Submitted:

25 April 2024

Posted:

25 April 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

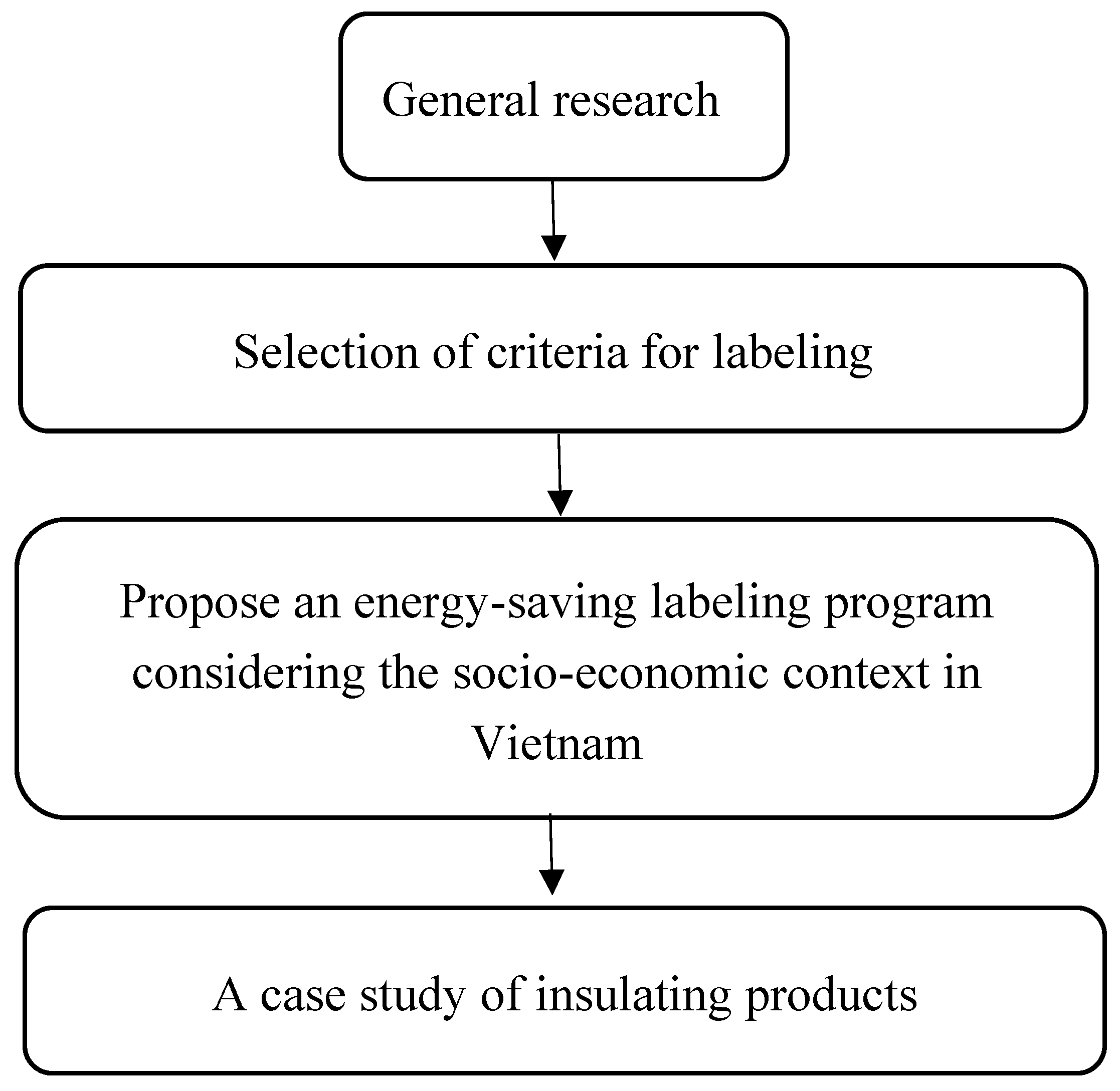

2. Materials and Methods

- (i)

- General research

- (ii)

- Selection of criteria for labeling

- (iii)

- Proposal of an energy-saving labeling program for building materials in Vietnam

- (iv)

- Case study of insulating products

3. Results and Discussion

3.1. Selection of Criteria for Labeling

3.1.1. Light-Transmitting Materials and Product Parts

3.1.2. Materials Involved in Wall- and Roof-Covering Structures

3.1.3. Finishing Materials Involved in External Covering Structures, Building Roofs, and Exterior Paving Materials

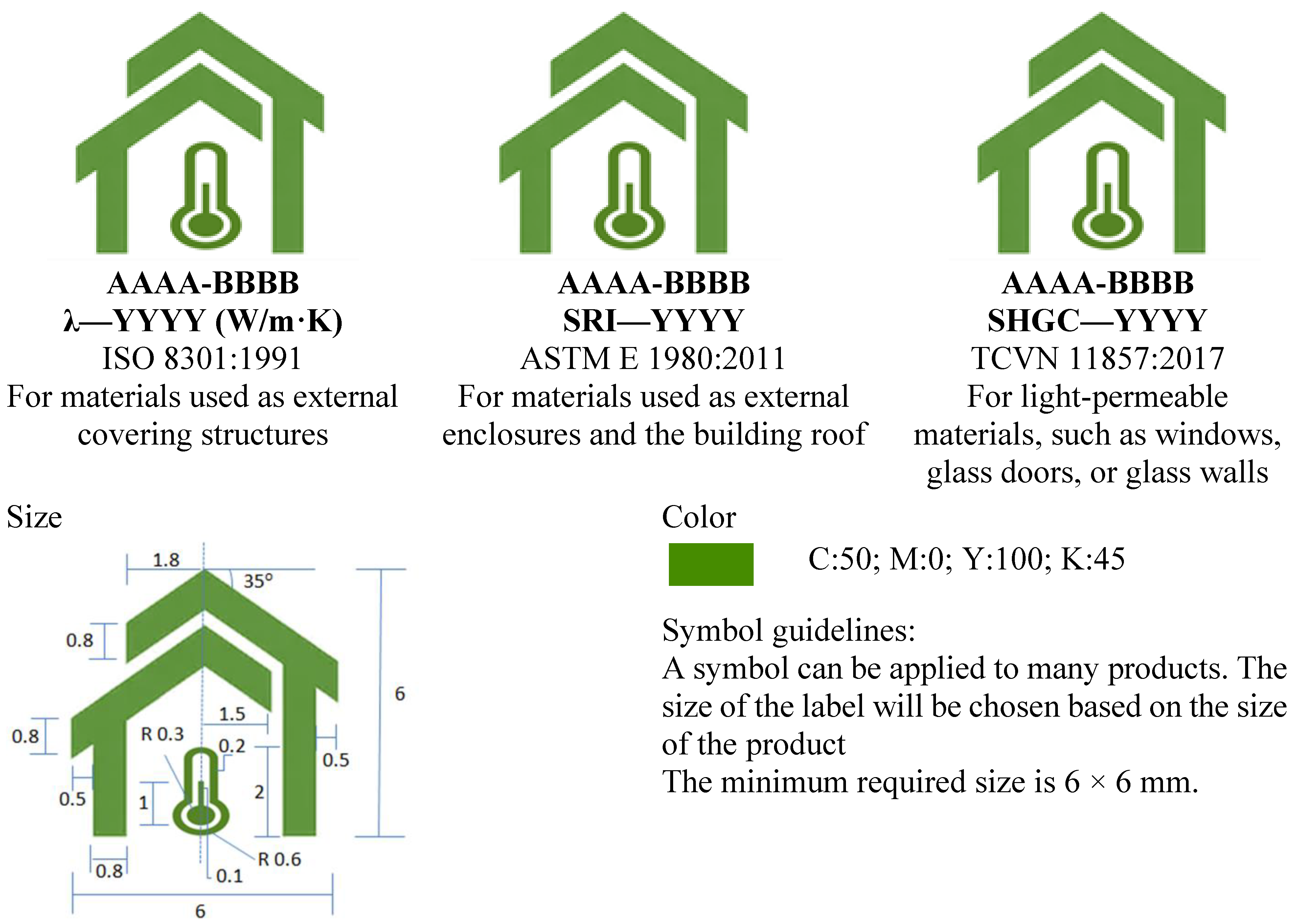

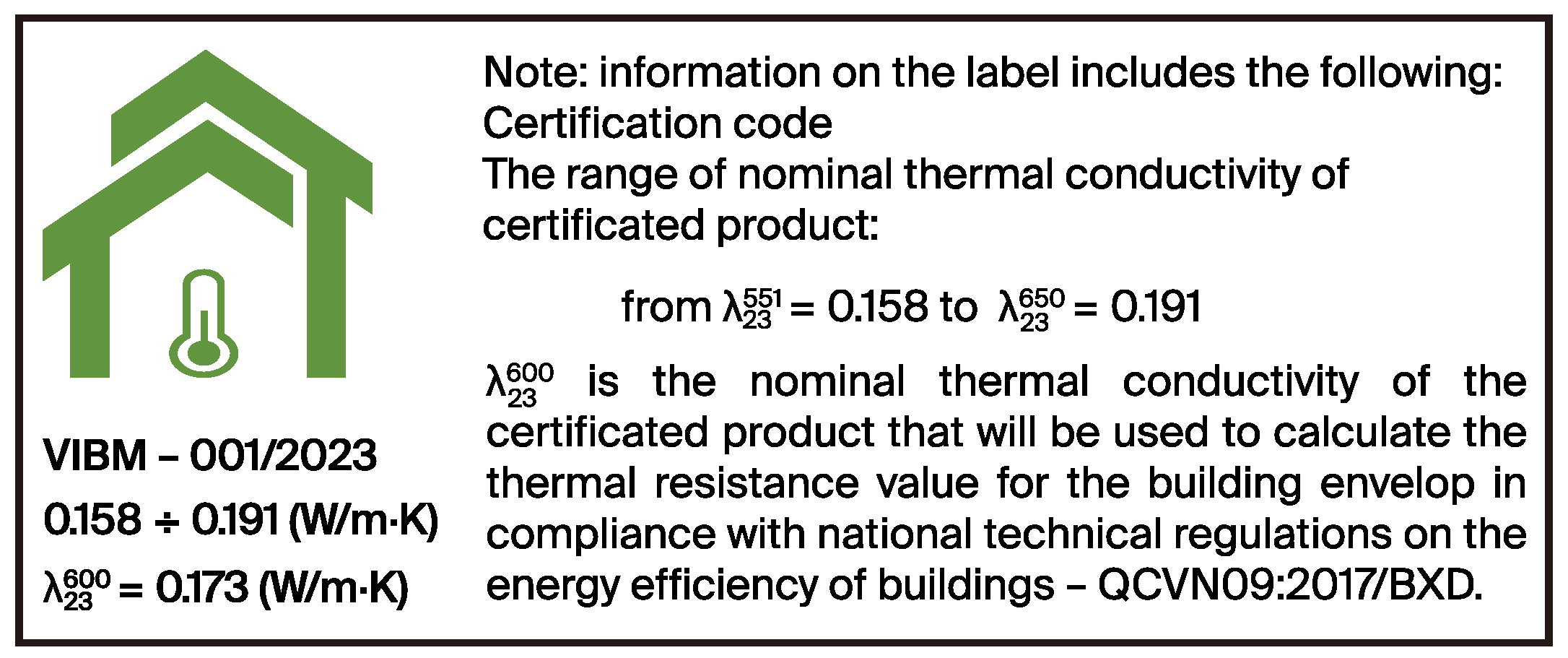

3.2. Proposed Labeling Format

- For building materials or construction products used as external coverings (including walls and rooftops), the thermal conductivity λ (W/m·K) must be declared.

- For building materials or construction products applied to external enclosures and the building roof, including the finish coating, information on the SRI must be provided.

- For building materials and construction products that are light-permeable, such as windows, glass doors, or glass walls, information on the SHGC of the product must be declared.

3.3. Proposed Labeling Program

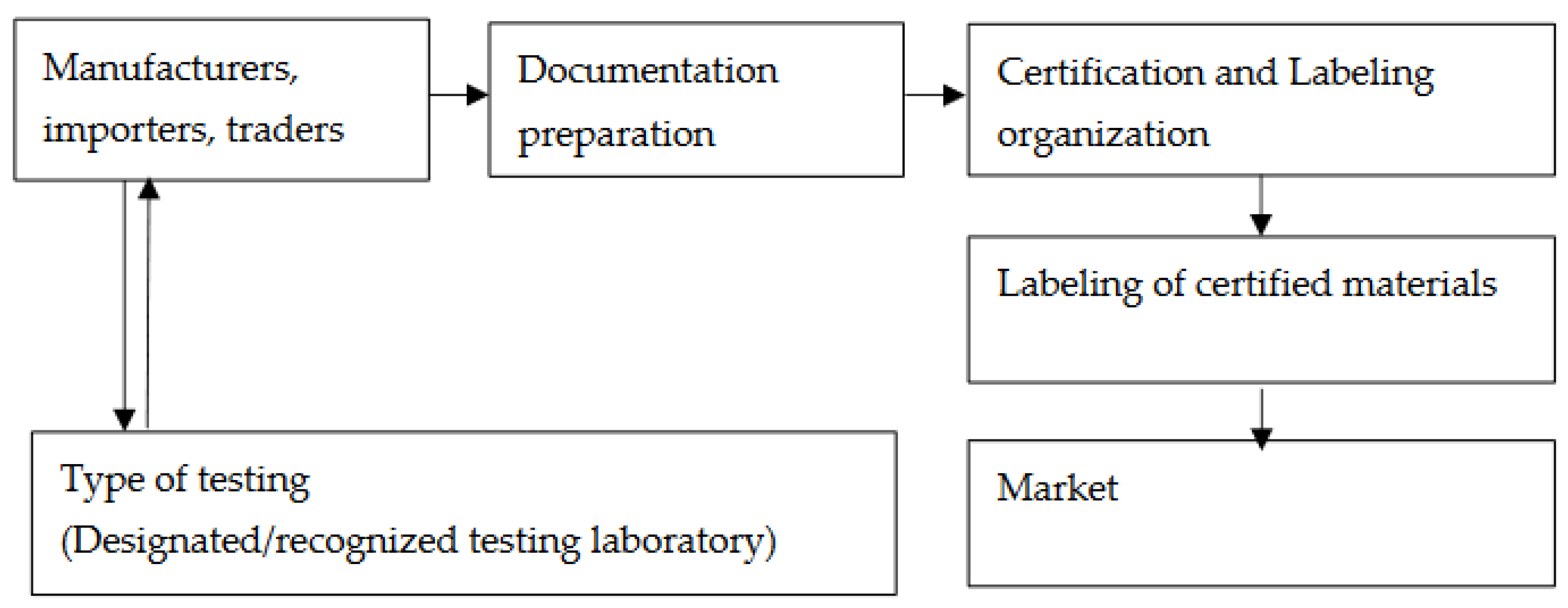

3.4. Proposed Labeling Process

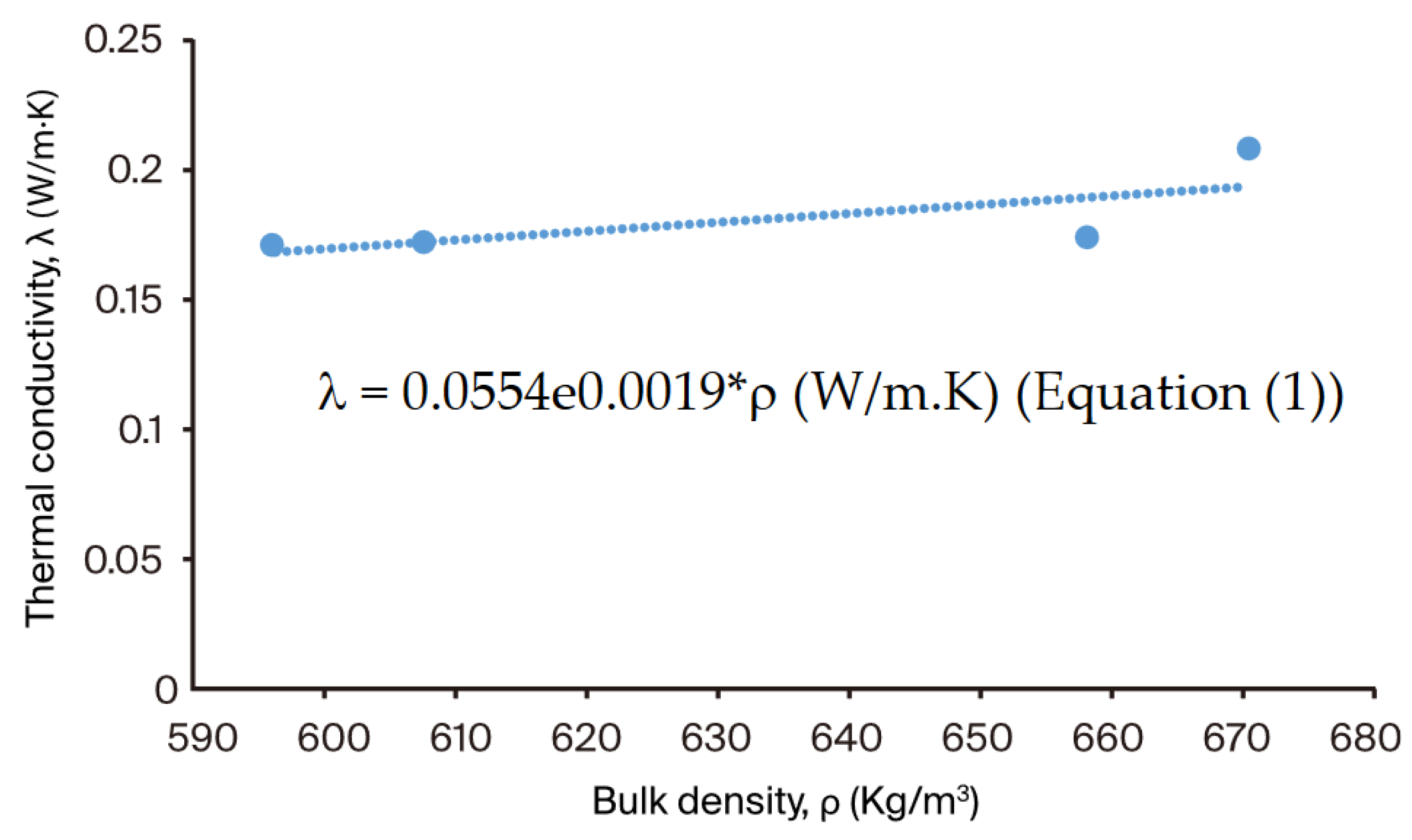

3.5. Case Study of Insulating Product

4. Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Payam, N.; Fatemeh, J.; Mohammad, M., T.; Mohammad, G.; Muhd, Z.A. M. A Global Review of Energy Consumption, CO2 Emissions and Policy in the Residential Sector (with an Overview of the Top Ten CO2. Renewable and Sustainable Energy Reviews 2015, 843–862. [Google Scholar] [CrossRef]

- Amani, N.; Hosseini, S. Effective Factors on Eco Labeling Building-Construction, Materials and Components. AMR 2011, 374–377, 1254–1257. [Google Scholar] [CrossRef]

- Harrington, L.; Damnics, M. Energy Labelling and Standards Programs Throughout the World. The National Appliance and Equipment Energy Efficiency Committee, 2004.

- Economidou, M.; Atanasiu, B.; Staniaszek, D.; Maio, J.; Nolte, I.; Rapf, O.; Laustsen, J.; Ruyssevelt, P.; Strong, D.; Zinetti, S. Europe’s Buildings under the Microscope. A Country-by-Country Review of the Energy Performance of Buildings; Buildings Performance Institute Europe: Berlin, Germany, 2011. [Google Scholar]

- Evans, M.; Halverson, M.; Vu, L.; Yu, S.; Nguyen, H. A Road Map to Building Material Testing and Rating in Developing Countries, ACEEE: Washington, DC, USA, 2016.

- Park, D.J.; Yu, K.H.; Yoon, Y.S.; Kim, K.H.; Kim, S.S. Analysis of a Building Energy Efficiency Certification System in Korea. Sustainability 2015, 7, 16086–16107. [Google Scholar] [CrossRef]

- National Fenestration Rating Council 2016. Available online: https://www.nfrc.org/ (accessed on 22 April 2024).

- Wang; Tae; Kim Development of a Green Building Materials Integrated Platform Based on Materials and Resources in G-SEED in South Korea. Sustainability 2019, 11, 6532. [CrossRef]

- Decision 04/2017/QD-TTg List of Products under VNEEP. Available online: https://extendmax.vn/vietnam-regulations-on-energy-efficiency-decision-04-2017-qd-ttg (accessed on 26 October 2023).

- Circular No. 36/2016/TT-BCT, Regulations on Energy Labeling for Energy-Using Vehicles and Equipment under the Management of the Ministry of Industry and Trade. Available online: http://vanban.chinhphu.vn/default.aspx?pageid=27160&docid=188835 (accessed on 26 October 2023).

- Construction Industry Grows Rate, Construction Magazine. 2023. Available online: https://tapchixaydung.vn/toc-do-tang-truong-nganh-xay-dung-trong-9-thang-nam-2023-dat-617-20201224000020094.html (accessed on 14 December 2023).

- Law No. 50/2010/QH12 of 2011 on Economical and Efficient Use of Energy|ESCAP Policy Documents Managment. Available online: https://policy.asiapacificenergy.org/node/2758 (accessed on 27 December 2023).

- Decree No. 21/2011/NĐ-CP Implementation of the Energy Efficiency and Conservation Law. 2011. Available online: http://vanban.chinhphu.vn/default.aspx?pageid=27160&docid=202835 (accessed on 27 December 2023).

- Law 62/2020/QH14 Amendments to Construction Law. Available online: https://vanbanphapluat.co/law-62-2020-qh14-amendments-to-construction-law (accessed on 27 December 2023).

- National Technical Regulation on Energy Efficiency Buildings | ESCAP Policy Documents Management. Available online: https://policy.asiapacificenergy.org/node/1107 (accessed on 6 June 2023).

- LawNet Decision No. 280/QD-TTg Dated March 13, 2019 on Approval for National Program for Thrifty and Efficient Use of Energy for the Period of 2019 -2030 280/QD-TTg,Quyết Định 280 2019. Available online: https://lawnet.vn/en/vb/Decision-280-QD-TTg-2019-approval-for-national-program-for-thrifty-and-efficient-use-of-energy-6E098.html (accessed on 6 June 2023).

- Decision No. 882/QĐ-TTg on Aproval of National Action Plan on Green Growing in the period of 2021-2030. Available online: http://chinhphu.vn/?pageid=27160&docid=206215 (accessed on 18 April 2024).

- Decree, No. 15/2021/NĐ-CP on Detail requirement of implementation on Construction Law. Available online: http://vanban.chinhphu.vn/default.aspx?pageid=27160&docid=202756 (accessed on 18 April 2024).

- LawNet Decree, No. 06/2021/ND-CP Dated January 26, 2021 on Elaborating on the Implementation of Several Regulations on Quality Management, Construction and Maintenance of Construction Works 06/2021/ND-CP,Nghị Định 06 2021. Available online: https://lawnet.vn/en/vb/Decree-No-06-2021-ND-CP-quality-management-construction-maintenance-of-construction-works-71E42.html (accessed on 27 December 2023).

- Decision, No. 385/QĐ-BXD: Approving Climate Change Action Plan in the Construction Sector for the 2022–2030 Period with Vision towards 2050 to Fulfill Vietnam’s Commitments in COP 26. 2022. Available online: https://moc.gov.vn/vn/Pages/ChiTietVanBan.aspx?vID=3895&TypeVB=1 (accessed on 27 December 2023).

- Decision 04/2017/QD-TTg List of Products under VNEEP. Available online: https://extendmax.vn/vietnam-regulations-on-energy-efficiency-decision-04-2017-qd-ttg (accessed on 26 October 2023).

- LEED Rating System |, U.S. Green Building Council. Available online: https://www.usgbc.org/leed (accessed on 27 December 2023).

- TCVN 7959:2011 Autoclaved Aerated Concrete (AAC). Available online: https://luatvietnam.vn/xay-dung/tieu-chuan-tcvn-7959-2011-gach-be-tong-khi-chung-ap-aac-162647-d3.html (accessed on 18 April 2024).

| Type of Label | Applicable Product | Indicator |

|---|---|---|

| NFRC | Windows, doors, skylights | U-factor, Solar heat gain coefficient (SHGC), visible light transmission(VLT), air leakage, condensation resistance |

| Energy Star | Wall insulation | R values |

| CRRC | Roofing products | Solar reflectance, thermal emittance, solar reflective index (SRI) |

| Country | Labeling organization | Status | Indicator |

|---|---|---|---|

| Denmark | Vindues | Voluntary | Uw, g, AU/Aw |

| Finland | Energy | Voluntary | Uw, L |

| France | Union des | Voluntary | Uw, Sw |

| Portugal | ADENE | Voluntary | Uw, G, L |

| Slovakia | Energakma | Voluntary | Uw, G, L |

| Spain | ASEFAV | Voluntary | Uw, G, L |

| Switzerland | EQ | Voluntary | Uw, L |

| Great Britain | BFRC Certass BSI |

Voluntary | Uw, G, L AU/Aw |

| Policy | Details | Year | Reference |

|---|---|---|---|

| Energy Efficiency and Conservation Law | Obligations of Key Energy Users:

|

2010 | [12] |

| Decree No. 21/2011/NĐ-CP Implementation of the Energy Efficiency and Conservation Law | Definition of the Key Energy User Entities:

|

2011 | [13] |

| Construction Law | Incentives for the assessment and certification of energy-efficient buildings and green buildings are regulated by the Law on Construction (amended in 2020). Article 10, Clause 4: “The state has a policy incentive to carry out investment activities and certification of energy saving, efficiency, and natural resource consumption of buildings while ensuring environmental requirements…” Article 162, Clause 2: Ministry of Construction: “Promulgating and organizing the implementation of criteria for buildings using efficiency energy and natural resources”. |

2014, amended in 2020 | [14] |

| National regulation on energy efficiency of buildings—QCVN09:2017/BXD | This regulation provides mandatory technical standards for the design, construction, or retrofitting of buildings with a gross floor area of 2500 m2 or larger of the following types: offices, hotels, hospitals, schools, commercials buildings, and residential buildings. The requirements of this regulation apply to the building envelope, ventilation and air conditioning systems, lighting systems, and other electrical equipment. | 2017 | [15] |

| Decision No. 280/QĐ-TTg: approving the National Program on Economic and efficient use of energy in the period 2019–2030 |

|

2019 | [16] |

| Decision No. 882/QĐ-TTg: National Action Plan on Green Growth for the period 2021–2030 | This Decision approves the National Action Plan on Green Growth for the period 2021–2030, which emphasizes the implementation of activities to develop standards, sets of criteria, and guidelines for the assessment and certification of building materials that are energy-saving, green, environmentally friendly, and produce low carbon emissions. | 2020 | [17] |

| Decree No. 15/2021/NĐ-CP: Regulations detailing some content on construction investment management (specifying some contents of the Construction Law). | Article 7. Energy-efficient, resource-saving, and green construction:

|

2021 | [18] |

| Decree No. 06/2022/ND-CP: Regulations to mitigate greenhouse gas emissions and protect the ozone layer | This Decree stipulates that the minimum greenhouse gas emission reduction target for the period up to 2030 in the construction sector is 74.3 million tons CO2eq. | 2022 | [19] |

| Decision No. 385/QĐ-BXD: Approving a climate change action plan in the construction sector for the 2022–2030 period, with a view to fulfilling Vietnam’s commitments based on COP26 by 2050 | Exploiting and producing building materials:

|

2022 | [20] |

| Area | U0max (W/m2·K) | R0min (m2·K/W) |

|---|---|---|

| Building envelopes | 1.8 | 0.56 |

| Flat roofs | 1 | 1 |

| Material | Initial SRI Value |

|---|---|

| Roofs with small slopes (≤2:12) | ≥78 |

| Roofs with large slopes (>2:12) | ≥29 |

| Parking lots | ≥29 |

| Road, sidewalks, yards | ≥29 |

| Step | Operations |

|---|---|

| Step 1 | Prepare application guided by certification organization |

| Step 2 | Conduct type testing at designated/recognized laboratories (ISO/IEC 17025-accredited) |

| Step 3 | Prepare documentation and send to certification organization |

| Step 4 | Label products and add them to the market |

| Property | Value | |||

|---|---|---|---|---|

| Specimen 1 | Specimen 2 | Specimen 3 | Specimen 4 | |

| Nominal density (kg/m3) | 600 | 600 | 600 | 600 |

| Measured density (kg/m3) | 595.86 | 670.46 | 607.56 | 658.11 |

| Measured thermal conductivity, λ (W/m·K) | 0.17038 | 0.20715 | 0.17154 | 0.17321 |

| No. | Nominal Bulk Density (kg/m3) | Nominal Thermal Conductivity (W/m·K) |

|---|---|---|

| 1 | 600 | |

| 2 | 551 | |

| 3 | 650 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).