Submitted:

08 May 2024

Posted:

10 May 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

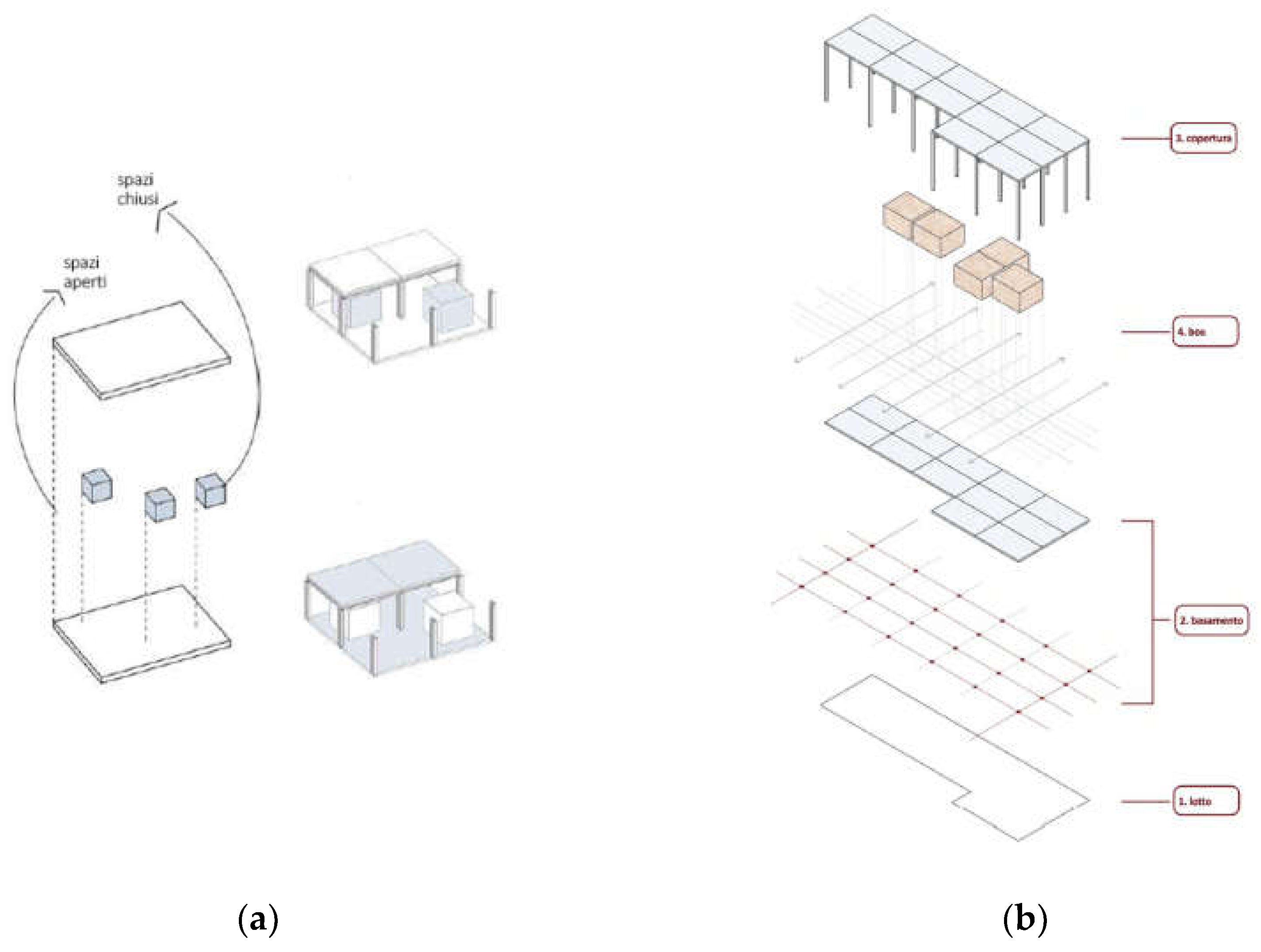

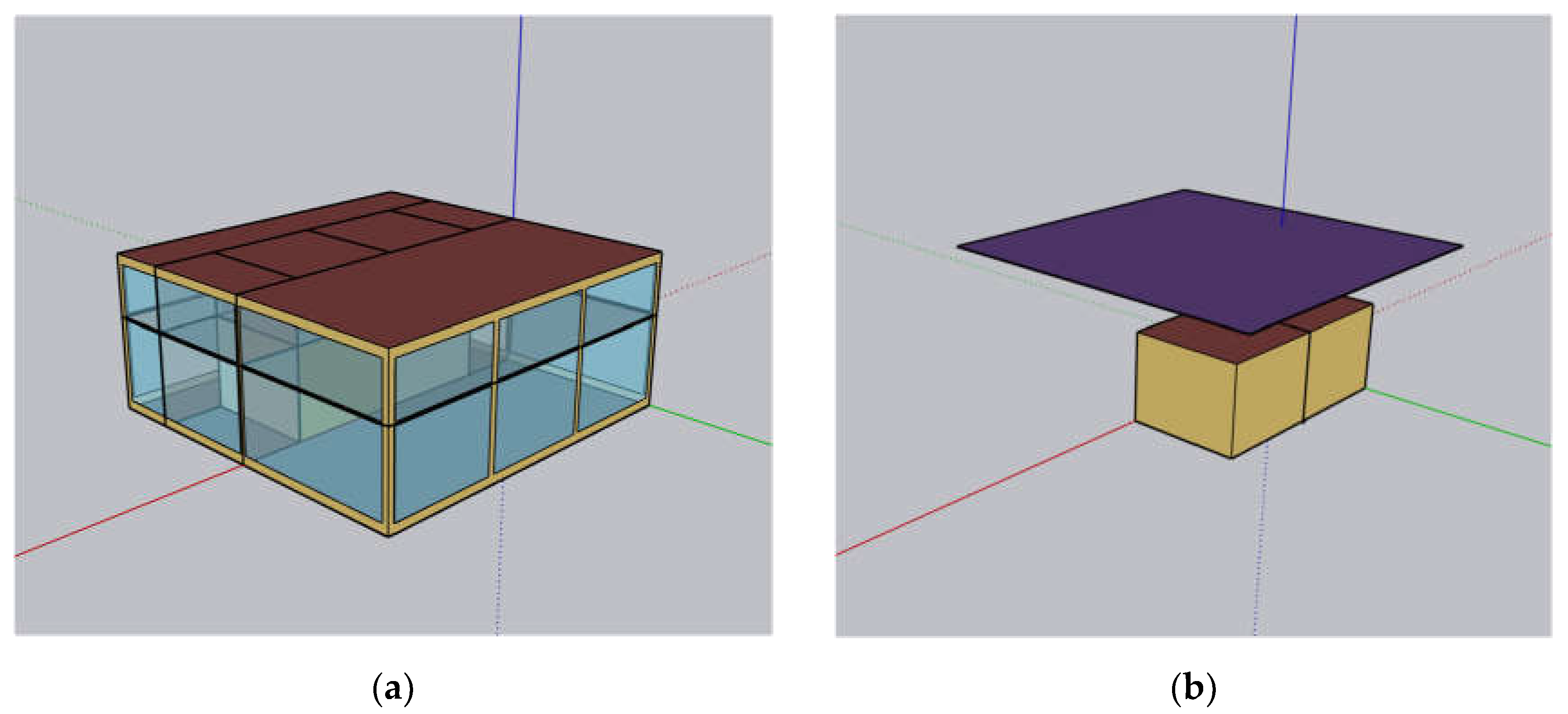

- Model definition. In the first part, the conceptual framework and the preliminary design for the non-conventional sanitary spaces are described, by investigating the benefits of a safe space as a generator space for care services and community.

- Technology definition. Then, the technological requirements of the system have been defined, by comparing the use of a panel structure to traditional structures (tents and shelters) in terms of sustainability, flexibility, and low-impact technologies.

- Energy simulations. Finally, the energy efficiency and environmental impact of the model are analyzed, using a model simulator (Energy Plus and Openstudio).

3. Model Analysis

3.1. Definition of the Prototype and Requirements

- Finally, the model is divided into two different components, defined by the concept's needs:

- The common space, which is more flexible and adaptable to the dimensions, fluxes, and shape of the lot;

| Table 1 | Emergency Tent |

Shelter | Panels | |

|---|---|---|---|---|

| Sustainability | Energy efficiency | 1 | 3 | ? |

| Renewable implementation | 2 | 3 | 2 | |

| Indoor quality | 1 | 3 | ? | |

| Flexibility | Adaptability to external conditions | 1 | 1 | 3 |

| Implementation and composition of the system | 1 |

2 |

3 |

|

| Construction | Speed of Construction | 3 | 2 | 2 |

| Economic solutions | 3 | 2 | 1 | |

3.2. Simulation

3. Results

3.1. Simulation Results – Bolzano Area

3.1.1. Bolzano – Simulation 1

3.1.2. Bolzano – Simulation 2

| Table 5 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TZ- BOX |

0 | 1804 | 861 | 862 | 442 | 1798 | 711 | 639 | 872 | 521 | 244 | 6 |

| TZ- PLATFORM |

3554 | 594 | 500 | 618 | 321 | 303 | 278 | 286 | 526 | 479 | 379 | 992 |

3.1.3. Bolzano – Simulation 3

| Table 6 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TZ- BOX |

0 | 1955 | 915 | 959 | 578 | 2079 | 737 | 544 | 607 | 359 | 27 | 0 |

| TZ- PLATFORM |

3518 | 654 | 542 | 624 | 338 | 367 | 316 | 326 | 582 | 483 | 419 | 591 |

3.2. Simulation Results – Palermo Area

3.2.1. Palermo – Simulation 1

| Table 7 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TZ- BOX |

0 | 0 | 275 | 1223 | 661 | 1364 | 534 | 512 | 1059 | 1241 | 1295 | 596 |

| TZ- PLATFORM |

157 | 1054 | 765 | 693 | 308 | 336 | 359 | 311 | 685 | 786 | 767 | 2539 |

3.2.2. Palermo – Simulation 2

| Table 8 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TZ- BOX |

0 | 0 | 282 | 1247 | 828 | 1768 | 1017 | 753 | 1021 | 769 | 739 | 336 |

| TZ- PLATFORM |

157 | 1059 | 794 | 860 | 637 | 700 | 582 | 516 | 1243 | 683 | 289 | 1240 |

3.2.3. Palermo – Simulation 3

| Table 8 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TZ- BOX |

0 | 0 | 141 | 1222 | 896 | 1775 | 1055 | 783 | 975 | 758 | 770 | 385 |

| TZ- PLATFORM |

147 | 1043 | 790 | 881 | 641 | 695 | 600 | 530 | 1240 | 672 | 292 | 1229 |

3.2.4. Palermo – Simulation 4

| Table 9 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TZ- BOX |

0 | 0 | 431 | 1526 | 735 | 1439 | 548 | 554 | 1211 | 1475 | 822 | 19 |

| TZ- PLATFORM |

127 | 1134 | 844 | 755 | 350 | 386 | 377 | 351 | 733 | 827 | 802 | 2074 |

3.1. Simulation Results – No Platform as Thermal Zone

| Table 10 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| BOLZANO | 0 | 2336 | 933 | 1359 | 570 | 2478 | 431 | 284 | 263 | 106 | 0 | 0 |

| PALERMO | 0 | 331 | 1157 | 1336 | 706 | 1797 | 666 | 679 | 1284 | 740 | 64 | 0 |

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Brunoro, S.; Mensi, L. A Modular Structure for Immediate and Transitory Interventions to Guarantee Access to Basic Healthcare in Italy. Sci 2023, 5, 17. [CrossRef]

- Al-Atrash, F.Z., Hamdan, M., Mualla, R., Energy efficient shelter for displaced person: Towards sustainable camps. Bauphysik 2023, 45,3. [CrossRef]

- Paparella, R.; Caini, M. Sustainable Design of Temporary Buildings in Emergency Situations. Sustainability 2022, 14, 8010. [CrossRef]

- Bologna, R.; Terpolilli, C. (a cura di), Emergenza del Progetto. Progetto dell’Emergenza. Architetture Con-Temporaneità; Jodidio, P., Ed.; Federico Motta Editore: Milano, Italy, 2005; Temporary Architecture Now!, TASCHEN GMBH, Bonn 2011.

- Falasca, C.C. Architetture ad Assetto Variabile. Modelli Evolutivi per L’habitat Provvisorio; (Tecnologia e Progetto 3); Alinea Editrice: Firenze, Italy, 2000.

- Pan, W.; Zhang, Z. Evaluating Modular Healthcare Facilities for COVID-19 Emergency Response—A Case of Hong Kong. Buildings 2022, 12, 1430. [CrossRef]

- Smolova, M.; Smolova, D. Emergency architecture. Modular construction of healthcare facilities as a response to pandemic outbreak. E3S Web Conf. 2021, 274, 01013. [CrossRef]

- Wallemacq, P.; House, R. Economic Losses, Poverty & Disaster, 1998–2017. CRED & UNISDR. Available online: https://www.preventionweb.net/files/61119_credeconomiclosses.pdf (accessed on 26th April 2024).

- World Health Organization. Available online: https://www.who.int/news-room/questions-and-answers/item/determinants-of-health (accessed on 26th April 2024).

- Hay, A., Gomez-Palacio, A., Martyn, N., Planning resilient communities, in I. Linkov, J. Palma-Oliveira (Eds.), Resilience and Risk, NATO Science for Peace and Security Series C: Environmental Security, Springer, Dordrecht, 2017, pp. 313–326. [CrossRef]

- Hall, E.T., La dimensione nascosta che cosa è la prossemica? Bompiani, Firenze, Italy, 1969.

- Cornaro, C., Sapori, D., Bucci, F., Pierro, M., Corrado, G., Thermal performance analysis of an emergency shelter using dynamic building simulation. Energy and Buildings 2015, 88,122-134.

- Lv, T.; Liu, B.; Liu, R.; Zhu, L.; Huo, Y.; Ji, M. Construction and Electrothermal Performance Evaluation of a Solar-Powered Emergency Shelter. Energies 2024, 17, 118. [CrossRef]

- UNHCR. Available online: https://emergency.unhcr.org/emergency-assistance/shelter-camp-and-settlement/shelter-and-housing/emergency-shelter-solutions-and-standards (accessed on 26th April 2024).

| Table 2 | ||||

|---|---|---|---|---|

| OSB | 0,012 | 0,10 | 530 | 1000 |

| Mineral Wool | 0,08 | 0,034 | 80 | 1000 |

| Wood Fiber | 0,08 | 0,037 | 110 | 2100 |

| XPS | 0,12 | 0,036 | 32 | 1700 |

| Woodbeton | 0,40 | 0,26 | 1350 | 1880 |

| Polycarbonate | 0,06 | 0,21 | 200 | 1170 |

| Aluminum | 0,01 | 172 | 2800 | 962 |

| S275 | 0,21 | 45 | 7850 | 502 |

| Table 3 | Bolzano | Palermo |

|---|---|---|

| Weather file | Bolzano - ITA IGDG WMO#=160200 | PALERMO - ITA IWEC Data WMO#=164050 |

| Latitude | 46,47 | 38,18 |

| Longitude | 11,33 | 13,10 |

| Elevation | 791 ft | 112 ft |

| Table 4 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TZ- BOX |

0 | 1874 | 845 | 874 | 447 | 1818 | 707 | 610 | 868 | 493 | 216 | 8 |

| TZ- PLATFORM |

3556 | 601 | 499 | 631 | 305 | 298 | 278 | 288 | 515 | 470 | 385 | 934 |

| 1 | Interviews with the Private Association were conducted in 2022. Medical professionals were asked about above-cited topics. Private Association participating in the initiative were in the Emilia-Romagna region: Biavati Association of Bologna, Caritas of Ferrara, Caritas of Reggio Emilia, Sokos Association of Bologna, in Marche region: Caritas of Senigallia. Starting from December 2023, thanks to this association, to volunteer working in education for refugees, and Refuges Welcome, we are collecting questionnaires from refugees and undocumented immigrants which confirm the necessity of support from the community and psychological diseases caused by social status, violence, and loneliness. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).