Submitted:

08 May 2024

Posted:

10 May 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

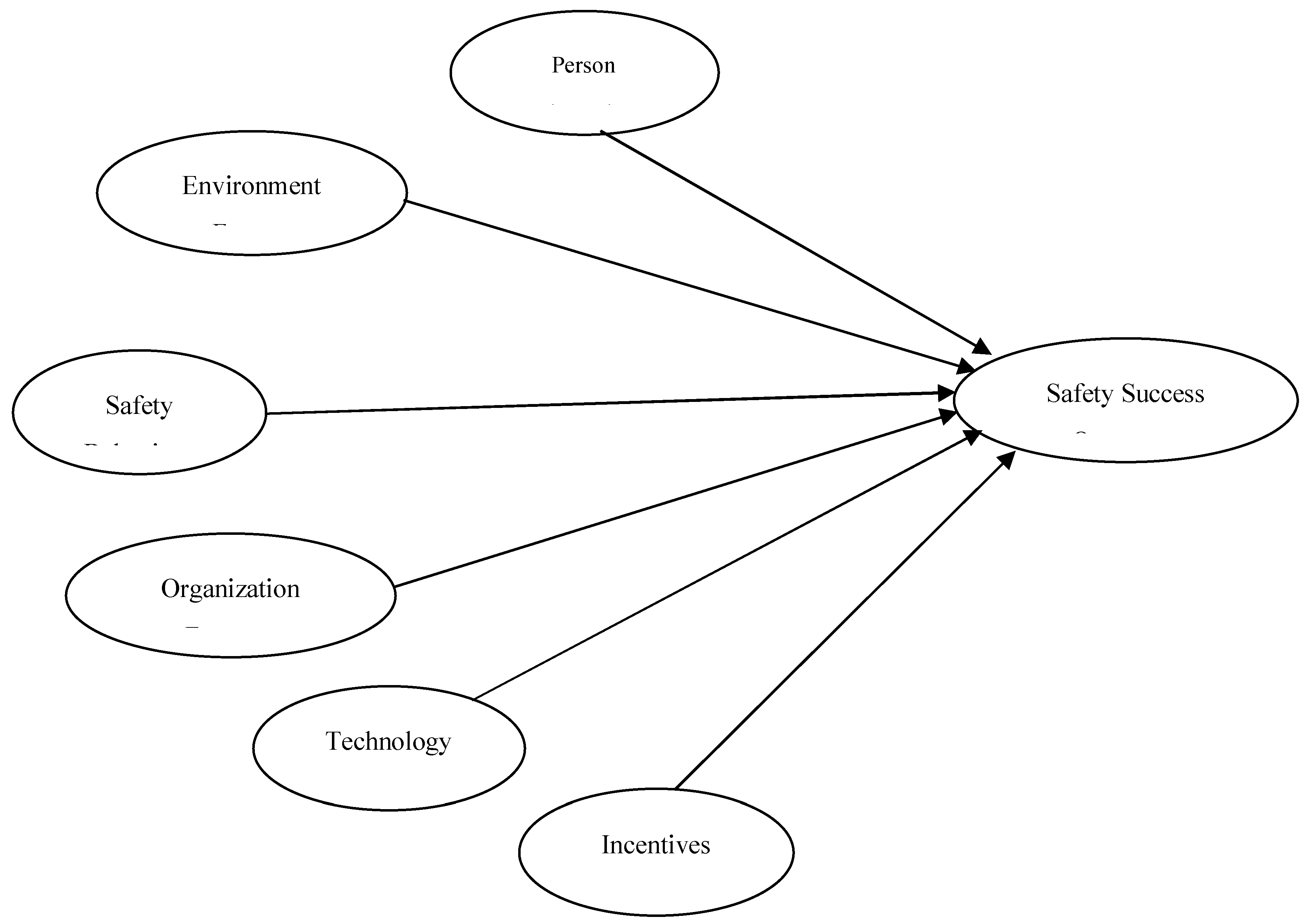

2. Sustainable Safety Constructs, Strategies and Methods for the Framework

3. Discussion

3.1 Person Dimension

3.2 Environment Factor

3.3 Safety Behaviour

3.4 Organisation Features

3.5 Technology

3.6 Incentives

4. Conclusion and Recommendations

References

- Abrey, M and Smallwood, JJ, 2014. The effects of unsatisfactory working conditions on productivity in the construction industry. [CrossRef]

- Arboleda, C.A., Abraham, D.M., 2004. Fatalities in trenching operations: analysis using models of accident causation. Journal of Construction Engineering and Management 130 (2), 273–280. [CrossRef]

- Biggs, H.C., Sheahan, V.L., Dinsdag, D., 2007. Risk management and injury prevention: competencies, behaviours, and attitudes to safety in the Construction industry. Aust. J. Rehabil. Counsell. 13 (02), 63–67. [CrossRef]

- Biswas, Gourab, Bhattacharya, Arkajit, & Bhattacharya, Rina. (2017). Occupational health status of construction workers: A review. International Journal of Medical Science and Public Health, 6(4), 669-675. [CrossRef]

- Blackmon, R.B., and Gramopadhye, A.K., Journal of Construction Engineering and Management, vol. 121, no. 2, pp. 166-171, (1995).

- Blockley, D. (1995), Process re-engineering for safety”, Proceedings of risk Engineering and Management in Civil, Mechanical and Structural Engineering, 22 February, ICE, London, pp. 51-66.

- Breslin FC, Smith P. Age-related differences in work injuries: a multivariate, population-based study. Am J Ind Med 2005;48(1):50-6. [CrossRef]

- Bronkhorst, B., 2015. Behaving safely under pressure: the effect of job demands, resources, and safety climate on employee physical and psychosocial safety behavior. J. Saf. Res. 55, 63–72. [CrossRef]

- Buchanan, J., C. Raffaele, N. Glozier, and A. Kanagaratnam. 2016. Beyond mentoring: Social support structures for young Australian carpentry apprentices. Research Rep. Adelaide, SA, Australia: National Centre for Vocational Education Research.

- Chaher Zid, Narimah Kasim, Hocine Benseghir, Muhammad Nomani Kabir and Abdullah Bin Ibrahim (2018) Developing an Effective Conceptual Framework for Safety Behaviour in Construction Industry. International Conference on Civil and Environmental Engineering (ICCEE 2018). Volume 65, 2018 pp. 1-12.

- Cheng, T., and Teizer, J., Real-time resource location data collection and visualization technology for construction safety and activity monitoring applications, Automation in Construction 34 (2013) 3–15. [CrossRef]

- Cheng, T., Venugopal, M., Teizer, J., Vela, P.A., Performance evaluation of ultra-wideband technology for construction resource location tracking in harsh environments, Automation in Construction 20 (8) (2012) 1173–1184 (Elsevier). [CrossRef]

- Choudhry, R.M., Accident Analysis & Prevention, vol. 70, pp. 14-23, 2014/09/01/(2014).

- Choudhry, R.M., and Fang, D., 2008. Why operatives engage in unsafe work behaviour: Investigating factors on construction sites. Safety Science, 46, 566–584.

- Choudhry, R.M, Fang, D, Mohamed, S. 2007. The nature of safety culture: A survey of the state-of-the-art. Safety Science 45 (2007) 993–1012. [CrossRef]

- Choudhry, R.M., Fang, D. and Mohamed, S (2007) Developing a Model of construction safety culture. Journal of management in engineering, 23(4),207-212.

- Chunlin Wu, Dongping Fang, Nan Li (2015). Roles of owners' leadership in construction safety: The case of high-speed railway construction projects in China. International Journal of Project Management 33 (2015) 1665–1679. [CrossRef]

- Clarke, S., 2006. The relationship between safety climate and safety performance: a metaanalytic review. J. Occup. Health Psychol. 11 (4), 315–327. [CrossRef]

- Cooke, T., Lingard, H., Blismas, N., Stranieri, A., ToolSHeD: the development and evaluation of a decision support tool for health and safety in construction design, Engineering, Engineering Construction and Architectural Management 15 (4) (2008) 336–351.

- Cooper, M.A., Cotton, D., 2000. Safety training: a special case? Journal of European Industrial Training 24 (9), 481.

- Cui, L., Fan, D., Fu, G., Zhu, C.J., 2013. An integrative model of organizational safety behavior. J. Saf. Res. 45, 37–46. [CrossRef]

- Dahl, O., Olsen, E., 2013. Safety compliance on offshore platforms: a multi-sample survey on the role of perceived leadership involvement and work climate. Saf. Sci. 54, 17–26. [CrossRef]

- Dekker, S., 2014. Safety Differently: Human Factors for a New Era, 2nd ed. CRC Press, Oakdale, Canada, pp. 2014.

- Dembe AE, Erickson JB, Delbos R. Predictors of work-related injuries and illnesses: national survey findings. J Occup Environ Hyg 2004;1(8):542-50. [CrossRef]

- De Silva, N., and Wimalaratne P.L.I., 2012. OSH management framework for workers at construction sites in Sri Lanka, Engineering, Construction and Architectural Management, 19(4), 369 – 392.

- Didla, S., Mearns, K., & Flin, R. (2009). Safety citizenship behaviour: A proactive approach to risk management. Journal of Risk Research, 12(3–4), 475–483. [CrossRef]

- Expert Advisory Panel on Occupational Health and Safety. Report and recommendations to the Minister of Labour. Toronto, ON: Ontario Ministry of Labour; 2010.

- Fang, D.P., Chen, Y., Wong, L., 2006. Safety climate in construction industry: a case study in Hong Kong. Journal of Construction Engineering and Management 132 (6), 573–584. [CrossRef]

- Fang, D.P., Xie, F., Huang, X.Y., L I, H., 2004. Factor analysis-based studies on construction workplace safety management in China. International Journal of Project Management 22, 43–49. [CrossRef]

- Feng, Y. (2013). “Effect of safety investments on safety performance of building projects.” Saf. Sci., 59, 28–45. [CrossRef]

- Furnham, A. (2008). The psychology of behaviour at work. The individual in the organization (2nd ed.) Hove and New York, NY: Psychology Press.

- Gould, F.E and Joyce, N.E, Construction Project Management. Pearson, 2013.

- Griffin, M. A., & Neal, A. (2000). Perceptions of safety at work: A framework for linking safety climate to safety performance, knowledge, and motivation. Journal of Occupational Health Psychology, 5(3), 347–358. [CrossRef]

- Grytnes, R., M. Grill, A. Pousette, M. Törner, and K. J. Nielsen. 2018. “Apprentice or student? The structures of construction industry vocational education and training in Denmark and Sweden and their possible consequences for safety learning.” Vocations Learn. 11 (1): 65–87. [CrossRef]

- Guangbin Wang, Muyang Liu, Dongping Cao and Dan Tan, 2022. Identifying high-frequency– low-severity construction safety risks: an empirical study based on official supervision reports in Shanghai. Engineering, Construction and Architectural Management Vol. 29 No. 2, 2022 pp. 940-960. DOI 10.1108/ECAM-07-2020-0581. [CrossRef]

- Gürcanlı, G.; Baradan, S.; Uzun, M. Risk perception of construction equipment operators on construction sites of Turkey. Int. J. Ind. Ergon. 2015, 46, 59–68. [CrossRef]

- Guz, A.N. and Rushchitsky, J.J., 2009. Scopus: A system for the evaluation of scientific journals. International Applied Mechanics, 45(4), p.351. [CrossRef]

- Han, S., Saba, F., Lee, S., Mohamed, Y. and Peña-Mora, F. (2014), “Toward an understanding of the impact of production pressure on safety performance in construction operations”, Accident Analysis and Prevention, Vol. 68, pp. 106-116. [CrossRef]

- Hale, A., Borys, D., 2013a. Working to rule or working safely? Part 2: the management of safety rules and procedures. Saf. Sci. 55, 222–231. [CrossRef]

- Heinrich, H.W. (1936), Industrial Accident Prevention, McGraw-Hill, New York, NY.

- Heng Li, Miaojia Lu, Shu-Chien Hsu, Matthew Gray, Ting Huang, 2015. Proactive behaviour-based safety management for construction safety improvement. Safety Science 75 (2015) 107–117.

- Hinze, J., and Godfrey, R. (2003). “An evaluation of safety performance measures for construction projects.” J. Constr. Res., 4(01), 5–15. [CrossRef]

- Hinze J, Wiegand F. Role of designers in construction worker safety. J Constr Eng Manage 1992;118(4):677–84. [CrossRef]

- Hofmann DA, Burke MJ, Zohar D. 100 years of occupational safety research: from basic protections and work analysis to a multilevel view of workplace safety and risk. J Appl Psychol 2017;102(3):375. [CrossRef]

- Hossain,M.Z, Sohel, F., Shiratuddin, M.F., Laga, H, A comprehensive survey of deep learning for image captioning, ACM Comput. Surv. 51 (2019) 1–36, . [CrossRef]

- Hu, X.W., Griffin, M.A., Bertuleit, M., 2016. Modelling antecedents of safety compliance: incorporating theory from the technological acceptance model. Saf. Sci. 87, 292–298. [CrossRef]

- Huang Yh, Lee J, McFadden AC, Rineer J, Robertson MM. Individual employee perceptions of Group-level Safety Climate (supervisor referenced) versus Organization-level Safety Climate (top management referenced): associations with safety outcomes for lone workers. Accid Anal Prev 2017; 98:37-45. [CrossRef]

- ICAO, D. (2013). 9859 Safety Management Manual. Edisi.

- Ismail, F., Hashim, A.E., Ismail, R. and Majid, M.Z.A (2009) The operationalisation of safety culture for the Malaysian construction organisations´, International Journal of Business and Management, 4(9), 226-237. [CrossRef]

- Jergeas, G. (2009). Improving construction productivity on Alberta oil and gas capital projects. Management department of civil engineering, Schulich School of Engineering. Alberta: University of Calgary.

- Jia, M., A. Komeily, Y. Wang, and R. S. Srinivasan. 2019. “Adopting Internet of Things for the development of smart buildings: A review of enabling technologies and applications.” Autom. Constr. 101 (May): 111–126. [CrossRef]

- Langford, D., Rowlinson, S.M., Sawacha, E., 2000. Safety behaviour and safety management: its influence on the attitudes of workers in the UK construction industry. Eng., Construct. Archit. Manage. 7 (2), 133–140.

- Lay AM, Saunders R, Lifshen M, Breslin FC, Lamontagne AD, Tompa E, et al. The relationship between occupational health and safety vulnerability and workplace injury. Saf Sci 2017; 94:85-93. [CrossRef]

- Lee, C. H., Tsai, M. H., Lin, K. Y., and Kang, S. C. (2012). “iSafe: An innovative iPad system for construction site safety audits.” Proc., 14th Int. Conf. on Computing in Civil and Building Engineering (ICCCBE 2012).

- Li, F., Jiang, L., Yao, X., Li, Y., 2013. Job demands, job resources and safety outcomes: the roles of emotional exhaustion and safety compliance. Accid. Anal. Prev. 51, 243–251. [CrossRef]

- Lingard H, Cooke T, Blismas N. Do perceptions of supervisor’s safety responses mediate the relationship between perceptions of the organizational safety climate and incident rates in the construction supply chain? J Constr Eng Manag 2012;138(2):234-41.

- Lingard, H., Rowlinson, S., 2005. Occupational Health in Construction Project Management. Spoon Press, USA and Canada. Lingard, H., Yesilyurt, Z., 2003. The Effect of attitudes on the occupational safety actions of australian construction workers: the results of a field study. J. Construct. Res. 4 (1), 59–69. [CrossRef]

- Locke, E. A., & Latham, G. P. (2002). Building a practically useful theory of goal setting and task motivation: A 35-year odyssey. American Psychologist, 57, 705-717. [CrossRef]

- Manjula, N.H.C., and Nayanthara De Silva, (2014). Factors influencing safety behaviours of construction workers. The 3rd World Construction Symposium 2014: Sustainability and Development in Built Environment 20 – 22 June 2014, Colombo, Sri Lanka.

- Mattson, M., Torbiörn, I., Hellgren, J., 2014. Effects of staff bonus systems on safety behaviours, Human Resource Management Review 24 (2014) 17–30.

- Mayer, J. M., Schuler, R. P., & Jones, Q. (2012, October). Towards an understanding of social inference opportunities in social computing. In Proceedings of the 2012 ACM International Conference on Supporting Group Work (pp. 239-248).

- Mohamed, S., 2003. Scorecard approach to benchmarking organisational safety culture in construction. Journal of Construction Engineering and Management, 129 (1), 80–88.

- Mohanad K. Buniya, Idris Othman, Riza Yosia Sunindijo, Ahmed Farouk Kineber, Eveline Mussi, Hayroman Ahmad. Barriers to safety program implementation in the construction industry, Ain Shams Engineering Journal, Volume 12, Issue 1,2021, Pages 65-72,ISSN 2090-4479. [CrossRef]

- Nadeem, U., Shah, S.A.A, Sohel, F., Togneri, R., Bennamoun, M., Deep learning for scene understanding, Handbook of Deep Learning Applications, Springer International Publishing, Cham, 2019, pp. 21–51, , . [CrossRef]

- Nepal, M.P., Park, M. and Son, B. (2006), “Effects of schedule pressure on construction performance”, Journal of Construction Engineering and Management, Vol. 132 No. 2, pp. 182-188. [CrossRef]

- Nnaji, C., and A. A. Karakhan. 2020. “Technologies for safety and health management in construction: Current use, implementation benefits and limitations, and adoption barriers.” J. Build. Eng. 29 (May): 101212. [CrossRef]

- Oh JH, Shin EH. Inequalities in nonfatal work injury: the significance of race, human capital, and occupations. Soc Sci Med 2003;57(11):2173-82. [CrossRef]

- Okpala, I., C. Nnaji, and A. A. Karakhan. 2020. “Utilizing emerging technologies for construction safety risk mitigation’ pract. Periocd. Struct. Des. Constr. 25 (2): 04020002. [CrossRef]

- Oswald, D., Sherratt, F. and Smith, S. (2019), “Managing production pressures through dangerous informality: a case study”, Engineering, Construction and Architectural Management, Vol. 26 No. 11, pp. 2581-2596. [CrossRef]

- Patton, A. (1972). Why incentive plans fail. Harvard Business Review, 50(3), 58–66.

- Pidgeon, N., and O’Leary, M., 2000. Man-made disasters: why technology and organisations (sometimes) fail. Safety Science, 34, 15-30.

- Pinto, A.; Nunes, I.L.; Ribeiro, R.A. Occupational risk assessment in construction industry—Overview and reflection. Saf. Sci. 2011, 49, 616–624. [CrossRef]

- Praino, G., Sharit, J., 2016. Written work procedures: Identifying and understanding their risks and a proposed framework for modeling procedure risk. Saf. Sci. 82, 382–392. [CrossRef]

- Premji S, Smith P. Education-to-job mismatch, and the risk of work injury. Inj Prev 2013;19(2):106-11. [CrossRef]

- Smith PM, Saunders R, Lifshen M, Black O, Lay M, Breslin FC, et al. The development of a conceptual model and self-reported measure of occupational health and safety vulnerability. Accid Anal Prev 2015; 82:234-43. [CrossRef]

- Safe Work Australia, 2015a. Work Health & Safety Perceptions Construction Industry, Safe Work Australia February 2015 Canberra ACT 2601.

- Shin, M, Lee,H.S., Park, M, Moon, M, and Han, S., Accident Analysis & Prevention, vol. 68, pp. 95-105, 2014/07/01/(2014).

- Sousa, Vitor, Almeida, Nuno M, & Dias, Luís A. (2014). Risk-based management of occupational safety and health in the construction industry–Part 1: Background knowledge. Safety science, 66, 75-86. [CrossRef]

- Stranks, J., 2000. The Handbook of Health and Safety Practice, fifth ed. Prentice Hall, London.

- Sun, J., Lei, K., Cao, L., Zhong, B., Wei, Y., Li, J. and Yang, Z. (2020), “Text visualization for construction document information management”, Automation in Construction, Vol. 111, 103048. [CrossRef]

- Tam, C.M., Zeng, S.X., Deng, Z.M., 2004. Identifying elements of poor construction safety management in China. Safety Science 42, 569–586. [CrossRef]

- Toole, T.M., 2002. Construction site safety roles. Journal of Construction Engineering and Management 128 (3), 203–210.

- Torghabeh, Z.J.; Hosseinian, S.S.; Ressang, A. Relative Importance of Hazards at Construction Sites. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Wollerau, Switzerland, 2013; pp. 867–871.

- Othman, M., Xia, F., & Khan, A. N. (2015). Context-aware mobile cloud computing and its challenges. IEEE Cloud Computing, 2(3), 42-49. [CrossRef]

- Wadick, P. Safety culture among subcontractors in the domestic housing construction industry. Struct. Surv. 2010, 28, 108–120. [CrossRef]

- Wei, Z, Jennifer, W, and Rafael, S, Construction safety and digital design: A review, Automation in Construction 22 (2012) 102–111.

- Yakubu, D.; Bakri, I.M. Evealuation of safety and health performance on construction sites (Kuala Lampur). J. Mgmt. Sustain. 2013, 3, 100.

- Yeo, C. J., J. H. Yu, and Y. Kang. 2020. “Quantifying the effectiveness of IoT technologies for accident prevention.” J. Manage. Eng. 36 (5): 04020054. [CrossRef]

- Zohar D. The effects of leadership dimensions, safety climate, and assigned priorities on minor injuries in work groups. J Organ Behav 2002;23(1):75-92. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).