Submitted:

21 April 2024

Posted:

22 April 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Results & Discussion

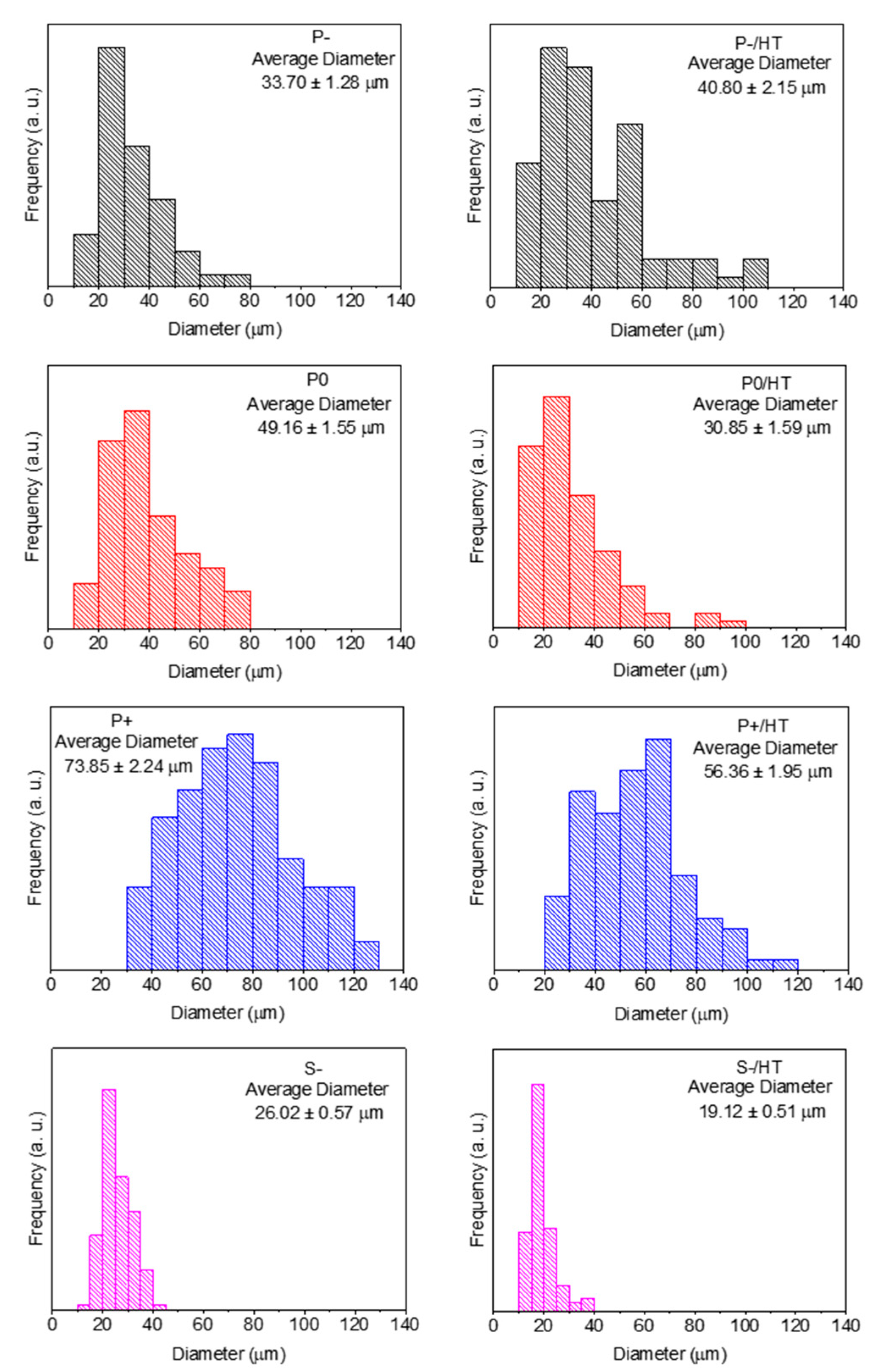

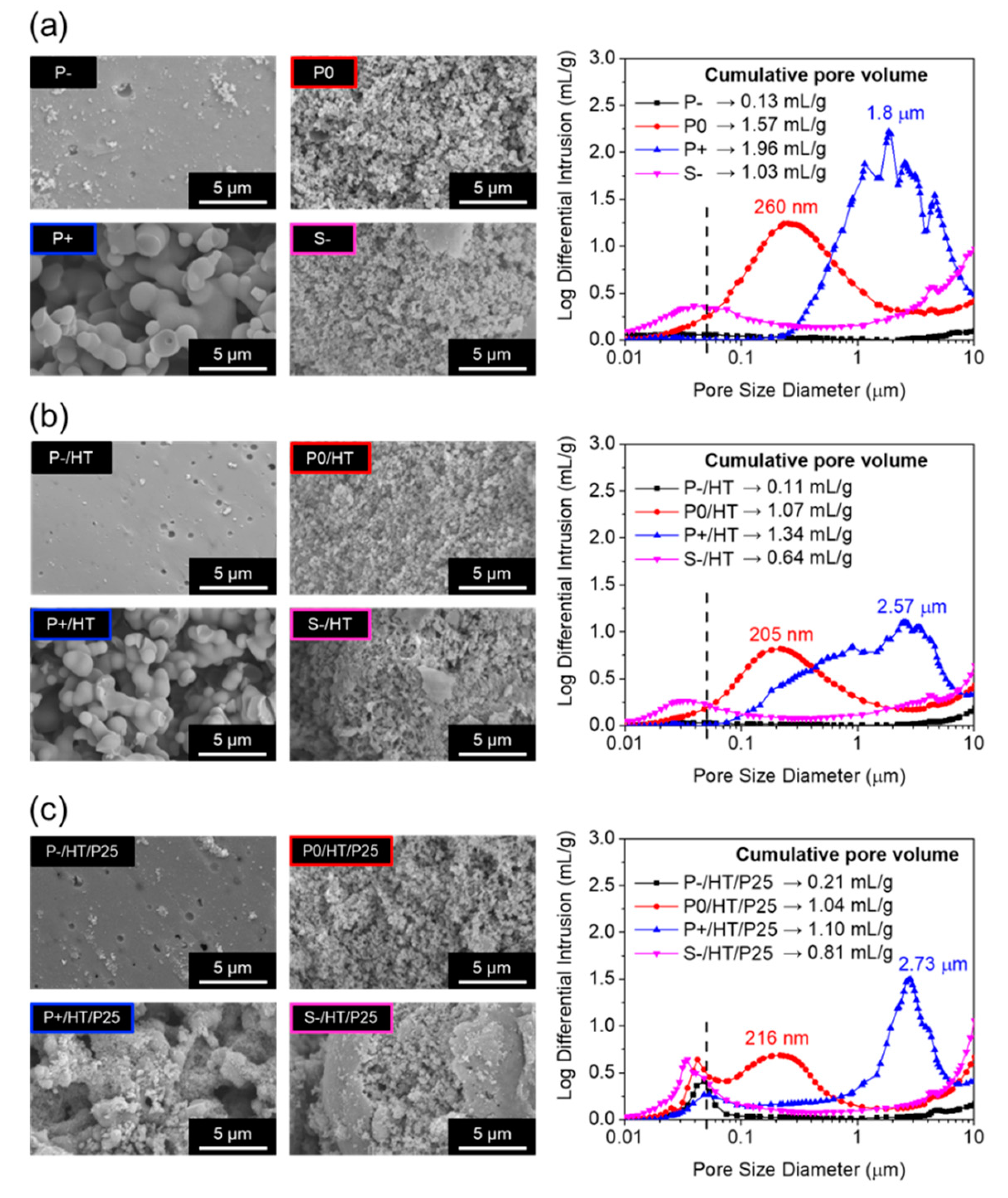

2.1. Characterization of the MICROSCAFS® before and after Heat Treatment and Photocatalyst (P25 TiO2 NPs) Loading

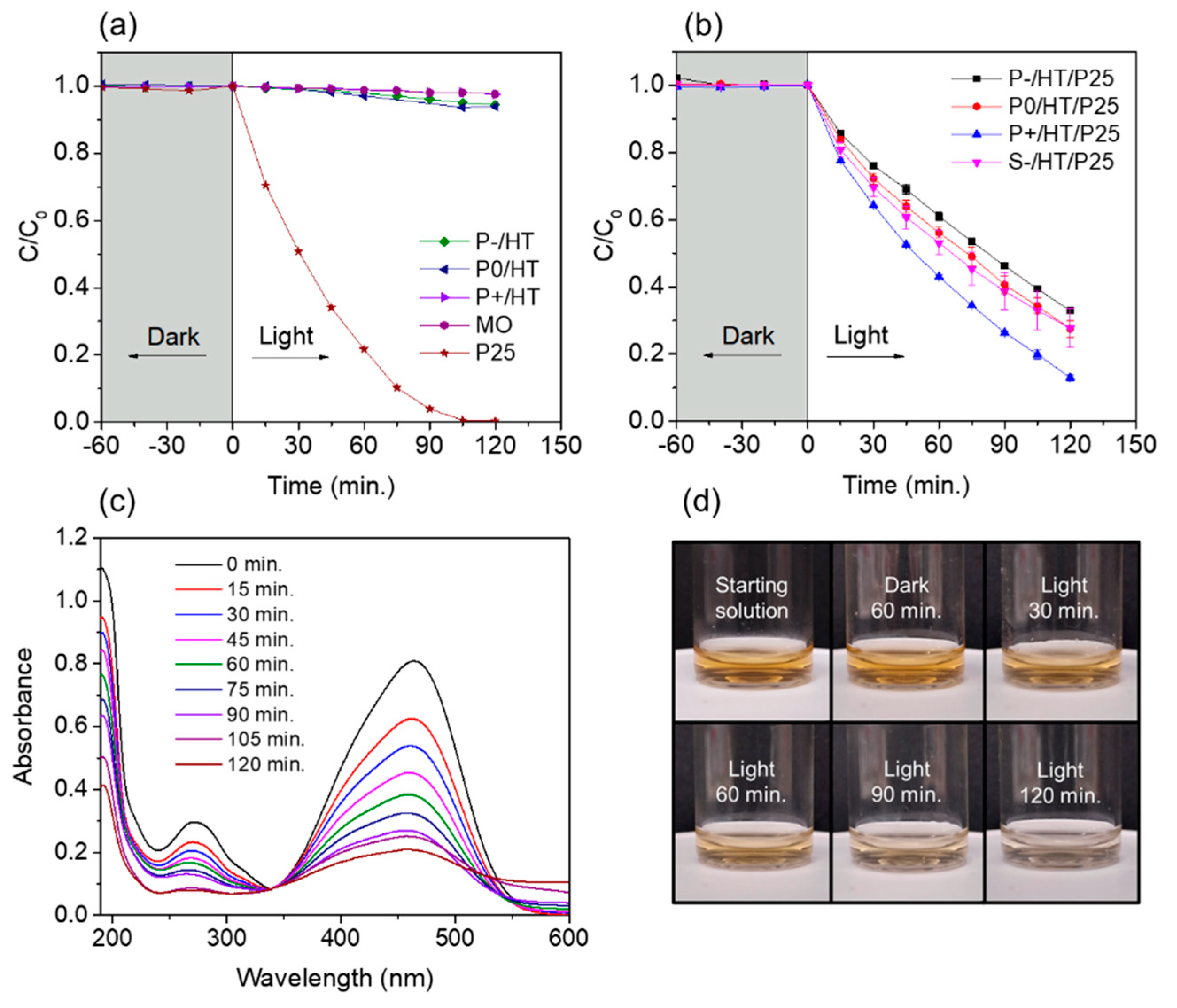

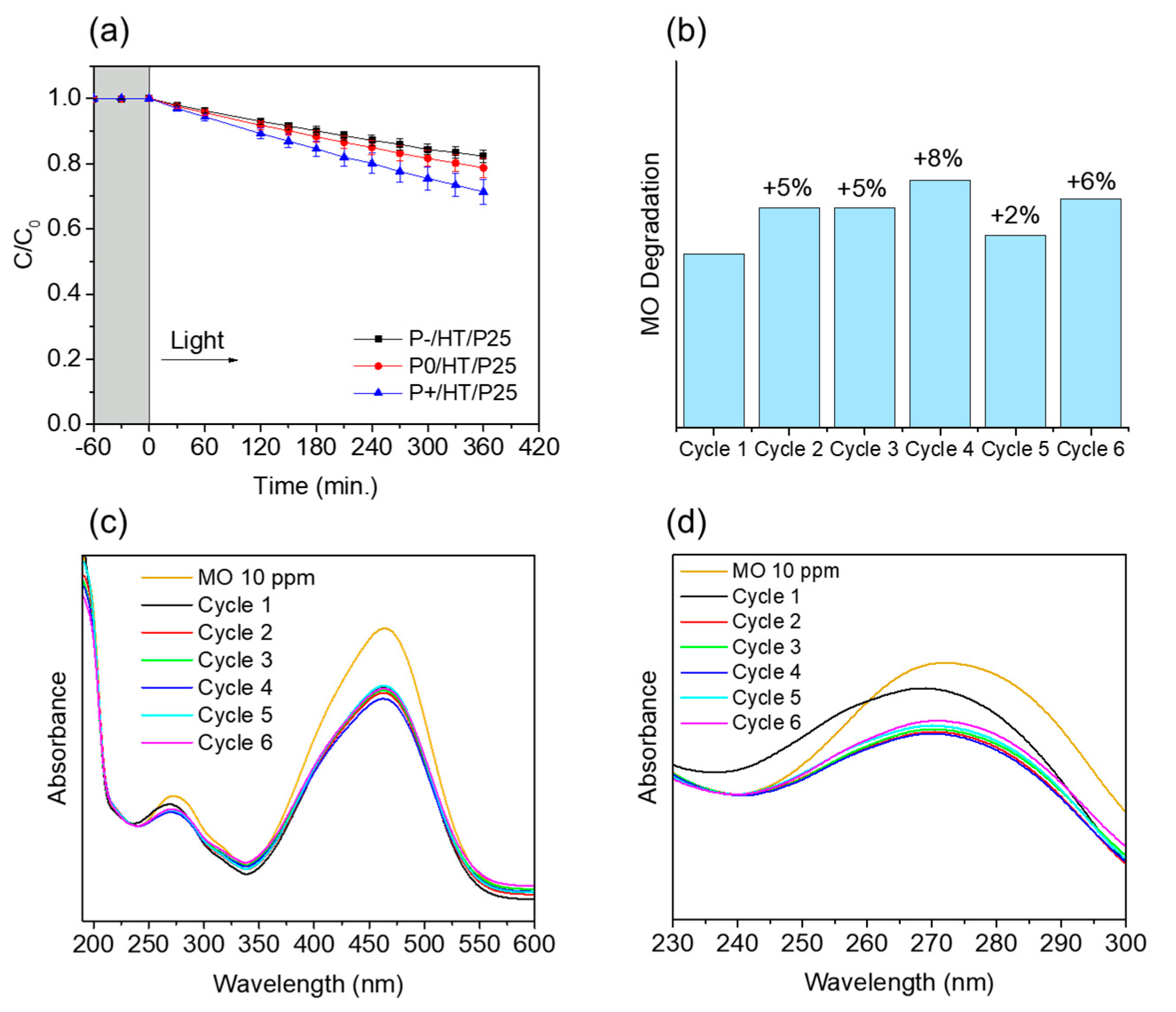

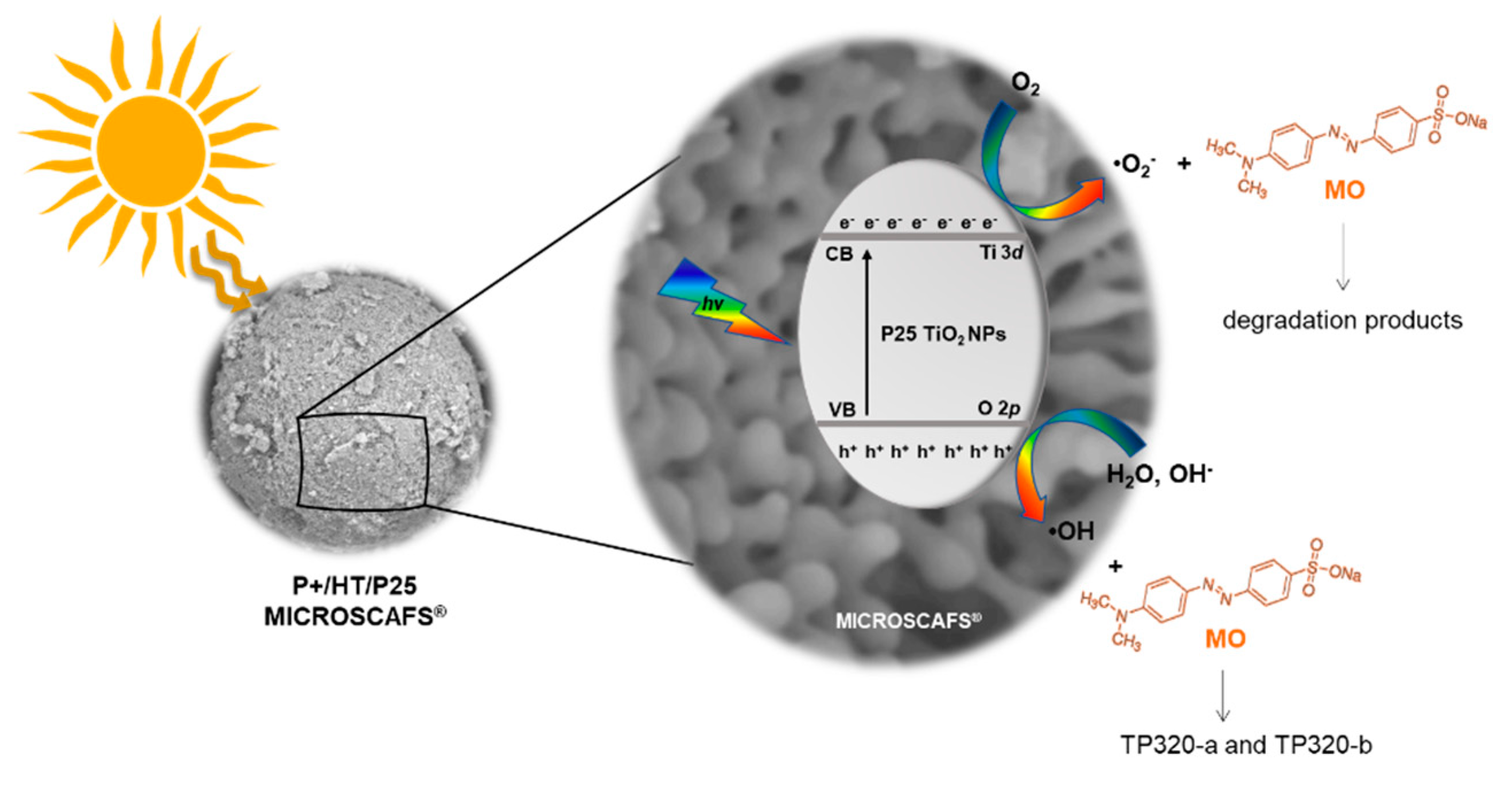

2.2. Photocatalytic Studies on the P25 TiO2 NPs Loaded MICROSCAFS®

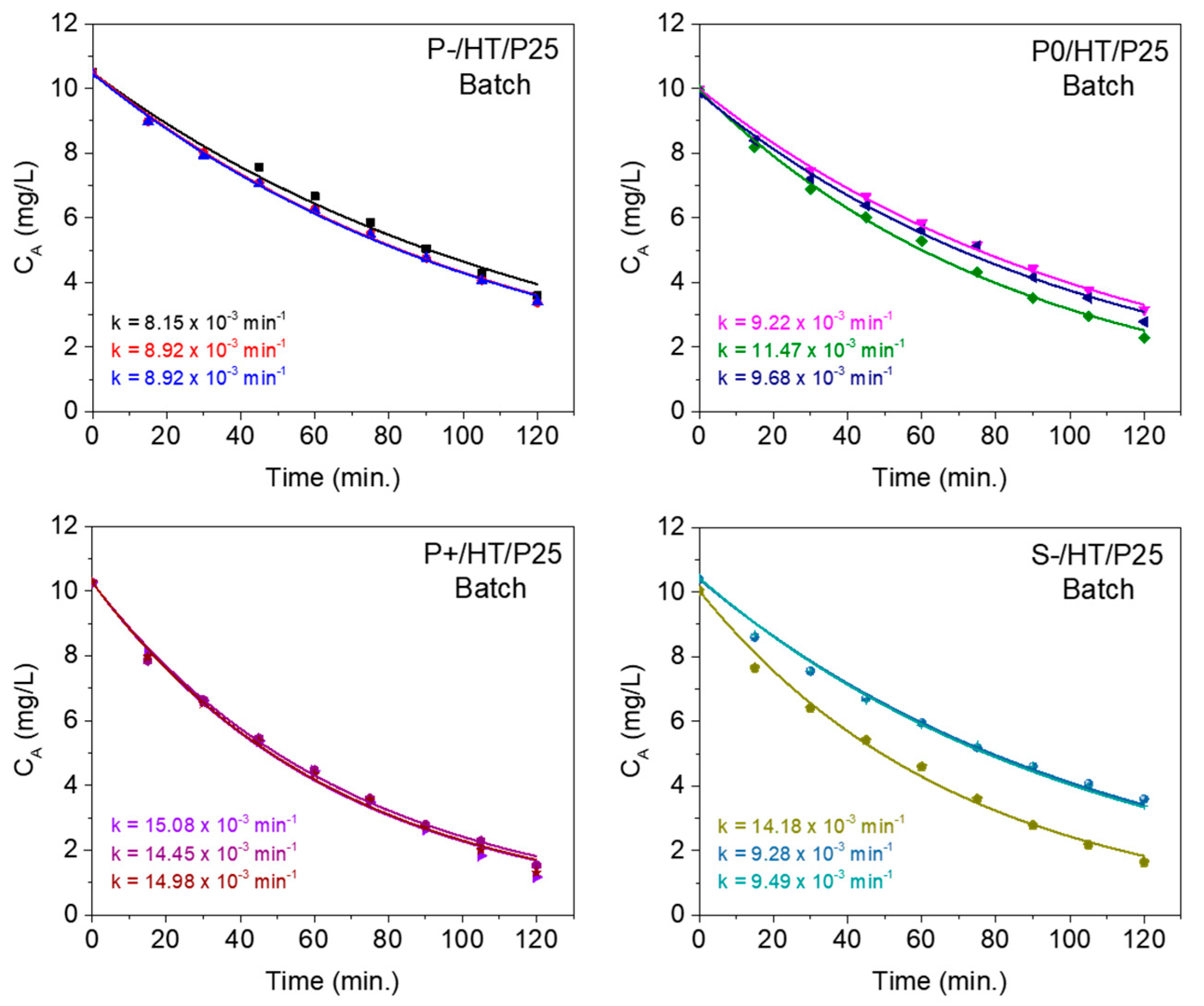

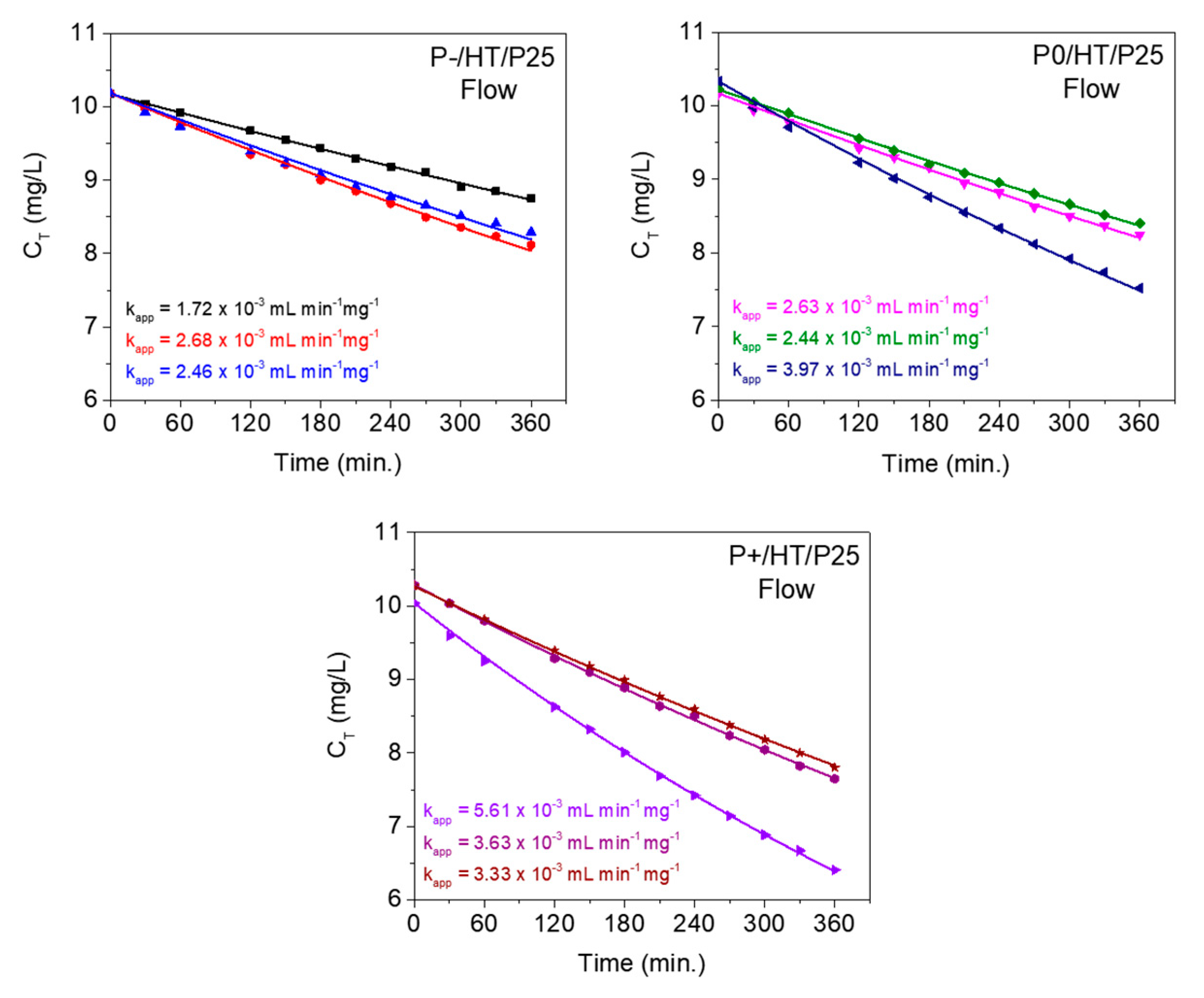

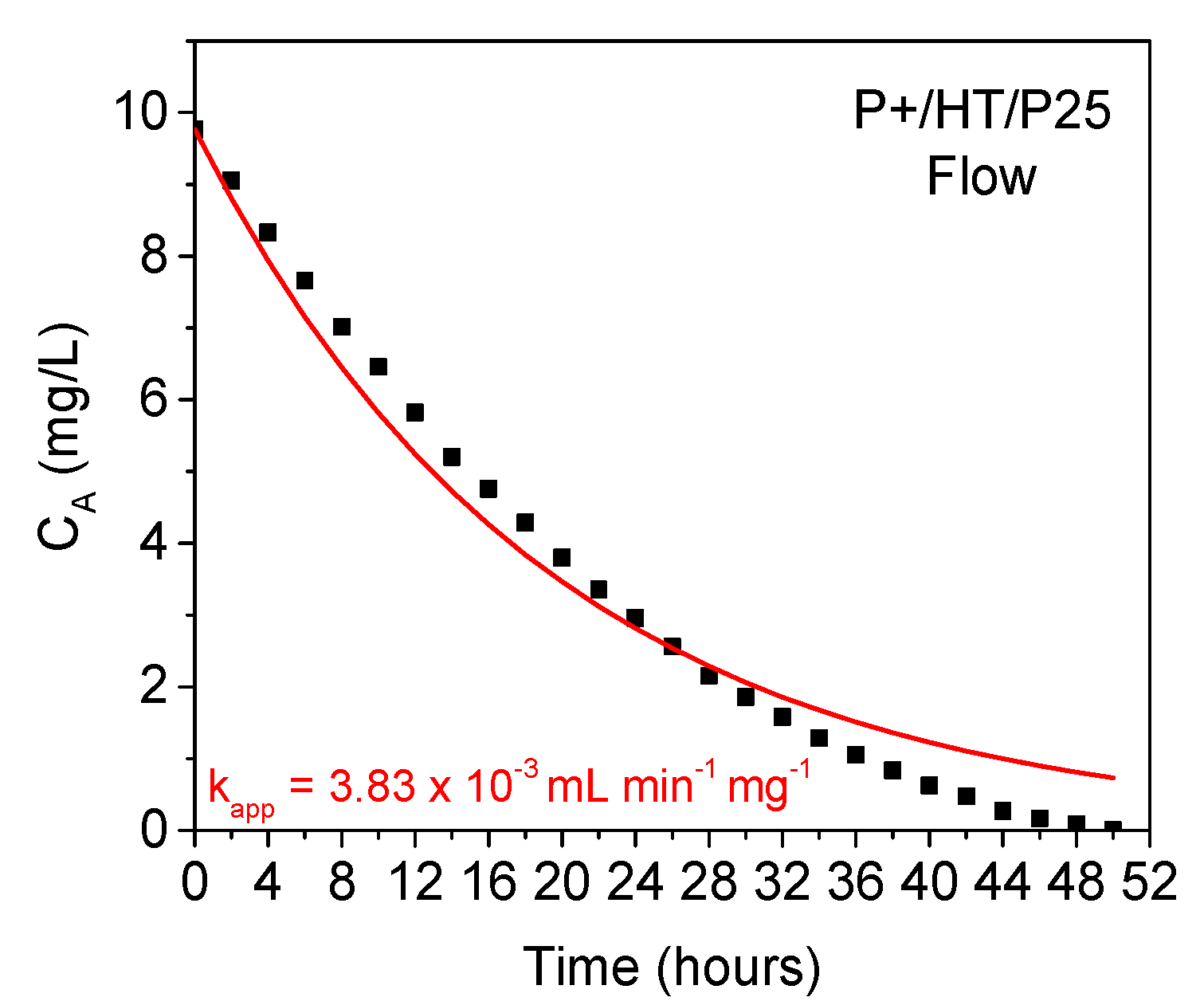

2.3. Kinetics Studies

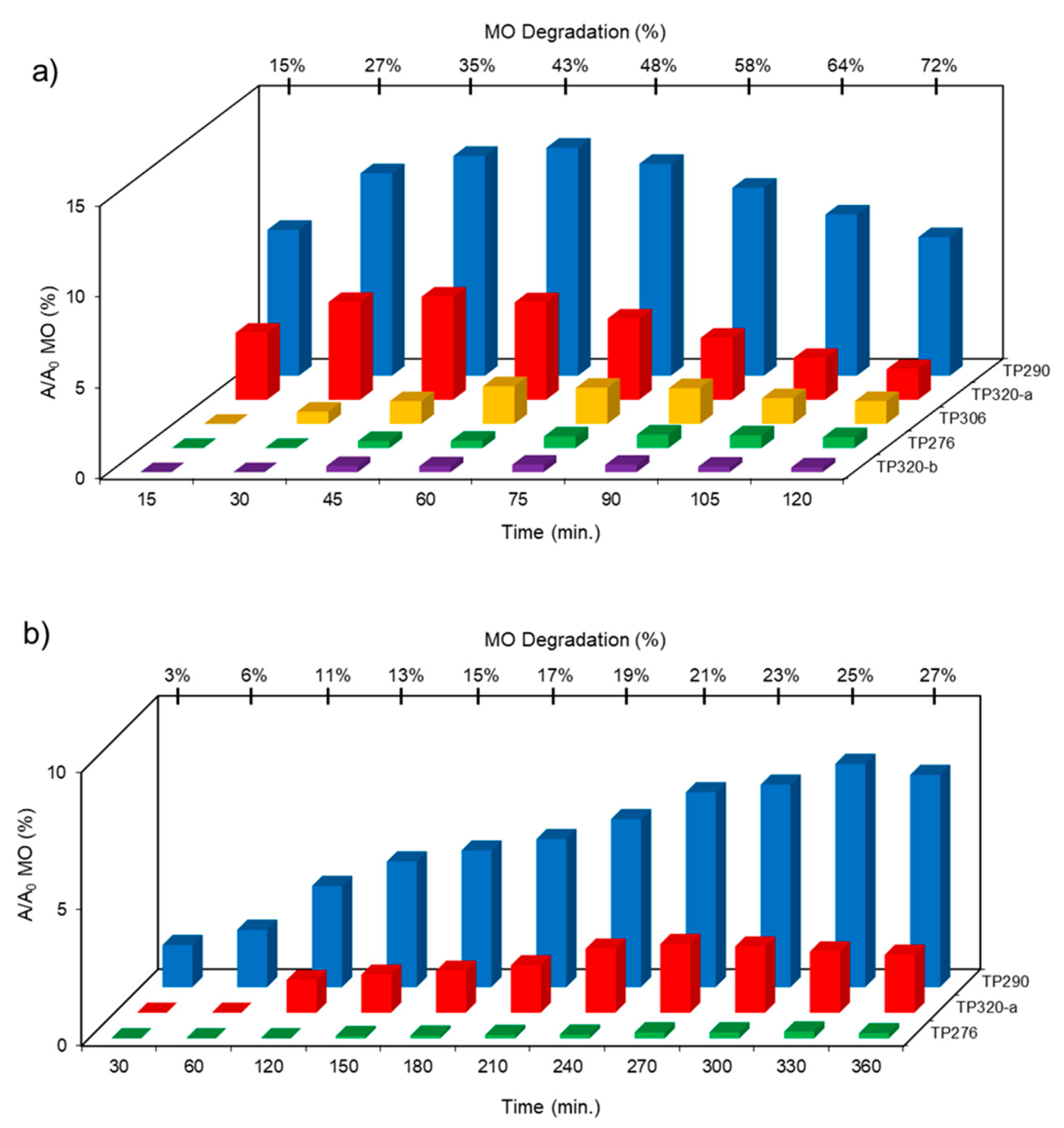

2.4. Study of the By-Products from Photocatalytic MO Degradation

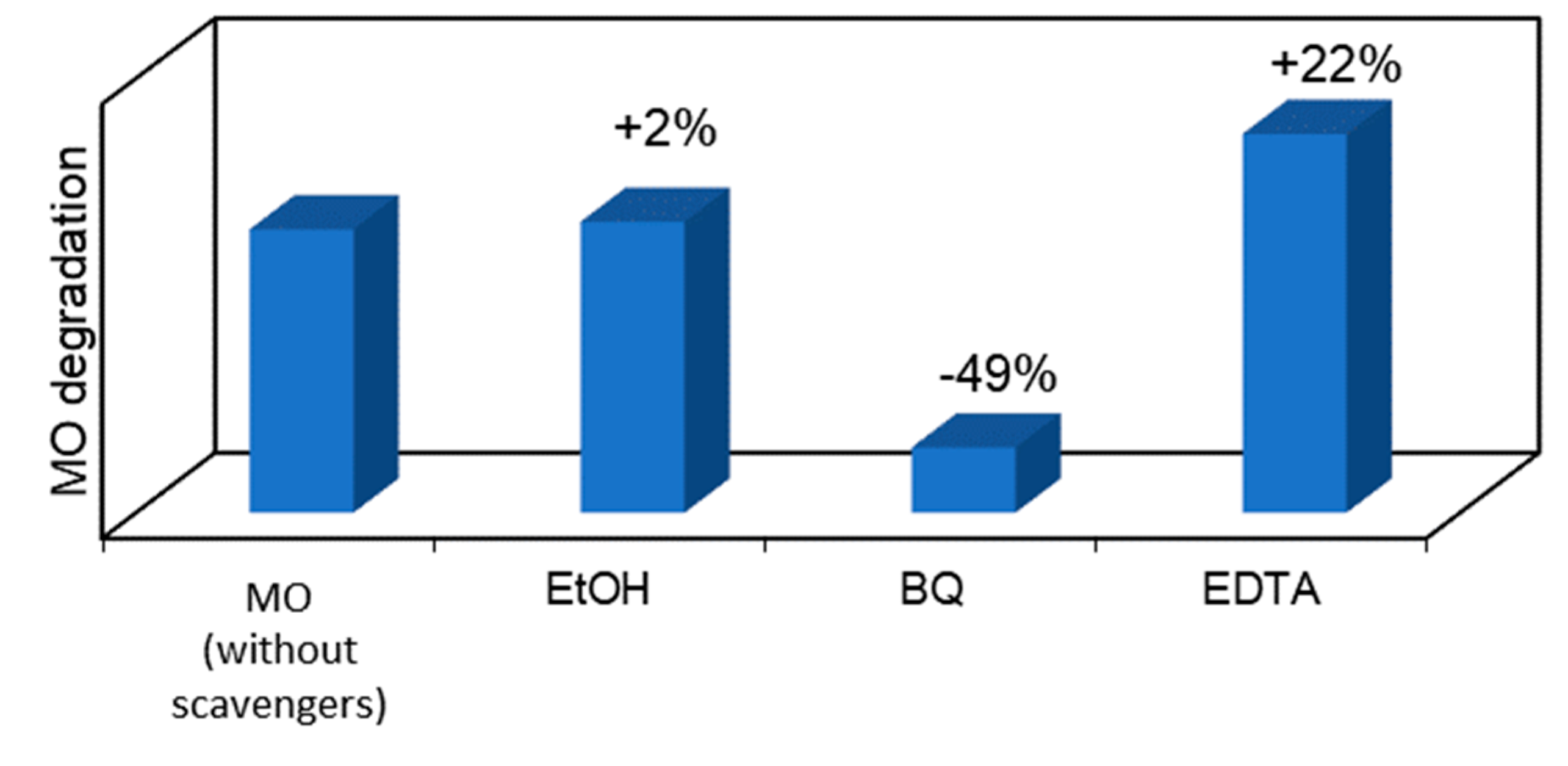

2.5. Scavenger’s Study on the Photocatalytic MICROSCAFS® and Photocatalysis Mechanistic Study

3. Materials and Methods

3.1. Materials

3.2. Synthesis of the MICROSCAFS®

3.3. Preparation of the Photocatalytic MICROSCAFS®

3.4. Characterization

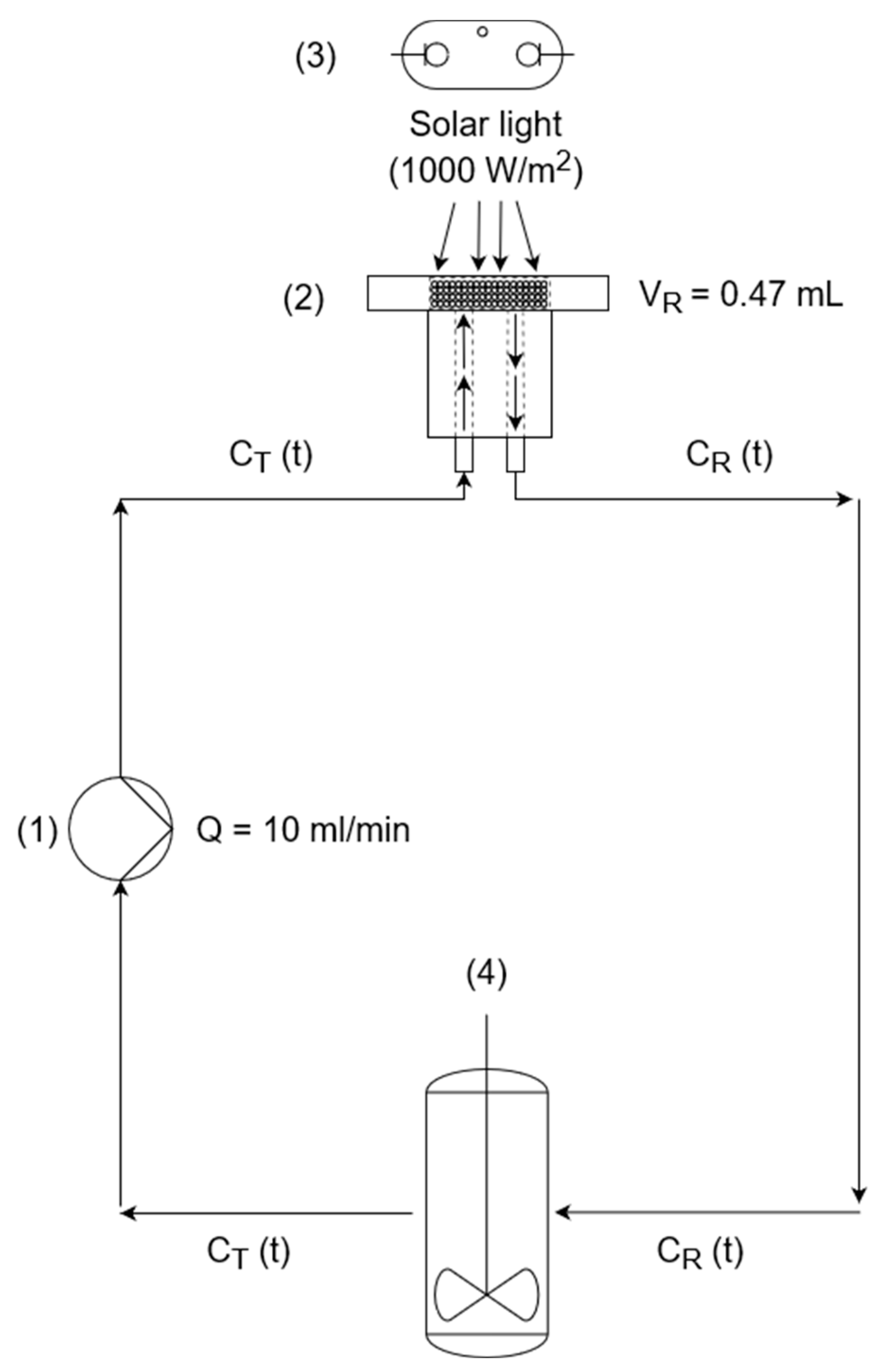

3.5. Photocatalytic Tests

3.6. Kinetics Modeling of the Photocatalytic Performance

3.7. Analytical Methods for Photocatalysis By-Products Determination

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Declaration of competing interest

Acknowledgments

Conflicts of Interest

References

- Lin, J.; Ye, W.; Xie, M.; Seo, D.H.; Luo, J.; Wan, Y.; Van der Bruggen, B. Environmental Impacts and Remediation of Dye-Containing Wastewater. Nat Rev Earth Environ 2023, 4, 785–803. [Google Scholar] [CrossRef]

- Saravanan, A.; Deivayanai, V.C.; Kumar, P.S.; Rangasamy, G.; Hemavathy, R. V; Harshana, T.; Gayathri, N.; Alagumalai, K. A Detailed Review on Advanced Oxidation Process in Treatment of Wastewater: Mechanism, Challenges and Future Outlook. Chemosphere 2022, 308, 136524. [Google Scholar] [CrossRef] [PubMed]

- Mancuso, A.; Iervolino, G. Synthesis and Application of Innovative and Environmentally Friendly Photocatalysts: A Review. Catalysts 2022, 12, 1074. [Google Scholar] [CrossRef]

- Rauf, M.A.; Ashraf, S.S. Fundamental Principles and Application of Heterogeneous Photocatalytic Degradation of Dyes in Solution. Chemical Engineering Journal 2009, 151, 10–18. [Google Scholar] [CrossRef]

- Park, S.; Choi, G.R.; Lee, J.C.; Kim, Y.C.; Oh, D.; Cho, S.; Lee, J.-H. Organic and Inorganic Binder-Coating Properties for Immobilization of Photocatalytic ZnO Nanopowders. Research on Chemical Intermediates 2010, 36, 819–825. [Google Scholar] [CrossRef]

- Jiang, Y.; Liu, A. Cornstalk Biochar-TiO2 Composites as Alternative Photocatalyst for Degrading Methyl Orange. Environmental Science and Pollution Research 2023, 30, 31923–31934. [Google Scholar] [CrossRef]

- Marques, A.C.; Vale, M.; Vicente, D.; Schreck, M.; Tervoort, E.; Niederberger, M. Porous Silica Microspheres with Immobilized Titania Nanoparticles for In-Flow Solar-Driven Purification of Wastewater. Global Challenges 2021, 5, 2000116. [Google Scholar] [CrossRef] [PubMed]

- Wu, A.; Wang, D.; Wei, C.; Zhang, X.; Liu, Z.; Feng, P.; Ou, X.; Qiang, Y.; Garcia, H.; Niu, J. A Comparative Photocatalytic Study of TiO2 Loaded on Three Natural Clays with Different Morphologies. Appl Clay Sci 2019, 183, 105352. [Google Scholar] [CrossRef]

- Lucchini, M.A.; Lizundia, E.; Moser, S.; Niederberger, M.; Nyström, G. Titania-Cellulose Hybrid Monolith for In-Flow Purification of Water under Solar Illumination. ACS Appl Mater Interfaces 2018, 10, 29599–29607. [Google Scholar] [CrossRef]

- Stewart, B.D.; Andrews, L.G.; Pelletier, B.S.; Daly, C.A.; Boyd, J.E. Porous PMMA-Titania Composites: A Step towards More Sustainable Photocatalysis. Journal of Water Process Engineering 2015, 8, 179–185. [Google Scholar] [CrossRef]

- Lei, P.; Wang, F.; Gao, X.; Ding, Y.; Zhang, S.; Zhao, J.; Liu, S.; Yang, M. Immobilization of TiO2 Nanoparticles in Polymeric Substrates by Chemical Bonding for Multi-Cycle Photodegradation of Organic Pollutants. J Hazard Mater 2012, 227–228, 185–194. [Google Scholar] [CrossRef]

- Ökte, A.N.; Karamanis, D.; Tuncel, D. Dual Functionality of TiO2-Flyash Nanocomposites: Water Vapor Adsorption and Photocatalysis. Catal Today 2014, 230, 205–213. [Google Scholar] [CrossRef]

- Almeida da Silva, T.C.; Marchiori, L.; Oliveira Mattos, B.; Ullah, S.; Barud, H. da S.; Romano Domeneguetti, R.; Rojas-Mantilla, H.D.; Boldrin Zanoni, M.V.; Rodrigues-Filho, U.P.; Ferreira-Neto, E.P.; et al. Designing Highly Photoactive Hybrid Aerogels for In-Flow Photocatalytic Contaminant Removal Using Silica-Coated Bacterial Nanocellulose Supports. ACS Appl Mater Interfaces 2023, 15, 23146–23159. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.; Dong, H.; Tapa, A.R.; Shamsi, J.; Shayeh, J.S.; Trokourey, A.; Liu, B.; Zhao, X.; Xie, Y. NaBr-Assisted Aqueous Synthesis of Perovskite-Embedded PbBr(OH) Hierarchical Nanostructures for Dye Photodegradation. ACS Appl Nano Mater 2023, 6, 2538–2548. [Google Scholar] [CrossRef]

- Wu, J.; Ke, K.; Qin, N.; Lin, E.; Kang, Z.; Bao, D. Magnetically Retrievable Fe3O4@SiO2@ZnO Piezo-Photocatalyst: Synthesis and Multiple Catalytic Properties. J Colloid Interface Sci 2023, 636, 167–175. [Google Scholar] [CrossRef] [PubMed]

- Sun, G.; Li, N.; Zuo, S.; Shen, W.; Wu, M.; Li, Q.; Shi, M.; Ma, J. Piezo-Photocatalysis over Phase-Engineered MoSe2 Modified Bi2WO6 Hierarchical Microspheres: Utilizing Piezoelectric Effect to Enhance Photocatalytic Performance. Ceram Int 2022, 48, 37242–37252. [Google Scholar] [CrossRef]

- Wang, J.; Sgarzi, M.; Němečková, Z.; Henych, J.; Licciardello, N.; Cuniberti, G. Reusable and Antibacterial Polymer-Based Nanocomposites for the Adsorption of Dyes and the Visible-Light-Driven Photocatalytic Degradation of Antibiotics. Global Challenges 2022, 6, 2200076. [Google Scholar] [CrossRef]

- Imran, M.; Ashraf, W.; Hafiz, A.K.; Khanuja, M. Synthesis and Performance Analysis of Photocatalytic Activity of ZnIn2S4 Microspheres Synthesized Using a Low-Temperature Method. ACS Omega 2022, 7, 22987–22996. [Google Scholar] [CrossRef] [PubMed]

- Qin, M.; Jin, K.; Li, X.; Wang, R.; Zhao, Y.; Wang, H. Bi Nanosphere-Decorated Oxygen-Vacancy BiOBr Hollow Microspheres with Exposed (110) Facets to Enhance the Photocatalytic Performance for the Degradation of Azo Dyes. New Journal of Chemistry 2022, 46, 12410–12418. [Google Scholar] [CrossRef]

- Kim, J.; Jo, S.; Lee, W.; Lim, J.; Seung Lee, T. Moving Photocatalyst of a Titanium Dioxide-Based Micromotor Asymmetrically Decorated with Conjugated Polymer Dots. Mater Des 2022, 219, 110743. [Google Scholar] [CrossRef]

- Li, X.; Raza, S.; Liu, C. Preparation of Titanium Dioxide Modified Biomass Polymer Microspheres for Photocatalytic Degradation of Rhodamine-B Dye and Tetracycline. J Taiwan Inst Chem Eng 2021, 122, 157–167. [Google Scholar] [CrossRef]

- Liang, H.; Wang, S.; Lu, Y.; Ren, P.; Li, G.; Yang, F.; Chen, Y. Highly Efficient and Cheap Treatment of Dye by Graphene-Doped TiO2 Microspheres. Water Science and Technology 2020, 83, 223–232. [Google Scholar] [CrossRef]

- He, J.; Liu, Q.; Zhang, Y.; Zhao, X.; Zhang, G.; Xiao, B.; Fu, K. In Situ Synthesis of the Mesoporous C–TiO2 Microspheres Derived from Partial Hydrolysis Tetrabutyl Titanate for Enhanced Photocatalytic Degradation under Visible Light. Mater Res Bull 2023, 161, 112168. [Google Scholar] [CrossRef]

- Feng, X.; Gu, L.; Wang, N.; Pu, Q.; Liu, G. Fe/N Co-Doped Nano-TiO2 Wrapped Mesoporous Carbon Spheres for Synergetically Enhanced Adsorption and Photocatalysis. J Mater Sci Technol 2023, 135, 54–64. [Google Scholar] [CrossRef]

- Ren, X.; Zhang, X.; Guo, R.; Li, X.; Peng, Y.; Zhao, X.; Pu, X. Hollow Mesoporous G-C3N4/Ag2CrO4 Photocatalysis with Direct Z-Scheme: Excellent Degradation Performance for Antibiotics and Dyes. Sep Purif Technol 2021, 270, 118797. [Google Scholar] [CrossRef]

- Vale, M.; Loureiro, M. V.; Ferreira, M.J.; Marques, A.C. Silica-Based Microspheres with Interconnected Macroporosity by Phase Separation. J Solgel Sci Technol 2020, 95, 746–759. [Google Scholar] [CrossRef]

- Vale, M.; Orišková, S.; Mariquito, A.; Reis, L.; Pinto, M.; Marques, A.C. Multicomponent Oxide Microspheres with Designed Macroporosity (MICROSCAFS®): A Customized Platform for Chemicals Immobilization. RSC Adv 2023, 13, 12951–12965. [Google Scholar] [CrossRef]

- Loureiro, M. V.; Vale, M.; De Schrijver, A.; Bordado, J.C.; Silva, E.; Marques, A.C. Hybrid Custom-Tailored Sol-Gel Derived Microscaffold for Biocides Immobilization. Microporous and Mesoporous Materials 2018, 261, 252–258. [Google Scholar] [CrossRef]

- Marques, A.C.; Vale, M. Macroporosity Control by Phase Separation in Sol-Gel Derived Monoliths and Microspheres. Materials 2021, 14, 4247. [Google Scholar] [CrossRef]

- Fernandes, S.M.; Barrocas, B.T.; Nardeli, J.V.; Montemor, M.F.; Maçoas, E.; Oliveira, M.C.; de Carvalho, C.C.C.R.; Lauria, A.; Niederberger, M.; Marques, A.C. Maximizing Photocatalytic Efficiency with Minimal Amount of Gold: Solar-Driven TiO2 Photocatalysis Supported by MICROSCAFS® for Facile Catalyst Recovery. J Environ Chem Eng 2024, 12, 112043. [Google Scholar] [CrossRef]

- Loureiro, M. V.; Ciriminna, R.; Lourenço, M.J.; Santos, L.F.; De Schrijver, A.; Bordado, J.C.; Pagliaro, M.; Marques, A.C. Organically-Modified Silica Based Microspheres for Self-Curing Polyurethane One Component Foams. Microporous and Mesoporous Materials 2017, 244, 244–250. [Google Scholar] [CrossRef]

- Marques, A.C.; Loureiro, M. V.; Lourenço, M.J.; De Schrijver, A.; Bordado, J.C. Amino Surface Functionalized Microcapsules as Curing Agents for Polyurethane Foams. Materials and Manufacturing Processes 2017, 32, 1304–1309. [Google Scholar] [CrossRef]

- Nagar, N.; Devra, V. A Kinetic Study on the Degradation and Biodegradability of Silver Nanoparticles Catalyzed Methyl Orange and Textile Effluents. Heliyon 2019, 5, e01356. [Google Scholar] [CrossRef]

- Benz, D.; Van Bui, H.; Hintzen, H.T.; Kreutzer, M.T.; van Ommen, J.R. Mechanistic Insight into the Improved Photocatalytic Degradation of Dyes for an Ultrathin Coating of SiO2 on TiO2 (P25) Nanoparticles. Chemical Engineering Journal Advances 2022, 10, 100288. [Google Scholar] [CrossRef]

- Luna, A.L.; Matter, F.; Schreck, M.; Wohlwend, J.; Tervoort, E.; Colbeau-Justin, C.; Niederberger, M. Monolithic Metal-Containing TiO2 Aerogels Assembled from Crystalline Pre-Formed Nanoparticles as Efficient Photocatalysts for H2 Generation. Appl Catal B 2020, 267, 118660. [Google Scholar] [CrossRef]

- Williams, P.A.; Ireland, C.P.; King, P.J.; Chater, P.A.; Boldrin, P.; Palgrave, R.G.; Claridge, J.B.; Darwent, J.R.; Chalker, P.R.; Rosseinsky, M.J. Atomic Layer Deposition of Anatase TiO2 Coating on Silica Particles: Growth, Characterization and Evaluation as Photocatalysts for Methyl Orange Degradation and Hydrogen Production. J Mater Chem 2012, 22, 20203–20209. [Google Scholar] [CrossRef]

- Ljubas, D.; Smoljanić, G.; Juretić, H. Degradation of Methyl Orange and Congo Red Dyes by Using TiO2 Nanoparticles Activated by the Solar and the Solar-like Radiation. J Environ Manage 2015, 161, 83–91. [Google Scholar] [CrossRef]

- Morales-García, Á.; Macià Escatllar, A.; Illas, F.; Bromley, S.T. Understanding the Interplay between Size, Morphology and Energy Gap in Photoactive TiO2 Nanoparticles. Nanoscale 2019, 11, 9032–9041. [Google Scholar] [CrossRef]

- Comparelli, R.; Fanizza, E.; Curri, M.L.; Cozzoli, P.D.; Mascolo, G.; Passino, R.; Agostiano, A. Photocatalytic Degradation of Azo Dyes by Organic-Capped Anatase TiO2 Nanocrystals Immobilized onto Substrates. Appl Catal B 2005, 55, 81–91. [Google Scholar] [CrossRef]

- Kokilavani, S.; Alaraidh, I.A.; Okla, M.K.; Chandran, P.; Mohebaldin, A.; Soufan, W.; AL-ghamdi, A.A.; Abdel-Maksoud, M.A.; AbdElgawad, H.; Thomas, A.M.; et al. Efficient Photocatalytic Degradation of Methyl Orange and Malachite Green by Ag3PO4 Decorated BiOBr Nanoflower under Visible Light: Performance Evaluation, Mechanism Insights and Toxicology of the by-Products. J Alloys Compd 2022, 909, 164703. [Google Scholar] [CrossRef]

- Putri, R.A.; Safni, S.; Jamarun, N.; Septiani, U.; Kim, M.-K.; Zoh, K. Kinetics Studies on Photodegradation of Methyl Orange in the Presence of C-N-Codoped TiO2 Catalyst. Egypt J Chem 2019, 62, 563–575. [Google Scholar] [CrossRef]

- Baiocchi, C.; Brussino, M.C.; Pramauro, E.; Prevot, A.B.; Palmisano, L.; Marcı̀, G. Characterization of Methyl Orange and Its Photocatalytic Degradation Products by HPLC/UV–VIS Diode Array and Atmospheric Pressure Ionization Quadrupole Ion Trap Mass Spectrometry. Int J Mass Spectrom 2002, 214, 247–256. [Google Scholar] [CrossRef]

- Liu, T.; Wang, L.; Lu, X.; Fan, J.; Cai, X.; Gao, B.; Miao, R.; Wang, J.; Lv, Y. Comparative Study of the Photocatalytic Performance for the Degradation of Different Dyes by ZnIn2S4: Adsorption, Active Species, and Pathways. RSC Adv. 2017, 7, 12292–12300. [Google Scholar] [CrossRef]

- Mills, A.; Williams, G. Methyl Orange as a Probe of the Semiconductor–Electrolyte Interfaces in CdS Suspensions. J. Chem. Soc., Faraday Trans. 1 1987, 83, 2647–2661. [Google Scholar] [CrossRef]

- Osawa, R.A.; Barrocas, B.T.; Monteiro, O.C.; Conceição Oliveira, M.; Florêncio, M.H. Photocatalytic Degradation of Amitriptyline, Trazodone and Venlafaxine Using Modified Cobalt-Titanate Nanowires under UV–Vis Radiation: Transformation Products and in Silico Toxicity. Chemical Engineering Journal 2019, 373, 1338–1347. [Google Scholar] [CrossRef]

- Ismail, L.; Rifai, A.; Ferronato, C.; Fine, L.; Jaber, F.; Chovelon, J.-M. Towards a Better Understanding of the Reactive Species Involved in the Photocatalytic Degradation of Sulfaclozine. Appl Catal B 2016, 185, 88–99. [Google Scholar] [CrossRef]

- Kim, K.-S.; Kam, S.K.; Mok, Y.S. Elucidation of the Degradation Pathways of Sulfonamide Antibiotics in a Dielectric Barrier Discharge Plasma System. Chemical Engineering Journal 2015, 271, 31–42. [Google Scholar] [CrossRef]

- Dirany, A.; Sirés, I.; Oturan, N.; Özcan, A.; Oturan, M.A. Electrochemical Treatment of the Antibiotic Sulfachloropyridazine: Kinetics, Reaction Pathways, and Toxicity Evolution. Environ Sci Technol 2012, 46, 4074–4082. [Google Scholar] [CrossRef]

- Fabiańska, A.; Białk-Bielińska, A.; Stepnowski, P.; Stolte, S.; Siedlecka, E.M. Electrochemical Degradation of Sulfonamides at BDD Electrode: Kinetics, Reaction Pathway and Eco-Toxicity Evaluation. J Hazard Mater 2014, 280, 579–587. [Google Scholar] [CrossRef]

- Vale, M.; Marques, A.C. Mechanistic Study of the Formation of Multicomponent Oxide Porous Microspheres (MICROSCAFS®) by Cryo-Scanning Electron Microscopy. Gels 2023, 9, 704. [Google Scholar] [CrossRef]

- Landi, S.; Segundo, I.R.; Freitas, E.; Vasilevskiy, M.; Carneiro, J.; Tavares, C.J. Use and Misuse of the Kubelka-Munk Function to Obtain the Band Gap Energy from Diffuse Reflectance Measurements. Solid State Commun 2022, 341, 114573. [Google Scholar] [CrossRef]

- Makuła, P.; Pacia, M.; Macyk, W. How To Correctly Determine the Band Gap Energy of Modified Semiconductor Photocatalysts Based on UV–Vis Spectra. J Phys Chem Lett 2018, 9, 6814–6817. [Google Scholar] [CrossRef] [PubMed]

- Barrocas, B.; Chiavassa, L.D.; Conceição Oliveira, M.; Monteiro, O.C. Impact of Fe, Mn Co-Doping in Titanate Nanowires Photocatalytic Performance for Emergent Organic Pollutants Removal. Chemosphere 2020, 250, 126240. [Google Scholar] [CrossRef] [PubMed]

- Barrocas, B.T.; Oliveira, M.C.; Nogueira, H.I.S.; Fateixa, S.; Monteiro, O.C. Ruthenium-Modified Titanate Nanowires for the Photocatalytic Oxidative Removal of Organic Pollutants from Water. ACS Appl Nano Mater 2019, 2, 1341–1349. [Google Scholar] [CrossRef]

- Osawa, R.; T. Barrocas, B.; C. Monteiro, O.; Oliveira, M.C.; Florêncio, M.H. Photocatalytic Degradation of Cyclophosphamide and Ifosfamide: Effects of Wastewater Matrix, Transformation Products and in Silico Toxicity Prediction. Science of The Total Environment 2019, 692, 503–510. [Google Scholar] [CrossRef] [PubMed]

| Sample Acronym | Average Kinetic Rate Constant k (mL min-1 mg-1) |

Average Apparent Flow Reaction Rate Constant kapp (mL min-1 mg-1) |

|---|---|---|

| P-/HT/P25 | (3.47 ± 0.1) × 10-2 | (2.28 ± 0.3) × 10-3 |

| P0/HT/P25 | (4.40 ± 0.3) × 10-2 | (3.01 ± 0.5) × 10-3 |

| P+/HT/P25 | (6.45 ± 0.08) × 10-2 | (4.19 ± 0.7) × 10-3 |

| S-/HT/P25 | (4.99 ± 0.7) × 10-2 | n. a. |

| Supported Photocatalyst System | Radiation Source | Reactor Type and pH | Reactor Volume and Initial Concentration of MO Solution | Photocatalyst (Active Phase)/Pollutant Mass Ratio | MO Degradation at 464 nm |

k (Batch) or kapp (Flow) (mL min-1 mg-1) |

Ref., Year |

|---|---|---|---|---|---|---|---|

| P25 TiO2 NPs supported in SiO2-TiO2 MICROSCAFS® (11.5 mg batch; 46 mg flow) (23 wt% loading) |

Solar simulator Xe lamp, 100 W, 1000 W/m2 (1 sun) |

Batch pH=7 | 50 mL, 10 mg/L |

23 | 87% in 120 min. | (6.45 ± 0.08) × 10-2 | Present study |

| Flow pH=7 |

0.47 mL, 10 mg/L |

23 | 29% in 360 min. | (4.19 ± 0.7) × 10-3 | |||

| Commercial anatase TiO2 (11 mg, 2-3 µm) supported in biochar (75% wt% loading) |

Hg lamp, 500 W |

Batch pH = 6.3 |

30 mL, 60 mg/L |

6 | ~99% in 60 min. | 1.39 × 10-1 | [6], 2023 |

| Synthesized anatase TiO2 (66 mg) supported in SiO2 MICROSCAFS®, (22 wt% loading) | Solar simulator Xe lamp, 100 W, 1000 W/m2 (1 sun) |

Flow pH=7 |

100 mL, 20 mg/L |

33 | 30% in 375 min. | 1.36 × 10-3 | [7], 2021 |

| Synthesized anatase TiO2 (2 mg) supported on natural clays (~11 wt% loading) |

Xe lamp, 500 W |

Batch pH=n/d |

20 mL, 10 mg/L |

10 | 90% in 150 min. | 1.20 × 10-1 | [8], 2019 |

| Synthesized anatase TiO2 (19 mg) supported on cellulose nanofibrils (17 wt% loading) | Solar simulator Xe lamp, 100 W, 1000 W/m2 (1 sun) |

Flow pH=7 |

100 mL, 20 mg/L |

10 | 21% in 200 min. | 5.79 × 10-3 | [9], 2018 |

| P25 TiO2 (16 mg) supported in porous PMMA wafers (loading n/d) |

UV-LED | Batch pH =n/d |

60 mL, 10 mg/L |

27 | 28% in ~30 min. | 4.08 × 10-2 | [10], 2015 |

| P25 TiO2 (50 mg) supported on fly ash (25 wt% loading) | Black light lamps, 320-440 nm | Batch pH=8.5 |

200 mL, 3.27 mg/L |

76 | 50% in 170 min. | 6.40 × 10-3 | [12], 2014 |

| Anatase TiO2 layer (~9.8 mg) deposited on 500 nm SiO2 spheres (10 wt% loading) | Xe lamp, 300 W |

Batch pH=n/d |

90 mL, 20 mg/L |

5 | 90% in 120 min. | 1.65 × 10-1 | [36], 2012 |

| P25 TiO2 (10 mg) supported on a PVA film (loading n/d) |

UV 300 nm lamps, 6x8 W, 90 ±10 µW/cm2 |

Batch pH=n/d |

10 mL, 15 mg/L |

67 | ~100% in 300 min. | 1.30 × 10-2 | [11], 2012 |

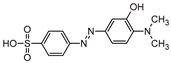

| Compound | Structure | tR (min) |

Proposed empirical formula |

[M-H]− [m/z (Δ ppm) mSigma] |

|---|---|---|---|---|

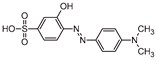

| MO |  |

9.5 | C14H15N3O3S | [304.0770 (-2.9; 6.5)] |

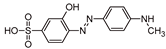

| TP320-a |  |

10.9 | C14H15N3O4S | [320.0722 (-3.7; 9.2)] |

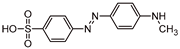

| TP306 |  |

9.0 | C13H13N3O4S | [306.0562 (-2.7;12.5)] |

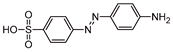

| TP290 |  |

7.8 | C13H13N3O3S | [290.0614 (-3.2; 10.5)] |

| TP276 |  |

5.8 | C12H11N3O3S | [276.0453 (-3.2; 21.6)] |

| TP320-b |  |

3.9 | C14H15N3O4S | [320.0712 (-0.2; 9.7)] |

| Compound | Acute Toxicity | Chronic Toxicity | |||||||

|---|---|---|---|---|---|---|---|---|---|

| (mg/L) | (mg/L) | ||||||||

| Fish (LC50) | Daphnid (LC50) | Green Algae (EC50) | Fish (ChV) | Daphnid (ChV) | Green Algae (ChV) | ||||

| MO | 1513.99 | 793.35 | 424.07 | 134.62 | 61.88 | 92.88 | |||

| TP320-a | 173.97 | 39.22 | 192.16 | 15.97 | 7.47 | 91.02 | |||

| TP320-b | 592.29 | 97.78 | 512.74 | 49.07 | 18.64 | 245.03 | |||

| TP306 | 433.60 | 76.62 | 395.85 | 36.73 | 14.60 | 188.80 | |||

| TP290 | 4479.49 | 2231.63 | 967.94 | 375.25 | 151.23 | 189.43 | |||

| TP276 | 922.37 | 2.07 | 9.26 | 5.36 | 0.13 | 13.94 | |||

| Harmless - LC50/EC50/ChV > 100 | Harmful - 100 > LC50/EC50/ChV > 10 | Toxic - 10 > LC50/EC50/ChV > 1 | Very toxic - LC50/EC50/ChV < 1 | ||||||

| Sample Acronym | Volume of GPTMS (mL) | Volume of Span® 80 (mL) | Mass of Pluronic® P123 (g) |

|---|---|---|---|

| P- | 10.4 | 6.0 | 0 |

| P0 (reference) | 13.8 | 6.0 | 0 |

| P+ | 17.3 | 6.0 | 0 |

| S- | 13.8 | 7.7 | 2.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).