Submitted:

29 April 2024

Posted:

29 April 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Materials

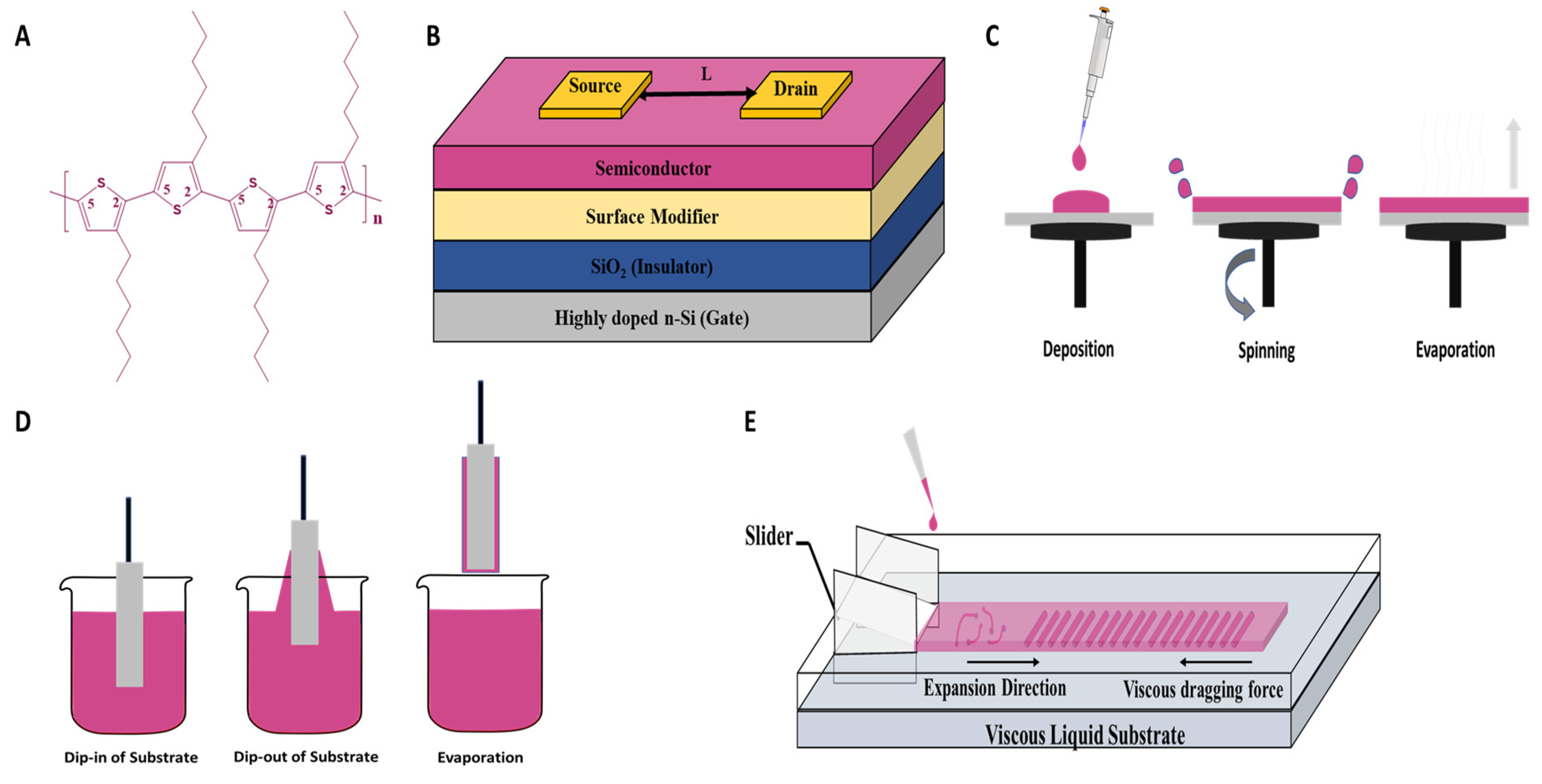

2.2. Thin film and Device Fabrication

2.2.1. Spin Coating

2.2.2. Dip Coating

2.2.3. Unidirectional Floating Film Transfer Method

2.3. Thin Film and Device Characterizations

2.3.1. Optical and Microstructural Characterizations

2.3.2. Contact Angle Measurement

2.3.3. Electrical Characterizations

3. Results

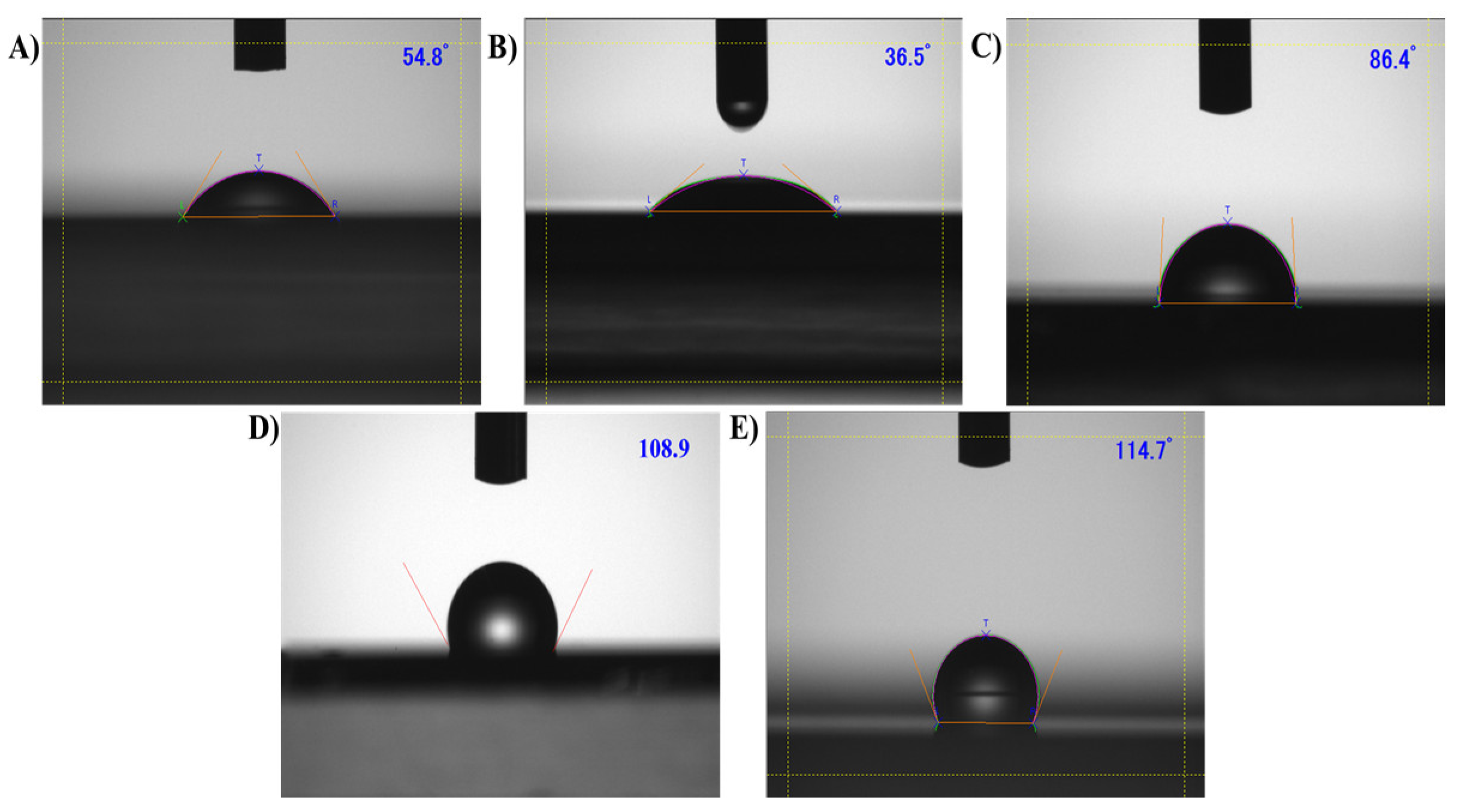

3.1. Contact Angle Goniometry

3.2. Optimization of Thin Film Fabrication

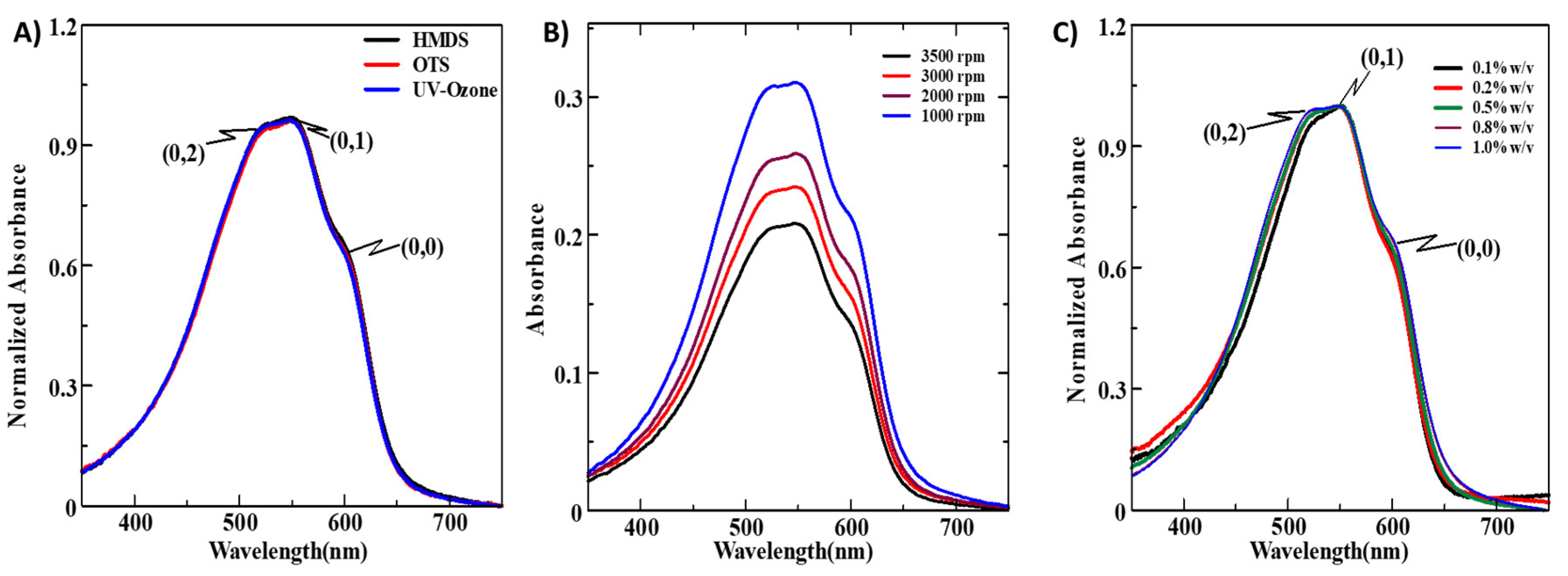

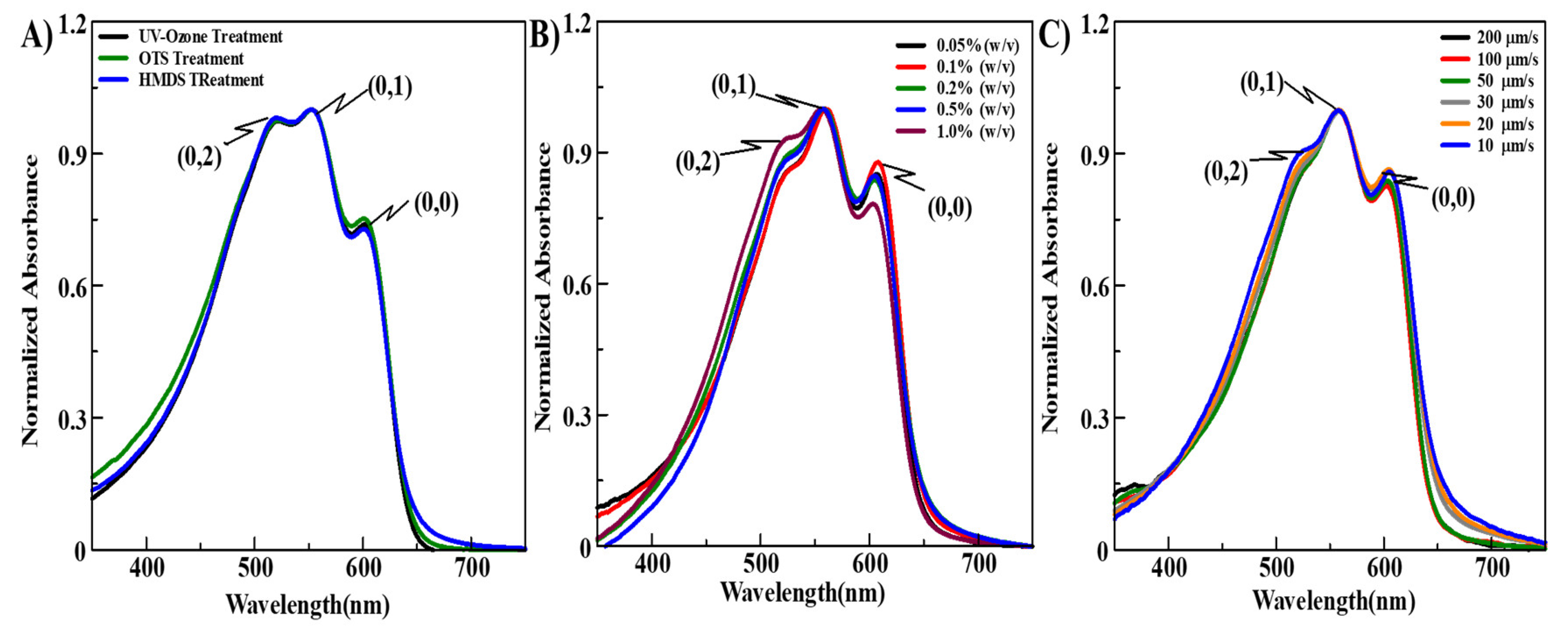

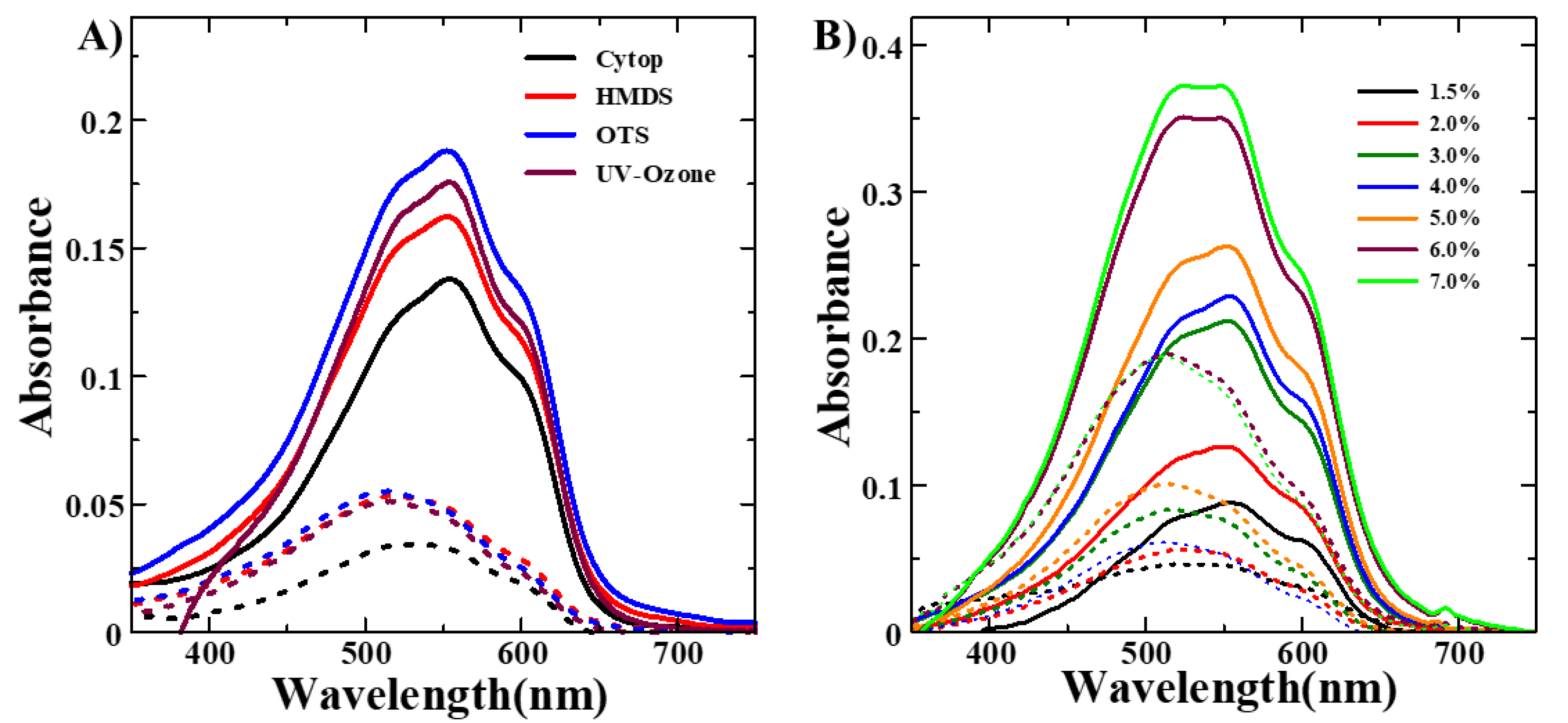

3.2.1. Spin-Coated Thin Films

3.2.2. Dip-Coated Thin Films

3.2.3. UFTM Fabricated Thin Films

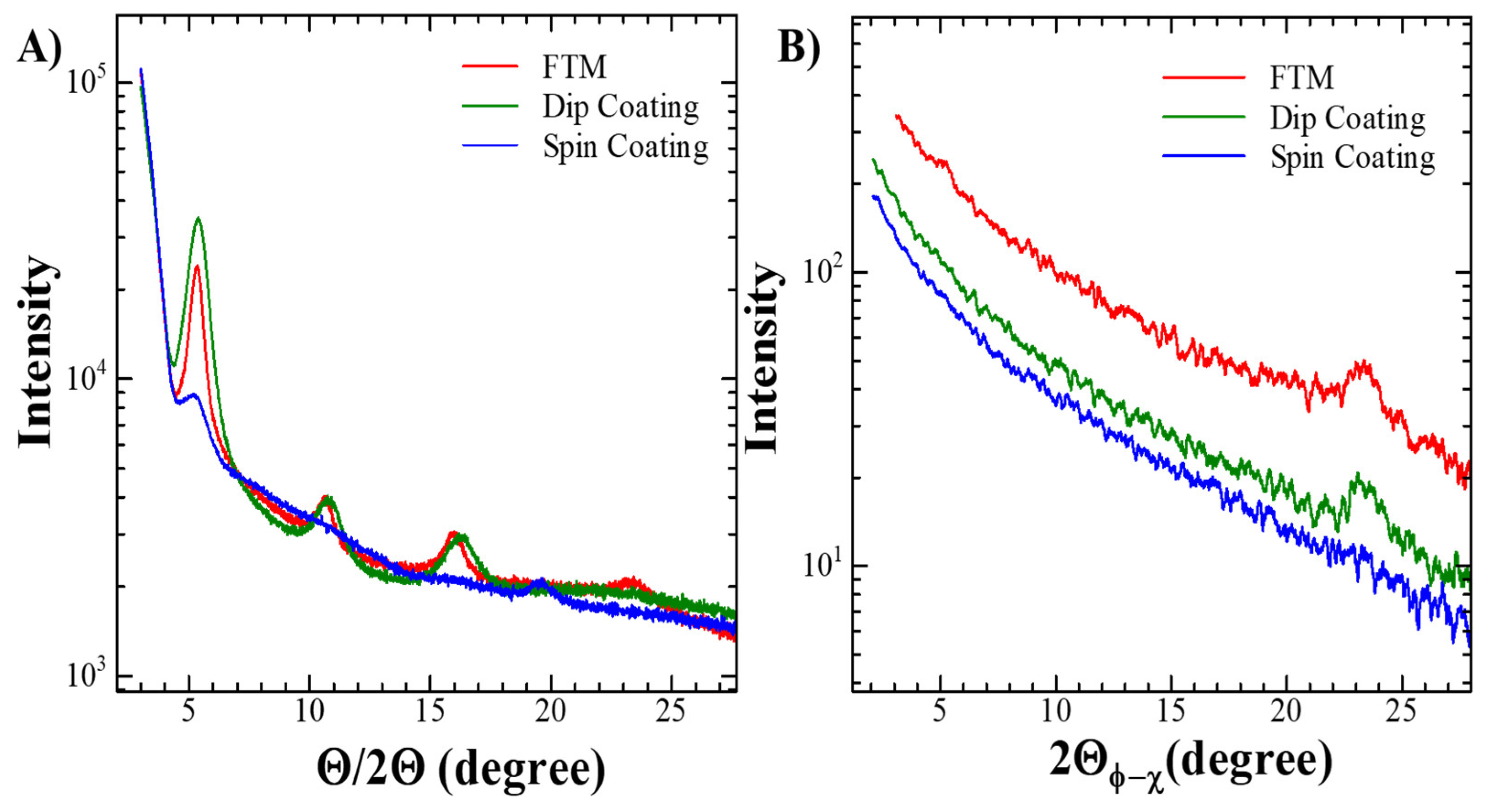

3.3. Microstructural Characterization

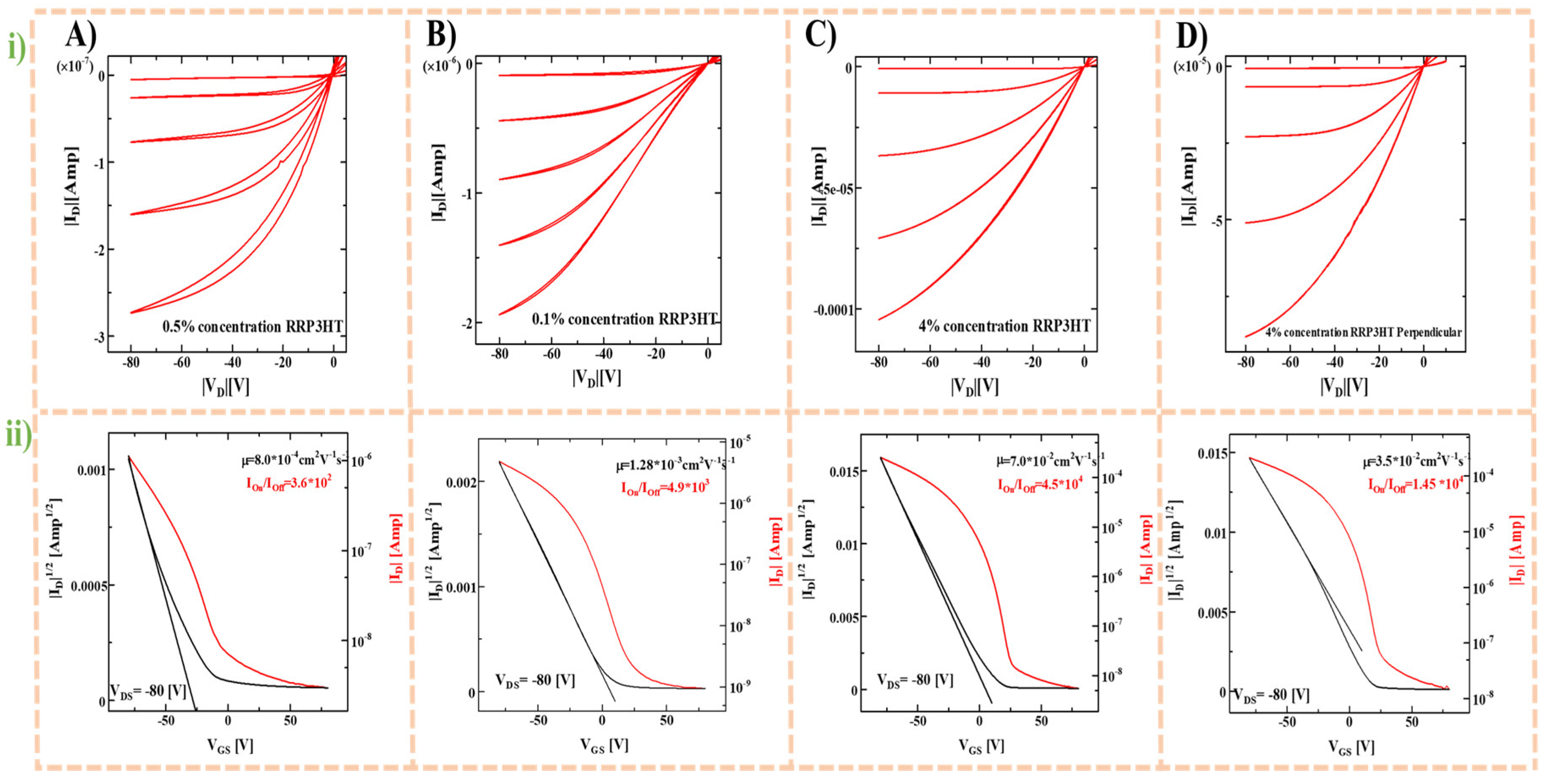

3.4. Electrical Characterization

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- W. M. Arden, The International Technology Roadmap for Semiconductors—Perspectives and challenges for the next 15 years. Curr Opin Solid State Mater Sci 2002, 6, 371–377. [Google Scholar] [CrossRef]

- M.C. Petty, Molecular Electronics, John Wiley & Sons, Ltd., Chichester, UK, 2007. [CrossRef]

- M. Ikawa, T. Yamada, H. Matsui, H. Minemawari, J. Tsutsumi, Y. Horii, M. Chikamatsu, R. Azumi, R. Kumai, T. Hasegawa, Simple push coating of polymer thin-film transistors. Nat Commun 2012, 3, 1176. [Google Scholar] [CrossRef]

- L. Sun, Y. Kurosawa, H. Ito, Y. Makishima, H. Kita, T. Yoshida, Y. Suzuri, Solution processing of alternating PDMS/SiOx multilayer for encapsulation of organic light emitting diodes. Org Electron 2019, 64, 176–180. [Google Scholar] [CrossRef]

- A. Sandström, H.F. Dam, F.C. Krebs, L. Edman, Ambient fabrication of flexible and large-area organic light-emitting devices using slot-die coating. Nat Commun 2012, 3, 1002. [Google Scholar] [CrossRef] [PubMed]

- L. Yuan, S. Liu, W. Chen, F. Fan, G. Liu, Organic Memory and Memristors: From Mechanisms, Materials to Devices. Adv Electron Mater 2021, 7. [Google Scholar] [CrossRef]

- Marrocchi, D. Lanari, A. Facchetti, L. Vaccaro, Poly(3-hexylthiophene): synthetic methodologies and properties in bulk heterojunction solar cells. Energy Environ Sci 2012, 5, 8457. [Google Scholar] [CrossRef]

- J. Xu, H.-C. Wu, C. Zhu, A. Ehrlich, L. Shaw, M. Nikolka, S. Wang, F. Molina-Lopez, X. Gu, S. Luo, D. Zhou, Y.-H. Kim, G.-J.N. Wang, K. Gu, V.R. Feig, S. Chen, Y. Kim, T. Katsumata, Y.-Q. Zheng, H. Yan, J.W. Chung, J. Lopez, B. Murmann, Z. Bao, Multi-scale ordering in highly stretchable polymer semiconducting films. Nat Mater 2019, 18, 594–601. [Google Scholar] [CrossRef]

- J. Y. Oh, S. Rondeau-Gagné, Y.-C. Chiu, A. Chortos, F. Lissel, G.-J.N. Wang, B.C. Schroeder, T. Kurosawa, J. Lopez, T. Katsumata, J. Xu, C. Zhu, X. Gu, W.-G. Bae, Y. Kim, L. Jin, J.W. Chung, J.B.-H. Tok, Z. Bao, Intrinsically stretchable and healable semiconducting polymer for organic transistors. Nature 2016, 539, 411–415. [Google Scholar] [CrossRef] [PubMed]

- H. Sirringhaus, 25th Anniversary Article: Organic Field-Effect Transistors: The Path Beyond Amorphous Silicon. Advanced Materials 2014, 26, 1319–1335. [Google Scholar] [CrossRef]

- H. Sirringhaus, Device Physics of Solution-Processed Organic Field-Effect Transistors. Advanced Materials 2005, 17, 2411–2425. [Google Scholar] [CrossRef]

- J. L. Mi, X.B. Zhao, T.J. Zhu, J.P. Tu, Improved thermoelectric figure of merit in n-type CoSb3 based nanocomposites. Appl Phys Lett 2007, 91. [Google Scholar] [CrossRef]

- J. -F. Chang, B. Sun, D.W. Breiby, M.M. Nielsen, T.I. Sölling, M. Giles, I. McCulloch, H. Sirringhaus, Enhanced Mobility of Poly(3-hexylthiophene) Transistors by Spin-Coating from High-Boiling-Point Solvents. Chemistry of Materials 2004, 16, 4772–4776. [Google Scholar] [CrossRef]

- J. Noh, S. Jeong, J.-Y. Lee, Ultrafast formation of air-processable and high-quality polymer films on an aqueous substrate. Nat Commun 2016, 7, 12374. [Google Scholar] [CrossRef] [PubMed]

- Y. Yabuuchi, G. Uzurano, M. Nakatani, A. Fujii, M. Ozaki, Uniaxial orientation of poly(3-hexylthiophene) thin films fabricated by the bar-coating method. Jpn J Appl Phys 2019, 58, SBBG04. [Google Scholar] [CrossRef]

- M. Brinkmann, L. Hartmann, L. Biniek, K. Tremel, N. Kayunkid, Orienting Semi-Conducting π-Conjugated Polymers. Macromol Rapid Commun 2014, 35, 9–26. [Google Scholar] [CrossRef]

- S. Nagamatsu, W. Takashima, K. Kaneto, Y. Yoshida, N. Tanigaki, K. Yase, K. Omote, Backbone Arrangement in “Friction-Transferred” Regioregular Poly(3-alkylthiophene)s. Macromolecules 2003, 36, 5252–5257. [Google Scholar] [CrossRef]

- A. Salleo, R.J. Kline, D.M. DeLongchamp, M.L. Chabinyc, Microstructural Characterization and Charge Transport in Thin Films of Conjugated Polymers. Advanced Materials 2010, 22, 3812–3838. [Google Scholar] [CrossRef]

- R. Noriega, J. Rivnay, K. Vandewal, F.P. V. Koch, N. Stingelin, P. Smith, M.F. Toney, A. Salleo, A general relationship between disorder, aggregation and charge transport in conjugated polymers. Nat Mater 2013, 12, 1038–1044. [Google Scholar] [CrossRef]

- J. Puetz, M.A. Aegerter, Dip Coating Technique, in: Sol-Gel Technologies for Glass Producers and Users. Springer US, Boston, MA, 2004: pp. 37–48. [CrossRef]

- H. Rai, K. Vivek Gaurav, S. Pradhan, M. Desu, S. Sharma, S. Nagamatsu, S.S. Pandey, Vertical Distribution of Molecular Orientation and Its Implication on Charge Transport in Floating Films of Conjugated Polymers. Physica Status Solidi (a), 2023; 220. [CrossRef]

- N. Kumari, S. Sharma, S. Nagamatsu, S.S. Pandey, Orientation of Semiconducting Polymers via Swift Printing and Drawing Techniques for High Performance Organic Electronic Devices, in: 2020 27th International Workshop on Active-Matrix Flatpanel Displays and Devices (AM-FPD), IEEE, 2020: pp. 67–70. [CrossRef]

- M. Pandey, N. Kumari, S. Nagamatsu, S.S. Pandey, Recent advances in the orientation of conjugated polymers for organic field-effect transistors. J Mater Chem C Mater 2019, 7, 13323–13351. [Google Scholar] [CrossRef]

- M. Pandey, A. Gowda, S. Nagamatsu, S. Kumar, W. Takashima, S. Hayase, S.S. Pandey, Rapid Formation and Macroscopic Self-Assembly of Liquid-Crystalline, High-Mobility, Semiconducting Thienothiophene. Adv Mater Interfaces 2018, 5, 1700875. [Google Scholar] [CrossRef]

- M. Pandey, S. Nagamatsu, S.S. Pandey, S. Hayase, W. Takashima, Orientation Characteristics of Non-regiocontrolled Poly (3-hexyl-thiophene) Film by FTM on Various Liquid Substrates. J Phys Conf Ser 2016, 704, 012005. [Google Scholar] [CrossRef]

- Appendix C: Contact Angle Goniometry, in: Surface Design: Applications in Bioscience and Nanotechnology, Wiley, 2009: pp. 471–473. [CrossRef]

- H. -W. Zan, C.-W. Chou, Effect of Surface Energy on Pentacene Thin-Film Growth and Organic Thin Film Transistor Characteristics. Jpn J Appl Phys 2009, 48, 031501. [Google Scholar] [CrossRef]

- S. C. Lim, S.H. Kim, J.H. Lee, M.K. Kim, D.J. Kim, T. Zyung, Surface-treatment effects on organic thin-film transistors. Synth Met 2005, 148, 75–79. [Google Scholar] [CrossRef]

- Jon Griffin, Emma Spooner, Hadi Hassan, Spin Coating: Complete Guide to Theory and Techniques, Ossila (n.d.). https://www.ossila.com/pages/spin-coating#:~:text=As%20mentioned%20above%2C%20spin%20coating,at%20the%20expense%20of%20consistency (accessed February 20, 2024).

- R. Förch, H. Schönherr, A.T.A. Jenkins, eds., Surface Design: Applications in Bioscience and Nanotechnology, Wiley, 2009. [CrossRef]

- F.C. Spano, Erratum: “Modeling disorder in polymer aggregates: The optical spectroscopy of regioregular poly(3-hexylthiophene) thin films” [J. Chem. Phys. 122, 234701 (2005)]. J Chem Phys 2007, 126. [CrossRef]

- F. C. Spano, C. Silva, H- and J-Aggregate Behavior in Polymeric Semiconductors. Annu Rev Phys Chem 2014, 65, 477–500. [Google Scholar] [CrossRef] [PubMed]

- M. Baghgar, J.A. Labastide, F. Bokel, R.C. Hayward, M.D. Barnes, Effect of Polymer Chain Folding on the Transition from H- to J-Aggregate Behavior in P3HT Nanofibers. The Journal of Physical Chemistry C 2014, 118, 2229–2235. [Google Scholar] [CrossRef]

- J. Clark, J.-F. Chang, F.C. Spano, R.H. Friend, C. Silva, Determining exciton bandwidth and film microstructure in polythiophene films using linear absorption spectroscopy. Appl Phys Lett 2009, 94. [Google Scholar] [CrossRef]

- F. C. Spano, Modeling disorder in polymer aggregates: The optical spectroscopy of regioregular poly(3-hexylthiophene) thin films. J Chem Phys 2005, 122. [Google Scholar] [CrossRef]

- G. Wang, T. Hirasa, D. Moses, A.J. Heeger, Fabrication of regioregular poly(3-hexylthiophene) field-effect transistors by dip-coating. Synth Met 2004, 146, 127–132. [Google Scholar] [CrossRef]

- S. Sharma, A.K. Vats, L. Tang, F. Kaishan, J. Toyoda, S. Nagamatsu, Y. Ando, M. Tamagawa, H. Tanaka, M. Pandey, S.S. Pandey, High field-effect mobility in oriented thin films of D-A type semiconducting polymers by engineering stable interfacial system. Chemical Engineering Journal 2023, 469, 143932. [Google Scholar] [CrossRef]

- M. Pandey, Y. Sugita, J. Toyoda, S. Katao, R. Abe, Y. Cho, H. Benten, M. Nakamura, Unidirectionally Aligned Donor–Acceptor Semiconducting Polymers in Floating Films for High-Performance Unipolar n -Channel Organic Transistors. Adv Electron Mater, 2023; 9. [CrossRef]

- R.G.S. Goh, E.R. Waclawik, N. Motta, J.M. Bell, Influence of dispersed carbon nanotubes on the optical and structural properties of a conjugated polymer, in: J.-C. Chiao, A.S. Dzurak, C. Jagadish, D. V. Thiel (Eds.), 2005, p. 60370Z. [CrossRef]

- K. Sugiyama, T. Kojima, H. Fukuda, H. Yashiro, T. Matsuura, Y. Shimoyama, ESR and X-ray diffraction studies on thin films of poly-3-hexylthiophene: Molecular orientation and magnetic interactions. Thin Solid Films 2008, 516, 2691–2694. [Google Scholar] [CrossRef]

- N. Kumari, M. Pandey, S. Nagamatsu, M. Nakamura, S.S. Pandey, Investigation and Control of Charge Transport Anisotropy in Highly Oriented Friction-Transferred Polythiophene Thin Films. ACS Appl Mater Interfaces 2020, 12, 11876–11883. [Google Scholar] [CrossRef]

- H. Yang, S.W. LeFevre, C.Y. Ryu, Z. Bao, Solubility-driven thin film structures of regioregular poly(3-hexyl thiophene) using volatile solvents. Appl Phys Lett 2007, 90. [Google Scholar] [CrossRef]

- D. M. DeLongchamp, B.M. Vogel, Y. Jung, M.C. Gurau, C.A. Richter, O.A. Kirillov, J. Obrzut, D.A. Fischer, S. Sambasivan, L.J. Richter, E.K. Lin, Variations in Semiconducting Polymer Microstructure and Hole Mobility with Spin-Coating Speed. Chemistry of Materials 2005, 17, 5610–5612. [Google Scholar] [CrossRef]

- S. Sharma, N. Kumari, S. Nagamatsu, M. Nakamura, S.S. Pandey, Bistable Resistive Memory Switches fabricated by Floating Thin Films of Conjugated Polymers. Materials Today Electronics 2023, 4, 100043. [Google Scholar] [CrossRef]

- H. Rai, K. Vivek Gaurav, S. Pradhan, M. Desu, S. Sharma, S. Nagamatsu, S.S. Pandey, Vertical Distribution of Molecular Orientation and Its Implication on Charge Transport in Floating Films of Conjugated Polymers. Physica Status Solidi (a) (2023). [CrossRef]

- L. Xue, X. Gao, K. Zhao, J. Liu, X. Yu, Y. Han, The formation of different structures of poly(3-hexylthiophene) film on a patterned substrate by dip coating from aged solution. Nanotechnology 2010, 21, 145303. [Google Scholar] [CrossRef]

- N. Yadav, K. Bhargava, N. Kumari, S.S. Pandey, V. Singh, Comparative analysis of metal diffusion effects in polymer films coated with spin coating and floating film transfer techniques. Synth Met 2020, 264, 116378. [Google Scholar] [CrossRef]

- N. Kumari, M. Pandey, K. Hamada, D. Hirotani, S. Nagamatsu, S. Hayase, S.S. Pandey, Role of device architecture and AlOX interlayer in organic Schottky diodes and their interpretation by analytical modeling. J Appl Phys, 2019; 126. [CrossRef]

| Polymer Conc. (w/v) | Surface Modifiers/Dichroic Ratio | |||

|---|---|---|---|---|

| UV-Ozone | HMDS | OTS | CYTOP | |

| 1.5% | 1.8 | |||

| 2.0% | 2.5 | |||

| 3.0% | 3.1 | |||

| 4.0% | 4.2 | 4.1 | 4.0 | 4.3 |

| 5.0% | 3.5 | |||

| 6.0% | 2.3 | |||

| 7.0% | 2.1 | |||

| Fabrication Techniques | Concentration (w/v) | Thickness (nm) | Carrier mobility (cm2V-1s-1) | On-off Ratio |

|---|---|---|---|---|

| Spin-coating | 0.5 % | 34 | 8.0 × 10-4 | 3.6 × 102 |

| Dip-coating | 0.1 % | 29 | 1.3 × 10-3 | 4.9 × 103 |

| UFTM | 4.0 % | 23 | 7.0 × 10-2 | 4.5 × 104 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).