1. Introduction

More and more textiles are being produced worldwide, meaning global production volume has tripled since 1975 [

1]. In the period from 2000 to 2014, the number of garments produced doubled [

2,

3] (p. 18), with around 14 items of clothing produced, on average, worldwide per person per year [

2]. These trends appear to be growing unchecked and are being further fuelled by the trend for “fast fashion”, which is now being replaced by “ultra fast fashion”. Textiles are being worn less and less, to the point that they are sometimes becoming more like a disposable commodity. Wahnbeck et al. [

4] found that on average a third of clothing in Germany is never worn or worn less than once. This ever increasing quantity of textiles is linked to serious environmental consequences, namely the textile chain is one of the major global producers of greenhouse gases, with estimates ranging up to a share of 10%

1. Up to 35% of the microplastics released can be traced back to textiles [

5] (p. 21). Clothing accounts for between 2% and 10% of the various environmental impacts of consumption in the European Union [

6]. Worldwide, only 13% of textile fibres are recycled; only 1% is fibre-to-fibre recycled [

3] (p. 20). At the same time, textile production has been relocated to countries with low social and environmental standards due to the comparative economic advantages.

Some opposing trends have become evident in recent years. The accident involving the container ship “Ever Given” in the Suez Canal in 2021 highlighted the vulnerability of global supply chains and current global military conflicts show that supply chains must be made more resilient. Such a transition requires the transformation from a linear to a circular textile economy. A circular economy could considerably improve the resilience of the textile supply chain, reduce environmental stresses and promote domestic industries.

In light of the above, this article looks at the development and application of circular textiles. Textile circularity is still the exception. The aim of a circular textile economy should be to use textiles and textile fibres for as long as possible or to keep them in the textile cycle. The feasibility study “Digital technologies as enablers of a resource-efficient, circular B2B textile industry“ (DiTex), funded by the German Federal Ministry of Education and Research (BMBF), demonstrated that this is possible

2. This research project focused on textile circularity in three commercial applications. These were chosen because large volumes of identical textiles with a known composition are used here, there are established logistics through textile services in terms of their use and there are long-standing business relationships between bulk buyers, textile services and manufacturers. This means that optimal starting points for largely closed-loop cycles can be created. Workwear and bed linen were specifically selected. The three textiles were developed as prototypes and geared to the respective areas of use in a cooperative process with those responsible for the respective applications. Textile development took into account the requirements of fibre regeneration in the product design and focused on innovative chemical recycling solutions. The three textiles were trialled for several months. Spectroscopic and textile-technological tests, washing tests and practical using tests were carried out to study the material properties and resistance. Screening life cycle assessments were carried out for the textile lines. The textile rental or leasing business model was used as an alternative to buying.

The article is structured as follows: Chapter 2 looks at the current level of knowledge on the various topics dealt with in this article. The following Chapter 3 provides the conceptual/methodological background. The findings of the different analyses conducted are presented in Chapter 4, including an examination of the results of the spectroscopic and textile-technological tests, user acceptance and environmental directional certainty. This is followed in Chapter 5 by a discussion of the findings, looking at the key intervention points in the textile chain and the role of recycling. The final Chapter 6 summarises the findings and derives a number of conclusions.

2. State of the Art

The subject of a circular economy has become increasingly important both scientifically and politically in recent years. This is shown by the various definitions of a circular economy: Kirchherr et al. [

7] could find 221 definitions. In terms of policy, the subject of a circular economy is highlighted by the European New Green Deal [

8]. The European Commission defines circular economy as “an economic system whereby the value of products, materials and other resources in the economy is maintained for as long as possible, enhancing their efficient use in production and consumption, thereby reducing the environmental impact of their use, minimising waste and the release of hazardous substances at all stages of their life cycle, including through the application of the waste hierarchy” [

9] (p. 26). The need to act is determined by the annually published Circular Gap Report

3, which points out the low level of global circularity: while it amounted to 9.1% in 2018, it fell to 7.2% in 2023. The gap is therefore widening. This also applies to textiles, which are currently only managed in a circular way to a limited extent. To address this, the European Commission is placing the focal point of its circular strategy on textiles [

10]. The EU textile strategy is aimed at companies, retailers, consumers and civil society. The scientific community has presented studies on the environmental effects of the textile industry in a variety of ways and from different perspectives, e.g. Beton et al. [

6], Ellen MacArthur Foundation [

3] as well as Manshoven et al. [

11]. Charter et al. [

12], Duhoux et al. [

13] focused on creative and design issues, and Dzhengiz et al. [

14], Niinimäki et al. [

15] analysed the impact of fashion trends. There have been studies on longevity by Cooper el al. [

16] and Gimkiewicz et al. [

17]. The Ellen MacArthur Foundation [

18] broached the issue of producer responsibility. Circular business models in the textile industry have been examined by Arnold et al. [

19], Furferi [

20], Poldner et al. [

21]. Studies by AFBW [

22], ETP Fibres Textiles Clothing [

23], Köhler et al. [

24] are more broadly based and focus on the perspective of a circular textile economy.

The role of recycling as an integral part of a circular textile economy has also been analysed repeatedly. ISO 5157

4 defines recycling in the textile value chain as follows: “Activities to obtain recovered resources for use in a product, excluding energy recovery.” Various technologies can be used [

25]: Mechanical recycling, based on breaking and cutting the textiles, is technologically well advanced with a TRL (Technology Readiness Level) 9 (as at 2021) [

25]. The original components are largely retained, while the quality of the output from shortened recycled fibres, fluff/lint and dust is reduced. Thermal recycling is based on the use of thermal energy to extract raw materials. Thermo-mechanical recycling, suitable for thermo-plastic polymers such as polyester, uses a melting process to produce granules/pellets or staple fibres/filaments; existing additives (e.g. dyes) are not removed. The quality of the output also decreases with increasing recycling cycles; TRL levels for textiles are in the range of 3-6 here (as at 2021) [

25]. Chemical recycling is based on dissolving processes (polymer recycling) or chemical reactions to extract raw materials. Current R&D activities are aimed at using cotton waste to produce a cellulose pulp and regenerated cellulose fibres [

26,

27,

28]. Some technology owners are already achieving TRLs of 7-9 (as at 2021) [

25], and new technologies are being advertised in the industry, e.g. by Eeden

5, Lenzing/RefibraTM

6, SaXcell

7, Evrnu®/Nucycl®

8 or Ioncell®

9. Monomer recycling, where polymers are broken down into their basic monomer components or oligomers, is also being developed. In the area of textiles, commercial activities are limited on a small scale to synthetic fibre polyamide, e.g. from carpets and fishing nets (as at 2021: TRL 9) [

25], while monomer recycling of polyester textiles is still evolving (as at 2021: TRL 4-7 [

25]; RITTEC/project revolTEX®

10). Poly cotton can be recycled using different technologies, e.g. dissolving (as at 2021: TRL 5) [

25], hydro-thermal (as at 2021: TRL 6-7) [

25] and enzymatic processes (as at 2021: TRL 5), which are currently being developed. A demonstration plant for recycling poly cotton has been launched by “Worn again technologies”

11.

In accordance with the European Waste Framework Directive [

29], a decision is to be taken on the introduction of targets for reuse and recycling, in addition to the mandatory separate collection of textile waste from 2025

12. In order for recycled fibres to be used in the same way as primary fibres, they must have comparable qualities. Due to material stresses that occur during mechanical and thermal recycling, the use of secondary raw materials mostly requires the addition of primary fibres or only enables them to be used in products with lower requirements than the original product. Chemical recycling technologies can provide high-quality raw materials as output, but are currently energy and resource-intensive.

However, recycling only accounts for part of the environmental impact. Life cycle assessment methods are widely used to quantify the overall environmental impact of textile production and use. The life cycle assessment tool is standardised in ISO 14040 and 14044 [

30,

31] and is applied in both scientific research and industry. Applied research uses life cycle assessment methods to determine the environmental impact of textile products, to identify their optimisation potential along their life cycle stages and to evaluate measures to reduce the environmental burdens of textile products. Depending on the research questions there are major differences between the analysed systems. This can concern fibres, products, environmental impact categories and life cycle stages. For instance, Sandin et al. [

32] and van der Velden et al. [

33] examined a number of natural and artificial textile fibres, while other authors limited their analysis to individual fibres or groups of fibres (e.g., to artificial cellulose fibres [

34], or natural fibres [

35]). Depending on the research question, the functional unit varies and can, for example, range from the representation per kg of fabric to finished clothing products (e.g., T-shirt [

36], or jeans [

37]). The kind and number of environmental impact categories and the life cycle impact assessment (LCIA) methods used also vary depending on the scope of the study. According to review articles, climate change potential (in CO₂ equivalents) and energy resources are dealt with in most studies, followed by acidification potential and eutrophication [

38,

39]. The system boundaries also vary and may represent a complete life cycle (cradle to grave) or individual life cycle stages (see [

40] for the supply of cotton fibres). In recent years, the focus has been on the circular textile economy and the evaluation of different end-of-life scenarios, including reuse, i.e., the prolonged use of textile products, and textile recycling (e.g. [

38,

41,

42,

43]).

The starting points for influencing the textile chain should also be geared to the sales channels. Various sales channels need to be considered, with sales to private consumers accounting for the largest share. However, sales to commercial clients are also of significant importance. These include, in particular workwear

13 and flat linen. Europe, for example, is the second-largest market worldwide for workwear after the USA [

45] (p. 11). For Europe, the market volume in 2022 is estimated at € 8.8 billion and further growth by more than 45% is expected until 2028

14. The share of workwear as a proportion of the total EU textile market was estimated at around 5% for 2015 [

45] (p. 13). More detailed data is available for Germany: According to this, the majority of all workers are equipped with professional, work and protective clothing. In 2019, 22 million out of a total of 42 million employees in Germany were provided with work and/or protective clothing

15. The volume for 2019 is estimated at € 1.4 billion and that for personal protective equipment at around € 1.5 billion [

46] (p. 20). In addition to workwear, the commercial market for flat linen, which includes bed linen, towels, tablecloths, napkins, (shower) curtains and tea towels, is also relevant: In 2014, sales in the EU in the textile service market alone amounted to between € 4.3 and € 4.9 billion [

47] (p. 6). The high outsourcing rates for flat linen in the hotel industry as early as the beginning of the 2010s and also the price pressure from commercial buyers limited further sales growth in the Western European markets [

47] (p. 6). Up to the start of the COVID-19 pandemic, however, real turnover is likely to have been higher. Although workwear also includes the “hotel” trade, “flat linen” is a key product group in this sector. In 2014, annual turnover according to the European Textiles Services Association (ETSA) [

47] (p. 3) was € 2.1 to € 2.3 billion. Sales to commercial clients have interesting material properties: in contrast to private textile consumption, large quantities of textiles with a known composition are sold in this sector. At the same time, a manageable number of players have considerable power and influence as bulk buyers, which could also be used for selective and environmentally oriented procurement [

48]. In addition, it is comparatively easier to record these commercial textiles after use as they can be bundled together by type and fibre composition. It follows from this that commercially used textiles have the potential to be pioneers for a sustainable transformation of the textile industry.

A transformation of textiles towards sustainability requires a closer intermeshing of production and use. Involving users enables manufacturers to understand their views, interests, experiences and habits better and therefore also produce in a more targeted way. Increasingly more attention has been paid to this active interaction through terms such as “participatory product development”, “user-centred production”, “user involvement”, “co-creation”, “open innovation” or “design thinking”; these methods differ from market research (such as surveys, focus groups, participatory observations, see [

49]), where users play a passive role. Under this heading, Cooper [

50], Hoffmann et al. [

51], Hoffmann [

52], Jamal et al. [

53], Peters et al. [

54] presented various conceptual thoughts on participatory product development presented, which have also been applied in the area of textiles [

55,

56,

57,

58]. The involvement of users is seen as having the potential for learning processes to occur on the part of both users and companies in the direction of sustainability and for the developed products to better understand, address and implement the needs of consumers, while at the same time providing impetus for a sustainable orientation of the textile industry. It is also expected to reduce overproduction and rejects and therefore conserve resources

16.

3. Material and methods

In the “DiTex” project, three textile prototypes were developed for use in the commercial sector. This process was participatory and took into account various perspectives, which are discussed in Chapter 3.1. As a result of this development process, three specific textiles were produced, whose characteristics are described in Chapter 3.2. These textiles were trialled for several months and subjected to quality analyses (see Chapter 3.3). The environmental impact of textiles was compared with the impact of non-circular, conventional reference textiles through screening life cycle assessments (see Chapter 3.4). User satisfaction was determined through user surveys (see Chapter 3.5).

3.1. Participatory Textile Development

The development of the three textiles was carried out in close cooperation with the transdisciplinary research alliance and was inspired by the design method and way of thinking “Design Thinking” for overcoming complex challenges with open solution spaces. This development process was characterised in particular by the fact that different perspectives, needs and requirements, especially those of users and textile manufacturers, were identified and linked in an iterative process. Initially, a status quo analysis of existing conventional products was carried out. Optimisation potential in terms of longevity, leasing suitability and recyclability was derived from this and integrated in the requirements for the new textiles (see Chapter 3.2). The suitability of the material combinations for the selected recycling flows was confirmed by a so-called “circular product check”

17 from the company circular.fashion. Eliciting specific requirements for fibre-to-fibre recycling, such as colour, construction, finishes, chemical treatments, certifications and other parameters of textile products, served as a basis for this process. Six market dialogues were also conducted in the course of the “DiTex”-project to take into account the customer and market premises and challenges. These dialogue processes with commercial and public bulk buyers and their textile suppliers focused on the underlying conditions for switching from textile purchasing to textile leasing and from virgin fibres to recycled fibres and placed the emphasis on: product requirements and user expectations, distribution and contract design, recycling capacities and know-how, market potential and supply security, sustainability certification, reflection and evaluation.

3.2. Designing the Three Textile Prototypes

The key data determined based on the participatory textile development can be summarised in a few specifications: Circular textiles must be durable and easily repairable. The fabric must be able to withstand stress during the utilisation phase. Comfort is essential for acceptance and long use. User comfort for the wearer is achieved through the properties of the fibre material, the fabric construction and the product design. Air and moisture exchange, density and opacity of the fabric and the fit are all factors that determine wearing and use comfort. A high-quality finish increases the service life. The sewing thread must not only match the fabric in terms of color, structure and thickness, but the material of the thread must also match that of the fabric. Careful sampling and quality control can prevent premature product failure. The focus for the woven and knitted fabrics should be on structure types that have proven to be hard-wearing and durable. These specifications were summarised in the product data sheets (

Tables S4-S6), which set out the key technological data for the three textile prototypes, thereby defining the composition of the three textiles (see

Table 1), which was then produced and subjected to a practical test.

The polo shirt consists of 100% recycled polyester, including buttons and sewing thread. No components need to be removed prior to recycling. The polo shirt was made of piqué knit, and the cuffs and the collar of rib knit, so it is designed as a classic, comfortable polo shirt. It meets the conditions for polyester-cotton recycling processes.

As a classic business shirt, the business shirt has the most complex construction. The shirt has a reflective “POLICE” imprint and a silver-coloured button for the epaulette. These two elements are not recyclable and must be removed prior to recycling (detrimming). The shirt consists of a hard-wearing twill fabric made of 62% organic cotton and 38% recycled polyester.

The

bed linen made of 50% r30 lyocell

18 and 50% recycled polyester was given an envelope closure with no closing elements such as buttons, zip, velcro. No elements need to be removed for the recycling. The developed bed linen is made from satin fabric. As the lyocell fibre can be damaged by overdrying, it is challenging for commercially used textiles. It could be dried without any problems in the practical test thanks to an optimised fabric surface and adjusted ironing speed in the laundry.

3.3. Textile-Technological and Spectroscopic Tests

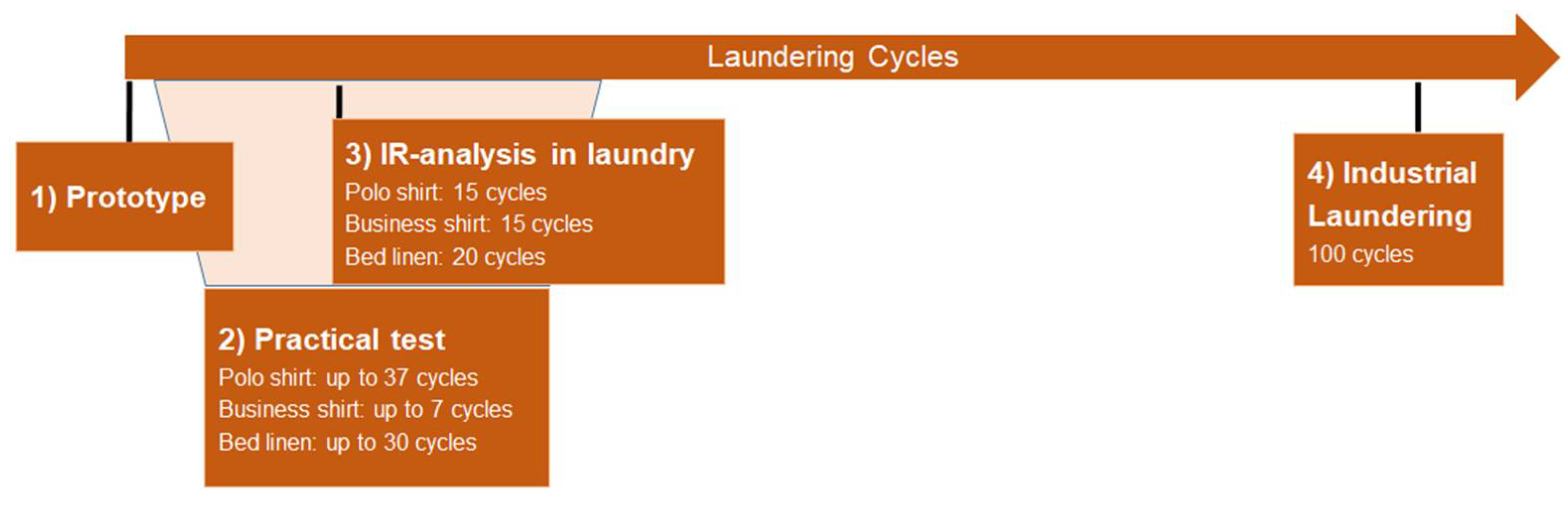

To assess the quality, a combination of textile-technological and spectroscopic tests were carried out. The first test unit was conducted on the prototype to assess its leasing suitability and to validate the design for the practical test. Further analysis was carried out during and after the practical test to assess the performance of the textiles under practical conditions. After completion of the practical test, part of the textiles were subjected to further laundering treatments (up to 100 cycles) under industrial conditions and then to a final test.

Figure 1.

Overview of the study units. (Source: own compilation)

Figure 1.

Overview of the study units. (Source: own compilation)

Hohenstein Quality Standards (HQS) 703, 704 and 705, which include the requirements for business shirts, polo shirts and bed linen when used as leased textiles [

1], served as the basis for the textile-technological tests focussing on the prototype. The focus and the corresponding limitation of the tests was on the assessment of the fabric in relation to colour fastness, mechanical properties, properties related to laundering and comfort properties. Depending on the test, the prototype was analysed in its condition when new or after a defined number of washing and drying cycles in accordance with DIN EN ISO 15797

19 [

59]. After the practical test and industrial laundering, the analysis of the textiles comprised a visual assessment accompanied by individual tests on selected samples.

The spectroscopic measurements included a combination of UV-Vis, near-infrared (NIR) and mid-infrared (MIR) spectroscopy (multimodal spectroscopy), with which the material composition and quality properties such as loss of gloss, colour fastness, yellowing, wear or material ageing were analysed. The samples were measured without any further pre-treatment. For each sample, three measurements were taken at various places on the outside of the samples. Three different mobile spectrometers were used for the spectroscopic measurements in real time directly on site in the laundries, which can cover the entire optical range from 300 nm to 2.5 µm in terms of data fusion. The devices are portable, easy to use and do not require a complex laboratory environment.

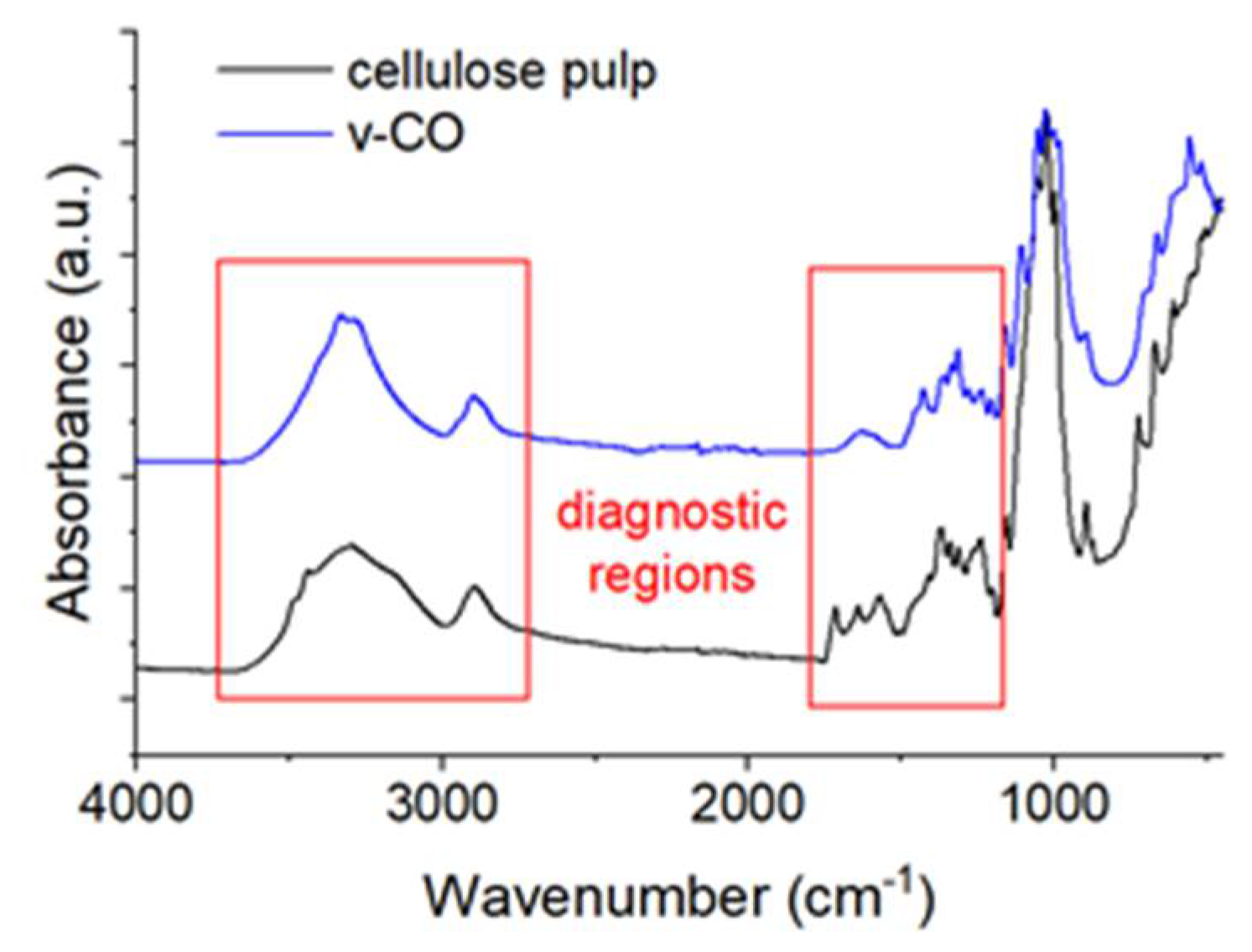

The developed business shirts were recycled together with the polo shirts in a pilot plant operated by RITTEC Umwelttechnik. Their material composition was chosen in such a way that both textiles collectively meet a sufficiently high polyester content. The revolPET® technology is based on selective PET depolymerisation of plastic composites or textile blends by means of alkaline hydrolysis of the ester bond. The extracted r-TA was polycondensed into new r-PET and spun into a yarn that was used as the weft yarn for a fabric pattern. To evaluate the quality of the recycled products, both the monomers and the PET obtained from their subsequent polymerisation were analysed using Fourier Transform Infrared Spectroscopy (FTIR).

3.4. Screening Life Cycle Assessment

As an established method for evaluating the environmental impact of products and services, the life cycle assessment is particularly suitable for determining the environmental impact of textiles associated with their production and use. Therefore, a screening life cycle assessment based on the international standards for product life cycle assessments ISO 14040 and 14044 [

30,

31] was used, where the environmental impact of all input and output flows of the analysed textiles are considered along their entire life cycle (cradle to grave).

In the screening life cycle assessment, the three newly developed textiles in the DiTex project (polo shirt, business shirt and bed linen) and their respective conventional variants (reference) were analysed and compared with each other. The variants mainly differ in terms of their fibre composition (see

Table 1) as well as the implementation of recycling at the end of the textile’s life.

All processes along the product life cycle were analysed. These included in particular: raw material extraction, textile production (including spinning, weaving or knitting, finishing and tailoring), all transport processes, use of the textile (including washing and associated logistics) as well as recycling, including new production of the textiles as well as use or disposal of all resulting waste materials.

In a first step, all environmental impact categories considered as standard in life cycle assessments were screened. In a second step, those environmental impact categories were identified that are sufficiently relevant for the underlying research question and show significant differences in the scenarios considered. These were then examined in a third step in a detailed follow-up analysis. The key environmental impact categories for the textile chain are climate change, non-renewable energy resources, water, land and phosphate footprint as well as acidification and ozone depletion (

Table 2).

3.5. Accompaniment of the Practical Tests

Between summer 2021 and spring 2022, the three developed textiles were tested under real conditions at selected public institutions: The polo shirt was tested at the civil defence department of the district of Lippe/Germany and processed by a laundry, the business shirt was tested at the Logistics Centre, Lower Saxony/Germany and by the police in the Interior Ministry of Lower Saxony in Hanover/Germany and processed by a large textile services provider and the bed linen was tested by the Munich Erding Federal Police Headquarters and in a hotel in the district of Cham/Germany and processed by a laundry. The test user institutions contributed technical specifications for the products, such as product dimensions, finished dimensions, quantities, and were involved in the sampling process and in conducting the practical tests. During the use phase lasting several months, the textile service periodically handed out clean textiles to the test users and collected them again after use in order to wash, dry and, if necessary, repair them before they were reused.

Each of the three practical tests was in particular scientifically accompanied by three elements: (1) User surveys before, during and after the practical tests on expectations, assessment of the textiles in use and satisfaction through an online form via the survey website sli.do. A poll on the performance of the textiles was conducted with questions about the design, pilling (little fuzz balls on the surface), durability and the physiological impact of the clothing. Questions on acceptance related on the one hand to the use of recycled fibres and the entire circularly designed product and on the other hand to the use of a leased textile laundered by the textile service. (2) Monthly enquiries to the textile service regarding specific consumption data of the laundry (e.g. water consumption, detergents and washing auxiliaries used), laundering parameters (washing temperature, drying method and relevant parameters), current usage data from the practical tests and the suitability of the textiles for the textile service (e.g. twisting of the fabric, pilling, dimensional stability, colour fastness). (3) Regularly recorded online meetings (30 to 90 minutes long) with the test users and representatives of users, manufacturers and textile services on operational implementation and continuous monitoring of the practical tests.

4. Results

The three textiles developed in the “DiTex”-project were each subjected to a practical test, as described above. After completion of the practical tests, the three textiles (polo shirt, business shirt, bed linen) underwent various quality tests, in order to generate statements regarding performance, see Chapter 4.1. The business shirts and polo shirts used were recycled in a pilot plant operated by RITTEC Umwelttechnik; see Chapter 4.2 for the results. The textiles must win the acceptance of users; for more on this, see Chapter 4.3. Not only user acceptance is crucial, but also the environmental directional certainty compared to the reference textiles; this is discussed in Chapter 4.4.

4.1. Performance

4.1.1. Polo Shirt

The analysis of the prototype (see

Table S1) showed a high level of mechanical stability and colour fastness of the knitted fabric. Good properties relating to laundering were achieved in terms of self-smoothing and seam twisting, while acceptable dimensional changes could only be obtained with tumble-drying. The thermal resistance and water-vapour resistance (“breathability”) enable a pleasant feeling of comfort, which may, however, be limited by the low water vapour absorption capacity (Fi) of the polyester fabric.

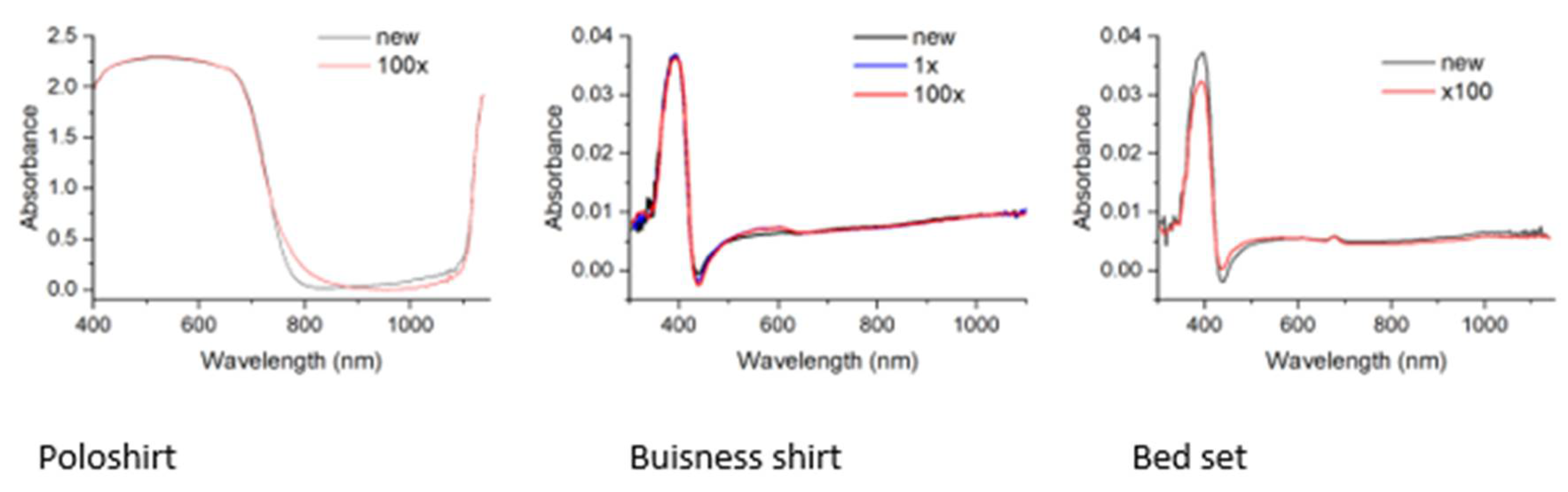

Visual assessment and spectroscopic analysis were carried out for 61 textiles of the practical test and 25 textiles after industrial laundering up to 100 cycles. With the exception of the seams coming loose, the textiles have an almost comparable overall visual appearance to the prototypes after use and industrial laundering and show no measurable changes in mechanical stability (bursting strength). This is consistent with the spectroscopic measurements, which do not reveal any significant changes in the textiles in the mid-infrared and near-infrared range and therefore no significant degradation processes in the materials can be detected. The UV-Vis spectra show slight changes in the red range from 770 nm (see

Figure 1), which can be attributed to oxidative or photochemical reactions caused, for example, by the impact of detergents, sun radiation or other factors. The change in the shape of the spectra may also be caused by slight changes in the texture of the material surface. This does not lead to any major changes in the visual appearance.

4.1.2. Business Shirt

The analysis of the prototype (see

Table S2) showed good comfort properties and acceptable laundering properties of the blended fabric. In the area of mechanical properties, the material has sufficient tensile strength to stand up to “normal” stresses, but low stability under abrasion stress (wear resistance, pilling). In washing tests (ISO 15797, up to 50 cycles) no major changes in the visual appearance of the prototype could be detected.

Visual assessment and spectroscopic analysis were carried out for 40 textiles of the practical test and 29 and 28 textiles after industrial laundering up to 15 and 100 cycles, respectively. After use and laundering under practical conditions, no serious reduction in tensile strength up to 100 cycles was observed. This is reflected in the spectroscopic measurements, which do not reveal any significant changes. This indicates that no severe material losses occurred during use and the washing process. Locally, however, noticeable fabric damage could be detected after 100 laundry cycles (shoulder and lower back area), the cause of which is associated with the choice of components (shoulder buttons) or process management, but could not be precisely identified. Changes in the UV-Vis range indicate changes in the degree of whiteness (420 - 610 nm) after one laundry cycle, which were also clearly visible and stable for up to 100 cycles (see

Figure 2). They are attributed to the use of optical brighteners in the detergent. No surface changes were detected, even after 100 laundry cycles.

4.1.3. Bed Linen

Visual assessment and spectroscopic analysis were carried out for 25 textiles (pillow, duvet) of the practical test and 25 textiles (duvet) after industrial laundering up to 100 cycles. After use and laundering in the practical phase, the textiles exhibit a robust fabric appearance and no major changes to the fabric. The loss of tensile strength after 100 cycles is 10-20%, with no severe changes observed between completion of the practical test (approx. 30 cycles) and the washing tests (100 cycles). The results (see

Table S3) are consistent with the spectroscopic measurements, with which no verifiable changes could be detected in the textiles analysed in the mid and near-infrared range. This indicates that the chemical composition of the textiles remained largely unchanged during the washing cycles. In the visible range (450 - 600 nm) a slight change in the degree of whiteness was observed. This could be attributable to changes in the physical properties of the textiles or to contamination during the practical test, but these changes were minimal.

4.1.4. Conclusions

All three developed textiles exhibit no serious changes to the fabric during the practical phase. The materials are highly resistant, even under industrial washing conditions, while material losses could not be observed. Further practical tests are needed to place a special focus on the impact of the stresses during the use phase.

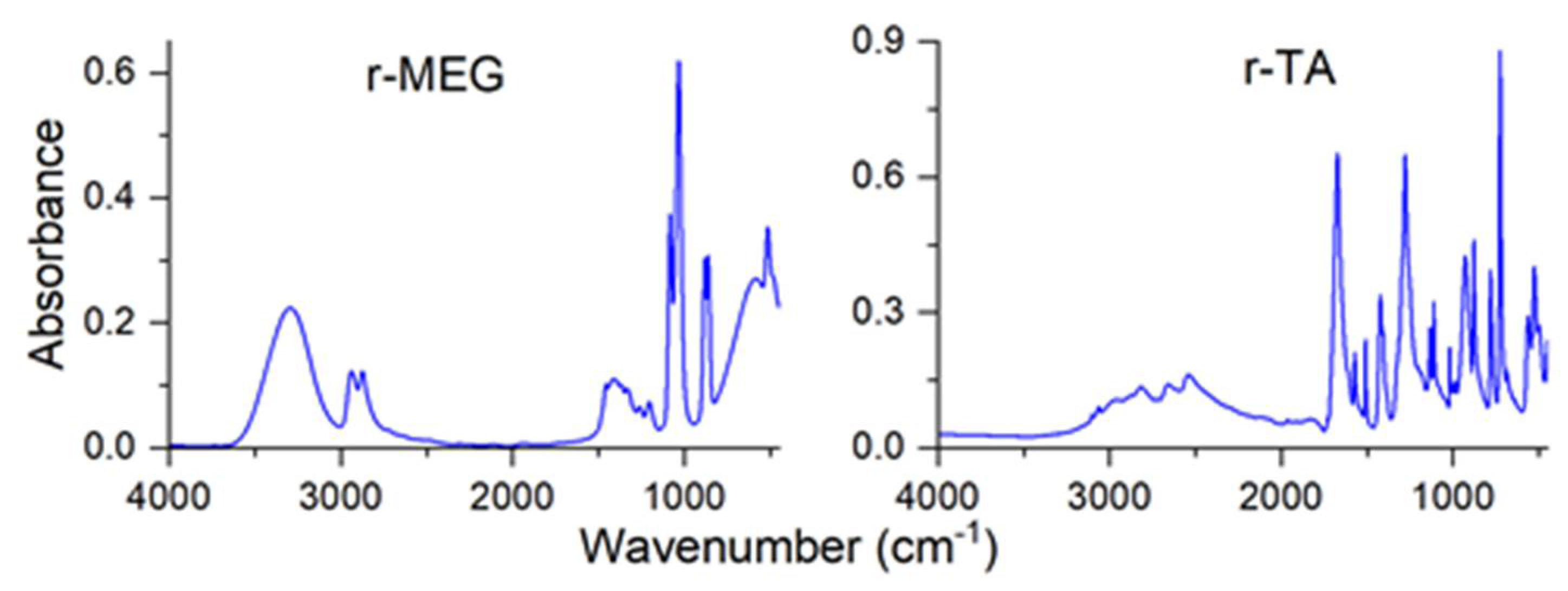

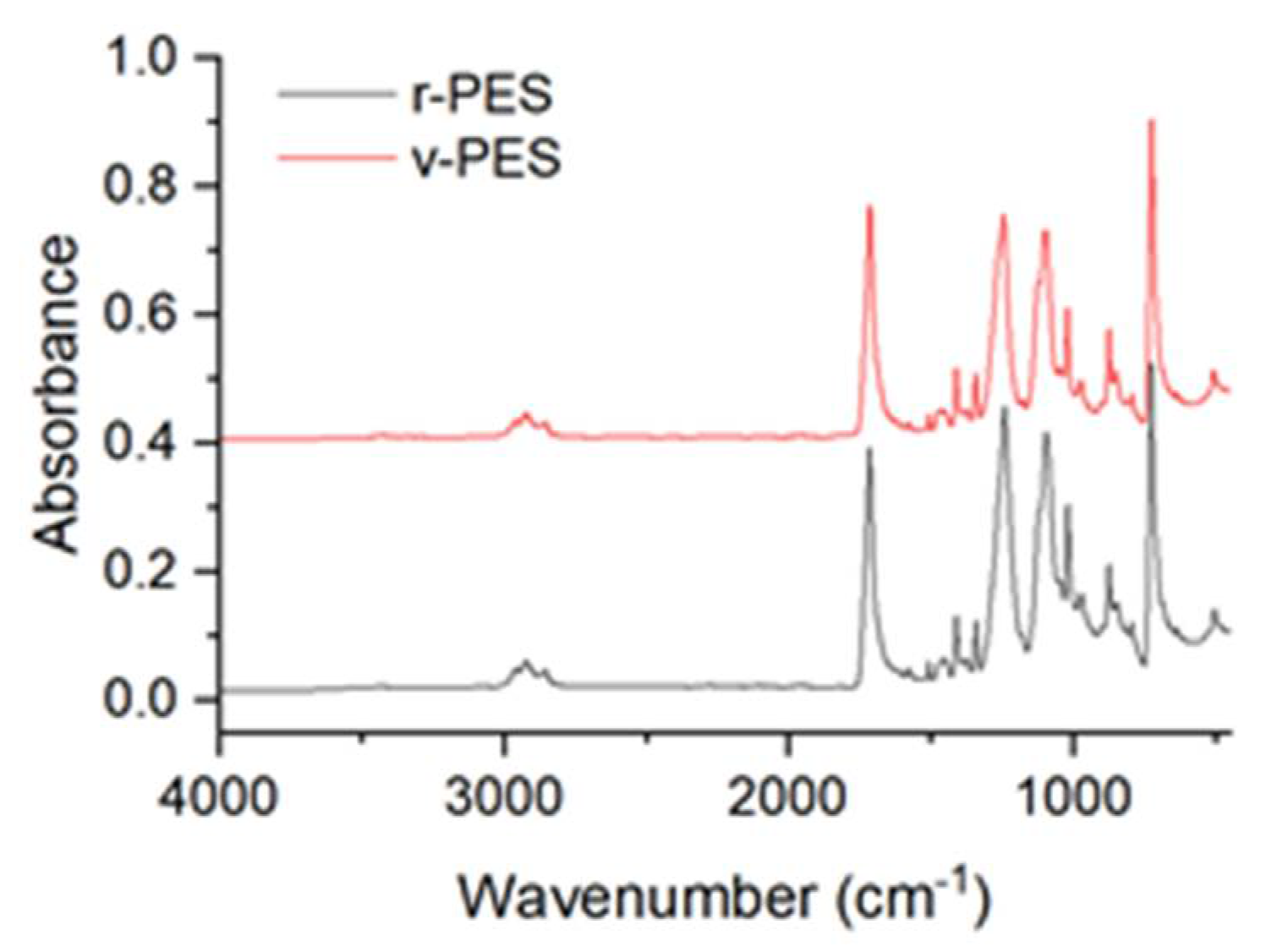

4.2. Spectroscopic Testing of Recycled Products

Of the recycled products, the two monomers r-TA (recycled terephthalic acid), r-MEG (recycled ethylene glycol), a section of fabric with the recycled polyester weft yarn and the solid fraction (cellulose residues), which did not react, were analysed spectroscopically. The recycled products were compared with the reference materials v-PES (virgin polyester) and cotton, in order to determine whether there were differences in their chemical composition or structure. The results of the measurements are shown in

Figure 3 and

Figure 4.

The experimental spectra are consistent with the reference spectra and indicate a high level of substance purity and complete depolymerisation of the polyester.

The infrared spectra of the recycled materials and the new materials are very similar and show no significant differences in their chemical composition. The results suggest that the quality of the recycled materials is comparable with the quality of the new materials, at least at molecular level. Other factors such as strength, pilling or other physical product properties should also be taken into account.

The non-reacting fraction was washed and dried and presents as a brownish powder. The spectra show clear differences compared with the other materials studied so far.

The infrared spectrum indicates the formation of more strongly bound hydroxyl groups and the formation of hydrogen bonds. Other new peaks also appear, indicating changes in the functional groups in cotton. Changes in the absorption bands indicate modification of the crystallinity of the cellulose during alkaline treatment. The spectrum also widens and partially loses its fine structure.

Overall, the treatment with concentrated sodium hydroxide solution leads to significant changes in the infrared spectrum, which are attributable to the stronger chemical reaction with the cotton fibre and the changes in the crystal structure and the functional groups.

Whether the cellulose residues from the depolymerisation are suitable for further use can only be decided after additional chemical analysis. This was not carried out due to the end of the project.

4.3. User Acceptance

The assessment of the three developed and tested textiles in use in the practical tests varied. The business shirt made from organic cotton and recycled polyester and the bed linen made from r30 lyocell and recycled polyester were considered suitable for the tested applications by users and the textile service. The 100% recycled polyester polo shirt also proved suitable for the textile service. On the other hand, around half of users rated the polo shirt as unsuitable for the requirements of their everyday work. Almost 50% of participants in the user survey cited rapid sweating as a difference to their usual work polo shirt, which is attributed to the material composition.

Users especially expressed reservations about the high artificial fibre content, although a general rejection of recycled fibres was not observed. When recycled fibres were mixed with natural fibres or cellulose-based fibres such as lyocell, which offer a familiar wearing/use feeling, neither concerns nor negative assessments of textiles with a high recycled fibre content were observed. Elements of the Design for Circularity were not perceived as objectionable either. Feedback from users showed that for workwear especially the fit is crucial when it comes to everyday suitability and acceptance. What fits well and is comfortable is worn willingly, regardless of whether it contains recycled or recyclable fibres. Modified details with a view to recycling at the end of life are largely accepted as long as they do not radically change the functionality and familiar look of the product. There were only occasional complaints about the omission of a collar stay on the business shirt or a zip on the bed linen.

All three textiles proved to be suitable for use as a rental textile from the point of view of the textile service. The successful maintenance of the DiTex bed linen containing quantities of the innovative r30 lyocell material for textile services required an adjustment of the care parameters and therefore a certain amount of flexibility and willingness to adapt by the laundry. The DiTex business shirt and DiTex polo shirt were generally rated as suitable and easy to handle by the textile services. The digital tracking IDs incorporated in each case also turned out to be uncomplicated to use.

In terms of the business model of workwear as rental textiles, users particularly felt that the minimal effort in terms of purchasing and maintenance was an advantage over the use of workwear as private property. Users stressed that for the successful, long-term establishment of a textile service, the laundry exchange logistics (delivery and collection) must be easy to integrate in the daily work routine and should not involve any excessive additional effort.

In the practical tests, no repairs were carried out due to the nature of the project. No defects occurred in the bed linen and polo shirt over the course of the practical test that would have required repair. The defects occurring in the business shirt during the practical test were considered repairable with the exception of the repeated thinning of the fabric in the lower back area.

In the practical tests for the DiTex polo shirt and the DiTex business shirt, fewer test persons than expected took part in the surveys via sli.do. A total of 54 responses were collected for the polo shirt and 44 for the business shirt over the three surveys. One possible reason for this is that some of the test persons did not have a work smart phone. While the survey could be easily accessed on a smart phone via the QR code, this group of users had to find time to respond to the survey on a computer or on their private smart phone in addition to their usual practical tasks. Another reason for the relatively low participation could be that the surveys were split into three sub-surveys at different times, requiring a higher coordination effort by test users and users. The results of the user surveys in these two practical tests are therefore quantitatively less representative, but they do indicate qualitative trends, especially as the test persons who took part made intensive use of the free text input option. By contrast, in the practical test for the developed bed linen a total of 1,637 responses were obtained and the results can be seen as representative.

4.4. Environmental Impacts along the Textiles’ Life Cycle

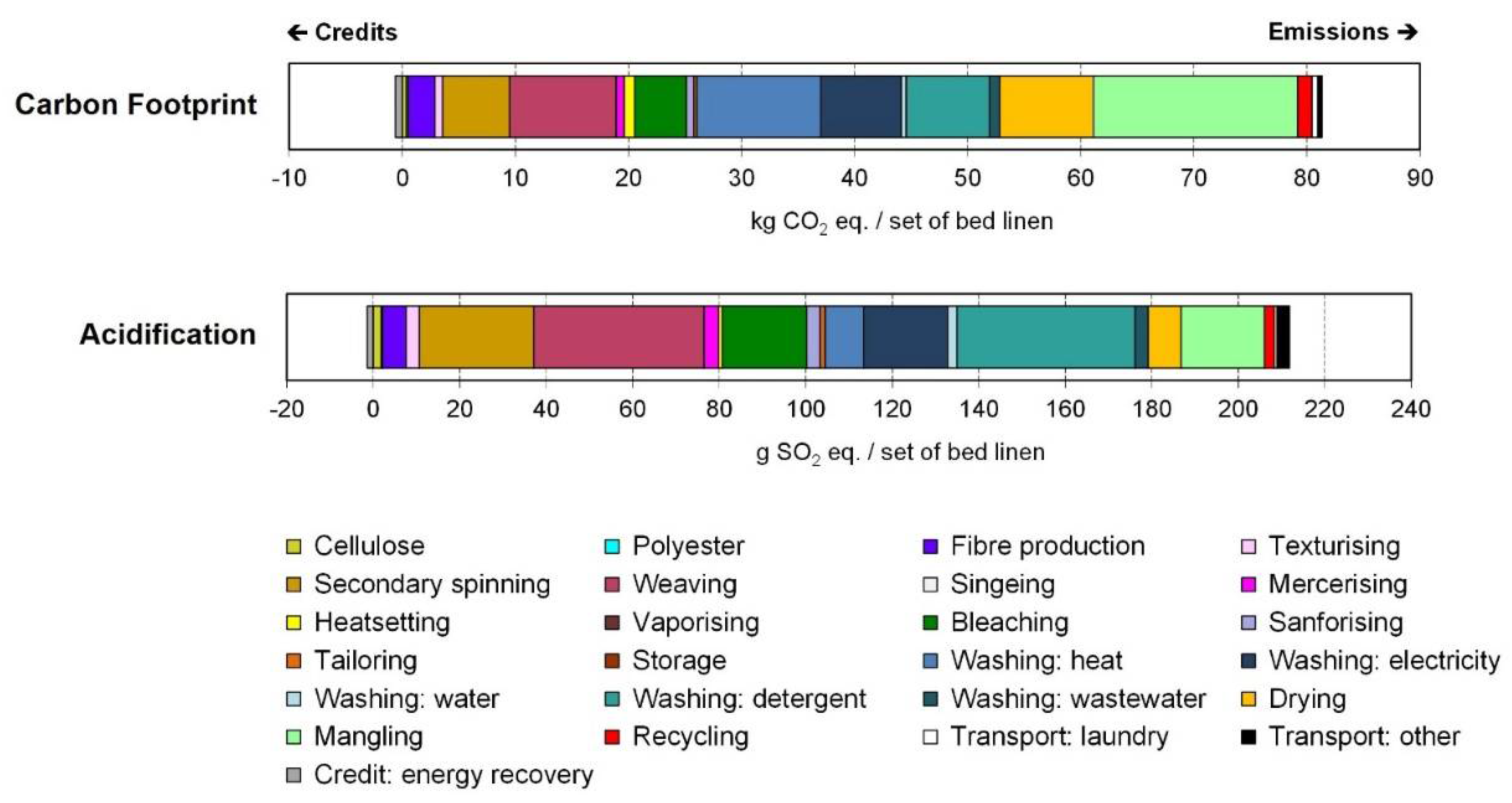

This chapter shows the results of the screening life cycle assessment. After presenting the carbon footprint and acidification based on the example of the newly developed bed linen, the effects of the fibre conversion on all the considered environmental impact categories are presented, selected life cycle stages are explained and the role of the service life of textiles is discussed.

4.4.1. Significance of Individual Life Cycle Stages for the Overall Result

The impact on climate change is over 80 kg CO₂ equivalent per set of bed linen with varying contributions by life cycle stage: the manufacture of the textile fabric and the textile finishing make up roughly a third of the total emissions; usage including washing and drying account for approximately two-thirds of the total emissions (

Figure 6). A typical useful life of 100 wash cycles was assumed. The fibre material of the r30lyocell/rPES mix plays a minor role in the carbon footprint. For the polo shirt and the business shirt with 50 assumed use cycles each, the share of usage accounts for around half of the carbon footprint [

67,

68]. The significance of the partial contributions also differs according to the environmental impact category. In the case of the bed linen, manufacture and finishing on the one hand and use on the other each account for half of the acidification (

Figure 6).

In the following, selected contributions of the analysed textiles are discussed and further environmental impact categories are considered.

4.4.2. Large Environmental Impact of Primary, Conventionally Produced Cellulose Fibres in Several Categories

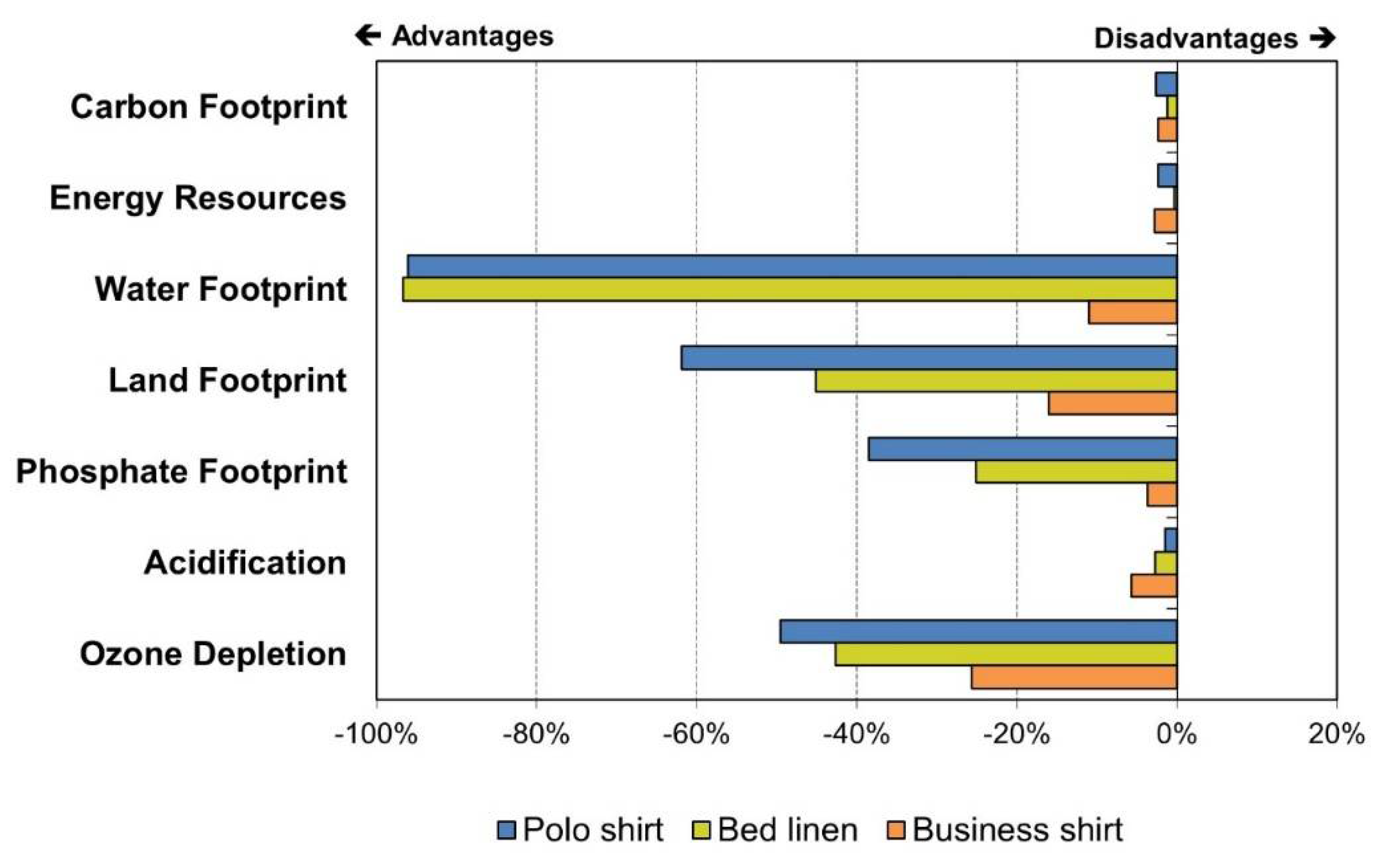

In the case of the textiles analysed in this study made from typically used fibre types such as cotton and polyester, the following feasible fibre conversions were identified:

From cotton to (recycled) polyester

From cotton to regenerated cellulose fibres

From conventional cotton to organic cotton

In the following, the effect of the respective fibre conversion is demonstrated using selected environmental impacts as examples.

Polo Shirt: Use of (Recycled) Polyester Instead of Cotton

The polo shirt reference product has a high cotton content. This has a high environmental impact due to agricultural cultivation and the associated water and land requirements [

40]. The use of 100% polyester or - better still - recycled polyester instead of a cotton/polyester mix leads to significant environmental benefits, particularly with regard to the water footprint of the polo shirt (

Figure 7). A decisive factor here is not so much the use of recycled fibres but rather the avoidance of agriculturally grown cotton. This also results in significant reductions in the land and phosphate footprint. Only small savings are achieved in terms of the carbon footprint, use of non-renewable energy sources and acidification.

Bed linen: Use of Regenerated Cellulose Fibres Instead of Cotton

Bed linen is produced from a high proportion of cellulose-based fibres such as cotton. Cotton fibres can be replaced by regenerated cellulose fibres such as lyocell in many cases, which are mainly produced from pulp of forestry origin. The life cycle assessment shows that primarily by avoiding the agricultural cultivation of cotton significant benefits can be achieved with regard to the water, land and phosphate footprint and ozone depletion (

Figure 7). Only very small to no benefits can be achieved in terms of the carbon footprint, use of non-renewable energy sources and acidification. The use of regenerated cellulose fibres instead of cotton can consequently reduce the environmental impact of textiles significantly. For the production of cellulose fibres, however, the irrigation requirements for forest plantations to obtain the necessary pulp should be kept to a minimum. Another source of raw materials to obtain fibres is cellulose residues, for example from recycling.

Business Shirt: Use of Organic Cotton Instead of Conventional Cotton

There is also debate over whether organically grown cotton has a lower environmental impact than conventional cotton. On the one hand, in organic farming a larger area of land is needed to produce the same quantity of cotton due to lower yields; on the other hand, the organic cultivation of cotton involves certain ecosystem services compared to conventional production and has advantages from a biodiversity perspective. This leads to advantages if we consider the overall land footprint (

Figure 7). As the impact of organic cotton on other environmental aspects is comparable to that of conventional cotton, there are clear environmental advantages to be gained by switching to organic cotton.

4.4.3. Large Carbon Footprint Due to High Energy Requirements in Production and Laundry

The production of textiles and the washing and drying processes during use have a major impact on the environment. This is mainly attributable to the energy used (electricity, heat). In the case of bed linen, the washing and drying processes make up around two-thirds of the total carbon footprint (

Figure 6). The individual washing and drying processes vary depending on the textile [

67,

68]. In addition, the range of energy input needed for the individual laundry processes is very wide and can amount to 2-3 times the emissions per kg of laundry when using old and less efficient laundry technologies [

69]. The range of the associated carbon footprints increases further, depending on the energy sources used to generate electricity and heat.

4.4.4. A Long Service Life Leads to a Reduction in the Environmental Impact

Extending the service life of textiles usually leads to a reduction in the environmental impact. In the case of textiles, a longer service life is characterised by a larger number of use and washing cycles. The result is that a proportionately smaller quantity of fibres has to be produced (e.g., polyester fibres) or extracted (e.g., cotton fibres) per use of a textile and therefore fewer textiles are produced. This is also reflected in the findings of the life cycle assessment: extending the service life has a significantly positive effect, in particular on those environmental impacts that depend primarily on raw material extraction and textile production. This applies, for example, to the water footprint, which is largely determined by the cultivation of cotton, but also other environmental impacts such as the carbon footprint caused by the production of the textiles themselves [

69].

In the case of environmental impacts that are particularly characterised by processes in the laundry, the potential savings through longevity is smaller, as the higher the number of washing cycles, the greater the environmental impact.

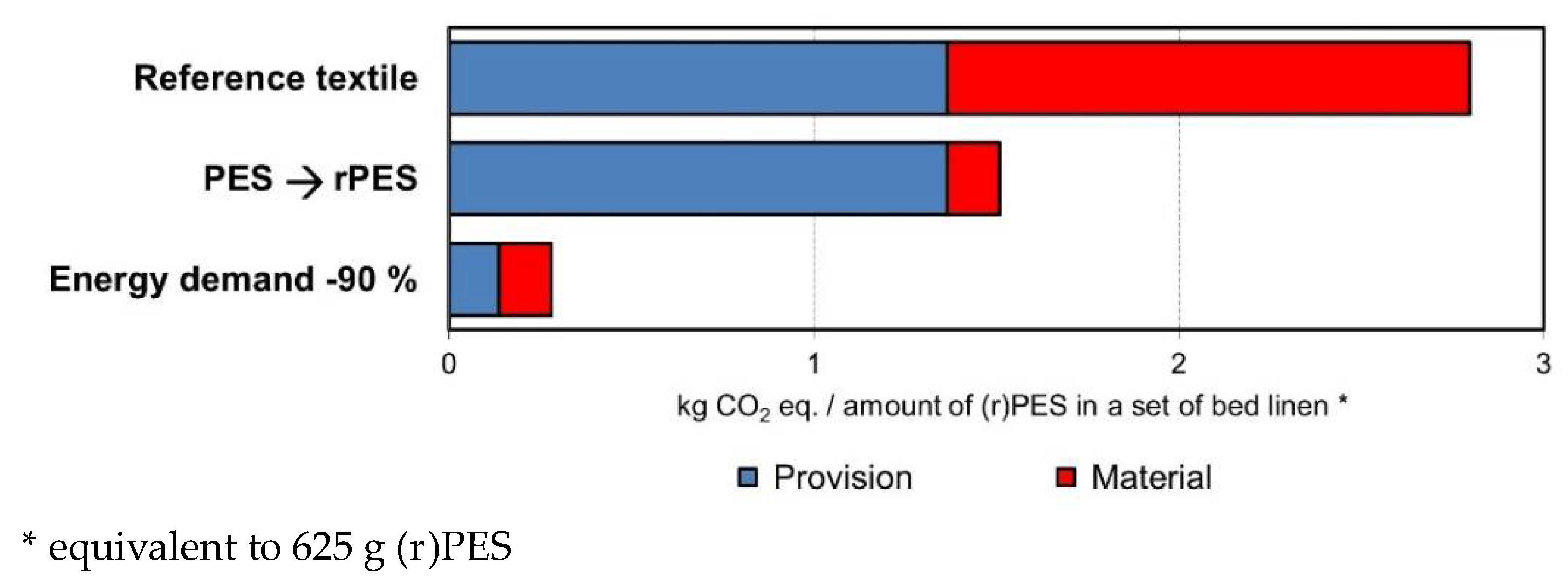

4.4.5. Small Reduction in Environmental Impact by Recycling Polyester

The results of the life cycle assessment of the analysed textiles show that recycling polyester has very little influence on the examined environmental impact categories for the underlying system boundary [

67,

68]. For this reason, using textile fibres made from recycled polyester leads neither to significant savings nor to notable disadvantages compared to the reference textile in the environmental impact categories considered.

Figure 8 shows the results for the carbon footprint of only the (recycled) polyester content of the bed linen - apart from energy resources, the other environmental impacts such as the water footprint are not significantly affected. The following scenarios are considered: use of fossil polyester (PES) in the reference bed linen, use of recycled polyester (rPES) in the reference bed linen and use of recycled polyester with a 90% reduction in the energy required for recycling.

In principle, using recycled material instead of primary material reduces the carbon footprint and the use of fossil energy resources, but this is negligible in relation to the entire life cycle of the bed linen (see

Figure 6). The reason for this is that the energy required for the manufacture and usage phase of the textile is around a hundred times higher than the difference between the two polyester variants. Even with a drastically reduced energy requirement (-90%), no significant savings can be achieved compared to the rest of the life cycle.

Author Contributions

Conceptualization, Kai Nebel; Methodology, Martina Gerbig, Kim Hecht, Christina Klusch, Kai Nebel; Formal Analysis, Martina Gerbig, Kim Hecht, Christina Klusch; Investigation, Martina Gerbig, Kim Hecht, Christina Klusch, Barbara Boldrini, Kai Nebel; Resources, X.X.; Data Curation, X.X.; Writing – Original Draft Preparation, Sven Gärtner, Martina Gerbig, Hanna Karg, Kim Hecht, Christina Klusch, Kai Nebel, Frieder Rubik; Writing – Review & Editing, Frieder Rubik; Visualization, Barbara Boldrini; Supervision, Frieder Rubik; Project Administration, Frieder Rubik; Funding Acquisition, Frieder Rubik. All authors have read and agreed to the published version of the manuscript.