Submitted:

08 May 2024

Posted:

08 May 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Parameters Affecting Hydrokinetic Turbine Efficiency and Power Generation

3. Performance Enchantment Methods

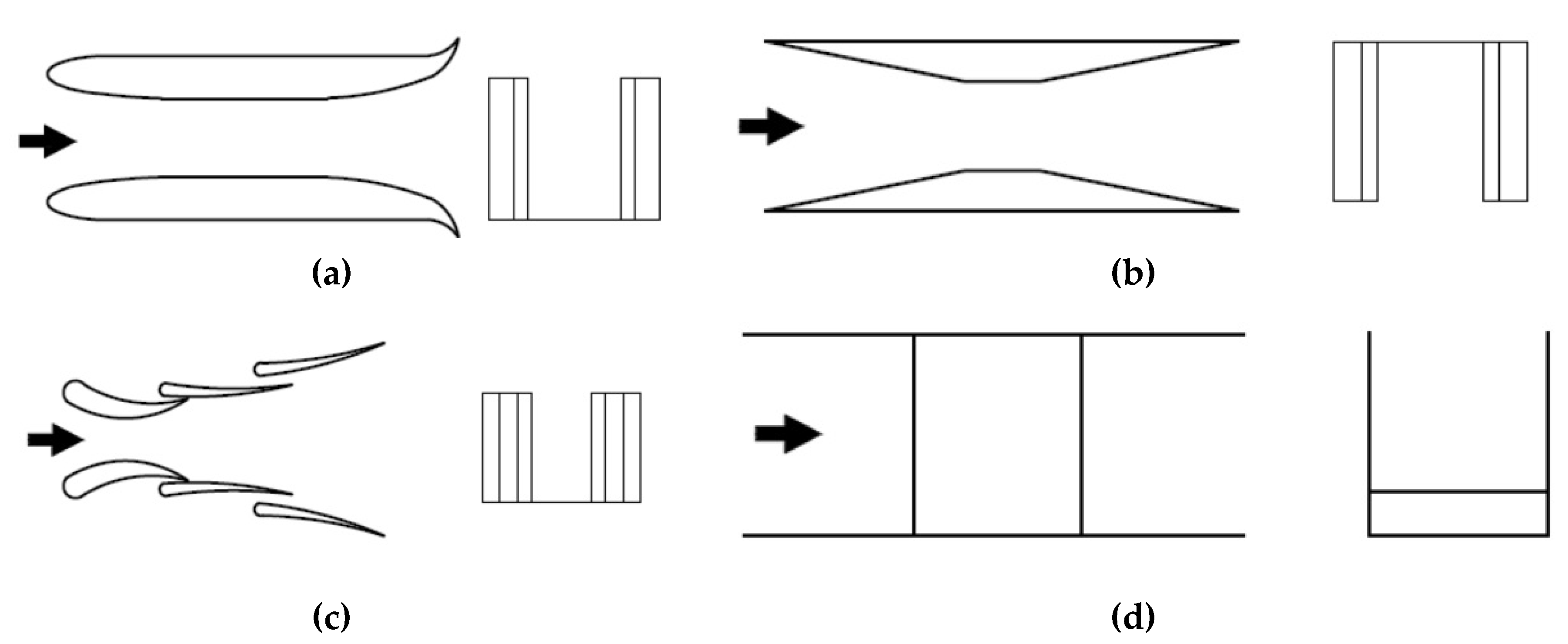

3.1. Cylindrical Casing

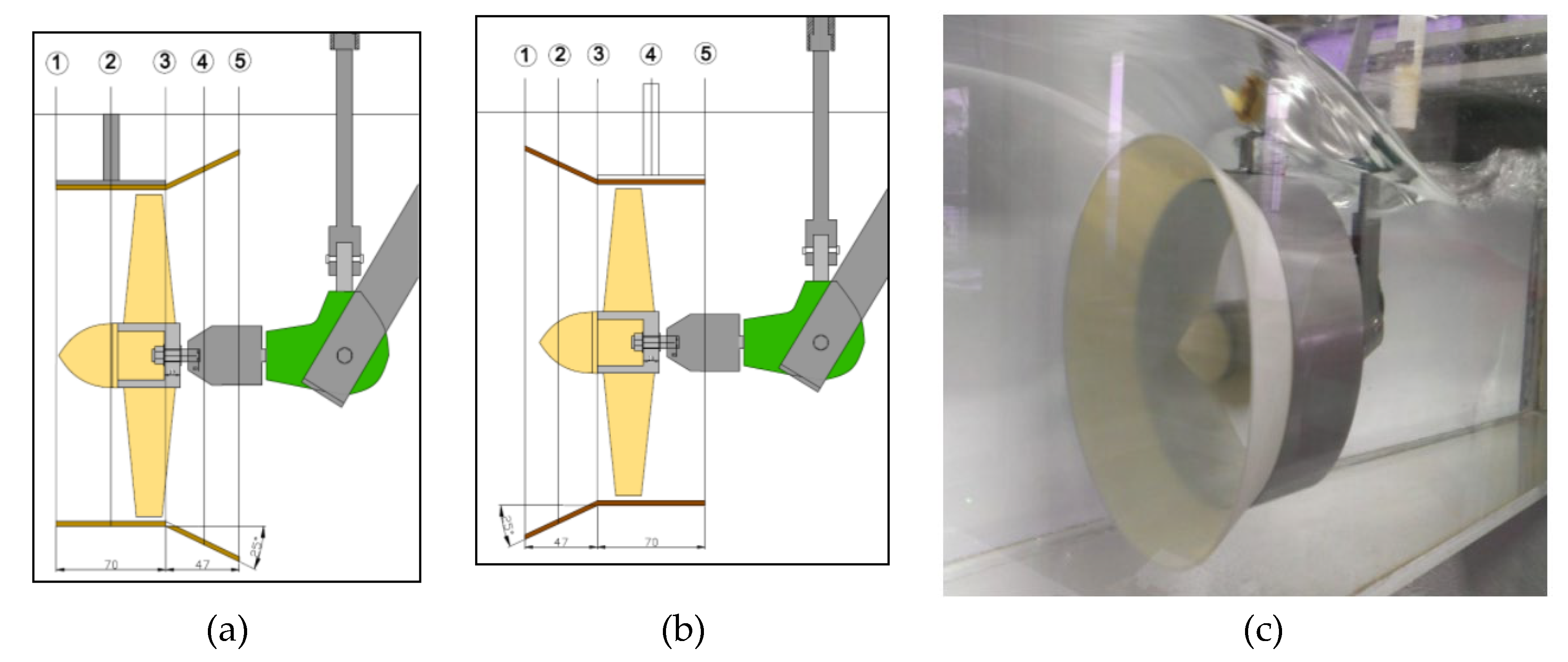

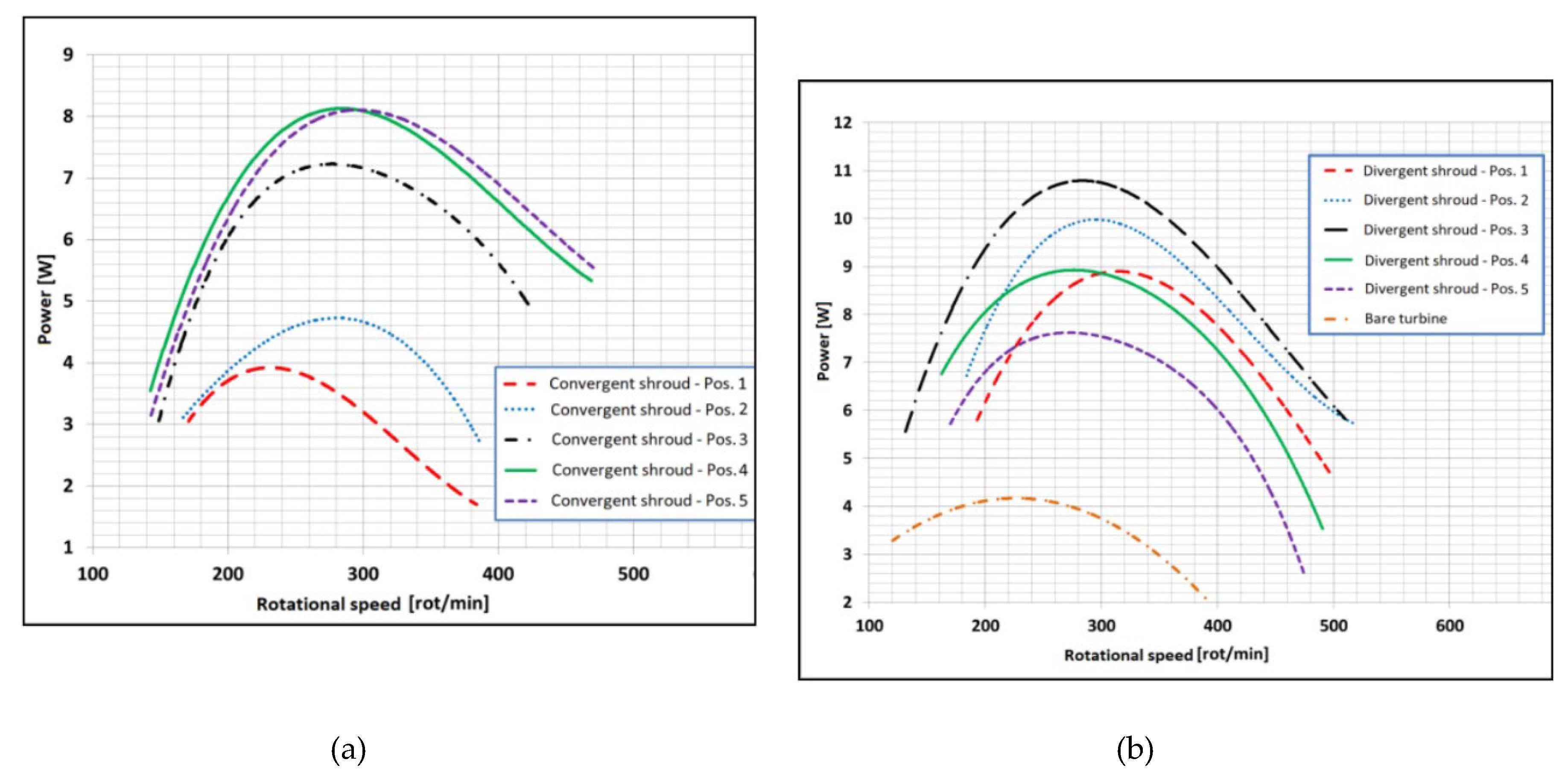

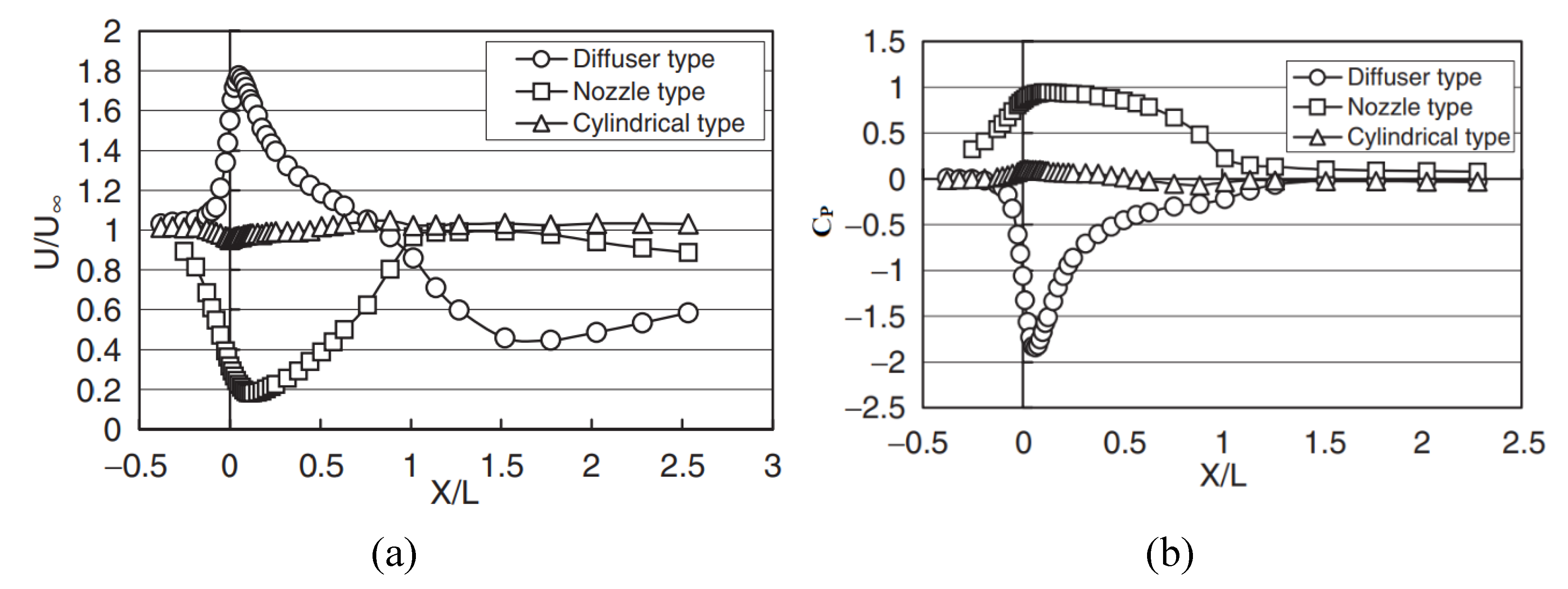

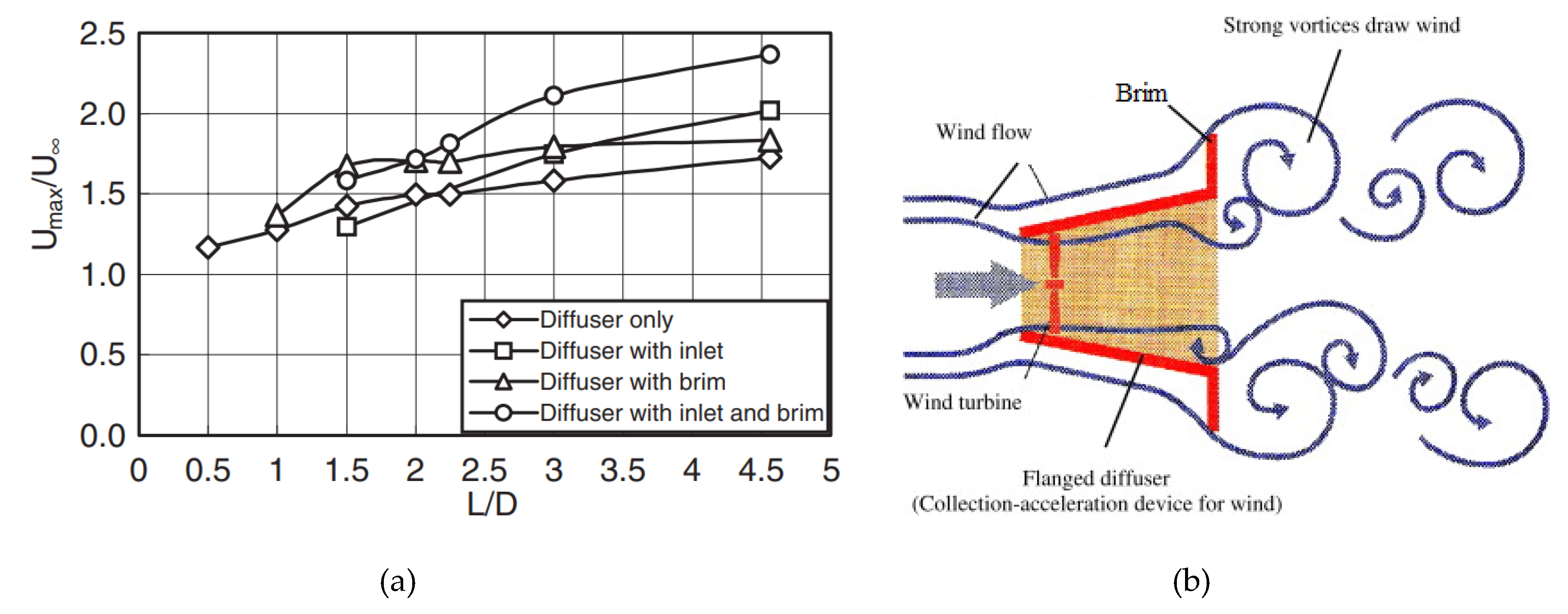

3.2. Conical Casing (Diffuser)

3.3. Channel Modifications

3.4. System of Sequientially Placed Axial Kinetic Turbines

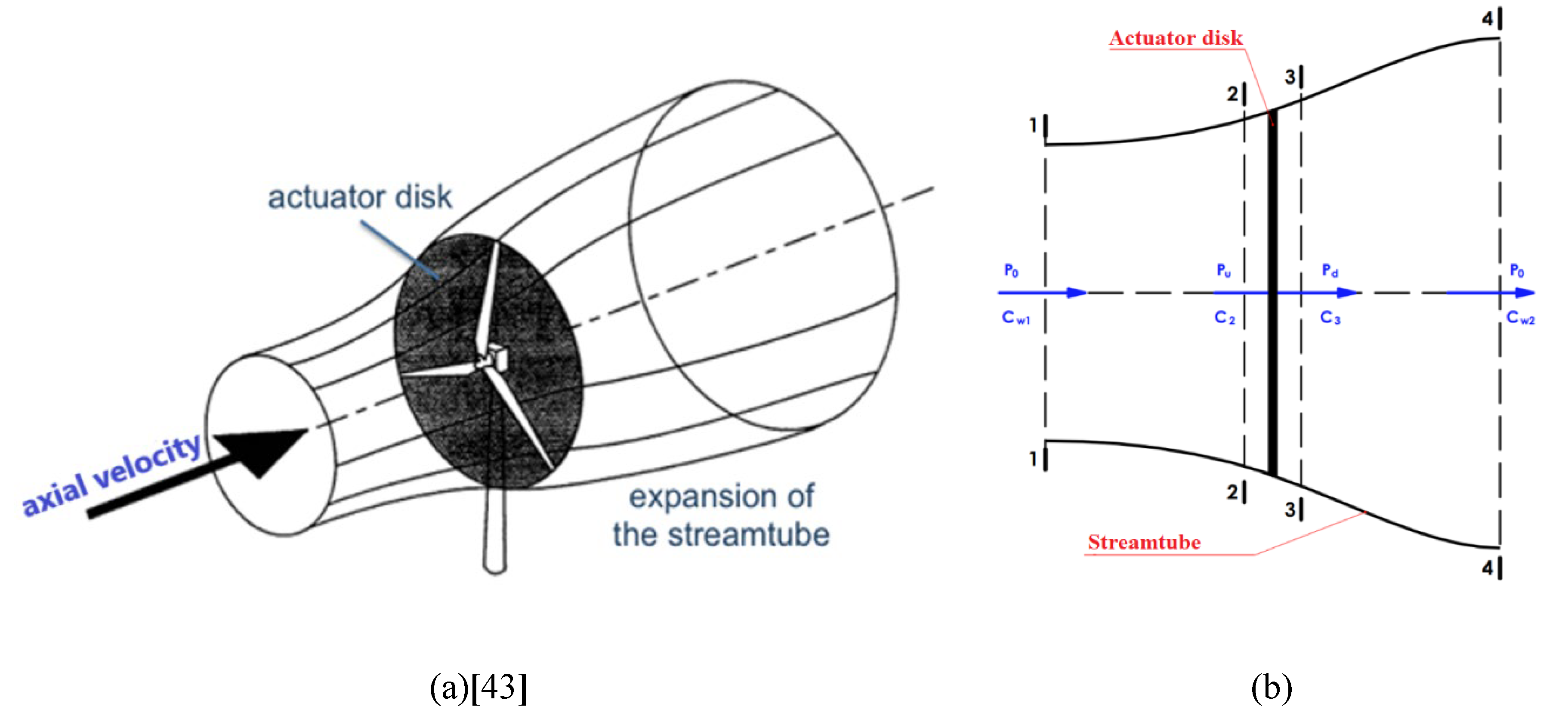

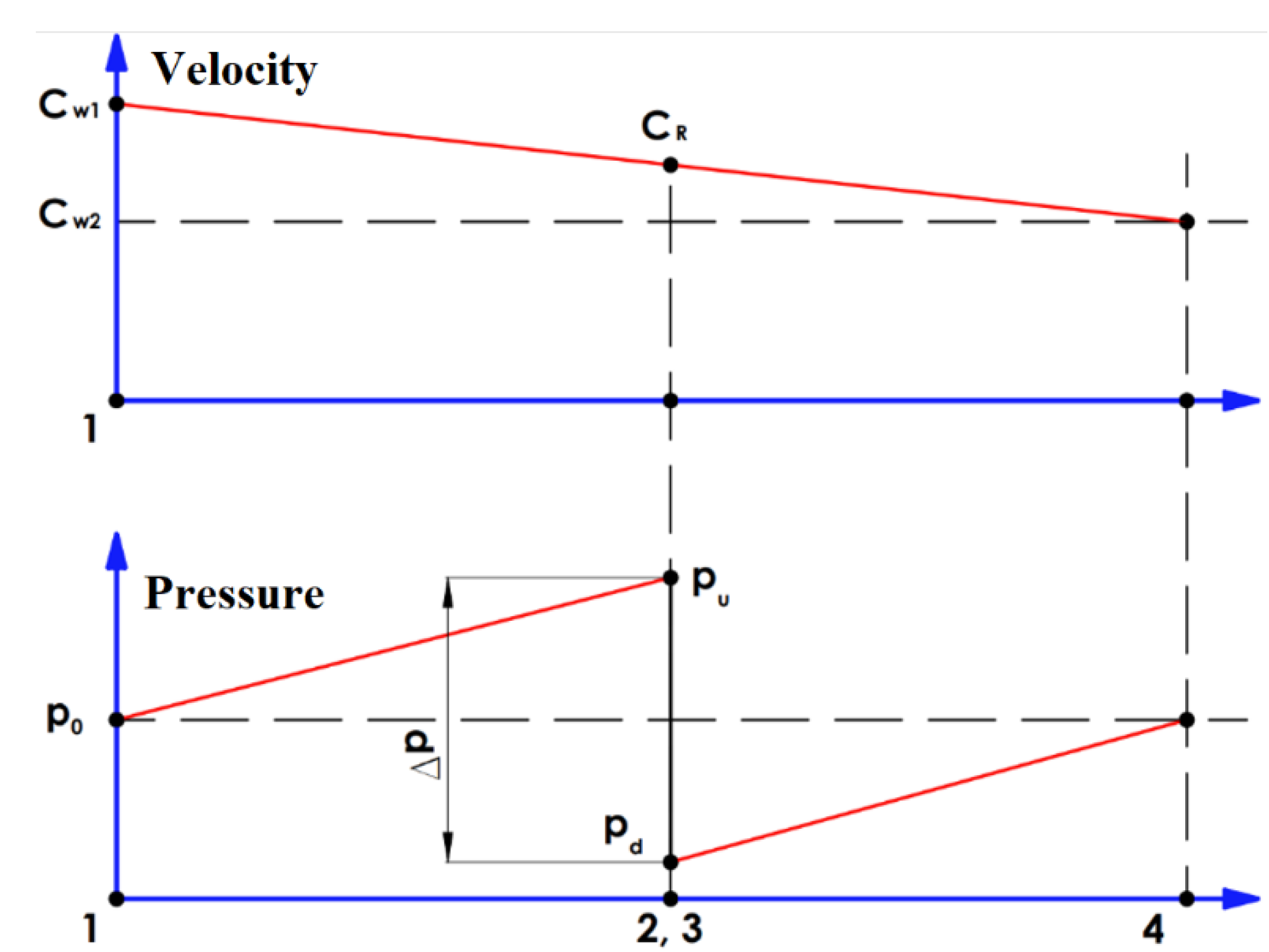

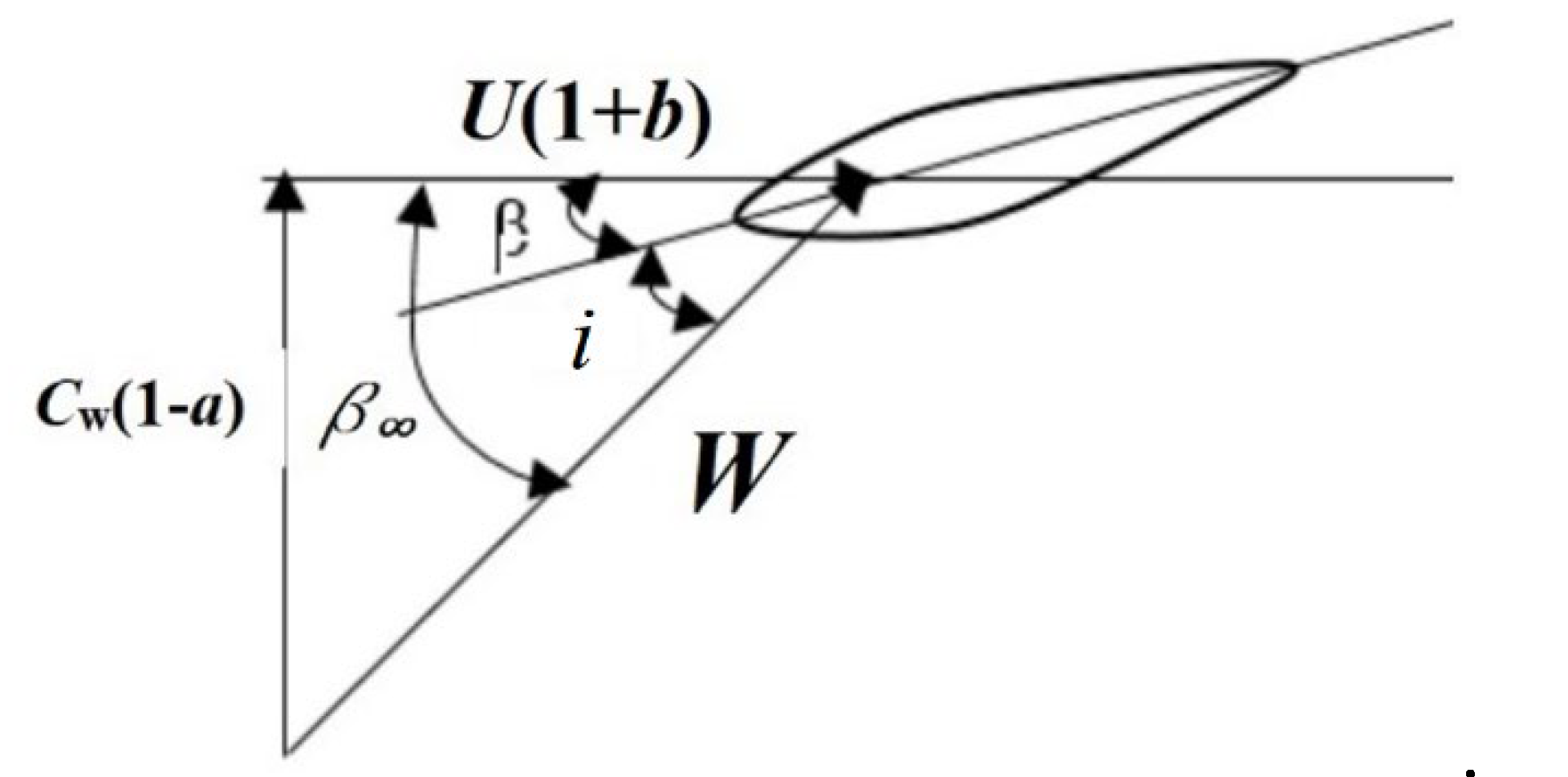

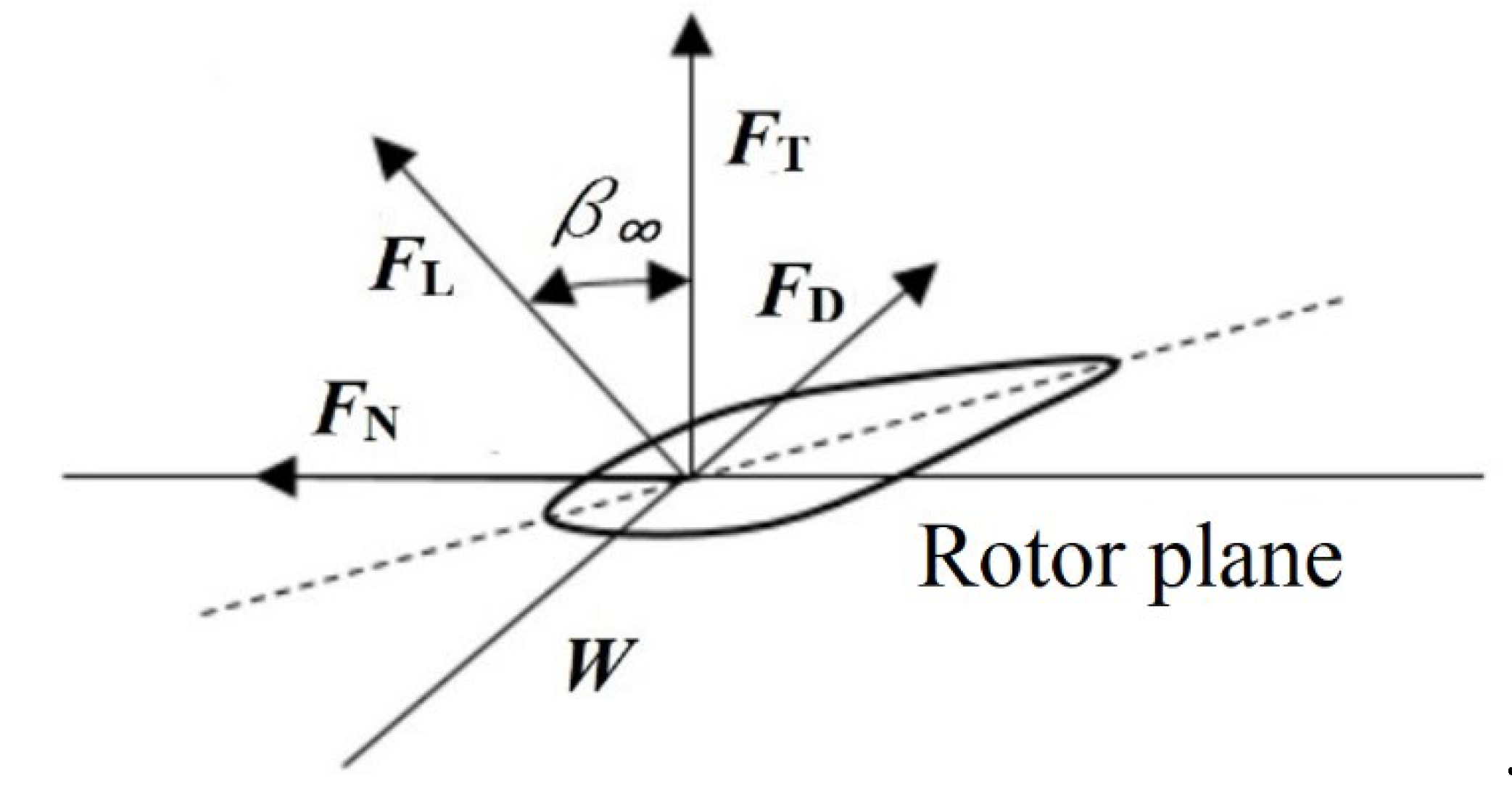

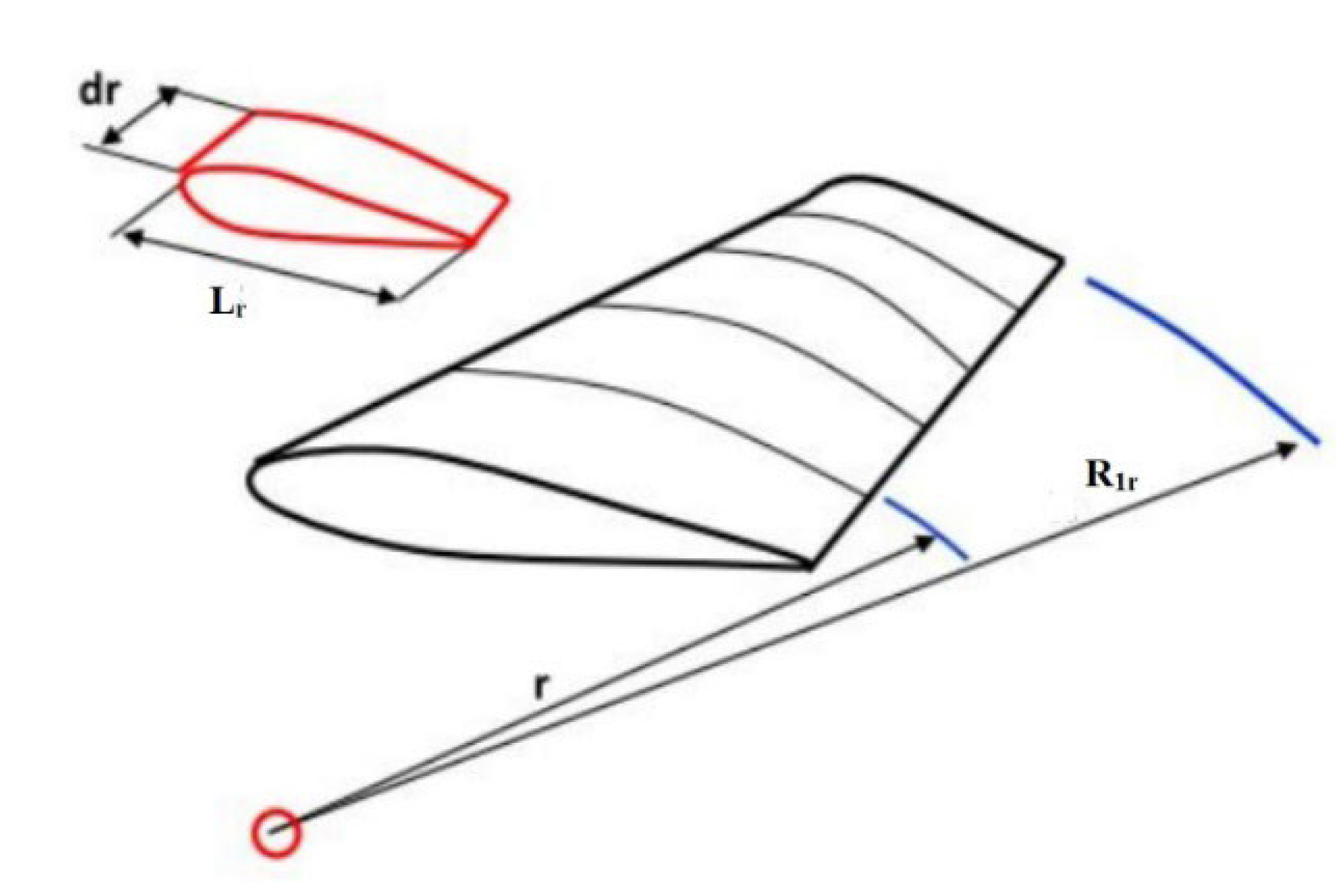

4. Calculation of Axial Kinetic Turbine

- – the outer diameters of the oscliating disk and the runner are identical;

- – the flow is stationary, incompressible and continuous;

- – viscous friction forces are neglected;

- – the vorticity of the flow around the disk is neglected;

- – the stream velocity near the disk is the same;

- – the blade cascade is composed of an infinity number of infinitely thin blades.

5. An Overview of Published Articles

6. Installation Examples

- Oscilla Power's Triton-C design [62] is a floating turbine designed for ocean currents. The turbine has a passive steering system that pivots the turbine rotor along the water flow.

- Verdant Power's Free Flow System [63].

- Minesto's Deep Green [64] is a hydrokinetic turbine mounted on a mobile kite-like platform. It moves in a trajectory resembling the shape of the number eight.

- Blue Energy's VIVACE (Vortex Induced Vibration Aquatic Clean Energy) [65] generates electricity from flowing water using the vibrations induced by vortices.

- When choosing the type of hydrokinetic turbine for a specific location, the following factors should be taken into account:

- Water velocity: the turbine will generate the maximum amount of electricity if its rated speed approaches or matches the prevailing stream velocity in the control area.

- Depth, which will specify the type of the turbine.

- Capital investment.

- Durable and reliable construction requiring minimal maintenance throughout the service life.

8. Conclusions

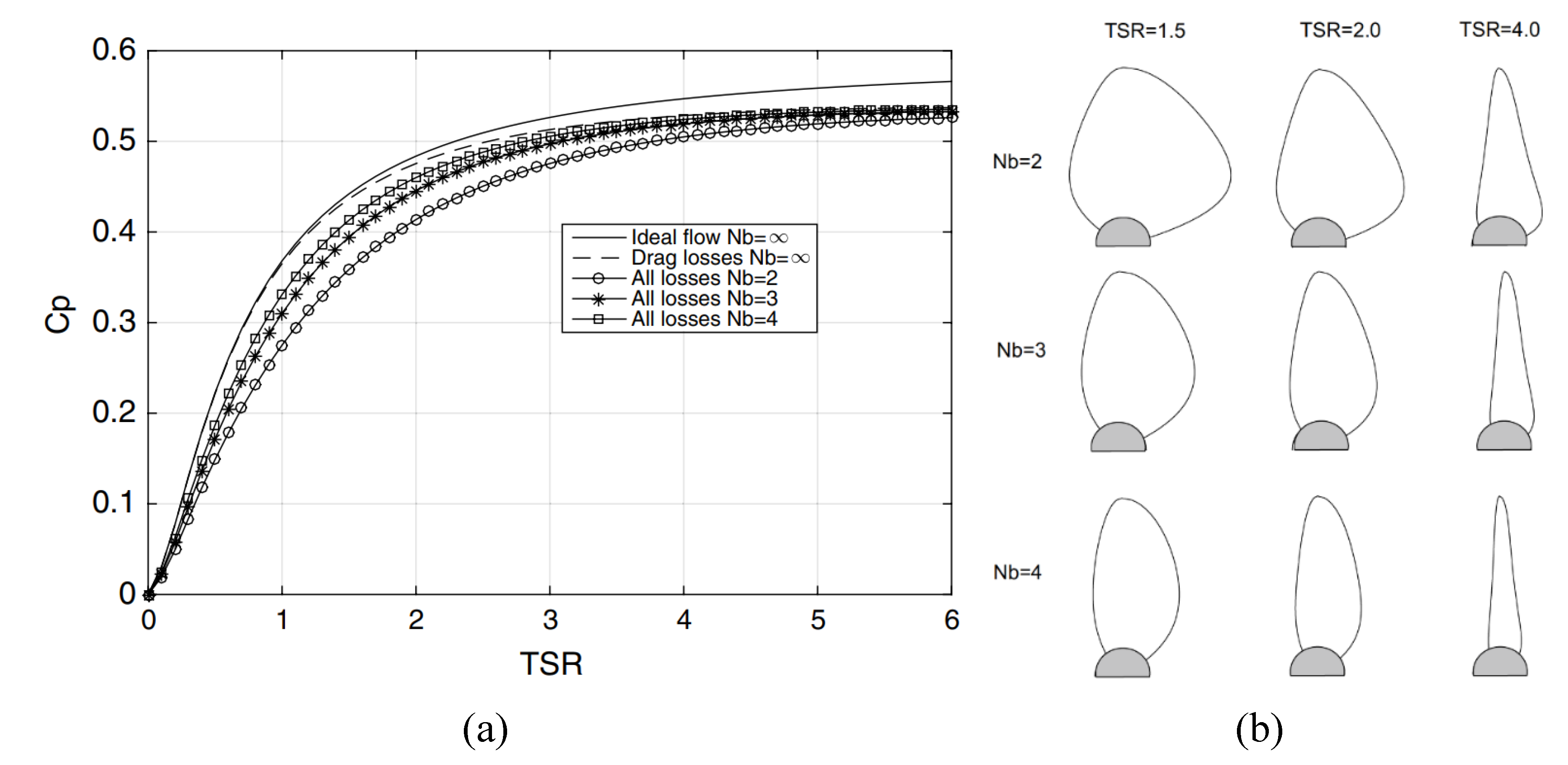

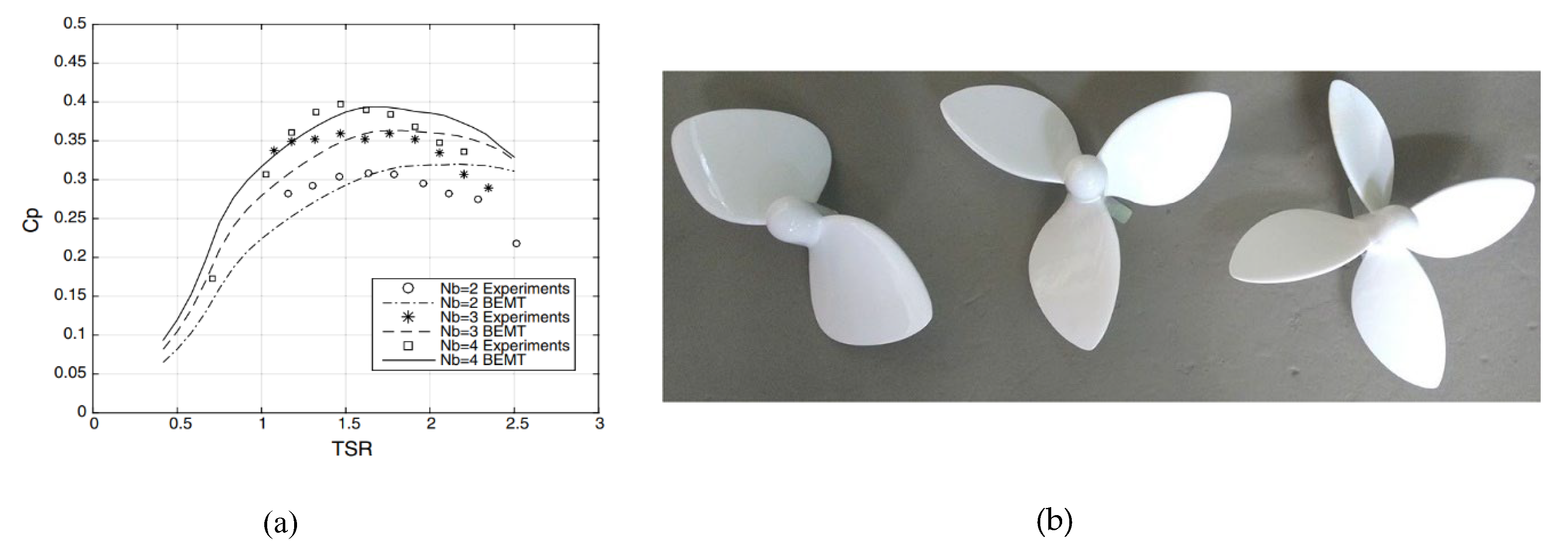

- Maximum power is obtained with a four-bladed runner. It shoud be noted that difference in efficiency between four-baded and three-bladed runner is small and the choice should be made on the basis of the generated power and the capital investment.

- The optimal tip speed ratio depends on the active area of the working blades. Higher rotational speeds can be achieved with thinner blades.

- Rounding of the tip section of the working blades can increase the turbine’s efficiency. According to the authors, the benefits are 47%.

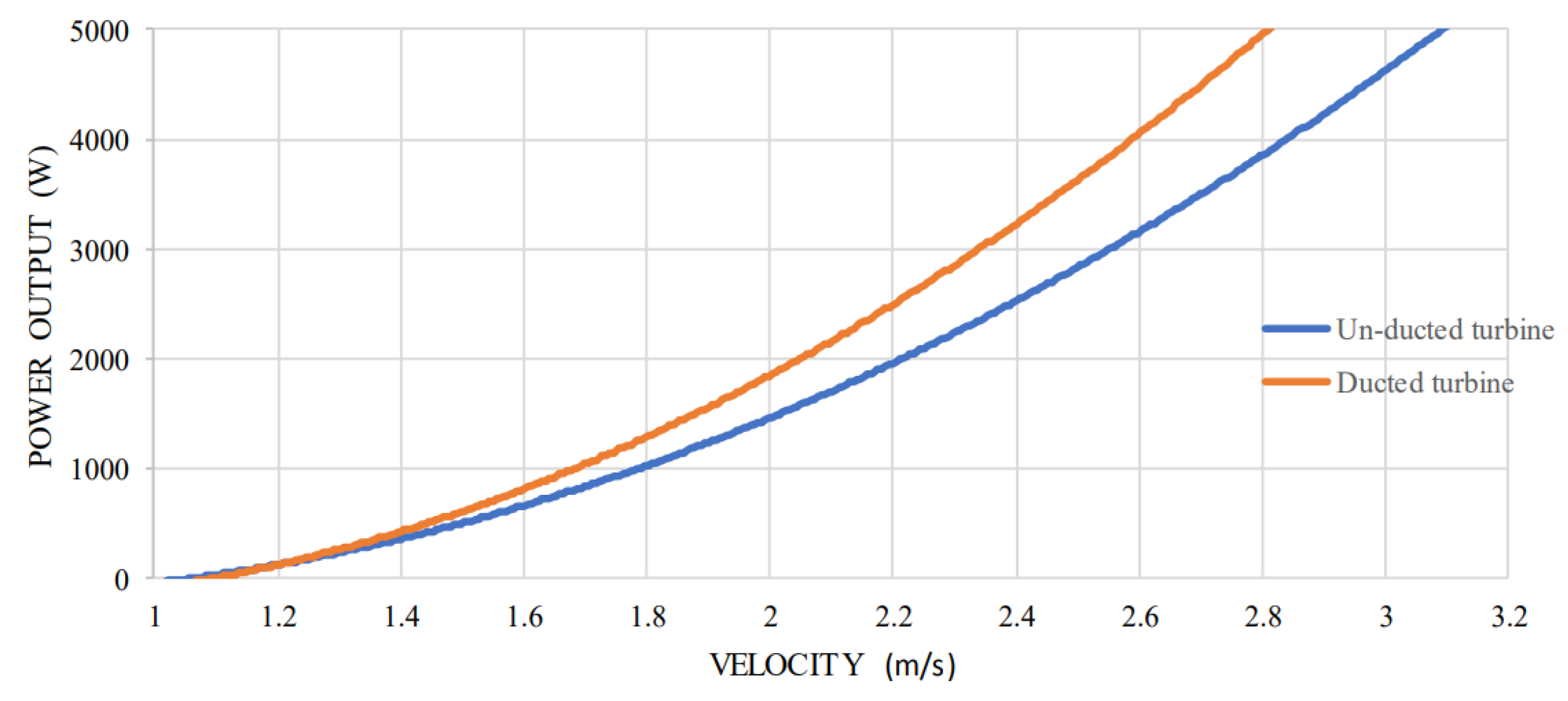

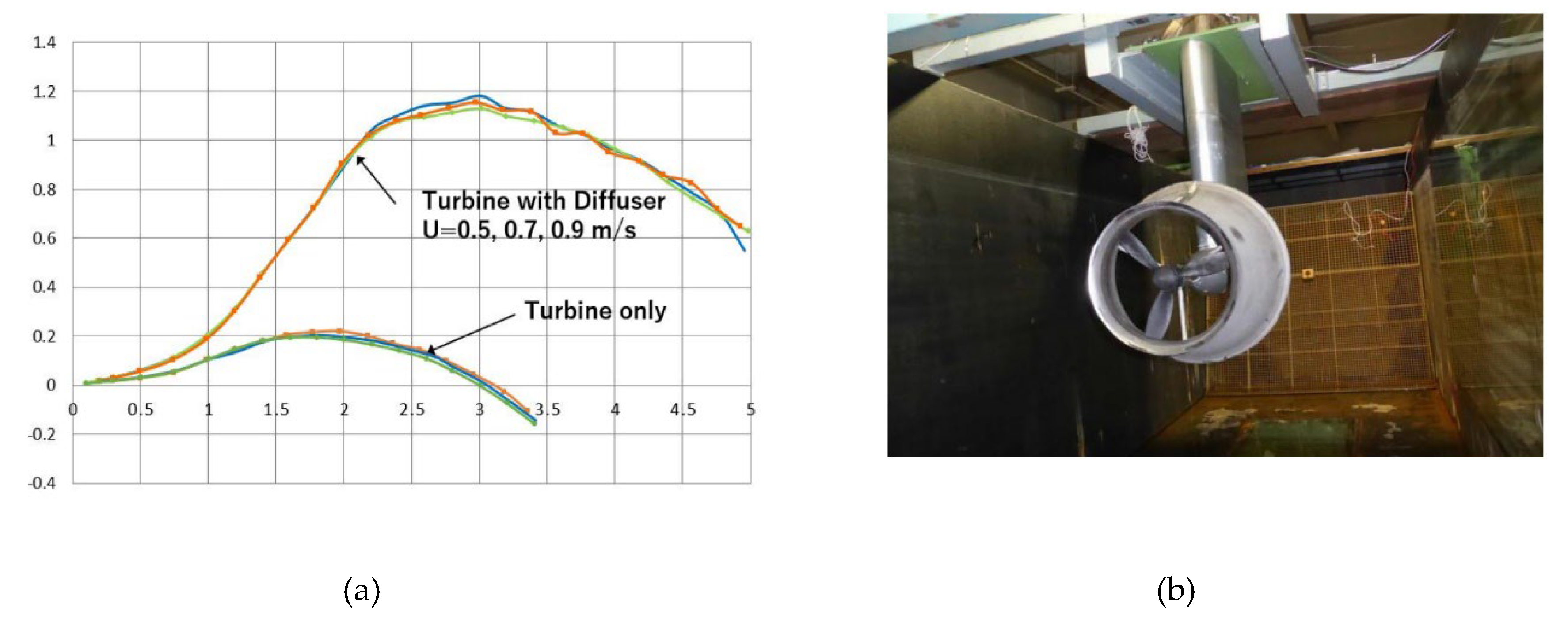

- Placing the turbine runner inside a cylindrical casing increases the generated electrical power. The benefits are greater at higher stream velocities.

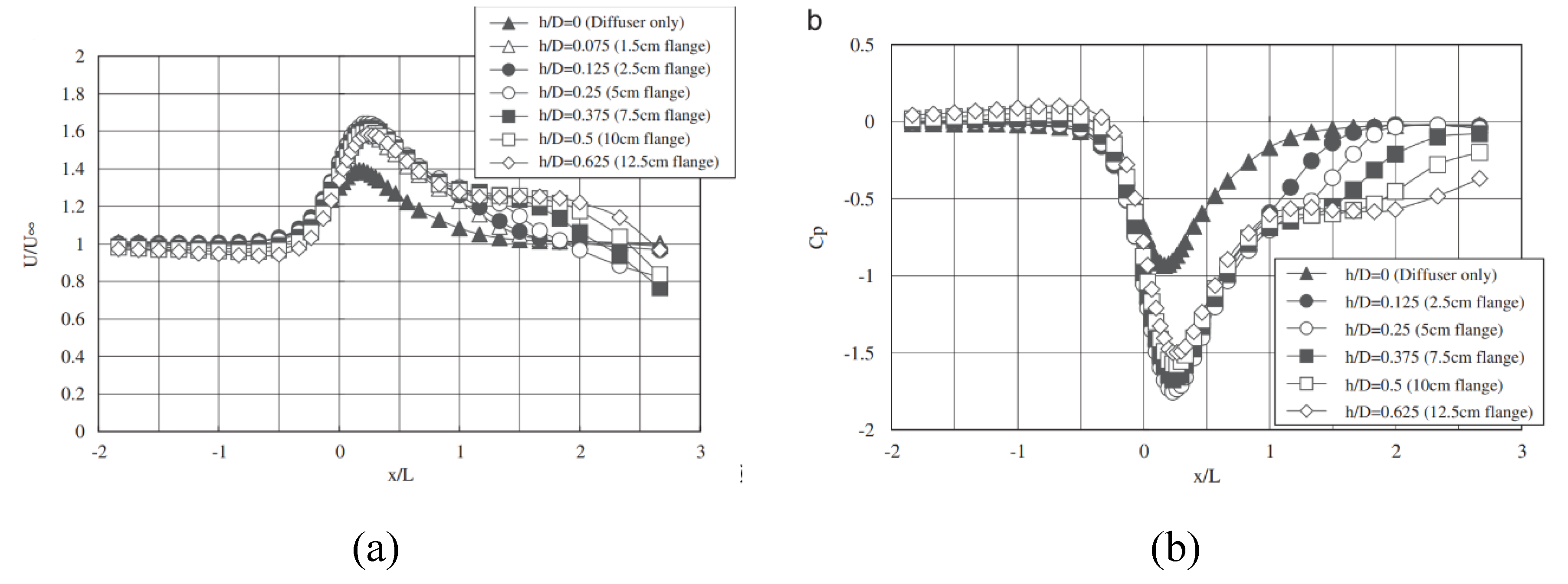

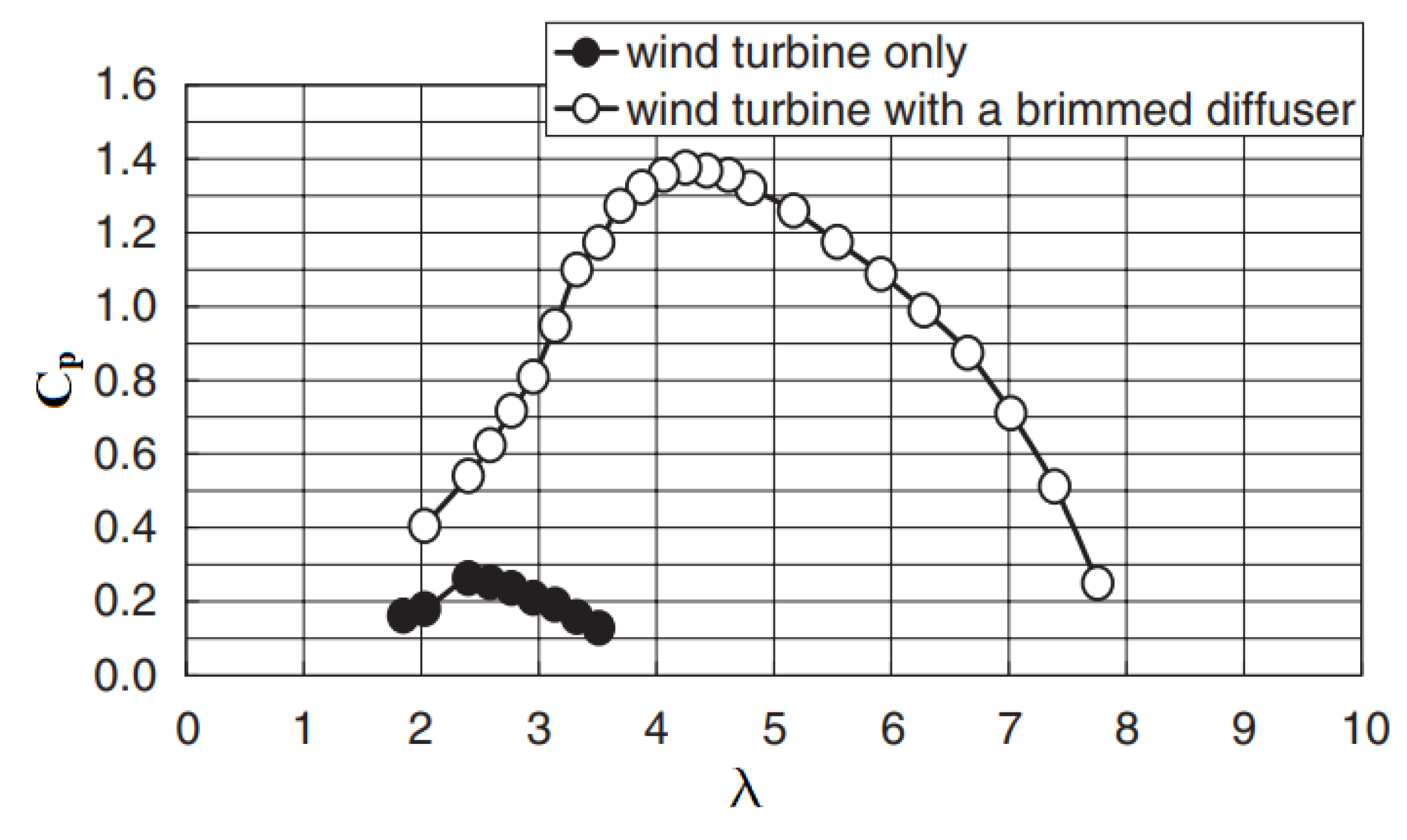

- Placing the turbine runner inside a cylindrical casing that ends in a diffuser increases the stream velocity through the turbine. The effect can be improved by adding a flange around the outlet section. The benefits are nearly 5 times higher efficiency.

Funding

References

- Balaras, A.; Dascalaki, E., G; Patsioti, M.; Droutsa, K., G.; Kontiyiannidis, S.; Cholewa, T. Carbon and Greenhouse Gas Emissions from Electricity Consumption in European Union Buildings. Building 2024, 14. [Google Scholar] [CrossRef]

- Schulze, M.; Hunger, M.; Doll, P. Simulating river flow velocity on global scale. ADGEO 2006, 5, 133–136. [Google Scholar] [CrossRef]

- Eltner, A.; Sardemann, H.; Grundmann, J. Flow velocity and discharge measurement in rivers using terrestrial and unmanned-aerial-vehicle imagery. HESS 2020, 24, 1429–1445. [Google Scholar] [CrossRef]

- Valdes, R., E.; Yosry, A., G.; Ferrauiuolo, R.; Jimenez, A.; Pacheco, M., F. Experimental Comparison between Hydrokinetic Turbines: Darrieus vs. Gorlov. Environ. Sci. Proc. 2022, 21. [Google Scholar] [CrossRef]

- Dudhgaonkar, P.; Duraisamu, N.; Jalihal, P. Energy extraction from ocean currents using straight bladed cross-flow hydrokinetic turbine. IJOCS 2017.

- Duerr, A., E., S.; Dhanak, M., R. Hydrokinetic power resource assessment of the Florida Current. MTS/IEEE SEATTLE, 2010. [Google Scholar]

- Tewari, U.; Karl, K. Hydrokinetic Energy for Enlighting the Future of Rural Communities in Uttarakhand. THDC.

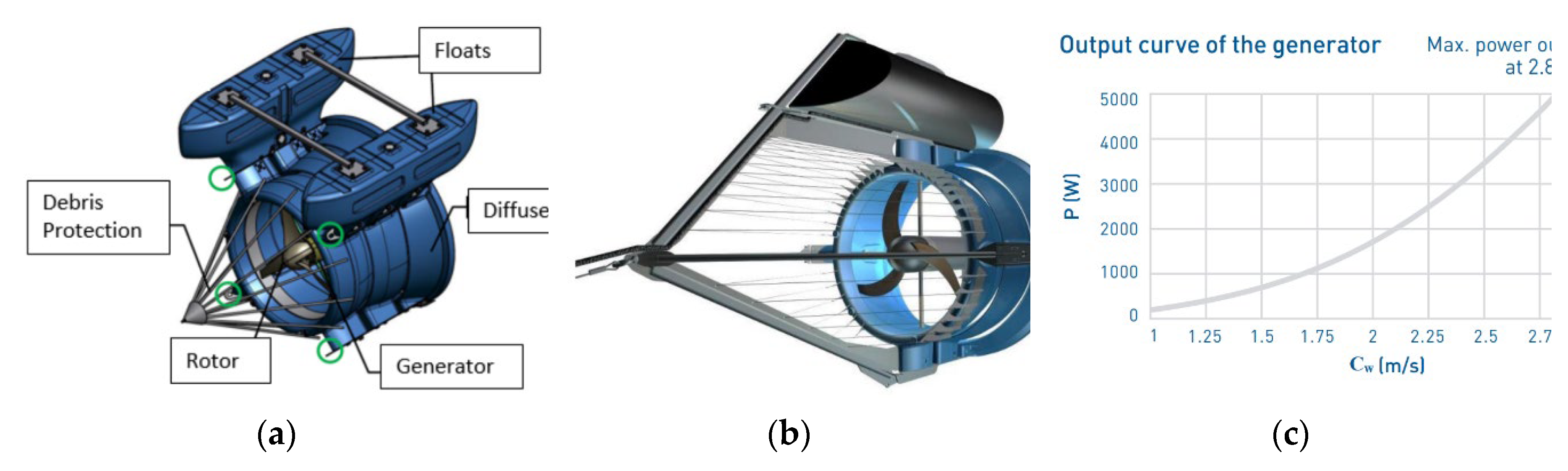

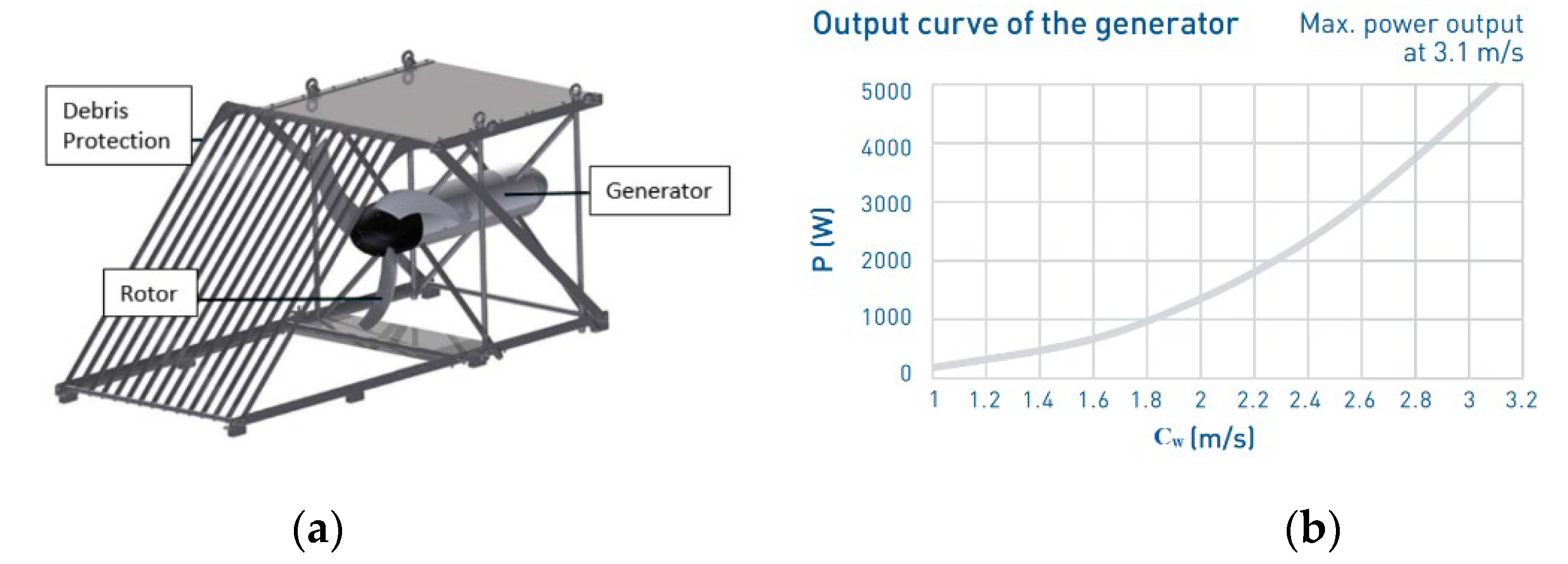

- SMART HYDRO POWER. Available online: https://www.smart-hydro.de (accessed on 15 03 2024).

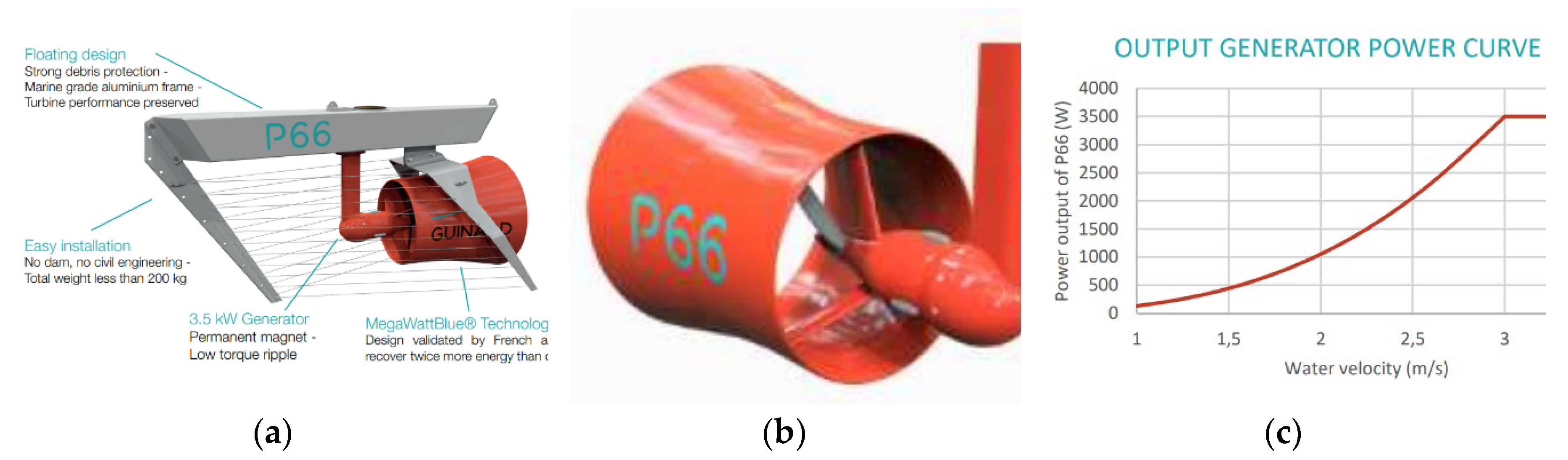

- River and tidal hydrokinetic turbines. Available online: https://www.guinard-energies.bzh (accessed on 15 03 2024).

- SMART FREE STREAM TURBINE. Available at: https://smart-hydro.de/wp-content/uploads/2015/12/Datasheet_SMART_Freestream.pdf (accessed on 16 03 2024).

- Todorov, G; V., Obretenov; K., Kamberov; T., Ivanov; T., Tsalov; B., Zlatev. Concept and Physical Prototyping of Micro Hydropower System Using Vertical Crossflow Turbine. EFEA, 2021, 1-4.

- Todorov, G; K. Kamberov; M., Semkov. Improvement of undershot water wheel performance through virtual prototyping. AIP Conf. Proc. 2021, 2333. [Google Scholar]

- Samso, R.; Crespin, J.; Garcia-Olivares, A.; Sole, J. Examining the Potential of Marine Renewable Energy: A Net Energy Perspective. Sustainability 2023, 15. [Google Scholar] [CrossRef]

- Godinho, F.; Costa, S.; Pinheiro, P.; Reis, F.; Pinheiro, A. Integrated Procedure for Environmental Flow Assessment in Rivers. Environ. Process. 2014, 1, 137–147. [Google Scholar] [CrossRef]

- Danube river basin. Available at: https://www.icpdr.org/danube-basin/danube-river-basin (accessed on 15 03 2024).

- History of the Rhine River. Available at: https://www.britannica.com/place/Rhine-River/History (accessed on 15 03 2024).

- The Neman River. Available at: https://en.wikipedia.org/wiki/Neman (accessed on 15 03 2024).

- The Narva River. Available at: http://www.nrwr.net/93eng.html (accessed on 15 03 2024).

- The Strømmen River. Available at: https://www.studycountry.com/wiki/what-is-fastest-flowing-river-in-europe#google_vignette (accessed on 15 03 2024).

- The Angara River. Available at: https:/www.worldatlas.com/articles/where-does-the-angara-river-flow.html (accessed on 15 03 2024).

- The Lena River. Available at: https://www.feow.org/ecoregions/details/608 (accessed on 15 03 2024).

- Zou, R.; Che, C.; Cao, J.; Wang, Q. The Flow of the Yangtze River Inverted From a Continuous Global Navigation Satellite System Station. Geophys. Res. Lett. 2023, 50. [Google Scholar] [CrossRef]

- Patel, C., G.; Gundaliya, P., J. Calculating Discharge Carrying Capacity of River Tapi. IJERT 2014, 3. [Google Scholar]

- Rio Grande Flow. Avaliable at: https://ibwcsftpstg.blob.core.windows.net/wad/DailyReports/flowdata.htm (accessed on 15 03 2024).

- Shams, A.; Hussian, T., A.; Al-Mukhtar, M. Modeling Flow Patterns in Tigris River – Baghdad Using the CCHE2D model. Earth Environ. Sci. 2022, 1120.

- Das, T., K.; Islam, R.; Khallil, E.; Mamun, A.; Kundu, D. Design Optimization and Economic Analysis of a Hybrid System for a Hilly Area in Bangladesh. LNME, 93 105.

- The Nile River. Available at: https://www.touregypt.net/egypt-info/magazine-mag05012001-magf4a.htm (accessed on 15 03 2024).

- Oberg, K.; Shelton, J., M.; Gardiner, E., P.; Jackson, P., R. Discharge and Other Hydraulic Measurements for Characterizing the Hydraulics of Lower Congo River. IAHR Congress.

- Nwoko, D., U. Modelling Velocity Distribution in 3-D for Nun River, Niger Delta Nigeria. Curr. j. appl. 2017, 20. [Google Scholar] [CrossRef]

- Tigabu, M., T.; Guta, D., G.; Admasu, B., T. Economics of Hydro-Kinetic Turbine for off-grid Application: A Case Study of Gumara River, Upper Blue Nile, Amhara, Ethiopia. IJRER 2019, 9. [Google Scholar]

- Lust, E., L. ; B., H., Benjamin; K., A., Flack. Performance characteristics of a cross-flow hydrokinetic turbine in current only and current and wave conditions. Ocean Eng. 2021, 219.

- Guillaud, N.; G. , Balarac; E., Goncalves; J., Zanette. Large Eddy Simulations on Vertixal Axis Hydrokinetic Turbines and flow phenomena analysis. IOP Conf. Ser.: Earth Environ. 2016, 49, 10. [Google Scholar]

- Xu, W.; G. , Xu; W., Duan; Z., Song; J., Lei. Experimental and numerical study of a hydrokinetic turbine based on tandem flapping hydrofoils. Energy 2019, 174, 375–385. [Google Scholar] [CrossRef]

- NUST Research & Innovation. . Available online: https.

- Niebuhr, C. M.; Dijk, M.; Neary, V. S.; Bhagwan, N. A review of hydrokinetic turbines and enhancement techniques for canal installations: Technology, applicability and potential. Renew. Sustain. Energy Rev. 2019, 113. [Google Scholar] [CrossRef]

- ://twitter.com/Research_NUST/status/1376861664868454403 (accessed on 15 03 2024).

- Jabbar, A., B.; Al-Quraishi; Asmuin, N. , Z; Nazir N., F.; et. al. CFD Investigation of Empty Flanged Diffuser Augmented Wind Turbine. Int. J. Integr. Eng. 2020, 12. [Google Scholar]

- Venturi effect. Available at: https://www.wassertec.co.za/explanation-venturi-effect-applications/ (accessed on 15 -03 2024). 2024.

- The Actuator Disk Model. Available at: https://www.e-education.psu.edu/aersp583/node/470 (accessed on 15 03 2024).

- El khchine, Y.; Sriti, M. Improved Blade Element Momentum theory (BEM) for Predicting the Aerodynamic Performances of Horizontal Axis Wind Turbine Blade (HAWT). Tech. Mech. 2018, 38. [Google Scholar]

- Benini, E. Significance of blade element theory in performance prediction of marine propellers. Ocean Eng. 2004, 31, 957–974. [Google Scholar] [CrossRef]

- Liu, S.; Janajreh, I. Development and application of an improved blade element momentum method model on horizontal axis wind turbines. IJEEE 2012, 3. [Google Scholar] [CrossRef]

- Actuatror disk 3D scheme. Available at: https://www.e-education.psu.edu/aersp583/node/470 (accessed on 15.03.2024).

- Betz’s Law. Available at: https://www.scribd.com/document/342343083/Betz-s-law-pdf (accessed on 20.03 2024).

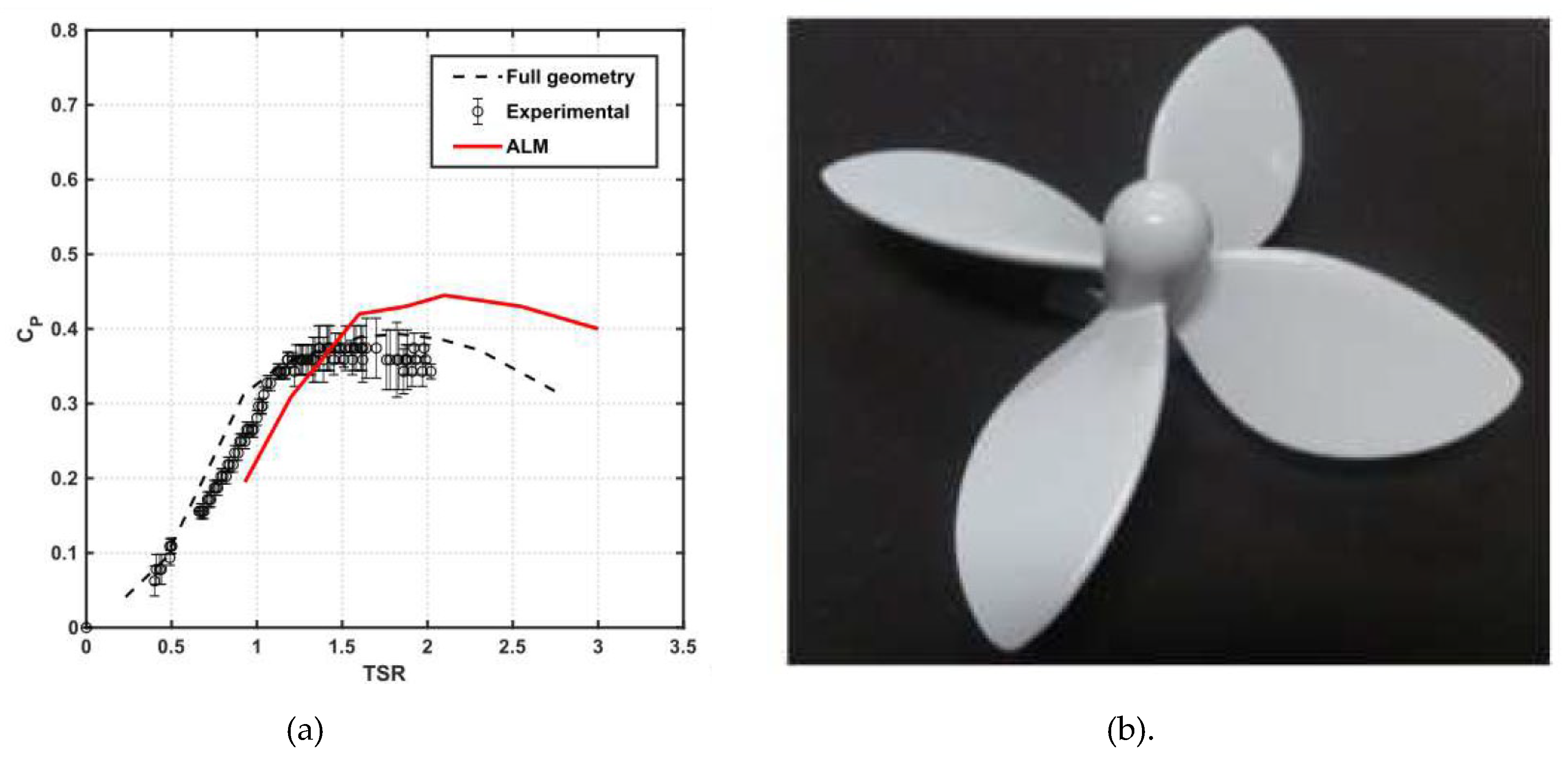

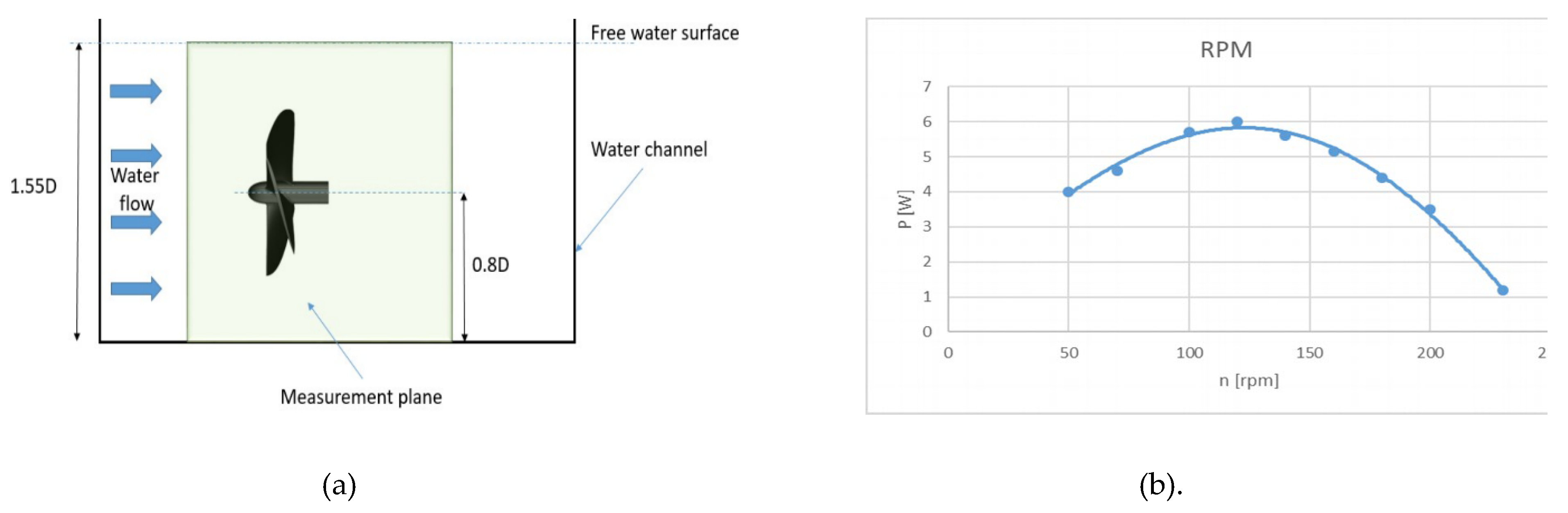

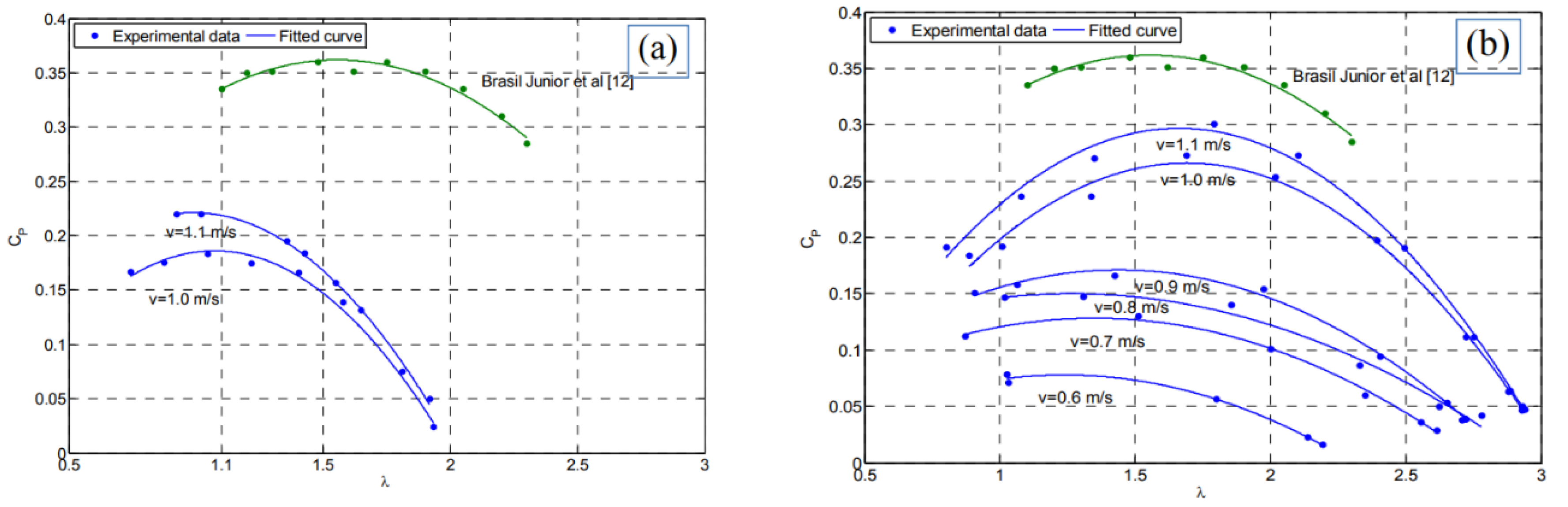

- Marianela, M., M.; Rafael, C.; Faria, M.; Michael, P.; et al. On the wake of propeller hydrokinetic turbines: Numerical simulations and experiments. Proc. J. Braz. Soc. Mech. Sci. Eng. 2023. [Google Scholar]

- University of Brasilia. Available at: https://www.unb.br/.

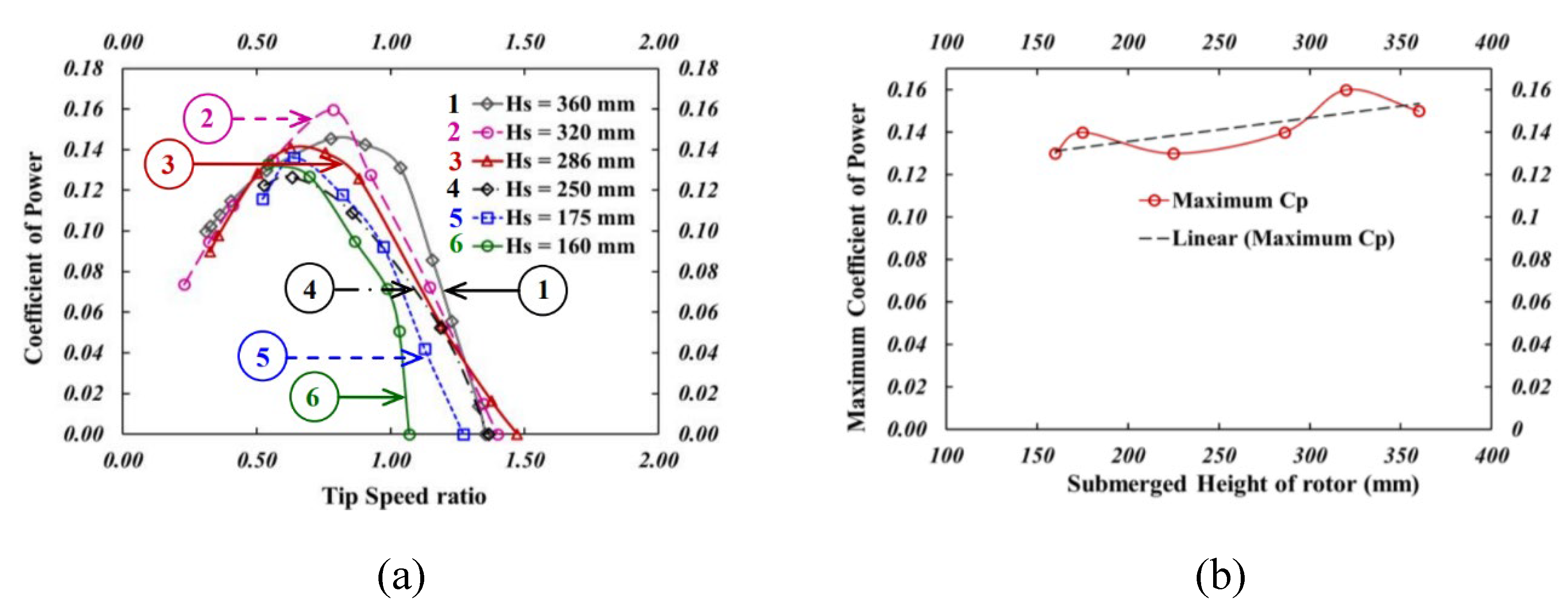

- Vimal, P.; Dixit, S.; Mohit, P.; Nisarg, R. Experimental Investigations of Hydrokinetic Axial Flow Turbine. Proc. WCE 2016, II.

- Pournazeri, S.; Aghsaee, P.; Mantilla, R.; Markfort, C. Optimization and initial testing of a model-scale horizontal axis hydrokinetic turbine. IIHR, 2016. [Google Scholar]

- Paul, D. et al. Experimental study of the flow induced by an axial hydrokinetic turbine. IOP Conf. Ser.: Earth Environ. Sci. 1136 2023.

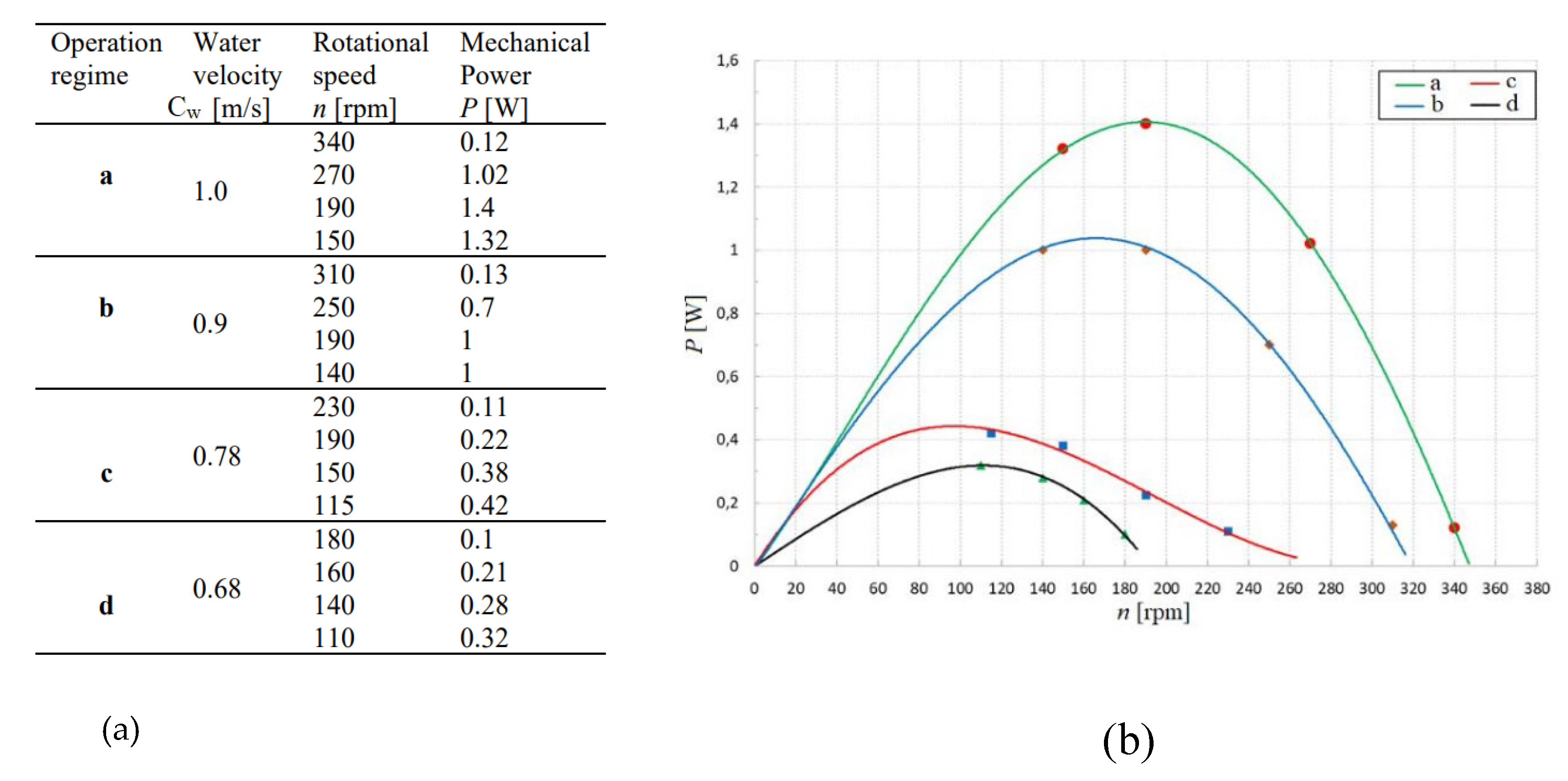

- Bucur, D. M. Experimental investigation of small axial hydro-kinetic turbines. IOP Conf. Ser.: Earth Environ. Sci. 1079, 2022. [Google Scholar]

- Patel, C.; Rathod, V; Patel, V. Experimental Investigations of Hydrokinetic Turbine Providing Fillet at the Leading Edge Corner of the Runner Blades. J. Appl. Fluid Mech. 2023, 16, 865–876. [Google Scholar]

- Chihaia, R.; El-Leathey, L; Circuimaru, G. ; Tănase, N. Increasing the energy conversation efficiency for shrouded hydrokinetic turbinrs using experimental analysis on a scale model. EENVIRO. 2019, 85. [Google Scholar]

- Dharmesh, D., J.; Vimal, K., P.; SVMIT, N. Experimental Investigation of Axial Flow Horizontal Axis Water Turbine with Fix Vane Angle. IJEDR 2014, 2.

- Nedelcu, A.; Bunea, F.; Danca, P., A.; Chihaia, R., A.; Babutanu, C., A.; Marin, D.; Ciocan, G., D. Experimental research on a hydrokinetic turbine model. IOP Conf. Ser.: Earth Environ. Sci. 2021, 664. [Google Scholar] [CrossRef]

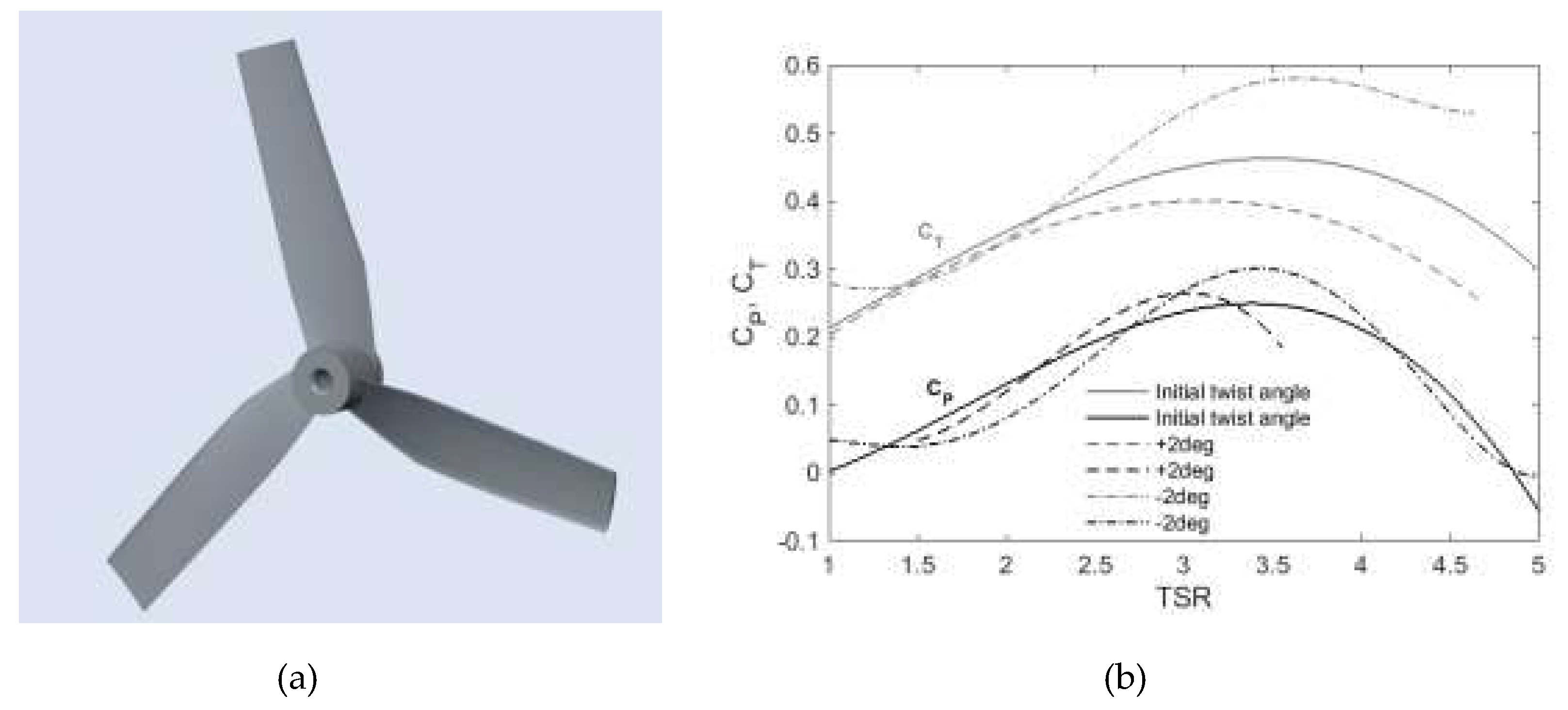

- Antonio C., P; Rafael, B., J.; Mendes, C., F.; Taygoara, T., W.; Noguera, R.; Oliveira, F. On the design of propeller hydrokinetic turbines: the effect of the number of blades. J. Braz. Soc. Mech. Sci. Eng, 2019. [Google Scholar]

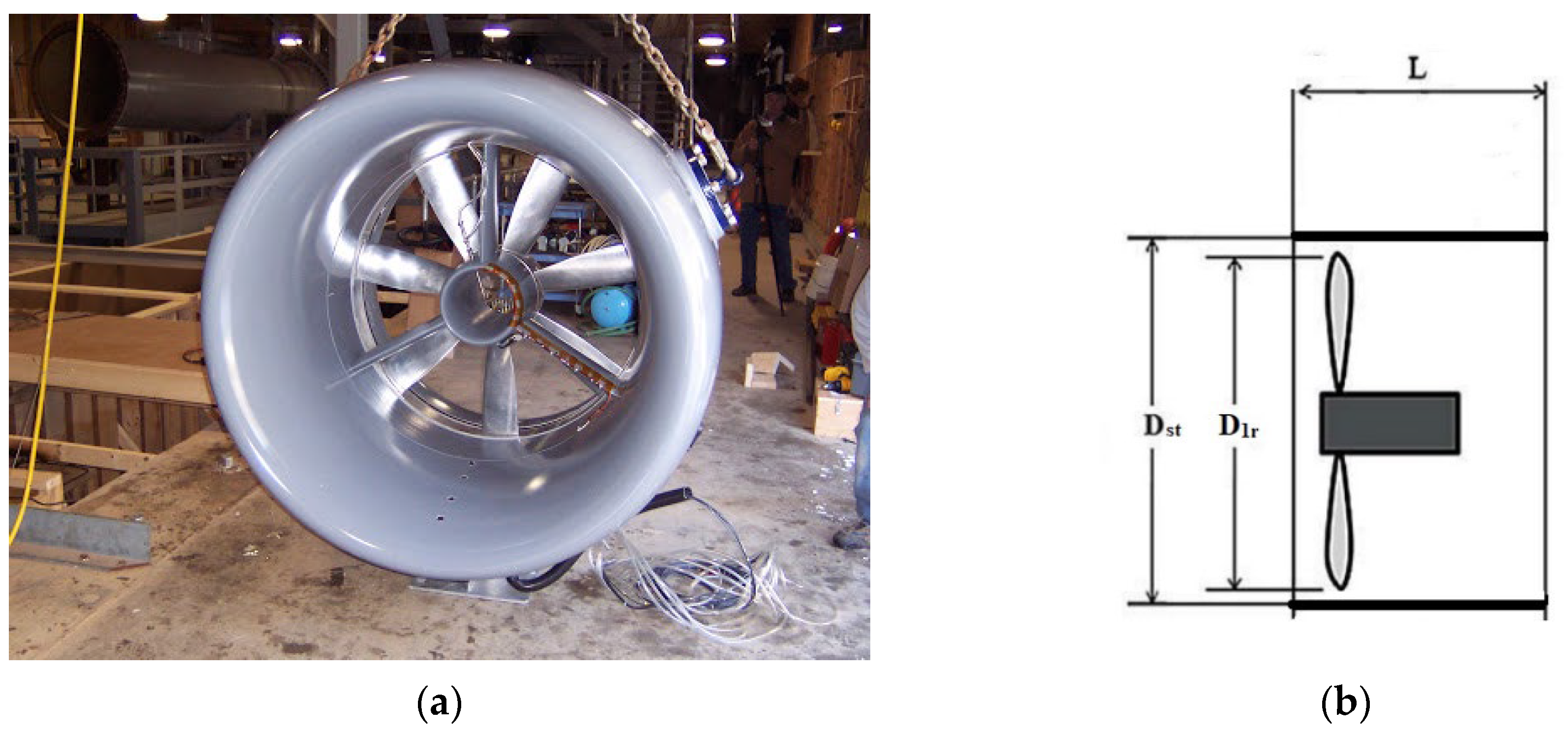

- Kyozuka, Y.; Sakaguchi, D.; Sueyoshi, M.; Hu, Ch. A floating/submersible shrouded tidal current turbine system applicable in low speed tidal flow. Proc. Of the 13th EWTEC 1 2019.

- Von Karman Institute for Fluid Dynamics. Available at: https://www.vki.ac.be/ (accessed at 18.03.2024).

- Institute of Applied Mechanics, Kyushu University in Japan. Available at: https://www.riam.kyushu-u.ac.jp/en/index-e.html (accessed on 15.03.2024).

- Ohya, O.; Karasudani, T.; Sakurai, A.; Abe, K.; Inoue, M. Development of a shrouded wind turbine with a flanged diffuser. J. Wind Eng. Ind. Aerodyn 2008, 96, 524–539. [Google Scholar] [CrossRef]

- REPORT OF THE COMMITTEE TO STUDY THE CONCEPT & COMMERCIAL APPLICATIONS OF HYDRO KINETIC TURBINE DEVELOPED BY M/s MACLEC. Available online: https://cea.nic.in/wp-content/uploads/he___td/2022/07/Final_Report_on_SHK_Turbine_by_Maclec-1.pdf (accessed on 15 03 2024).

- River, Tidal, and Ocean Current Hydrokinetic Energy Technologies: Status and Future Opportunities in Alaska. Available at: https://tethys.pnnl.gov/sites/default/files/publications/Johnson_Pride_2010.pdf (accessed on 15 03 2024).

- Review of Triton –, C. Available at: https://www.oscillapower.com/triton-c (acessed on 22.03.2024).

- Review of Verdant Power's Free Flow System. Available at: https://verdantpower.com/ (accessed on 23.03.2024).

- Swedish tidal kite developer Minesto. Available at: https://minesto.com/ (accessed on 23.03.2024).

- Blue Energy Canada. Available at: https://www.bluenergy.com/ (accessed om 23.03.2024).

| № | Europe | Speed, m/s | Asia | Speed, m/s | Africa | Speed, m/s |

|---|---|---|---|---|---|---|

| 1 | Danube | 2.22-2.5 [15] | Angara | 1-2 [20] | Nile | 2.1 [27] |

| 2 | Rhine | 1.66 [16] | Lena | 1.11-1.67 [21] | Congo | 4 [28] |

| 3 | Nemunas | 1 [17] | Yangtze | 2-3 [22] | Nun | 0.85-1.54 [29] |

| 4 | Narva | 1.5 [18] | Tapi | 1.53-3.24 [23] | Gumara | 1-3 [30] |

| 5 | Strömmen | 1.94 [19] | Rio Grande | 0.45-2.68 [24] | - | - |

| 6 | - | - | Tigris | 0.7 -1.6 [25] | - | - |

| 7 | - | - | Matamuhuri | 2.4-4 [26] | - | - |

| № | RPM of Rotor | Torque (Nm) |

Protor (Watt) |

Phyd (Watt) |

Cp | Ω (rad/s) |

TSR λ |

Net load (N) |

|---|---|---|---|---|---|---|---|---|

| 1 | 62.500 | 0.033 | 0.218 | 5.831 | 0.037 | 6.545 | 2.356 | 3.335 |

| 2 | 59.435 | 0.048 | 0.299 | 5.831 | 0.051 | 6.224 | 2.241 | 4.807 |

| 3 | 59.406 | 0.070 | 0.433 | 5.831 | 0.074 | 6.221 | 2.240 | 6.965 |

| 4 | 55.556 | 0.101 | 0.588 | 5.831 | 0.101 | 5.818 | 2.094 | 10.104 |

| 5 | 53.461 | 0.131 | 0.736 | 5.831 | 0.126 | 5.598 | 2.015 | 13.145 |

| 6 | 63.610 | 0.184 | 1.035 | 5.831 | 0.178 | 5.614 | 2.021 | 18.443 |

| 7 | 50.761 | 0.180 | 0.954 | 5.831 | 0.164 | 5.316 | 1.914 | 17.952 |

| № | Project name | Power | Company | Constraints | Location |

|---|---|---|---|---|---|

| 1. | Chilla Power Channel |

25 kW | DLZ Corp., US | Submerged turbine Low debris handling capability Require constant depth of operation. |

Chilla canal, Dehradun Uttarakhand, India |

| 2. | Neyveli Lignite Corporati on Ltd. | 4x5 kW (total 20kW) |

M/s Smart Hydropower(G erman) in collaboration with M/s Imp Powers(Indian) | High flow velocity requirement (3.1 m/s) Intricate blade shape High debris protection required |

Neyveli Lignite Corporation India, Chennai, Tamil Nadu, India |

| 3. | Kakkad HEP | 5x5 kW (total 25 kW) |

M/s Imp Powers (an Indian firm in technological collaboration with M/s Smart Hydropower, Germany) | Project Allotted | Kerala, India |

| № | Project name | Company | Constraints | Location |

|---|---|---|---|---|

| 4. | Sluice of Dutch icon Afsluitdijk, Wadden Sea |

M/s Torcado | • High Flow velocity (4.2 m/s/) and depth requirement (4 meters) | UK |

| 8. | RITE Project | M/s Verdant, USA | Minimum flow velocity of 2.2 m/s High depth requirement Blade complexity Debris protection requirement |

Canada and USA |

| 9. | HyTide 1000 | M/s Voith Hydro | High depth requirement Severely affected by debris High flow velocity requirement |

Jindo, Korea |

| Company | Location | Device | Stage of Technology | Capacity |

|---|---|---|---|---|

| Atlantis Resources Corporation | UK | Nereus | Scale model sea trials | 150 kW |

| Clean Current Power Systems |

Canada | Clean Current tidal turbine generator | Full scale prototype | 65 kW |

| Free Flow Power | Gloucester, MA | SmarTurbine Generator | Scale model tank testing | 10 kW |

| Free Flow 69 | UK | Osprey | Scale model sea trials | 1 kW |

| Hammerfest Strom UK | UK | Tidal Stream Turbine | Full scale prototype | 300 kW |

| HydroCoil Power, Inc. | Wynnewood, PA | HydroCoil | Scale model sea trials | 20-40 kW |

| Hydro Green Energy | Huston, TX | Hydro+ | Commercial | 35 kW |

| Maine Current Turbines | UK | SeaGen | Full scale prototype | 300 kW-1.2 MW |

| Natural Currents Energy Services |

Highland, NY | RED HAWK Tidal Turbine | Scale model sea trials | 125 kW |

| Ocean Flow Energy | UK | Evopod | Scale model sea trials | 1 kW |

| Ocean Renewable Power Company | Fall River, MA | ORPC Turbine Generating Unit | Scale model sea trials | 32 kW |

| OpenHydro | Ireland | Open-Centre Turbine | Full scale prototype | 250 kW-1 MW |

| Robert Gordon University | UK | Sea Snail | Full scale prototype | 150 kW |

| SMD Hydrovision | UK | TidEl | Scale model tank testing | 500 kW |

| Swanturbine Ltd. | UK | Swanturbine | Scale model sea trials | 330 kW |

| Tidal Energy Pty. Ltd. |

Australia | Davidson-Hill Venturi Turbine |

Scale model sea trials | Unavailable |

| Tidal Generation Ltd. | UK | DEEP-Gen | Full scale prototype | 500 kW |

| Tidal Steam | UK | Triton | Scale model tank testing | 10 MW |

| Tocardo Tidal Energy Ltd. | Netherlands | Tocardo Aqua 2800 | Full scale prototype | 32 kW |

| University of Strathclyde | UK | Contra-Rotating Marine Turbine(CoRMaT) | Scale model sea trials | 30 kW |

| Verdant Power | New York, NY | Free Flow System | Full scale prototype | 35 kW-1 MW |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).