Submitted:

07 May 2024

Posted:

08 May 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Inventory on Animal-Husbandry Enterprises

- Herd size;

- Type of products and annual production volumes;

- Prices of products;

- Annual quantity of animal feed;

- Annual quantity of waste generated;

- Annual electricity consumption;

- Annual consumption of fossil fuels.

2.2. Waste Sampling and Characterization

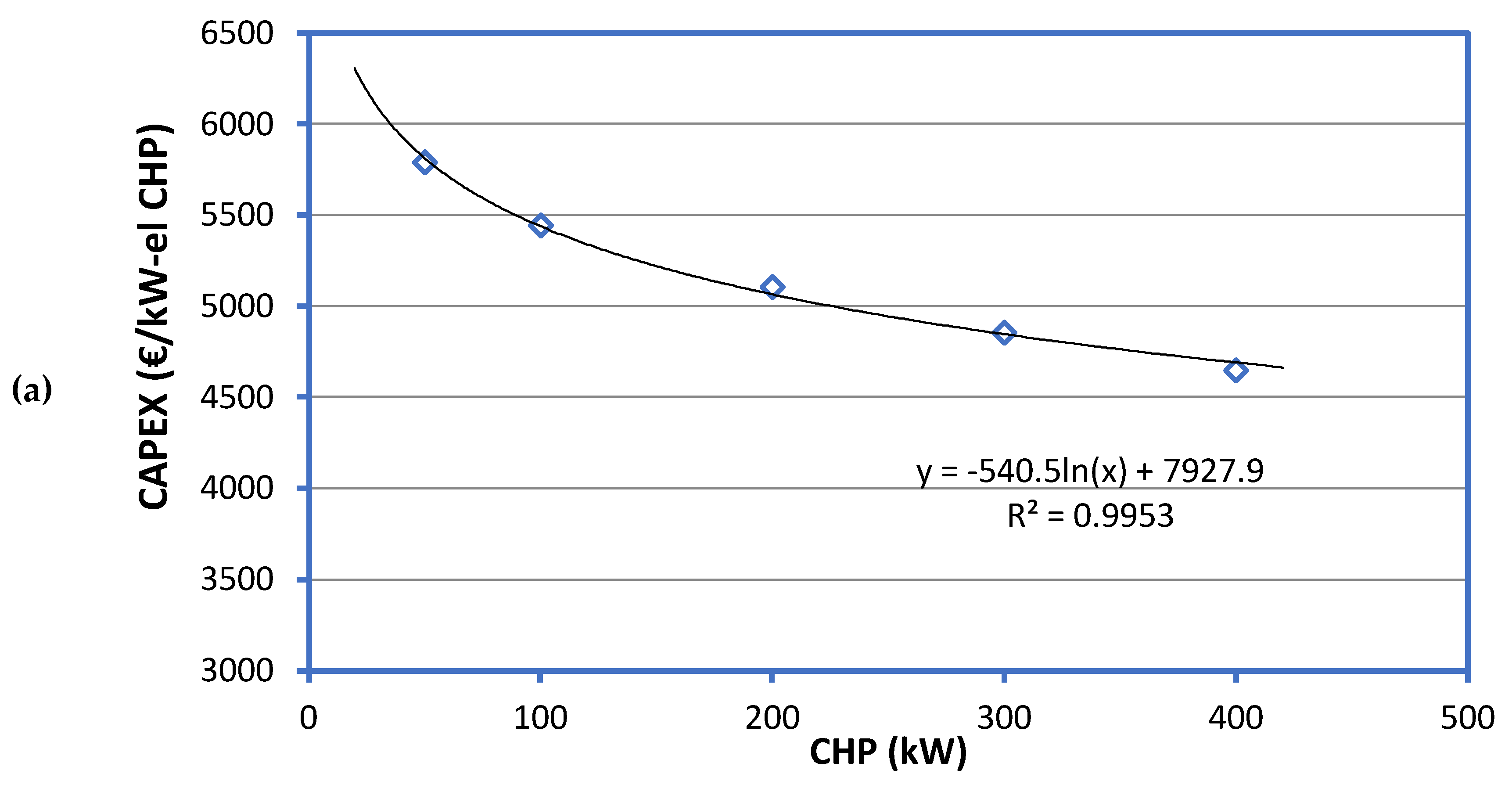

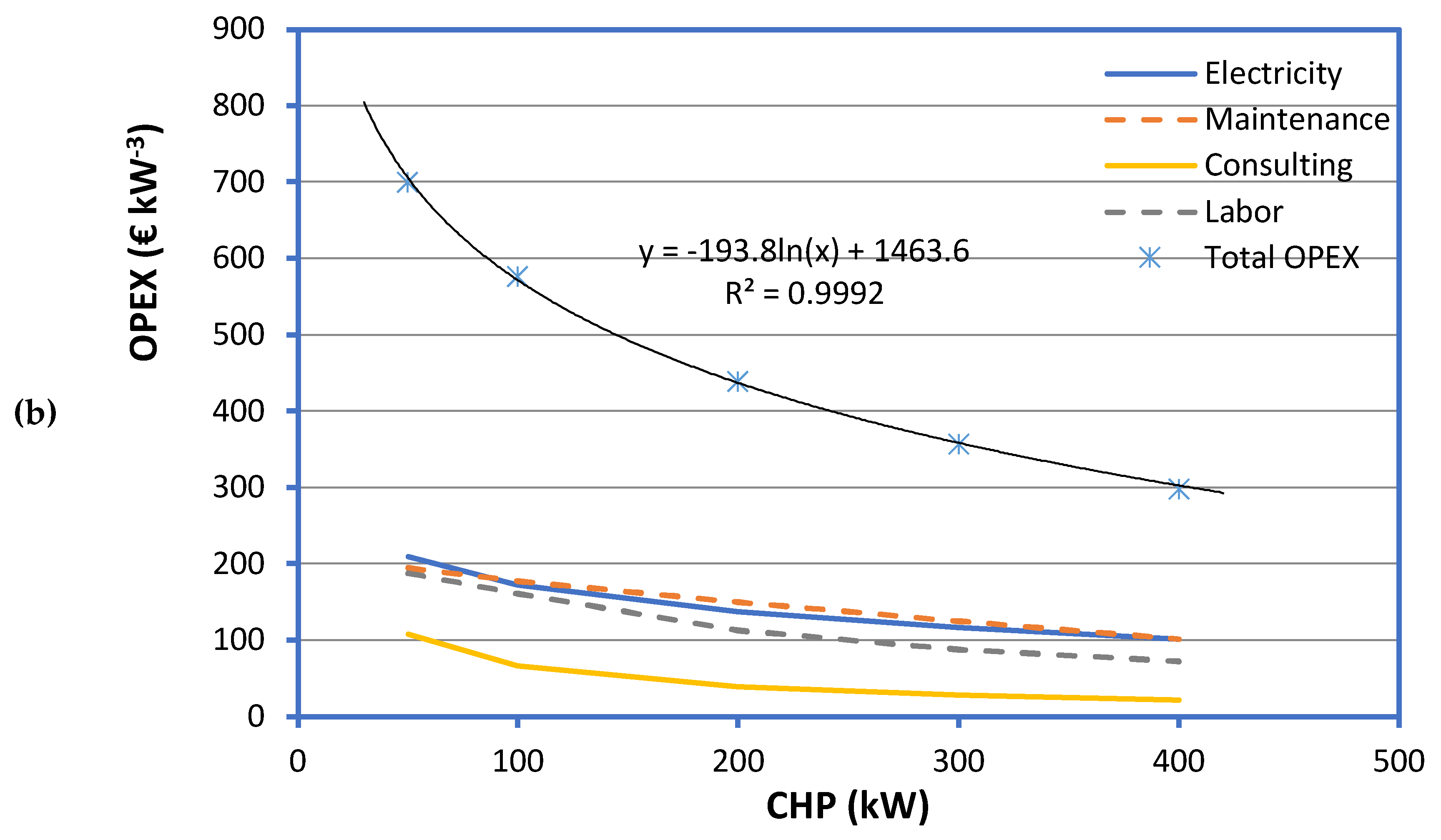

2.3. Anaerobic Digester Techno-Economic Assessment

3. Results

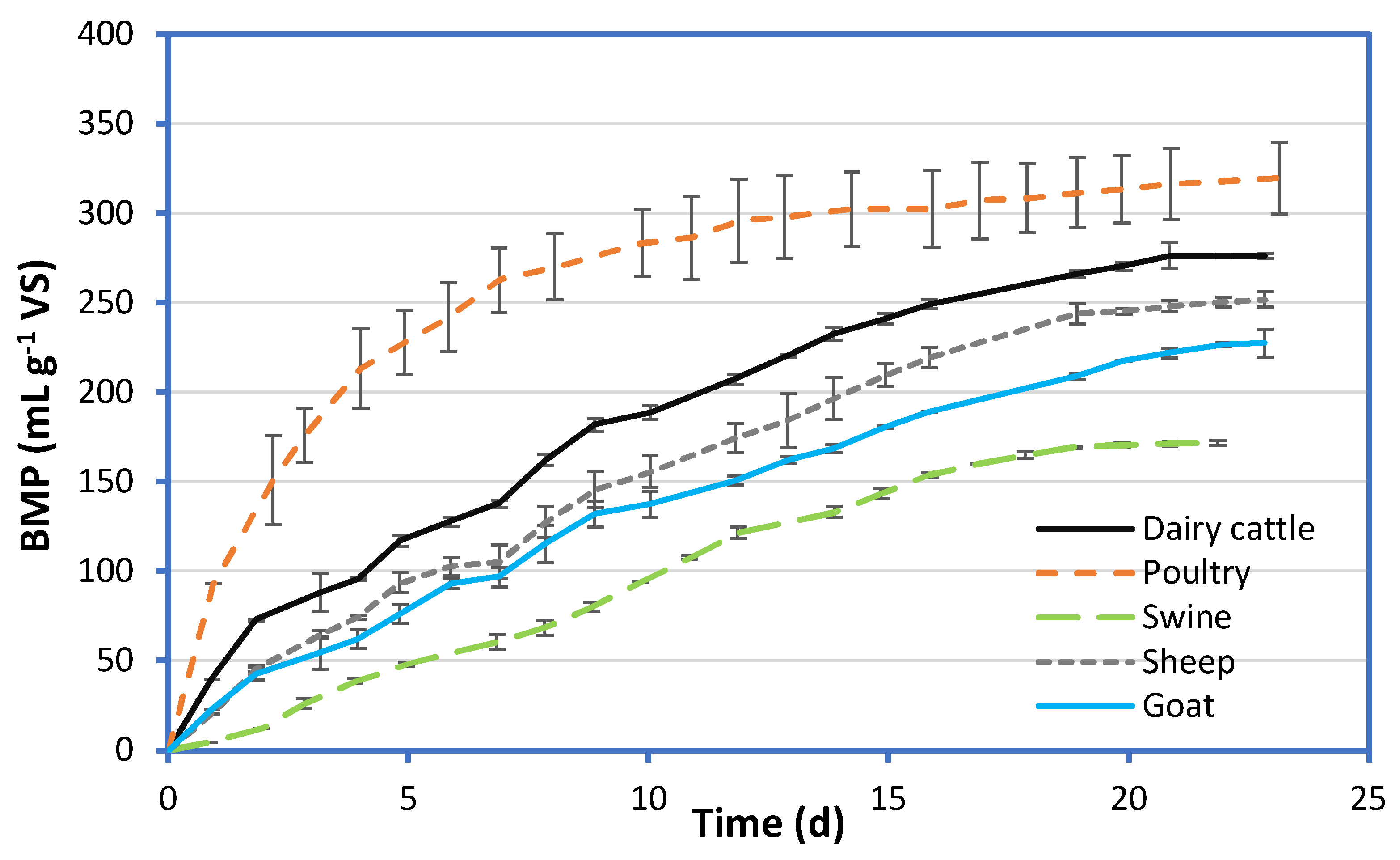

3.1. Waste Characteristics and Biochemical Methane Potential

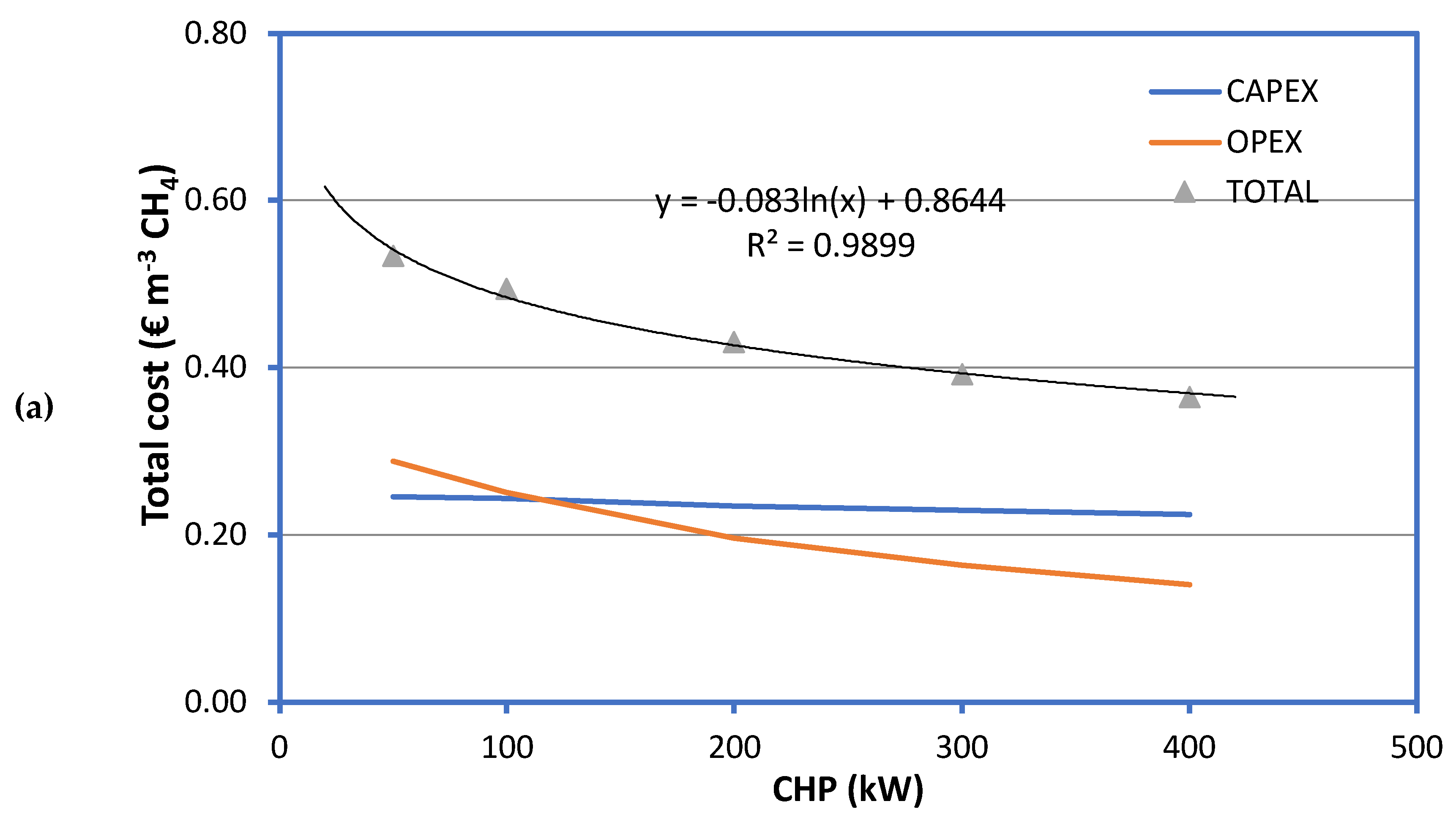

3.2. Techno-Economic Evaluation

3.3. Livestock Enterprise Inventory

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jones, R. Manure matters: historical, archaeological and ethnographic perspectives, ed.; Ashgate Publishing, Ltd, 2013.

- Bayu, W.; Rethman, N.F.G.; Hammes, P.S. The role of animal manure in sustainable soil fertility management in sub-Saharan Africa: a review. J. Sustain. Agr. 2005, 25.2, 113–136. [Google Scholar] [CrossRef]

- Varma, V.S.; Parajuli, R.; Scott, E.; Canter, T.; Lim, T.T.; Popp, J.; Thoma, G. Dairy and swine manure management- Challenges and perspectives for sustainable treatment technology. Sci. Total Environ. 2021, 778, 146319. [Google Scholar] [CrossRef]

- Kupper, T.; Hani, C.; Neftel, A.; Kincaid, C.; Buhler, M.; Amon, B.; VanderZaag, A. Ammonia and greenhouse gas emissions from slurry storage-A review. Agr. Ecosyst. Environ. 2020, 300, 106963. [Google Scholar] [CrossRef]

- Qi, J.; Yang, H.; Wang, X.; Zhu, H.; Wang, Z.; Zhao, C.; Li, B.; Liu, Z. State-of-the-art on animal manure pollution control and resource utilization. J. Environ. Chem. Eng. 2023, 11.5, 110462. [Google Scholar] [CrossRef]

- Guo, J.; Zheng, L.; Li, Z.; Zhou, X.; Cheng, S.; Zhang, L.; Zhang, Q. Effects of various pyrolysis conditions and feedstock compositions in the physicochemical characteristics of cow manure-derived biochar. J. Clean. Prod. 2021, 311, 127458. [Google Scholar] [CrossRef]

- Kalogiannis, A.; Vasiliadou, I.A.; Spyridonidis, A.; Diamantis, V.; Stamatelatou, K. Biogas production from chicken manure wastes using an LBR-CSTR two-stage system: process efficiency, economic feasibility, and carbon dioxide footprint. J. Chem. Technol. Biot. 2022, 97.10, 2952–2961. [Google Scholar] [CrossRef]

- Calbry-Muzyka, A.; Madi, H.; Rusch-Pfund, F.; Gandiglio, M.; Biollaz, S. Biogas composition from agricultural sources and organic fraction of municipal solid waste. Renew. Energ. 2022, 181, 1000–1007. [Google Scholar] [CrossRef]

- Tiong, Y.W.; Sharma, P.; Xu, S.; Bu, J.; An, S.; Foo, J.B.L.; Wee, B.K.; Wang, Y.; Lee, J.T.E.; Zhang, J.; He, Y.; Tong, Y.W. Enhancing sustainable crop cultivation: the impact of renewable soil amendments and digestate fertilizer on crop growth and nutrient composition. Environ. Pollut. 2024, 342, 123132. [Google Scholar] [CrossRef]

- Hussain, Z.; Mishra, J.; Vanacore, E. Waste to energy and circular economy: the case of anaerobic digestion. J. Enterprise Inf. Manag. 2020, 33.4, 817–838. [Google Scholar] [CrossRef]

- Boscolo, M.; Bregant, L.; Miani, S.; Padoano, E.; Piller, M. An enquiry into the causes of an explosion accident occurred in a biogas plant. Process Saf. Prog. 2020, 39.1, e12063. [Google Scholar] [CrossRef]

- Obileke, K.; Nwokolo, N.; Makaka, G.; Mukumba, P.; Onyeaka, H. Anaerobic digestion: technology for biogas production as a source of renewable energy-A review. Energy Environ. 2021, 32.2, 191–225. [Google Scholar] [CrossRef]

- Sorensen, J.F.L.; Jorgensen, H.P. Rural development potential in the bioeconomy in developed countries: The case of biogas production in Denmark. Sustainability 2022, 14.17, 11077. [Google Scholar] [CrossRef]

- Winquist, E.; Van Galen, M.; Zielonka, S.; Rikkonen, P.; Oudendag, D.; Zhou, L.; Greijdanus, A. Expert views on the future development of biogas business branch in Germany, The Netherlands, and Finland until 2030. Sustainability 2021, 13.3, 1148. [Google Scholar] [CrossRef]

- Pavicic, J.; Novak Mavar, K.; Brkic, V.; Simon, K. Biogas and biomethane production and usage: technology development, advantages and challenges in Europe. Energies 2022, 15.8, 2940. [Google Scholar] [CrossRef]

- Bremond, U.; Bertrandias, A.; Steyer, J.P.; Bernet, N.; Carrere, H. A vision of European biogas sector development towards 2030: Trends and challenges. J. Clean. Prod. 2021, 287, 125065. [Google Scholar] [CrossRef]

- Pellegrini, G.; de Mattos, C.S.; Otter, V.; Hagelaar, G. Exploring how EU agri-food SMEs approach technology-driven business model innovation. Int. Food Agribus. Man. 2023, 26.3, 577–595. [Google Scholar] [CrossRef]

- Diamantis, V.; Erguder, T.H.; Aivasidis, A.; Verstraete, W.; Voudrias, E. Wastewater disposal to landfill-sites: a synergistic solution for centralized management of olive mill wastewater and enhanced production of landfill gas. J. Environ. Manage. 2013, 128, 427–434. [Google Scholar] [CrossRef] [PubMed]

- Spyridonidis, A.; Vasiliadou, I.A.; Akratos, C.S.; Stamatelatou, K. Performance of a full-scale biogas plant operation in Greece and its impact on the circular economy. Water 2020, 12.11, 3074. [Google Scholar] [CrossRef]

- Tang, Y.; Li, Y.; Yuan, X.; Pimm, A.; Cockerill, T.T.; Wang, Q.; Ma, Q. Estimation of emissions factors from purchased electricity for European countries: impacts on emission reduction of electricity storage. Environ. Sci. Technol. 2022, 56.8, 5111–5122. [Google Scholar] [CrossRef]

- Rice, E.W.; Bridgewater, L. ; American Public Health Association (eds) Standard methods for the examination of water and wastewater. American Public Health Association, 2012 Washington D.C.

- Eftaxias, A.; Georgiou, D.; Diamantis, V.; Aivasidis, A. Performance of an anaerobic plug-flow reactor treating agro-industrial wastes supplemented with lipids at high organic loading rate. Waste Manage. Res. 2021, 39.3, 508–515. [Google Scholar] [CrossRef]

- Yousuf, A.; Sultana, S.; Monir, M.U.; Karim, A.; Rahmaddulla, S.R.B. Social business models for empowering the biogas technology. Energ. Source Part B 2017, 12.2, 99–109. [Google Scholar] [CrossRef]

- Nevzorova, T.; Kutcherov, V. Barriers to the wider implementation of biogas as a source of energy: A state-of-the-art review. Energy Strateg. Rev. 2019, 26, 100414. [Google Scholar] [CrossRef]

- Burg, V.; Troitzsch, K.G.; Akyol, D.; Baier, U.; Hellweg, S.; Thees, O. Farmer’s willingness to adopt private and collective biogas facilities: an agent-based modeling approach. Resour. Conserv. Recy. 2021, 167, 105400. [Google Scholar] [CrossRef]

| Parameter | TS (g kg-1) | VS (g kg-1) | VS/TS | BMP (mL g-1 VS) |

|---|---|---|---|---|

| Dairy cattle | 83.1±4.6 | 70.1±4.1 | 0.84 | 276±3 |

| Poultry | 692.5±4.1 | 554.6±6.5 | 0.80 | 320±19 |

| Swine | 22.3±2.5 | 15.1±3.5 | 0.68 | 172±2 |

| Sheep | 352.2±14.4 | 236.3±8.9 | 0.67 | 252±6 |

| Goat | 717.0±3.4 | 606.0±22.4 | 0.85 | 227±9 |

| Parameter | Dairy cattle | Poultry | Swine | Sheep/goat |

|---|---|---|---|---|

| Herd size | 680 | 412 000 | 5 550 | 2 000 |

| Product type | Milk | Meat (LW) | Meat (LW) | Milk |

| Price (€ tn-1) | 400-500 | 1500-2500 | 1200-1600 | 1200-1600 |

| Production (tn yr-1) | 2 740 | 1 200 | 1 280 | 200 |

| Feed (tn yr-1) | 5 300 | 200 | 4 000 | 2 000 |

| Wastes (tn tn-1) | 7.2 | 0.8 | 8.6 | 6.0 |

| Electricity (kWh tn-1) | 119 | 96 | 140 | 100 |

| Fuel (kg tn-1) | 13 | 83 | 9 | 20 |

| Parameter | Dairy cattle | Poultry | Swine | Sheep/goat |

|---|---|---|---|---|

| Waste (tn yr-1) | 20 000 | 960 | 11 000 | 1 200 |

| VS content (kg tn-1) | 70 | 555 | 15 | 420 |

| BMP (L kg-1 VS) | 280 | 310 | 160 | 220 |

| CH4 (m3 yr-1) | 390 000 | 175 000 | 26 000 | 110 000 |

| Electricity (kWh yr-1) | 1 500 000 | 660 000 | 90 000 | 400 000 |

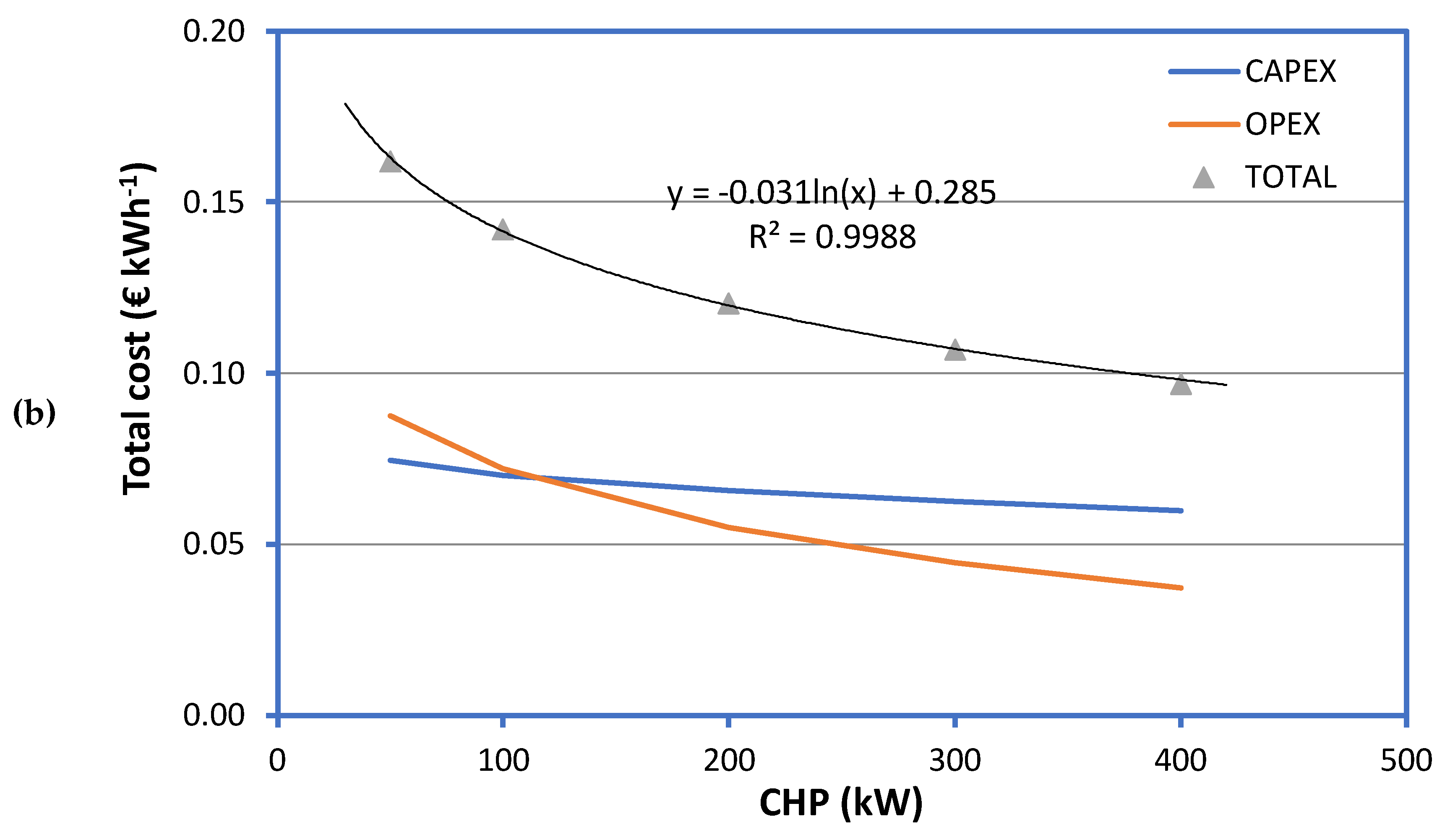

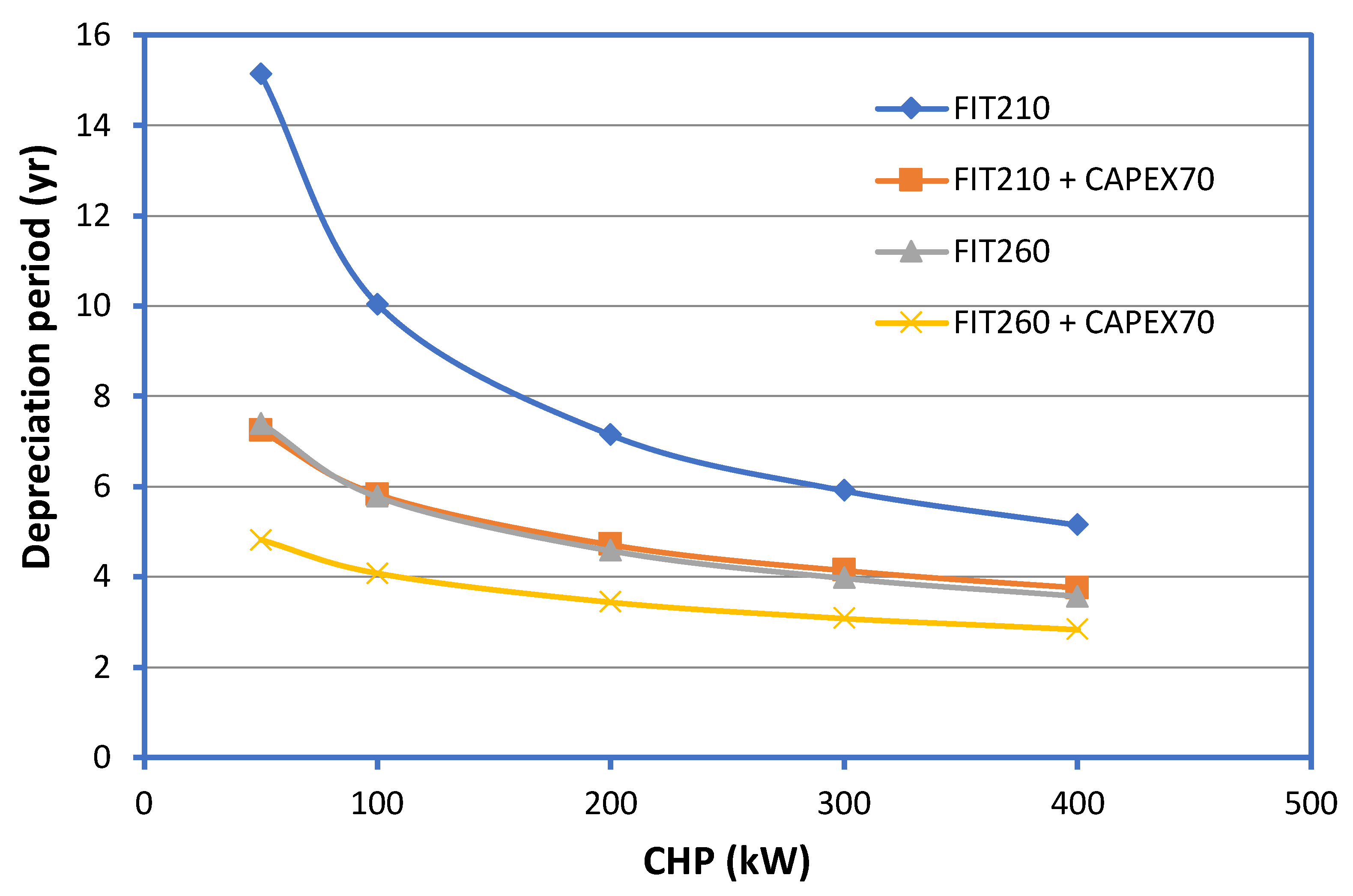

| CHP kW | 200 | 100 | 20 | 50 |

| Digester capex | 1 000 000 | 550 000 | -- | 300 000 |

| Annual CAPEX (€ yr-1) | 100 000 | 55 000 | -- | 30 000 |

| Annual OPEX (€ yr-1) | 100 000 | 60 000 | -- | 40 000 |

| Total cost (€ yr-1) | 200 000 | 115 000 | -- | 70 000 |

| Total income (€ yr-1) | 390 000 | 170 000 | -- | 104 000 |

| Total profit (€ yr-1) | 260 000 | 93 000 | -- | 55 000 |

| Annual turnover | 1 200 000 | 2 400 000 | 1 800 000 | 300 000 |

| Profit (%) | 22% | 4% | -- | 18% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).