1. Introduction

Sustainability emerges as a critical facet discernible across various domains, including agriculture [

1], farming [

2], education [

3], supply chain [

4] as well as within the realm of production processes. The notion of sustainability originated within the realm of forestry, delineating the principle of abstaining from harvesting beyond the capacity of the forest’s regenerative capacity. [

5] The concept of collaboration between an industrial robot and a human in a shared space has sparked a fascinating initiative to develop an intelligent robotic entity with enhanced communication and collaboration abilities. The goal of this initiative is to facilitate efficient and harmonious interaction between robots and human beings [

6,

7,

8,

9,

10]. Significant progress in this field has been made since the first decade of the 21st century when robots began to partially collaborate with humans [

11]. This became possible due to the development of surveillance and monitoring solutions for human resources [

12] and the use of advanced sensor systems [

13]. These advancements have enabled robots to work efficiently alongside humans, including the ability to predict human behavior and adapt to their needs during collaborative processes. These robots can operate collectively in teams, showcasing their capability to execute intricate, time-sensitive missions by collaboratively leveraging their unique capabilities and design. [

14] Collaborative robots are tools created to facilitate open collaboration between robots and humans. Opening up the space between humans and robots can bring numerous benefits, such as improving the quality, efficiency, and effectiveness of manufacturing workflows, reducing the space occupied by the production flow served by them, and more. This collaboration paradigm represents not only a technological evolution but also a significant shift in how systems like robots are perceived and integrated into complex industrial environments.

Although concerns exist regarding the possibility of collaborative robots replacing human labour [

15,

16,

17], the simplicity in design and programming of these robots, coupled with their ability to interact with humans, contributes to a broader acceptance of them as an integral part of the workforce [

18,

19]. Regardless of the viewpoint adopted, be it with human involvement or in its absence, cutting-edge manufacturing technologies are developed, cater to human needs, and operate in conjunction with human operators [

20]. This acceptance enhances cooperation and productivity within mixed teams composed of both robots and humans. The seamless integration of collaborative robots into the human workforce not only optimizes processes but also strengthens collaborative relationships, paving the way for increased productivity and enhanced efficiency.

Considering the increasing advancement in the global implementation of collaborative and industrial robots, it can be argued that human concerns are somewhat justified. However, the history of previous industrial revolutions reveals that human life has undergone dramatic changes during these tumultuous periods [

21,

22]. The transformations brought about by collaborative robots represent a continuum in the evolution of society and the work environment, illustrating human adaptability and the capacity of people to capitalize on new opportunities within technological progress.

The collaboration between humans and robots, also known as Human-Robot Collaboration (HRC), leads to the achievement of more efficient tasks with superior process quality and task optimization [

23,

24,

25]. This efficiency can be attributed to the fact that, through collaboration with the robot, humans are motivated to maintain the pace set by it. Even though the operating speed of the collaborative robot may be reduced compared to its maximum capabilities, it can surpass the initial speed of human labour. The synergistic collaboration between humans and robots represents a significant step towards optimizing work processes and enhancing the overall performance of industrial activities.

2. Materials and Methods

2.1. Literature Review

Collaborative robots (cobots) represent a significant innovation in the field of production, transforming the way human workers and machines collaborate. This transition towards collaboration has opened new horizons for the efficiency and quality of industrial processes.

Before conducting a literature review, it was imperative to clearly outline the objectives of this scientific research. The complexity of the collaborative robot integration process, involving the definition of appropriate methods and steps, was taken into account. Given this crucial aspect, the creation of a flowchart was deemed essential to establish a coherent framework for identifying and delimiting the requirements necessary for the implementation of these robots. This methodological approach represents a strategic effort to efficiently and appropriately guide the collaborative robot integration process within the existing literature, thereby contributing to the clarification and optimization of the research direction.

A significant observation arising from the widespread integration of collaborative robots has been the absence of a coherent mathematical model for assessing the total costs and profitability of this investment in an industrial context. Mindful of this gap, the authors deemed it essential to formulate and present a robust mathematical model designed for the precise estimation of costs and the evaluation of profitability associated with the large-scale implementation of collaborative robots. Furthermore, to underscore the relevance and applicability of this model, a practical demonstration was proposed and conducted, thereby highlighting the feasibility and effectiveness of this analytical tool in a real-world context. Another fundamental objective of this investigation was dedicated to analyzing the investment costs associated with collaborative robots, thus making a significant contribution to understanding the financial complexity of their integration into the industrial environment.

The relevance and rigor of this literature review are anchored in a well-defined methodology and the use of two fundamental research resources: Web of Science and Scopus. These platforms serve as the starting point for the authors’ analysis, ensuring comprehensive coverage of research in the field of collaborative robots, with particular attention given to works published in the last decade.

Additionally, relevant information about electricity suppliers in Romania has been integrated into the analysis, and the use of specific data from the National Bank of Romania has been incorporated into the process of converting costs from the national currency, lei, to euros. This approach was adopted to ensure the coherence and appropriate comparability of financial data in the research context.

Throughout the last decades, research in the field of collaborative robots has experienced exponential growth. From the initial practical implementations to the development of advanced technological solutions, the literature reflects remarkable progress and the diversity of applications for these robots in industries such as automotive, electronics, and assembly.

Previous investigations have thoroughly analyzed the costs involved in adopting cobotic technology. From the initial investments in acquisition and integration to the ongoing costs of maintenance and personnel training, the literature provides a comprehensive perspective on the financial aspects associated with the implementation of collaborative robots in production environments.

Enhancing quality in production processes remains a crucial objective. Literature studies examine how collaborative robots can influence and optimize the quality of finished products. Aspects such as real-time quality control, error detection, and process standardization are major areas of interest in current research.

In addition to costs and quality, collaborative robots have demonstrated significant potential in improving operational efficiency and increasing flexibility in the production chain. Through their adaptability to various tasks and ability to collaborate seamlessly with human workers, cobots can significantly contribute to optimizing the entire production process.

Synthesizing existing research, a complex landscape emerges regarding the impact of collaborative robots on costs and quality in production. While some studies emphasize significant benefits and the potential for positive transformations in the industry, others draw attention to challenges and aspects that require closer investigation.

Despite notable progress, there are significant gaps in fully understanding how collaborative robots influence costs and quality in production. This literature review highlights the ongoing need for research to address these gaps and provide valuable guidance for the industry. Future studies should delve deeper into the complex interactions between robots and the human workforce, develop predictive models for long-term cost assessment, and identify innovative solutions for optimizing quality in collaborative production environments.

In summary, the literature review not only highlights the notable progress and achievements in the field of collaborative robots but also the challenges and key directions for future research. This comprehensive analysis provides a complex and well-founded perspective on the impact of these technologies on costs, quality, and efficiency in the context of industrial production.

2.2. Related Work & Research

In recent years, collaborative robots have evolved into an indispensable presence in state-of-the-art manufacturing facilities, making significant contributions to ensuring high safety standards and enhancing flexibility in manufacturing processes [

26,

27]. Distinguished by their smaller size and weight compared to their predecessors, namely industrial robots, these technological collaborators [

28] stand out for their flexibility, which can be likened to that of a human worker [

29].

Ensuring quality, optimizing efficiency, and maximizing effectiveness are essential pillars for maintaining an organization’s competitiveness in a dynamic and ever-changing environment. Collaborative robots become viable tools, contributing significantly to improving the quality, efficiency, and effectiveness of production workflows [

30,

31,

32]. As quality assurance instils confidence in customers in the product manufacturing process, efficiency and effectiveness contribute to achieving excellence in the field of production. Manufacturing excellence can translate into achieving larger volumes in a shorter timeframe or with more efficient resource utilization, precisely adhering to the correct steps of the production process and achieving a satisfactory quality level for customers.

Collaborative robots bring significant improvements to process quality by reducing the number of rejects generated by human errors or unknown factors. Additionally, efficiency is enhanced by maintaining a consistent pace imposed by the collaborative robot. In cases where human resources encounter difficulties in completing tasks within a suitable timeframe, the collaborative robot can wait, opening up opportunities for further optimizations in collaboration with the human operator.

Increased efficiency is achieved through consistent adherence to the same steps every time, precisely following the final work instructions and eliminating deviations. This high level of consistency significantly contributes to the overall effectiveness of processes, bringing substantial benefits in terms of operational efficiency and customer satisfaction.

In the specialized literature, collaborative robots are recognized as entities integrated into various manufacturing-related sectors, playing an active role in processes such as wire harness assembly, screwing or unscrewing, distributing various materials, as well as picking and placing [

33,

34,

35,

36,

37]. Collaborative robots, in contrast to their predecessors, stand out for their increased flexibility, successfully enabling a wide range of processes, including object manipulation, welding, finishing applications, machining, and assembly. These robotic entities can also be integrated with visual control systems, thereby contributing to the enhancement of efficiency and precision in the execution of operations.

Through this scientific paper, the authors aim to discuss various hypotheses related to the integration of collaborative robots into serial production flows in the automotive industry. The detailed structure of this scientific paper is as follows: in chapter 3, a process was designed where integration requirements were explained in detail, presented in the form of a flowchart illustrating how one or more collaborative robots can be successfully incorporated within an organizational context. In subchapter 4.1, the authors developed mathematical models related to the implementation costs that an organization may face when integrating collaborative robots. Following this chapter,

Section 4.2 presents the practical demonstration of the mathematical model, using real data obtained from various suppliers.

These considerations have been brought into discussion as a result of a detailed investigation of scientific literature, revealing significant gaps regarding the thorough study of these aspects.

This scientific paper not only analyzes essential aspects of integrating collaborative robots into the global industrial environment but also proposes innovative perspectives on how these technological collaborators can reconfigure and enhance mass production processes. Additionally, the simplified mathematical models provide not only a theoretical approach but also practical tools for evaluating the costs and benefits associated with the integration of collaborative robots.

By identifying and addressing the detailed integration requirements and associated costs, this paper stands at the forefront of research on optimizing the implementation of collaborative robots in the automotive industry. This rigorous approach opens new horizons for operational efficiency and organizational competitiveness, serving as a significant source of inspiration for future research and practical implementations in the field of collaborative robots.

3. Requirement Tracing Process for the Implementation of Collaborative Robots

Collaborative robots are mechanically designed in the form of robotic arms, equipped with joints similar to those of a human arm: base, shoulder, elbow, wrist 1, wrist 2, and wrist 3. Their integration into the operator’s working environment is achieved with great ease. By this definition, the idea is outlined that a collaborative robot is an articulated robotic entity explicitly designed to share the workspace with the human operator. This characteristic sets it apart from traditional robots, highlighting the direction in which robotic technology is evolving towards collaboration and direct interaction with the human workforce.

The integration of collaborative robots has experienced continuous expansion, aiming to facilitate cooperation between humans and robotic entities within the industrial domain [

9,

25]. This evolution reflects the direction in which technology is heading towards a tighter and more efficient interaction between humans and robots in the production environment.

Collaborative robots represent a viable alternative to offset the rising costs associated with human labour, which are becoming increasingly expensive [

38], harder to hire, and challenging to discipline to achieve the desired level of efficiency [

39]. Due to their capability to perform a variety of applications, collaborative robots can be easily integrated into various stages of industrial processes, making a significant impact, ranging from the production of semi-finished goods [

40] to packaging and palletizing operations of finished products [

41]. This remarkable adaptability gives collaborative robots a crucial role in optimizing efficiency and versatility in the contemporary industrial domain.

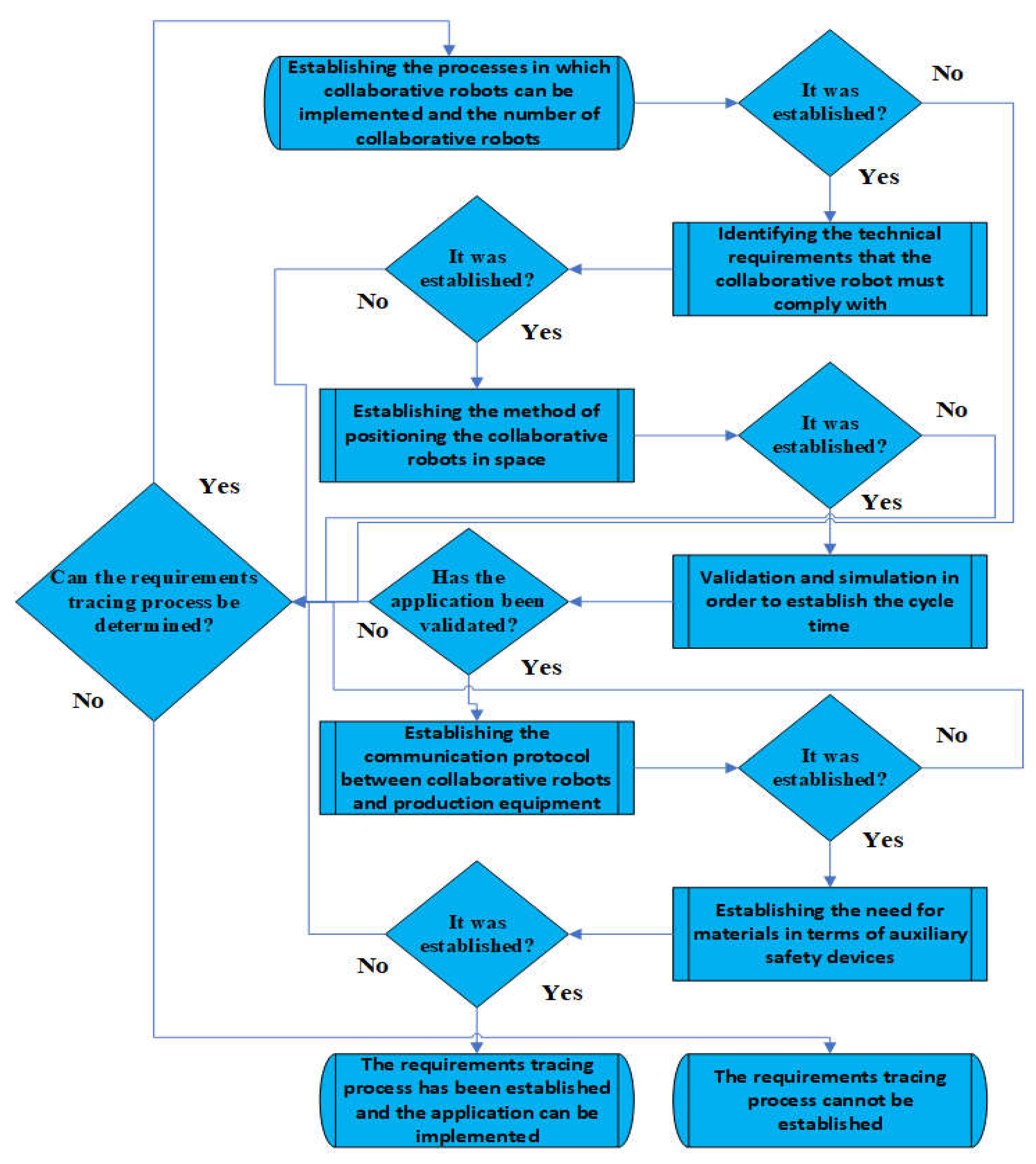

In the process of integrating collaborative robots into an industrial organization, researchers have identified a lack of well-defined steps for evaluating the feasibility of their implementation in manufacturing workflows. This deficiency can lead to the deployment of unorganized activities, with the potential to steer the organization toward incorrect conclusions and, consequently, to invest in a dysfunctional or technically unsatisfactory application in terms of efficiency and effectiveness. Aware of this situation and drawing on accumulated experience, researchers have developed and detailed a flowchart, as presented in

Figure 1. This constitutes an essential visual resource, providing a coherent framework for the efficient evaluation and implementation of collaborative robots in the industrial environment.

The main activities established by the authors include:

Establishing the processes in which collaborative robots can be implemented and the number of collaborative robots;

Identifying the technical requirements that the collaborative robot must comply with;

Establishing the method of positioning the collaborative robots in space;

Validation and simulation in order to establish the cycle time;

Establishing the communication protocol between collaborative robots and production equipment;

Establishing the need for materials in terms of auxiliary safety devices.

These steps require a progressive approach, with the transition to the next activity only after the successful completion of the preceding one. Due to the possibility of an activity not concluding successfully, the authors have introduced decision points after the completion of each stage. Thus, if an activity does not conclude successfully, the developer must assess the possibility of resuming the requirements tracing process. If feasible, the resumption of activities starting from the first stage is mandated. Conversely, if the requirements tracing process cannot be accomplished, it will be concluded that the implementation of collaborative robots cannot be carried out in a manner that meets the organization’s performance requirements. If the entire process concludes successfully, then the application is deemed feasible for the organization. This strategic approach ensures that the implementation of collaborative robots proceeds rigorously and efficiently, adapting to the specific challenges of each stage.

Within the execution of these activities, essential technical aspects are outlined to determine the budget required for the investment:

The number of collaborative robots that can be ordered and their positioning within the process;

Identification of the technical-functional characteristics of the collaborative robot suitable for the application. These characteristics may include the speed of the collaborative robot, repeatability, the range of motion, and the payload it must handle;

By knowing the speed, precision, range of motion, and spatial position of the collaborative robot, its movements can be simulated to assess whether it aligns with expectations regarding cycle time. This evaluation can be performed using production simulation programs such as Visual Components, RobotStudio, etc.

A definitive list of digital or analogue signals used in communication is developed, and the communication protocol and the number of signals are verified. This aspect ensures checking whether the collaborative robot has sufficient electrical inputs and outputs. Additionally, it ensures that the surrounding environment’s equipment can communicate through the chosen communication protocol and whether the collaborative robot has appropriate capabilities for communication through this protocol;

In the next step, the integrator or organization can determine the material requirements for auxiliary safety devices. With this information, the organization can perform the corresponding budgeting. At the same time, the previous assembly and electromechanical role of these devices are specified.

4. Mathematical Model for Implementation Costs of Collaborative Robots

4.1. Theoretical Approach of the Proposed Model

Implementation costs encompass all expenses incurred by an organization in the process of implementing collaborative robots. These costs can be categorized into:

Indirect costs, which include expenses related to the acquisition of collaborative robots, support devices, gripping devices, auxiliary safety systems, etc.;

Direct costs, represented by expenses associated with the consumption of electrical energy and the payment of employees responsible for the integration of collaborative robots.

For the calculation of the total implementation costs, the authors propose the following formula:

where:

TC represents the total implementation costs of collaborative robots;

CI – indirect costs of implementing collaborative robots;

CD – direct costs of implementing collaborative robots.

The indirect costs associated with the implementation of collaborative robots stem from procurement expenses from suppliers. For the integration of such solutions, the organization must acquire:

The collaborative robot, accompanied only by the control box and tablet;

Support devices to which collaborative robots will be mounted. These may include structures or metal frames with increased strength;

Gripping devices used by collaborative robots for the handling or fixation of products;

The control box of the safety system, which includes the safety PLC, safety relays, and other electrical components;

Safety barriers and scanners;

Auxiliary emergency buttons.

These expenses can be reduced through negotiations with suppliers or distributors providing the necessary items.

Thus, for indirect costs, the authors have formulated and proposed the following calculation formula:

where:

CI represents the indirect costs of implementing collaborative robots;

NRC – number of integrated collaborative robots;

PRC – the price of a collaborative robot;

NS – number of supports for the mechanical fixation of collaborative robots in the production line space;

PS – the price of support or structures;

NDP – number of gripping devices;

PDP – price of a gripping device;

CESS – the price of an electrical control box for the safety system. In cases where the safety system is integrated into the electrical box of existing equipment in the proximity of collaborative robots, the costs of the control apparatus of the system will be included in the costs of auxiliary components CA. It is imperative to implement in situations where the collaborative robot performs movements at considerable speeds or uses dangerous devices, requiring an additional security system concurrently with NBS, PBS, NSP, and PSP.

NBS – number of safety barriers;

PBS – price of a set of safety barriers;

NSP – number of perimeter scanners;

PSP – the price of a perimeter scanner;

CA – the total expenses regarding certain auxiliary components used in the integration of collaborative robots. These may include emergency buttons, reset buttons, cables, wires, etc.

Direct costs associated with implementation stem from compensating the human resources involved in the project, as well as the related energy expenses. Compensation for human resources involved in the project is based on the number of hours worked for its realization. The project involves multiple employed personnel contributing to its management. Each employee has distinct responsibilities, and duties are distributed as follows:

The project manager plans and organizes the efficient execution of project activities, overseeing progress in time and budget;

Electromechanical technicians are responsible for assembling mechanical and electrical equipment, including the fixation and assembly of structures, collaborative robots, their devices, and safety systems, as well as making and securing electrical and pneumatic connections, as applicable;

Personnel specialized in programming collaborative robots and the safety system.

If the personnel is experienced and well-organized in the collaborative robot integration process, the time dedicated to these activities will be shorter, resulting in a significant reduction in direct costs. For the assessment of direct costs, the authors deemed it appropriate to formulate a calculation equation:

where:

CD represents the direct costs of implementing collaborative robots;

NOMP – number of hours worked by the project manager;

SOMP – hourly salary of the project manager;

NOTE – number of hours worked by the electromechanical technician;

SOTE – hourly salary of the electromechanical technician;

NOP – number of hours worked by the programmer or programming personnel;

SOP – hourly salary of the programmer;

CRE – energy resource expenses.

This formula can be adapted based on the number and salaries of individuals involved in project execution.

Before initiating a collaborative robot implementation project, it is crucial to establish a budget to which it must adhere throughout the implementation. During the project’s execution, the estimated budget must not be exceeded. Budgeting represents the sum of all estimated costs in a project. For more secure budgeting, it is recommended to add to this total sum a percentage as an index to correct errors in the estimation of total costs. Applying this correction index is recommended because, as currently observed, prices tend to increase rapidly. Thus, there is a risk that from the budgeting moment to the acquisition moment, the prices of items necessary in the project may change, ultimately leading to exceeding the budget. For this reason, accurate estimation is essential, ensuring that the budget is at least equal to or greater than the total implementation costs:

where:

BP represents the estimated budget for the implementation of the project;

TC – the total implementation costs of collaborative robots.

Moreover, the investment needs to be recovered within the shortest possible time frame. Collaborative robots are designed to perform repetitive operations. The investment recovery in a production flow with collaborative robots is feasible when they operate consistently over multiple shifts. The complexity of the products should fall within the limits of the maximum useful task that the collaborative robot can handle and be in line with the capabilities of gripping or handling devices. For this reason, it is recommended to implement collaborative robots in high or mass-production workflows, where the product range is limited, but the production process is continuous.

Many organizations in the market opt for the implementation of collaborative robots due to their ability to reduce production costs. By lowering these costs, organizations can achieve increased profit from the sale of each product. This efficiency is attained through:

Collaborative robots can easily take over repetitive operations, executing them efficiently each time. Therefore, both the reduction in the number of operators for repetitive operations and the decrease in the number of non-conformities can be quantified in monetary units, ultimately representing costs for the organization. The authors have proposed the following calculation formula to assess the profitability of the investment in the implementation of collaborative robots:

where:

RCO represents the total annual cost reduction achieved by reducing the number of operators performing repetitive operations following the implementation of collaborative robots;

RCRA – the total annual cost reduction achieved by reducing rejects from the manufacturing flow through the implementation of collaborative robots;

NA – the number of years over which the investment is to be amortized;

TC – the total implementation costs of collaborative robots;

CRA – the estimated costs of electrical energy consumed by collaborative robots per year.

In the formula, both RCO and RCRA must be expressed in monetary units.

Simultaneously, the organization can decide on the number of years over which it intends to amortize the investment. By performing this calculation, a comparison can be made between the obtained value and the total sum of the implementation costs of collaborative robots, including the estimated costs of electrical energy consumed by them over the operating years. If the costs are not amortized within the desired interval (N

A), the investment is not profitable.

where:

CRA represents the estimated annual electrical energy costs that the organization will have to bear. These costs are incurred due to the operation of collaborative robots and are represented in monetary units;

PKWO – the price of electrical energy consumption;

CEER – the estimated electrical energy consumption of the collaborative robot per hour;

NOF – the number of operating hours of the collaborative robot per day;

NZA – the number of working days per year in which the collaborative robot will operate in the manufacturing flow;

NR – the number of collaborative robots present in the application.

Achieving a precise calculation of the return on investment in the integration of collaborative robots is crucial before investing. An investment in a collaborative robot application must lead to the reduction of manufacturing costs for the product and expenses generated by rejects, thus amortizing the investment over a specific number of years. If the investment payback period is too long or the benefits to the manufacturing flow are minimal compared to the implementation costs, such an investment is not recommended.

Theoretical calculation methods have been proposed for both direct and indirect costs, including a method for assessing the return on investment and the estimated annual electrical energy costs. Additionally, the importance of budgeting the project in the preliminary phase has been highlighted, emphasizing how it needs to be correlated with the total implementation costs of collaborative robots.

4.2. The Practical Application of a Mathematical Model in Order to Manage the Implemen-Tation Costs within the INITIATION of a project with Collaborative Robots

To validate the formulations developed in subsection 4.1, it was deemed necessary to apply them in practice. For this purpose, a manufacturing flow requiring the implementation of two collaborative robots will be considered.

In the initial stage, the collaborative robot flow is operated by four operators, responsible for picking up and placing products on the production line. The reduction of the number of operators serving the manufacturing flow to two is imperative. Considering these aspects, the feasibility of implementing two collaborative robots to replace two operators will be calculated. The budget allocated for such implementation is 100,000 euros.

The total implementation costs are calculated as the sum of direct and indirect costs. To determine the total implementation costs, it is necessary to evaluate both direct and indirect costs.

Number of integrated collaborative robots (NRC);

Price of a collaborative robot (PRC);

Number of supports for the mechanical fixation of collaborative robots in the production line space (NS);

Price of a support or structure (PS);

Number of gripping devices (NDP);

Price of a gripping device (PDP);

Price of an electrical control box for the safety system (PCESS);

Number of safety barriers (NBS);

Price of a set of safety barriers (PBS);

Number of perimeter scanners (NSP);

Price of a perimeter scanner (PSP);

Total costs related to specific auxiliary components (CA).

In order to perform this calculation, price quotes were requested from various sources, and thus,

Table 1 was developed based on the received quotations.

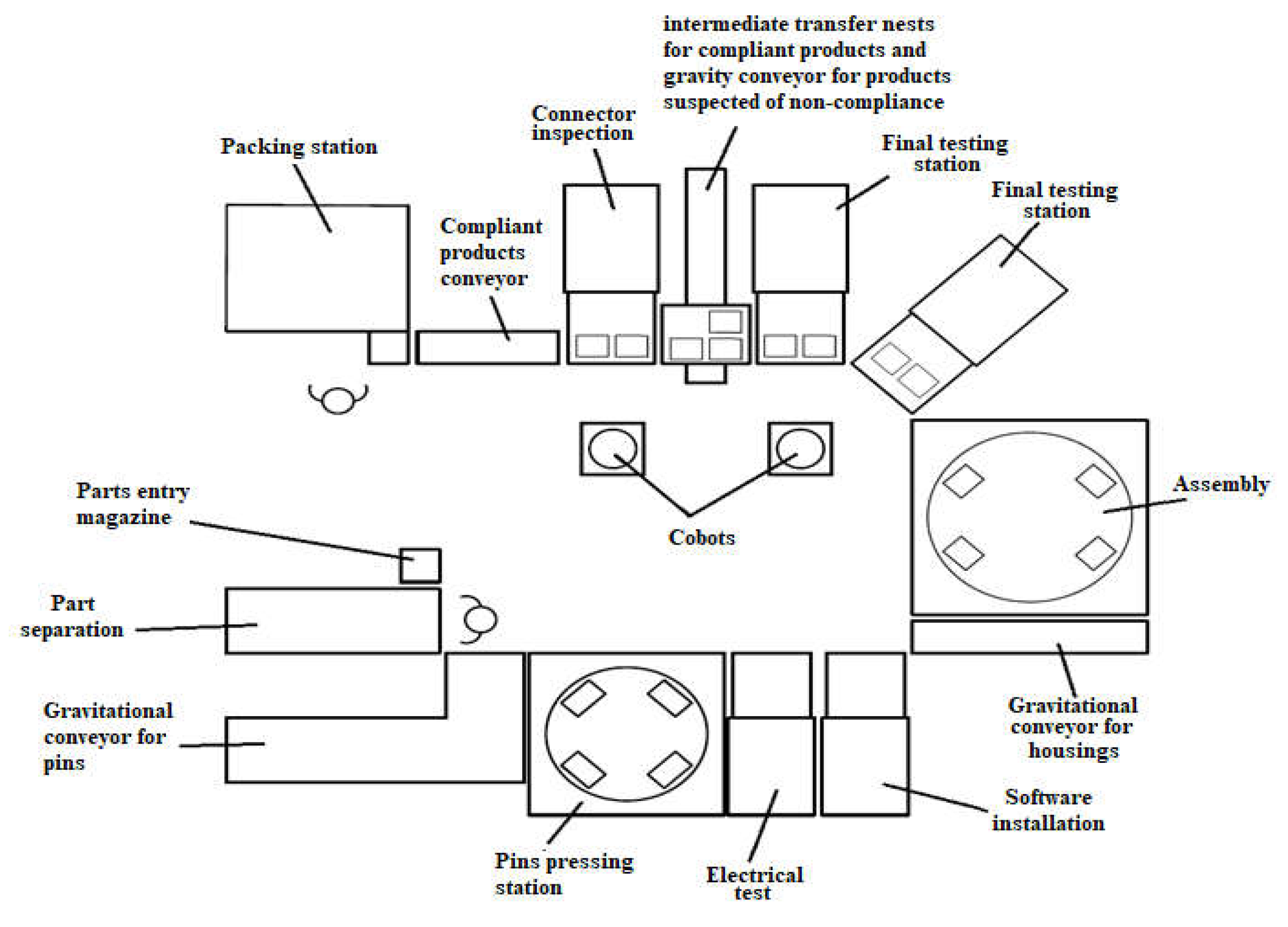

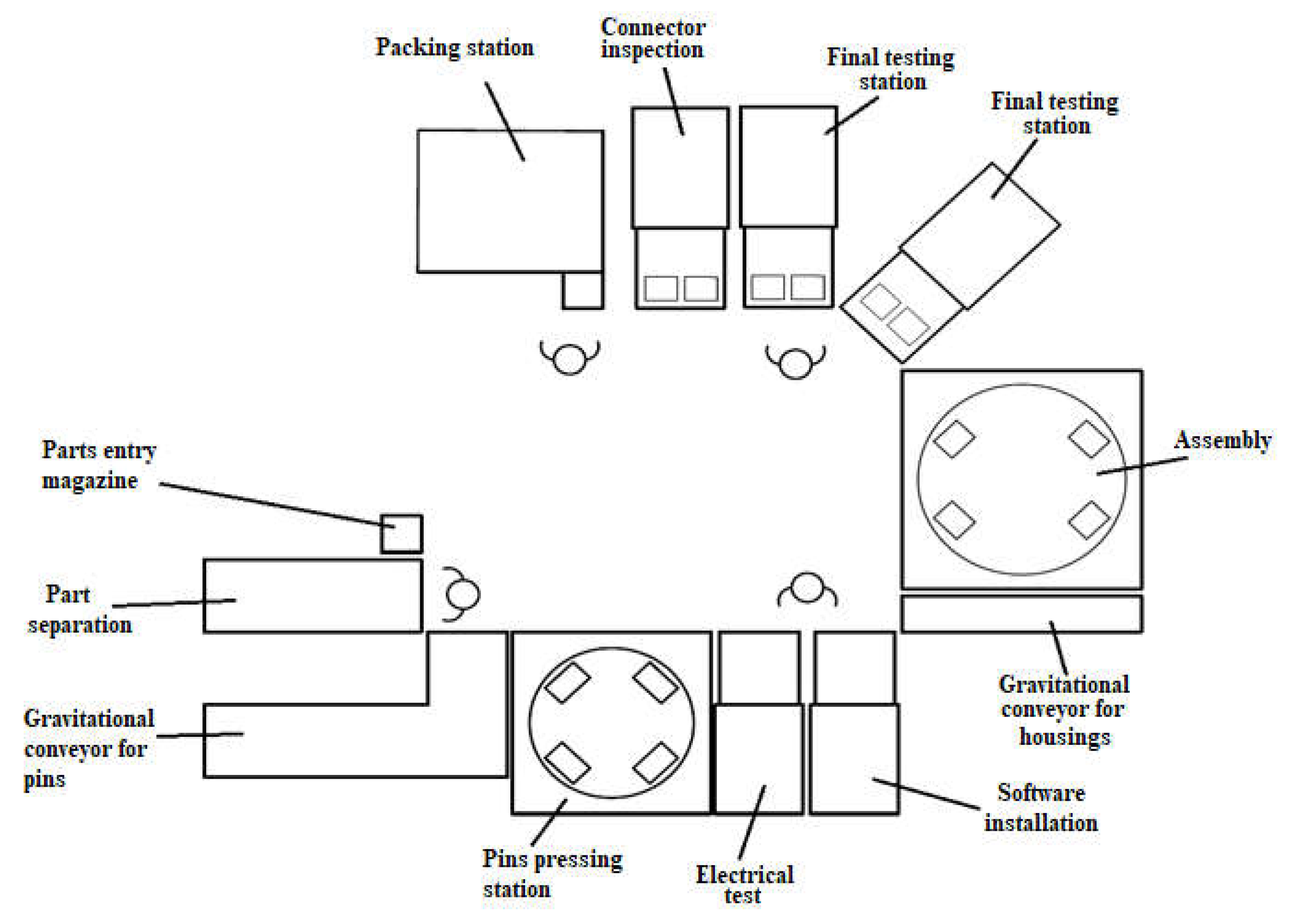

The manufacturing flow for which the calculation is performed can be visualized in

Figure 2. The number of pieces was estimated according to the need to implement two collaborative robots in this manufacturing flow.

Considering the mentioned aspects and applying the formula for indirect costs, formula 2, the direct costs associated with the implementation of the two collaborative robots can be calculated.

In the total costs related to specific auxiliary components (CA), the following are included:

A gravitational conveyor for compliant products destined for packaging;

A table with three intermediate transfer nests for compliant parts and a gravity conveyor for non-compliant products;

Assembly screws;

Wires or cables for making the necessary electrical connections;

Five perimeter scanners, two mounted horizontally and three vertically (safety barriers were not considered, as they are not applicable in the presented case).

After calculating indirect costs, it is necessary to perform calculations for direct costs. These consist of:

Number of working hours of the project manager – NOMP;

Hourly salary of the project manager – SOMP;

Number of working hours of the electromechanical technician – NOTE;

Hourly salary of the electromechanical technician – SOTE;

Number of working hours of the programmer – NOP;

Hourly salary of the programmer – SOP;

Energy consumption costs – CRE.

The following aspects are taken into consideration:

It is estimated that the project manager will work for three weeks on this project, which is a total of 120 hours;

The estimated salary for a project manager is 80 RON gross per hour. Converting the amount into currency, we get 16.24 Euros per hour;

It is estimated that the electromechanical technician will work for two weeks on the project, which is a total of 80 hours;

The estimated hourly salary for an electromechanical technician is 49 RON gross per hour. Converting the amount into euros, we will get 9.95 Euros per hour;

It is estimated that the programmer will work for one week on this project, which is a total of 40 hours;

The estimated hourly salary for a programmer is 100 RON gross. Converting the amount into currency, we will get 20.30 Euros per hour;

It is estimated expenses of approximately 2,500 RON for the electrical energy used in the project. Converting the amount into euros, the total sum is 507.56 Euros.

The euro exchange rate used for the conversion is 1 EUR = 4.9255 RON, according to [

42].

The direct costs are estimated based on the current market conditions and the authors’ experience in implementing collaborative robots. Taking into account all the mentioned aspects and following formula 3, the following outcomes will be obtained:

Once the direct costs and indirect costs have been obtained, a calculation for the total implementation costs of collaborative robots can be made according to formula 1. Thus, the following outcomes will be obtained:

The budget considered in this context was 100,000 €. Considering this assumption and formula 4, the estimated budget for project implementation could be compared with the total implementation costs of collaborative robots.

Following the previous recommendations, a percentage was added to the total implementation costs, considered as an adjustment index for the total estimated costs, to ensure that the budget will not be exceeded. The correction index considered is 15%, and the results are as follows:

It can be observed that even if prices increase by 15%, the project budget will not be exceeded. Due to this aspect, it can be considered that the budget allocated for such a project is appropriate.

Figure 3.

Transforming the production flow into a flow with collaborative robots.

Figure 3.

Transforming the production flow into a flow with collaborative robots.

Next, it was considered necessary to demonstrate that such an investment is also profitable in the long run for an organization. This aspect can be confirmed or refuted by applying formula 5. To perform such a calculation, the following data is required:

The total annual cost reduction in monetary units, is achieved by reducing a certain number of operators performing repetitive operations through the implementation of collaborative robots – RCO;

The total annual cost reduction in monetary units, is achieved by reducing defects in the manufacturing process through the implementation of collaborative robots – RCRA;

The number of years in which the investment is intended to be amortized – NA;

The total implementation costs of collaborative robots, in monetary units – TC;

The estimated costs of electricity consumed by collaborative robots per year, in monetary units – CRA.

R

CO represents an index that can be calculated. First and foremost, it is necessary to calculate the number of operators used:

where:

N represents the total number of operators used per month to operate the line;

O – the number of operators servicing the line that can be replaced by collaborative robots;

S – the number of shifts per month.

The authors have opted for the calculation with eight operators per shift, as only they could be replaced by collaborative robots in the presented application. A net salary of 3,200 RON per operator was considered. If in 2021, for an operator to receive a net salary of 3,200 RON, the organization must pay a gross salary of 5,471 RON, according to [

43], in 2022 and 2023, the organization must pay a gross salary of 5,594 RON. Conversion from lei to euro was made using the exchange rate of 4.9255 RON [

42]. The following figures were obtained:

where:

TS represents the total gross salaries received by operators on all shifts per month;

N – the total number of operators;

€ – the gross monthly salary received by an operator.

Taking into account the mentioned aspects, the authors further calculated the total reduced costs per year in monetary units, resulting from the reduction of a certain number of operators:

RCRA represents a value in monetary units that can also be calculated. To perform such a calculation, it is necessary to collect certain data regarding the manufacturing process. To apply the method in this situation, the authors considered that 35% of all non-conforming products are due to the operator. The manufacturing process produces a total of 800,000 products each year, of which only 785,000 conforming products are delivered to the customer. The cost of one product is 40 euros per piece.

Considering the mentioned aspects, the authors calculated the total annual rejects, a number from which the total annual rejects due to the operator’s work can be calculated.

where:

TPA represents the total products manufactured in one year using the operator work mode;

PCMO – the number of conforming products from the manufacturing process where the operator work mode is used;

TRAO – the total annual rejects in the operator work mode;

RDO – the total annual rejects due to the operator work mode;

RCRA – the total reduced costs per year in monetary units, resulting from the reduction of rejects in the manufacturing process through the implementation of collaborative robots;

PPB – the price of the product per piece.

Next, in order to complete the calculation, it was necessary to compute the estimated costs of electricity consumed by collaborative robots per year, CRA, according to formula 6. To perform this calculation, an investigation into the following was required:

PKWO represents the price of electricity consumption;

CEER – the estimated hourly electricity consumption of the collaborative robot;

NF – the number of hours the collaborative robot operates per day;

NZA – the number of working days per year in which the collaborative robot will operate in the manufacturing process;

NR – the number of collaborative robots existing in the application.

The final price of electricity with VAT for organisations on December 30, 2023, according to [

44], is:

1.3 lei / kWh for high voltage;

1.3 lei / kWh for medium voltage;

1.3 lei / kWh for low voltage.

The authors want to emphasize that the current price is currently capped by the Romanian government for non-cash clients, and it is a variable aspect. Due to this aspect, prices are capped regardless of the voltage type. Collaborative robots operate at low voltage, so we will consider the price of 1.3 lei / kWh in the calculation. This price converted to euros is 0.26 euros / kWh according to [

42].

Figure 4.

Types of collaborative robots from Universal Robots [

45].

Figure 4.

Types of collaborative robots from Universal Robots [

45].

Collaborative robots from Universal Robots have the following energy consumption according to [

46]:

UR3 eSeries averages 100 W per hour during operation. This consumption is similar to that of a desktop computer;

UR5 eSeries has an average consumption of 200 W per hour during operation. The consumption is similar to that of a gaming console;

UR10 eSeries and UR16 eSeries have an average consumption of 350 W per hour when in operation. Both models have consumption similar to a household blender;

UR20 eSeries averages 500 W per hour during operation. The consumption is similar to that of a washing machine.

The organization operates 24 hours a day, 7 days a week. One shift represents 8 hours. The organization operates for 354 days a year, with the remaining days being vacation days.

Considering the mentioned aspects, the following aspects have been determined:

Applying formula 6, the following aspects have been determined:

The mathematically demonstrated data or those that needed to be taken into account when checking the profitability of the investment in a collaborative robot project:

Considering that all the data is available, the profitability of the investment in the collaborative robot project can be determined by applying formula 5 as follows:

Where, to recap:

RCO represents the total reduced costs per year resulting from the reduction of a certain number of operators performing repetitive operations through the implementation of collaborative robots;

RCRA – the total reduced costs per year resulting from the reduction of rejects in the manufacturing process through the implementation of collaborative robots;

NA – the number of years in which the investment is intended to be amortized;

TC – the total costs of implementing collaborative robots;

CRA – the estimated costs of electrical energy consumed by the collaborative robots per year.

The investment stands out for its remarkable profitability for the organization. On the left side of the equation, costs show a significant reduction over the course of two years after the integration of collaborative robots, while on the right side, the organization’s investment for the same period is reflected in a collaborative robot working environment.

5. Results

The flowchart of the requirements tracing process for the implementation of collaborative robots, presented in chapter 3, aims to graphically illustrate the recommended progressive steps by the authors to achieve a functional, efficient, and effective application. These steps not only define multiple technical considerations and needs but also facilitate proper budgeting. Moreover, in cases where the implementation of such an application is not feasible, the flowchart prevents inadequate investment, thus preventing the irrecoverable loss of the invested amount. The activities are clearly defined in the flowchart, indicating when they should be carried out, thereby contributing to avoiding chaos and simplifying their monitoring throughout the project. This structured approach brings significant benefits, ensuring coherence and success in the implementation of collaborative robots within the industrial environment.

In chapter 4, the formulas originally developed by the authors in subchapter 4.1 have been demonstrated, applied, and validated through this work. The conclusion was reached by developing and applying a mathematical model for calculating implementation costs, reducing costs, comparing the budget allocated to a collaborative robot project, and evaluating the profitability of the investment. These formulas can be essential tools for organizations in managing costs associated with the implementation of collaborative robots. In subchapter 4.2, by applying the proposed mathematical model, a potential cost reduction of 638,067.84 Euro over two years is identified, achievable through an initial investment of 88,686.92 Euro. In the second year, the collaborative robot operating strategy includes an estimated addition of 1,547.27 Euros per year. This additional cost, subject to variations depending on the electricity tariff, implementation duration, and the number of collaborative robots, represents an important variable in the overall equation, with the potential to influence the financial outcomes of this initiative.

6. Discussion

The integration of collaborative robots into the production environment is a complex process, and defining requirements is a crucial step to ensure the success of this implementation. A holistic approach, such as the one mentioned in this research, provides a solid foundation for the further development of this process. The use of methodologies like IDEF0 can contribute to a more detailed and clear specification of technical and functional requirements.

The investment calculation, focused on Universal Robots’ collaborative robots, brings into discussion the variability of costs depending on the supplier. This flexibility can influence managerial decisions and guide the direction towards financially optimal solutions.

It’s important to emphasize that, despite the meticulous approach, the calculations performed did not cover critical aspects such as wage increases for human labour, wage differences based on specific geographic areas, the impact of inflation, or changes in electricity costs. At the same time, the hypothesis of potential defects in collaborative robots during the operating and amortization period was not considered, as they would normally be under warranty. Maintenance costs were not included in the analysis, as collaborative robots do not require periodic maintenance. These variables, although omitted at this stage, should be taken into account in subsequent stages of investment evaluation, ensuring a comprehensive and accurate analysis of the financial impact. Additionally, the statement of the payback period and other assumptions was designed to facilitate the application of the formulations in various contexts. However, any organizational entity, armed with this data, can promptly implement these formulas.

The mathematical model and flowchart developed in this research represent innovative contributions to the scientific field. They have been formulated within a generic framework, designed to adapt to various contexts within industrial organizations. Their significance lies in their ability to serve as tools for assessing the profitability of collaborative robot integration, providing organizations with the necessary means to make informed decisions regarding the efficiency and sustainability of this process.

Both the mathematical model, offering a quantifiable perspective on the associated costs, and the flowchart, illustrating the progressive steps in the integration process, serve as essential guides. These tools contribute to outlining clear directions and avoiding unsustainable or inefficient decisions in the implementation of collaborative robots.

By adopting a generic approach to these contributions, flexibility is provided to tailor them to the specific needs of different organizations, thereby consolidating their value in various industrial environments. These tools not only offer a static analysis but, by their nature, encourage a dynamic and adaptable approach, essential in the face of ongoing changes in the technological and industrial domains.

In the future perspective, it is essential to consider the rapid technological evolution and the potential impact of innovations on the requirements for implementing collaborative robots. Continuous monitoring of trends in technological development, such as the introduction of advanced sensors, artificial intelligence, and emerging technologies, will allow for the constant adaptation of implementation strategies. It is also crucial to keep pace with legislative and regulatory changes in the field to ensure compliance with industrial and safety standards.

In a broader approach, possibilities for collaboration between organizations can be explored for the exchange of best practices and experiences in integrating collaborative robots. This knowledge exchange could contribute to optimizing processes and accelerating the adoption of this technology in the global industrial environment.

These future directions bring a dynamic and proactive dimension to the discussion, anticipating challenges and opportunities that may arise as technology advances and the industrial context evolves.

7. Conclusions

The scientific paper aims to highlight the beneficial effects of using collaborative robots in industrial organizations, the positive impact on optimization, and the reduction of production costs, ultimately leading to increased profitability.

Structured into seven main chapters, the paper begins with an introduction to collaborative robots and a preliminary research overview in Chapter 1.

From the detailed analysis of the literature in Chapter 2.1, a comprehensive perspective on the impact of collaborative robots in the industrial sector is outlined. Notable advancements, highlighted by increased efficiency, quality optimization, and production process flexibility, certify the significant potential of these technologies. However, existing gaps are observed, especially regarding the detailed assessment of long-term costs and profitability in their integration. In this context, the need for future investigations to clarify these aspects and propose innovative solutions is emphasized. The literature review provides a solid framework for approaching collaborative robot integration, emphasizing the need for a holistic perspective on costs and quality in the context of industrial production. Thus, researchers and industry professionals are encouraged to continue investigations, focusing on developing predictive models and practical solutions to maximize the benefits of this technology in collaborative production environments. Chapter 2.2 focuses on a detailed study of the field, examining specific relevant aspects found in the specialized literature.

In Chapter 3, attention is directed towards developing a flowchart for the process of establishing requirements for the implementation of collaborative robots. This provides a graphical representation of the recommended progressive steps by the authors to achieve a functional, efficient, and effective application. These steps include determining technical considerations and needs, facilitating proper budgeting, and preventing potential misguided investments.

In Chapter 4, subchapter 4.1, the authors develop a mathematical model for cost management of implementation, analysing total costs, profitability, and electricity consumption. Direct and indirect costs are distinguished, and the proposed model provides solutions for their calculation. By successfully implementing the mathematical model described in subchapter 4.2, the perspective of a significant cost reduction of 638,067.84 Euros over two years opens up, requiring an initial investment of 88,686.92 Euros. In the second year, the specific collaborative approach with robots introduces an anticipated addition of 1,547.27 Euros per year. It is emphasized that this addition, sensitive to variables such as electricity tariffs, implementation duration, and the number of collaborative robots, is a crucial factor in the overall equation, with the potential to exert a significant influence on the project’s financial outcomes.

In Chapter 5, a synthesis of the findings presented in the scientific manuscript was provided, elucidating the culmination of empirical investigations.

Within the discussions, chapter 6 highlights the meticulous process of integrating collaborative robots into the production environment. The mathematical model and flowchart are the cornerstones of this research, providing a clear and detailed conceptual framework for analysing requirements, costs, and implementation steps. The investment calculation, focused on Universal Robots’ collaborative robots, underscores the need for a flexible approach, considering cost variability and the critical implications of factors such as salary increases, inflation, and changes in electricity costs. This comprehensive approach highlights the complexity of managerial decision-making processes and the constant need for adaptation to environmental conditions. Looking ahead, the research outlines a dynamic landscape, emphasizing the importance of adapting to rapid technological changes and evolving legislative contexts. Recommendations for collaboration between organizations are a key point of discussion, highlighting the potential for process optimization and accelerating the adoption of collaborative technology in the global industrial environment. Thus, chapter 6 provides a reference framework for future approaches, emphasizing the complexity and dynamism of this technological and industrial transformation.

Certain research directions can be outlined. Future research directions could involve utilizing the formulations from the paper to assess the differences between industrial robots and collaborative robots in a comparable working environment. Despite the rising costs, the study demonstrates that collaborative robots remain a viable option for optimizing production costs.

Regarding costs, another potential research direction could be the development of predictive models for the long-term evolution of costs, considering factors such as inflation, changes in component prices, and related technologies. This could contribute to a more precise implementation budget planning and anticipation of future expenses associated with the use of collaborative robots.

The contributions made in this paper are deemed original, and the authors believe that the proposed objectives have been achieved by presenting clear and verifiable scientific data.

Author Contributions

Conceptualization, A.M.Ț., V.G. and Ș.Ț; methodology, A.M.Ț.; software, V.G. and Ș.T.; validation, A.M.Ț., A.B.P. and M.D.; formal analysis, M.D., V.G.; investigation, V.G. and Ș.Ț.; resources, V.G. and A.M.Ț.; data curation, V.G. and Ș.T.; writing—original draft preparation, V.G. and A.M.Ț.; writing—review and editing, A.M.Ț., Ș.T. and A.B.P.; visualization, M.D. and A.M.Ț.; supervision, A.M.Ț.; project administration, A.M.Ț. and A.B.P.; funding acquisition, N/A. All authors have read and agreed to the published version of the manuscript.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kim, H.; Kim, D. Deep-Learning-Based Strawberry Leaf Pest Classification for Sustainable Smart Farms. Sustainability 2023, 15, 7931. [Google Scholar] [CrossRef]

- Mahfuz, S.; Mun, H.-S.; Dilawar, M.A.; Yang, C.-J. Applications of Smart Technology as a Sustainable Strategy in Modern SwineFarming. Sustainability 2022, 14, 2607. [Google Scholar] [CrossRef]

- Kuhlman, T.; & Farrington, J. What is sustainability? Sustainability 2010, 2(11), 3436–3448.

- Crawford, J.; & Cifuentes-Faura, J. Sustainability in higher education during the COVID-19 pandemic: A systematic review. Sustainability 2022, 14(3), 1879.

- Shen, B. Sustainable fashion supply chain: Lessons from H&M. Sustainability 2014, 6(9), 6236–6249. [Google Scholar] [CrossRef]

- Liu, H.; Wang, L. Human motion prediction for human-robot collaboration. Journal of Manufacturing Systems 2017, 44, 287–294. [Google Scholar] [CrossRef]

- Liu, H.; Wang, L. Remote human–robot collaboration: A cyber–physical system application for hazard manufacturing environment. Journal of Manufacturing Systems 2020, 54, 24–34. [Google Scholar] [CrossRef]

- Agravante, D. J.; Cherubini, A.; Sherikov, A.; Wieber, P. B.; Kheddar, A. Human-humanoid collaborative carrying. IEEE Transactions on Robotics 2019, 34(4), 833–846. [Google Scholar] [CrossRef]

- Shirine, E.; Marei, M.; Weidong, L.; Zahid, U. Cobot programming for collaborative industrial tasks: An overview. Robotics and Autonomous Systems 2019, 116, 162–180. [Google Scholar] [CrossRef]

- Zanchettin, M.; Croft, E.; Ding, H.; Li, M. Collaborative Robots in the Workplace. IEEE Robotics & Automation Magazine 2018, 25(2), 16-17. [CrossRef]

- Koubaa, A.; Abdelmajid, K. Cooperative Robots and Sensor Networks 2014. Berlin: Springer-Verlag 2014. [CrossRef]

- Pereira, F. G.; Vassallo, R. F.; Salles, E. O. T.; Human-robot interaction and cooperation through people detection and gesture recognition. J. Control, Automat. Elect. Syst. 2013, 24(3), 187-198. [CrossRef]

- Krueger, B.; Nickolay, B.; Schulz, O. Imagebased 3D-surveillance in man-robot-cooperation. Proc. INDIN ’04 2nd IEEE Int. Conf. Ind. Informat. 2004, 411-420. [CrossRef]

- Seraj, E.; Chen, L.; Gombolay, M. C. A hierarchical coordination framework for joint perception-action tasks in composite robot teams. IEEE Transactions on Robotics 2021, 38, 139–158. [Google Scholar] [CrossRef]

- Dekker, F.; Salomons, A.; Waal, J. V. D. Fear of robots at work: the role of economic self-interest. Socio-Economic Review 2017, 15(3), 539-562. [CrossRef]

- Kozak, M.; Kozak, S.; Kozakova, A.; Martinak, D. Is Fear of Robots Stealing Jobs Haunting European Workers? A Multilevel Study of Automation Insecurity in the EU. IFAC-PapersOnLine 2020, 53(2), 17493-17498. [CrossRef]

- Hinks, T. Fear of robots and life satisfaction,” International Journal of Social Robotics 2021, 13, 327-340. [CrossRef]

- You, S.; Robert, L. P. Human–Robot Similarity and Willingness to Work with a Robotic Co-worker. 13th ACM/IEEE International Conference on Human-Robot Interaction (HRI), Chicago, IL, USA, 2018, 251-260. [CrossRef]

- Poór, P.; Broum, T.; Basl, J. Role of collaborative robots in industry 4.0 with target on education in industrial engineering. In 2019 4th international conference on control, robotics and cybernetics (CRC) IEEE, 2019, 42-46. [CrossRef]

- Wang, B.; Zheng, P.; Yin, Y.; Shih, A.; Wang, L.; Kheddar, A. Toward human-centric smart manufacturing: A human-cyber-physical systems (HCPS) perspective. Journal of Manufacturing Systems 2022, 63, 471–490. [Google Scholar] [CrossRef]

- Mokyr, J. The lever of riches: Technological creativity and economic progress. Oxford University Press 1991. [CrossRef]

- Mokyr, J.; Vickers, C.; Ziebarth, N. L. The history of technological anxiety and the future of economic growth: Is this time different? Journal of economic perspectives 2015, 29(3), 31–50. [Google Scholar] [CrossRef]

- Conti, C. J.; Varde, A. S.; Wang, W. Task quality optimization in collaborative robotics. 2020 IEEE International Conference on Big Data (Big Data), Atlanta, GA, USA, 2020, pp. 5652-5654. [CrossRef]

- Badia, S. B. I; Silva, P. A.; Branco, D.; Pinto, A.; Carvalho, C.; Menezes, P.; Almeida, J.; Pilacinski, A. Virtual Reality for Safe Testing and Development in Collaborative Robotics: Challenges and Perspectives. Electronics 2022, 11, 1726. [Google Scholar] [CrossRef]

- Proia, S.; Carli, R.; Cavone, G.; Dotoli, M. Control techniques for safe, ergonomic, and efficient human-robot collaboration in the digital industry: A survey. IEEE Transactions on Automation Science and Engineering 2021, 19(3), 1798–1819. [Google Scholar] [CrossRef]

- Grau, A.; Indri, M.; Lo Bello, L.; Sauter, T. Robots in Industry: The Past, Present, and Future of a Growing Collaboration With Humans. IEEE Industrial Electronics Magazine 2021, 15(1), 50–61. [Google Scholar] [CrossRef]

- Sherwani, F.; Asad, M. M.; Ibrahim, B. S. K. K. Collaborative Robots and Industrial Revolution 4.0 (IR 4.0). International Conference on Emerging Trends in Smart Technologies (ICETST), Karachi, Pakistan, 2020, 1-5. [CrossRef]

- Accorsi, R.; Tufano, A.; Gallo, A.; Galizia, F. G.; Cocchi, G.; Ronzoni, M.; Manzini, R. An application of collaborative robots in a food production facility. Procedia Manufacturing 2019, 38, 341–348. [Google Scholar] [CrossRef]

- Zeng, F.; Xiao, J.; Liu, H. Force/torque sensorless compliant control strategy for assembly tasks using a 6-DOF collaborative robot. IEEE Access 2019, 7, 108795–108805. [Google Scholar] [CrossRef]

- Țîtu, A. M.; Gusan, V. The Influence of Collaborative Robots on the Quality, Efficiency and Effectiveness of Automotive Manufacturing Flows. In: Karabegović, I., Kovačević, A., Mandžuka, S. (eds) New Technologies, Development and Application V. NT 2022, Springer, Cham, 472. [CrossRef]

- Bloss, R. Collaborative robots are rapidly providing major improvements in productivity, safety, programing ease, portability and cost while addressing many new applications. Industrial Robot: An International Journal 2016, 43(5), 463-468. [CrossRef]

- Richards, D. Escape from the factory of the robot monsters: agents of change. Team Performance Management: An International Journal 2017, 23(1/2), 96-108. [CrossRef]

- Navas-Reascos, G. E.; Romero, D.; Stahre, J.; Caballero-Ruiz, A. Wire Harness Assembly Process Supported by Collaborative Robots: Literature Review and Call for R&D. Robotics 2022, 11, 65. [Google Scholar] [CrossRef]

- Li, R.; et. al. Unfastening of Hexagonal Headed Screws by a Collaborative Robot. IEEE Transactions on Automation Science and Engineering 2020, 17(3), 1455–1468. [CrossRef]

- Gautam, M.;; Fagerlund, H.; Greicevci, B.; Christophe, F.; Havula, J. Collaborative Robotics in Construction: A Test Case on Screwing Gypsum Boards on Ceiling. 5th International Conference on Green Technology and Sustainable Development (GTSD), Ho Chi Minh City, Vietnam, 2020, 88-93. [CrossRef]

- Gomes, N. M.; Martins, F. N.; Lima, J.; Wörtche, H. Reinforcement Learning for Collaborative Robots Pick-and-Place Applications: A Case Study. Automation 2022, 3, 223–241. [Google Scholar] [CrossRef]

- Zhang, J.; Wan, W.; Tanaka, N.; Fujita, M.; Harada, K. Integrating a Manual Pipette into a Collaborative Robot Manipulator for Flexible Liquid Dispensing. arXiv preprint 2022. [Google Scholar] [CrossRef]

- Macke, J.; Genari, D. Systematic literature review on sustainable human resource management. Journal of cleaner production 2019, 208, 806–815. [Google Scholar] [CrossRef]

- Razak, A.; Sarpan, S.; Ramlan, R. Effect of leadership style, motivation and work discipline on employee performance in PT. ABC Makassar. International Review of Management and Marketing 2018, 8(6), 67. [Google Scholar] [CrossRef]

- Ojstersek, R.; Javernik, A.; Buchmeister, B.; The impact of the collaborative workplace on the production system capacity: Simulation modelling vs. real-world ap-plication approach. Advances in Production Engineering & Management 2021, 16(4), 431-442. [CrossRef]

- Lamon, E.; Leonori, M.; Kim, W.; Ajoudani, A. Towards an Intelligent Collaborative Robotic System for Mixed Case Palletizing. 2020 IEEE International Conference on Robotics and Automation (ICRA), France, 2020, 9128-9134. [CrossRef]

- BNR. (2023, 03 25). Curs BNR azi. Retrieved from Curs BNR: https://www.cursbnr.ro/curs-bnr-azi.

- 3200 lei Net - Calcul Salariu Brut. (2023, December 30). Retrieved from Calculator Salarii: http://www.calculator-salarii.ro/3200-net-calcul-salariu-brut/.

- Oferte, prețuri și tarife - Electrica Furnizare S.A. - Clienți noncasnici. (2023, December 30). Retrieved from Electrica Furnizare - Clienti noncasnici - Electrica Furnizare S.A. - Clienți noncasnici: https://www.electricafurnizare.ro/business/preturi-si-tarife.

- Collaborative robotic arms | Automation with collaborative robots | UR. (2023, December 31). Retrieved from Robotic Arms for Industrial Collaborative Robots | Cobot robots from Universal Robots: https://www.universal-robots.com/ro/?_gl=1*crq7lr*_up*MQ..&gclid=Cj0KCQiA7YyCBhD_ARIsALkj54qsCnxQNzqQ7yKtTwa98wFi5LmCbMhrDRoj3SiTLugvHpfEaMPChLoaAjshEALw_wcB.

- Cobots and electricity use: one less thing to worry about. (2022, 11 23). Retrieved from Collaborative robotic automation | Cobots from Universal Robots: https://www.universal-robots.com/blog/cobots-and-electricity-use-one-less-thing-to-worry-about.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).