1. Introduction

In contemporary Chinese cities, rapid population growth and urbanization, the continuous expansion of commercial and industrial centers, has led to a sharp increase in car ownership, and the problem of traffic congestion has spread from big cities to smaller and medium-sized ones, making urban transportation a hot topic of widespread concern at all levels of society. Therefore, cycling, as an environmentally friendly, economical and healthy way to relieve traffic congestion, has gradually become the first choice for people to travel. In Kunming, for example, between 2006 and 2012, electric bicycles effectively replaced many urban car trips [

1]. According to statistics, the proportion of cycling trips has increased from about 5% a few years ago to more than 10%, and continues to grow, and it is expected to continue to grow in the future [

2]. According to the annual data of domestic road traffic accidents from 2019 to 2022 released by the National Bureau of Statistics (

Table 1) [

3], the total number of bicycle and motorcycle traffic accidents increased from 19.3% in 2019 to 20.2% in 2022. This increasing trend has aroused people's concerns about bicycle and motorcycle safety, and the traffic safety of cyclists has become an important issue of social concern. Every year, tens of thousands of vehicle collisions worldwide result in the death of a large number of two-wheeler cyclists, while causing huge economic losses [

4]. In automobile-two-wheeler crashes, head injuries are the most common type of injury that causes fatalities and serious injuries among cyclists [

5,

6,

7]. Studies have shown that wearing a helmet can effectively reduce head injuries suffered by cyclists in traffic accidents [

8,

9,

10]. An analysis of the clinical features of 15,345 patients with traumatic brain injury (TBI) across 35 hospitals in Henan Province [

11], the proportion of injuries caused by riding electric bicycles was 25.5% (2481/9731), which has become one of the main causes of traffic accidents. In addition, it has been reported that about 55% of cycling deaths are due to head injuries [

12]. For cyclists, helmets are their only protection against injuries such as TBI [

13,

14,

15,

16]. Jiangsu Province was the first to formally implement the "Regulations on the Administration of Electric Bicycles in Jiangsu Province" [

17]. In the following years, similar laws were also implemented in various provinces and cities [

18,

19,

20,

21]. Studies have shown that mandatory helmet-wearing legislation has been associated with a substantial decrease in the number of e-bike roadway fatalities, with a year-on-year reduction in fatalities of 2.21% [

22].

Common life protective helmets are mainly composed of four parts: shell parts, adjusting devices, hard lining parts, and soft lining parts [

23], where the hard lining parts and soft lining parts are collectively referred to as pads. In these components, the pad absorbs energy through viscoelastic compression to relieve acceleration to the head [

24], thereby reducing the risk of head injury to the rider [

25]. The majority of cushions are typically composed of synthetic cellular materials like expanded polypropylene (EPP) and expanded polystyrene (EPS), and the density of the cushion material is often adjusted to achieve the best energy absorption effect [

26]. In recent years, scholars at home and abroad have devoted themselves to studying the head protection, heat dissipation and shock absorption performance of various advanced materials and innovative structures implanted in helmets, starting with the application of helmet padding materials and structures. This article reviews the most current designs of existing helmet liner materials, structures, and biomimetic structures and their protective properties, with a particular focus on the application of bio-inspired structures and materials for energy absorption in protective helmets. The paper will look at the innovativeness, practicability, and feasibility of the various design options, and based on this, it will provide an outlook on the possible challenges, limitations, and future directions for the field in the present time.

2. The Development of Helmet Liners

Helmets have long been employed as a main type of protection, covering the head from weapons and any kind of penetration [

27]. Simultaneously, helmet liner is a kind of soft padding located inside the helmet, and in ancient times, warriors usually added some soft materials such as leather, fabric, and grass as helmet liners inside the helmet. Hard leather, brass, or iron were the most common materials used to make ancient war helmets. The ancient Greeks' bronze helmets are notable examples (

Figure 1) [

28]. Although these bronze helmets were able to defend against direct attacks such as swords and arrows, they had to be improved due to the poor energy absorption and weight of the bronze material. With the advent of the Middle Ages, warfare technology advanced, and the helmet design became more complex. The helmet liner has been improved accordingly, with thicker fabrics, padding or cotton, etc., to provide better protection and reduce pressure on the helmet, as well as to enhance the comfort of wearing the helmet. With the development of metallurgical technology, helmet materials have gradually evolved from metal products to more advanced materials, such as steel and alloys. With the development of metallurgical technology, helmet materials have gradually evolved from metal products to more advanced materials, such as steel and alloys. In the 1940s, military and civilian helmets were commonly built of a robust steel casing with a plastic and cotton fiber interior. During World War II, the US Armed Forces used the M1 steel helmet in both European and Pacific theaters (

Figure 2) [

28]. The gasket material was made of high-elastic rubber material, and the whole helmet was relatively lightweight, allowing the wearer to move more flexibly, reducing the burden on the head and neck, and improving the survivability and mobility of soldiers in combat. With changes in the form of warfare, the combat environment, and the development of new materials, the U.S. military has designed advanced combat helmets (ACH). The inner surface of the ACH is regularly arranged with a set of discrete foam pads [

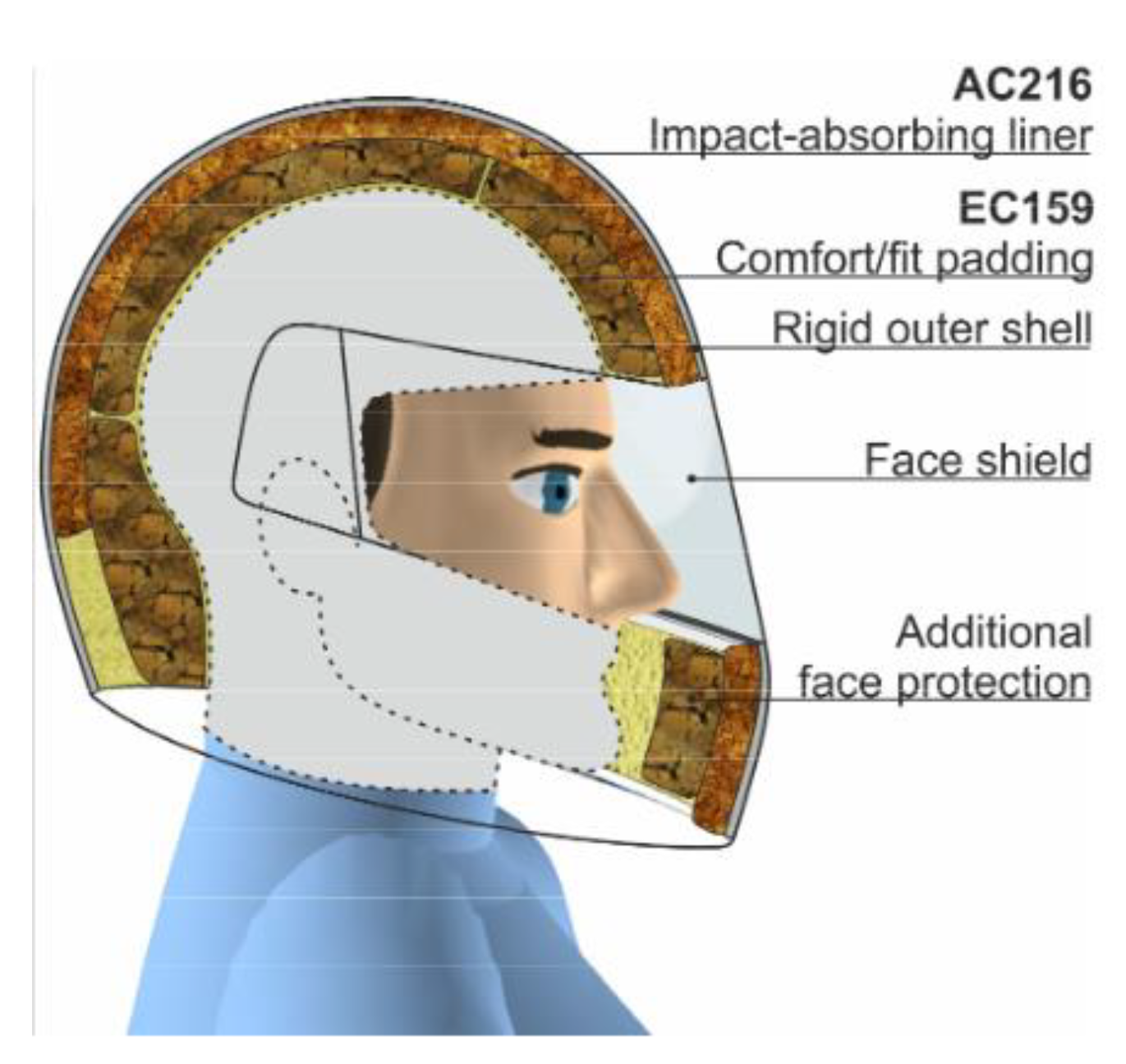

29], which helps to improve the energy absorption performance of the helmet and reduce the force from external shocks, thereby improving the overall level of helmet protection. The geometry of the ACH helmet is depicted in

Figure 3 [

29].

Helmet padding has evolved from ancient leather, fabric, and other soft materials to modern foam plastics, rubber, and other new materials. While continuously improving the helmet's energy absorption, comfort, and adaptability, it has also significantly improved the helmet's protective performance, greatly reducing the risk of fatal head injuries.

2. The Main Materials of Helmet Padding

2.1. Head Protection Performance

When a pedestrian is engaged in a traffic collision, a shock to the head can produce multiple forms of brain damage, which can be separated into focal and diffuse brain injuries based on their clinical symptoms [

30]. Focal brain injury is due to linear acceleration of the head, while diffuse brain injury is mainly related to rotational acceleration. As a result, it is critical to lessen the linear and rotational acceleration that the head experiences.

Mosleh et al. [

31] suggested an anisotropic EPS composite foam concept to reduce head rotational acceleration, hence minimizing the risk of brain injury. Experimental studies have shown that the concept of polystyrene composite foam has great application potential in applications such as protective helmets. Vanden Bosche et al. [

32] investigated the usage of anisotropic polyethersulfone foam (

Figure 4) [

32] in bicycle helmet liners. The results show that the peak rotational acceleration of polyethersulfone (PES) foam helmets is about 40% lower than that of EPS foam helmets, and PES foam has the potential to replace EPS liners. Ramirez et al. [

33] fabricated spray polyuria elastomer (SPUA) foams with densities of 98kg/m3, 170kg/m3, and 230kg/m3 and integrated them into helmet liners for FMVSS motorcycle helmet testing. The results showed that the use of additional SPUA foam liners on top of existing EPS foam liners successfully reduced peak acceleration by 17%. In the field of equestrian helmets, Cui et al. [

34,

35] found that the decrease in peak acceleration depends on the contact area, the stress distribution along the cushion thickness, and dissipative plastic energy density (DPED). To lower peak linear acceleration, functional gradient foam (FGF) cushions should be utilized instead of discrete foam layers. To achieve the results of reducing both rotational and linear accelerations, Maheswaran et al. [

36] investigated quasi-static compressive shear response of freestanding vertically oriented carbon nanotubes (VAVNT) foams under different initial precompression conditions. The results demonstrate that VAVNT can tolerate substantial shear strain at a low shear stress level under an enormous compressive shear load. This indicates that VAVNT foam can minimize linear acceleration and rotational acceleration by absorbing normal impact. In motorcycle helmet liner materials, Shuaeib et al. [

37] confirmed that EPP foam is widely used due to its multi-impact protection properties and the potential to improve ventilation systems. However, EPP foam is still deficient in head protection due to its material characteristics. In quasi-static compression and shear testing on three VN foams, Bailly et al. [

38] discovered that vinyl nitrile foam helmet liners were thought to minimize head rotation acceleration more than EPP foam helmet liners. Chang et al. [

39] investigated the influence of filler materials (type and density) on the protective performance of the head and found that ethylene vinyl acetate copolymer (EVA) foam outperformed EPP foam.

2.2. Cushioning Performance

The helmet liner is an important component of shock absorption and comfort in the overall helmet design. Wu et al. [

40,

41] added polyethylene (PE) foam padding to industrial and construction helmets, and the results showed that helmets with PE foam padding can greatly improve the shock absorption performance against large impacts. On the one hand, cushioning materials have an impact on shock absorption and cushioning. Mosleh et al. [

31], Kroeker et al. [

42], Huang et al. [

43] and Drane et al. [

44] all confirmed that selecting the right material density or material thickness can significantly improve energy absorption performance. On the other hand, cork is a naturally porous, non-renewable material that is highly resistant to crashes, and due to its viscoelastic behavior, it has good resilience after compression, which is an ideal property in multi-impact applications [

45]. Buil et al. [

46] used cork and its derivatives instead of traditional EPS liners. However, to solve the non-renewable problem of cork materials, Fernandes et al. [

45] further investigated whether there were materials that could be synthesized into cork, and finally found that agglomerated cork liners were excellent materials for synthesizing cork liners. Black cork has excellent thermal stability, while agglomerated cork can absorb high energy. Kaczyński et al. [

47] discovered that merging two cork materials (agglomerated and black) into a cork composite sandwich structure combines their advantages, but also has good cushioning properties. It has also been used in electric helmets (

Figure 5) [

47].

2.3. Heat Dissipation Performance

In recent years, studies have found that the effectiveness of heat dissipation directly affects the comfort of wearing a helmet. In an inventive move to regulate the interior temperature of a motorcycle helmet, Sinnappoo et al. [

48] introduced a paraffin phase change material (PCM) cloth to the interlayer between the scalp and the helmet liner. Textile materials have a positive impact on helmet heat dissipation, as studies have demonstrated that employing PCM materials as textile liners may lower the temperature within the helmet by 3.8 degrees Celsius. Bhinder et al. [

49] The carbon nanotube (CNT) nano-filler was incorporated into polyurethane (PU) foam. After experimental comparison, the combination of CNT-reinforced polyurethane foam has better heat dissipation performance than the EPS foam currently used. This combination is expected to become a more suitable replacement for helmet liners. Kim et al. [

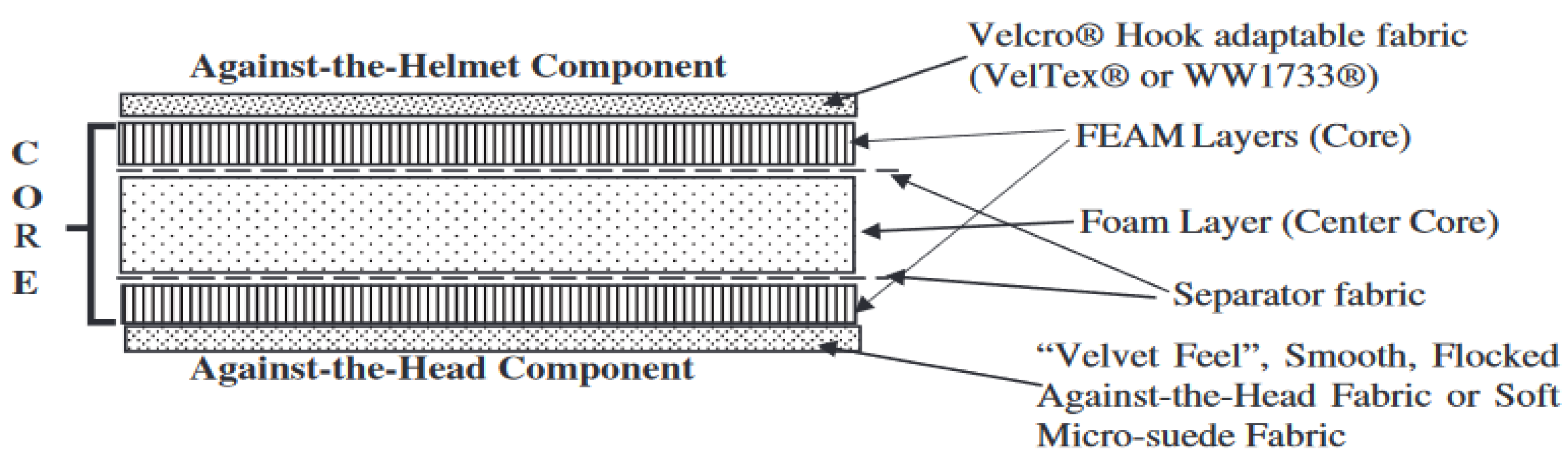

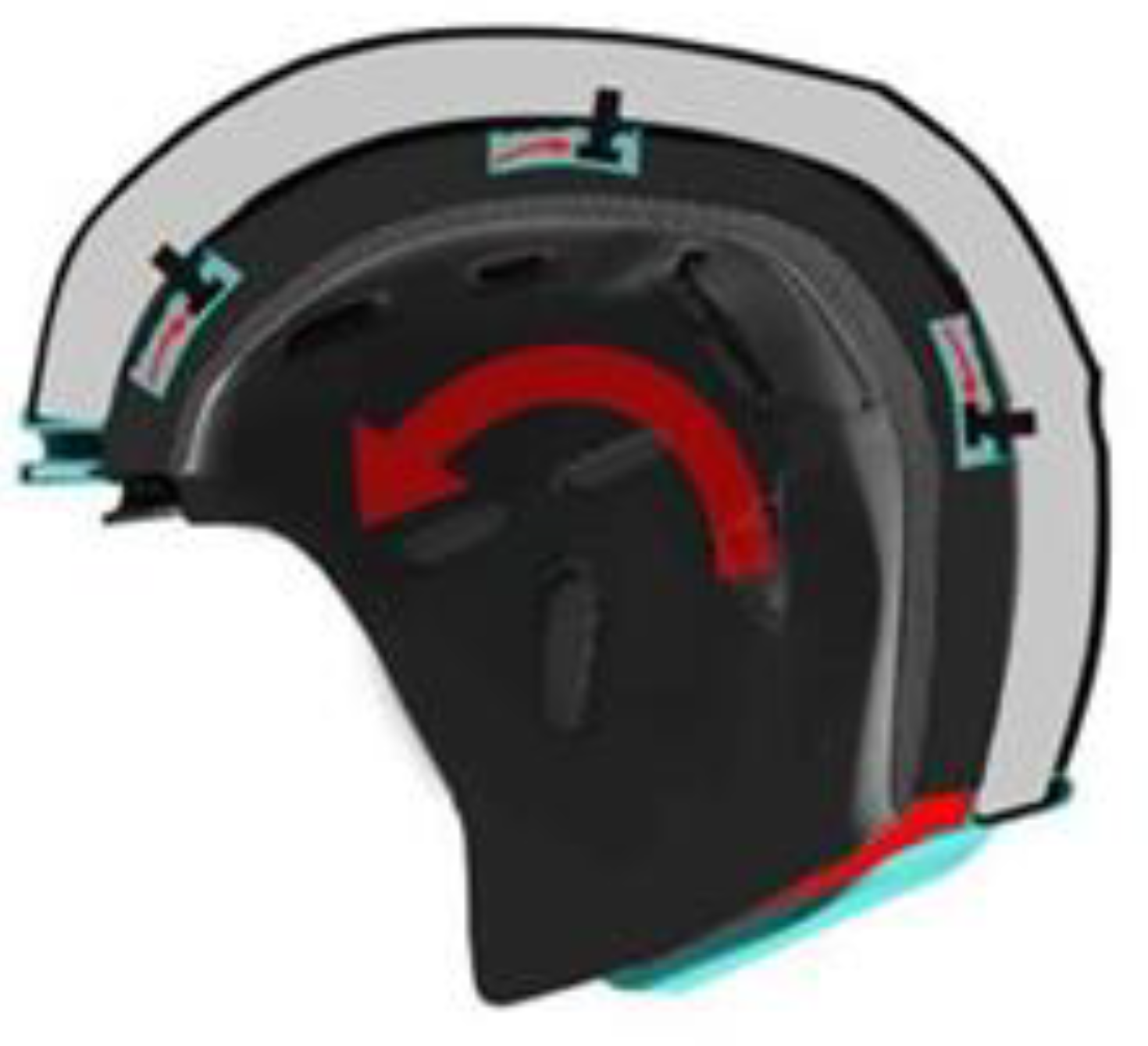

50] designed a combination of foam and flocking energy-absorbing material (FEAM) layer elements (

Figure 6) [

50], which has been shown to combine the advantages of foam materials (light weight) with FEAM's excellent impact absorption characteristics, breathability, comfort, perspiration, and heat management. Many studies have started with the heat dissipation properties of materials, but few scholars have studied active cooling methods. Consequently, Jain et al. [

51] presented a passive cooling technique based on a multifunctional liner made of eicosane and evenly dispersed graphene oxide nanosheets, as well as a composite thermal liner. Studies have shown that the pad has good thermal management properties and can be used to develop lightweight heat-dissipating helmets.

3. The Main Structure of the Helmet Liner

3.1. Honeycomb Structure

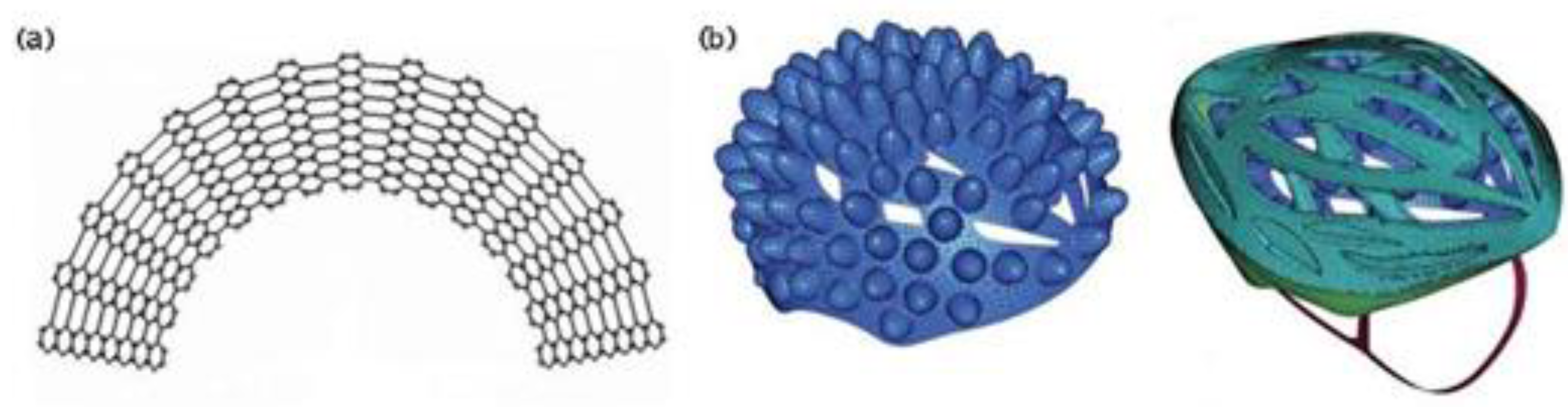

In recent years, research has focused on exploring new helmet liner structures, and honeycomb structures have become a hot research topic due to their stress structures consisting of many hexagonal or hexagonal-like small units. In [

52], Kholoosi et al. presented a hierarchical honeycomb structure design (

Figure 7a) [

52]. The honeycomb structure was designed as an EPP foam with a thickness of 5.9 mm and covered with ABS (a terpolymer of acrylonitrile, butadiene, and styrene monomers) plastic layer as an energy absorber for the helmet. In contrast to EPS foam, the honeycomb structure exhibits a longer energy absorption period and reduced acceleration of impact force transmission to the user, according to the data. What result would the combination of the two produce? In order to further increase the energy dissipation characteristics and hence raise the safety of head injuries, Bhudolia et al. [

53] suggest a novel way for creating hybrid EPS/honeycomb structural foams utilizing an integrated manufacturing process. As a consequence of the accompanying foam densification and the honeycomb's elastic buckling properties, the integrated EPS honeycomb hybrid lining's energy absorption capacity has been demonstrated to improve by 20%, according to the findings of the Roadstone impact test. As a result, integrated manufacturing methods have gradually become the main design principle for researchers. The research of Li et al. [

54] is to optimize the configuration of honeycomb packing geometry and foam density of helmet linings to increase helmets' protective performance. In addition to the honeycomb structure, there are also conical structures studied by Teng et al. [

55] (

Figure 7b), Ingrole [

56], which discovered new tensile and inflated pillar structures, and spherical structures studied by Toboła et al. [

57], all of which have good research prospects.

3.2. Lattice Structure

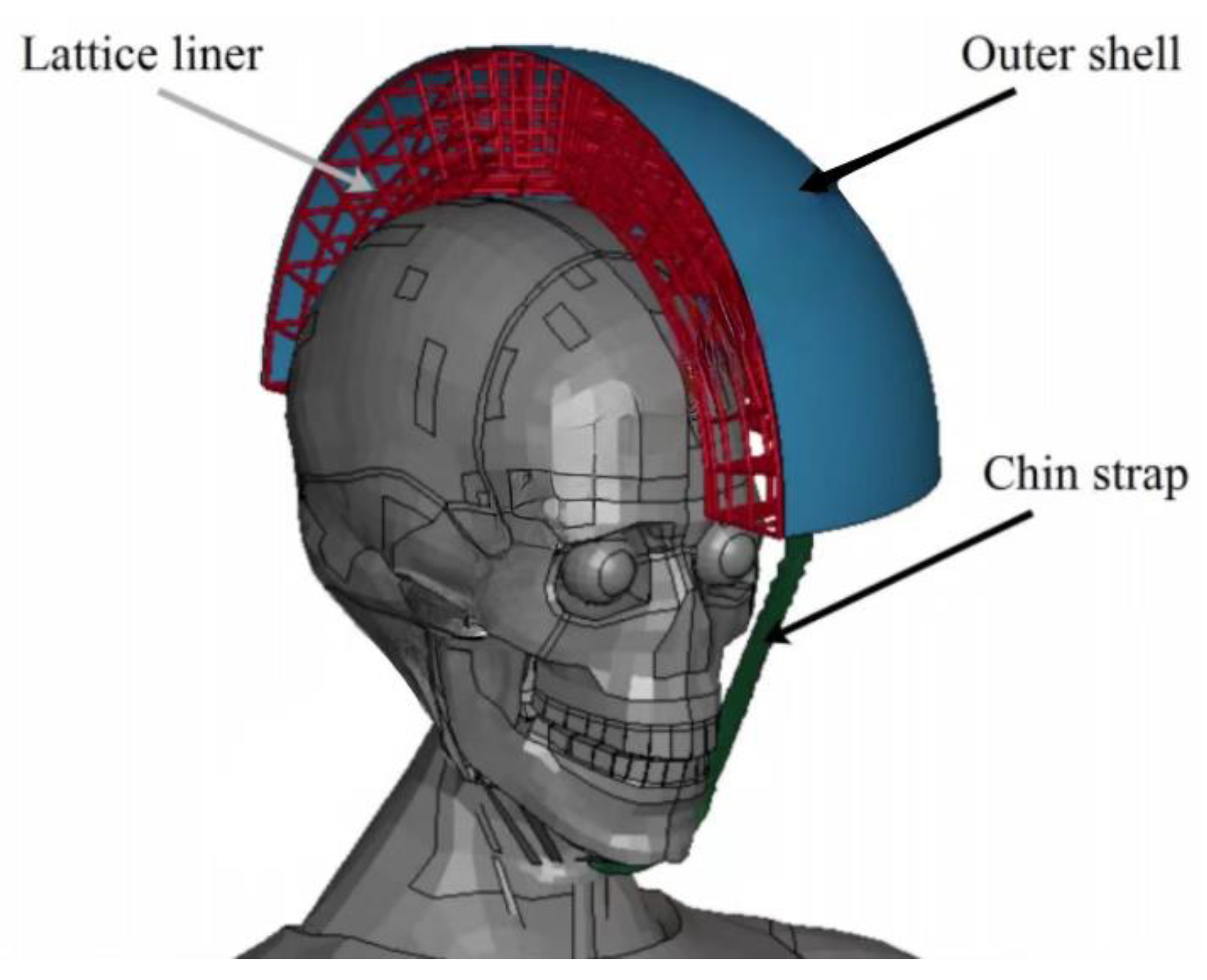

A lattice structure is a common design in helmet liners, which is formed by a series of cross-interwoven lines or grids, similar to the arranged structure of a crystal. The lattice structure can provide better stability and support, and it can effectively maintain the shape and structure of the helmet, preventing excessive deformation or damage when exposed to external pressure, thus protecting the wearer's head. Previously, to verify whether the lattice structure is suitable for helmet liners, Khosroshahi et al. [

58] evaluated the performance of the lattice liner topology (

Figure 8) [

58] as a helmet liner structure. The results showed that the prismatic lattice outperformed the tetrahedral lattice and EPS foam commonly used in helmets in preventing traumatic brain injury (TBI). On this basis, Khosroshahi et al. [

59] also studied the feasibility of using layered lattice pads for helmets. Studies have shown that helmets with layered lattice structure pads can be considered as a new generation of helmet energy-absorbing pads. On the other hand, as additive manufacturing becomes more efficient, traditionally fabricated structures can be replaced by 3D printing technologies with specific application characteristics. For example, Clough et al. [

60] used additive manufacturing technology to fabricate a honeycomb structure of a lattice-based impact attenuator. After several impact experiments, it was found that this structure can effectively reduce head acceleration.

3.3. Fillable Structure

When it comes to helmet liner structures, honeycomb structures, lattice structures, and cone structures are often mentioned, but Goel [

61] suggested a novel approach to helmet liner construction, namely the addition of materials that fill the passages inside the liner with either solid or liquid substances. Digital models and experiments have shown that the use of viscous fluids in the sandwich structure for drop testing can improve the impact attenuation effect of the helmet. On this basis, La Fauci et al [

62] proposed a shear thickening fluid based on boronated organosilicon to fill the chambers of the the liner’s impact energy dissipating pads to form a new type of helmet liner (

Figure 9) [

62], and the study's findings demonstrated that, in terms of impact energy attenuation, this method was the most efficient.

4. Bionic Structure

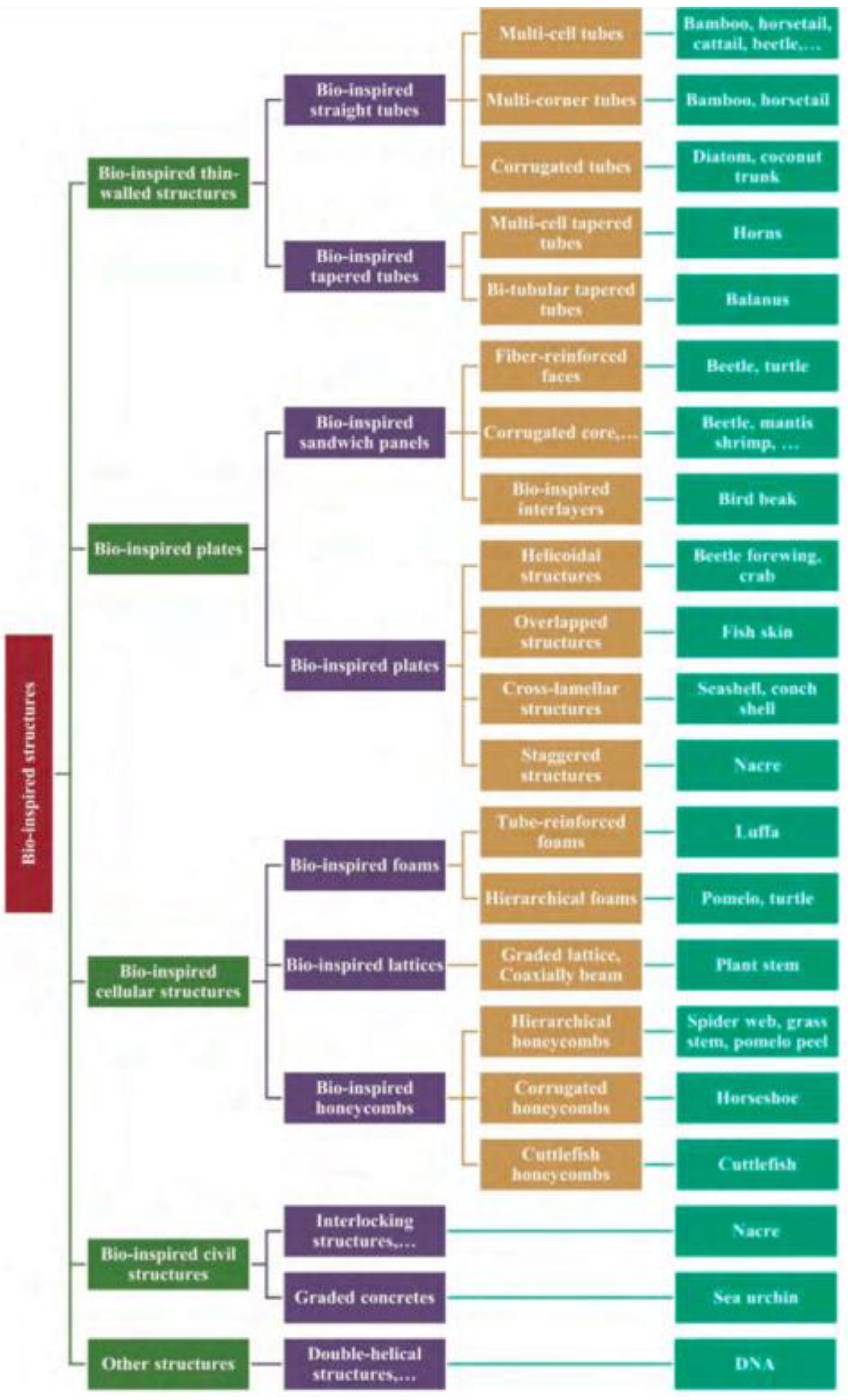

As a novel technology, biomimetic structures were not widely employed as energy-absorbing materials until about 2000, and the complexity of producing these structures hampered their promotion. Many bionic structures, inspired by biological models and advancements in fabrication processes, have been developed and demonstrated to be successful in energy absorption. Thus, throughout the past several years, bionic structures have been developed more and more rapidly. As seen in

Figure 10, San Ha and Lu [

63] compile a wide range of current bioenergy absorption structures and categorize them into several groups according to their form and use. In general, energy absorption in a variety of engineering domains has demonstrated the promise of biomimetic approaches.

Studies have shown that improving the protective performance of helmets, relevant cushion materials, and structures can be inspired by a wide range of organisms (such as macadamia nuts, grapefruit, and horseshoes) [

64,

65,

66,

67]. Wang et al. [

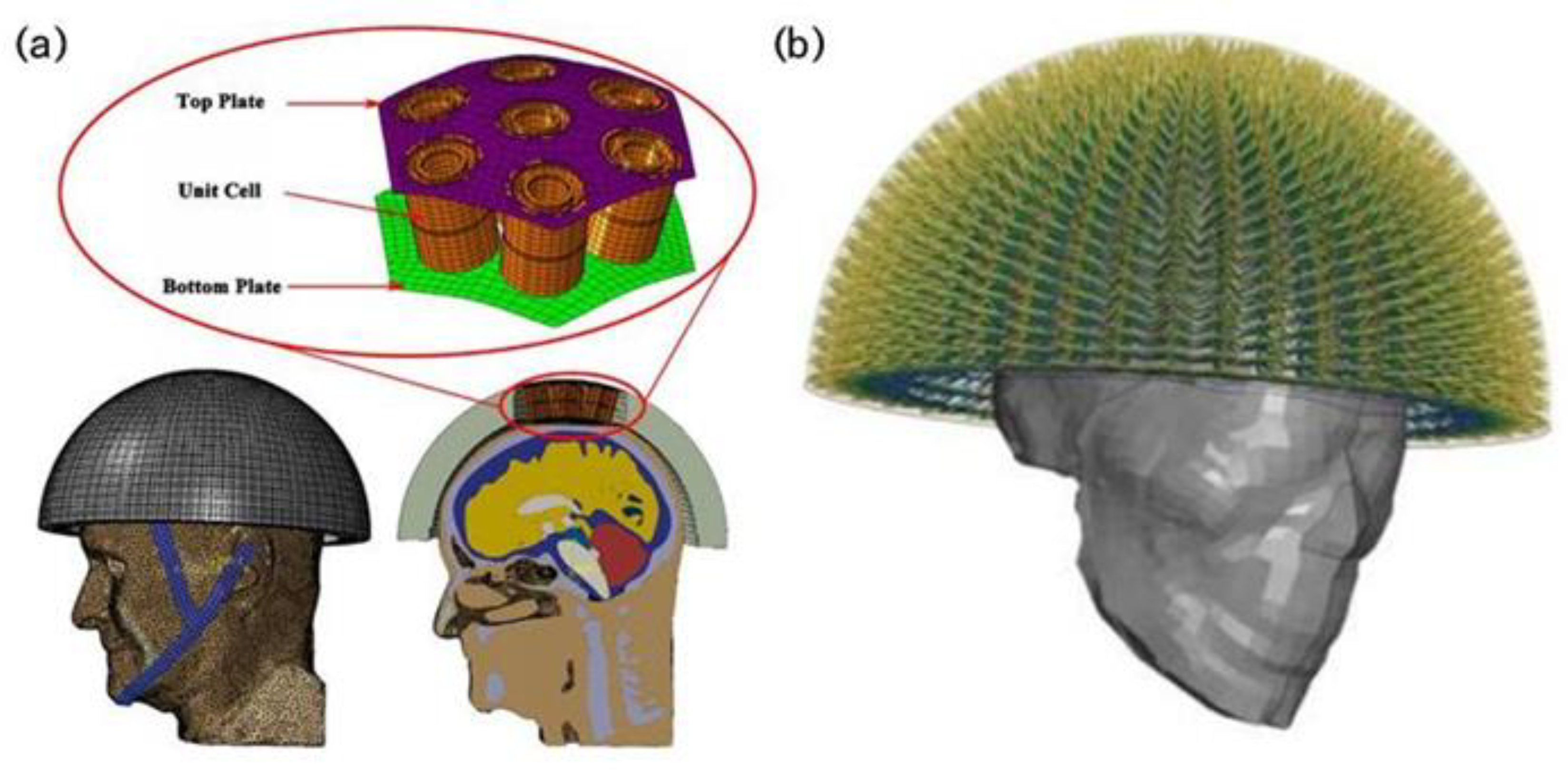

68] were inspired by this and discovered that the bovine hoof wall has a multilayer structure that can efficiently absorb the energy generated by crack propagation. They believe the novel bionic structure may be used in motorcycle helmets and sports' protective equipment. Leng et al. [

69] designed a helmet with a structure inspired by the characteristics of the ponytail and human spine. The research findings indicate that the ideal bionic ponytail structure (

Figure 11a) [

69] can lessen the kinetic energy brought on by rotational and linear accelerations, indicating the structure's possible use as a helmet liner. This finding also provides a means of exploring new bionic structures created by fusing animal bones and plant stalks. Chen et al. [

70] designed a hedgehog bionic helmet (

Figure 11b) [

70] with a hemispherical stretch mesh liner. According to the findings, stretch mesh-padded helmets performed better than unpadded or other padded designs, offering better protection. The findings of this study broaden the use of tensile materials and direct the creation of helmet liners that provide improved TBI relief.

In reference to the pyramid-shaped thorns on durian shells, Teng et al. [

55,

71] devised and created a hemispherical, pyramid-shaped hel-met liner out of ABS resin. When the top of the helmet is impacted by a free-falling body on a flat plate, its energy absorption is 13% higher than that of a helmet filled with EPS foam. Yang et al. [

72] created and prepared a two-way ripple sandwich structure based on the two-way ripple characteristics of the mantis shrimp jaw foot. This structure can reduce stress concentration in the uniaxial out-of-plane compression test and has an energy absorption that is 118% higher than that of the conventional triangular ripple sandwich structure. Liu and Xu [

73] devised a two-way staggered rectangular truncated cone pad by incorporating the two-way corrugated configuration of the mantis shrimp jaw foot and the pyramid-shaped spine arrangement of the durian shell into the helmet pad. In this paper, the dynamic behavior of gaskets with various pyramidal element structures during impact compression is studied. The findings demonstrate that the bidirectional cell's design and the reduction of the outer wall's inclination angle both enhance the helmet's ability to absorb energy. Of the helmets tested, the bidirectional staggered rectangular optic cone helmet has the highest specific energy absorption, measuring 1.3 times greater than that of the honeycomb helmet and 2.7 times higher than that of the gradient lattice. This also gives us new ideas for the application of helmet liner structures for animal and fruit internal structure combinations.

4. Conclusion

This article provides an exhaustive overview of the evolution of helmet liners and recent structural advances. The liner's progression is succinctly delineated, with material R&D moving away from traditional EPS foam towards composite foam and polymer composites. Structure research, meanwhile, is evolving from the initial honeycomb geometry to additive manufacturing techniques. Adopting lattice, inflatable, or bionic structures, Jiang et al. [

74] have endorsed the substantial benefits of 3D printing in industrial design, advocating the implementation of intricate structures via this technology. One-time molding, minimizing processing time, ensures accurate transmission of design parameters. Bionic structures, a nascent technology in helmet liners, show promising research potential due to their superior energy absorption capabilities. This article encapsulates the current design status of helmet liners, highlights existing potential issues and challenges, and proposes novel perspectives on future research directions for helmet liner materials and structural applications.

Based on current domestic and international research, future helmet liner material and structure research can focus on the following three areas.

(1) Integrate the novel helmet liner with the existing helmet model and fabricate a prototype to further evaluate its performance enhancement, rather than simply simulate it in finite element simulation software.

(2) Biomimetic design concepts can be extended to the examination of composite plant stem and animal bone structures.

(3) Additive manufacturing enables the use of cellular structures with enhancement and adjustment properties, facilitating lossless energy absorption in pads, potentially paving the way for reusable helmets.

Author Contributions

Conceptualization, B.Y.; methodology, B.Y.; software, X.Z. and B.Y.; validation, B.Y.; investigation, X.Z.; data curation, X.Z.; writing—original draft preparation, X.Z.; writing—review and editing, X.Z.; visualization, J.W.; supervision, X.L.; project administration, R.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by the National Natural Science Foundation of China (Grant No. 12372079) and the Natural Science Foundation of Jiangsu Province, China (Grant No. BK20201470, BK20220687) and Fund of Nanjing Institute of Technology (Grant No. CKJB202205).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Cherry, C.R.; Yang, H.; Jones, L.R.; He, M. Dynamics of electric bike ownership and use in Kunming, China. Transport Policy. 2016, 45, 127–135. [Google Scholar] [CrossRef]

- Electric two-wheeler industry white paper. Available online: https://www2.deloitte.com/cn/zh/pages/con-sumer-business/articles/electric-two-wheelers-industry-w-hi-tepaper.html. (accessed on 08 April 2024).

- China Road Traffic Accident Statistics Annual Report. Available online: https://data.stats.gov.cn/easyquery.htm?cn=C01-&zb=A0S0D01&sj=2023. (accessed on 08 April 2024).

- World Health Organization. Global status report on road safety. Geneva: WHO Press, 2023.

- Meng, H.; Mao, Z.; Ma, H.; Wang, F.; Xiao, Z.; Li, G. Head injury risk analysis of two-wheeled bicycle riders with airbag helmet protection. Medical Biomechanics. 2022, 37, 460–466. [Google Scholar]

- Beck, B.; Stevenson, M.; Newstead, S.; Cameron, P.; Judson, R.; Edwards, E.R.; Buncknill, A.; Johnson, M.; Gabbe, B. Bicycling crash characteristics: An in-depth crash investigation study. Accident Analysis & Prevention. 2016, 96, 219–227. [Google Scholar]

- Bukova-Zideluna, A.; Villerusa, A.; Lama, A. An overview of injured bicyclists in traffic accidents: analysis of traffic accident database in Latvia for the period 2010—2014. 2016 IRCOBI Conference Proceedings--International Research Council on the Biomechanics of Injury. 2016, 1-7.

- Li, R.; Hu, G.; Powis, B. Research progress on the current situation and intervention measures of helmet wearing by cyclists and passengers. Injury Medicine (Electronic Edition). 2015, 4, 48–53. [Google Scholar]

- Zhang, D.; Zhong, W.; Peng, Q.; Wu, S.; Lu, X. The effect of safety helmets on road traffic injuries of electric vehicle drivers. Sichuan Medical Journal. 2023, 44, 1041–1044. [Google Scholar]

- Song, Y.; Ma, W.; Shen, J.; Shen, J. Analysis and research on the relationship between helmet wearing and injury among electric vehicle drivers. China Urban and Rural Enterprise Health. 2020, 35, 7–9. [Google Scholar]

- Zhou, S.; Fu, X.; Ma, J.; Meng, E.; Yang, Z. Clinical characteristics analysis of 15345 hospitalized patientswith traumatic brain injury in Henan Province. Chinese Journal of Neurosurgery. 2022, 38, 452–455. [Google Scholar]

- Navindra, P.; Emily, C.; Dorothy, Z.; Bert, L.; Dan, C. Nonuse of bicycle helmets and risk of fatal head injury: a proportional mortality, case-control study. Cmaj. 2012, 184, E921–E923. [Google Scholar]

- Khor, D.; Inaba, K.; Aiolfi, A.; Delapena, S.; Benjamin, E.; Matsushima, K.; Strumwasser, A.M.; Demetriades, D. The impact of helmet use on outcomes after a motorcycle crash. Injury. 2017, 48, 1093–1097. [Google Scholar] [CrossRef]

- Hering, A.M.; Derler, S. Motorcycle helmet drop tests using a Hybrid III dummy. In IRCOBI Conference. Montpellier, France, 2000, 307-20.

- HØYE, A. Bicycle helmets–To wear or not to wear? Accident Analysis and Prevention. 2018, 117, 85–97. [Google Scholar] [CrossRef]

- Zhang, K. The impact of the policy of wearing safety helmets while driving electric vehicles in Suzhou on road traffic injuries. (Doctoral dissertation, Suzhou University). 2023.

- Xu, J. Research on Traffic Safety Governance Issues and Countermeasures for Electric Bicycles-Based on the Implementation of the Jiangsu Province Electric Bicycle Management Regulations. Legal Expo. 2021, (01), 174–175. [Google Scholar]

- List of Regulations on the Management of Electric Bicycles in Some Provinces and Cities. China Bicycle. 2022, (04), 46–51.

- Regulations on the Administration of Electric Bicycles in Nanchang City. Nanchang Daily. 2023-12-28(008).

- Regulations on the Management of Electric Bicycles in Nanning. Nanning Daily. 2023-10-21(004).

- Regulations on the Administration of Electric Bicycles in Jinzhong City. Jinzhong Daily. 2023-04-10(003).

- Huo, X.; Yang, L. Using governance to protect people's rights and interests and enhance people's well-being. Hebei Daily. 2023-04-21(006).

- Sun, X. Research on personalized helmet design method based on head shape characteristics. Science and Technology Innovation. 2018, 2018(29), 177–178. [Google Scholar]

- Liu, X. Preparation of modified polyurethane foam/UHMWPE fabric sandwich material and study on low speed impact performance. (Doctoral dissertation,Jiangnan University). 2023.

- Bliven, E.; Rouhier, A.; Tsai, S.; Willinger, R.; Bourdet, N.; Deck, C.; Madey, S.M.; Bottlang, M. A novel strategy for mitigation of oblique impacts in bicycle helmets. J. Forensic Biomed. 2019, 10. [Google Scholar]

- Fernandes, F.A.; Alves de Sousa, R.J.; Ptak, M.; Migueis, G. Helmet design based on the optimization of biocomposite energy-absorbing liners under multi-impact loading. Applied Sciences. 2019, 9, 735. [Google Scholar] [CrossRef]

- Fernandes, F.A.O.; De Sousa, R.A. Motorcycle helmets—A state of the art review. Accident Analysis & Prevention. 2013, 56, 1–21. [Google Scholar]

- Sone, J.Y.; Kondziolka, D.; Huang, J.H.; Samadani, U. Helmet efficacy against concussion and traumatic brain injury: a review. Journal of neurosurgery. 2017, 126, 768–781. [Google Scholar] [CrossRef]

- Kulkarni, S.G.; Gao, X.L.; Horner, S.E.; Zheng, J.Q.; David, N.V. Ballistic helmets–their design, materials, and performance against traumatic brain injury. Composite Structures. 2013, 101, 313–331. [Google Scholar] [CrossRef]

- Yu, C.; Lan, D.; Wang, F.; Wang, B.; Li, G. Study on the Effect of Passenger Car Windshield Angle on Pedestrian Head/Brain Injury. Vibration and Impact. 2020, 39, 189–197. [Google Scholar]

- Mosleh, Y.; Vander Sloten, J.; Depreitere, B.; Ivens, J. Novel composite foam concept for head protection in oblique impacts. Advanced Engineering Materials. 2017, 19, 1700059. [Google Scholar] [CrossRef]

- Vanden Bosche, K.; Mosleh, Y.; Depreitere, B.; Vander Sloten, J.; Verpoest, I.; Ivens, J. Anisotropic polyethersulfone foam for bicycle helmet liners to reduce rotational acceleration during oblique impact. Proceedings of the Institution of Mechanical Engineers, Part H: Journal of engineering in medicine. 2017, 231, 851–861. [Google Scholar] [CrossRef] [PubMed]

- Ramirez, B.J.; Gupta, V. Evaluation of novel temperature-stable viscoelastic polyurea foams as helmet liner materials. Materials & Design. 2018, 137, 298–304. [Google Scholar]

- Rueda, M.F.; Cui, L.; Gilchrist, M.D. Optimisation of energy absorbing liner for equestrian helmets. Part I: Layered foam liner. Materials & Design. 2019, 30, 3405–3413. [Google Scholar]

- Cui, L.; Rueda, M.F.; Gilchrist, M.D. Optimisation of energy absorbing liner for equestrian helmets. Part II: Functionally graded foam liner. Materials & Design. 2009, 30, 3414–3419. [Google Scholar]

- Maheswaran, B.; Chawla, K.; Thevamaran, R. Mitigating Oblique Impacts by Unraveling of Buckled Carbon Nanotubes in Helmet Liners. Experimental Mechanics. 2024, 64, 197–209. [Google Scholar] [CrossRef]

- Shuaeib, F.M.; Hamouda, A.M.S.; Wong, S.V.; Umar, R.R.; Ahmed, M.M. A new motorcycle helmet liner material: The finite element simulation and design of experiment optimization. Materials & design. 2007, 28, 182–195. [Google Scholar]

- Bailly, N.; Petit, Y.; Desrosier, J.M.; Laperriere, O.; Langlois, S.; Wagnac, E. Strain rate dependent behavior of vinyl nitrile helmet foam in compression and combined compression and shear. Applied Sciences. 2020, 10, 8286. [Google Scholar] [CrossRef]

- Chang, L.; Guo, Y.; Huang, X.; Xia, Y.; Cai, Z. Experimental study on the protective performance of bulletproof plate and padding materials under ballistic impact. Materials & Design. 2021, 207, 109841. [Google Scholar]

- Wu, J.Z.; Pan, C.S.; Ronaghi, M.; Wimer, B.M.; Reischl, U. Application of air-bubble cushioning to improve the shock absorption performance of type I industrial helmets. Engineering Failure Analysis. 2020, 117, 104921. [Google Scholar] [CrossRef]

- Wu, J.Z.; Pan, C.S.; Ronaghi, M.; Wimer, B.M.; Reischl, U. Application of polyethylene air-bubble cushions to improve the shock absorption performance of Type I construction helmets for repeated impacts. Bio-medical materials and engineering. 2021, 32, 1–14. [Google Scholar] [CrossRef]

- Kroeker, S.G.; Özkul, M.Ç.; DeMarco, A.L.; Bonin, S.J.; Siegmund, G.P. Density variation in the expanded polystyrene foam of bicycle helmets and its influence on impact performance. Journal of biomechanical engineering. 2020, 142, 041012. [Google Scholar] [CrossRef]

- Huang, X.; Zheng, Q.; Chang, L.; Cai, Z. Study on protective performance and gradient optimization of helmet foam liner under bullet impact. Scientific reports. 2022, 12, 16061. [Google Scholar] [CrossRef] [PubMed]

- Drane, P.; De Jesus-Vega, M.; Inalpolat, M.; Sherwood, J.; Orbey, N. Inductive quantification of energy absorption of high-density polyethylene foam for repeated blunt impact. Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications. 2020, 234, 531–545. [Google Scholar] [CrossRef]

- Fernandes, F.A.; Alves de Sousa, R.J.; Ptak, M.; Migueis, G. Helmet design based on the optimization of biocomposite energy-absorbing liners under multi-impact loading. Applied Sciences. 2019, 9, 735. [Google Scholar] [CrossRef]

- Buil, R.M.; Angulo, D.R.; Ivens, J.; Blasco, J.O.A. Experimental study of natural cork and cork agglomerates as a substitute for expanded polystyrene foams under compressive loads. Wood Science and Technology. 2021, 55, 419–443. [Google Scholar] [CrossRef]

- Kaczyński, P.; Ptak, M.; AO Fernandes, F.; Chybowski, L.; Wilhelm, J.; J. Alves de Sousa, R. Development and testing of advanced cork composite sandwiches for energy-absorbing structures. Materials. 2019, 12, 697. [CrossRef] [PubMed]

- Sinnappoo, K.; Nayak, R.; Thompson, L.; Padhye, R. Application of sustainable phase change materials in motorcycle helmet for heat-stress reduction. The Journal of the Textile Institute. 2020, 111, 1547–1555. [Google Scholar] [CrossRef]

- Bhinder, J.; Verma, S.K.; Agnihotri, P.K. Qualifying carbon nanotube reinforced polyurethane foam as helmet inner liner through in-situ, static and low velocity impact testing. Materials Science and Engineering: B. 2021, 274, 115496. [Google Scholar] [CrossRef]

- Kim, Y.K.; Chalivendra, V.B.; Lewis, A.F.; Fasel, B. Designing flocked energy-absorbing material layers into sport and military helmet pads. Textile Research Journal. 2020, 92, 2755–2770. [Google Scholar] [CrossRef]

- Jain, R.; Yadav, P.; Narayanan, T.N. Impact-Absorbing Thermally Dissipative Epoxy Composite Liner for Helmets. Advanced Engineering Materials. 2023, 25, 2201122. [Google Scholar] [CrossRef]

- Kholoosi, F.; Galehdari, S.A. Design, optimisation and analysis of a helmet made with graded honeycomb structure under impact load. International journal of crashworthiness. 2019. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Gohel, G.; Leong, K.F. Enhanced energy absorption characteristics of novel integrated hybrid honeycomb/polystyrene foam. Journal of Cellular Plastics. 2021, 57, 839–848. [Google Scholar] [CrossRef]

- Li, S.; Xiao, Z.; Zhang, Y.; Li, Q.M. Impact analysis of a honeycomb-filled motorcycle helmet based on coupled head-helmet modelling. International Journal of Mechanical Sciences. 2021, 199, 106406. [Google Scholar] [CrossRef]

- Teng, T.L.; Liang, C.C.; Nguyen, V.H. Assessment of a bicycle helmet liner with semispherical cones. Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications. 2016, 230, 344–352. [Google Scholar] [CrossRef]

- Ingrole, A.A. Auxetic and hybrid structure designs and advanced manufacturing study for energy absorption improvements. (Doctoral dissertation, The Florida State University). 2018.

- Toboła, W.; Papis, M.; Jastrzębski, D.; Perz, R. Experimental research of energy absorbing structures within helmet samples made with the additive manufacturing method-preliminary study. Acta of Bioengineering & Biomechanics. 2023, 25.

- Khosroshahi, S.F.; Duckworth, H.; Galvanetto, U.; Ghajari, M. The effects of topology and relative density of lattice liners on traumatic brain injury mitigation. Journal of biomechanics. 2019, 97, 109376. [Google Scholar] [CrossRef]

- Khosroshahi, S.F.; Tsampas, S.A.; Galvanetto, U. Feasibility study on the use of a hierarchical lattice architecture for helmet liners. Materials Today Communications. 2018, 14, 312–323. [Google Scholar] [CrossRef]

- Clough, E.C.; Plaisted, T.A.; Eckel, Z.C.; Cante, K.; Hundley, J.M.; Schaedler, T.A. Elastomeric microlattice impact attenuators. Matter. 2019, 1, 1519–1531. [Google Scholar] [CrossRef]

- Goel, R. Study of an advanced helmet liner concept to reduce TBI: experiments & simulation using sandwich structures (Doctoral dissertation, Massachusetts Institute of Technology). 2011.

- La Fauci, G.; Parisi, M.; Nanni, A.; Crosetta, L.; Pugno, N.M.; Colonna, M. Design and proof-of-concept of an advanced protective system for the dissipation of tangential impact energy in helmets, based on non-Newtonian fluids. Smart Materials and Structures. 2023, 32, 044004. [Google Scholar] [CrossRef]

- San Ha, N.; Lu, G. A review of recent research on bio-inspired structures and materials for energy absorption applications. Composites Part B: Engineering. 2020, 181, 107496. [Google Scholar]

- Bührig-Polaczek, A.; Fleck, C.; Speck, T.; Schüler, P.; Fischer, S.F.; Caliaro, M.; Thielen, M. Biomimetic cellular metals—using hierarchical structuring for energy absorption. Bioinspiration & biomimetics. 2016, 11, 045002. [Google Scholar]

- Thielen, M.; Schmitt, C.N.Z.; Eckert, S.; Speck, T.; Seidel, R. Structure–function relationship of the foam-like pomelo peel (Citrus maxima)—an inspiration for the development of biomimetic dam** materials with high energy dissipation. Bioinspiration & biomimetics. 2013, 8, 025001. [Google Scholar]

- Zhang, W.; Yin, S.; Yu, T.X.; Xu, J. Crushing resistance and energy absorption of pomelo peel inspired hierarchical honeycomb. International Journal of Impact Engineering. 2019, 125, 163–172. [Google Scholar] [CrossRef]

- Lazarus, B.S.; Luu, R.K.; Ruiz-Pérez, S.; Bezerra, W.B.A.; Becerra-Santamaria, K.; Leung, V.; Durazo, V.H.L.; Jasiuk, I.; Barbosa, J.D.; Meyers, M.A. Equine hoof wall: Structure, properties, and bioinspired designs. Acta Biomaterialia. 2022, 151, 426–445. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Huang, Y.; Zhou, B.; Li, W.; Chen, H. Nanoindentation and hierarchy structure of the bovine hoof wall. Materials. 2021, 14, 289. [Google Scholar] [CrossRef] [PubMed]

- Leng, B.; Ruan, D.; Xu, S.; Tse, K.M. Conceptual Design and Parametric Optimization of a New Multileveled Horsetail Structure for Bicycle Helmets. Advanced Engineering Materials. 2023, 2300884. [Google Scholar] [CrossRef]

- Chen, Z.; Li, J.; Wu, B.; Chen, X.; Ren, X.; Xie, Y.M. A novel bio-inspired helmet with auxetic lattice liners for mitigating traumatic brain injury. Smart materials and structures. 2023, 32, 105020. [Google Scholar] [CrossRef]

- Teng, T.L.; Liang, C.C.; Nguyen, V.H. Innovative design of bicycle helmet liners. Proceedings of the Institution of Mechanical Engineers, Part L: Journal of materials: Design and applications. 2014, 228, 341–351. [Google Scholar] [CrossRef]

- Yang, X.; Ma, J.; Shi, Y.; Sun, Y.; Yang, J. Crashworthiness investigation of the bio-inspired bi-directionally corrugated core sandwich panel under quasi-static crushing load. Materials & Design. 2017, 135, 275–290. [Google Scholar]

- Liu, B.; Xu, X. Numerical study on energy absorption performance of novel bionic helmet liner. Materials Today Communications. 2023, 37, 107369. [Google Scholar] [CrossRef]

- Jiang, M.; Yan, J.; Chen, J. Three dimensional printing of military helmet inner liner structure based on topology optimization technology. Journal of Ordnance Industry. 2017, 38, 1845–1853. [Google Scholar]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).