1. Introduction

Directional forming processes usually lead to the formation of an anisotropic grain structure in metals, called texture. This is known to cause multiple effects, the most obvious of which are direction-dependent material properties. Such behavior is particularly evident in metal extrusion profiles and sheet metal. Both products have already undergone highly directional forming during the production processes. For subsequent deformation steps, the material behavior is strongly dependent on the resulting direction-dependent strength. Therefore, it is essential to take the anisotropy of pre-deformation and the resulting microstructure into account when investigating multi-stage forming processes, e.g., the forging of extruded profiles or rolling followed by deep drawing.

In finite element (FE) simulations, the relationship between the stresses and the direction-dependent deformation behavior is usually described by classical anisotropic material models such as Hill [

1], Barlat [

2,

3] , Cazacu [

4], or similar. These models typically use measured anisotropy coefficients that are applied to the entire component. However, local changes in the anisotropy coefficients during the material deformation are usually not covered. For this purpose, methods that take the local microstructure evolution into account must be applied.

While multiple approaches have been used to calculate the development of local anisotropy [

5], a distinction must be made between approaches for calculating the interactions of individual crystals (full-field single-crystal) and mesoscopic (polycrystal) approaches. When using single-crystal approaches, only a smaller number of crystals are usually considered due to the computational intensity of the methods [

6,

7]. In contrast, the mesoscopic approach allows for the simulation of larger components [

8]. A representative of this mesoscopic approach is the VPSC (visco-plastic self-consistent [

9]) model, developed by the Los Alamos National Laboratory.

Due to the numerical effort involved, texture calculation methods were previously mainly performed without taking the component geometry into account. Today’s availability of high computing power has made approaches such as CPFE (crystal plasticity finite element [

7]) methods or the implementation of the VPSC model in finite element calculation routines [

8] possible. This means that complex part geometries, manufacturing processes or process chains can now be simulated, including the texture evolution.

In the work of Li et al. [

10], they implemented a crystal plasticity model for precipitation-hardenable aluminum alloys in LS-DYNA

®. Li et al. found a good agreement between experimental and simulated results for AA6060 in the T6 state. Properties such as the strain-hardening rate, plastic anisotropy and Bauschinger effect could be captured very well. The model is very well suited for parametric studies where the influence of the precipitate volume fraction or the precipitate aspect ratio can be investigated.

The deep-drawing process of a cup made of AA 6K21 was simulated in the work of Wang et al. [

11] by means of a quarter model in LS-DYNA

®. They used anisotropic Drucker, Hill48 and YLD91 yield functions and compared the results with the implementation of a CPFEM model in ABAQUS. The texture was considered by an RVE (representative volume element) containing 800 grains and applied to the full-field CPFEM. They found a good agreement of the position and height of ears, especially for the CPFEM implementation in ABAQUS. The numerical effort, however, was approx. 13 times higher than that of the constitutive models in explicit LS-DYNA

®.

In the work of Asgharzadeh et al. [

12], the CPFEM was applied by an RVE model to a low-carbon steel. Their focus was on the effect of second-phase particles on the mechanical properties. Dog-bone specimens were cut out of a heat-treated steel tube and the properties were determined by uniaxial tensile tests. Here, as well as in the work of Wang et al. [

11], a multitude of parameters need to be determined. Nevertheless, only a single uniaxial tensile test in the ED was used to calibrate the CP (crystal plasticity) parameters using a 3D RVE (representative volume element). It took 60 days to run the CPFEM simulation with the RVE model of the virtual tensile test. To solve this issue, they used a “homogenization” procedure for the second-phase particles to reduce the numerical effort by 99%. Although a good agreement between experiments and simulations could be achieved, only a tensile test based on an RVE was simulated.

Another way to increase the numerical efficiency is to apply the VPSC model. The VPSC model was already used by Zhang et al. [

13] to simulate the local texture evolution in the porthole die extrusion of hollow profiles for the automobile industry. However, the VPSC model was applied as standalone code to predict the local anisotropy of certain flow lines and to fit a Barlat YLD2004-18p flow rule. For the prediction of the spatial variation of plastic strain near the weld seams, the fitted material model was applied in an LS-DYNA

® simulation. A good agreement could be found between DIC measurements and FEM results.

More crystallographically complex materials and effects like twinning in magnesium alloys were already investigated using elasto-viscoplastic self-consistent (EVPSC) models by Bhattacharyya [

14]. Although the standalone code was used and therefore the geometry neglected, good results could be obtained for the very complex phenomenon of twinning in magnesium alloys.

Engler et al. [

15] already modeled the earing formation for EN AW-3104 by performing FE simulations of the cup-drawing process and used the results to derive boundary conditions for the standalone VPSC computations. The VPSC code afterward calculates the yield information according to the determined load history for the radial elongation under different in-plane angles. The yield information was afterward introduced by Hill’s yield criterion [

16]. Two-dimensional axial symmetric models, as well as a three-dimensional model, where earing was already predicted, are presented in [

15]. Pronounced earing could be found at 0° and 90° to the rolling direction (RD) for recrystallized sheets and at 45° for the as-rolled state [

15].

A version of the VPSC model for integrated use in the FE solver ABAQUS was published in 2018 by Zecevic et al. [

8]. They implemented the VPSC code as a material subroutine in ABAQUS and applied it to a Taylor impact test of a cylinder made of tantalum. During the impact test, a good agreement of the resulting texture could be achieved even for high strain rates.

In this paper, the VPSC code described in [

8] was implemented in the LS-DYNA

® solver as a user-defined subroutine for implicit calculations. Several adaptations in the LS-DYNA solver and the FE-VPSC code of [

8] were necessary to allow the multitude of variables for the VPSC model to be stored for each element and timestep.

The functionality is demonstrated for texture development calculations by means of compression and deep-drawing simulations. Keeping in mind that, in future works, several slip systems, and possibly temperatures, are to be considered, the simple Voce hardening law was applied in the VPSC model. The Voce model needs four parameters per slip system and temperature, which keeps the calibration parameters as low as possible. Since the aim of this work is to give details about the implementation of the FE-VPSC model as a material subroutine (UMAT) in LS-DYNA®, only a crystallographically simple FCC material (EN AW-6082) using one slip system was considered. Due to the available material (rectangular extruded profile), the characterization could be performed in all three main directions (ED, ND, TD). However, this material could not be used for deep-drawing experiments. The material model parameters were therefore determined from the compression tests and used in the show-case example of the cup drawing. Experimental results and details about the cup drawing example will be later published using another material (sheet metal).

3. Results and Discussion

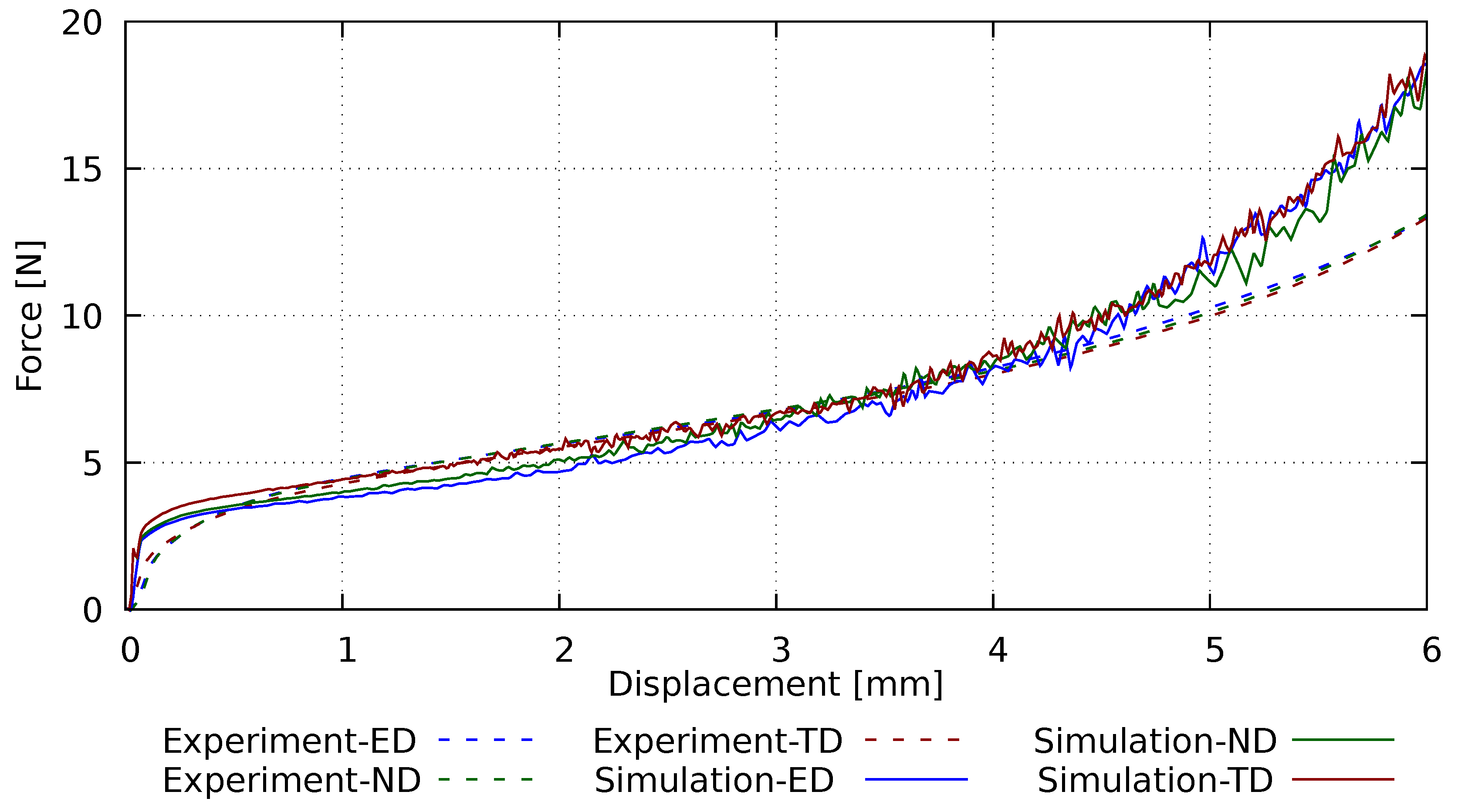

To investigate the effects of an existing texture on the material behavior during a simulated forming process, LS-DYNA® in combination with the FE-VPSC model was used. The resulting simulations of a compression and a deep-drawing test are analyzed and compared with a similar FE setup using an isotropic and anisotropic material model.

The parameters for the experimental setup and the corresponding simulations are given in

Table 1 for the compression test and

Table 2 for the deep-drawing test.

R denotes the sample radius,

H the sample height,

t the sheet thickness for the deep-drawing test,

the forming rate in the compression test and

,

the inner and outer radius of the punch in the deep-drawing test. The number of elements (

N), the number of iterations (

I) and the simulation time per element and iteration (

) for the forming simulations are also provided. Due to the uniform distribution of the anisotropy in the extruded aluminum profile, all FEs start with the same input texture; see

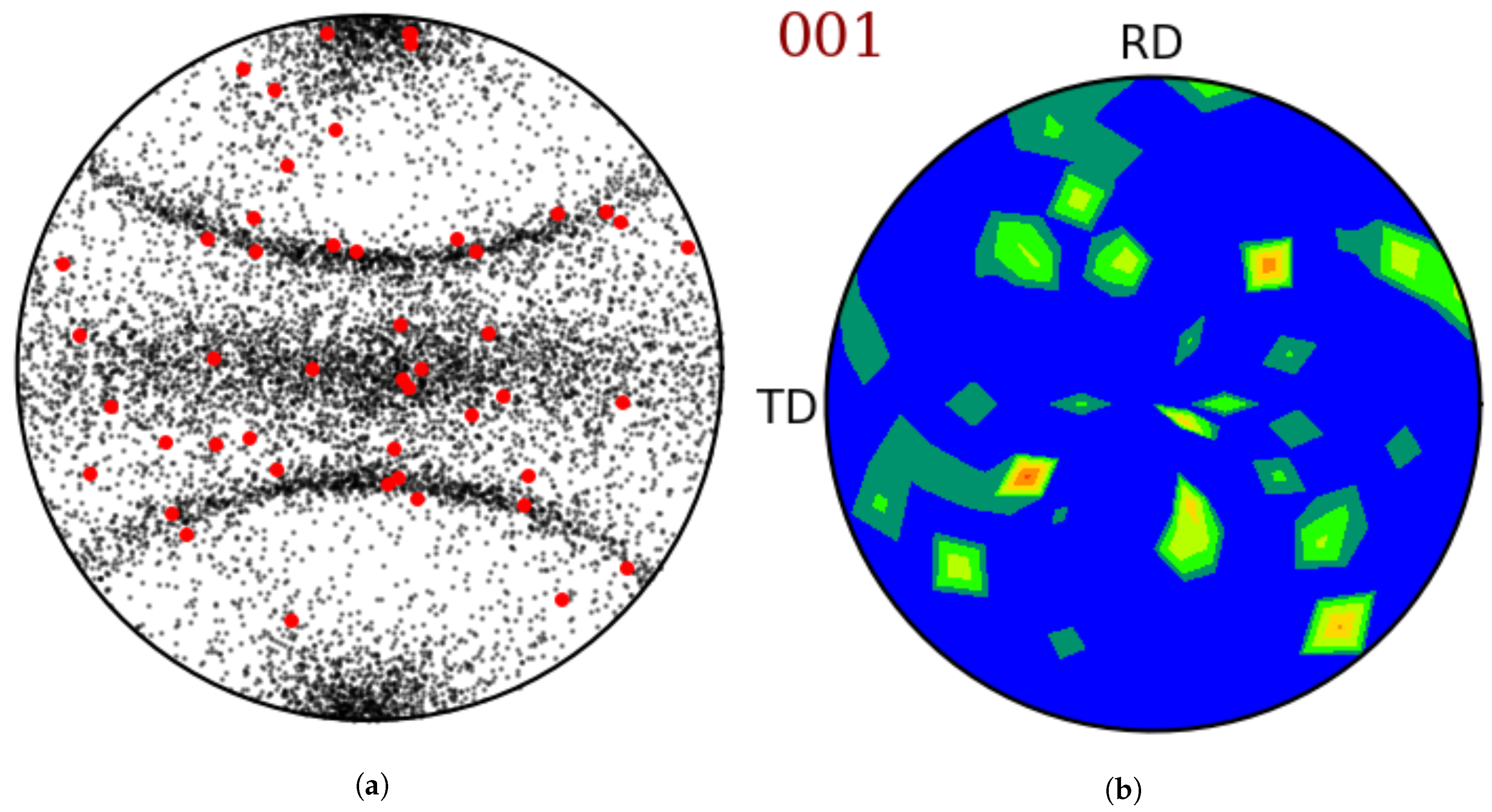

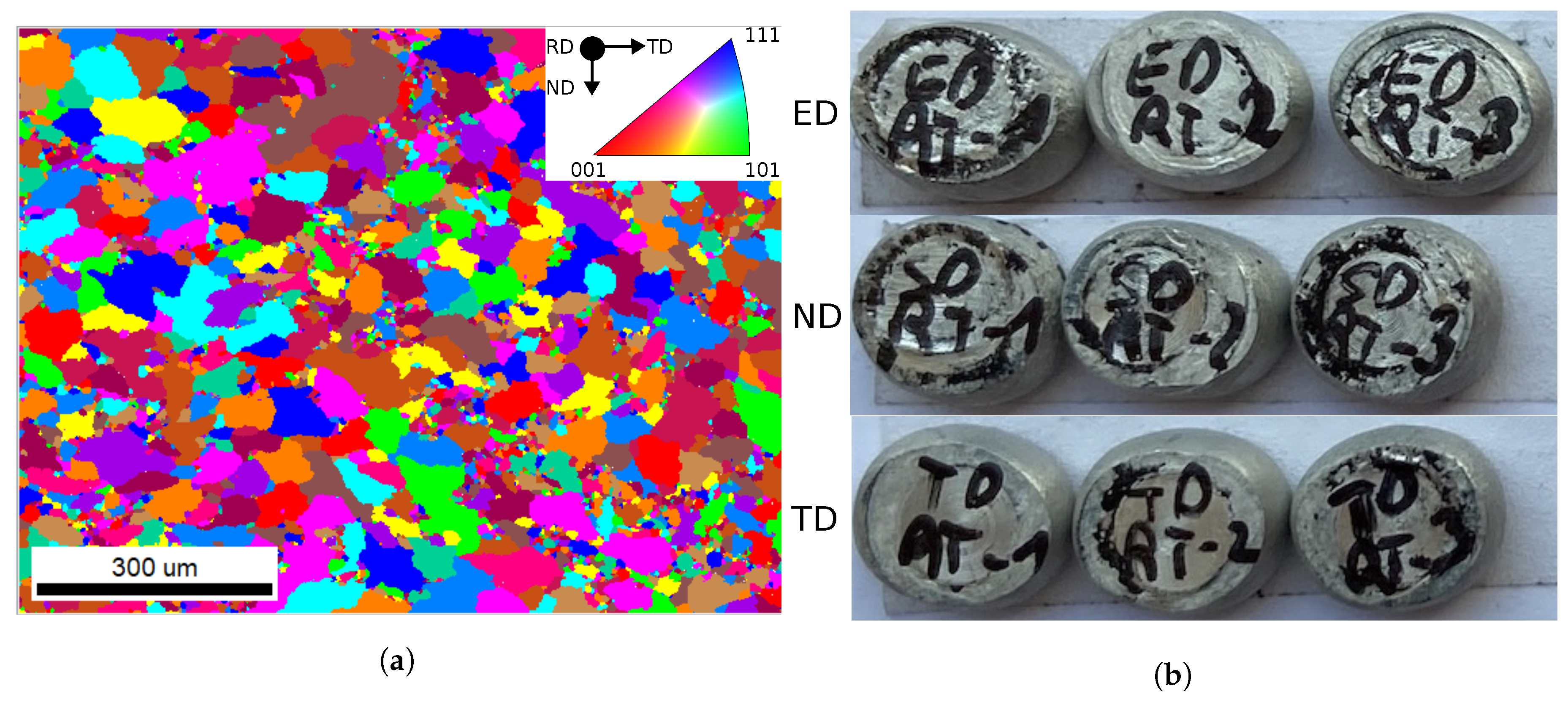

Figure 2.

In the results of the respective simulations, which are presented below, ED refers to the extrusion direction of the sheet metal. Furthermore, TD (transversal direction) denotes the sheet width and ND (normal direction) the profile thickness.

3.1. Compression Test Simulation

In the compression test, a cylinder was compressed at a constant deformation rate. The test setup is shown in

Figure 4a, and

Table 1 contains the relevant parameters.

The resulting geometry from the reference simulation with an isotropic material model is also shown in

Figure 4a. Due to the isotropy, the result is completely rotationally symmetrical and has no preferred direction of deformation. However, in reality, there is often an ovality when compressing samples made of rolled material [

22] or extruded profiles (see

Figure 2b). Such a behavior can be caused by the inherent texture and corresponding mechanical anisotropy of the sample. As the material deforms more easily in directions of low mechanical strength, the sample gets distorted accordingly. The result of the FE-VPSC simulation in

Figure 2b also shows such an oval shape, providing proof of the successful interaction of material texture via the FE-VPSC model and the deformation path superimposed by LS-DYNA

®.

The colors of the FEs in

Figure 4b show different (average) crystal orientations in correspondence to the rolling direction, as briefly described in

Section 2.2. As all FEs start with the same initial texture, this is a clear indication for the texture evolution to be calculated individually for each element. The pole figures of two simulated elemental textures after deformation are shown in

Figure 4b.

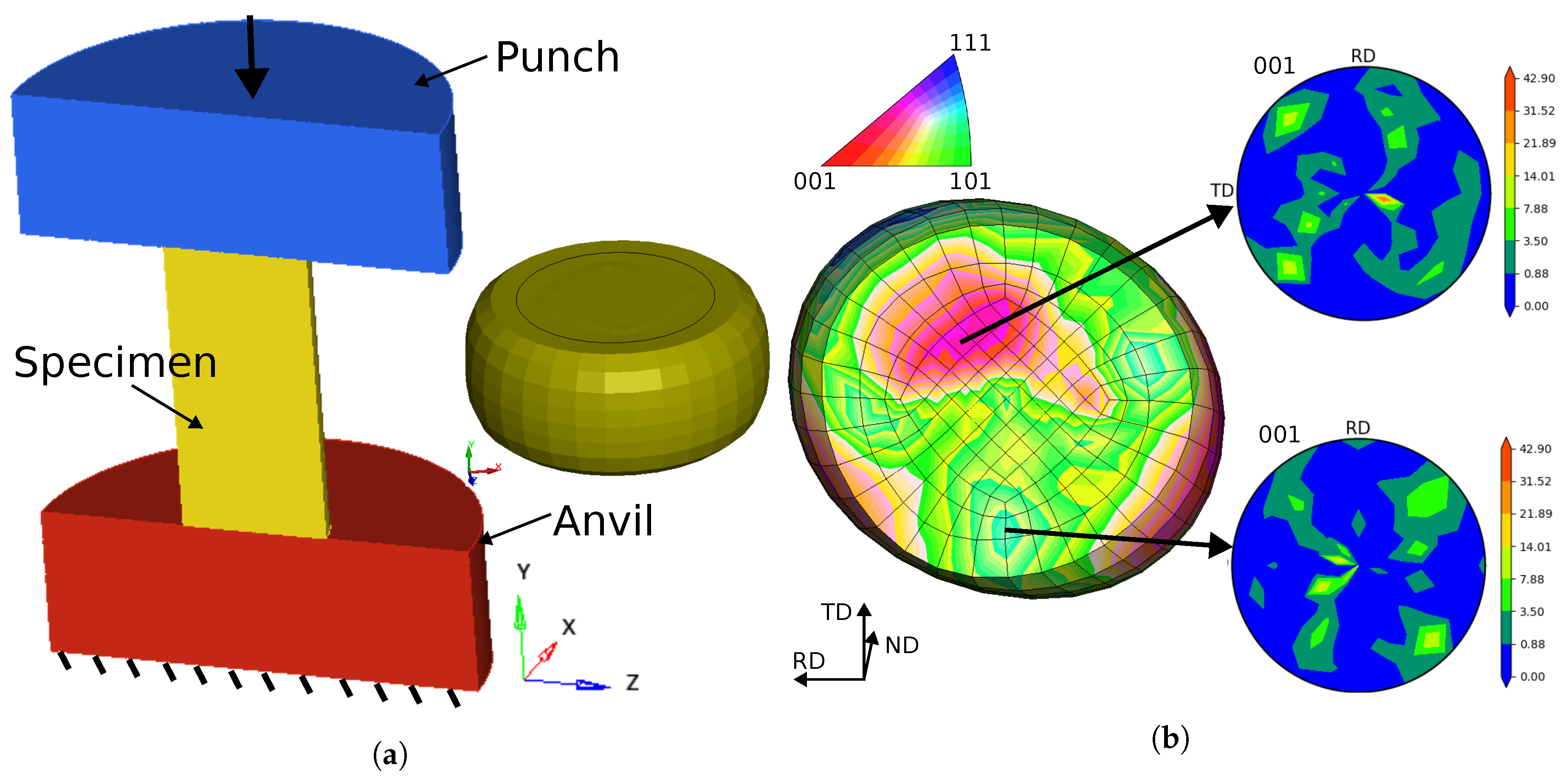

3.2. Deep-Drawing Simulation

Deep-drawing operations are important industrial processes that are used to form metal sheets into various (complex) part geometries, e.g., automotive parts. For our investigation, we simulated the cup-drawing process, which is relatively simple but a well-known test in material characterization. Pronounced earing was already found by Engler et al. [

15] at 0° and 90° to the rolling direction (RD) for recrystallized sheets and at 45° for the as-rolled state.

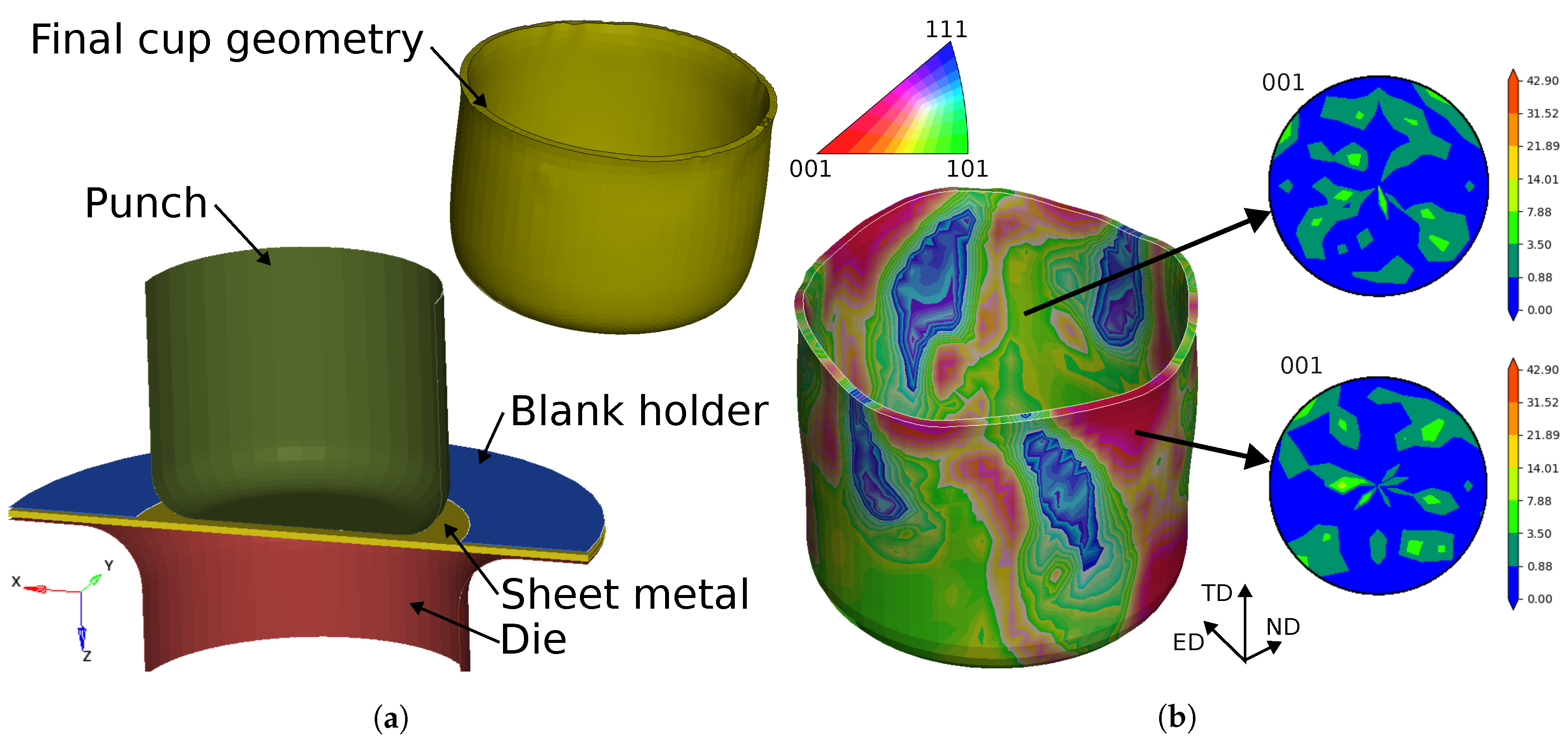

In contrast to Engler et al., we introduced the VPSC model directly into the FEM code and therefore obtained the anisotropic behavior in a two-way coupling between mechanical calculation and texture evolution. Our test setup and the isotropic reference simulation are shown in

Figure 5a. The relevant parameters are summarized in

Table 2. The punch, blank holder and die were modeled as rigid bodies and meshed with shell elements. However, since the FE-VPSC model is currently only implemented for solid elements, the workpiece is meshed with three layers of solid elements.

Similar to the compression test, the isotropic material model produces a rotationally symmetrical result; see

Figure 5a. On the other hand, the result of the FE-VPSC simulation in

Figure 5b clearly shows variations in the texture. As the initial texture is identical for all FEs at the start of the simulation, the texture evolution is caused by the complex displacement fields of this simulation. The pole figures of two different FEs, depicted for verification, show that differences exist both between each element and in comparison to the initial texture in

Figure 1b.

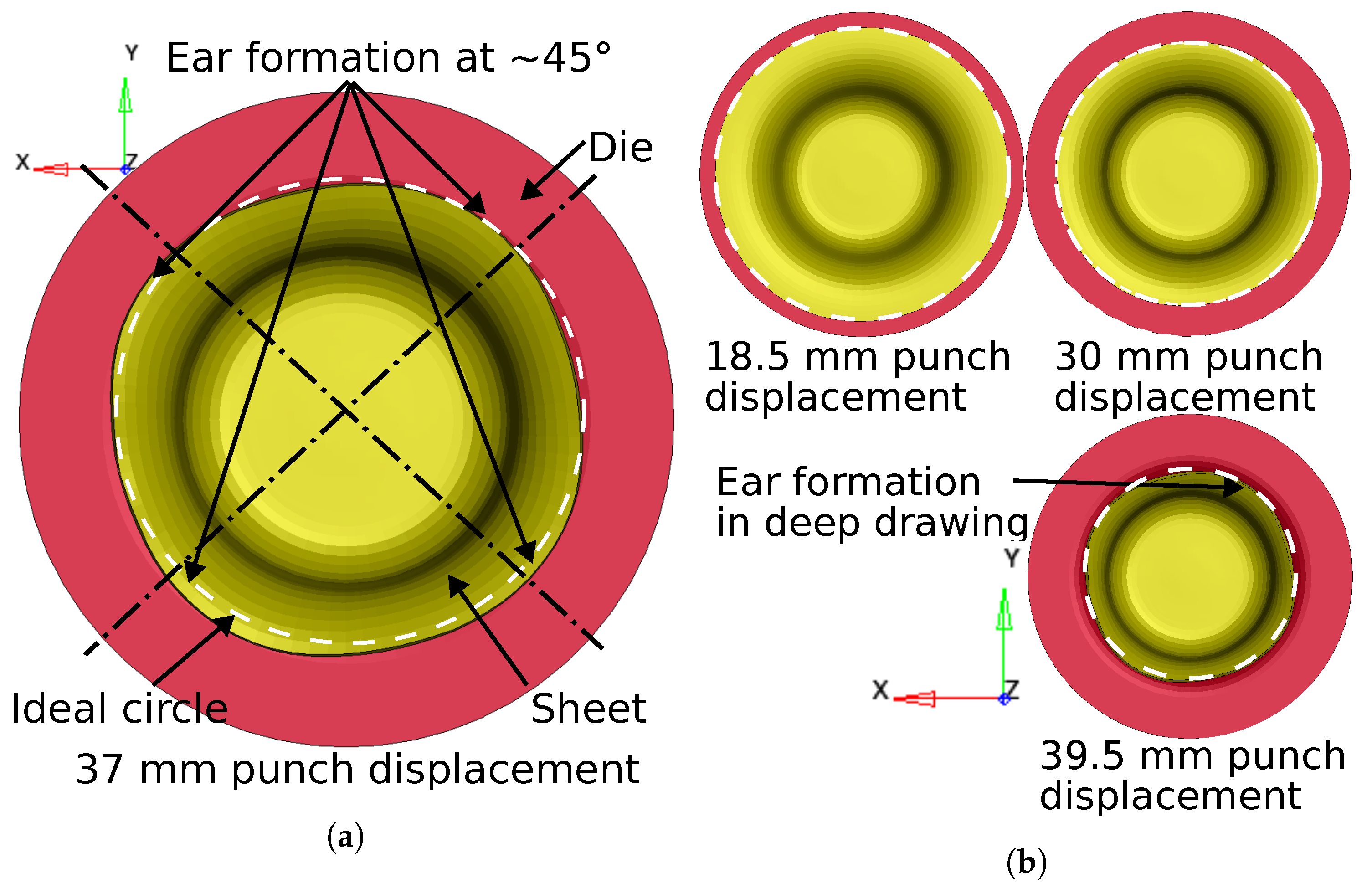

The most striking result of this calculation is the formation of four so-called ears. Earing is a well-known effect of textured materials that also occurs regularly in experiments [

15]. The anisotropic profile properties, caused by the pronounced texture from the extrusion process, lead to earing of the drawn cup. According to Engler et al. [

15], the formation of ears occurs in the flange under the blank holder. Material behavior similar to this description was reproduced by the simulation model, where the ears form at approximately 45° to the extrusion direction in the as-extruded state; see

Figure 6.

4. Conclusions

An efficient way of modeling the local texture development during the deformation of metals by using a mesoscopic approach was presented. The VPSC (visco-plastic self-consistent) model was used to simulate the texture evolution in an EN AW-6082 aluminum profile during a simple compression test and in a cup-drawing operation. By implementing the VPSC model in the context of the finite element method, the effects of the material texture on the mechanical material properties as well as the forming behavior for entire components can be shown directly. In contrast to simpler phenomenological approaches to modeling material anisotropy, the evolution of the local texture during forming can be described and investigated.

In our work, we have shown the following:

By implementing the VPSC model in the FEM framework of LS-DYNA®, even industry-relevant part sizes could be simulated in a reasonable time.

By applying a texture clustering algorithm, the numerical effort could be successfully reduced.

The developed visualization method based on the averaging of crystal orientations converted to quaternions gives a good first overview of the changes in the texture.

The first results for the compression tests show an oval specimen geometry, similar to the experiments.

The cup-drawing simulation also showed the earing phenomenon, which is typical for this kind of test.

It is thought that the prediction and analysis of local correlations in the microstructure with external boundary conditions and process parameters will help to optimize individual processes and process chains. The mesoscopic (polycrystal) approaches employed in the VPSC model allow for more detailed investigations of forming processes of real components. In contrast to some full-field methods, the enormous computing capacities and elaborate preparation of input data can be significantly reduced.

The implementation of the FE-VPSC model for shell elements should make it more convenient for sheet-metal-forming processes in the future. This is thought to result in a significant acceleration in the currently still extensive calculation times. With further improvements in computational efficiency, e.g., the implementation of the clustering algorithm for the VPSC calculation itself, improvements in the parallelization procedures, ..., phenomenological approaches could be replaced in the future.

The results presented here are still a proof of concept. Since the extruded profile material could not be used for deep-drawing experiments, only the simulation of the cup-drawing process was shown. Subsequently, investigations using another material (sheet metal) are planned to validate the simulated cup-drawing results and to prove the accuracy of the predictions.