with universal “Isobus” terminals (ISO 11783) [25], which allows connection to various implements, however, none of its interfaces showed compatibility with the “Vicon RS-EDW” spreader. In a first approach, an analysis and budget proposal were requested from the “Kverneland” group, the current representative of this equipment, to make the distributor compatible with the new monitoring and control system (IC). The proposal involved modifying the entire plate mechanical system, updating the control system, and replacing the spreader actuators and sensors. This solution had an extremely high cost (of around 15,000 Euros), for a 20-year-old spreader and with no guarantee that it could, in the end, achieve the proposed objective and the correct functioning of the solution.

When integrating equipment that is not compatible with the “Isobus” terminal (as is the case of “Ferticontrol”), “Ag Leader” has several “CANBUS” modules for the IC monitor, which allow connection to controllers, sensors and actuators of older equipment, including the “Application Rate” (AR), the “Spinner Spreader Control” (SSC) and the “Auxiliary Input” (AI) modules.

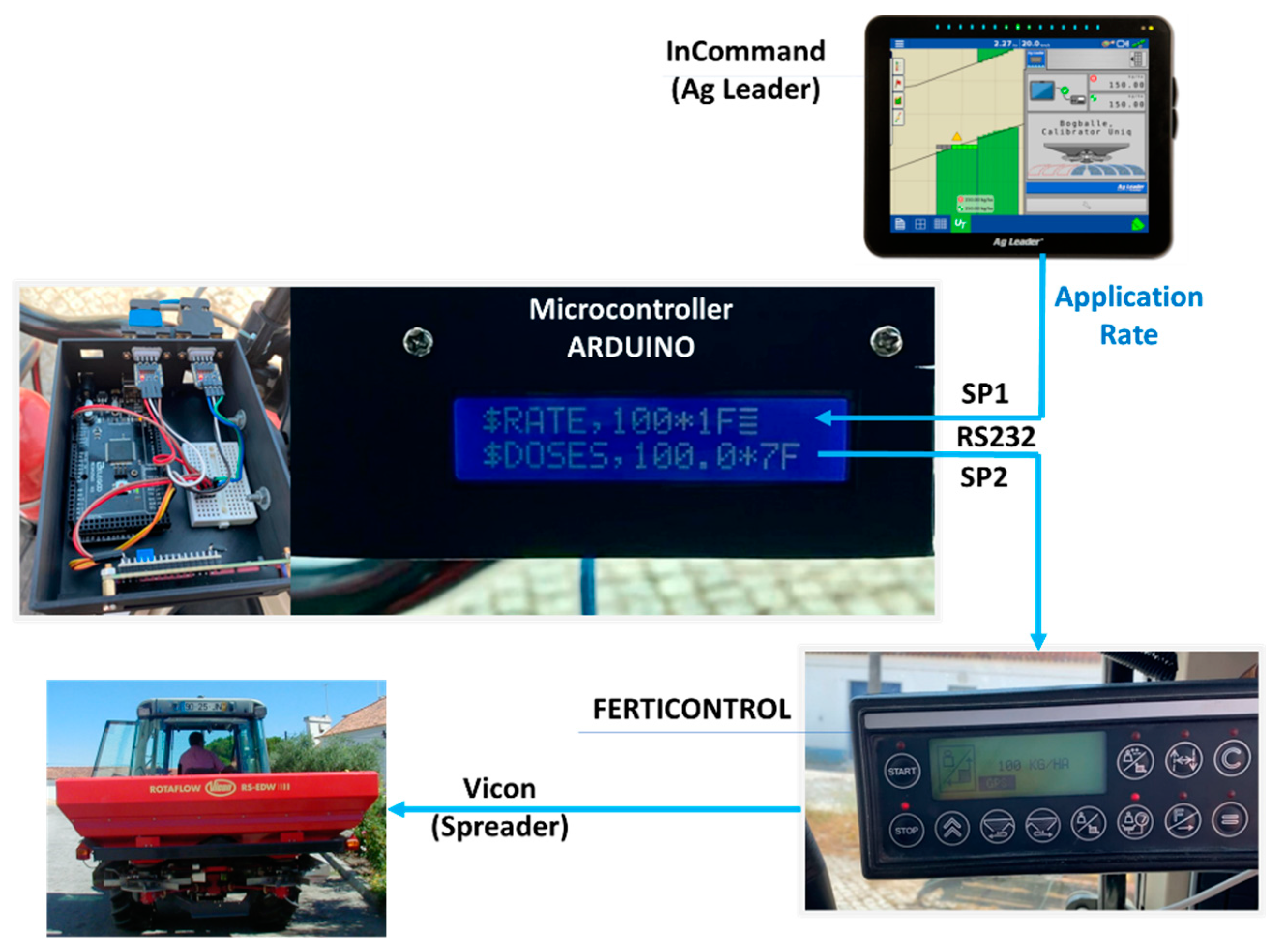

Figure 5 schematically shows the proposed solution for VRT control of “Vicon RS-EDW” spreader based on a “Arduino” microcontroller and open-source software to make the “In-Command” (Ag Leader) compatible with the “Ferticontrol”.

3. Results and Discussion

A working configuration of the fertilizer application in the "Direct Command" (DC) system was carried out, using the "IC" monitor and the "AR" module. A “serial RS232” connection was established with the PC and, using an algorithm developed in “Python” programming language, it was possible to send instruction messages through "IC" (current proposal), for example, with the prescription rate of “100 kg ha-1” (“$RATE,100*1F”).

Similarly, the "Fieldstar" monitor was configured with an existing job on a "PCMCIA" card, so as to obtain the message it sends to "Ferticontrol" also for a "100 kg ha-1" prescription. A connection was made between the "Fieldstar" and the "Ferticontrol" with a “serial RS232” connection in “T” format, allowing simultaneous connection to the PC. A “Python” algorithm was used to capture the content of the message ("$DOSES,0.00,100.0,100.0,100.0*7F") via the PC's “serial RS232”. Knowing the message that "Ferticontrol" needed to assume the programmed density, a “serial RS232” communication test was carried out between the PC and "Ferticontrol". First, the message captured in the previous step ("$DOSES,0.00,100.0,100.0,100.0*7F") was sent and accepted by the “Ferticontrol” monitor. Next, the content of the message was changed, varying the prescription rate from 100 to 300 kg ha-1 ("$DOSES,0.00,300.0,300.0*7F"), but it was not recognized by "Ferticontrol".

Two messages were analyzed ("$DOSES,0.00,100.0,100.0,100.0*7F" and "$DOSES,0.00,0.0,0.0,0.0*7E"), which had been obtained from the "Fieldstar" monitor (prescriptions that were programmed on the memory card with 100 and 0 kg ha-1, respectively) to try to decipher the message's encryption. It turned out that the last two characters varied depending on the content of the message. These characters acted as a checksum, used in "Fieldstar" - "Ferticontrol" communication. A “Python” algorithm was developed to decipher the system's checksum calculation pattern. The use of an “XOR” (exclusive) checksum was verified. A “Python” algorithm was developed to calculate the checksum to be added at the end of each “Ferticontrol” command message.

After message decoding (encryption and checksum;

Figure 6), it was necessary to test the operation of the spreader control system.

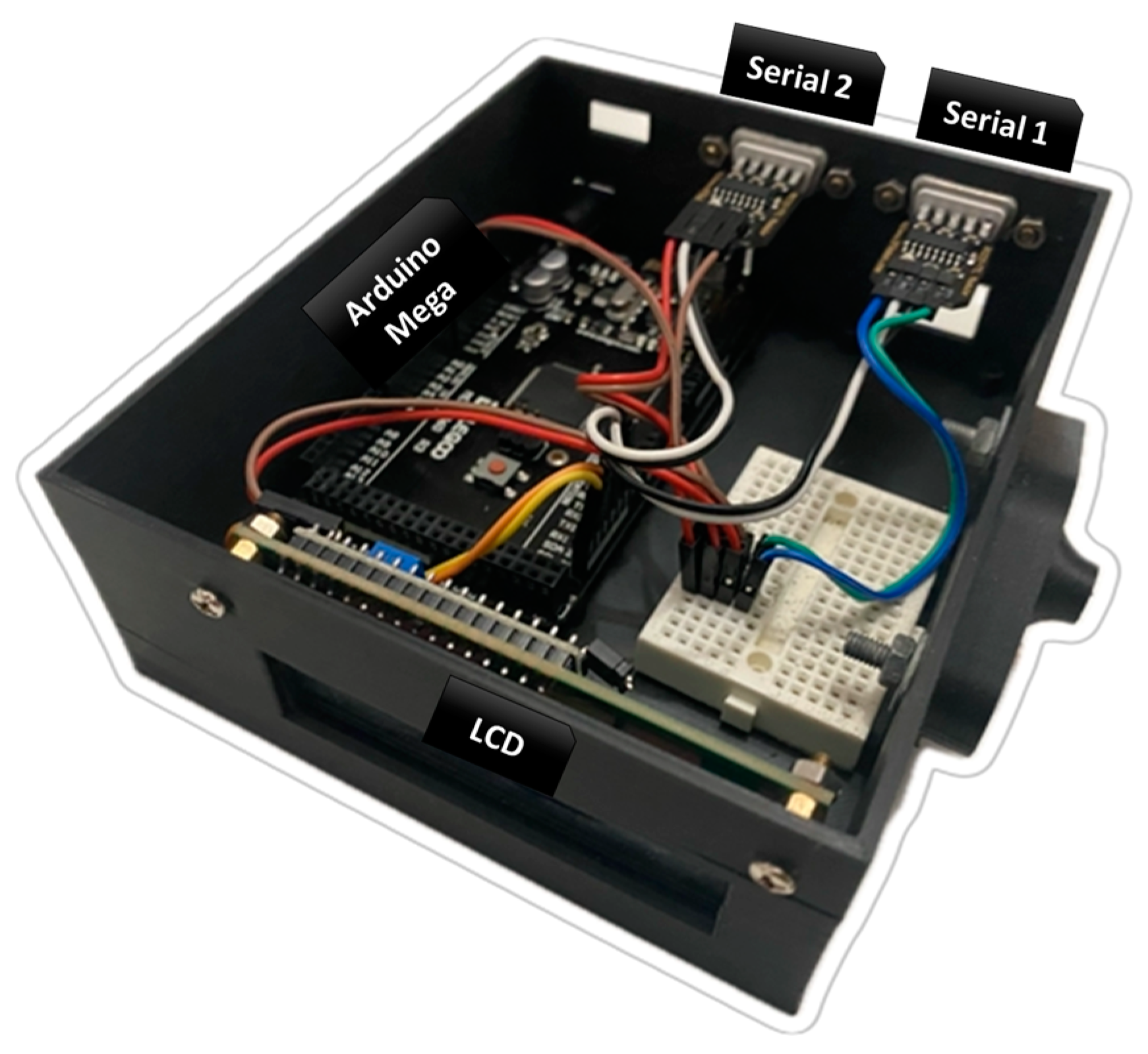

As this equipment is daily used in the farm, it would not be available during the communication test period. For this reason, an emulator system was developed on the “Raspberry Pi”, with two “RS232” serial ports: in essence, it simulated sending the command instruction from the "IC" through one “RS232” serial port (SP1) and receiving the corresponding command instruction from the converter system, which in this case was the PC, through the second “RS232” serial port (SP2;

Figure 7). The command received by the emulator would be the instruction sent to "Ferticontrol", which was displayed on a screen for format checking. This system allowed the communication algorithm and conversion of command messages to be robustized. Electronic circuit boards and case used in the device are presented in

Figure 8.

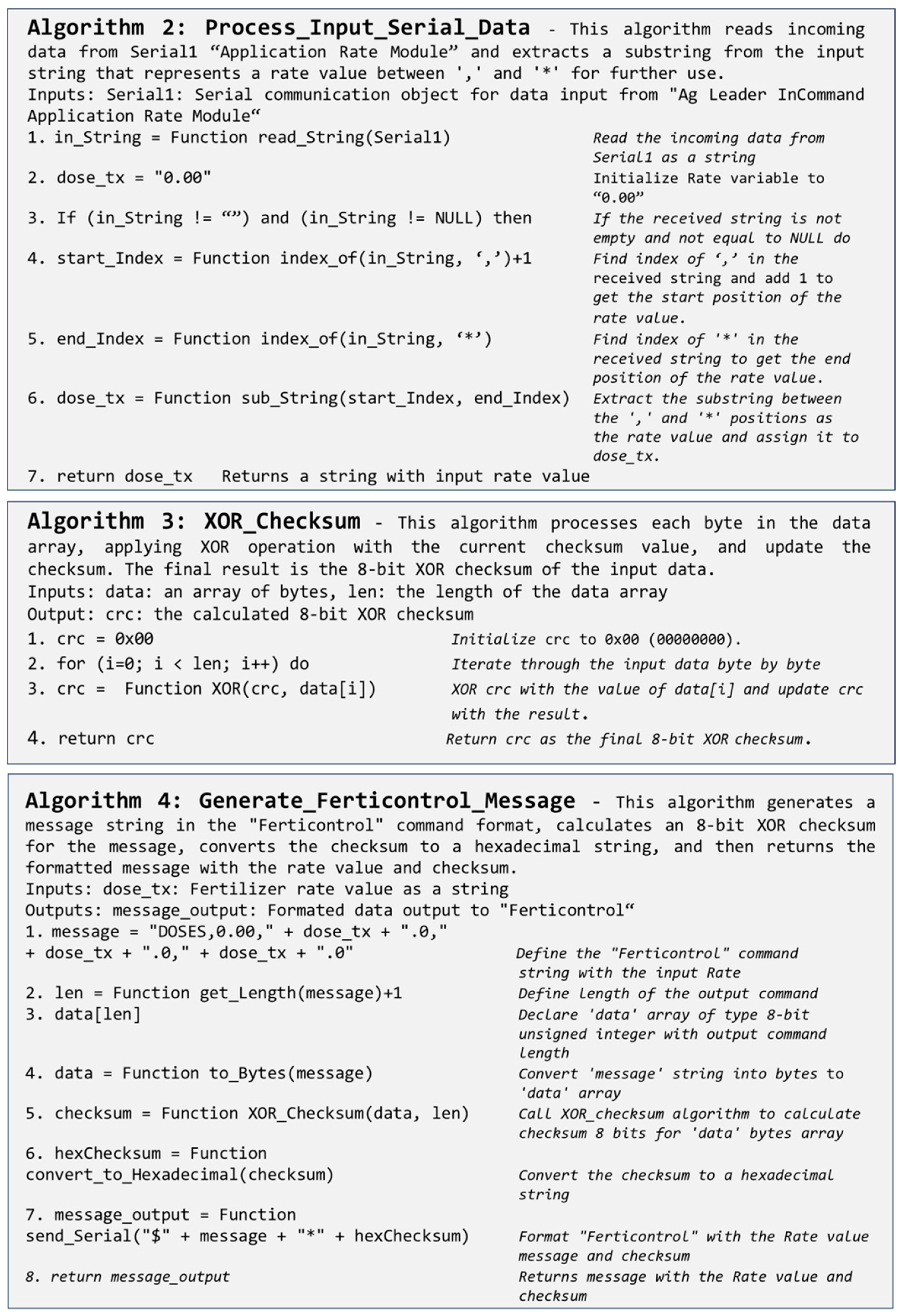

Using a PC with an algorithm developed in "Python", which converted the instruction command from "InCommand" to "Ferticontrol", a connection was made on the tractor between the "IC" monitor, the "AR" module and "Ferticontrol". A prescription map was designed for field operational tests. In these tests, an adjustment of 0.5 seconds was needed to synchronize the messages.

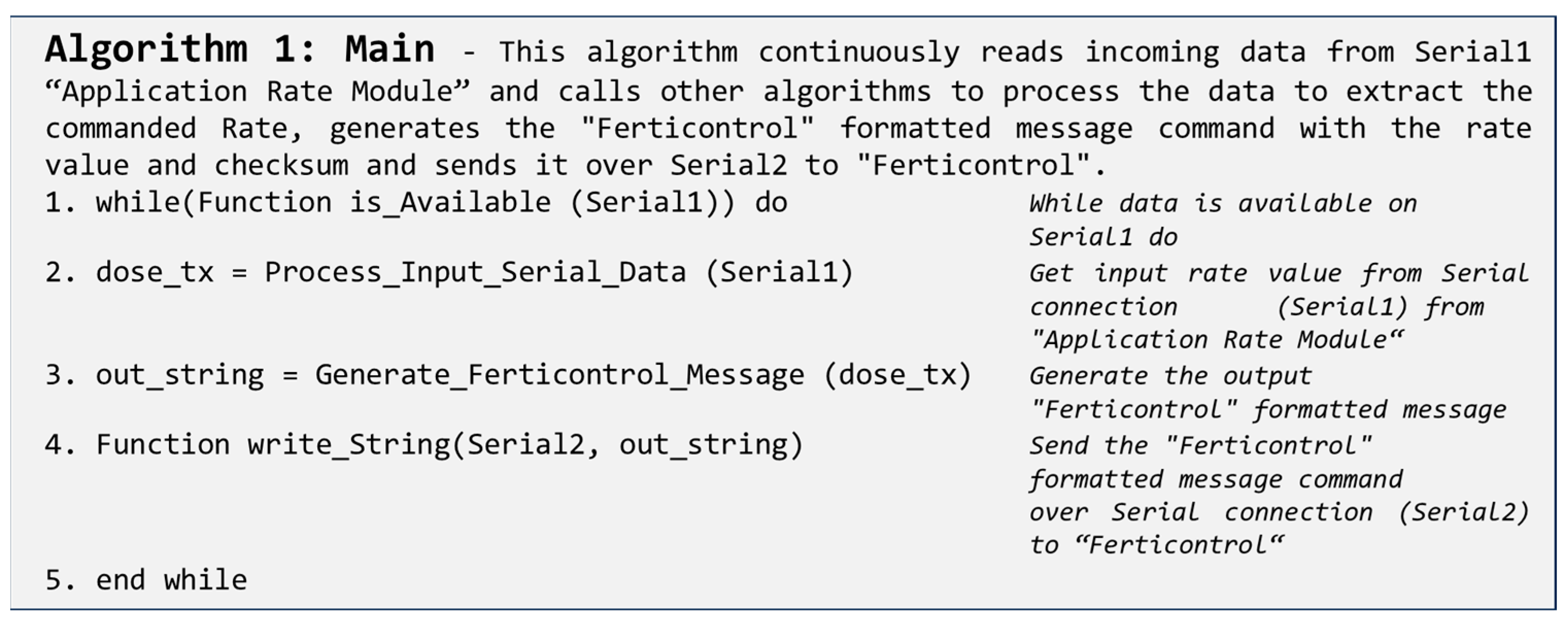

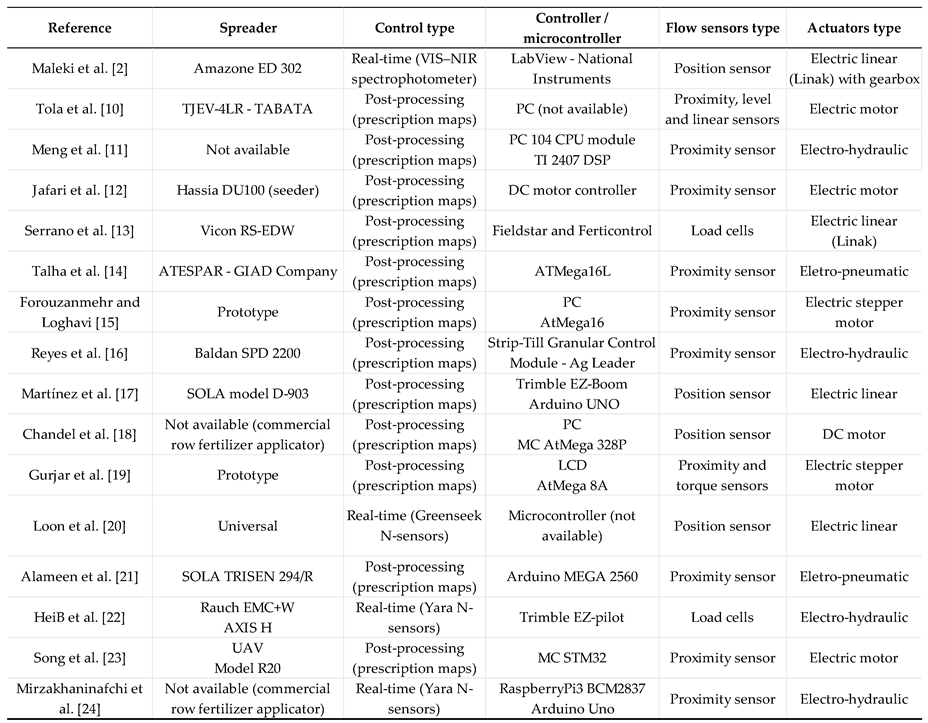

The conversion system, developed in “Python” on PC, was migrated to an “Arduino” microcontroller with two “RS232” serial ports. This system works in a continuous loop, where every 0.5 seconds it receives the command message from the “IC”, converts and sends it to the “Ferticontrol” monitor. The algorithms developed are presented in

Figure 9 and 10. The message received and sent was displayed on a display connected to “Arduino”. Field tests were carried out based on the prescription map, with all the equipment mounted on the tractor (

Figure 11). The tests showed that the "Ferticontrol" monitor assumed the programmed prescription rate ("Direct Command"), depending on the location of the tractor at the field.

The results obtained in the bench or field tests show that it is possible to control the “Vicon RS-EDW” spreader in VRT mode, using the “Direct Command” software on the “InCommand” monitor from “Ag Leader”.

There could be other possible alternative approaches, for example, deactivating the “Vicon” distributor controller (“Ferticontrol”) and directly controlling the “Linak” actuators and sensors (load cells, level and magnetic proximity sensors) through a microcontroller. This option would provide greater possibilities for development (mechanical, electronic and informatic) and even greater flexibility in controlling the “Vicon” spreader, since the microcontroller would autonomously control the actuators and sensors, as carried out by Chandel et al. [18] or Gurjar et al. [19] and can even evolve into functions for cutting sections and recording the real fertilizer rate applied to the field. However, in addition to the added complexity, it would be necessary to disconnect the original control system from the spreader (“Ferticontrol”, load cells, level sensor, actuators) to make the connections to the “Arduino” microcontroller, and its development and testing, which would put the spreader inoperative for common agricultural activities on the farm for an indefinite period. It would also be necessary to redo all the calibration of the equipment and carry out field tests to validate the fertilizer rate applied by the spreader in accordance with the prescription map of the “Direct Command” software, similar to those carried out by various teams, for example: Serrano et al. [13], Mahmoodpour et al. [26] or Wan et al. [27].

The great advantage of the proposed system (

Figure 5) is the integration of all the original equipment of the “Vicon” spreader (controller, sensors, and actuators), maintaining both its functionality and, therefore, its permanent availability for the farm's agricultural activities, and the robustness of factory calibrations in terms of sensors (monitoring) and actuators (variable control) in fertilizer application. It did not require calibrations of the dosing systems to guarantee different application rates, as they are already parameterized and tested in previous tests with the “Ferticontrol” monitor [13].

The characteristics of the “hardware” and “software” used, which are easy to access and open source, allow the quick and accurate control of the “Vicon RS-EDW” spreader, in VRT mode, with the communication of the application rate between “InCommand” and “Ferticontrol” every 0.5 seconds. This short average response time to switch between the target fertilizer rates is similar to that obtained in other works with electric drive, such as Alameen et al. [21], who registered a response time of 6–11 microseconds, Al-Gaadi et al. [6], with average response time of 0.1 s or Tola et al. [10] and Meng et al. [11] with response time of 1–2 s to change from one fertilizer’s application rate to another. This response time will allow the equipment to accurately implement variable prescription maps, achieving effective variation in fertilizer application rates between different management zones. Serrano et al. [13], in tests under real field conditions in pastures, with this Vicon spreader and “Fiedstar” – “Ferticontrol” VRT systems led to a machine delay time of 6-7 seconds and an actual fertilization application rate around 90% of target rate. Jafari et al. [12] also recorded 5-7 s of response time in dynamic tests of a variable rate electrical controller, while Mirzakhaninafchi et al. [24], with an electro-hydraulic control system showed operational response time in the range of 3.5 to 5 s. Relatively to the accuracy, Yu et al. [28] developed a real-time measurement system, based on a weighing sensor, to measure the application rates of solid fertilizers and recorded approximately 3% application rate error in dynamic performance tests; on the other hand, Tola et al. [10], showed overall system errors of ± 5%, while Forouzanmehr and Loghavi [15] showed successful response to the target discharge rates of an electric drive system, with an overall mean error of 5.4%, which can, in some cases, reach 9%. In summary, Al-Gaadi et al. [6], in their review article based on previous research on the performance of the existing control and monitoring systems used in VRA of solid fertilizers, found high application accuracy. Depending on the actuation method employed, the map-based systems utilized for VRA of solid fertilizers operate with an overall accuracy ranging between 94% and 98%.

Since fertilization is a recognized and important component of agriculture, in terms of potential benefits for farmers, the significance of this VRT development is underscored by both its economic and environmental implications [6]. When fertilizers are applied uniformly, some parts of a field may be under-fertilized while other parts may be over-fertilized. In general, under-fertilization can result in yield and quality reduction; while over-fertilization can impose a danger to the environment i.e., deteriorate water quality, promote weed growth, may results in higher expense and lower profit [6]. Adding fertilizers to agricultural fields using modern methods can have many benefits such as improving the soil characteristics and plant growth habits, reducing production costs, and increasing productivity [6]. VRA systems have the advantage of enhancing the efficiency of the agricultural inputs by reducing the cost as well as limiting the environmental pollution [6].

In terms of future research perspectives, and despite the remarkable development of the systems currently used in VRA of solid fertilizers [6], it is important to continue this work through comparison between variable-rate and uniform fertilizer application [29] in order to increase the assimilation of precision agriculture among farmers and to demonstrate its efficiency at the field-scale given the numerous field variables that influence its accuracy.

4. Conclusions

This work presents a low-cost solution that would allow updating the control system (“Ferticontrol”) of a “Vicon RS-EDW” spreader for VRA, making it compatible with the “InCommand” system from “Ag Leader”. The solution proposed in this study is to update this “Vicon” spreader, as VRT has the potential and the versatility of responding to other brands and also other equipment, namely seeders and sprayers. The development shows that this solution is accessible to farmers in general. Fundamentally, farmers become aware of these developments so that they realize that there is a technological leap to be made and that the expensive initial investment that they made in equipment some years ago, which quickly became obsolete, can, after all, continue to have an economic return with the support of these partnerships.

This type of development and update to technologically obsolete agricultural machinery also creates a market opportunity, which can lead to the creation of small new enterprises providing technology-based services, in the first phase, evaluating each situation and choosing the best implementation options. These partnerships guarantee permanent innovation and represent a decisive step towards modern, technological, competitive, and sustainable agriculture, particularly important to low-resource farmers.

Author Contributions

Conceptualization, J.S., A.A. and C.E.; methodology, J.S. and A.A.; software, J.S., A.A. and C.E.; validation, J.S. and A.A.; formal analysis, J.S. and A.A.; investigation, J.S., A.A. and C.E.; resources, J.S., J.M.S. and F.M.; data curation, J.S..; writing—original draft preparation, J.S. and A.A..; writing—review and editing, J.S., A.A., S.S., J.M.S. and F.M.; visualization, S.S. and F.M.; supervision, J.S.; project administration, J.S. and J.M.S.; funding acquisition, J.S. and J.M.S. All authors have read and agreed to the published version of the manuscript.”

Funding

This research was funded by National Funds through FCT (Foundation for Science and Technology) under the Project UIDB/05183/2020 and by the projects HIBA-HUB Iberia Agrotech (Creación de un Ecosistema Plurirregional para la Agrodigitalización a través de los Digital Innovation HUB) and PEGADA 4.0 (Sustentabilidade da Atividade Agrícola Suportada por Processos e Tecnologias Inteligentes).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is unavailable due to privacy.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Lu, Y.; Liu, M.; Li, C.; Liu, X.; Cao, C.; Li, X.; Kan, Z. Precision fertilization and irrigation: Progress and applications. AgriEngineering 2022, 4, 626–655. [Google Scholar] [CrossRef]

- Maleki, M.R.; Mouazen, A.M. , De Ketelaere; B.; Ramon, H.; De Baerdemaeker, J. On-the-go variable-rate phosphorus fertilisation based on a visible and near-infrared soil sensor. Biosyst. Eng. 2008, 99, 35–46. [Google Scholar] [CrossRef]

- Serrano, J.; Shahidian, S.; Marques da Silva, J.; Paixão, L.; Calado, J.; Carvalho, M. Integration of soil electrical conductivity and indices obtained through satellite imagery for differential management of pasture fertilization. AgriEngineering 2019, 4, 567–585. [Google Scholar] [CrossRef]

- Mirzakhaninafchi, H.; Singh, M.; Dixit, A.K.; Prakash, A.; Sharda, S.; Kaur, J.; Nafchi, A.M. Performance assessment of a sensor-based variable-rate real-time fertilizer applicator for rice crop. Sustainability 2022, 14, 11209. [Google Scholar] [CrossRef]

- Serrano, J. , Peça, J., Marques da Silva, J., Shahidian, S. Medição e mapeamento da condutividade eléctrica aparente do solo em pastagens. Rev. Cienc. Agr. 2010, 2, 5–14. (In Portuguese) [Google Scholar]

- Al-Gaadi, K.A.; Tola, E.; Alameen, A.A.; Madugundu, R.; Marey, S.A.; Zeyada, A.M.; Edrris, M.K. Control and monitoring systems used in variable rate application of solid fertilizers: A review. J. King Saud University – Science 2023, 35(3), 102574. [Google Scholar] [CrossRef]

- Sharipov, G.M.; Heiß, A.; Eshkabilov, S.L.; Griepentrog, H.W.; Paraforos, D.S. Variable rate application accuracy of a centrifugal disc spreader using ISO 11783 communication data and granule motion modeling. Comput. Electron. Agric. 2021, 182, 106006. [Google Scholar] [CrossRef]

- Grisso, R.B.; Alley, M.; Thomason, W.; Holshouser, D.; Roberson, G.T. Precision farming tools: Variable-rate application. Virginia Cooperative Extension, Publication 442-505, 2011, pp. 1–16.

- Ess, D.R.; Morgan, M.T.; Parson, S. Implementing site-specific management: map-versus sensor-based variable rate application. Precision Agriculture, Purdue University, 2001, SSM-2-W.

- Tola, E.; Kataoka, T.; Burce, M.; Okamoto, H.; Hata, S. Granular fertiliser application rate control system with integrated output volume measurement. Biosyst. Eng. 2008, 101(4), 411–416. [Google Scholar] [CrossRef]

- Meng, Z.; Zhao, C.; Liu, H.; Huang, W.; Fu, W.; Wang, X. Development and performance assessment of map-based variable rate granule application system. J. Jiangsu University - Natural Science Edition 2009, 30(4), 338–342. [Google Scholar]

- Jafari, M.; Hemmat, A.; Sadeghi, M. Development and performance assessment of a DC electric variable-rate controller for use on grain drills. Comput. Electron. Agric. 2010, 73, 56–65. [Google Scholar] [CrossRef]

- Serrano, J.M.; Peça, J.O. , Shahidian, S. Evaluation of variable rate technology for fertilizer application in permanent pastures. J. Agri. Sci. Techn. A 2011, 1(4), 489–499. [Google Scholar]

- Talha, Z.; Tola, E.; Al-Gaadi, K.A.; Kheiralla, A. Pneumatic system for granular fertilizer flow rate control. Middle-East Journal of Scientific Research 2011, 8, 688–693. [Google Scholar]

- Forouzanmehr, E.; Loghavi, M. Design, development and field evaluation of a map-based variable rate granular fertilizer application control system. Agric. Eng. Int.: CIGR Journal 2012, 14(4), 255–261. [Google Scholar]

- Reyes, J.; Esquivel, W.; Cifuentes, D.; Ortega-Blu, R. Field testing of an automatic control system for variable rate fertilizer application. Comput. Electron. Agric. 2015, 113, 260–265. [Google Scholar] [CrossRef]

- Martínez, J.; Pérez Ruiz, M.; Castro, S.; Agüera Vega, J. Desarrollo de un prototipo universal para adaptación de equipos centrífugos de abono convencionales en equipos de aplicación variable. In Proceedings of the VIII Congreso Ibérico de Agroingeniería, Orihuela, Alicante, Espanha, 1–3 de junho 2015; pp. 967–975. [Google Scholar]

- Chandel, N.; Mehta, C.; Tewari, V.K.; Nare, B. Digital map-based site-specific granular fertilizer application system. Current Science 2016, 111, 1208–1213. [Google Scholar] [CrossRef]

- Gurjar, B.; Sahoo, P.K.; Kumar, A. Design and development of variable rate metering system for fertilizer application. J. Agric. Engin. 2017, 54(3), 12–21. [Google Scholar]

- Loon, J.V.; Speratti, A.; Govaerts, B. Precision for smallholder farmers: A small-scale-tailored variable rate fertilizer application kit. Agriculture 2018, 8(4), 48. [Google Scholar] [CrossRef]

- Alameen, A.A.; Al-Gaadi, K.A.; Tola, E. Development and performance evaluation of a control system for variable rate granular fertilizer application. Comput. Electron. Agric. 2019, 160, 31–39. [Google Scholar] [CrossRef]

- HeiB, A.; Paraforos, D.S.; Sharipov, G.M.; Griepentrog, H.W. Modeling and simulation of a multi-parametric fuzzy expert system for variable rate nitrogen application. Comput. Electron. Agric. 2021, 182, 106008. [Google Scholar]

- Song, C.; Zhou, Z.; Zang, Y.; Zhao, L.; Yang, W.; Luo, X.; Jiang, R.; Ming, R.; Zang, Y.; Zi, L.; Zhu, Q. Variable-rate control system for UAV-based granular fertilizer spreader. Comput. Electron. Agric. 2021, 180, 105832. [Google Scholar] [CrossRef]

- Mirzakhaninafchi, H.; Singh, M.; Bector, V.; Gupta, O.P.; Singh, R. Design and development of a variable rate applicator for real-time application of fertilizer. Sustainability 2021, 13, 8694. [Google Scholar] [CrossRef]

- Paraforos, D.S.; Sharipov, G.M.; Griepentrog, H.W. ISO 11783-compatible industrial sensor and control systems and related research: A review. Comput. Electron. Agric. 2019, 163, 104863. [Google Scholar] [CrossRef]

- Mahmoodpour, M.; Maleki, M.R.; Mollazade, K. A new approach for variable rate fertilization based on direct read of soil map image. Span. J. Agric. Res. 2022, 20(4), 1–15. [Google Scholar] [CrossRef]

- Wan, C.; Yang, J.; Zhou, L.; Wang, S.; Peng, J.; Tan, Y. Fertilization control system research in orchard based on the PSO-BP-PID control algorithm. Machines 2022, 10, 982. [Google Scholar] [CrossRef]

- Yu, J.H.; Kim, Y.J.; Ryu, K.H. Development of a controller for variable-rate application of granular fertilizer. J. Biosyst. Eng. 2006, 31(2), 108–114. [Google Scholar] [CrossRef]

- Katz, L.; Ben-Gal, A.; Litaor, M.I.; Naor, A.; Peres, M.; Bahat, I.; Netzer, Y.; Peeters, A.; Alchanatis, V.; Cohen, Y. Spatiotemporal normalized ratio methodology to evaluate the impact of field-scale variable rate application. Precis. Agric 2022, 23, 1125–1152. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).