Submitted:

30 April 2024

Posted:

30 April 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Dynamic Analysis of Casting Barrel

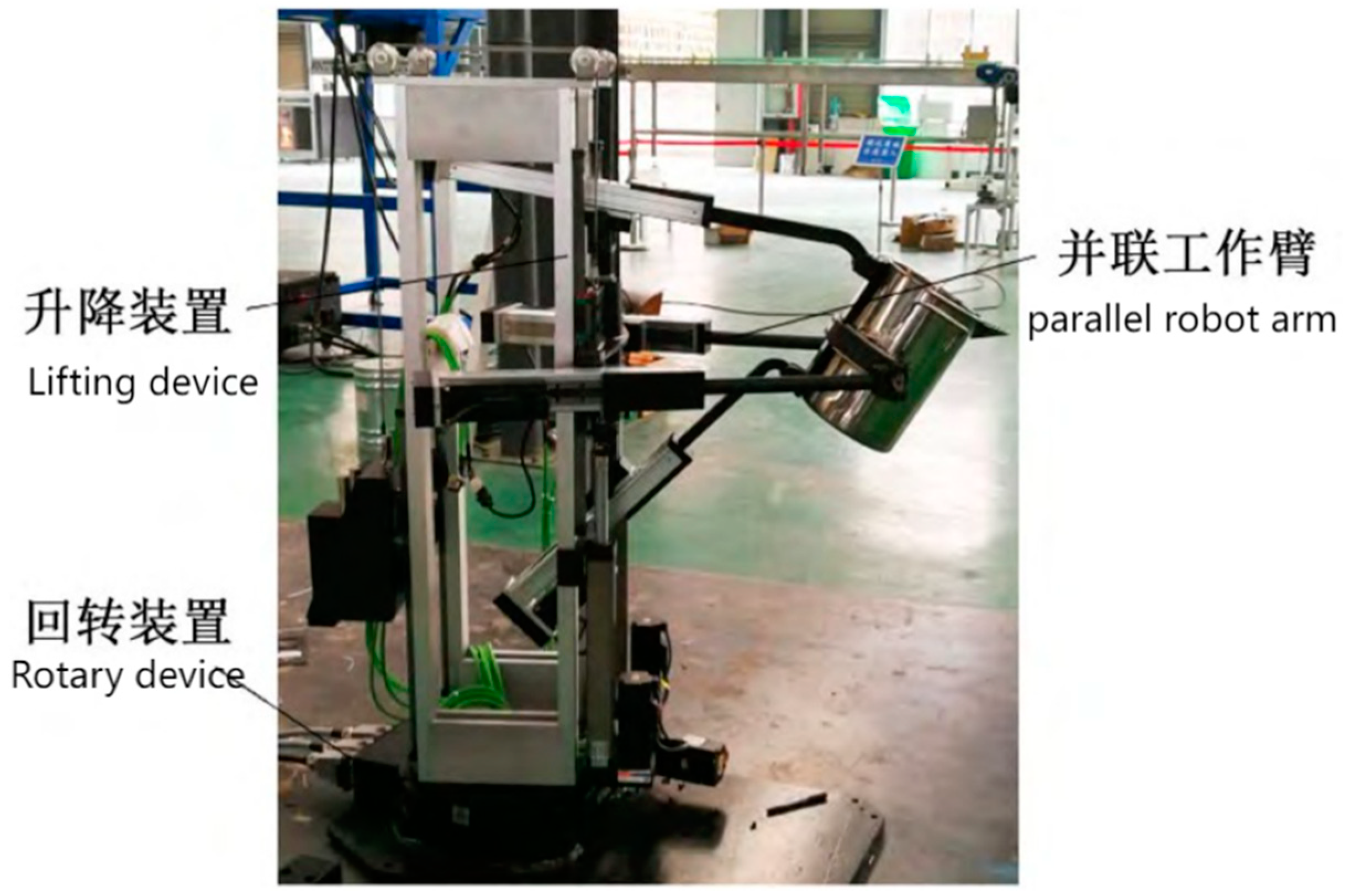

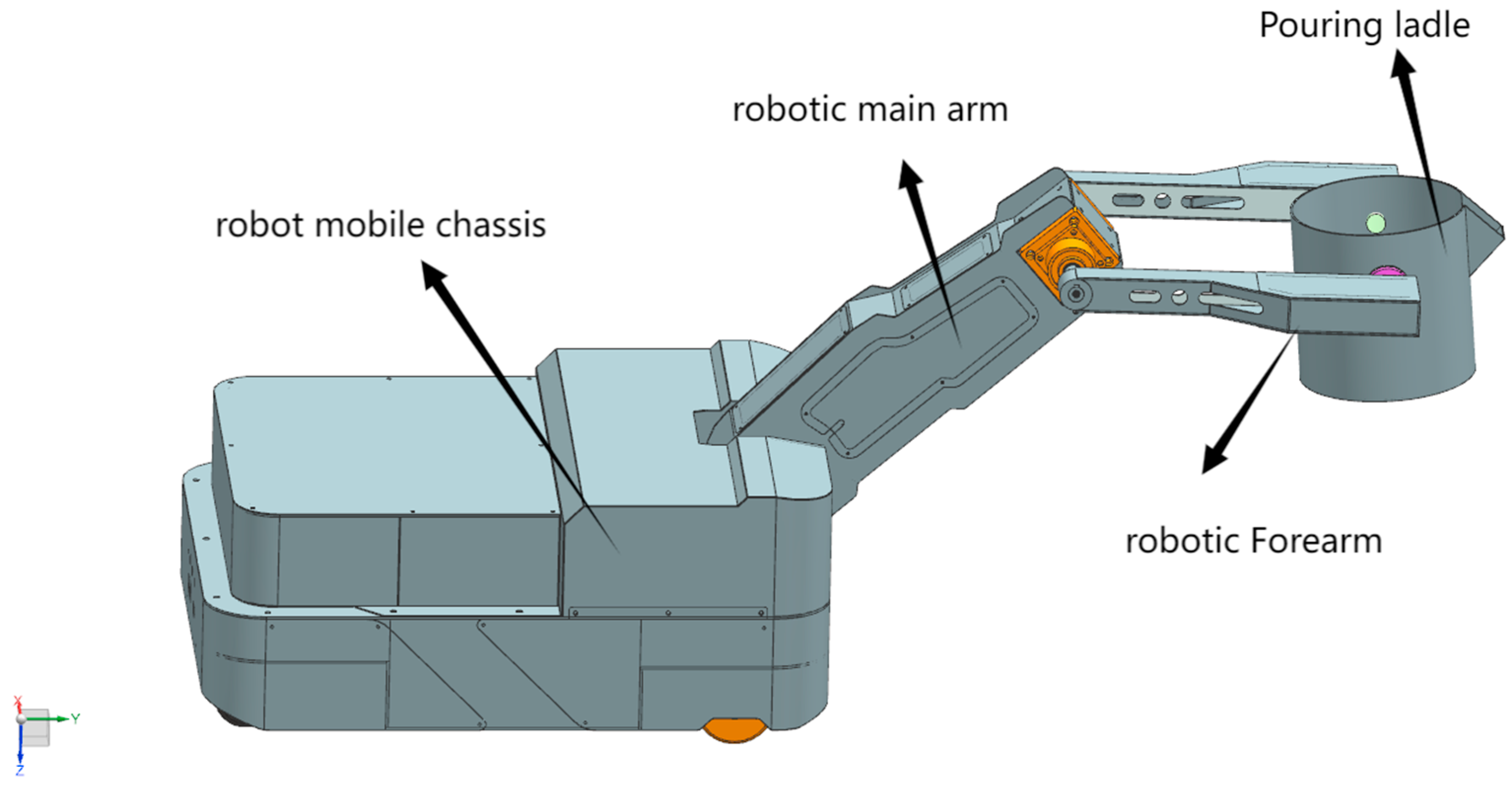

2.1. Robot 3D Modeling

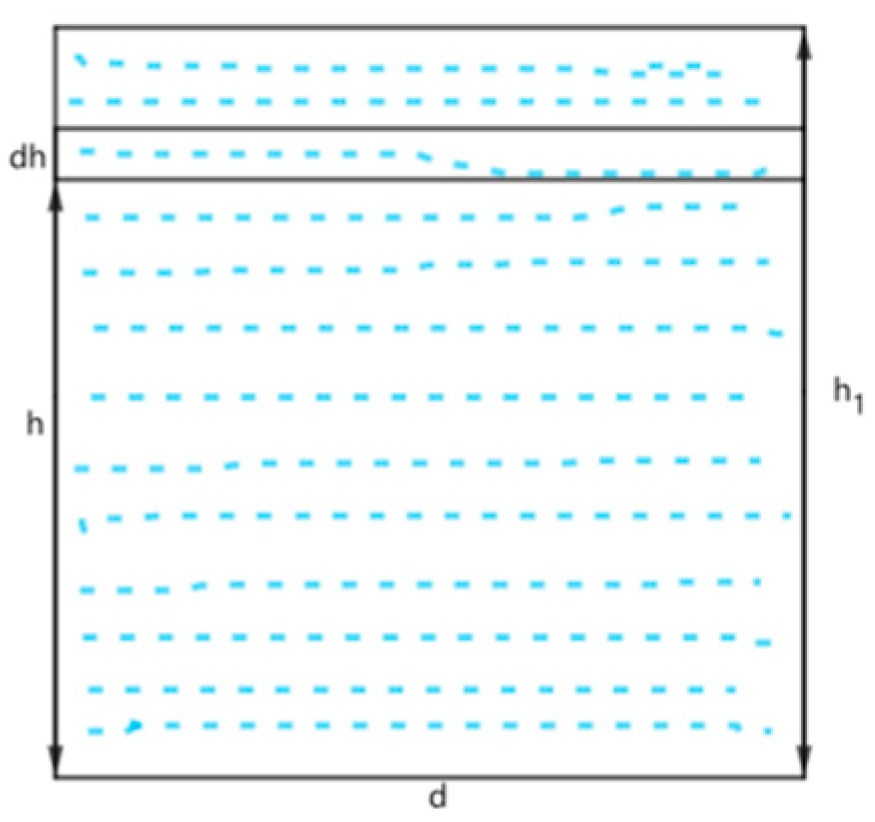

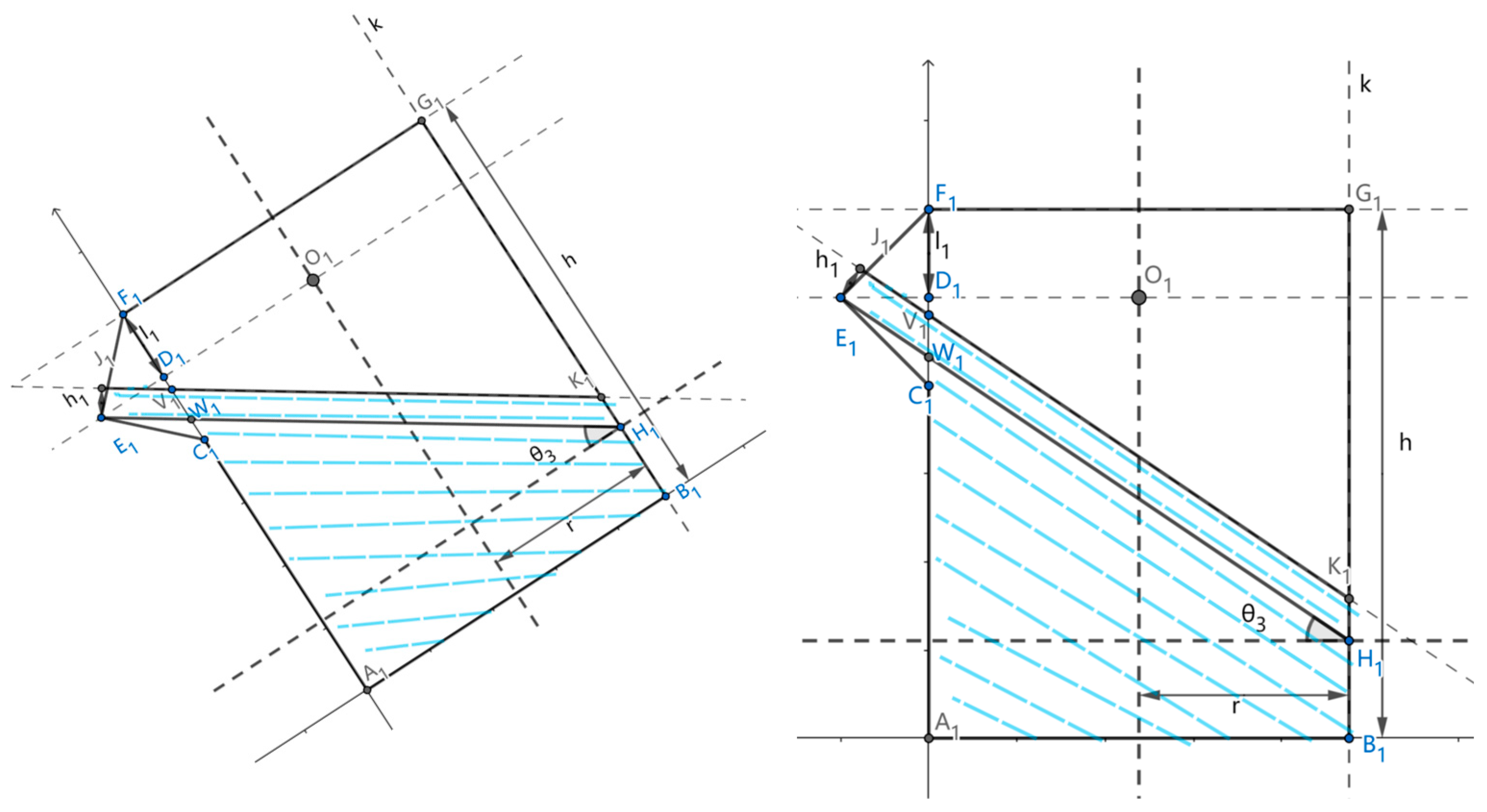

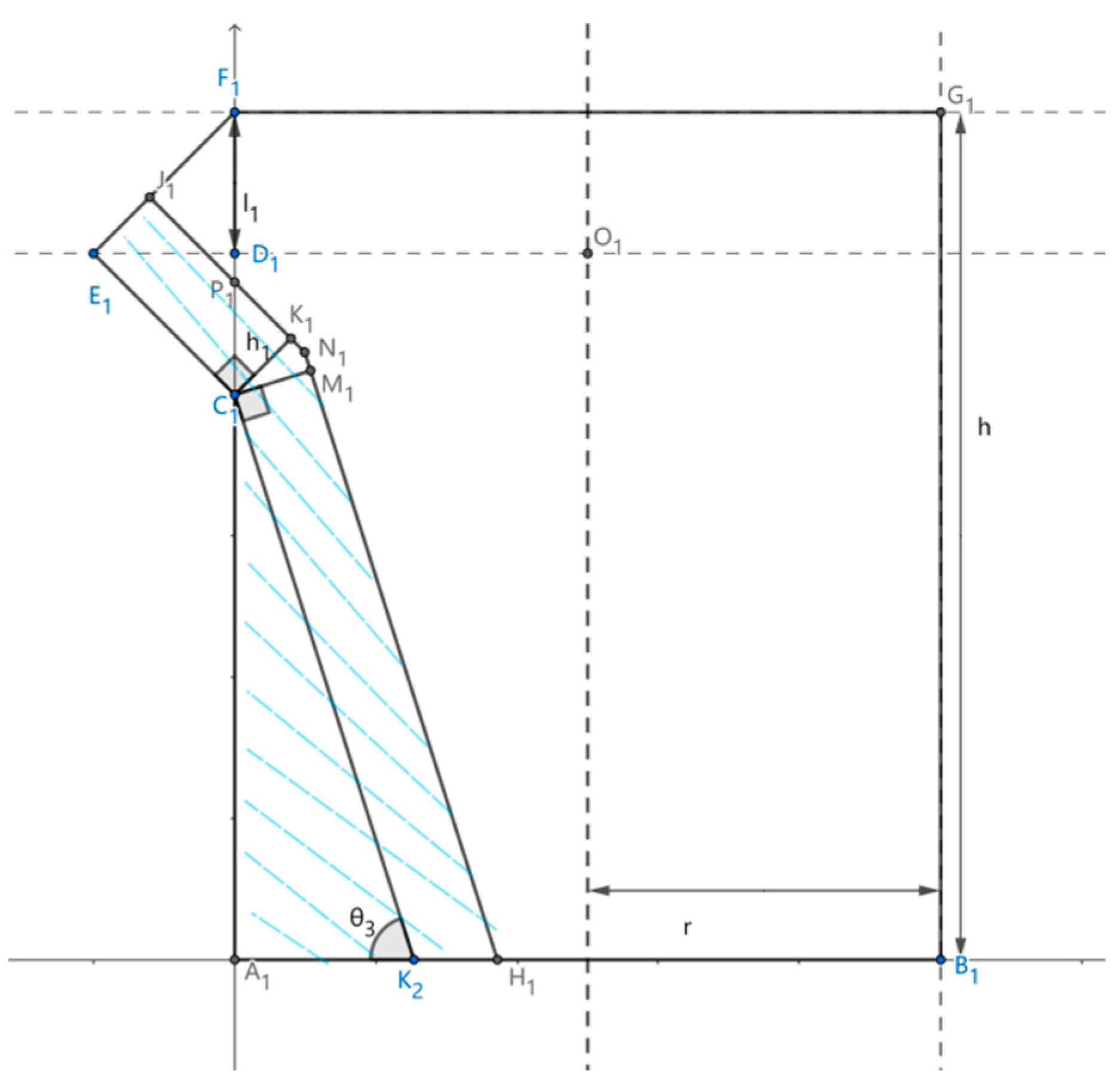

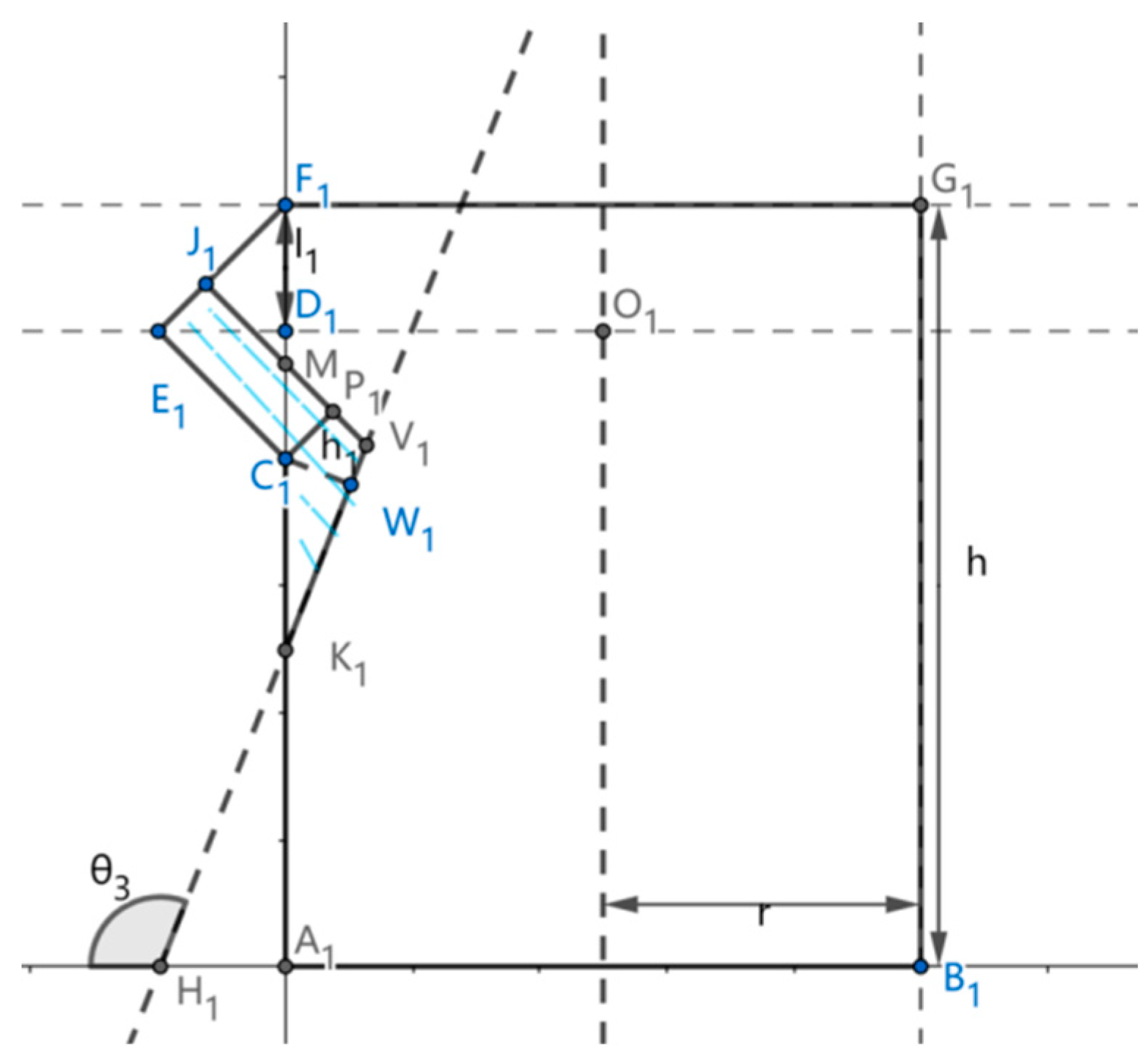

2.2. Differential Analysis of the Mouth of a Casting Barrel

2.3. Analysis of the Casting Drum Angle as a Function of the Remaining Volume of Liquid

2.4. Selection and Description of Design Parameters for Casting Drums

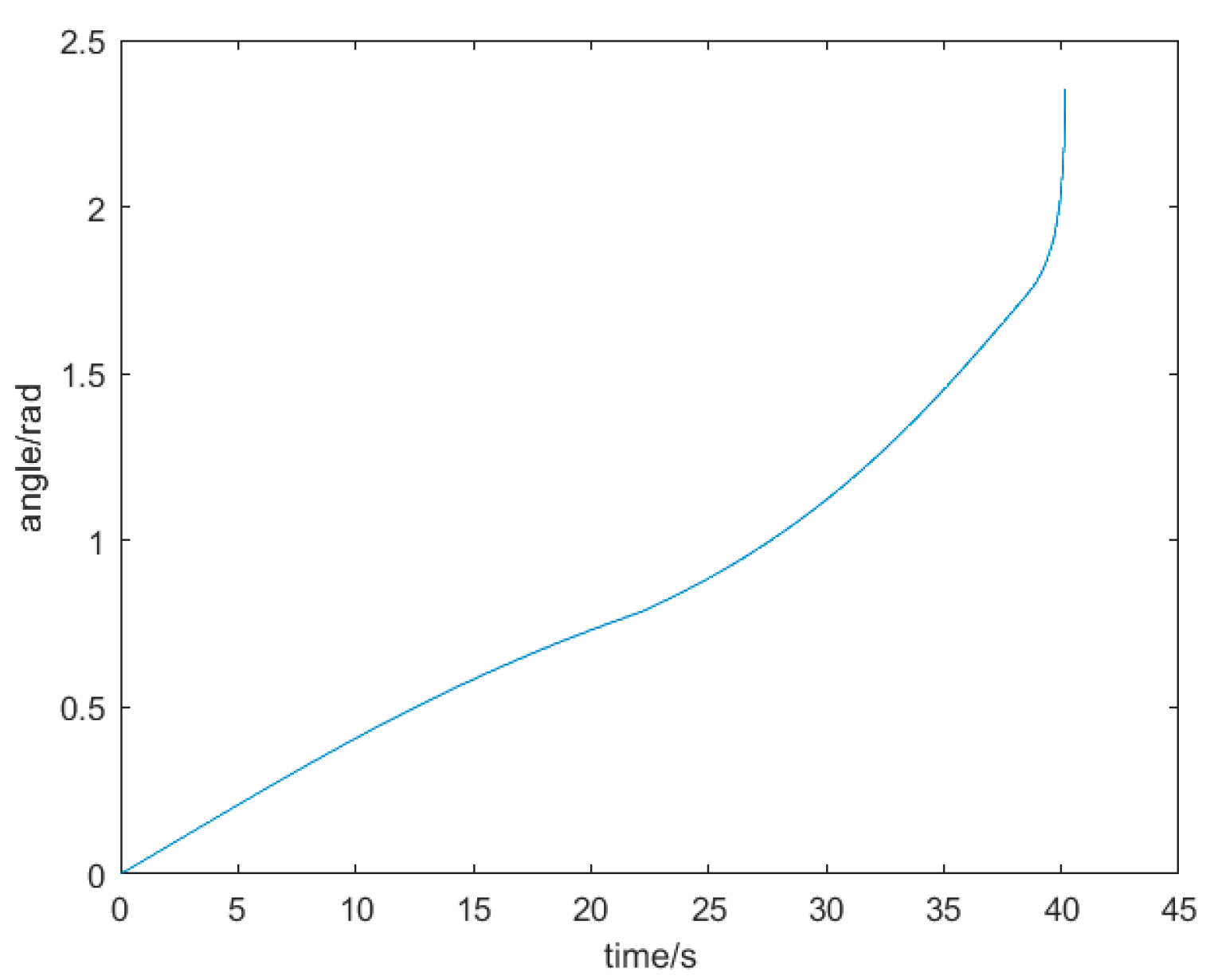

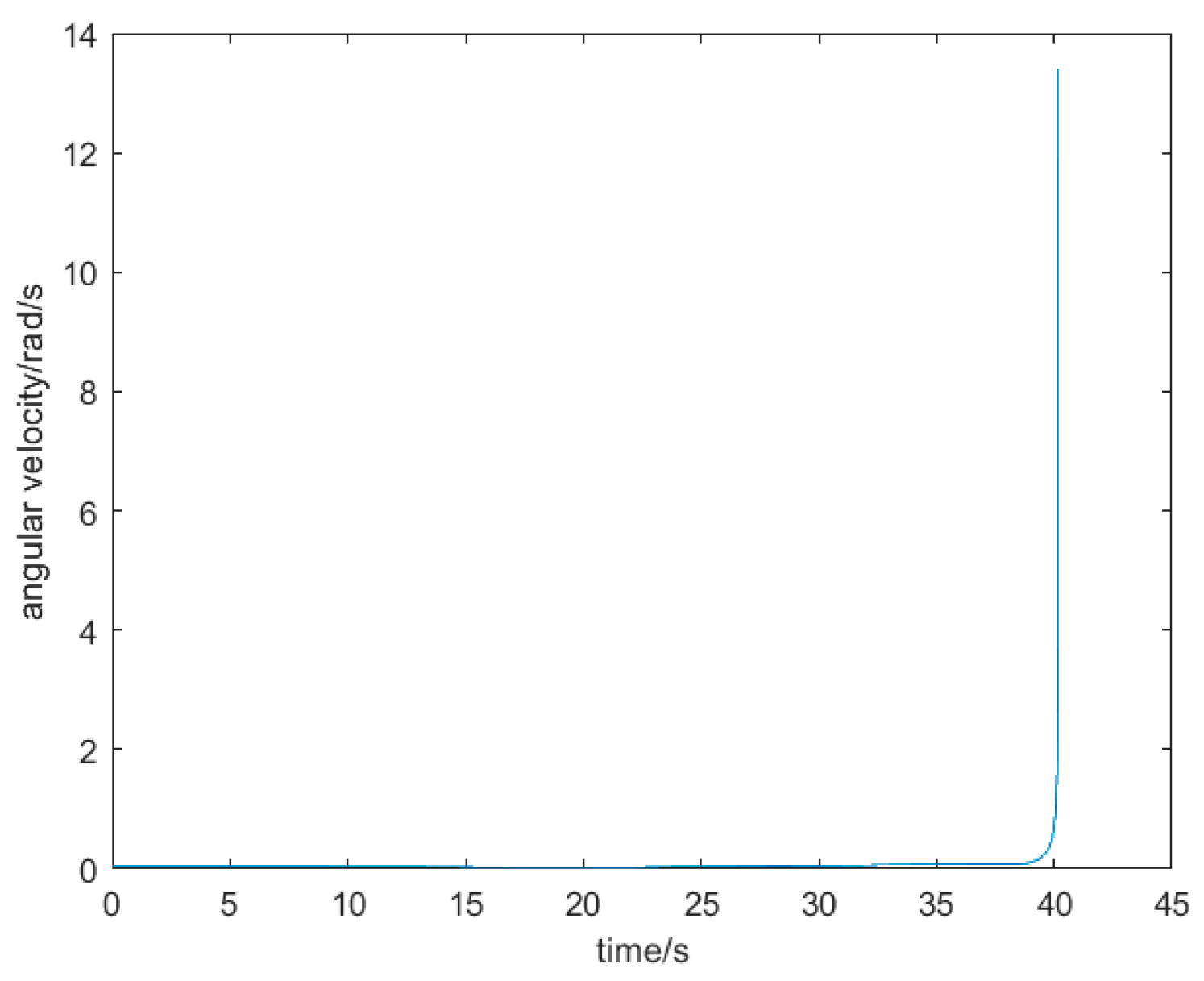

3. Simulation of Casting Drum Mechanics with Fifth-Degree Polynomial Interpolation and Fitting Approximation

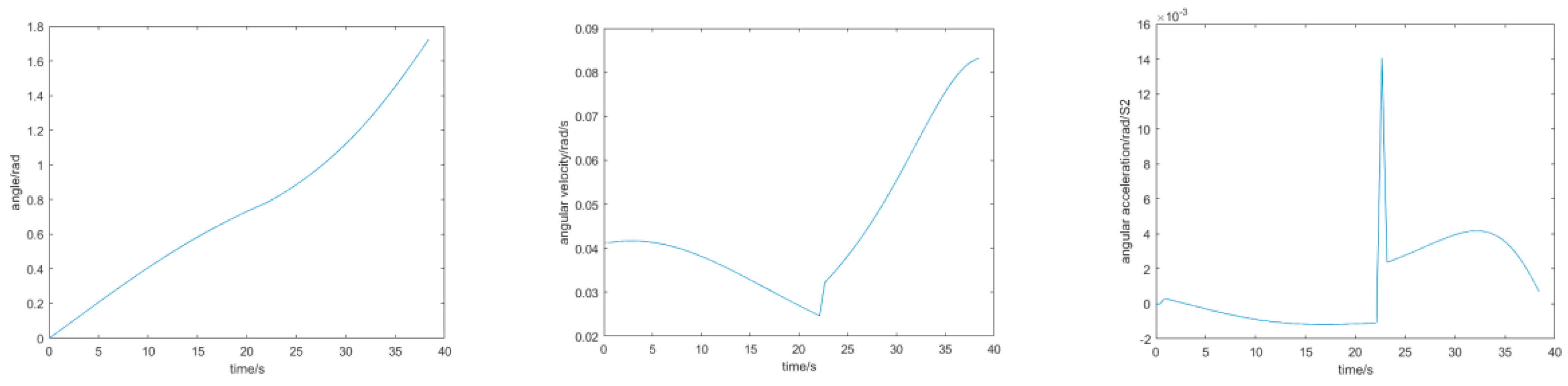

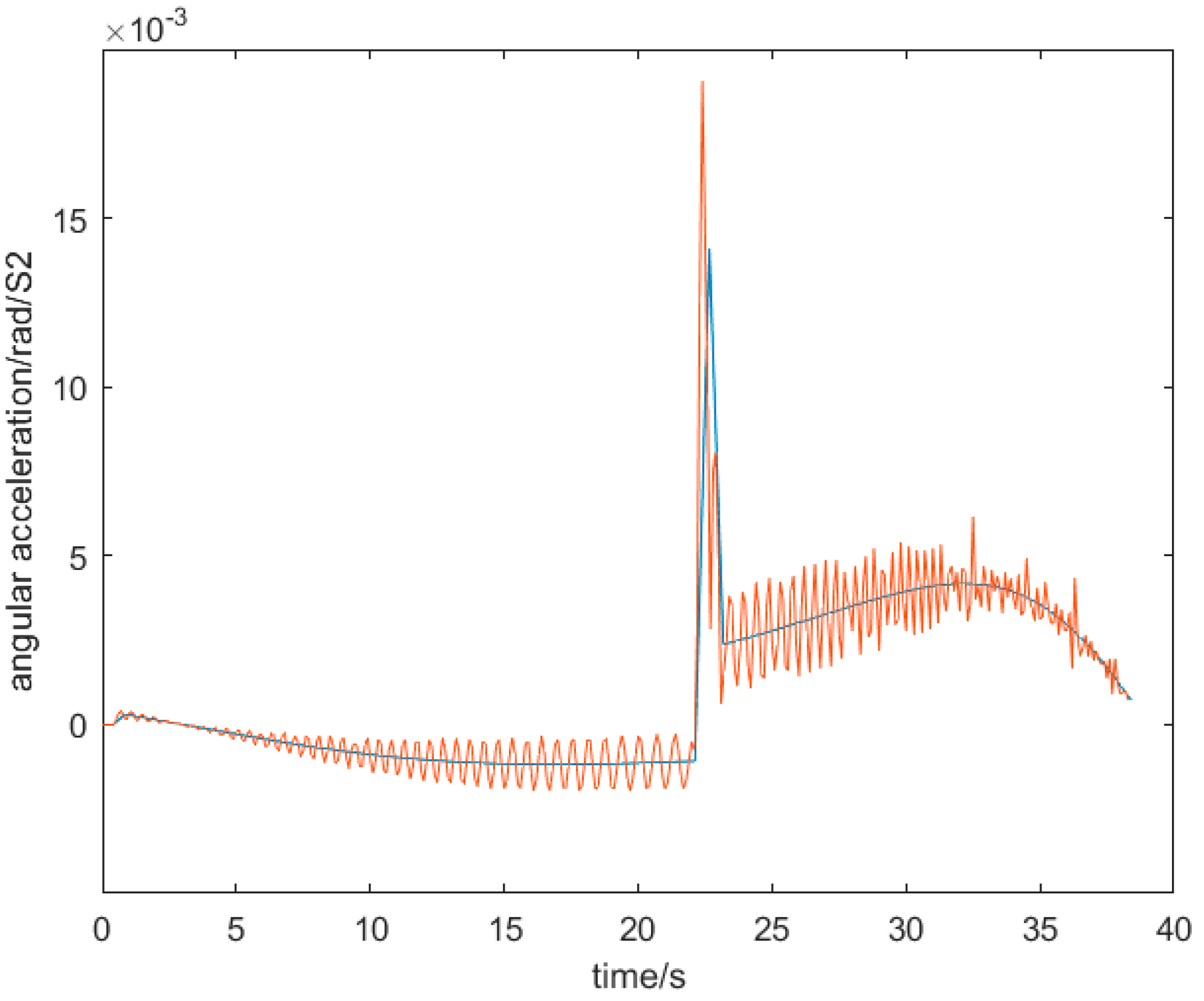

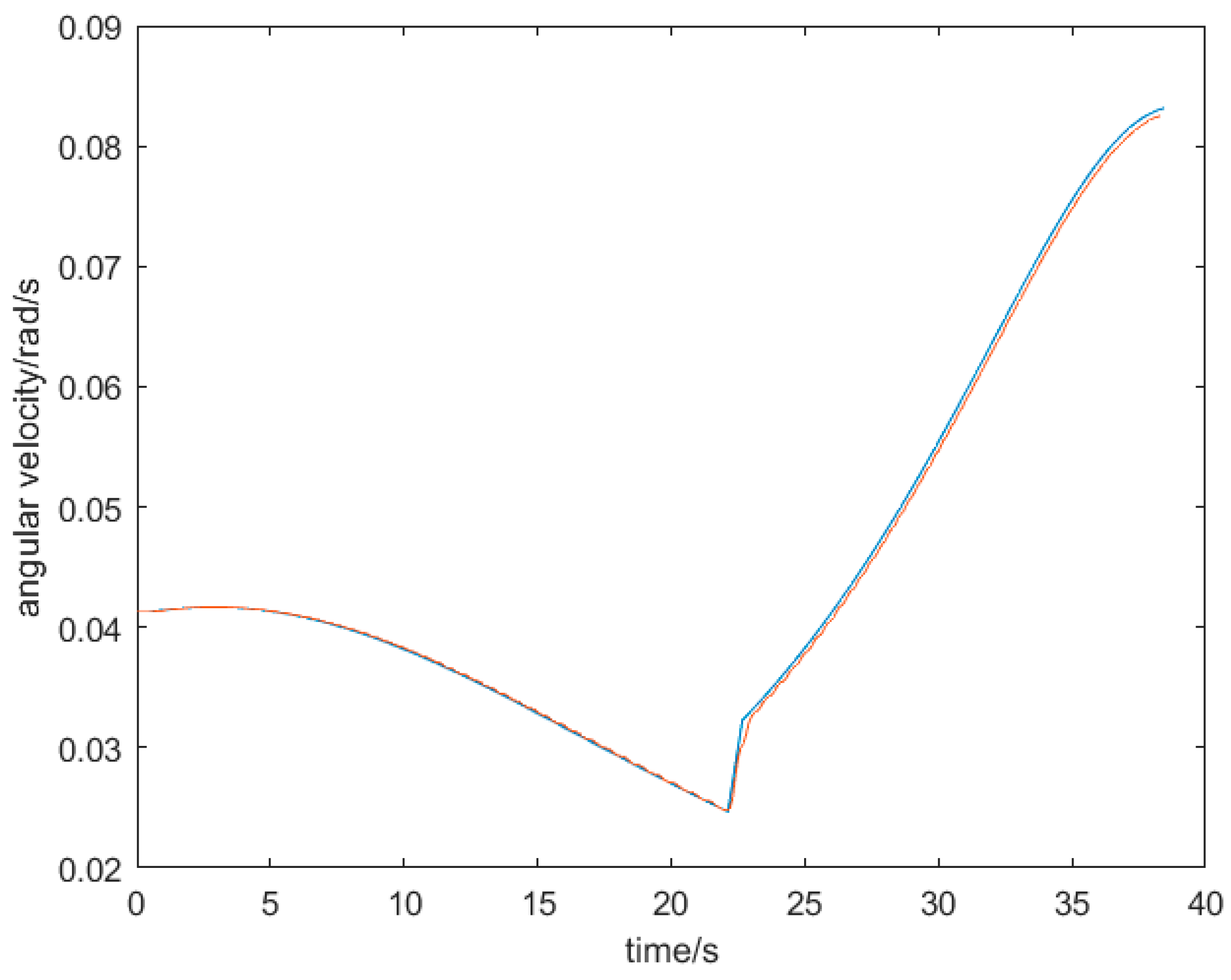

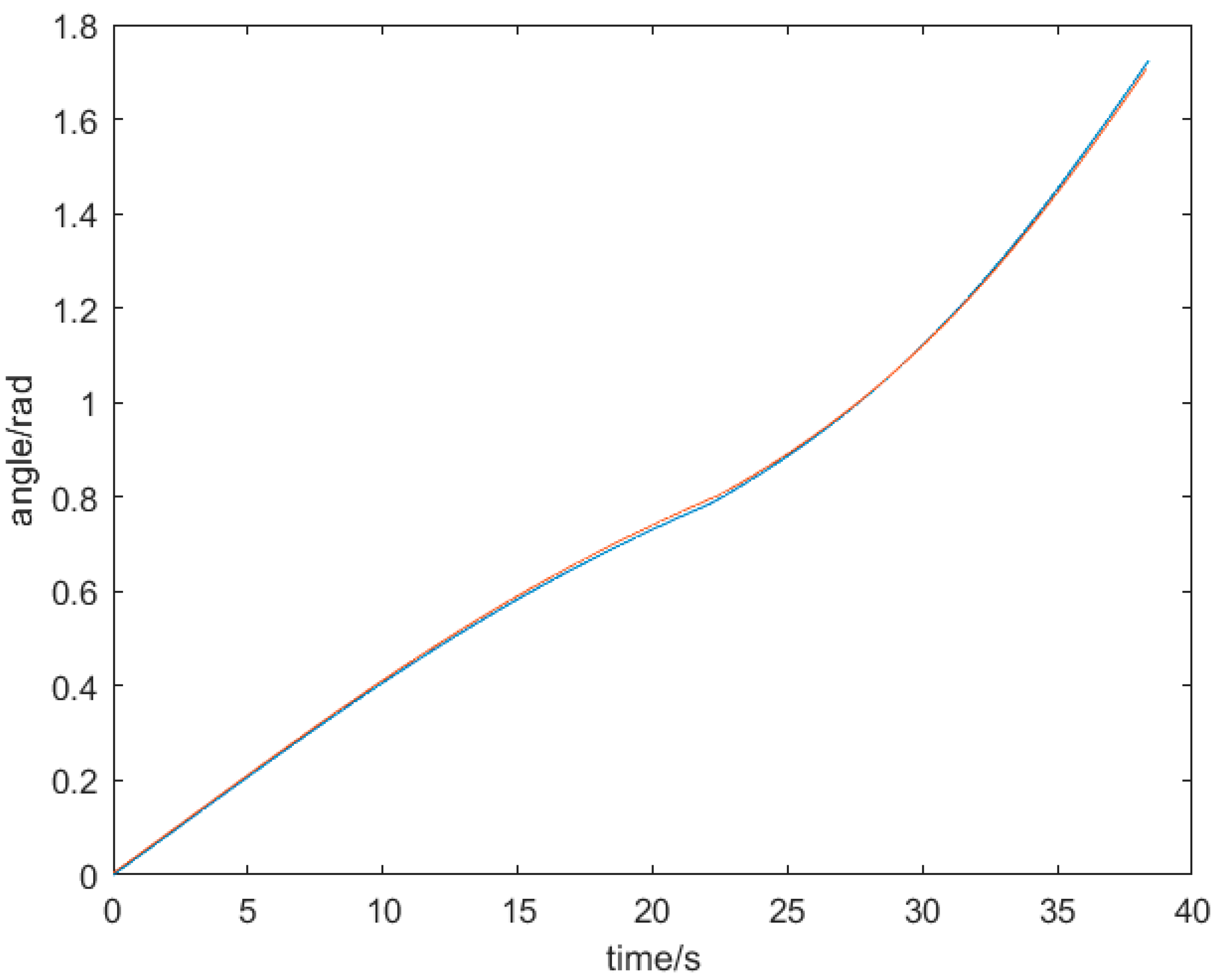

3.1. Simulation and Analysis of Casting Drum Dynamics

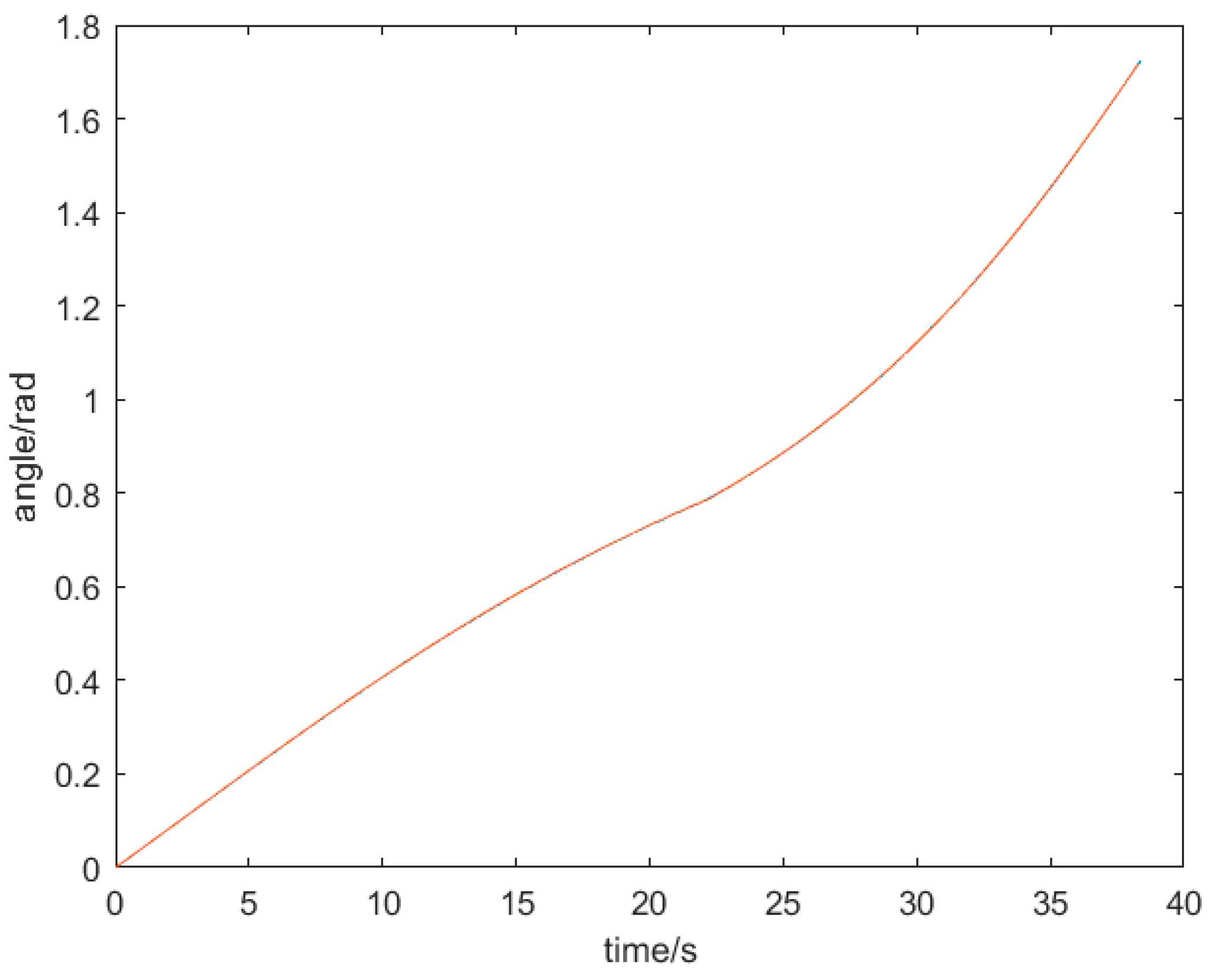

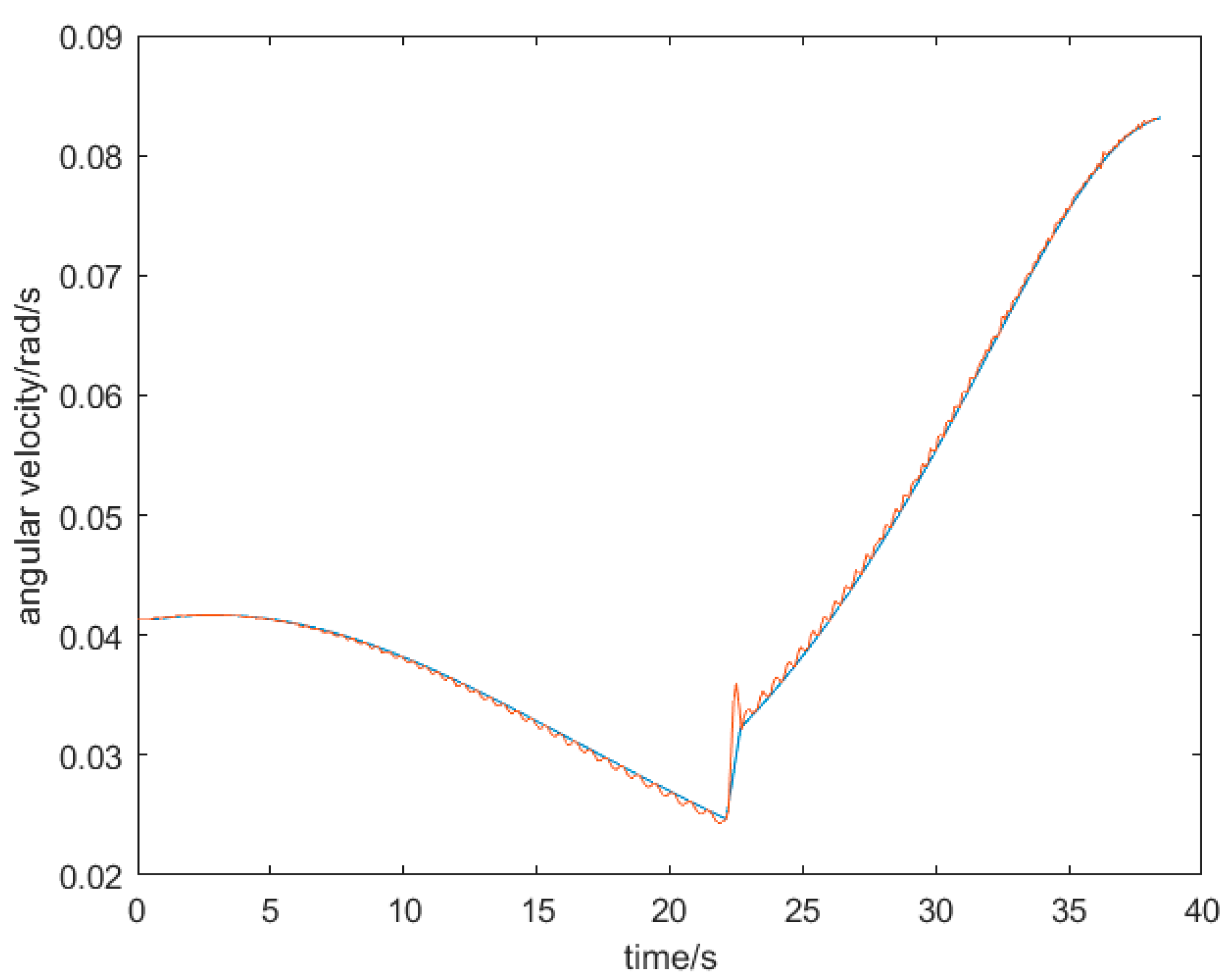

3.2. Fitted Approximation with Fifth Degree Polynomial Interpolation

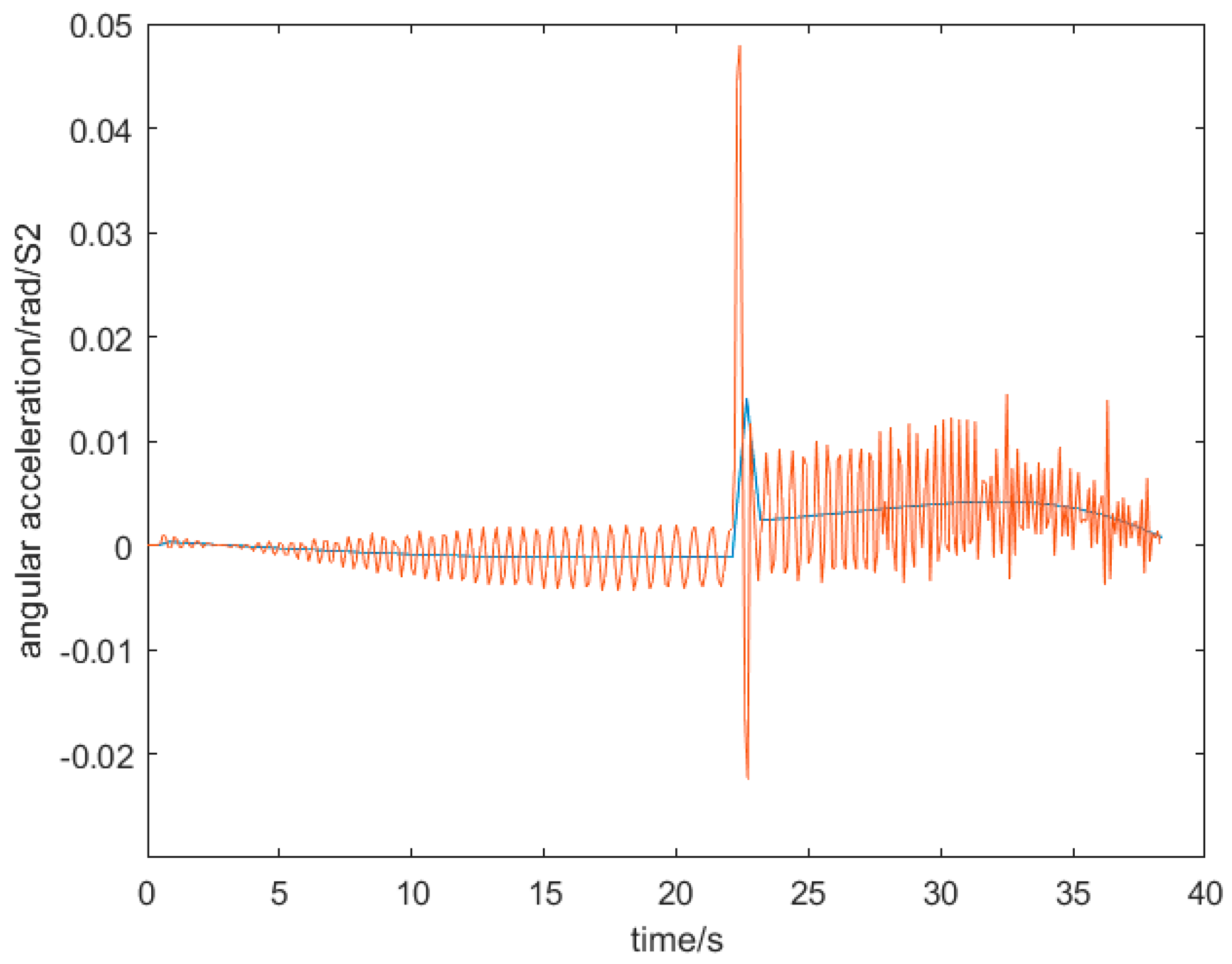

3.3. PID Algorithm Based on Discretization of Time and Angular Acceleration

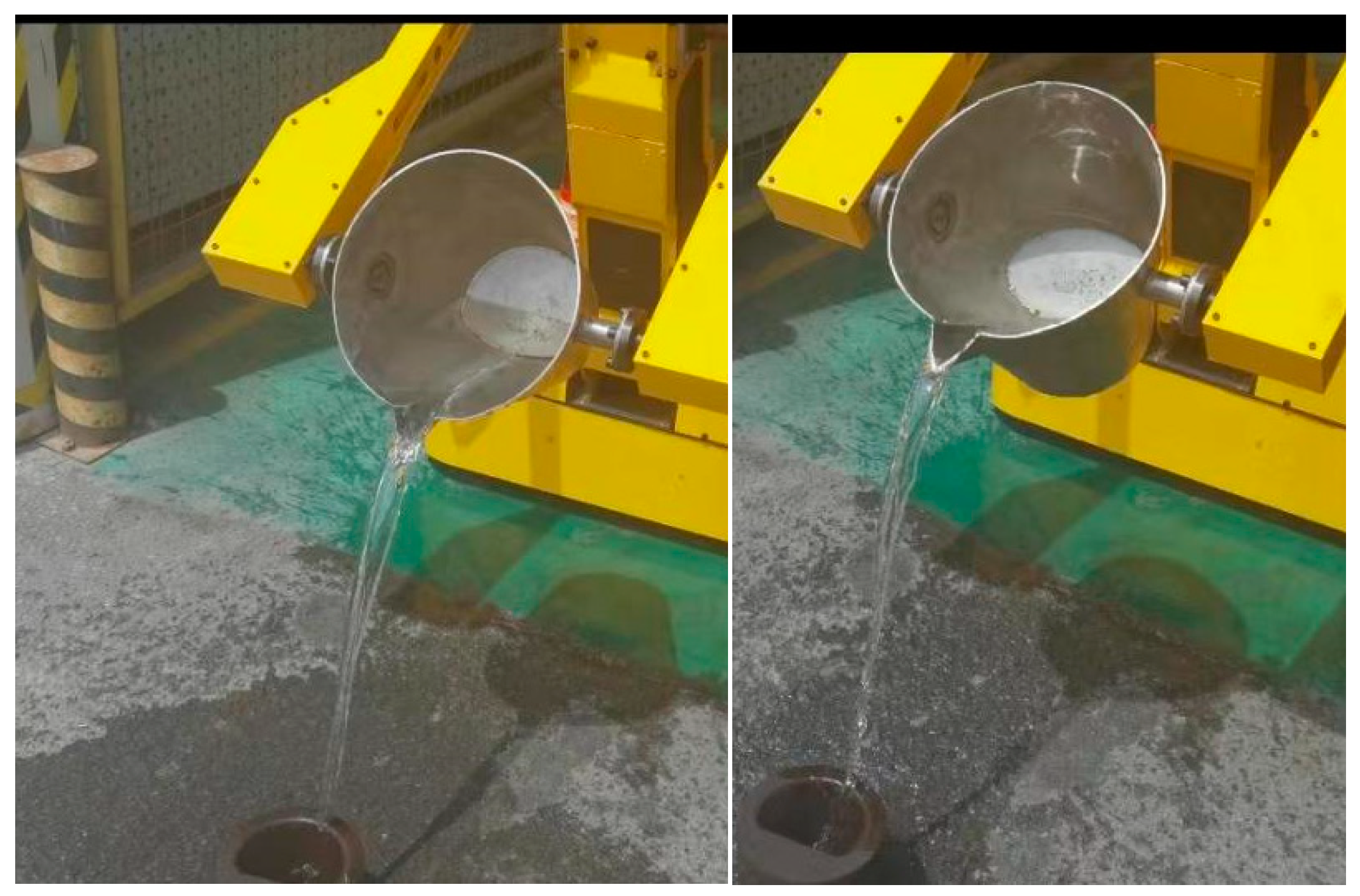

4. Experiment

4. Conclusion

Acknowledgments

References

- Kim, R., Balakirsky, S., Ahlin, K., Marcum, M., and Mazumdar, A. (January 22, 2021). "Enhancing Payload Capacity With Dual-Arm Manipulation and Adaptable Mechanical Intelligence." ASME. J. Mechanisms Robotics. April 2021; 13(2): 021012. [CrossRef]

- Ren Runrun. Structural design and performance analysis of movable casting robot in complex environment[D]. Anhui University of Technology,2019.

- Xu Chengke. Design and research of heavy-duty casting robot execution system[D]. Anhui University of Technology,2019.

- Zheng Yan. Design and motion characteristic analysis of the main body mechanism of heavy-duty casting robot[D]. Anhui University of Technology,2018.

- Ding Xuming. Kinematic analysis of heavy-duty casting robot[D]. Anhui University of Technology,2018.

- Yang Lin. Design of a four-degree-of-freedom heavy-duty casting robot[D]. Anhui University of Technology,2023. [CrossRef]

- Duan Hao. Design and research of hybrid movable self-balancing heavy-duty casting robot[D]. Anhui University of Technology,2022. [CrossRef]

- Wang Peng. Research on structure optimization and control of movable casting handling robot[D]. Anhui University of Technology,2020.

- Wang Chengjun,CHEN Xiaozhe,ZHANG Tianyu et al. Rail wheel type semi-automatic double side casting machine [P]. Anhui: CN104308135A,2015-01-28.

- Zou Daqun. An electro-hydraulic casting machine [P]. Shandong: CN103990785A,2014-08-20.

- Lei Xianhua,Zhu Shisha,LIU Jingang. Design of semi-automatic fixed-point tilting pouring table[J]. Foundry,2014,63(08):809-811.

- Zou Zhicheng,Zhang Yiyue,Jiang Hong. Segmented PID control system for quantitative casting of copper anodes[J]. Automation and Instrumentation, 2023,38(07):24-27. [CrossRef]

- Yuan Feng. A fuzzy adaptive PID-based control of disk quantitative casting[J]. World Nonferrous Metals,2022(23):151-153.

- Jiang Zhaohui,LiuXin,Gui Weihua et al. Numerical simulation of dynamic casting process in disk casting machine[J]. Journal of Central South University (Natural Science Edition),2018,49(06):1403-1413.

| Bottom radius r | barrel high | Vertical distance from mouth l1 | Wide mouthd |

|---|---|---|---|

| 12cm | 25.5cm | 3cm | 1.7cm |

| Moment/s | 5 | 7 | 9 | 11 | 13 | 15 | 17 | 19 |

|---|---|---|---|---|---|---|---|---|

| Volume/cm3 | 0 | 553.1 | 567.7 | 561.6 | 561.2 | 561.4 | 561.4 | 561.5 |

| Moment/s | 21 | 23 | 25 | 27 | 29 | 31 | 33 | 35 |

| Volume/cm3 | 565.3 | 570.3 | 548.8 | 561.0 | 561.8 | 560.5 | 562.8 | 560.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).