1. Introduction & Literature Review

1.1. Background

With global warming effects intensifying, the Paris Agreement was ratified by 195 parties in 2015, creating a target of limiting global temperature increases to 1.5ºC above pre-industrial levels [

1]. Meeting this aim requires drastic emissions reductions across industries, including the food industry. Total greenhouse gas (GHG) emissions from food systems account for one-third of the global anthropogenic total, through processes such as farming, land use changes and manufacturing [

2]. Even if fossil fuel emissions ceased immediately, current global food system trends prevent the achievement of the 1.5ºC goal [

3].

As the global population is predicted to reach 9.7 billion by 2050, global food demand will continue to increase rapidly, presenting significant climate change challenges [

4]. Therefore, growing interest has emerged in transitioning away from meat-intensive diets, minimising the environmental impacts of food systems whilst improving human health [

5,

6,

7]. However, meat consumption is projected to rise, with forecasts of global supply reaching 374 Mt by 2030 [

8]. To counteract the projected increase in meat consumption, various measures must be employed to reduce average meat consumption levels.

One potential solution involves switching to plant-based meat analogues (PBMAs), which mimic the taste and texture of conventional meat [

9]. Rather than utilising animal sources, PBMAs are created from protein extracted from plants, including soya beans, peas and wheat [

10]. With a similar sensory experience to traditional meat, PBMAs are more likely to be readily accepted by omnivores and bought as an acceptable substitute, providing the potential to displace emissions-intensive meat products [

11].

There are great prospects for PBMAs to be sold worldwide, with market projections of

$85 billion by 2030 [

12]. A growing consumer market means that it is crucial to assess the environmental impacts of current PBMAs and validate them as a credible, eco-friendly alternative to conventional animal meat. The most comprehensive methodology for quantifying environmental impacts for a product is life cycle assessment (LCA) [

13]. LCAs standardise comparisons of different products by capturing the environmental impacts of the production process, potentially encompassing raw material acquisition to waste management [

14].

1.2. Plant-Based Meat Analogues (PBMAs) & Production Methods (Extrusion)

PBMAs attempt to provide an equivalent protein content to meat counterparts, whilst maintaining a similar sensory experience [

12]. This requires a structuring process that replicates the fibrous texture of animal meat [

15]. Therefore, chosen plant-based proteins should possess the ability to retain liquids, gelatinise and be soluble [

16]. Currently, soya beans and peas are primary sources of plant-based protein, due to low costs and similar characteristics to meat protein [

17]. Oils and fats are also added to generate flavour [

12]. Additionally, binding agents, flavour enhancers and colouring agents are included for a closer resemblance to meat [

17].

Soy protein is frequently used for PBMAs, usually in the form of soy flour, soy protein concentrate or soy protein isolate [

18]. One advantage of soy protein is its 98% digestibility, ensuring that the ingested amino acids are available for the body to utilise [

19]. In particular, soy protein isolate (SPI) is the most refined form, being ideal for PBMAs with a protein content of over 90% [

20]. After dehulling, flaking and defatting soya beans, SPI is formed via alkali extraction and isoelectric precipitation [

21]. As soya beans are predominately cultivated abroad in the USA and South America [

22], studies that assess soy-based PBMAs should account for global supply chains or transportation associated with bringing soy protein to the UK.

However, risks could emerge if the general population cut meat from their diets completely, in favour of PBMAs. Animal foods facilitate the uptake of key plant-based nutrients like iron or vitamin B12, which are critical for human health and may not be naturally present in alternative proteins [

23]. Moreover, PBMAs are categorised as ultra-processed foods, with industrially processed or synthetically derived ingredients that could negatively impact human health [

24]. PBMA development must ensure that products are healthy and do not unintentionally increase undesirable nutrient uptake, such as saturated fats [

25].

PBMA commercial production typically employs top-down extrusion, with the ability for mass production and operational robustness [

26]. Extrusion involves a screw within an extrusion barrel forcing material through a shaped die, exposing the material to heat, pressure, moisture and mechanical energy [

27]. Three main steps occur: initial material preparation before insertion into the extruder; cooking and mixing within the extrusion barrel; and cooling within the die [

17]. Heat and shear within the screw barrel cause protein denaturation, gelatinisation and cross-linking [

28].

Twin-screw, intermeshed and co-rotating extruders are the standard extrusion equipment commercially [

28]. These allow for extrudates to have varying moisture content [

29], by adjusting the operating parameters of the extrusion barrel [

17]. One form of extrudate is low-moisture texturised vegetable proteins (TVPs), where high pressuring and depressurising in the extrusion barrel rapidly evaporates moisture from the material [

30]. Restructured products such as patties typically use low-moisture extruded material, by hydrating the extrudate, combining it with other ingredients and moulding it into desired shapes [

26].

1.3. Life Cycle Assessment (LCA) Overview & Studies on PBMAs

LCAs quantitatively analyse a product’s environmental impacts, spanning effects on ecology, resources and human health [

31]. There are 4 main stages for LCA studies. Firstly, the goal and scope for LCAs must be defined. The goal defines the purpose and intended audience of LCAs, whilst the scope decides what areas of the product life cycle are assessed [

31]. Then, an inventory analysis is conducted, describing the material and energy flows of the product system, as well as environment interactions [

32]. The third stage is impact assessment, where environmental impacts are classified, characterised, and weighted [

31]. Finally, interpretation of the LCA results occurs, with sensitivity checks also completed.

Existing LCA studies on PBMAs predict that the UK could annually save 9.5-11 million tonnes of CO

2e by switching away from beef patties containing imported meat, due to high environmental impacts from beef production [

33]. Commercial research is optimistic, with the Beyond Burger, a PBMA burger produced by Beyond Meat, evaluated to produce 90% less GHG emissions and consume 46% less non-renewable energy than meat equivalents [

34].

Previous LCA research has analysed PBMAs formed from various crops, such as soya beans, peas and whey [

35]. PBMAs have also been compared to other meat substitutes, with lab-grown meat or mycoprotein-based analogues possessing higher environmental impacts than soy-based substitutes, due to increased energy demand from medium cultivation [

36]. More recent PBMA studies have encompassed a wider range of environmental impact categories, accounting for factors such as acidification and ecotoxicity, although these studies have yet to make direct comparisons with British meat products [

30,

33].

1.4. Context and Justification of the research

Offsetting GHG emissions from growing meat consumption, by switching to meat substitutes, is important for achieving the UK government’s net-zero GHG emissions target by 2050 [

37]. PBMAs rank highly against other potential substitutes, with consumers more likely to implement alternatives if there are fewer radical changes in dietary behaviour [

38]. As a promising alternative to traditional meat, PBMAs should be rigorously assessed to ensure that the claimed environmental benefits are accurate and substantial enough to warrant potential incentivisation or policy development by governments [

39].

Currently, there has yet to be a comparative life cycle assessment between PBMA burgers and British beef burgers, with the most similar study utilising Irish beef [

33]. Generating a comparison between PBMA and UK-based beef burgers will allow findings to be more applicable in the UK, potentially influencing national government decisions on agriculture or science.

Moreover, all currently available LCA comparisons lack exact data on PBMA recipes, with specific ingredient composition, percentages and locations of sources being redacted [

40]. Due to redacted recipes, it is difficult for third parties to verify conclusions from reports published in collaboration with companies. Therefore, an LCA assessing the environmental impact of a PBMA with a publicly known ingredient composition will be beneficial for a fair and accurate comparison.

1.5. Goals of the Current Study

This article endeavours to assess the environmental impact of a PBMA burger patty against a UK-based beef equivalent, with the overall objective of quantifying potential climate change mitigation benefits if the UK switched to PBMAs. Through the work undertaken, the following objectives were fulfilled:

Create a detailed life cycle inventory for PBMA and beef burger patties, using secondary data to consider the supply chain from raw material extraction (cradle) to consumption (fork).

Develop a life cycle analysis model of both patties via LCA software.

Evaluate the environmental impacts of both patties, contextualising results against climate change targets.

Assess whether EU exportation, using homegrown ingredients or utilising soy protein concentrate greatly affect the environmental impact of PBMAs, through scenario analyses.

Conduct sensitivity and uncertainty analysis to investigate the robustness of results gathered, as well as provide verification.

2. Materials and Methods

2.1. Goal, Scope, Functional Unit & System Boundary Definition

The primary goal of this LCA was to comparatively assess the environmental impacts of a PBMA burger patty against a conventional British beef burger. Inputs and outputs for the life cycles of both burger patties were included. Additionally, a secondary aim of assessing the environmental impact of a PBMA with a publicly available recipe was fulfilled. Two products were investigated:

Meat Analogue (MA) – a 100 g plant-based burger patty produced in the UK, with globally sourced ingredients.

Beef Burger (BB) – a 100 g British beef burger patty produced in the UK.

A functional unit (FU) of a single 100 g burger patty was chosen.

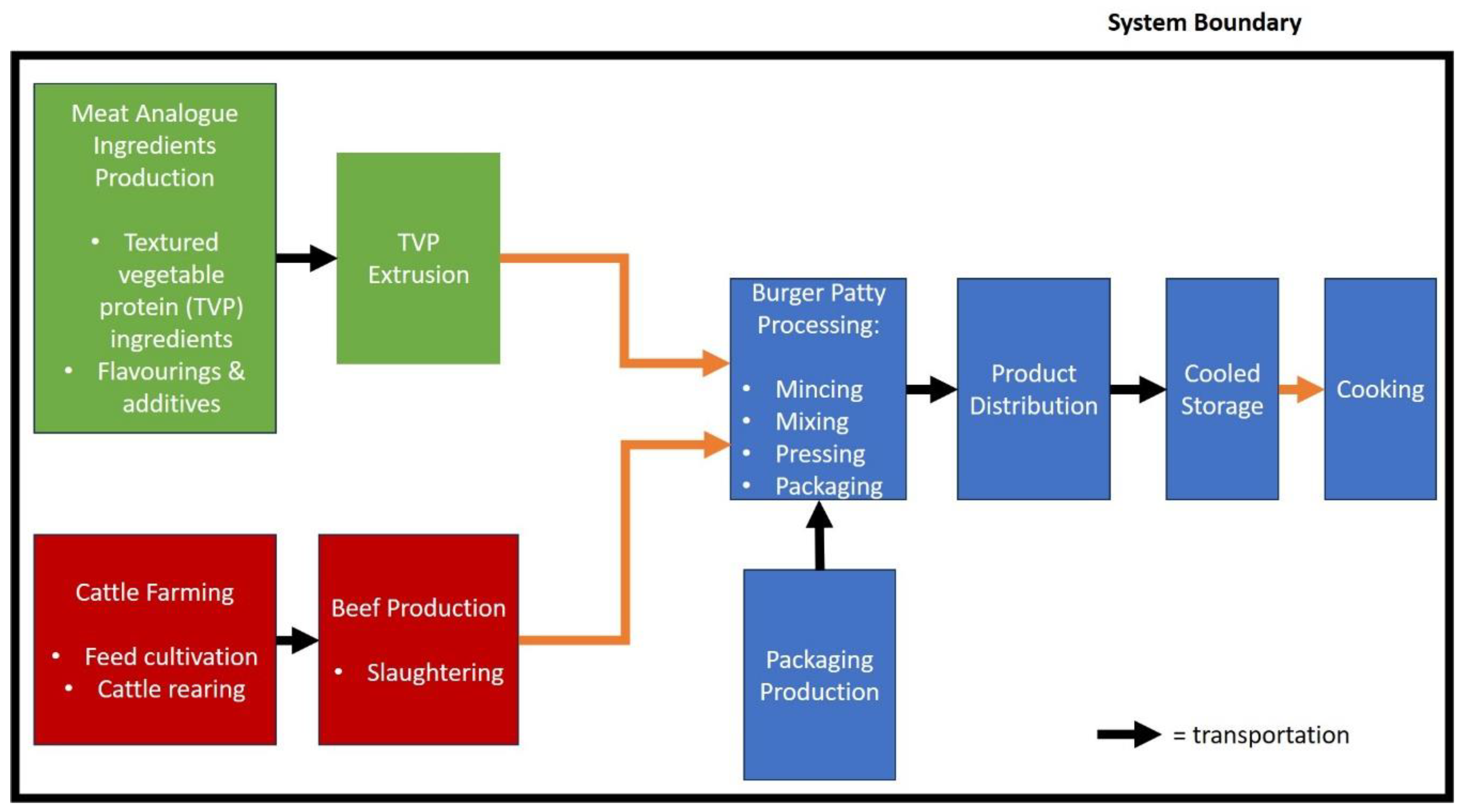

Figure 1 illustrates the system boundary implemented, with a “cradle-to-fork” approach spanning raw material production (cradle) to customer consumption (fork). With challenges in accurately modelling food waste, post-consumption stages are usually excluded from system boundaries of food-related LCAs [

35]. Therefore, end-of-life waste disposal was excluded from the analysed scope, similarly to previous LCA studies on PBMAs that neglected packaging disposal [

33,

34].

2.2. Life Cycle Inventory Analysis (LCIA)

2.2.1. Software, Data & Sources

The software utilised to conduct the LCA was SimaPro 9.5.0.2 [

41], alongside the following databases to model materials and processes: Agri-footprint v6.3 [

42], AGRIBALYSE v3.1.1 [

43], Ecoinvent 3.9.1 [

44], USLCI [

45] and WFLDB v3.5 [

46]. Processes from these databases were selected with an economic allocation assignment, similarly to other LCA studies [

30,

33]. The chosen characterisation method was ReCiPe v1.08, with a wide range of midpoint categories to analyse [

47].

This project relied on secondary data from multiple sources. Recipes for MA and BB patties were adapted from existing literature, as displayed in

Table 1 [

48,

49]. The original MA recipe contained small quantities of kappa carrageenan, sodium alginate and transglutaminase, which were not modelled in the accessible databases. Therefore, carboxymethylcellulose, also used in the Beyond Burger PBMA [

34], was selected as an alternative to replace these additives, with similar properties [

50,

51,

52]. The original BB recipe listed spices as an ingredient category: for this model, it was assumed to be entirely comprised of black pepper.

2.2.2. Meat Analogue Ingredients (Cultivation & TVP Extrusion)

The MA was comprised of 11 ingredients with varying locations of origin. Water was assumed to be readily available in industrial facilities, whilst the UK produces salt in commercial quantities [

53]. To model salt transportation from production sites to a factory via heavy goods vehicles (HGVs), an assumption of 100 km was implemented, in line with the average length of haul for a UK HGV [

54].

The other MA patty components were unlikely to be commercially cultivated or produced in the UK. This study modelled their production in countries with large commercial production, as listed in Table 3. Processes in the respective countries were modelled with Agri-footprint v6.3, AGRIBALYSE v3.1.1, Ecoinvent 3.9.1 and WFLDB v3.5 databases. These encompassed crop cultivation and ingredient production before shipment to the UK. Transportation modes and distances were defined using Product Environmental Footprint (PEF) guidelines [

55], estimating transoceanic distances with SeaRates [

56].

The main component for the MA patty was a texturised vegetable protein (TVP) based on a 5:4:1 mixture ratio of soy protein isolate (SPI), vital wheat gluten (WG) and cornstarch (CS) [

57]. Secondary data from multiple studies was incorporated to model TVP extrusion. The SPI:WG:CS mixture was designed for extrusion through a production scale twin-screw, co-rotating, water-cooled extruder, before conveyor-belt drying to a 10% moisture content [

30]. Using the TVP intermediate for patty formation required remoistening with water at a 1:12 ratio for 1 hour [

48]. Data for electricity and water consumption during extrusion, as well as noting a 7% waste stream output from machinery, was extracted from Saerens et al. [

30].

2.2.3. Beef Burger Ingredients & Production

The BB patty recipe in

Table 1 assumed 100% British beef, alongside the same methodology for water and salt as explained for MA patties in

Section 2.2.2. Potato starch was modelled as imports from the Netherlands [

58], whilst black pepper was modelled to be cultivated and transported from Vietnam [

59]. British beef relied on modelling from the World Food LCA Database (WFLDB) v3.5 [

46], with its inventory for UK beef farming and slaughtering. The majority of environmental burdens were allocated to cattle farming, due to the quantity of greenhouse gases emitted by cattle [

60].

According to the WFLDB, the quantity of raw fresh beef for 1 BB patty required 0.183 kg of beef cattle live weight. A 0.65 kg compound feed, comprised of materials such as silage, legumes, grains and bran, was required alongside 2.24 kg of grazed grass. Moreover, a distance of 230 km was covered by truck to transport the cows between the farm and the slaughterhouse [

46]. Slaughtering 0.183 kg of live cattle yielded 0.091 kg of fresh meat, which was utilised in the next stage of production. Economic allocation was used to attribute the environmental burden between the fresh beef, co-products and waste.

2.2.4. Shared Stages (Burger Processing, Packaging, Distribution, Storage & Cooking):

After the previous steps, the MA and BB patties shared the same stages for the rest of their inventories. Firstly, the beef and TVP extrudate were minced, passing through a meat grinder die [

48]. The remaining ingredients in

Table 1 were then added to the minced beef or TVP extrudate during mixing, before being pressed into burger patties [

30]. Energy consumption during mincing, mixing and pressing of the MA and BB patties was extracted from Saerens et al. [

30]. Moreover, to account for production waste from cleaning-in-place (CIP) of equipment, a 0.5% waste stream was assumed during burger processing, mimicking other production facilities [

61].

Packaging was modelled as a thermoformed polypropylene tray with a polyethylene lid film, similar to the Beyond Burger packaging [

34]. UK-produced packaging was assumed, requiring 100 km of lorry transportation to the BB/MA factory [

54]. After packaging, burger patties were then distributed via refrigerated lorries to retail centres, assuming a 100 km transportation distance. 4.35 km of consumer transport between homes and retail shops were estimated, according to average UK shopping trip distances [

62]. At home, the patties were modelled to require refrigeration for 3 days, consuming 0.034 kWh of energy [

63]. Finally, patty cooking was estimated to require 5 minutes on each side [

55], using 0.69 kWh of gas and 0.23 kWh of electricity [

63].

Table 2 and

Table 3 present the inventories for the BB and MA patties.

2.3. Scenario/Sensitivity Analyses

Scenario and sensitivity analyses were conducted to assess how various assumptions, uncertainties or calculations affect the reliability of results and subsequent conclusions. Four potential scenarios were considered:

- 3.

EU Exporting: The original model only analysed MA patties to be distributed and sold within the UK. However, considering potential impacts for MA patty exporting to the European Union (EU) is also important, with UK food and drink export sales to the EU reaching £6.9bn in the first half of 2023 [

73]. An alternative scenario of 100% exports to the EU, modelled with EU/UK centroids [

74], was evaluated against the original model. This scenario aimed to determine whether environmental merits existed for local PBMA manufacturing within countries, compared to centralised production before continental distribution.

- 4.

Homegrown MA Ingredients: In the main model, most MA patty ingredients were sourced from abroad, involving extensive shipping distances. The 2nd scenario assessed the impact of using ingredients obtained within the UK against ingredients from abroad, determining whether MA patties produced exclusively from homegrown ingredients were significantly more environmentally friendly. Homegrown ingredients were assumed to require 100 km of transportation from production sites to the factory, similar to the salt assumption in

Section 2.2.2.

- 5.

Soy Protein Concentrate Replacement: The designed MA patty utilises SPI, which requires significant refinement [

20]. A potential scenario of replacing SPI with soy protein concentrate (SPC), which has a less intensive production process, was evaluated against the main model [

17]. This scenario aimed to establish whether SPC usage generated substantially lower environmental impacts, therefore providing increased benefits for reducing GHG emissions.

- 6.

Alternative Characterisation Method: The original model results were generated via ReCiPe v1.08[

47]. However, differing characterisation methods can be influential on results of comparative LCA studies, generating different conclusions on the same model [

75]. To verify results, a sensitivity analysis was performed with an alternative characterisation method, IMPACT 2002+ v2.15 [

76].

2.4. Uncertainty Analysis

As the entire model was based on secondary data in literature and available life cycle inventory models in databases, the obtained results had certain degrees of uncertainty. To assess the robustness of results, an uncertainty analysis was conducted in SimaPro 9.5.0.2 via Monte Carlo analysis, performing 1000 simulation runs with repeated random sampling [

77]. Using a pedigree matrix, the Monte Carlo simulations tested the uncertainty of midpoint impact categories, scoring results based on the mean, standard deviation and coefficient of variation (CV) of runs to quantify statistical significance [

78].

3. Results & Discussion:

3.1. General Comparison between Meat Analogue & Beef Burger

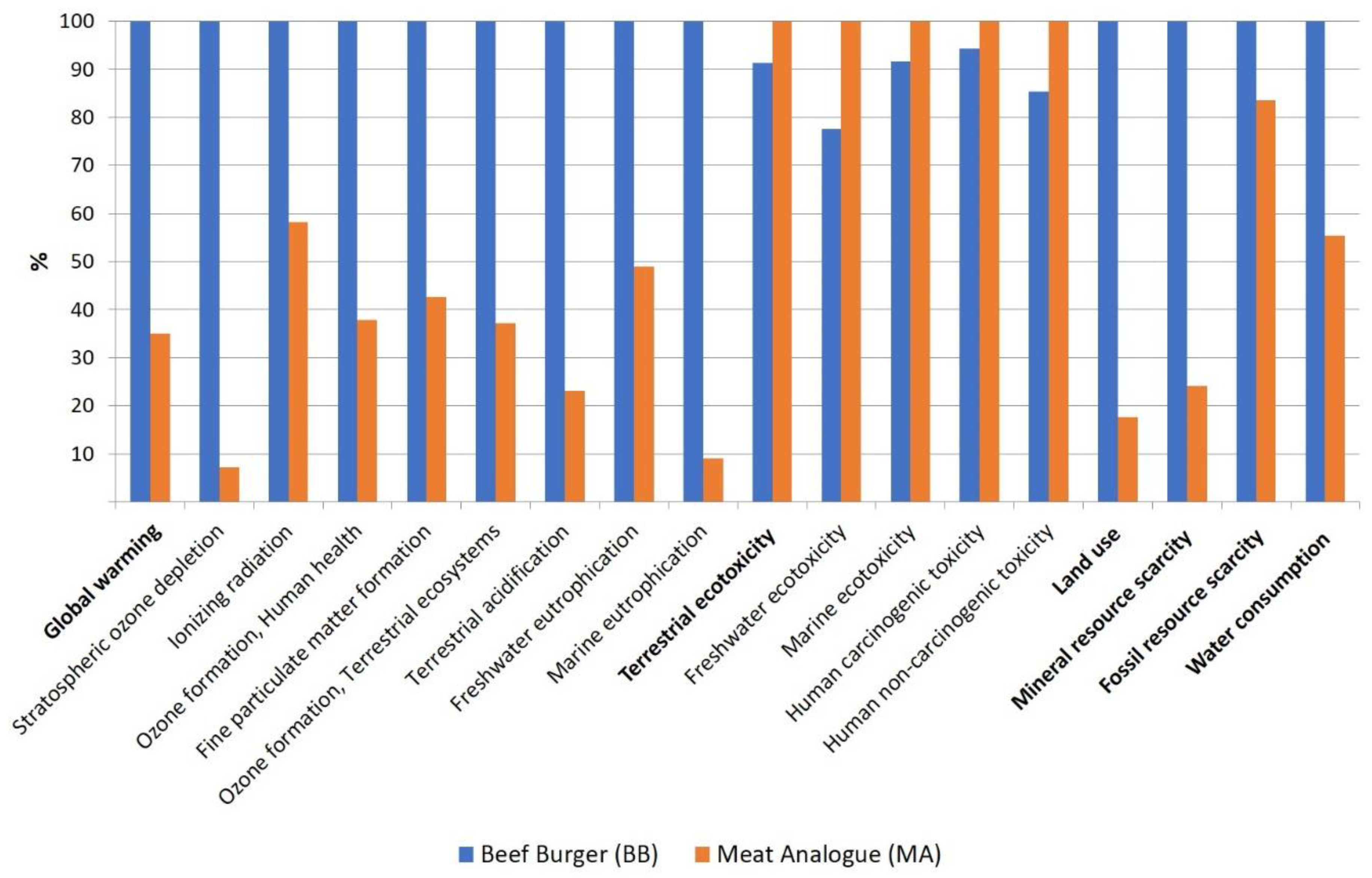

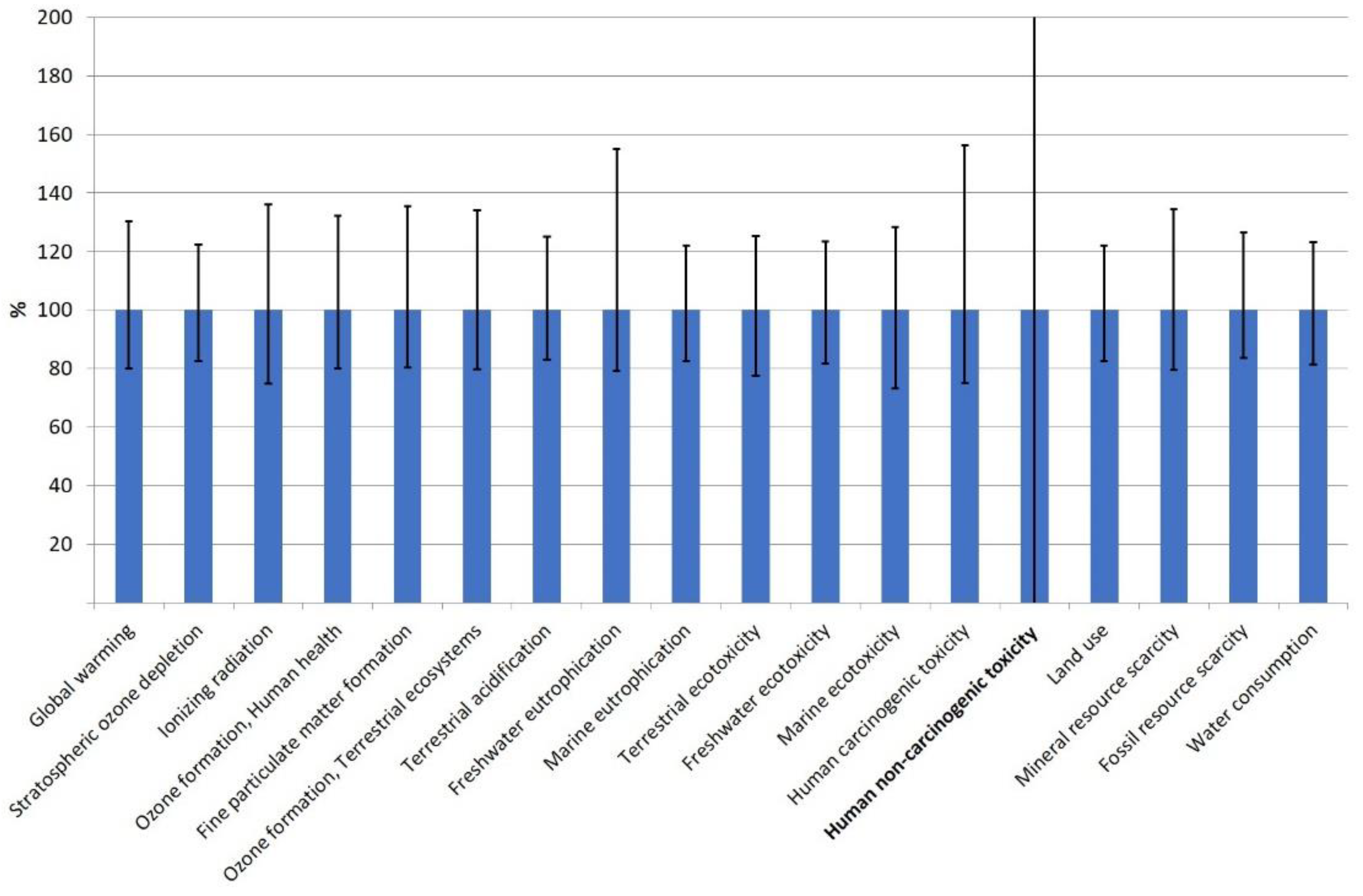

Figure 2 and

Table 4 display the overall environmental impact results for both patties. The BB patty had larger impacts in 13 out of 18 categories, relating to effects on resources and ecosystems. In key environmental impact categories, such as global warming, land use and water consumption, the impact of the MA patty was lower by 65%, 82% and 45% respectively, comparing similarly with previous studies [

33,

34]. Furthermore, the MA patty consumed fewer resources, 76% and 16% lower than the BB counterpart in mineral resource scarcity and fossil resource scarcity.

However, the MA patty had larger impacts in the 5 toxicity/ecotoxicity categories, differing from existing studies [

30,

33]. This could be attributed to the explicit use of SPI and WG in the MA recipe employed. SPI processing requires sodium hydroxide and hydrochloric acid [

79]. Although the chemicals are removed during production, having residues in the final SPI cannot be completely rejected [

80]. Additionally, fertiliser and pesticide usage for wheat cultivation is a high contributor to WG terrestrial ecotoxicity [

81].

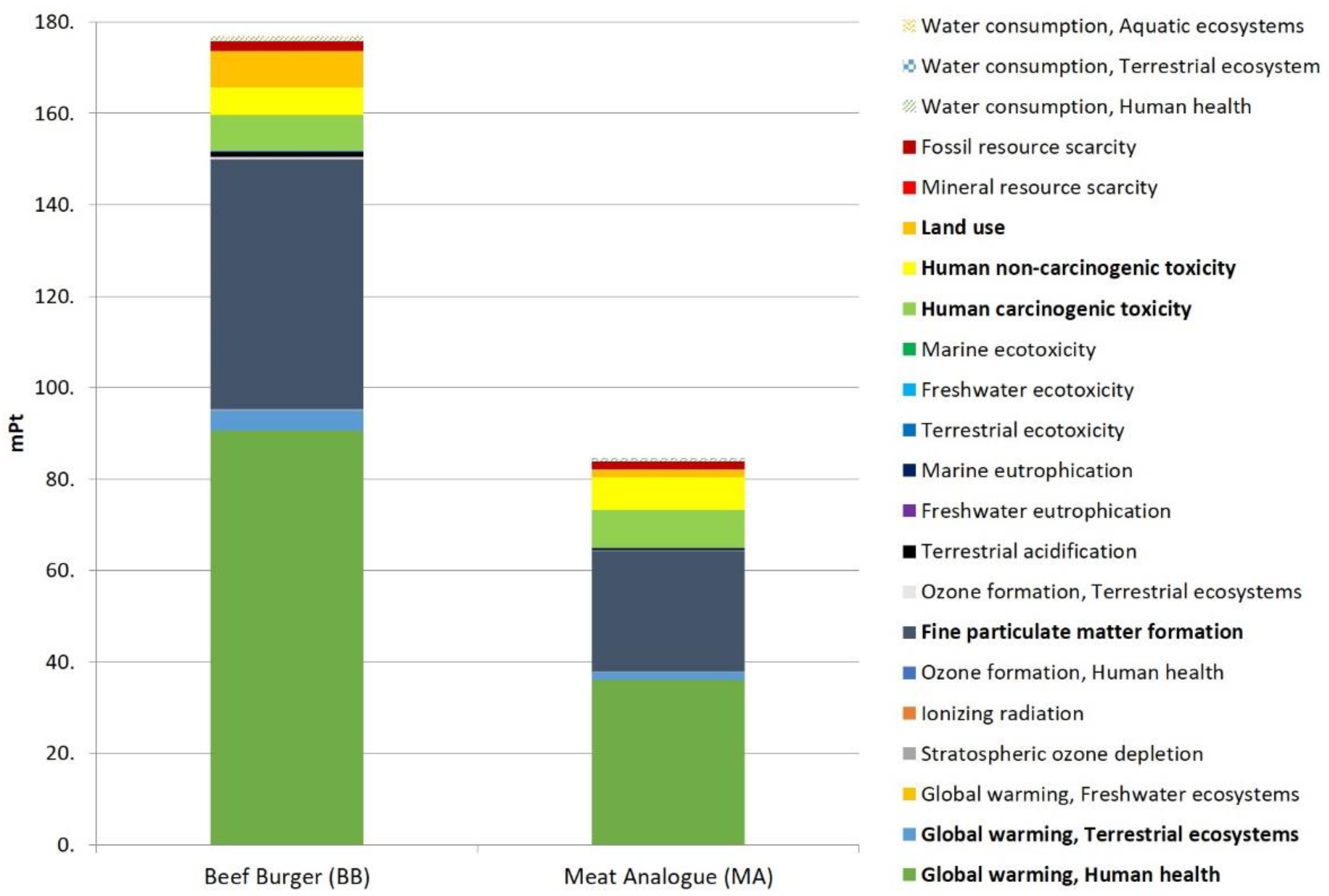

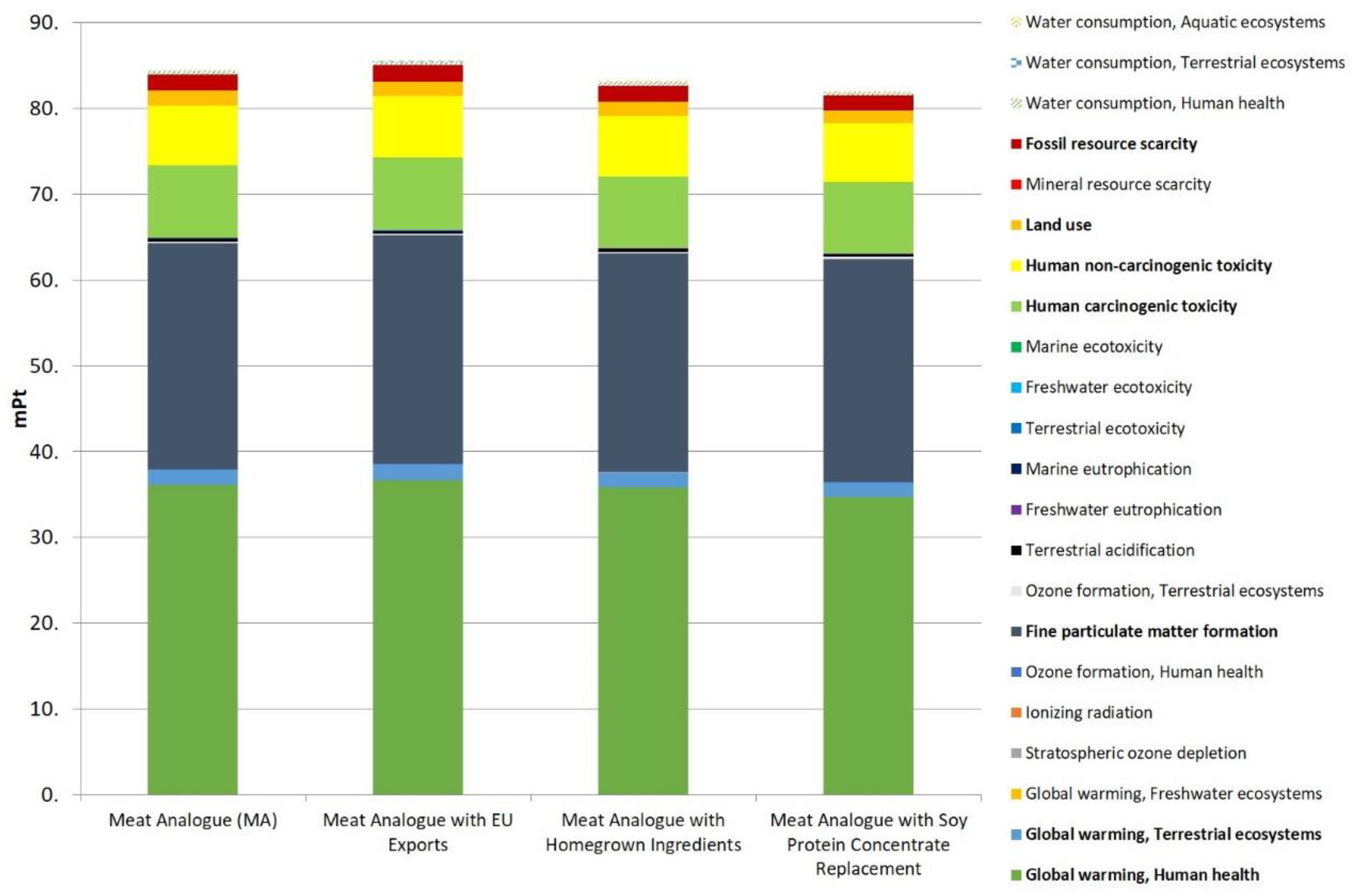

Single score comparisons allowed a visual representation of cumulative burden differences between both products, whilst also assessing which categories had the highest bearing on total environmental impacts. From

Figure 3, the BB patty had over double the cumulative burden (176.85 mPt) than its MA counterpart (84.4 mPt), being statistically significant according to the 20% rule, which stipulates substantial differences in LCA results occur with a difference of at least 20% [

82]. The substantially higher environmental impact of BB patties, compared to MA patties, is also corroborated by other meat substitute comparisons [

34,

83].

When examining individual components of the single score comparison in

Figure 2, the largest contributors to total burdens were: global warming, human health; global warming, terrestrial ecosystems; fine particulate matter formation; human carcinogenic toxicity; human non-carcinogenic toxicity; and land use. In particular, global warming accounted for 54% and 45% of the total environmental impact for BB and MA patties respectively. This corresponds favourably with Saerens, et al. [

30], where climate change categories were also the key contributors to the integrated environmental impacts of meat and MA patties. Therefore, further reducing MA patty impacts on global warming should be a primary concern for manufacturers, for example using greener fertilisers [

84].

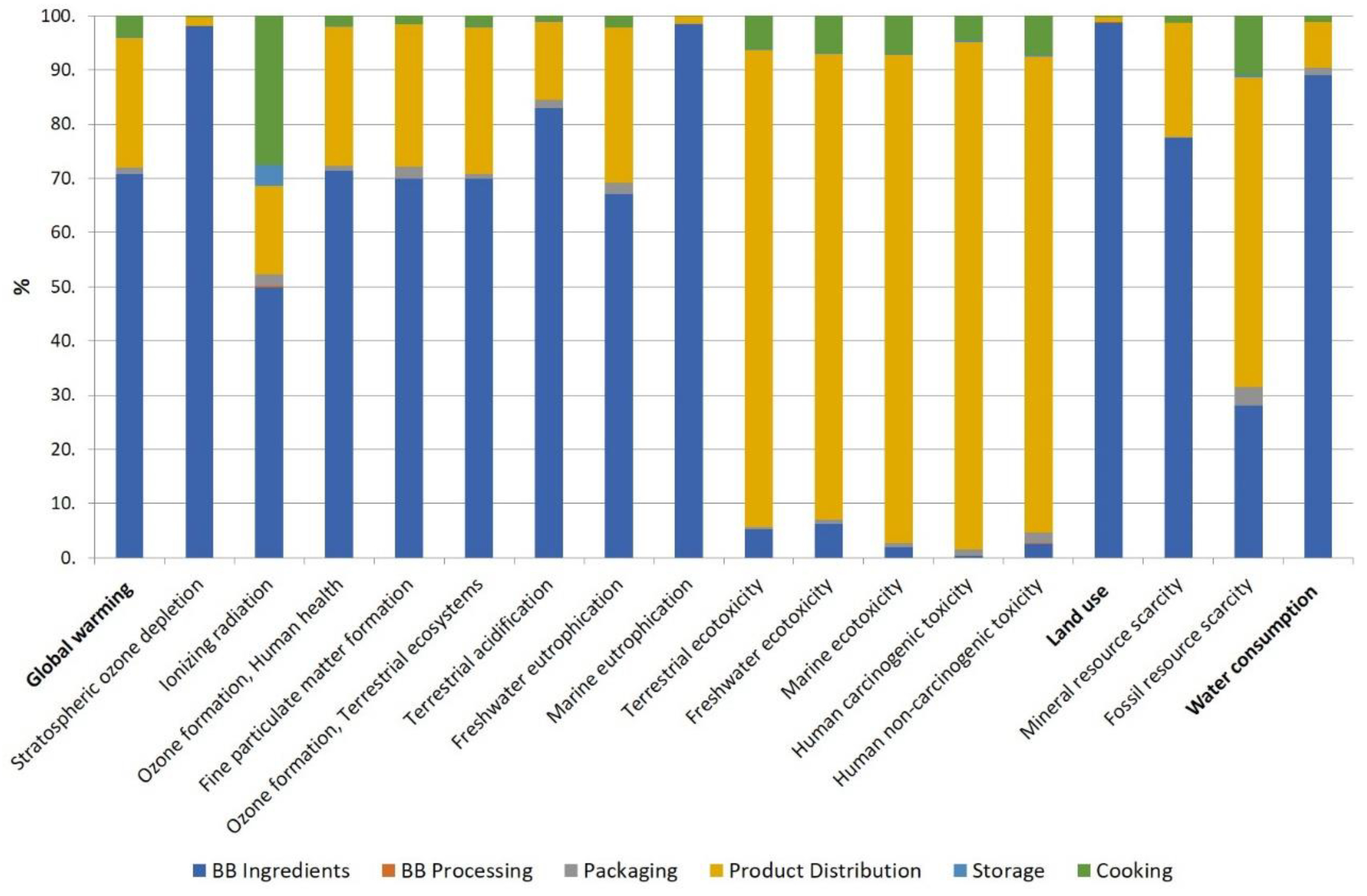

3.2. Individual Process Contributions for Patties

Figure 4 displays individual breakdowns in environmental impact results for the MA and BB patties, across product life cycles. As expected, BB ingredient production was the largest process contributor for most impact categories of the BB patty, supporting previous findings that agricultural production is the main source of environmental impact when assessing beef life cycles [

85]. BB ingredients accounted for at least 70% of global warming, terrestrial acidification, marine eutrophication, land use, mineral resource scarcity and water consumption burdens. Key factors for these outcomes were: enteric methane emissions from cattle for global warming; ammonia emissions from cattle rearing and grass cultivation for acidification/eutrophication; and cattle rearing for land use/water consumption [

33,

86,

87,

88].

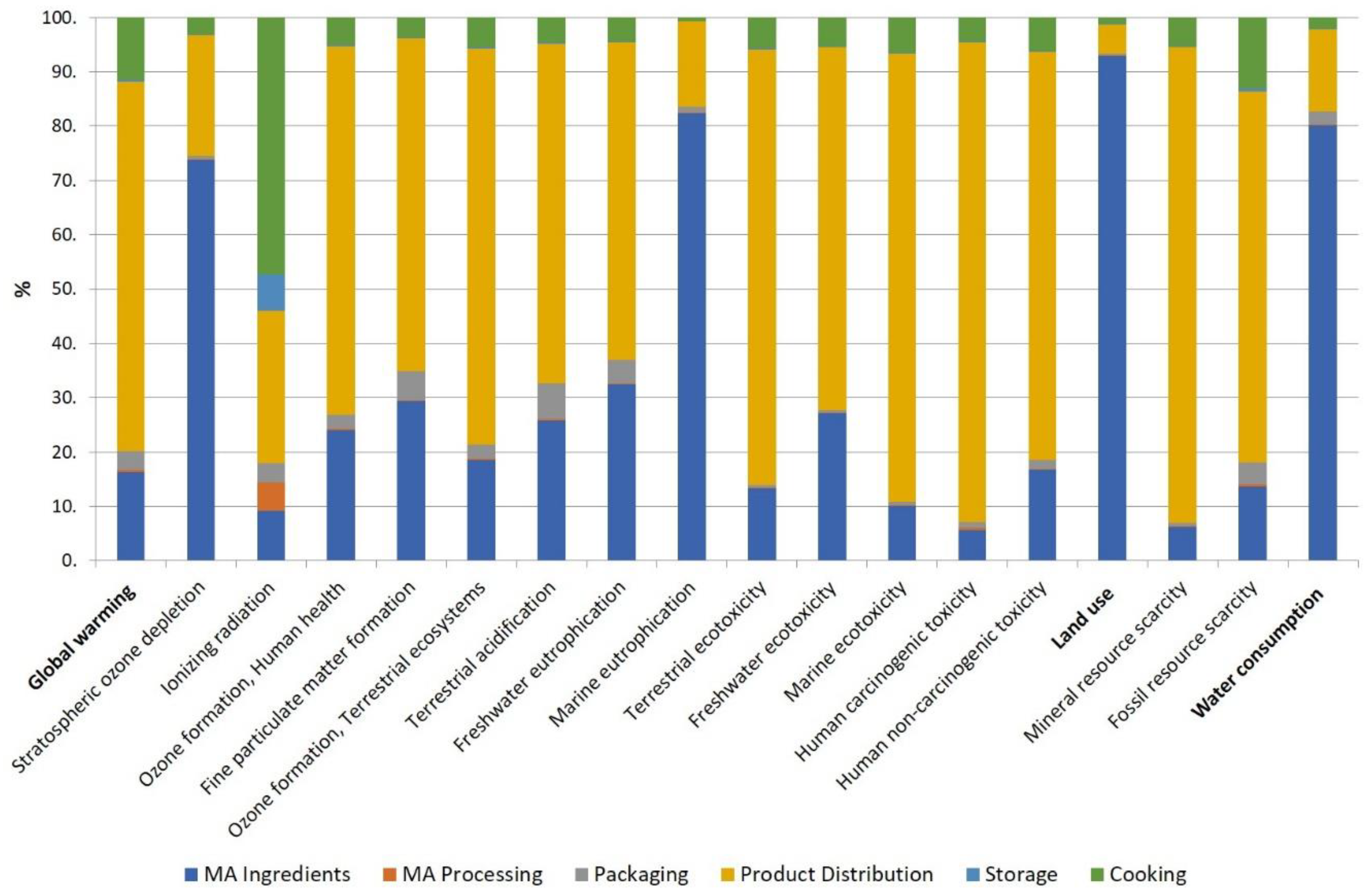

Nearly all MA patty midpoint categories were dominated by product distribution as shown in

Figure 5, differing from existing LCAs [

33,

34]. This may have resulted from the total product distribution distance of 104.35 km, as modelled in

Section 2.2.3. The bulk of product distribution requires refrigerated transport vehicles (RTVs), which typically use diesel engines to fuel energy-intensive systems that maintain refrigeration temperatures [

89]. Compared to standard vehicles, RTVs generate 15% more CO

2 emissions and 18% more NO

x emissions [

90]. However, MA ingredients were the largest process contributor to land use, marine eutrophication and water consumption. This corroborates research that soya bean and wheat cultivation require extensive land, water and fertiliser usage [

91,

92].

For both patties, product distribution was the predominant contributor to toxicity/ecotoxicity burdens. RTVs are associated with more frequent repairs and replacements, causing higher metal disposal rates that affect ecotoxicity [

93]. Moreover, RTVs emit multiple air pollutants, such as toxic diesel particulate matter [

94,

95].

3.3. Extrapolation Scenario Results

Average UK individuals consume 1.04 kg of burger patty annually [

96]. With the MA patties studied emitting 4.34 kg CO

2e less than BB counterparts, substituting all beef burger patties with plant-based patties, for the UK’s 67.0 million population [

97], would annually save 3 million tonnes CO

2e. This positive difference compares favourably to other extrapolated scenarios [

33], accounting for 0.74% of the UK’s yearly territorial GHG emissions [

98].

With the UK government targeting net-zero GHG emissions by 2050 [

99], many sectors require decarbonisation, including the food industry. Switching from BB patties to MA patties is an example of small adjustments in consumer habits that could contribute significantly to climate neutrality targets. These findings, modelled specifically for the UK, can educate consumers about the environmental benefits of incorporating PBMAs into their diet, as well as steering policy interventions from the UK government, who are looking to promote sustainable diet shifting [

39]. One potential policy to accelerate PBMA development is public funding, with a current example being the Canadian government investing CAN

$150 million in Protein Industries Canada, who develop plant-based food [

100].

3.4. Sensitivity and Scenario Analyses

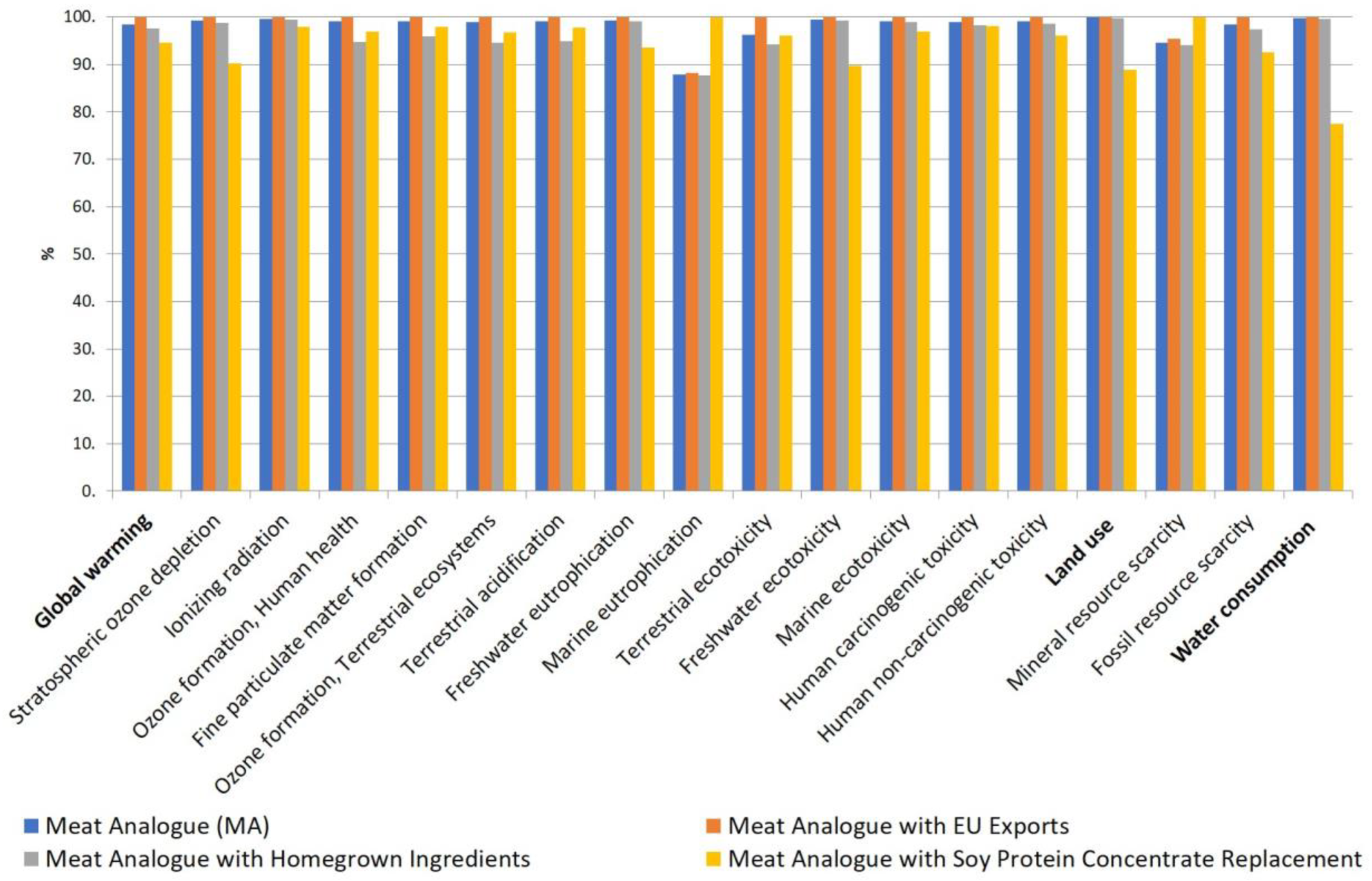

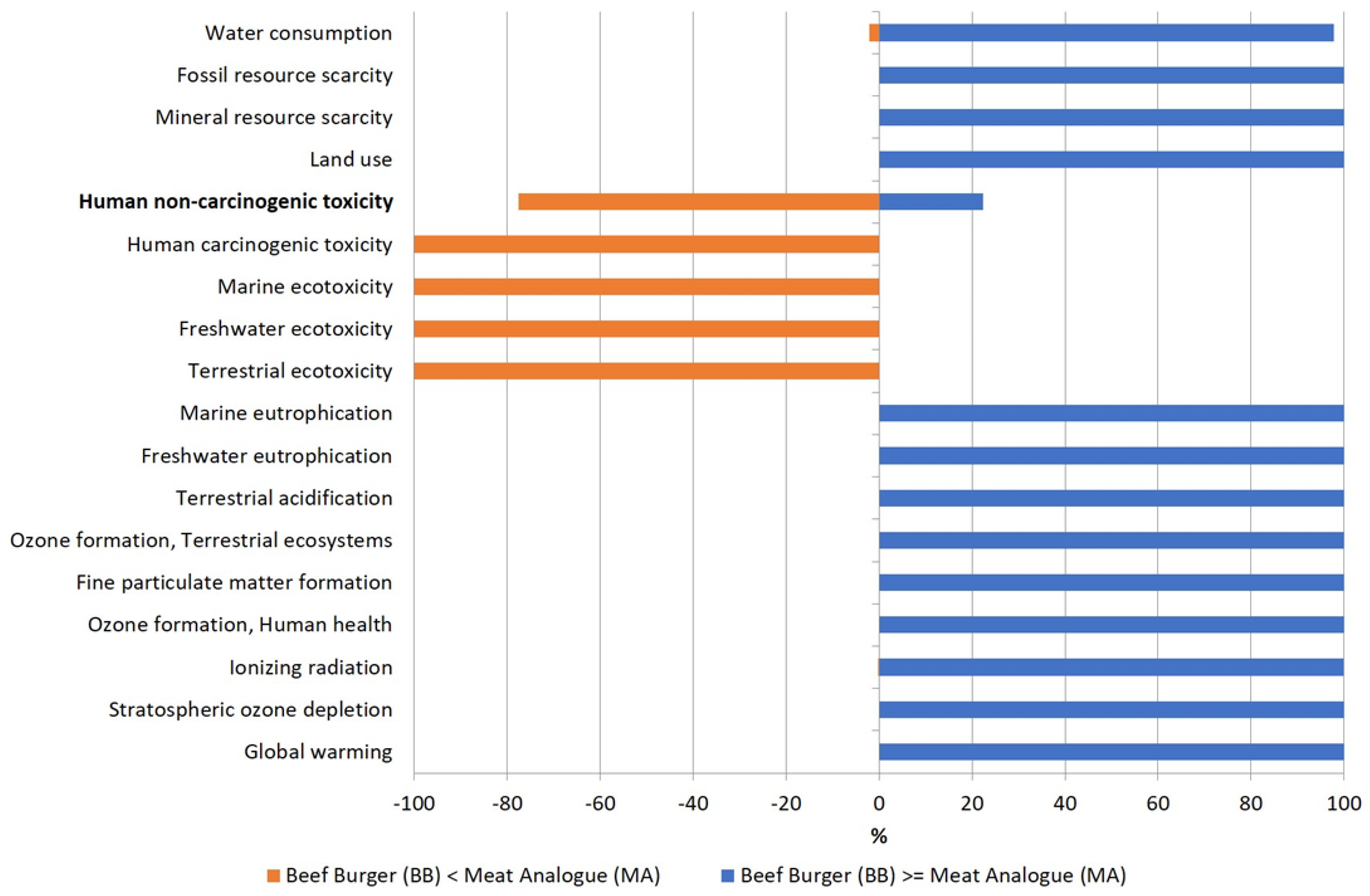

Sensitivity and scenario analyses were conducted to investigate the reliability of the study, with key results displayed in

Figure 6,

Figure 7,

Figure 8 and

Figure 9.

3.4.1. Exporting to EU

Comparing different product distribution scenarios indicated that there was no significant impact for exporting MA patties to the EU compared to only UK-wide distribution. For 100% EU exportation, the modelled scenario in

Figure 6 generated a minimally higher single score (85.5 mPt) than the original model of 100% distribution within the UK (84.4 mPt). Individual impact breakdowns in

Figure 7 displayed negligible differences between the original MA patty and the EU-exported MA patty, except in terrestrial ecotoxicity with only a 4% difference.

These results support the theory that extra energy consumed from longer transportation distances is outweighed by the initial energy requirements of refrigeration [

101]. Cargo volumes, which did not alter between scenarios, greatly influence energy usage during refrigeration. Therefore, no major environmental benefits were observed for manufacturing PBMA patties locally before internal distribution within countries. PBMA manufacturing could occur in centralised production centres before continental distribution, increasing control and cost-efficiency without suffering significant environmental drawbacks [

102].

3.4.2. Homegrown Ingredients

There were no significant differences between exclusively using UK-sourced ingredients and obtaining ingredients from various global sources. The scenario utilising only homegrown ingredients had a marginally lower single score (83.1 mPt) than the original model (84.4 mPt) in

Figure 6. For individual impacts, there were mostly imperceptible differences between both scenarios in

Figure 7, with minor deviations for ozone formation, human health (4.3%); fine particulate matter formation (3.1%); ozone formation, terrestrial ecosystems (4.4%); and terrestrial acidification (4.2%).

The fact that PBMA patties are less sensitive to whether ingredients are procured globally or locally is positive for PBMA manufacturing. Many crops required for PBMAs, like soya beans, are not native to the UK and are being currently cultivated elsewhere [

103]. In addition, crops with potential for UK-located cultivation can often be cheaper when imported from abroad [

104]. The obtained results suggest that PBMA patties can benefit from the economic advantages of cheaper imports, whilst maintaining similar environmental impacts.

3.4.3. Replacing Soy Protein Isolate (SPI) with Soy Protein Concentrate (SPC)

The 3

rd scenario replaced SPI with SPC, which requires fewer chemicals during production and is cheaper [

17]. The single score comparison in

Figure 6 exhibited only a small reduction in total environmental impact when using SPC (81.9 mPt) compared to the original patty (84.4 mPt). When analysing individual categories in

Figure 7, the only significant deviation between the SPI and SPC patties, according to the 20% rule, was water consumption, due to SPI requiring extra precipitation at acidic pH [

21]. Therefore, no substantial difference was discovered between MA patties utilising SPI or SPC. PBMAs could implement either ingredient, depending on costs and PBMA recipe formulations [

105].

3.4.4. Statistical Assessment of Scenario Analyses

To further establish the statistical significance of the analysed scenarios against the original model, a two-stage nested analysis of variance (ANOVA) on single scores was conducted [

106,

107]. Scenarios were characterised via the ReCiPe v1.08 method, which allows the option to evaluate results considering individualist (I), egalitarian (E) and hierarchist (H) points of view [

108]. Individualist views consider only short-term damage, egalitarian views evaluate all long-term damage, whilst hierarchist views combine both short-term and long-term damage. Applying different weighting sets to the 3 points of view generated 6 single scores for the same scenario [

109]: 3 for the particular weighting set (I/I, H/H, E/E) and 3 for the average weighting set (I/A, H/A, E/A).

The null hypothesis for the ANOVA test was that there were no differences in single scores generated from the original model and the various scenarios.

Table 5 displays single scores for each of the 6 weighting sets, whilst

Table 6 presents P-values calculated from the ANOVA test. All P-values were above 0.9, therefore the null hypothesis was accepted, with no statistical difference between results from the original model and the scenarios [

110].

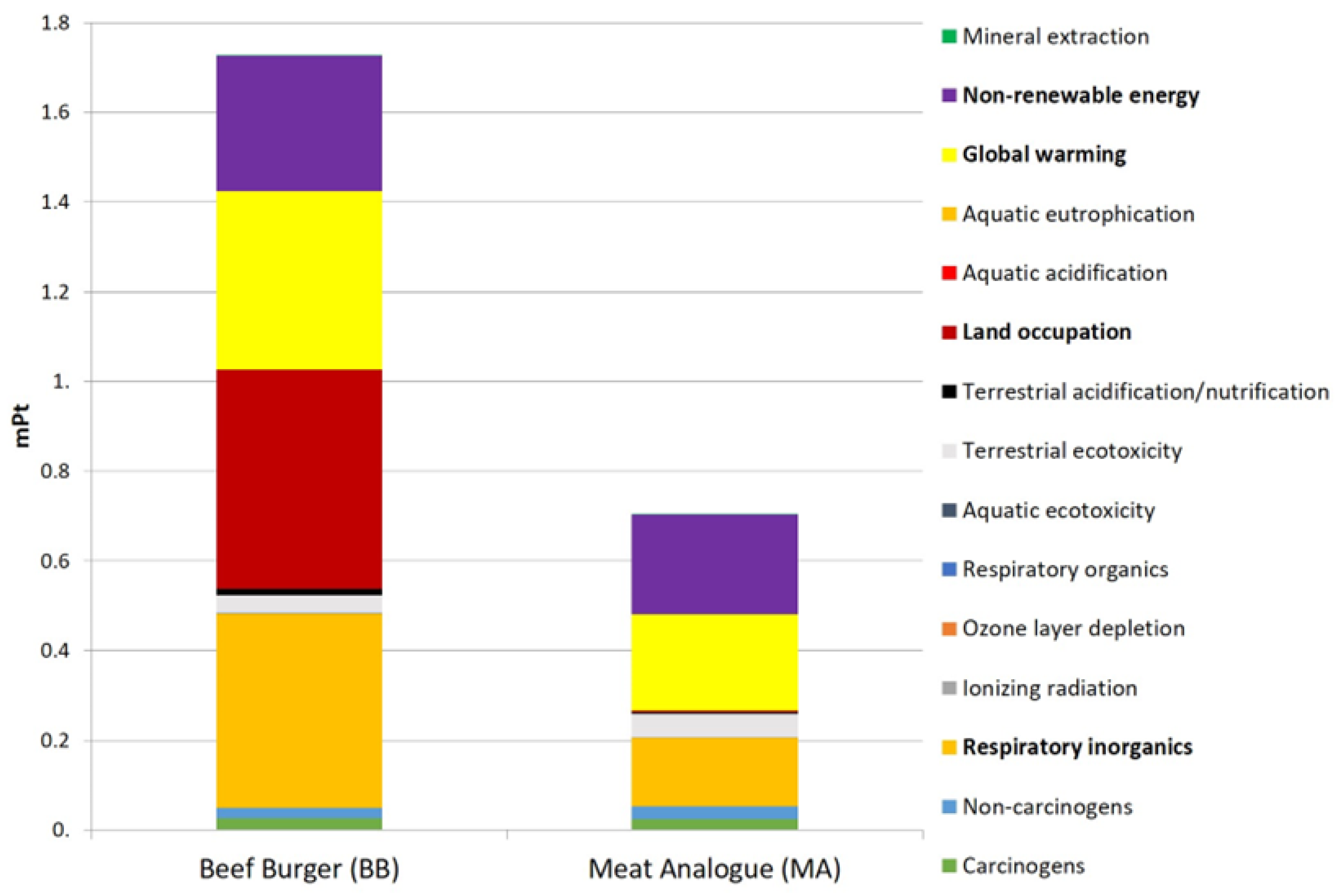

3.4.5. Alternative Characterisation Method

To validate the original model, the alternative IMPACT 2002+ characterisation method was applied. From the single score comparison in

Figure 8, BB patties (1.73 mPt) still demonstrated more than double the environmental impact compared to MA equivalents (0.70 mPt). Similarly to the original model, this difference was statistically significant, according to the 20% rule [

82]. Moreover, the highest contributors for total burdens were comparable to the original model, with global warming and respiratory inorganics also being key impacts.

From the percentage comparison of both patties in

Figure 9, using an alternative characterisation method replicated most conclusions drawn from the original model. The BB patty had the higher burden in 11 out of 15 categories. For key environmental impacts classifications, such as global warming, land use and mineral resource scarcity, MA patty impacts were lower by 46%, 99% and 40% respectively, being relatively comparable in size with findings in

Section 3.1. However, unlike the original model, the IMPACT 2002+ method analysed the MA patty to have a higher non-carcinogenic toxicity impact than the BB patty. This highlighted differences in calculating impacts from various characterisation methods and uncertainties involved, as discussed in

Section 3.5.

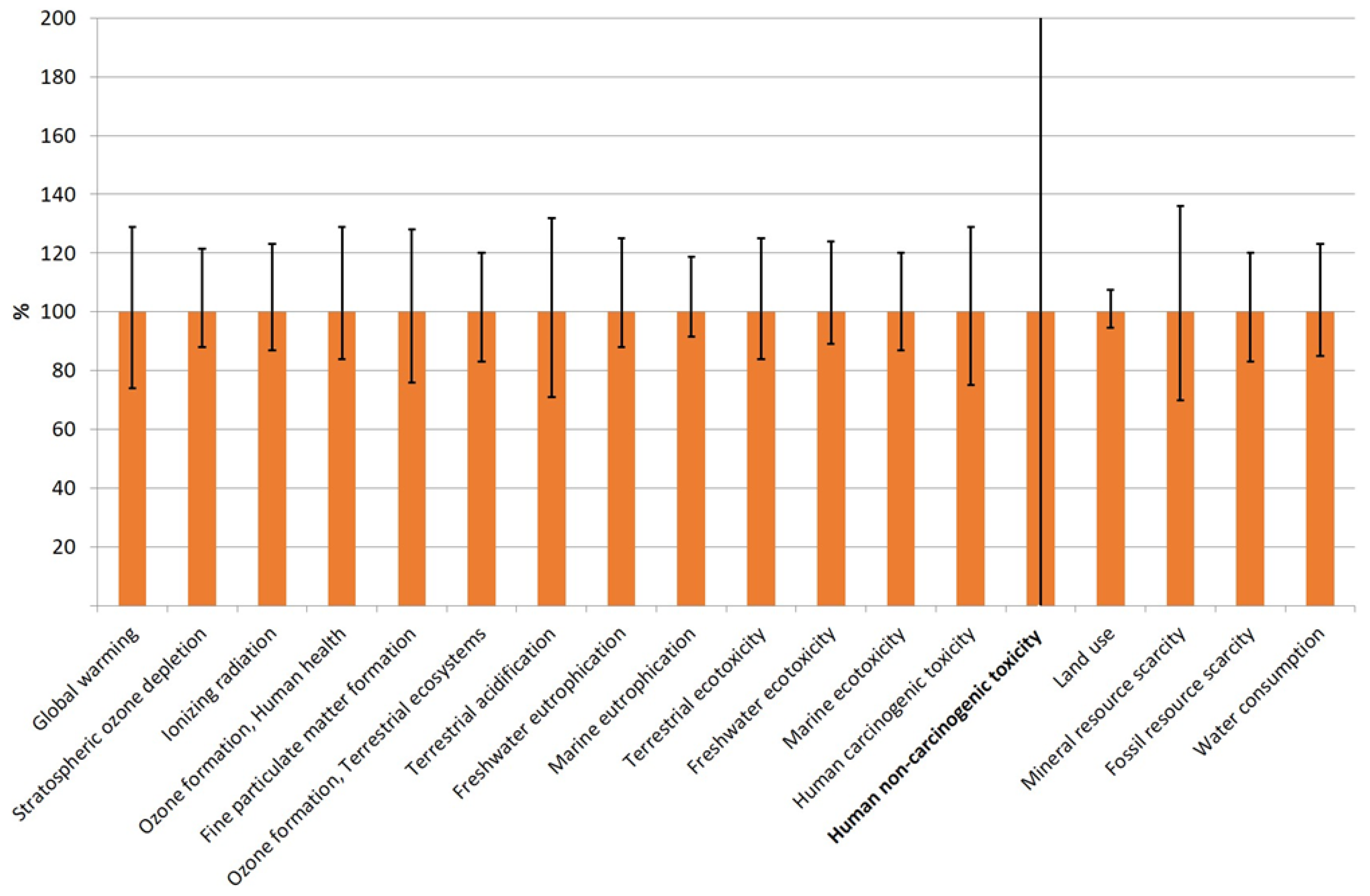

3.5. Uncertainty Analysis

To assess the robustness of LCIA data obtained, uncertainty analysis for both patties was conducted via 1000-run Monte Carlo simulations within SimaPro software.

Table 7 displays numerical results from the simulations, whilst

Figure 10 and

Figure 11 illustrate the 95% confidence intervals in absolute uncertainty for individual impact categories. From

Table 7, nearly all categories had moderate uncertainty levels under typical coefficient of variation (CV) thresholds of 20%, allowing specific conclusions to be drawn [

111]. Therefore, 17 of the 18 individual impact comparisons for the original model were validated, with reasonable confidence intervals as shown in

Figure 10 and

Figure 11. However, CV results for human non-carcinogenic toxicity were abnormally high, with 1796% for the BB patty and 1199% for the MA patty.

Figure 10 and

Figure 11 also reflect the large uncertainty for this category, indicating that conclusions regarding human non-carcinogenic toxicity possessed significant uncertainty.

Figure 12 presents the uncertainty of the difference between the patties. 17 of the 18 impact categories fulfilled a desired 95% certainty level of difference between the patties, therefore having statistically significant differences [

112]. The only category unable to meet the confidence threshold was human non-carcinogenic toxicity, which only had a 78% certainty that the BB patty had a lower impact than the MA patty. The uncertainty analysis verified the conclusions of the original model, that the MA patty performed better in resources/ecosystems categories whilst the BB patty had lower impacts in toxicity/ecotoxicity categories.

4. Conclusion

4.1. Summary

LCA methodology was applied to compare the environmental impacts of a MA patty against a BB equivalent. BB patties were discovered to have more than double the total environmental impact compared to MA counterparts (

Section 3.1). The global warming impact of the MA patty was 62% lower, which would result in 3 million tonnes of CO

2e saved if the UK population substituted all BB patties with MA patties (

Section 3.3). However, MA patties scored higher for toxicity/ecotoxicity categories. Ingredient production was highlighted as the highest process contributor for BB patties, whilst product distribution was the largest contributor for MA patties (

Section 3.2).

4.2. Relevance, Validity & Limitations

With the potential to save 0.74% of annual territorial GHG emissions, the PBMA data gathered could guide climate change mitigation strategies within the UK food industry, especially concerning government policy changes or economic incentivisation. Manufacturers could also utilise these results to improve future PBMA formulations, further reducing carbon footprints.

Results from this study could have wider implications beyond the UK. The LCA methodology employed here could be applied to quantify the climate change mitigation benefits of PBMAs over conventional meat products in other regions. This would inform policy decisions and consumer choices towards more sustainable diets on an international scale. Collaboration between academia, industry and governments will be essential in realising the full potential of PBMAs, as a key component of sustainable global food systems.

However, restrictions and subsequent simplifying assumptions were necessary during project completion. As primary data was unavailable, secondary data from literature was utilised instead. Moreover, using different databases was a key limitation when comparing patties. For the MA patty, other PBMA extrusion methods such as high-moisture extrusion were not assessed, which could have yielded differing results. Additionally, this study only analysed a known MA recipe incorporating soy-based protein, not examining patties formed with other plant-based proteins. For the BB patty, a mixed cattle-rearing scenario was considered, without separating the environmental impacts of grass-fed beef and intensively-farmed beef.

4.3. Further Research

Several avenues could be explored, based on the project limitations. Future peer-reviewed studies could transparently assess MA patties based on other plant-based proteins, such as pea protein or mycoprotein, with commercial recipes. Researching various proteins would uncover the most environmentally friendly PBMA options. Studying industrial-scale PBMA extrusion, with relevant energy consumption and waste information, would increase accuracy in projecting PBMA production requirements. In addition, LCAs utilising different functional units, for example, protein quality, would further explore environmental benefits from increased PBMA uptake. Finally, future research should meticulously analyse the nutritional composition of PBMAs and the potential impacts of long-term consumption on human health.

Author Contributions

Conceptualization, M.T., T.M., and F.S.; methodology, M.T., T.M., and F.S.; software, M.T., T.M., and F.S.; validation, M.T., T.M., and F.S.; formal analysis, M.T., and T.M; investigation, M.T.; resources, T.M., and F.S.; data curation, M.T.; writing—original draft preparation, M.T.; writing—review and editing, M.T., T.M., F.S., H.O., Z.T.A.; visualization, M.T., supervision, T.M., and F.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- United Nations/Framework Convention on Climate Change In Adoption of the Paris Agreement, 21st Conference of the Parties, Paris, France, 12 December 2015, Paris, France.

- Tubiello, F.N.; Rosenzweig, C.; Conchedda, G.; Karl, K.; Gütschow, J.; Xueyao, P.; Obli-Laryea, G.; Wanner, N.; Qiu, S.Y.; De Barros, J.; et al. Greenhouse gas emissions from food systems: building the evidence base. Environ. Res. Lett. 2021, 16, 065007. [Google Scholar] [CrossRef]

- Clark, M.A.; Domingo, N.G.G.; Colgan, K.; Thakrar, S.K.; Tilman, D.; Lynch, J.; Azevedo, I.L.; Hill, J.D. Global food system emissions could preclude achieving the 1.5° and 2°C climate change targets. Science. [CrossRef] [PubMed]

- United Nations Department of Economic and Social Affairs, P.D. World Population Prospects 2022: Summary of Results; UN DESA/POP/2022/TR/NO. 3; United Nations Publication: New York, 2022.

- Andreani, G.; Sogari, G.; Marti, A.; Froldi, F.; Dagevos, H.; Martini, D. Plant-Based Meat Alternatives: Technological, Nutritional, Environmental, Market, and Social Challenges and Opportunities. Nutrients 2023, 15, 452. [Google Scholar] [CrossRef] [PubMed]

- Tamasiga, P.; Miri, T.; Onyeaka, H.; Hart, A. Food Waste and Circular Economy: Challenges and Opportunities. Sustainability 2022, 14, 9896. [Google Scholar] [CrossRef]

- Tchonkouang, R.D.; Onyeaka, H.; Miri, T. From Waste to Plate: Exploring the Impact of Food Waste Valorisation on Achieving Zero Hunger. Sustainability 2023, 15, 10571. [Google Scholar] [CrossRef]

- OECD/FAO, 6. Meat. In OECD-FAO Agricultural Outlook 2021-2030, OECD Publishing: Paris, 2021; pp. 163-177.

- Alessandrini, R.; Brown, M.K.; Pombo-Rodrigues, S.; Bhageerutty, S.; He, F.J.; MacGregor, G.A. Nutritional Quality of Plant-Based Meat Products Available in the UK: A Cross-Sectional Survey. Nutrients 2021, 13, 4225. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.J.; Yong, H.I.; Kim, M.; Choi, Y.-S.; Jo, C. Status of meat alternatives and their potential role in the future meat market—A review. Asian-Australas. J. Anim. Sci. 1543. [Google Scholar] [CrossRef]

- Kerslake, E.; Kemper, J.A.; Conroy, D. What’s your beef with meat substitutes? Exploring barriers and facilitators for meat substitutes in omnivores, vegetarians, and vegans. Appetite 2022, 170, 105864. [Google Scholar] [PubMed]

- Ahmad, M.; Qureshi, S.; Akbar, M.H.; Siddiqui, S.A.; Gani, A.; Mushtaq, M.; Hassan, I.; Dhull, S.B. Plant-based meat alternatives: Compositional analysis, current development and challenges. Appl. Food Res. 2022, 2. [Google Scholar] [CrossRef]

- Finnveden, G.; Potting, J. Life Cycle Assessment. In Encyclopedia of Toxicology, 3rd ed.; Wexler, P., Ed.; Academic Press: Oxford, UK, 2014; pp. 74–77. [Google Scholar]

- Curran, M.A. Life Cycle Assessment: A review of the methodology and its application to sustainability. Curr. Opin. Chem. Eng. 2013, 2, 273–277. [Google Scholar] [CrossRef]

- Listrat, A.; Lebret, B.; Louveau, I.; Astruc, T.; Bonnet, M.; Lefaucheur, L.; Picard, B.; Bugeon, J. How Muscle Structure and Composition Influence Meat and Flesh Quality. Sci. World J. 2016, 2016, 3182746. [Google Scholar] [CrossRef] [PubMed]

- He, J.; Evans, N.M.; Liu, H.; Shao, S. A review of research on plant-based meat alternatives: Driving forces, history, manufacturing, and consumer attitudes. Comprehensive Reviews in Food Science and Food Safety 2020, 19, 2639–2656. [Google Scholar] [CrossRef] [PubMed]

- Kyriakopoulou, K.; Dekkers, B.; van der Goot, A.J., Chapter 6 - Plant-Based Meat Analogues. In Sustainable Meat Production and Processing, Galanakis, C.M., Ed. Elsevier: London, 2019; pp. 103-126.

- Berg, L.A.v.D.; Mes, J.J.; Mensink, M.; Wanders, A.J. Protein quality of soy and the effect of processing: A quantitative review. Front. Nutr. 2022, 9, 1004754. [Google Scholar] [CrossRef] [PubMed]

- Qin, P.; Wang, T.; Luo, Y. A review on plant-based proteins from soybean: Health benefits and soy product development. J. Agric. Food Res. 2022, 7, 100265. [Google Scholar] [CrossRef]

- Kutzli, I.; Weiss, J.; Gibis, M. Glycation of plant proteins via maillard reaction: Reaction chemistry, technofunctional properties, and potential food application. Foods 2021, 10, 376. [Google Scholar] [CrossRef] [PubMed]

- Guo, M., Chapter 7 - Soy Food Products and Their Health Benefits. In Functional Foods: Principles and Technology, Woodhead Publishing: Cambridge, UK, 2009; pp. 237-277.

- European Commission, EU-U.S. Joint Statement: The United States is Europe’s Main Soya Beans Supplier With Imports Up by 121%. In IP/19/2154, Brussels, 2019.

- van Vliet, S.; Kronberg, S.L.; Provenza, F. Plant-Based Meats, Human Health, and Climate Change. Frontiers in Sustainable Food Systems 2020, 4. [Google Scholar] [CrossRef]

- Shireen, A.; Wright, A.J. The Meat of the Matter: Plant-Based Meat Analogue versus Traditional Meat Product Nutritional Quality. Food Sci. Hum. Wellness 2024. [CrossRef]

- Tso, R.; Forde, C.G. Unintended Consequences: Nutritional Impact and Potential Pitfalls of Switching from Animal- to Plant-Based Foods. Nutrients 2021, 13, 2527. [Google Scholar] [CrossRef] [PubMed]

- Kinney, M.; Weston, Z.; Bauman, J. Overview of Plant-Based Meat Manufacturing - Plant-Based Meat Manufacturing by Extrusion; The Good Food Institute: 2019.

- Kazemzadeh, M.; Yacu, W.A. Design, and Operation for Different Food Applications. In Advances in Food Extrusion Technology, 1st ed.; Maskan, M., Altan, A., Eds.; CRC Press: Boca Raton, USA, 2012; pp. 1–68. [Google Scholar]

- Zhang, J.; Chen, Q.; Kaplan, D.L.; Wang, Q. High-moisture extruded protein fiber formation toward plant-based meat substitutes applications: Science, technology, and prospect. Trends Food Sci. Technol. 2022, 128, 202–216. [Google Scholar] [CrossRef]

- van Zuilichem, D.; Stolp, W.; Janssen, L. Engineering aspects of single- and twin-screw extrusion-cooking of biopolymers. J. Food Eng. 1983, 2, 157–175. [Google Scholar] [CrossRef]

- Saerens, W.; Smetana, S.; Van Campenhout, L.; Lammers, V.; Heinz, V. Life cycle assessment of burger patties produced with extruded meat substitutes. J. Clean. Prod. 2021, 306, 127177. [Google Scholar] [CrossRef]

- Farjana, S.H.; Parvez Mahmud, M.A.; Huda, N., Chapter 1 - Introduction to Life Cycle Assessment. In Life Cycle Assessment for Sustainable Mining, LaFleur, M., Ed. Elsevier: Amsterdam, Netherlands, 2021; pp. 1-13.

- Muralikrishna, I.V.; Manickam, V., Chapter Five - Life Cycle Assessment. In Environmental Management - Science and Engineering for Industry, McCombs, K., Ed. Butterworth-Heinemann: Oxford, UK, 2017; pp. 57-75.

- Saget, S.; Costa, M.P.; Santos, C.S.; Vasconcelos, M.; Styles, D.; Williams, M. Comparative life cycle assessment of plant and beef-based patties, including carbon opportunity costs. Sustain. Prod. Consum. 2021, 28, 936–952. [Google Scholar] [CrossRef]

- Heller, M.C.; Keoleian, G.A. Beyond Meat’s Beyond Burger Life Cycle Assessment: A detailed comparison between a plant-based and an animal-based protein source; CSS Report No. CSS18-10; University of Michigan: Ann Arbor, USA, 14 September, 2018; pp. 1-38.

- Allotey, D.K.; Kwofie, E.M.; Adewale, P.; Lam, E.; Ngadi, M. Life cycle sustainability assessment outlook of plant-based protein processing and product formulations. Sustain. Prod. Consum. 2023, 36, 108–125. [Google Scholar] [CrossRef]

- Smetana, S.; Mathys, A.; Knoch, A.; Heinz, V. Meat alternatives: Life cycle assessment of most known meat substitutes. Int. J. Life Cycle Assess. 2015, 20, 1254–1267. [Google Scholar] [CrossRef]

- Department for Business, Energy & Industrial Strategy UK becomes first major economy to pass net zero emissions law. Available online: https://www.gov.uk/government/news/uk-becomes-first-major-economy-to-pass-net-zero-emissions-law (accessed on 12 November 2023).

- Szenderák, J.; Fróna, D.; Rákos, M. Consumer Acceptance of Plant-Based Meat Substitutes: A Narrative Review. Foods 2022, 11, 1274. [Google Scholar] [CrossRef] [PubMed]

- UKRI, Innovate UK Alternative Proteins Roadmap: Identifying UK priorities; 10 June, 2022.

- De Marchi, M.; Costa, A.; Pozza, M.; Goi, A.; Manuelian, C.L. Detailed characterization of plant-based burgers. Sci. Rep. 2021, 11, 1–9. [Google Scholar] [CrossRef] [PubMed]

- PRé Sustainability B.V. SimaPro database manual - Methods library; Amersfoort, Netherlands, March, 2023; pp. 5-58.

- Blonk, H.; van Paassen, M.; Draijer, N.; Tyszler, M.; Braconi, N.; van Rijn, J. Agri-footprint 6 Methodology Report; Blonk: Gouda, Netherlands, 2023; pp. 1–13. [Google Scholar]

- Auberger, J.; Ayari, N.; Ceccaldi, M.; Cornelus, M.; Geneste, C. Agribalyse Change Report 3.0/3.1/3.1.1; ADEME: Angers, France, June, 2022; pp. 7–29. [Google Scholar]

- FitzGerald, D.; Sonderegger, T. Documentation of changes implemented in the ecoinvent database v3.9.1; ecoinvent Association: Zürich, Switzerland, 2022; pp. 4–15. [Google Scholar]

- Laboratory, N.R.E.U.S. Life Cycle Inventory Database. https://www.lcacommons.gov/lca-collaboration/National_Renewable_Energy_Laboratory/USLCI_Database_Public/datasets (5 February).

- Nemecek, T.; Bengoa, X.; Lansche, J.; Roesch, A.; Faist-Emmenegger, M.; Rossi, V.; Humbert, S. Methodological Guidelines for the Life Cycle Inventory of Agricultural Products - Version 3.5; Quantis & Agroscope: Lausanne & Zurich, Switzerland, 2019; pp. 9–72. [Google Scholar]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Samard, S.; Maung, T.-T.; Gu, B.-Y.; Kim, M.-H.; Ryu, G.-H. Influences of extrusion parameters on physicochemical properties of textured vegetable proteins and its meatless burger patty. Food Sci. Biotechnol. 2021, 30, 395–403. [Google Scholar] [CrossRef] [PubMed]

- Smetana, S.; Profeta, A.; Voigt, R.; Kircher, C.; Heinz, V. Meat substitution in burgers: Nutritional scoring, sensorial testing, and Life Cycle Assessment. Futur. Foods 2021, 4, 100042. [Google Scholar] [CrossRef]

- Tsirigotis-Maniecka, M. Alginate-, Carboxymethyl Cellulose-, and κ-Carrageenan-Based Microparticles as Storage Vehicles for Cranberry Extract. Molecules 2020, 25, 3998. [Google Scholar] [CrossRef] [PubMed]

- Domínguez-Courtney, M.F.; López-Malo, A.; Palou, E.; Jiménez-Munguía, M.T. Optimization Of Mechanical Properties Of Carboxymethyl Cellulose, Carrageenan And/Or Xanthan Gum Gels As Alternatives Of Gelatin Softgels Capsules. Journal of Multidisciplinary Engineering Science and Technology 2015, 2, 3132–3140. [Google Scholar]

- Nitcheu Ngemakwe, P.H.; Le Roes-Hill, M.; Jideani, V.A. Advances in gluten-free bread technology. Food Science and Technology International 2014, 21, 256–276. [Google Scholar] [CrossRef] [PubMed]

- Adnett, P. Commodity in Focus: Salt. Available online: https://www.export.org.uk/insights/trade-news/commodity-in-focus-salt/ (accessed on 28 February 2024).

- Government Office for Science Understanding the UK Freight Transport System; London, UK, February, 2019; pp. 11-20.

- European Commission PEFCR Guidance document - Guidance for the development of Product Environmental Footprint Category Rules (PEFCRs), version 6.3; Brussels, Belgium, May, 2018; pp. 44-139.

- SeaRates Distance & Time. Available online: https://www.searates.com/services/distances-time/ (accessed on 3 February 2024).

- Samard, S.; Gu, B.; Ryu, G.-H. Effects of extrusion types, screw speed and addition of wheat gluten on physicochemical characteristics and cooking stability of meat analogues. J. Sci. Food Agric. 2019, 99, 4922–4931. [Google Scholar] [CrossRef]

- Grommers, H.E.; van der Krogt, D.A. Modifications and Uses. In Starch, 3rd ed.; BeMiller, J., Whistler, R., Eds.; Academic Press: Oxford, UK, 2009; pp. 511–539. [Google Scholar]

- Tran, D.M.; Nguyen, T.H.; Huynh, T.U.; Do, T.O.; Nguyen, Q.-V.; Nguyen, A.D. Analysis of endophytic microbiome dataset from roots of black pepper (Piper nigrum L.) cultivated in the Central Highlands region, Vietnam using 16S rRNA gene metagenomic next-generation sequencing. Data Brief, 1081; 08. [Google Scholar] [CrossRef]

- Mogensen, L.; Hermansen, J.E.; Nguyen, L.; Preda, T. Environmental Impact of Beef by Life Cycle Assessment (LCA) - 13 Danish Beef Production Systems; DCA rapport No. 061; Danish Centre for Food and Agriculture: Aarhus, Denmark, 2015. [Google Scholar]

- SPX Corporation CIP and Sanitation of Process Plant; Charlotte, North Carolina, 5 February, 2013; pp. 4-19.

- Piecyk, M.; Allen, J.; Woodburn, A.; Cao, M. Online Grocery Shopping and Last-Mile Deliveries – Summary Report; Technical Report ENG-TR.022; Centre for Sustainable Road Freight: Cambridge, UK, 2021; pp. 1–6. [Google Scholar]

- EPD International AB Preserves and preparations of meat (including meat offal or blood) - Product Category Classification: UN CPC 2118; PCR 2016:05, Version 2.0; Stockholm, Sweden, 31 March, 2021; pp. 10-19.

- Nguyen, V.L. Spread of Phytophthora capsici in Black Pepper (Piper nigrum) in Vietnam. Engineering 2015, 07, 506–513. [Google Scholar] [CrossRef]

- Philip, M.; Attwood, J.; Hulme, A.; Williams, G.; Shipton, P. Evaluation of Weathering in Mixed Polyethylene and Polypropylene Products; PLA0007 - 008; The Waste & Resources Action Programme: Banbury, UK, 2004. [Google Scholar]

- United States Agency for International Development. Soy Protein Ingredients Commodity Fact Sheet. Available online: https://2012-2017.usaid.gov/what-we-do/agriculture-and-food-security/food-assistance/resources/soy-protein-ingredients-commodity (accessed on 29 January 2024).

- Ortolan, F.; Steel, C.J. Protein Characteristics that Affect the Quality of Vital Wheat Gluten to be Used in Baking: A Review. Compr. Rev. Food Sci. Food Saf. 2017, 16, 369–381. [Google Scholar] [CrossRef] [PubMed]

- Scott, P.; Pratt, R.C.; Hoffman, N.; Montgomery, R. Chapter 10 - Specialty Corns. In Corn, 3rd ed.; Serna-Saldivar, S.O., Ed.; Woodhead Publishing: Duxford, UK, 2019; pp. 289–303. [Google Scholar]

- Abao, L.N. Oilseeds and Products Annual - Philippines; RP2022-0021; United States Department of Agriculture: Washington, D.C., USA, 6 April, 2022; pp. 2-18.

- Slotte, S. Production process of carboxymethyl cellulose. Bachelor’s thesis, University of Oulu, Oulu, Finland, 2021.

- Cisse, L.; Mrabet, T. World Phosphate Production: Overview and Prospects. Phosphorus Res. Bull. 2004, 15, 21–25. [Google Scholar] [CrossRef] [PubMed]

- Dong, L.; Li, Y.; Wang, P.; Feng, Z.; Ding, N. Cleaner production of monosodium glutamate in China. J. Clean. Prod. 2018, 190, 452–461. [Google Scholar] [CrossRef]

- The Food and Drink Federation. Food & Drink Exporters Association H1 2023 Trade Snapshot. Available online: https://www.fdf.org.uk/globalassets/resources/publications/reports/trade-reports/trade-snapshot-h1-2023.pdf (accessed on 1 March 2024).

- Institut national de l’information géographique et forestière Après le Brexit, quel est désormais le centre géographique de l’UE? Available online: https://www.ign.fr/reperes/apres-le-brexit-quel-est-desormais-le-centre-geographique-de-lue (accessed on 24 February 2024).

- Owsianiak, M.; Laurent, A.; Bjørn, A.; Hauschild, M.Z. IMPACT 2002+, ReCiPe 2008 and ILCD’s recommended practice for characterization modelling in life cycle impact assessment: A case study-based comparison. Int. J. Life Cycle Assess. 2014, 19, 1007–1021. [Google Scholar] [CrossRef]

- Jolliet, O.; Margni, M.; Charles, R.; Humbert, S.; Payet, J.; Rebitzer, G.; Rosenbaum, R. IMPACT 2002+: A new life cycle impact assessment methodology. Int. J. Life Cycle Assess. 2003, 8, 324–330. [Google Scholar] [CrossRef]

- Shapiro, A., Monte Carlo Sampling Methods. In Handbooks in Operations Research and Management Science - Volume 10, Ruszczynski, A.; Shapiro, A., Eds. Elsevier Science: 2003; pp. 353-425.

- Ciroth, A.; Muller, S.; Weidema, B.; Lesage, P. Empirically based uncertainty factors for the pedigree matrix in ecoinvent. Int. J. Life Cycle Assess. 2013, 21, 1338–1348. [Google Scholar] [CrossRef]

- Berardy, A.; Costello, C.; Seager, T. In Life Cycle Assessment of Soy Protein Isolate, International Symposium on Sustainable Systems and Technologies, Dearborn, USA, 18-20 May 2015, Dearborn, USA.

- Chamba, M.V.M.; Hua, Y.; Murekatete, N.; Chen, Y. Effects of synthetic and natural extraction chemicals on yield, composition and protein quality of soy protein isolates extracted from full-fat and defatted flours. J. Food Sci. Technol. 2013, 52, 1016–1023. [Google Scholar] [CrossRef] [PubMed]

- Deng, Y.; Achten, W.M.; Van Acker, K.; Duflou, J.R. Life cycle assessment of wheat gluten powder and derived packaging film. Biofuels Bioprod. Biorefining 2013, 7, 429–458. [Google Scholar] [CrossRef]

- Matthews, H.S.; Hendrickson, C.T.; Matthews, D.H., Chapter 5: Data Acquisition and Management for Life Cycle Inventory Analysis. In Life Cycle Assessment: Quantitative Approaches for Decisions That Matter, Open access textbook, 2016; pp. 100-161.

- Khan, S.; Loyola, C.; Dettling, J.; Hester, J.; Moses, R. Comparative environmental LCA of the Impossible Burger with conventional ground beef burger; Impossible Foods: Lausanne, Switzerland, 27 February, 2019; pp. 12–48. [Google Scholar]

- Collett, K.; O’Callaghan, B.; Mason, M.; Godfray, C.; Hepburn, C. The climate impact of alternative proteins; Oxford Smith School of Enterprise and the Environment: Oxford, UK, May, 2021; pp. 5–22. [Google Scholar]

- Roy, P.; Nei, D.; Orikasa, T.; Xu, Q.; Okadome, H.; Nakamura, N.; Shiina, T. A review of life cycle assessment (LCA) on some food products. J. Food Eng. 2009, 90, 1–10. [Google Scholar] [CrossRef]

- Hristov, A.N.; Hanigan, M.; Cole, A.; Todd, R.; McAllister, T.A.; Ndegwa, P.M.; Rotz, A.; Jayasundara, S.; Appuhamy, J.R.N.; Kebreab, E.; et al. Review: Ammonia emissions from dairy farms and beef feedlots. Can. J. Anim. Sci. 2011, 91, 1–35. [Google Scholar] [CrossRef]

- Johnson, K.A.; Johnson, D.E. Methane emissions from cattle. J. Anim. Sci. 1995, 73, 2483–2492. [Google Scholar] [CrossRef] [PubMed]

- Broom, D.M. Land and Water Usage in Beef Production Systems. Animals 2019, 9, 286. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Li, Q.; Liu, G.; Xie, R.; Zou, Y.; Scipioni, A.; Manzardo, A. Evaluating the impact of refrigerated transport trucks in China on climate change from the life cycle perspective. Environ. Impact Assess. Rev. 2022, 97. [Google Scholar] [CrossRef]

- Yang, Z.; Tate, J.E.; Morganti, E.; Shepherd, S.P. Real-world CO2 and NOX emissions from refrigerated vans. Sci. Total. Environ. 2020, 763, 142974. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Cui, S.; Zhang, Q.; Xu, G.; Feng, Q.; Chen, C.; Li, Y. Optimizing Wheat Yield, Water, and Nitrogen Use Efficiency with Water and Nitrogen Inputs in China: A Synthesis and Life Cycle Assessment. Front. Plant Sci. 2022, 13, 930484. [Google Scholar] [CrossRef] [PubMed]

- Willaarts, B.; Flachsbarth, I.; Garrido, A. In Land and water requirements for soybean cultivation in Brazil: Environmental consequences of food production and trade, XIVth IWRA World Water Congress, Porto de Galinhas, Brazil, 25-29 September 2011, Porto de Galinhas, Brazil.

- Putman, B.; Rotz, C.A.; Thoma, G. A comprehensive environmental assessment of beef production and consumption in the United States. J. Clean. Prod. 2023, 402. [Google Scholar] [CrossRef]

- Thangavel, P.; Park, D.; Lee, Y.-C. Recent Insights into Particulate Matter (PM25)-Mediated Toxicity in Humans: An Overview. International Journal of Environmental Research and Public Health 2022, 19, 7511. [Google Scholar] [CrossRef]

- California Air Resources Board Fact Sheet for 2022 Amendments to the Airborne Toxic Control Measure for In-Use Diesel-Fueled Transport Refrigeration Units (TRU) and TRU Generator Sets, and Facilities Where TRUs Operate. Available online: https://ww2.arb.ca.gov/sites/default/files/2022-03/TRU%20ATCM%202022%20Amendments%20Fact%20Sheet_0.pdf (accessed on 6 March 2024).

- Department for Environment, Food & Rural Affairs, Family food dataset: UK - household purchases. Available online: https://assets.publishing.service.gov.uk/media/653a696280884d000df71b93/UKHHcons-14Sept2023i.ods (accessed on 6 March 2024).

- Office for National Statistics (ONS) Population estimates for the UK, England, Wales, Scotland and Northern Ireland: Mid-2021. Available online: https://www.ons.gov.uk/peoplepopulationandcommunity/populationandmigration/populationestimates/bulletins/annualmidyearpopulationestimates/mid2021 (accessed on 7 March 2024).

- Department for Energy Security and Net Zero 2022 UK greenhouse gas emissions: Final figures - statistical summary. Available online: https://assets.publishing.service.gov.uk/media/65c0cf2e70428200137521cd/2022-final-emissions-statistics-one-page-summary.pdf (accessed on 7 March 2024).

- Department for Energy Security & Net Zero Net Zero Government Initiative - UK Roadmap to Net Zero Government Emissions; London, UK, December, 2023; pp. 4-20.

- Pardoe, L. Raising the steaks: Developing a market for alternative protein in the UK. Social Market Foundation: London, UK, 6 September, 2021.

- du Plessis, M.J.; van Eeden, J.; Goedhals-Gerber, L.; Else, J. Calculating Fuel Usage and Emissions for Refrigerated Road Transport Using Real-World Data. Transportation Research Part D: Transport and Environment 2023, 117, 103623. [Google Scholar] [CrossRef]

- Almena, A.; Fryer, P.; Bakalis, S.; Lopez-Quiroga, E. Centralized and distributed food manufacture: A modeling platform for technological, environmental and economic assessment at different production scales. Sustain. Prod. Consum. 2019, 19, 181–193. [Google Scholar] [CrossRef]

- Coleman, K.; Whitmore, A.P.; Hassall, K.L.; Shield, I.; Semenov, M.A.; Dobermann, A.; Bourhis, Y.; Eskandary, A.; Milne, A.E. The potential for soybean to diversify the production of plant-based protein in the UK. Sci. Total. Environ. 2021, 767, 144903. [Google Scholar] [CrossRef] [PubMed]

- Benton, T.G.; Froggatt, A.; Wright, G.; Thompson, C.E.; King, R. Food Politics and Policies in Post-Brexit Britain; Energy, Environment and Resources Department and the Europe Programme, Chatham House: London, UK, January, 2019. [Google Scholar]

- Kyriakopoulou, K.; Keppler, J.K.; van der Goot, A.J. Functionality of Ingredients and Additives in Plant-Based Meat Analogues. Foods 2021, 10, 600. [Google Scholar] [CrossRef] [PubMed]

- Mendoza Beltran, A.; Prado, V.; Font Vivanco, D.; Henriksson, P.J.G.; Guinée, J.B.; Heijungs, R. Quantified Uncertainties in Comparative Life Cycle Assessment: What Can Be Concluded? Environmental Science & Technology 2018, 52, (4), 2152–2161. [Google Scholar]

- Quinn, G.P.; Keough, M.J. 9.1 - Nested (Hierarchical) Designs. In Experimental Design and Data Analysis for Biologists, Cambridge University Press: Cambridge, UK, 2002; pp. 208-220.

- Pushkar, S.; Yezioro, A. Life Cycle Assessment Meeting Energy Standard Performance: An Office Building Case Study. Buildings 2022, 12, 157. [Google Scholar] [CrossRef]

- Verbitsky, O.; Pushkar, S. ECO-INDICATOR 99, ReCiPe AND ANOVA FOR EVALUATING BUILDING TECHNOLOGIES UNDER LCA UNCERTAINTIES. Environ. Eng. Manag. J. 2018, 17, 2549–2559. [Google Scholar] [CrossRef]

- Infanger, D.; Schmidt-Trucksäss, A. P value functions: An underused method to present research results and to promote quantitative reasoning. Stat. Med. 2019, 38, 4189–4197. [Google Scholar] [CrossRef] [PubMed]

- Reed, G.F.; Lynn, F.; Meade, B.D. Use of Coefficient of Variation in Assessing Variability of Quantitative Assays. Clin. Vaccine Immunol. 2002, 9, 1235–1239. [Google Scholar] [CrossRef] [PubMed]

- Zeeb, C.N.; Burns, P.J. A Comparison of Failure Probability Estimates by Monte Carlo Sampling and Latin Hypercube Sampling; Colorado State University: Fort Collins, USA, January, 1998; pp. 1–30. [Google Scholar]

Figure 1.

Scheme of the LCA system boundary on a meat analogue and beef burger patty.

Figure 1.

Scheme of the LCA system boundary on a meat analogue and beef burger patty.

Figure 2.

Relative environment impact of beef burger and meat analogue patties.

Figure 2.

Relative environment impact of beef burger and meat analogue patties.

Figure 3.

Single score comparison of the beef burger and meat analogue patties.

Figure 3.

Single score comparison of the beef burger and meat analogue patties.

Figure 4.

Relative percentage distribution of impacts across life cycle stages for the beef burger patty.

Figure 4.

Relative percentage distribution of impacts across life cycle stages for the beef burger patty.

Figure 5.

Relative percentage distribution of impacts across life cycle stages for the meat analogue patty.

Figure 5.

Relative percentage distribution of impacts across life cycle stages for the meat analogue patty.

Figure 6.

Single score comparison of the meat analogue patty and selected scenarios.

Figure 6.

Single score comparison of the meat analogue patty and selected scenarios.

Figure 7.

Relative environment impact of the meat analogue patty and selected scenarios.

Figure 7.

Relative environment impact of the meat analogue patty and selected scenarios.

Figure 8.

Single score comparison of the beef burger and meat analogue patties, utilising the IMPACT 2002+ characterisation method.

Figure 8.

Single score comparison of the beef burger and meat analogue patties, utilising the IMPACT 2002+ characterisation method.

Figure 9.

Relative environment impact of beef burger and meat analogue patties, utilising the IMPACT 2002+ characterisation method.

Figure 9.

Relative environment impact of beef burger and meat analogue patties, utilising the IMPACT 2002+ characterisation method.

Figure 10.

95% confidence intervals in environmental impacts for the beef burger patty.

Figure 10.

95% confidence intervals in environmental impacts for the beef burger patty.

Figure 11.

95% confidence intervals in environmental impacts for the meat analogue patty.

Figure 11.

95% confidence intervals in environmental impacts for the meat analogue patty.

Figure 12.

Percentage certainty of statistical differences in individual impacts between beef burger and meat analogue patties.

Figure 12.

Percentage certainty of statistical differences in individual impacts between beef burger and meat analogue patties.

Table 1.

Recipes for the 100 g meat analogue and beef burger patties.

Table 1.

Recipes for the 100 g meat analogue and beef burger patties.

| Patty |

Ingredient |

Mass (g) |

| Meat Analogue (MA) |

Soy protein isolate (SPI) |

36.8 |

| Vital wheat gluten (WG) |

29.4 |

| Cornstarch (CS) |

7.4 |

| Water |

9.0 |

| Coconut oil |

12.5 |

| Carboxymethyl cellulose (CMC) |

3.0 |

| Sodium phosphate |

0.5 |

| Salt |

0.1 |

| Monosodium glutamate (MSG) |

0.5 |

| Black pepper |

0.4 |

| Beef Burger (BB) |

Beef meat (20% fat) |

90.5 |

| Potato starch |

4.0 |

| Salt |

1.0 |

| Black pepper |

0.5 |

| Water |

4.0 |

Table 2.

Inventory of a 100 g beef burger patty, with cradle-to-fork system boundaries.

Table 2.

Inventory of a 100 g beef burger patty, with cradle-to-fork system boundaries.

| Stage |

Input/Output/Process |

Units |

Input |

Output |

Source of Origin |

Source of Process / Information |

| Beef Production (Feed Cultivation) |

Fertiliser (N) |

kg |

0.032 |

|

UK |

WFLDB [46] |

| Fertiliser (P2O5) |

kg |

0.022 |

|

| Fertiliser (K2O) |

kg |

0.025 |

|

| Beef Production (Cattle Rearing) |

Feed for cattle |

kg |

0.65 |

|

UK |

WFLDB [46] |

| Grazed grass |

kg |

2.24 |

|

| Manure |

|

|

0.805 |

| Beef Production (Slaughtering) |

Beef cattle live weight, mixed system |

kg |

0.183 |

|

UK |

WFLDB [46] |

| Slaughtering waste, beef cattle |

kg |

|

0.092 |

| Beef, fresh meat at slaughterhouse |

kg |

0.091 |

|

| Other BB Ingredients |

Potato starch |

kg |

0.004 |

|

Netherlands [58] |

Agri-footprint [42] |

| Potato starch lorry transport |

kg*km |

3.6 |

|

European Commission [55] |

| Salt |

kg |

0.001 |

|

UK [53] |

Ecoinvent [44] |

| Salt lorry transport |

kg*km |

0.1 |

|

Assumption [54] |

| Black pepper (BP) |

kg |

0.0005 |

|

Vietnam [64] |

AGRIBALYSE [43] |

| BP container ship transport |

kg*km |

8.25 |

|

SeaRates [56] |

| BP lorry transport |

kg*km |

0.5 |

|

European Commission [55] |

| Tap water |

kg |

0.004 |

|

UK |

Ecoinvent [44] |

| Burger Processing |

Electricity for grinding/mixing |

kWh |

0.0022 |

|

|

Saerens et al. [30] |

| Losses from equipment cleaning |

kg |

|

0.5 |

|

Assumption [61] |

| Packaging |

Thermoformed polypropylene tray |

kg |

0.0235 |

|

UK [65] |

USLCI [45] |

| Polyethylene lid film |

kg |

0.0017 |

|

USLCI [45] |

| Lorry transport |

kg*km |

2.518 |

|

European Commission [55] |

| Distribution |

Burger transport, lorry with refrigeration machine |

kg*km |

12.5 |

|

|

EPD International AB [63] |

| Burger transport, passenger car |

km |

4.35 |

|

|

Piecyk et al. [62] |

| Storage |

Energy for cooling |

kWh |

0.034 |

|

|

EPD International AB [63] |

| Cooking |

Energy for cooking gas |

kWh |

0.69 |

|

|

European Commission [55] |

| Energy for cooking electricity |

kWh |

0.23 |

|

|

EPD International AB [63] |

| Cooked burger patty |

Item |

|

1 |

|

|

Table 3.

Inventory of a 100 g meat analogue patty, with cradle-to-fork system boundaries.

Table 3.

Inventory of a 100 g meat analogue patty, with cradle-to-fork system boundaries.

| Stage |

Input/Output/Process |

Units |

Input |

Output |

Source of Origin |

Source of Process / Information |

| TVP Protein Production |

Soy protein isolate (SPI) |

kg |

0.0398 |

|

USA [66] |

Agri-footprint [42] |

| SPI container ship transport |

kg*km |

338.1 |

|

SeaRates [56] |

| SPI lorry transport |

kg*km |

39.8 |

|

European Commission [55] |

| Vital wheat gluten (WG) |

kg |

0.0318 |

|

China [67] |

Agri-footprint [42] |

| WG container ship transport |

kg*km |

572.8 |

|

SeaRates [56] |

| WG lorry transport |

kg*km |

31.8 |

|

European Commission [55] |

| Cornstarch (CS) |

kg |

0.008 |

|

USA [68] |

Agri-footprint [42] |

| CS container ship transport |

kg*km |

67.6 |

|

SeaRates [56] |

| CS lorry transport |

kg*km |

8.0 |

|

European Commission [55] |

| Water influent |

kg |

0.0199 |

|

|

Saerens et al., Samard et al. [30,48] |

| Cooling water for extrusion |

kg |

1.4396 |

1.4396 |

|

Saerens et al. [30] |

| Electricity for extrusion |

kWh |

0.023 |

|

|

Saerens et al. [30] |

| Water vapour |

kg |

|

0.0098 |

|

Saerens et al. [30] |

| Combined waste from TVP production |

kg |

|

0.0063 |

|

Saerens et al. [30] |

| Other MA Ingredients |

Coconut oil (CO) |

kg |

0.0126 |

|

Philippines [69] |

Agri-footprint [42] |

| CO ship tanker transport |

kg*km |

220.5 |

|

SeaRates [56] |

| CO lorry transport |

kg*km |

12.6 |

|

European Commission [55] |

| Carboxymethylcellulose (CMC) |

kg |

0.003 |

|

Finland [70] |

Ecoinvent [44] |

| CMC container ship transport |

kg*km |

6 |

|

SeaRates [56] |

| CMC lorry transport |

kg*km |

1.2 |

|

European Commission [55] |

| Sodium phosphate (SP) |

kg |

0.0005 |

|

USA [71] |

Ecoinvent [44] |

| SP container ship transport |

kg*km |

4.3 |

|

SeaRates [56] |

| SP lorry transport |

kg*km |

0.5 |

|

European Commission [55] |

| Salt |

kg |

0.0001 |

|

UK [53] |

Ecoinvent [44] |

| Salt lorry transport |

kg*km |

0.01 |

|

Assumption [54] |

| Monosodium glutamate (MSG) |

kg |

0.0005 |

|

China [72] |

WFLDB [46] |

| MSG container ship transport |

kg*km |

9 |

|

SeaRates [56] |

| MSG lorry transport |

kg*km |

0.5 |

|

European Commission [55] |

| Black pepper (BP) |

kg |

0.0004 |

|

Vietnam[64] |

AGRIBALYSE [43] |

| BP container ship transport |

kg*km |

6.6 |

|

SeaRates [56] |

| BP lorry transport |

kg*km |

0.4 |

|

European Commission [55] |

| Burger Processing |

Electricity for grinding/mixing |

kWh |

0.0022 |

|

|

Saerens et al. [30] |

| Losses from equipment cleaning |

kg |

|

0.5 |

|

Assumption [61] |

| Packaging |

Thermoformed polypropylene tray |

kg |

0.0235 |

|

UK [65] |

USLCI [45] |

| Polyethylene lid film |

kg |

0.0017 |

|

USLCI [45] |

| Lorry transport |

kg*km |

2.518 |

|

European Commission [55] |

| Distribution |

Burger transport, lorry with refrigeration machine |

kg*km |

12.5 |

|

|

EPD International AB [63] |

| Burger transport, passenger car |

km |

4.35 |

|

|

Piecyk et al. [62] |

| Storage |

Energy for cooling |

kWh |

0.034 |

|

|

EPD International AB [63] |

| Cooking |

Energy for cooking gas |

kWh |

0.69 |

|

|

European Commission [55] |

| Energy for cooking electricity |

kWh |

0.23 |

|

|

EPD International AB [63] |

| Cooked burger patty |

Item |

|

1 |

|

|

Table 4.

Summary of environmental burdens for the 100 g beef burger and meat analogue patties.

Table 4.

Summary of environmental burdens for the 100 g beef burger and meat analogue patties.

| Impact category |

Unit |

Beef Burger (BB) |

Meat Analogue (MA) |

| Global warming |

kg CO2 eq |

6.67 |

2.33 |

| Stratospheric ozone depletion |

kg CFC11 eq |

3.19×10-5 |

2.30×10-6

|

| Ionizing radiation |

kBq Co-60 eq |

0.17 |

0.099 |

| Ozone formation, Human health |

kg NOx eq |

0.015 |

0.006 |

| Fine particulate matter formation |

kg PM2.5 eq |

0.0059 |

0.0025 |

| Ozone formation, Terrestrial ecosystems |

kg NOx eq |

0.015 |

0.0057 |

| Terrestrial acidification |

kg SO2 eq |

0.024 |

0.0055 |

| Freshwater eutrophication |

kg P eq |

0.0009 |

0.0004 |

| Marine eutrophication |

kg N eq |

0.003 |

0.0003 |

| Terrestrial ecotoxicity |

kg 1,4-DCB |

9.35 |

10.24 |

| Freshwater ecotoxicity |

kg 1,4-DCB |

0.15 |

0.19 |

| Marine ecotoxicity |

kg 1,4-DCB |

0.18 |

0.20 |

| Human carcinogenic toxicity |

kg 1,4-DCB |

0.14 |

0.15 |

| Human non-carcinogenic toxicity |

kg 1,4-DCB |

1.58 |

1.85 |

| Land use |

m2a crop eq |

4.02 |

0.71 |

| Mineral resource scarcity |

kg Cu eq |

0.04 |

0.01 |

| Fossil resource scarcity |

kg oil eq |

0.81 |

0.68 |

| Water consumption |

m3

|

0.05 |

0.03 |

Table 5.

Single scores for the meat analogue patty using various ReCiPe v1.08 weighting sets.

Table 5.

Single scores for the meat analogue patty using various ReCiPe v1.08 weighting sets.

| Scenario |

i/i |

h/h |

e/e |

i/a |

h/a |

e/a |

Mean |

| Original |

50.1 |

65.7 |

452.7 |

39.1 |

84.4 |

587.4 |

213.2 |

| EU Export |

51.1 |

67.4 |

462.3 |

39.9 |

85.5 |

600.0 |

217.7 |

| Homegrown |

49.6 |

64.7 |

449.5 |

38.7 |

83.1 |

583.4 |

211.5 |

| Concentrate |

48.6 |

63.7 |

443.5 |

37.8 |

81.9 |

575.7 |

208.5 |

Table 6.

P-values for ANOVA tests on single scores of the meat analogue patty utilising various ReCiPe v1.08 weighting sets.

Table 6.

P-values for ANOVA tests on single scores of the meat analogue patty utilising various ReCiPe v1.08 weighting sets.

| Scenario |

Original |

EU Export |

Homegrown |

Concentrate |

| Original |

X |

0.975 |

0.990 |

0.974 |

| EU Export |

|

X |

0.966 |

0.949 |

| Homegrown |

|

|

X |

0.983 |

| Concentrate |

|

|

|

X |

Table 7.

Uncertainty analysis results for beef burger and meat analogue patties via 1000-run Monte Carlo simulations. The coefficient of variation (CV) is the ratio of the standard deviation (SD) to the mean.

Table 7.

Uncertainty analysis results for beef burger and meat analogue patties via 1000-run Monte Carlo simulations. The coefficient of variation (CV) is the ratio of the standard deviation (SD) to the mean.

| Impact category |

Unit |

Beef Burger |

Meat Analogue |

| Mean |

SD |

CV |

Mean |

SD |

CV |

| Global warming |

kg CO2 eq |

6.7 |

0.74 |

11% |

2.3 |

0.27 |

15% |

| Stratospheric ozone depletion |

kg CFC11 eq |

0.00003 |

0.000003 |

10% |

2×10-6

|

2×10-7

|

9% |

| Ionizing radiation |

kBq Co-60 eq |

0.17 |

0.07 |

17% |

0.1 |

0.01 |

10% |

| Ozone formation, Human health |

kg NOx eq |

0.02 |

0.002 |

12% |

0.006 |

0.0005 |

15% |

| Fine particulate matter formation |

kg PM2.5 eq |

0.006 |

0.001 |

12% |

0.003 |

0.0003 |

14% |

| Ozone formation, Terrestrial ecosystems |

kg NOx eq |

0.02 |

0.002 |

12% |

0.006 |

0.0004 |

11% |

| Terrestrial acidification |

kg SO2 eq |