Submitted:

22 April 2024

Posted:

23 April 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Industry and Construction 4.0

2.1. Industry 4.0

2.1.1. 4IR Technologies and Principles

2.1.2. Industry 4.0 Trends in the Construction Sector

2.1.3. Impact of New Technologies

3. Methods

3.1. Data Collection Instrument

3.2. Sample Characterization

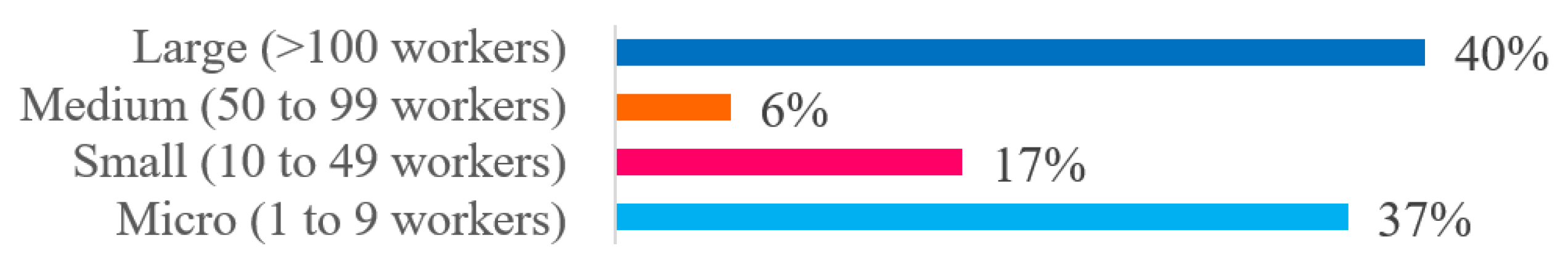

3.3. Characterization of Construction Companies

4. Results

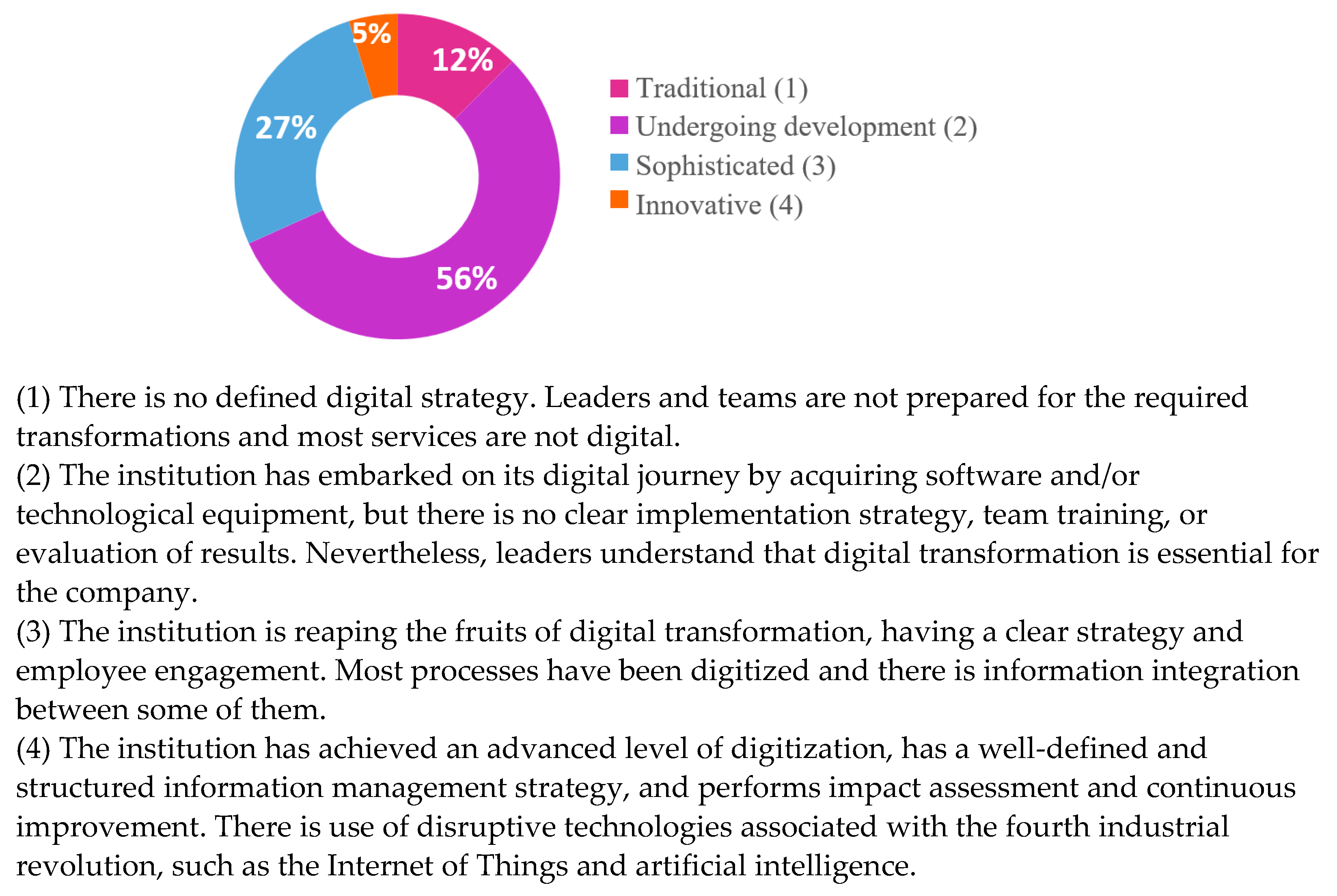

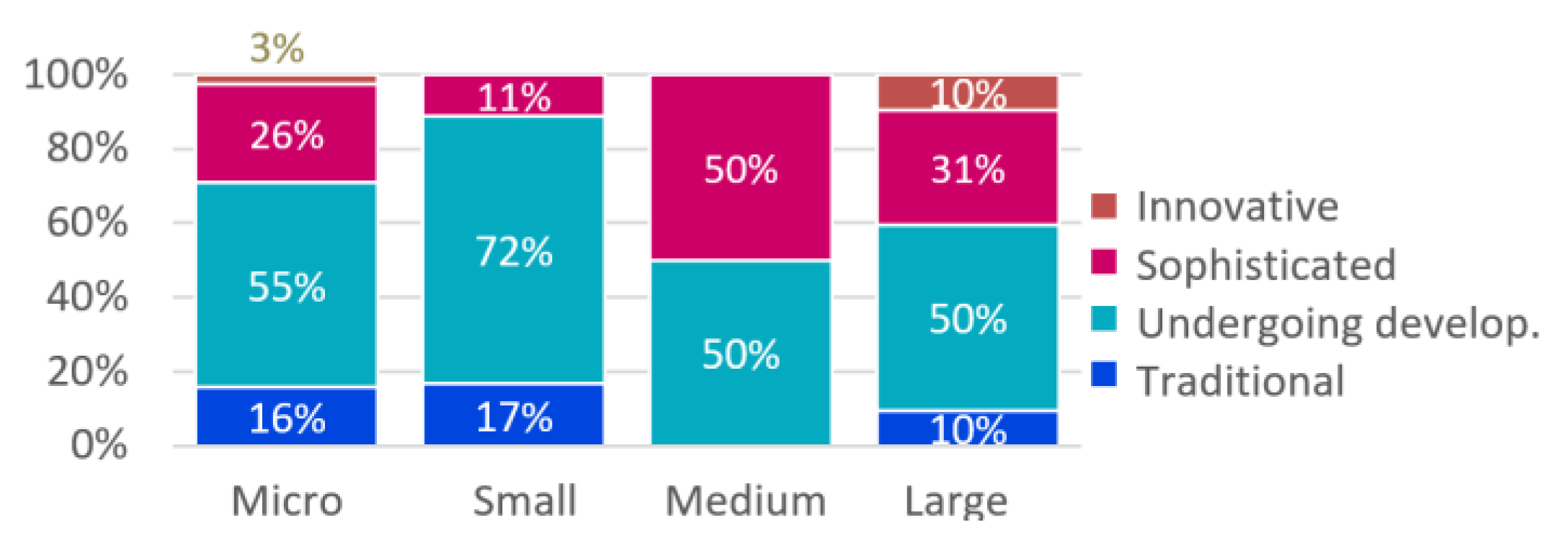

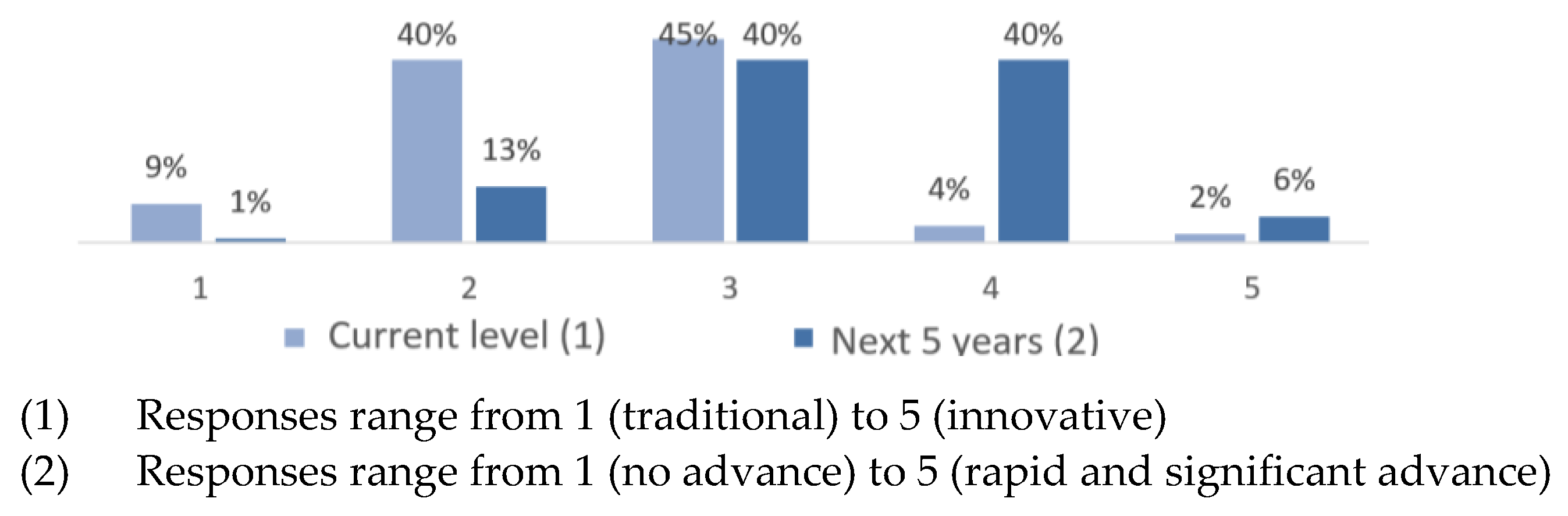

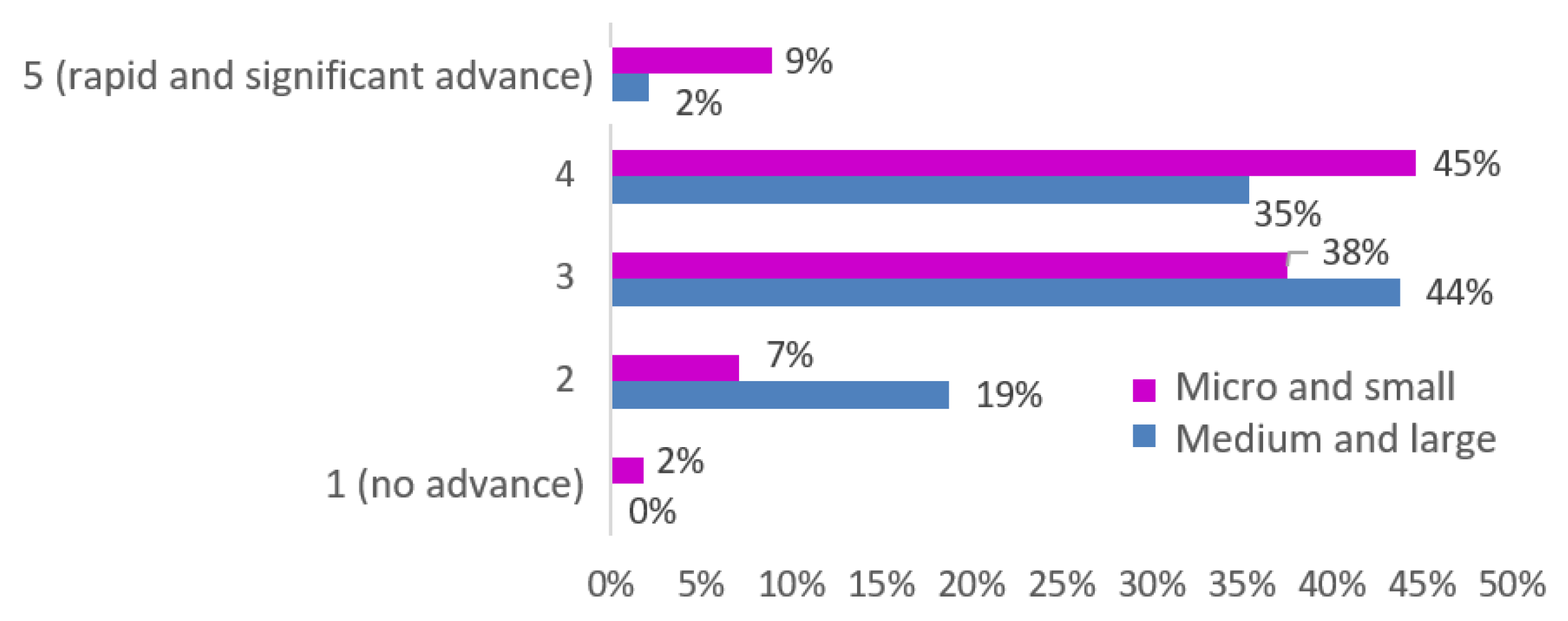

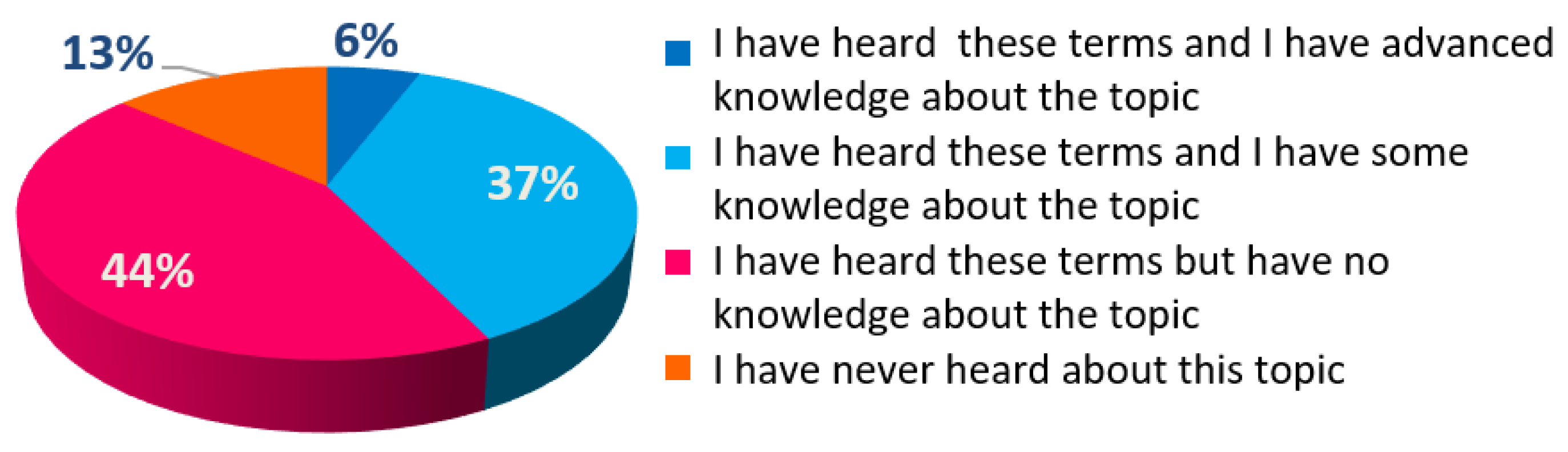

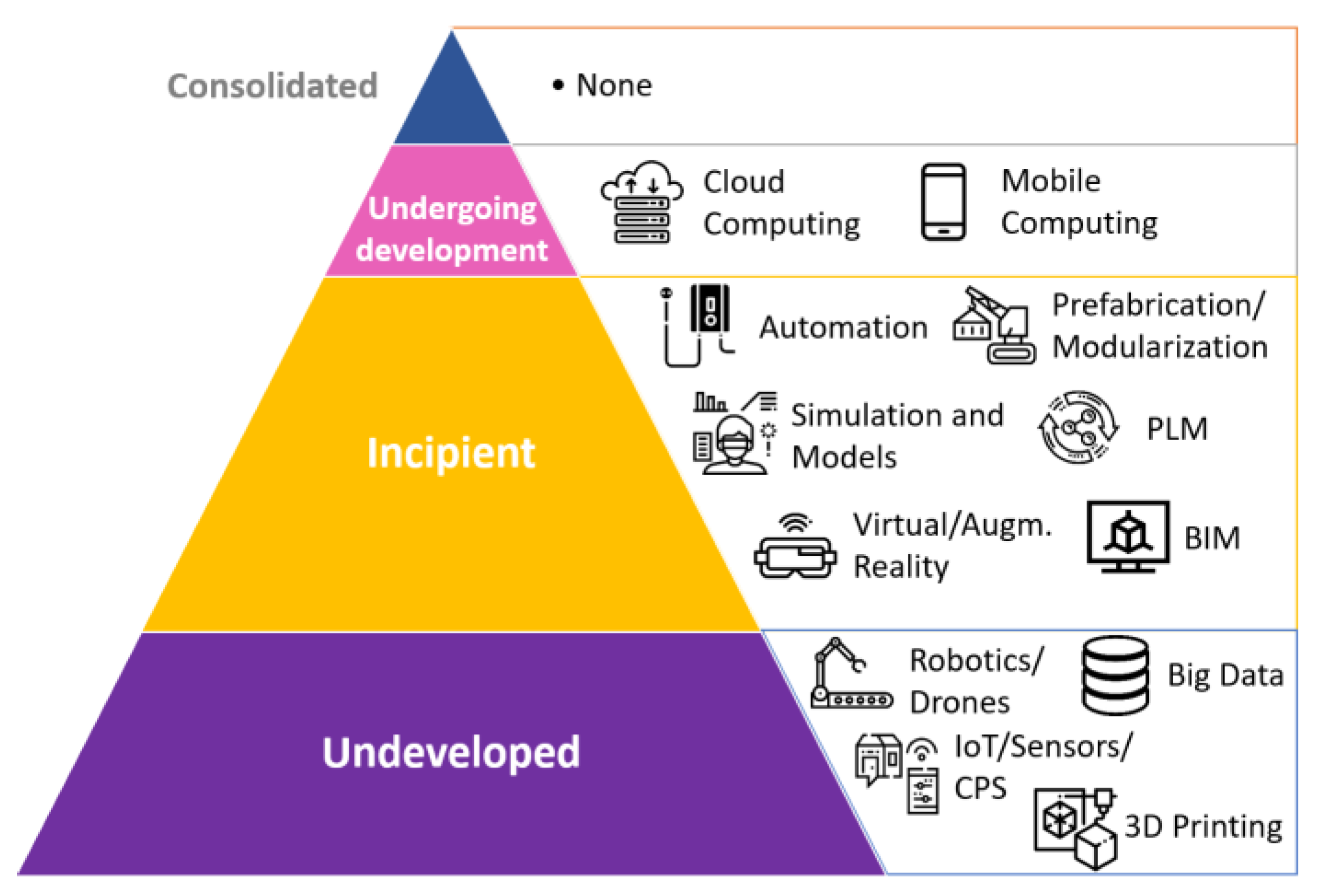

4.1. Technological Advancement in Construction

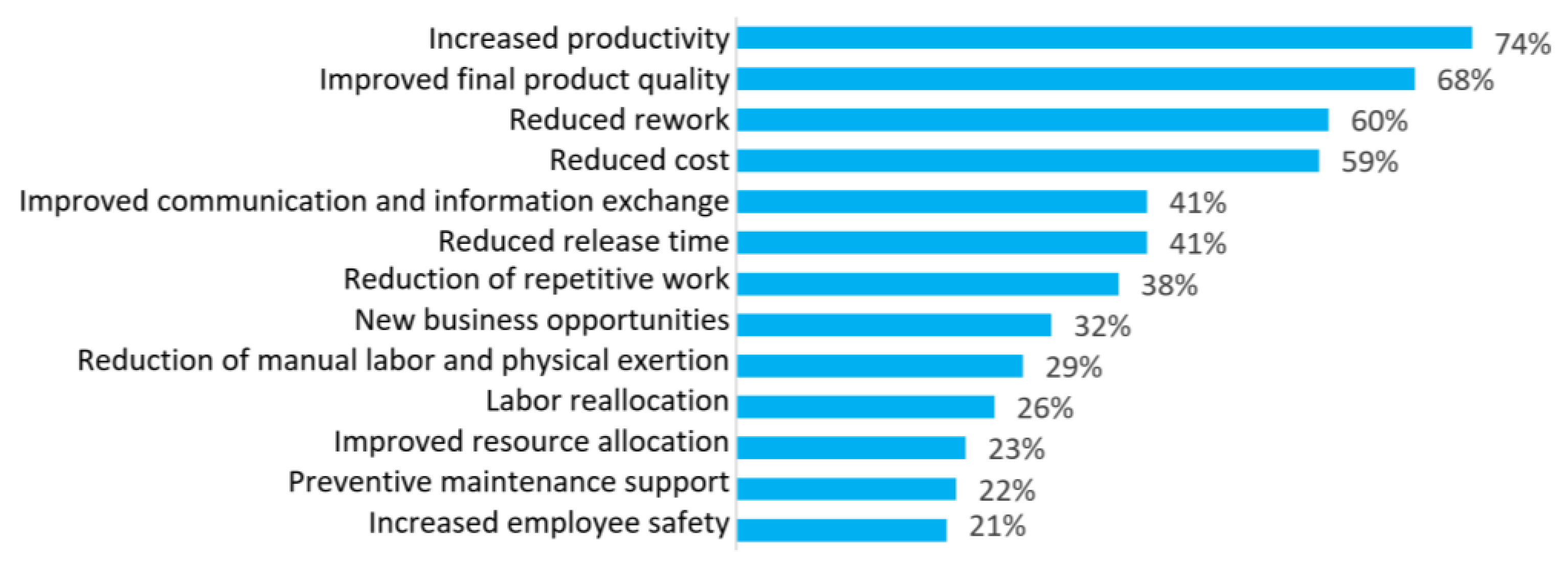

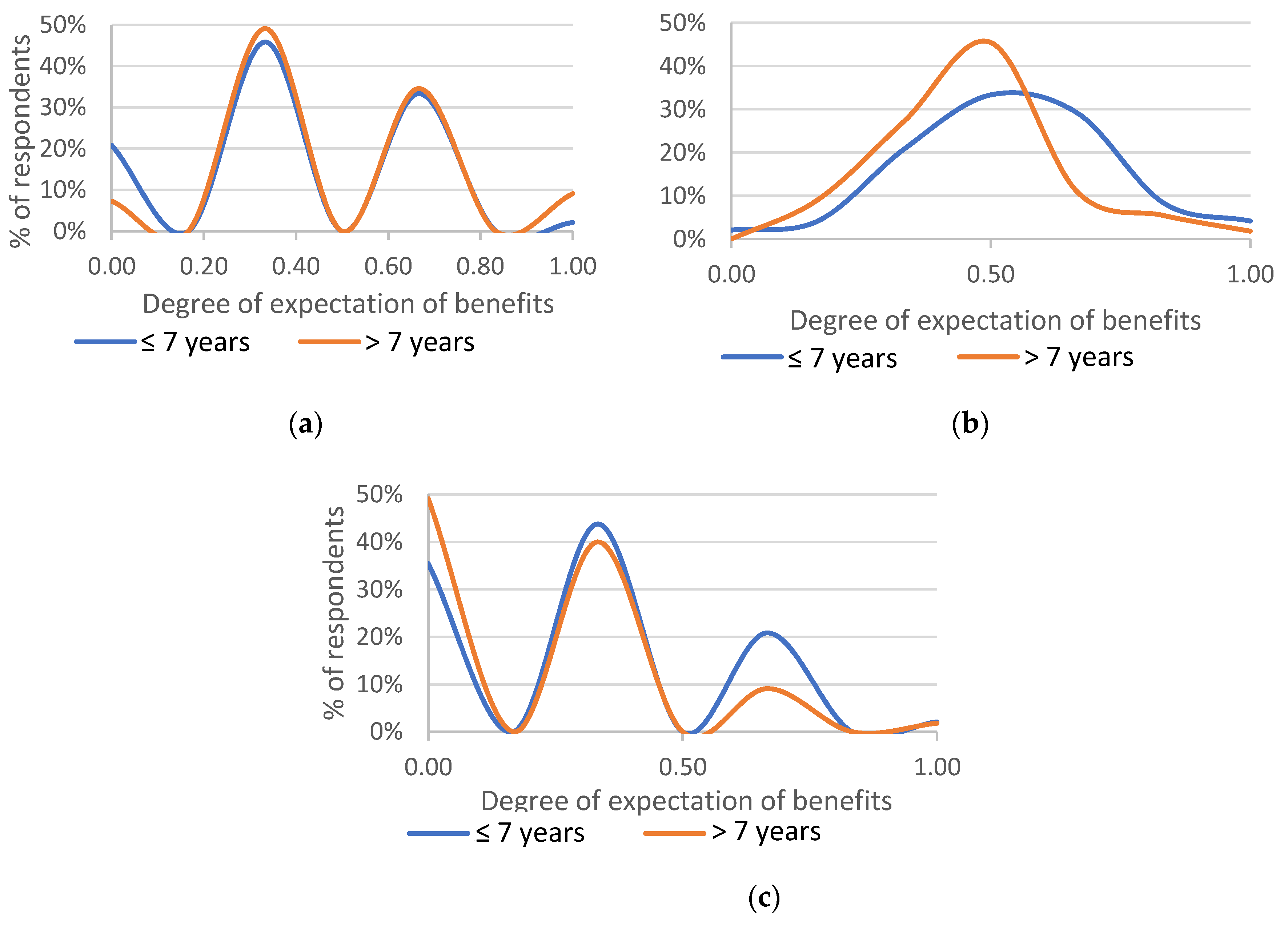

4.2. Expected Benefits of Technology Use

4.3. Potential of Industry 4.0 Technologies in Construction

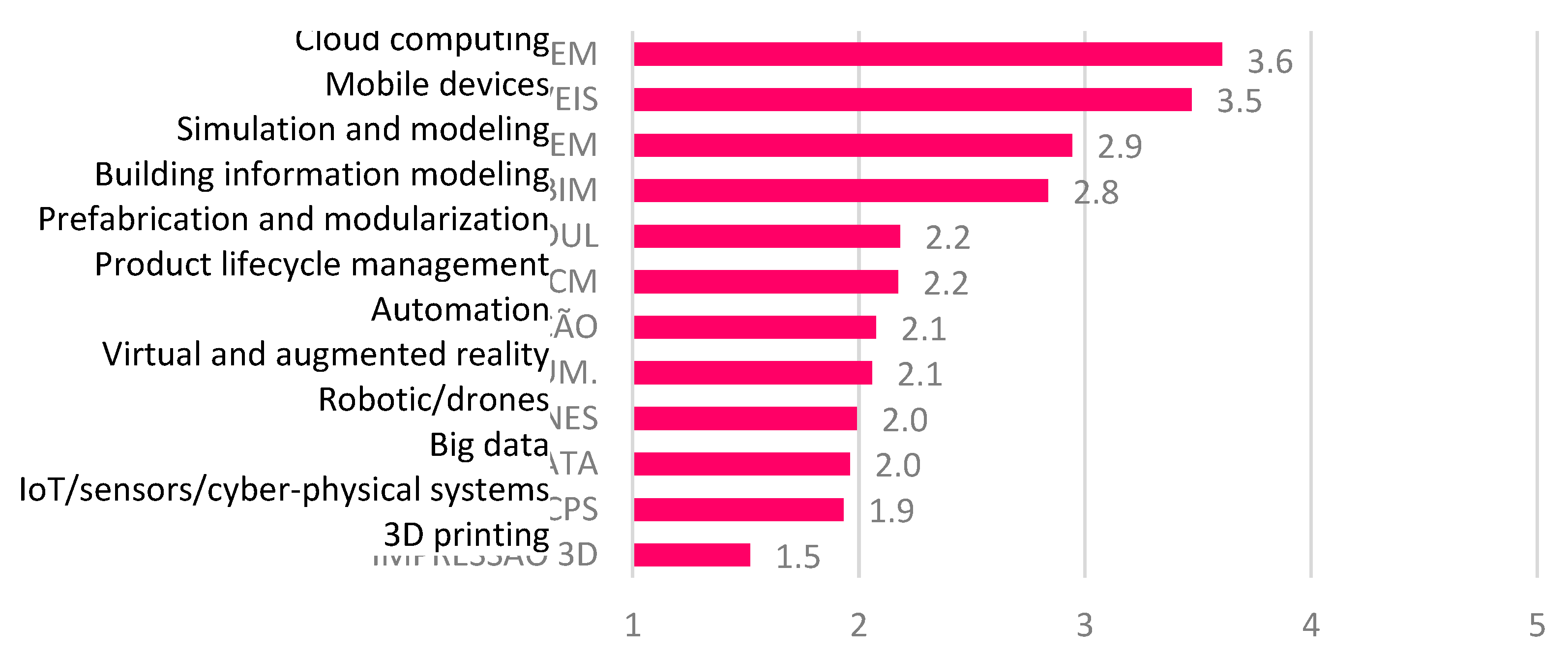

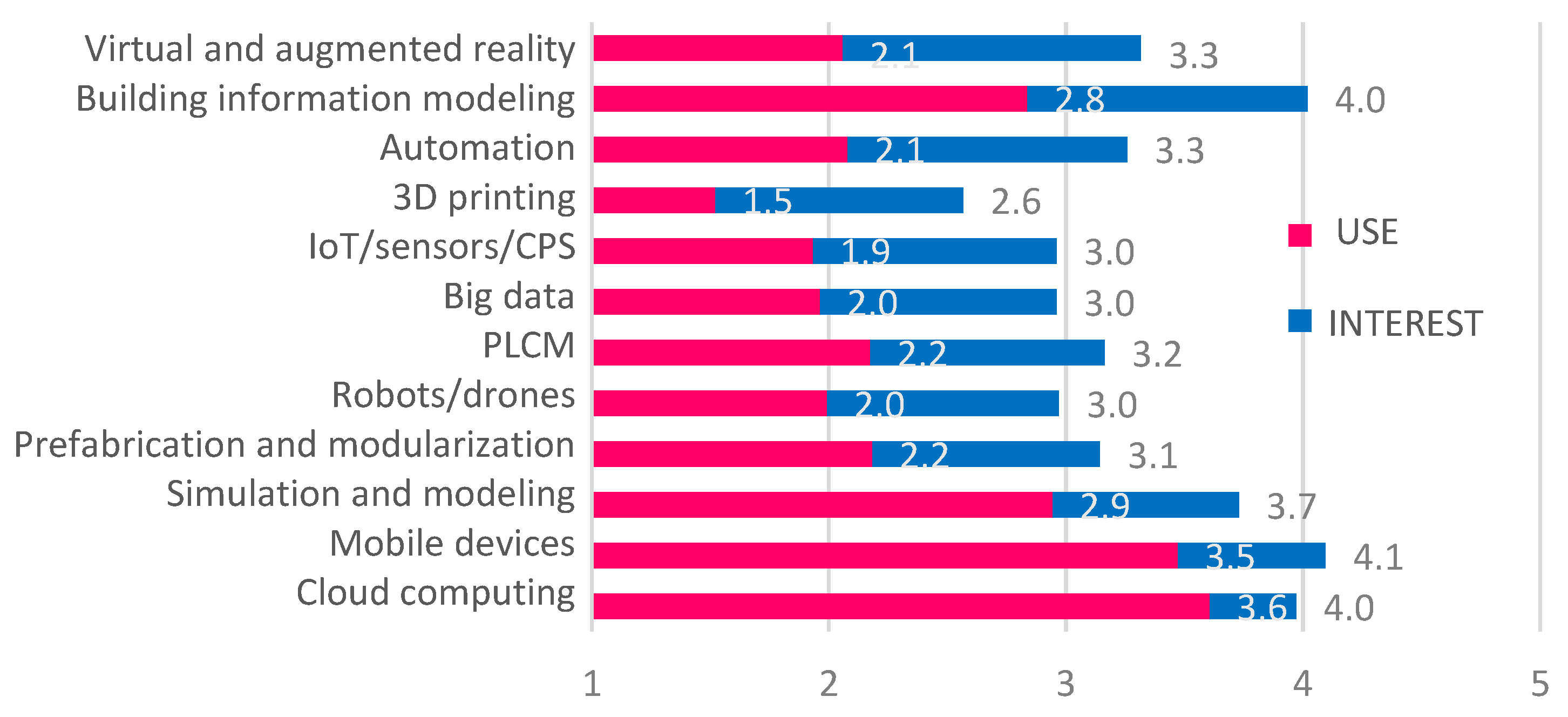

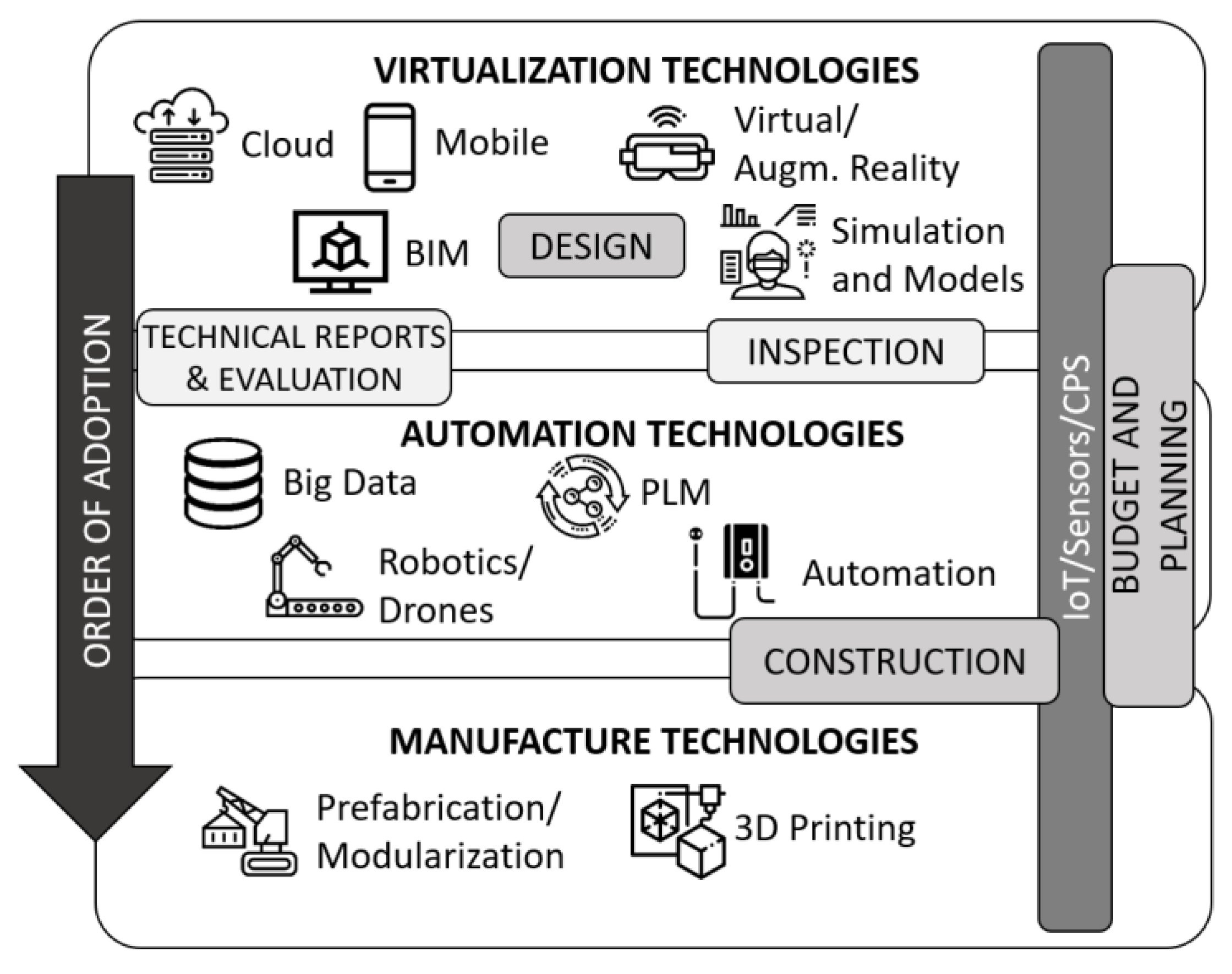

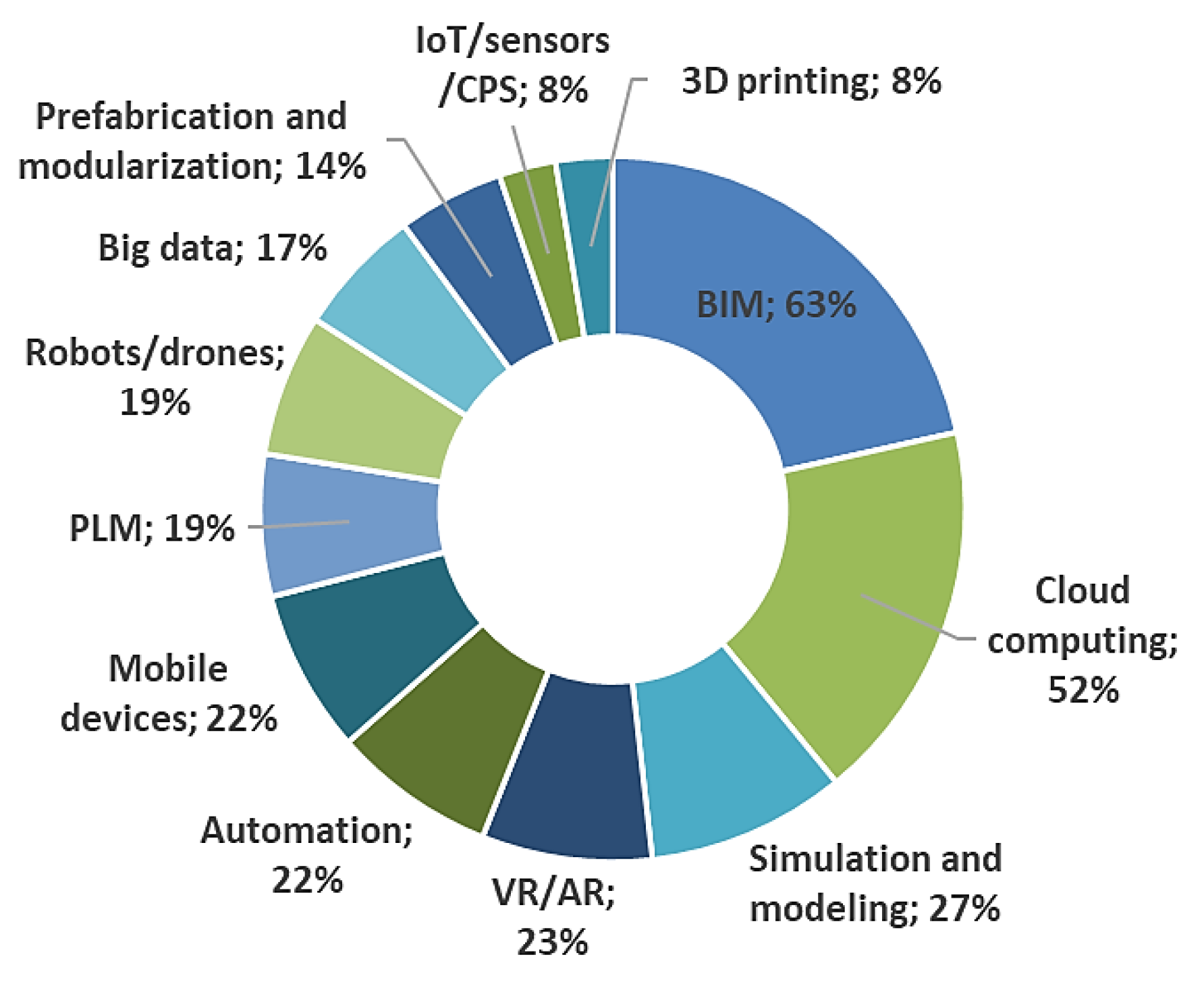

4.3.1. Use and Interest

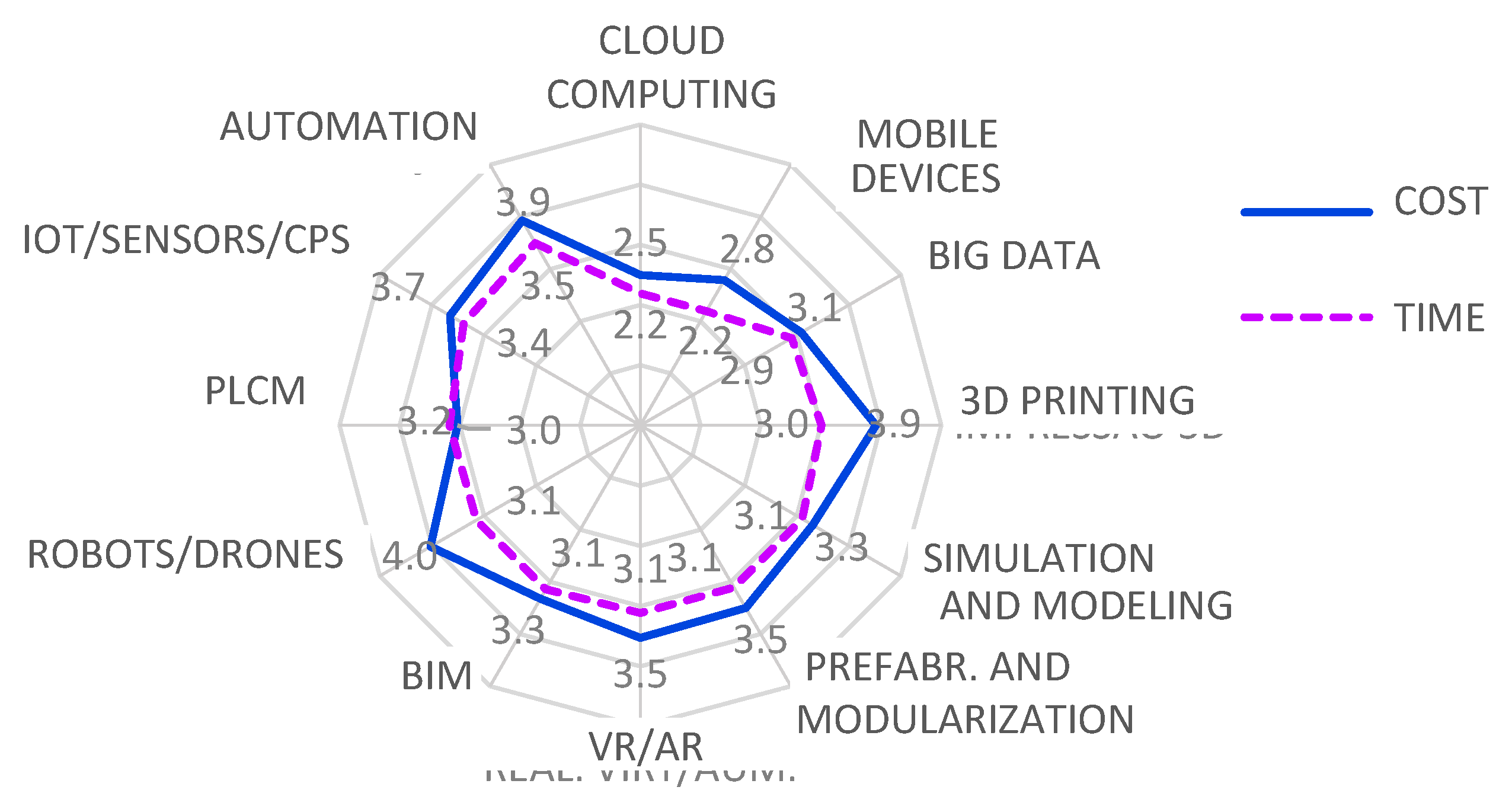

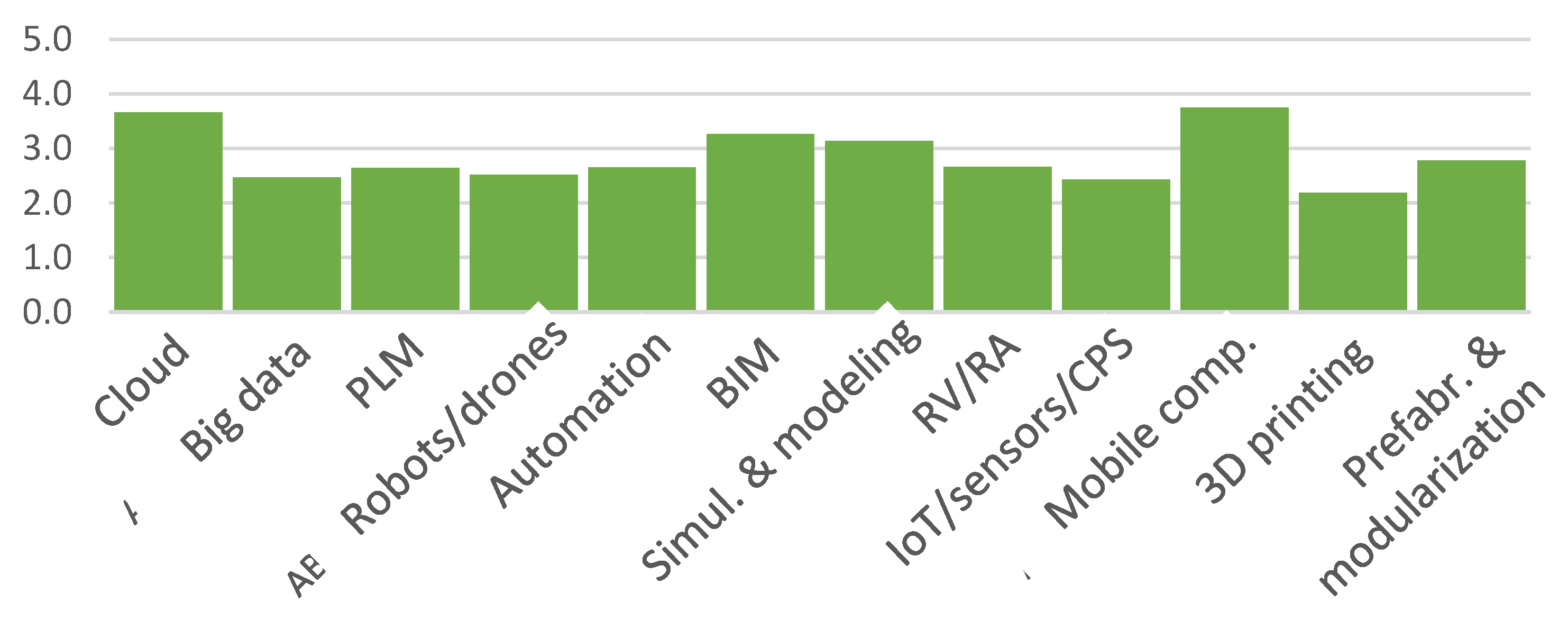

4.3.2. Perception of Cost, Time, and Preparedness of Companies to Adopt Emerging Technologies

4.3.3. Factors Influencing Use and Interest in Technologies

4.4. Preference of Respondents

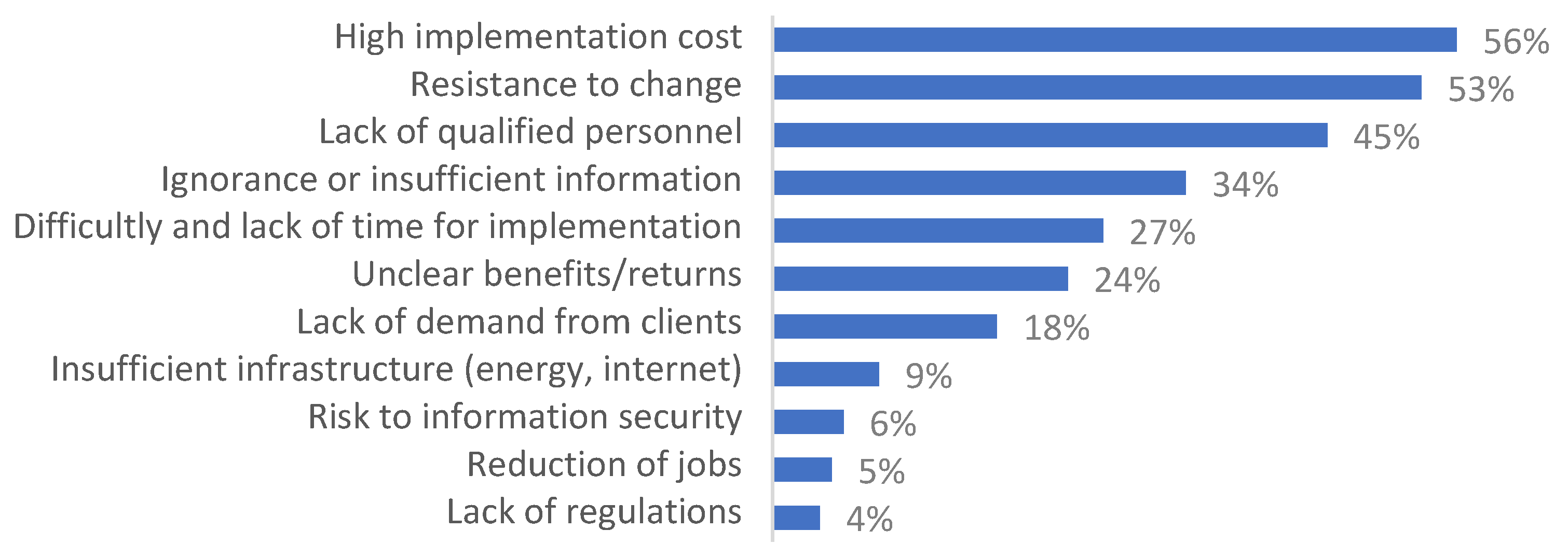

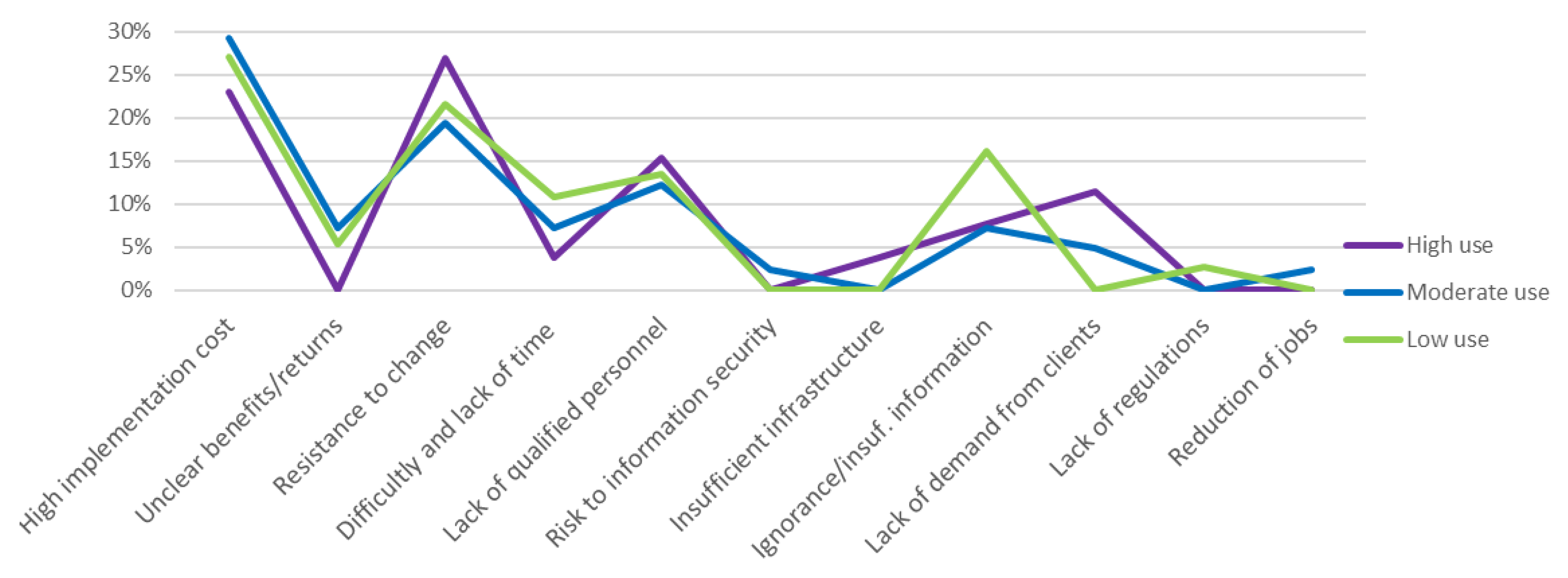

4.5. Barriers to Technology Adoption

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- H. Lasi, P. Fettke, H.-G. Kemper, T. Feld, M. Hoffmann, Industry 4.0, Business & Information Systems Engineering. 6 (2014) 239–242. [CrossRef]

- K. Schwab, A Quarta Revolução Industrial, 1st ed., São Paulo, 2016.

- H. Kagermann, W. Wahlster, J. Helbig, Recommendations for implementing the strategic initiative INDUSTRIE 4.0 - Final report of the Industrie 4.0 Working Group, Frankfurt, 2013.

- H. Kagermann, Change Through Digitization—Value Creation in the Age of Industry 4.0, in: Management of Permanent Change, 2015: pp. 23–45. [CrossRef]

- T.D. Oesterreich, F. Teuteberg, Understanding the implications of digitisation and automation in the context of Industry 4.0: A triangulation approach and elements of a research agenda for the construction industry, Comput Ind. 83 (2016) 121–139. [CrossRef]

- J. Menegon, L.C.P. da Silva Filho, The Impact of Industry 4.0 Concepts and Technologies on Different Phases of Construction Project Lifecycle: A Literature Review, Iranian Journal of Science and Technology, Transactions of Civil Engineering. (2022). [CrossRef]

- S.S. Kamble, A. Gunasekaran, S.A. Gawankar, Sustainable Industry 4.0 framework: Asystematic literature review identifying the current trends and future perspectives, Process Safety and Environmental Protection. 117 (2018) 408–425. [CrossRef]

- G.D.B.P. Porto, T.M.D.M. Kadlec, Mapeamento de estudosprospectivos de tecnologianarevolução 4.0: Um olhar para aindústria da construção civil., (2018) 70.

- CNI, SPECIAL SURVEY: Industry 4.0, 2016.

- P.B.L. PwC, Indústria 4.0: Digitizaçãocomovantagemcompetitiva no Brasil, 2016.

- F. Federação das Indústrias do Estado do Rio de Janeiro, indústria 4.0, 2016.

- A.S. Firmino, G.X. Perles, J.V. Mendes, J.E.A.R. da Silva, D.A.L. Silva, Towards Industry 4.0: a SWOT-based analysis for companies located in the Sorocaba Metropolitan Region (São Paulo State, Brazil), Gestão&Produção. 27 (2020) 1–21. [CrossRef]

- L.S. Dalenogare, G.B. Benitez, N.F. Ayala, A.G. Frank, The expected contribution of Industry 4.0 technologies for industrial performance, Int J Prod Econ. 204 (2018) 383–394. [CrossRef]

- M. Rubmann, M. Lorenz, P. Gerbert, M. Waldner, J. Justus, P. Engel, M. Harnisch, Industry 4.0: The Future of Productivity and Growth in Manufacturing Industries, 2015. [CrossRef]

- F. Longo, L. Nicoletti, A. Padovano, Smart operators in industry 4.0: A human-centered approach to enhance operators’ capabilities and competencies within the new smart factory context, Comput Ind Eng. 113 (2017) 144–159. [CrossRef]

- V. Paelke, Augmented Reality in the Smart Factory: Supporting Workers in an Industry 4.0. Environment, in: IEEE Emerging Technology and Factory Automation (ETFA), IEEE, 2014.

- A.G. Frank, L.S. Dalenogare, N.F. Ayala, Industry 4.0 technologies: Implementation patterns in manufacturing companies, Int J Prod Econ. 210 (2019) 15–26. [CrossRef]

- K. Witkowski, Internet of Things, Big Data, Industry 4.0 – Innovative Solutions in Logistics and Supply Chains Management, Procedia Eng. 182 (2017) 763–769. [CrossRef]

- ABIMAQ, NEO, Indústria 4.0: Mapeamento das tecnologias. Relatório Geral, 2018.

- T. Gerber, H. Bosch, C. Johnsson, Service Orientation in Holonic and Multi Agent Manufacturing and Robotics, Springer Berlin Heidelberg, Berlin, Heidelberg, 2013. [CrossRef]

- B. Meindl, N.F. Ayala, J. Mendonça, A.G. Frank, The four smarts of Industry 4.0: Evolution of ten years of research and future perspectives, Technol Forecast Soc Change. 168 (2021) 120784. [CrossRef]

- E.M. Rogers, Diffusion of innovations, Free Press, 1983.

- J.M. Müller, O. Buliga, K.I. Voigt, Fortune favors the prepared: How SMEs approach business model innovations in Industry 4.0, Technol Forecast Soc Change. 132 (2018) 2–17. [CrossRef]

- Keith Barrow, Pierre Verzat, Construction 4.0: delivering an infrastructure revolution, The Railway. (2018) 23–24.

- Karmakar, V.S.K. Delhi, Construction 4.0: what we know and where we are headed?, Journal of Information Technology in Construction. 26 (2021) 526–545. [CrossRef]

- M. Loosemore, Construction Innovation: Fifth Generation Perspective, Journal of Management in Engineering. 31 (2015) 04015012. [CrossRef]

- C. Merschbrock, B.E. Munkvold, Effective digital collaboration in the construction industry - A case study of BIM deployment in a hospital construction project, Comput Ind. 73 (2015) 1–7. [CrossRef]

- T. Dounas, D. Lombardi, W. Jabi, Framework for decentralised architectural design BIM and Blockchain integration, International Journal of Architectural Computing. 19 (2021) 157–173. [CrossRef]

- F. Bianconi, M. Filippucci, A. Buffi, Automated design and modeling for mass-customized housing. A web-based design space catalog for timber structures, Autom Constr. 103 (2019) 13–25. [CrossRef]

- S. Perera, S. Nanayakkara, M.N.N. Rodrigo, S. Senaratne, R. Weinand, Blockchain Technology: Is it Hype or Real in the Construction Industry?, J Ind Inf Integr. (2020) 100125. [CrossRef]

- Q. Meng, Y. Zhang, Z. Li, W. Shi, J. Wang, Y. Sun, L. Xu, X. Wang, A review of integrated applications of BIM and related technologies in whole building life cycle, Engineering, Construction and Architectural Management. 27 (2020) 1647–1677. [CrossRef]

- Z. Ma, J. Ma, Formulating the application functional requirements of a BIM-based collaboration platform to support IPD projects, KSCE Journal of Civil Engineering. 21 (2017) 2011–2026. [CrossRef]

- S.M. Hassan, M. Azab, A. Mokhtar, Smart concrete transportation in semi-automated construction sites, 2019 IEEE 10th Annual Information Technology, Electronics and Mobile Communication Conference, IEMCON 2019. (2019) 661–667. [CrossRef]

- T. Feucht, J. Lange, M. Erven, C.B. Costanzi, U. Knaack, B. Waldschmitt, Additive manufacturing by means of parametric robot programming, Construction Robotics. 4 (2020) 31–48. [CrossRef]

- P. Martinez, M. Al-Hussein, R. Ahmad, Intelligent vision-based online inspection system of screw-fastening operations in light-gauge steel frame manufacturing, International Journal of Advanced Manufacturing Technology. 109 (2020) 645–657. [CrossRef]

- M.B. Jensen, I.W. Foged, H.J. Andersen, A framework for interactive human–robot design exploration, International Journal of Architectural Computing. 18 (2020) 235–253. [CrossRef]

- R. Dai, E. Kerber, F. Reuter, S. Stumm, S. Brell-Cokcan, The digitization of the automated steel construction through the application of microcontrollers and MQTT, Construction Robotics. 4 (2020) 251–259. [CrossRef]

- C.P. Schimanski, G.P. Monizza, C. Marcher, D.T. Matt, Pushing digital automation of configure-to-order services in small and medium enterprises of the construction equipment industry: A design science research approach, Applied Sciences (Switzerland). 9 (2019) 1–22. [CrossRef]

- S. Moon, N. Ham, S. Kim, L. Hou, J.H. Kim, J.J. Kim, Fourth industrialization-oriented offsite construction: case study of an application to an irregular commercial building, Engineering, Construction and Architectural Management. 27 (2020) 2271–2286. [CrossRef]

- M. Ramsgaard Thomsen, P. Nicholas, M. Tamke, S. Gatz, Y. Sinke, G. Rossi, Towards machine learning for architectural fabrication in the age of industry 4.0, International Journal of Architectural Computing. 18 (2020) 335–352. [CrossRef]

- R. Bogue, What are the prospects for robots in the construction industry?, Industrial Robot. 45 (2018) 1–6. [CrossRef]

- J. Siwiec, Comparison of Airborne Laser Scanning of Low and High Above Ground Level for Selected Infrastructure Objects, Journal of Applied Engineering Sciences. 8 (2019) 89–96. [CrossRef]

- B. Chan, H. Guan, L. Hou, J. Jo, M. Blumenstein, J. Wang, Defining a conceptual framework for the integration of modelling and advanced imaging for improving the reliability and efficiency of bridge assessments, J Civ Struct Health Monit. 6 (2016) 703–714. [CrossRef]

- Z. Zhou, J. Irizarry, Y. Lu, A Multidimensional Framework for Unmanned Aerial System Applications in Construction Project Management, Journal of Management in Engineering. 34 (2018). [CrossRef]

- D. Heesom, P. Boden, A. Hatfield, A. de Los Santos Melo, F. Czarska-Chukwurah, Implementing a HBIM approach to manage the translocation of heritage buildings, Engineering, Construction and Architectural Management. (2020). [CrossRef]

- D. Reinhardt, M.H. Haeusler, K. London, L. Loke, Y. Feng, E. de Oliveira Barata, C. Firth, K. Dunn, N. Khean, A. Fabbri, D. Wozniak-O’Connor, R. Masuda, CoBuilt 4.0: Investigating the potential of collaborative robotics for subject matter experts, International Journal of Architectural Computing. 18 (2020) 353–370. [CrossRef]

- S. Sun, X. Zheng, J. Villalba-Díez, J. Ordieres-Meré, Data handling in industry 4.0: Interoperability based on distributed ledger technology, Sensors (Switzerland). 20 (2020) 1–22. [CrossRef]

- Tezel, E. Papadonikolaki, I. Yitmen, P. Hilletofth, Preparing construction supply chains for blockchain technology: An investigation of its potential and future directions, Frontiers of Engineering Management. 7 (2020) 547–563. [CrossRef]

- F. Elghaish, S. Abrishami, M.R. Hosseini, Integrated project delivery with blockchain: An automated financial system, Autom Constr. 114 (2020) 103182. [CrossRef]

- M. Hilal, T. Maqsood, A. Abdekhodaee, A hybrid conceptual model for BIM in FM, Construction Innovation. 19 (2019) 531–549. [CrossRef]

- W. Gao, Q. Su, J. Zhang, H. Xie, F. Wen, F. Li, J. Liu, Steel Bridge Construction of Hong Kong–Zhuhai–Macao Bridge, International Journal of Steel Structures. 20 (2020) 1498–1508. [CrossRef]

- D.W.M. Chan, T.O. Olawumi, A.M.L. Ho, Critical success factors for building information modelling (BIM) implementation in Hong Kong, Engineering, Construction and Architectural Management. 26 (2019) 1838–1854. [CrossRef]

- Marefat, H. Toosi, R. Mahmoudi Hasankhanlo, A BIM approach for construction safety: applications, barriers and solutions, Engineering, Construction and Architectural Management. 26 (2019) 1855–1877. [CrossRef]

- Banawi, Barriers to Implement Building Information Modeling (BIM) in Public Projects in Saudi Arabia, in: Advances in Intelligent Systems and Computing, 2018: pp. 119–125. [CrossRef]

- E. v. Suprun, R.A. Stewart, Construction innovation diffusion in the Russian Federation barriers, drivers and coping strategies, Construction Innovation. 15 (2015) 278–312. [CrossRef]

- M.A. Silverio-Fernandez, S. Renukappa, S. Suresh, Evaluating critical success factors for implementing smart devices in the construction industry: An empirical study in the Dominican Republic, Engineering, Construction and Architectural Management. 26 (2019) 1625–1640. [CrossRef]

- S. v. Ramani, A. Thutupalli, E. Urias, High-value hi-tech product introduction in emerging countries: The role and construction of legitimacy, Qualitative Market Research. 20 (2017) 208–225. [CrossRef]

- F. Bechhofer, L. Peterson, To interview or not to interview, in: Principles of Research Design in the Social Sciences, 1st ed., Routledge, 2012: p. 192.

- J.F. Hair, W.C. Black, B.J. Babin, R.E. Anderson, R.L. Tatham, Análisemultivariada de dados, 6th ed., 2009.

- A.G. Frank, M.N. Cortimiglia, J.L.D. Ribeiro, L.S. de Oliveira, The effect of innovation activities on innovation outputs in the Brazilian industry: Market-orientation vs. technology-acquisition strategies, Res Policy. 45 (2016) 577–592.

| Cluster | Concept/technology |

|---|---|

| Data intelligence | Cloud computing Big data Product lifecycle management |

| Robotics and automation | Robots/drones Automation |

| Virtual environments | Building information modeling Simulation/modeling Virtual and augmented reality |

| Smart technologies and objects | Internet of Things Mobile devices Embedded sensors/cyber-physical systems Digitization |

| Advanced manufacturing | Additive manufacturing Prefabrication and modularization |

| Technology | Applications |

|---|---|

| Cloud computing | A large amount of data can be stored and accessed from the cloud, facilitating information sharing between design team members and assisting in the development of designs collaboratively and simultaneously between individuals in different geographical locations. |

| Big data | Assists in the collection and selection of relevant information from the universe of available data. Has the potential to simplify database searches and assist in choosing between different alternatives of engineering designs and evaluating parameters, such as cost and energy efficiency, for each design alternative in a rapid and automated way. |

| Product lifecycle management | Data collected and stored are used to integrate and manage product information from the design to the manufacture and use phases until the end of a product’s useful life. |

| Robots and drones | Has the potential to replace human labor in everyday tasks. Drones can capture aerial images that enable and facilitate services such as construction and asset management, inspection, and maintenance. |

| Automation | Potential applications encompass several areas, such as quality monitoring of concrete trucks, soil compaction, parameter control during concreting, design automation, and building monitoring in the use phase. |

| Building information modeling | Tool for centralization of the information generated and accumulated at each stage of the construction process. |

| Simulation and modeling | Modeling and simulation of reality to foresee behaviors and characteristics of the final product and production stages. Can be used for simulation of construction processes, conflict identification, resource allocation, assessment of energy efficiency and flows of people, among others. |

| Virtual reality and augmented reality | Virtual environments that mimic reality and allow interaction and visualization of situations in real dimensions. |

| Internet of Things, sensors, and cyber-physical systems | Common physical systems equipped with sensors and devices that interact and exchange information among themselves and/or with an operator. Can be used to automate processes, control inventory, machinery, and human resources, track material transportation, and monitor the behavior of existing buildings and their facilities. |

| Mobile devices | Use of smartphones, tablets, and applications as tools to support communication and collaboration throughout the production cycle. |

| 3D printing | Printing of objects in three dimensions, comprising either entire buildings or individual parts for subsequent assemblage. |

| Prefabrication and modularization | Construction industrialization, mass production, and off-site parts production for later installation at the final destination. |

| Product benefits | Operational benefits | Side benefits |

|---|---|---|

| Improved final product quality [27,28,29,30,31,32,33,34,35,36,37] Reduced release time [34,38,39,40,41] Preventive maintenance support [31,42,43,44,45] |

Increased productivity [31,39,43,44] Reduced rework [32] Reduced cost [33,41,43,45,46] Improved communication and information exchange [27,28,32,47,48,49,50] Reduction of repetitive work [29,32,39,40,46] Reduction of manual labor and physical exertion [36,37,39,44,45,46,51] |

New business opportunities [28,31,43] Labor reallocation [38,39] Increased employee safety [31,41,46] |

| Reduced rework [32] |

| Variable | Description | Absolute frequency | Relative frequency |

|---|---|---|---|

| Academic degree | Architecture/Urban Planning | 12 | 12% |

| Civil Engineering | 88 | 85% | |

| Other | 4 | 4% | |

| Level of education | Doctoral degree | 5 | 5% |

| Undergraduate degree | 32 | 31% | |

| Master’s degree | 26 | 25% | |

| Specialization (postgraduate degree lato sensu) | 41 | 39% | |

| Field of expertise | Academic research/teaching | 7 | 7% |

| Project management | 33 | 32% | |

| Budget/planning | 22 | 21% | |

| Supervision | 14 | 13% | |

| Construction | 20 | 19% | |

| Technical evaluation | 2 | 2% | |

| Other | 6 | 6% | |

| Professional experience | 1 to 3 years | 28 | 27% |

| 4 to 6 years | 21 | 20% | |

| 7 to 10 years | 15 | 14% | |

| 11 to 15 years | 11 | 11% | |

| 16 to 20 years | 5 | 5% | |

| More than 20 years | 24 | 23% | |

| Sector | Private | 77 | 74% |

| Public | 27 | 26% |

| Response | Company size | |||

|---|---|---|---|---|

| Micro | Small | Medium | Large | |

| I have never heard about this topic | 11% | 11% | 0% | 19% |

| I have heard these terms but have no knowledge about the topic | 50% | 28% | 33% | 45% |

| I have heard these terms and I have some knowledge about the topic | 37% | 56% | 67% | 24% |

| I have heard these terms and I have advanced knowledge about the topic | 3% | 6% | 0% | 12% |

| Total number of responses | 38 | 18 | 6 | 42 |

| Technology | High use | Moderate use | Low use | F-value | |||

|---|---|---|---|---|---|---|---|

| Mean | SD | Mean | SD | Mean | SD | ||

| Mobile devices | 4.19 | 0.75 | 4.02 | 1.06 | 2.35 | 1.30 | 30.64*** |

| Cloud computing | 3.96 | 0.96 | 4.39 | 0.83 | 2.49 | 1.39 | 31.52*** |

| Simulation and modeling | 3.96 | 1.00 | 3.56 | 1.21 | 1.54 | 1.07 | 46.91*** |

| Building information modeling | 3.92 | 0.80 | 3.27 | 1.18 | 1.59 | 0.64 | 55.50*** |

| Virtual and augmented reality | 3.35 | 1.06 | 2.02 | 0.91 | 1.22 | 0.53 | 49.27*** |

| Product lifecycle management | 3.27 | 1.34 | 2.32 | 1.06 | 1.27 | 0.65 | 29.85*** |

| Automation | 3.15 | 0.73 | 2.24 | 1.20 | 1.16 | 0.50 | 39.31*** |

| Robots and drones | 3.04 | 1.04 | 1.85 | 1.01 | 1.41 | 0.76 | 23.82*** |

| Big data | 2.73 | 1.15 | 2.20 | 1.03 | 1.19 | 0.62 | 22.46*** |

| IoT, sensors, and CPS | 3.31 | 1.05 | 1.85 | 0.96 | 1.08 | 0.28 | 57.11*** |

| Prefabrication/modularization | 3.42 | 1.03 | 1.68 | 0.96 | 1.86 | 1.32 | 21.71*** |

| 3D printing | 2.65 | 1.02 | 1.24 | 0.54 | 1.05 | 0.23 | 57.22*** |

| % of respondents in each group | 25% | 39% | 36% | ||||

| Large and medium companies | 42% | 44% | 51% | ||||

| Micro and small companies | 58% | 56% | 49% | ||||

| Technology | Factor | Commonality | ||

|---|---|---|---|---|

| Virtualization | Automation | Manufacture | ||

| Cloud computing | 0.629 | 0.475 | −0.361 | 0.751 |

| Big data | 0.143 | 0.756 | 0.243 | 0.651 |

| PLM | 0.312 | 0.543 | 0.402 | 0.554 |

| Robots and drones | 0.053 | 0.721 | 0.217 | 0.570 |

| Automation | 0.383 | 0.608 | 0.199 | 0.556 |

| BIM | 0.861 | 0.137 | 0.234 | 0.815 |

| Simulation and modeling | 0.843 | 0.114 | 0.221 | 0.772 |

| VR and AR | 0.642 | 0.210 | 0.491 | 0.697 |

| IoT, sensors, CPS | 0.492 | 0.446 | 0.354 | 0.566 |

| Mobile devices | 0.540 | 0.489 | −0.117 | 0.544 |

| 3D printing | 0.205 | 0.279 | 0.686 | 0.591 |

| Prefabrication and modularization | 0.065 | 0.173 | 0.761 | 0.613 |

| Eigenvalue | 5.29 | 1.37 | 1.02 | |

| Cumulative variance (%) | 44.09 | 55.52 | 64.00 | |

| Cronbach’s alpha | 0.76 | 0.86 | 0.54 | |

| Factor | Virtualization | Automation | Manufacture | IoT | ||||

|---|---|---|---|---|---|---|---|---|

| Area | 0.075 | 0.072 | 0.285*** | 0.302* | 0.088 | 0.050 | 0.109 | 0.119 |

| Experience | −0.104** | −0.092** | −0.046 | −0.061* | −0.044 | −0.037 | −0.004 | −0.012 |

| Knowledge | 0.138 | 0.109 | 0.152* | 0.113 | 0.056 | 0.061 | −0.050 | −0.091 |

| Maturity | 0.538*** | 0.392*** | 0.283*** | 0.440*** | ||||

| Size | −0.151*** | −0.070 | 0.037 | −0.099 | ||||

| F-value | 2.711** | 8.518*** | 4.069*** | 5.919*** | 0.659 | 2.142* | 0.328 | 2.547** |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).