Submitted:

13 May 2024

Posted:

13 May 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

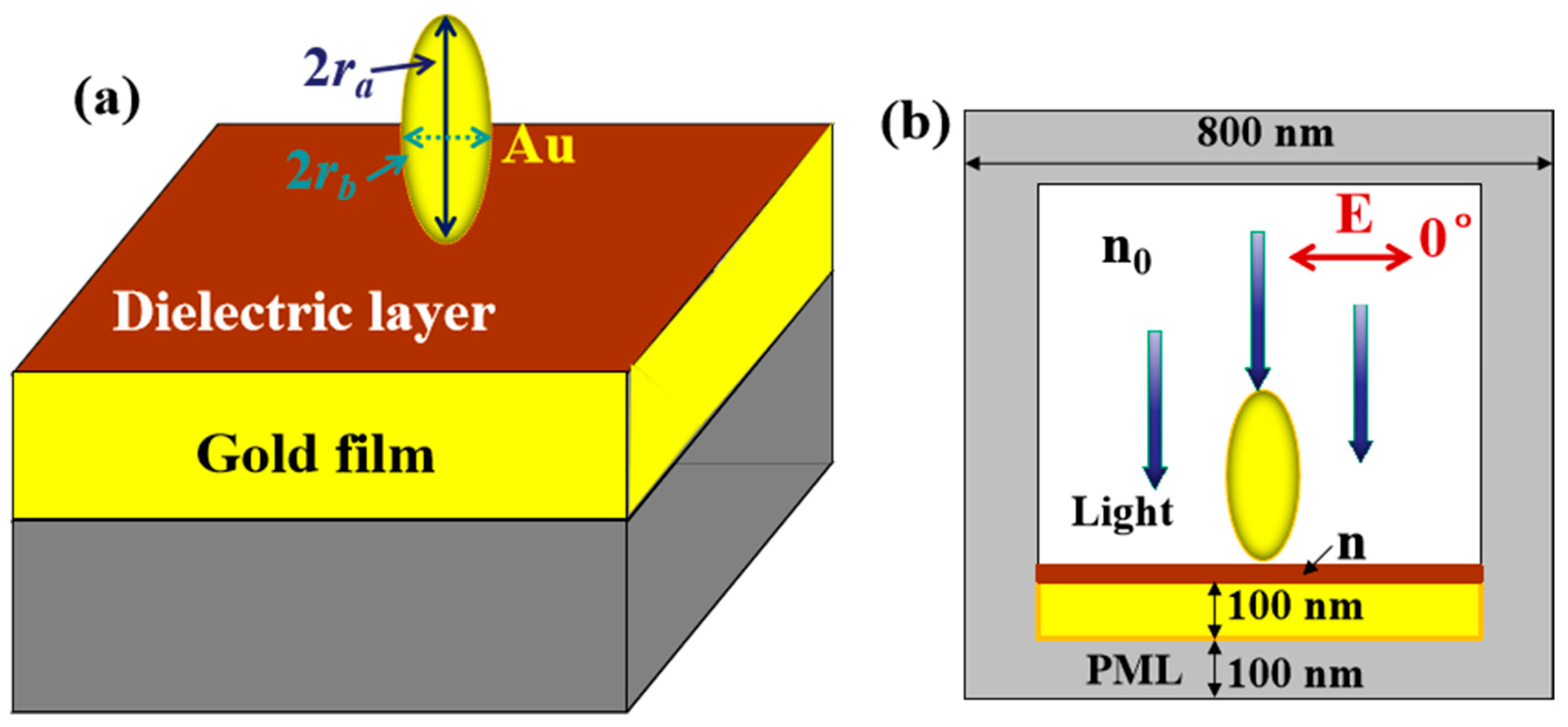

2. Simulation Model and Methods

3. Results and Discussion

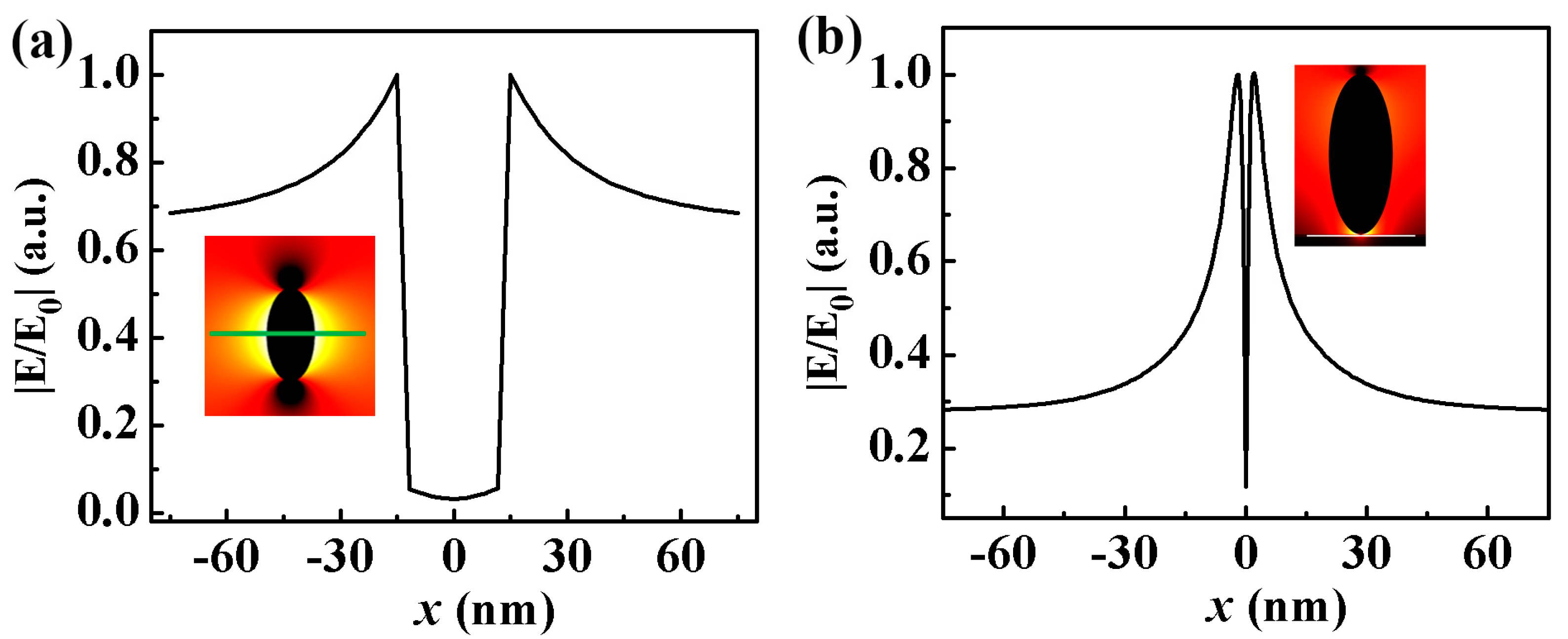

3.1. Electric Field Distribution on the Surface of GNEP and NPOM Structure

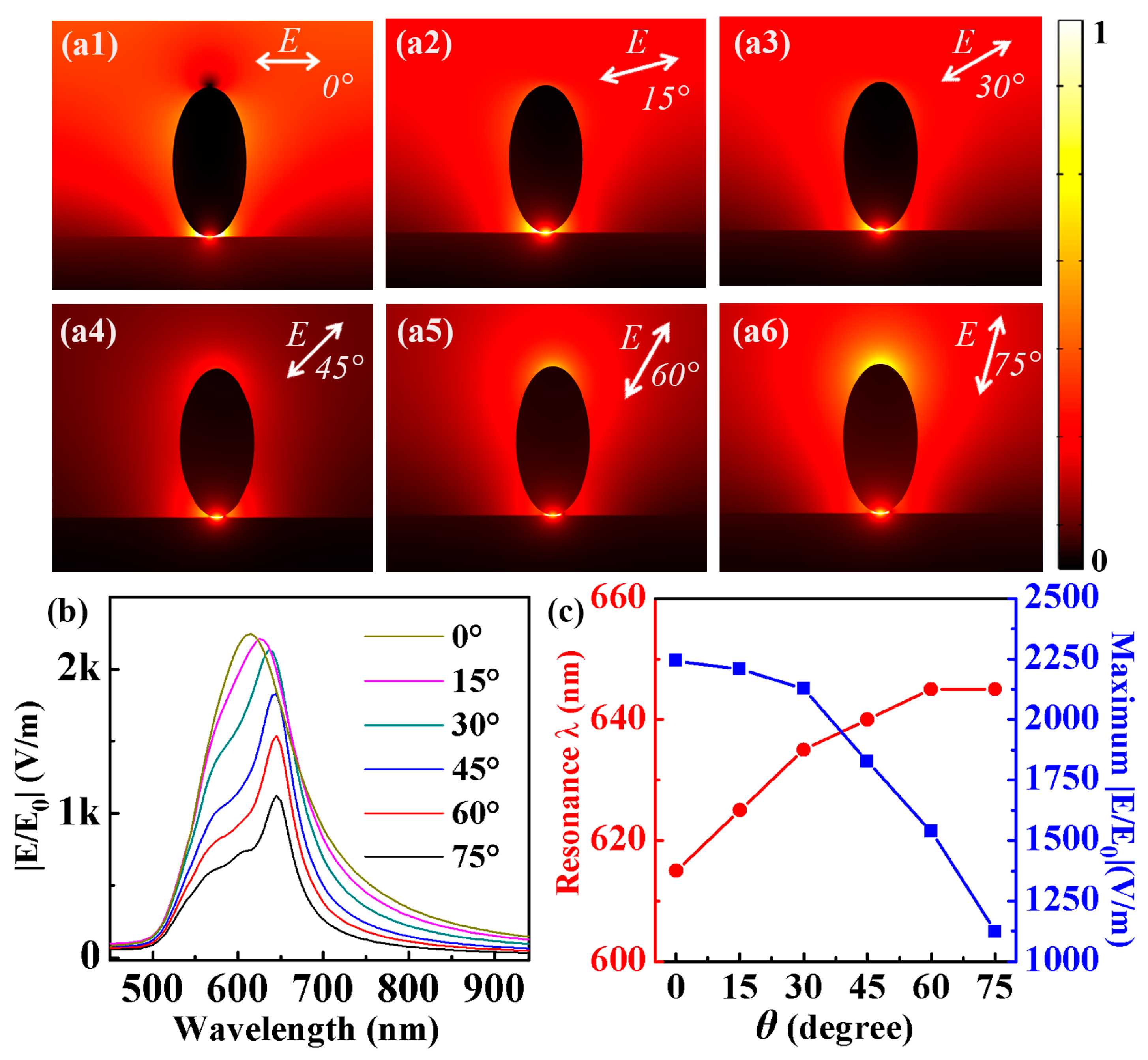

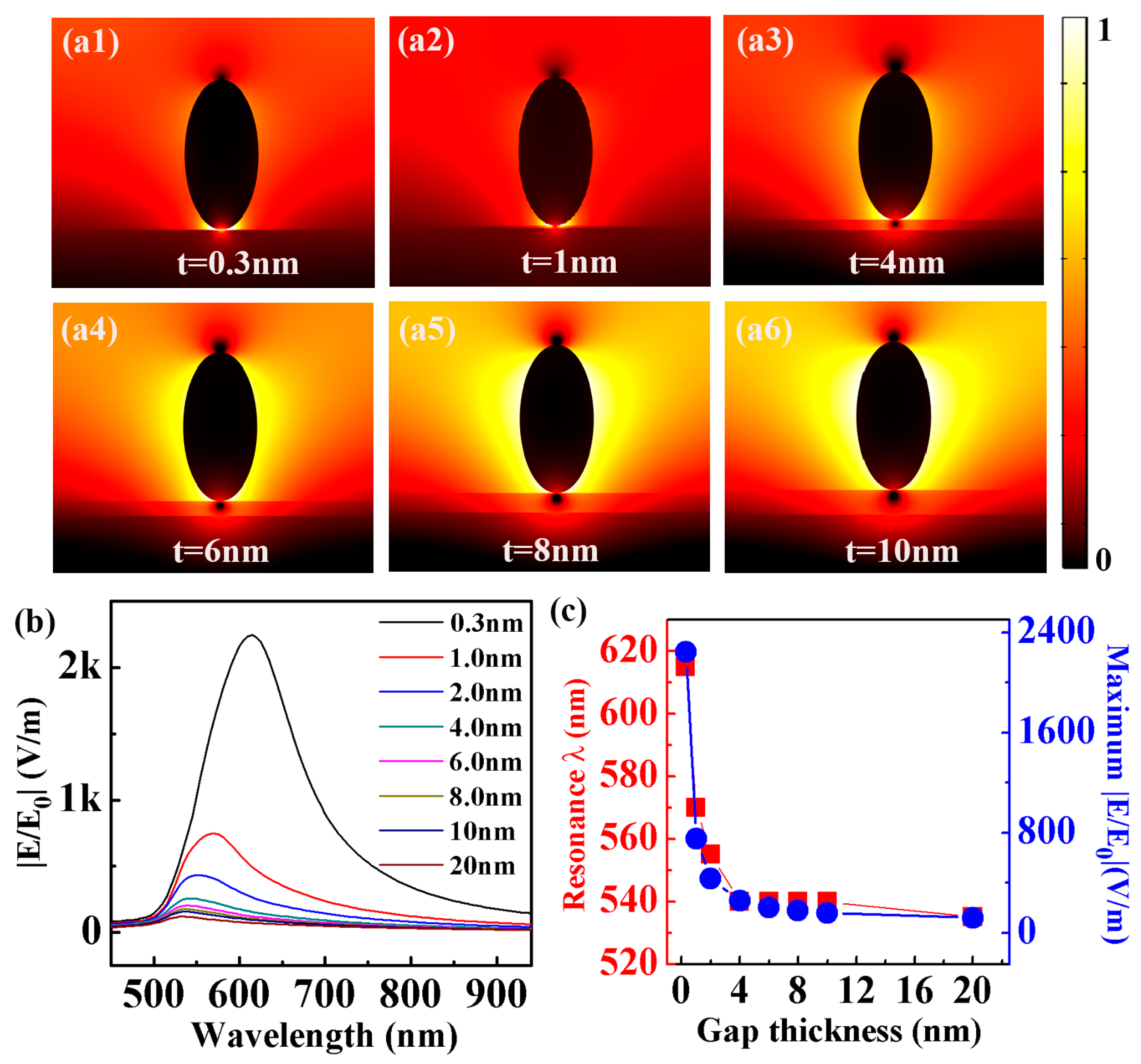

3.2. Electric Field Distribution of NPOM Structure at the Thickness of 0.3nm Dielectric Layer

3.3. Electric Field Distribution of NPOM Structure at the Thickness of 1nm Dielectric Layer

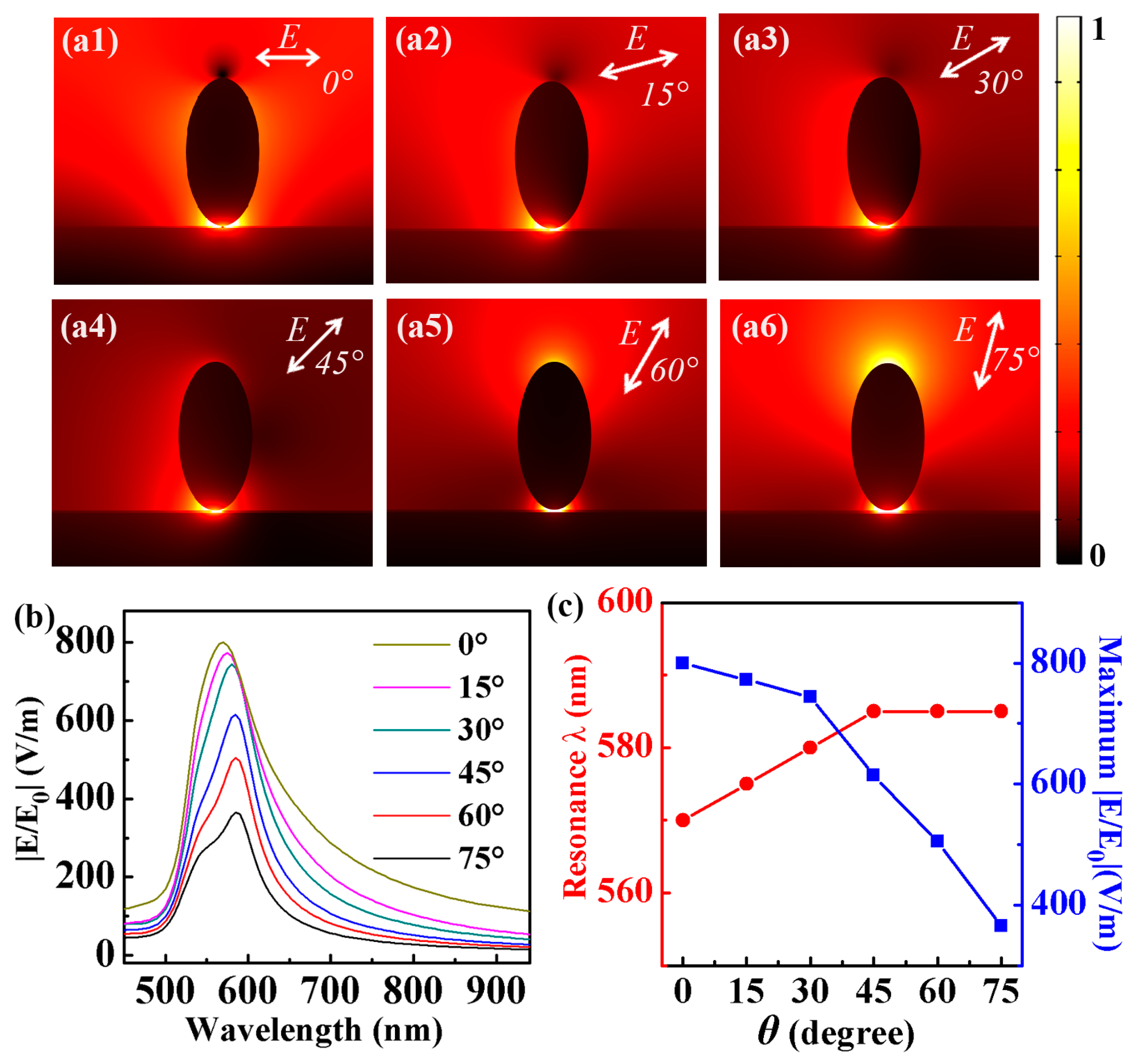

3.4. Electric Field Distribution of NPOM Structure at the Thickness of 4nm Dielectric Layer

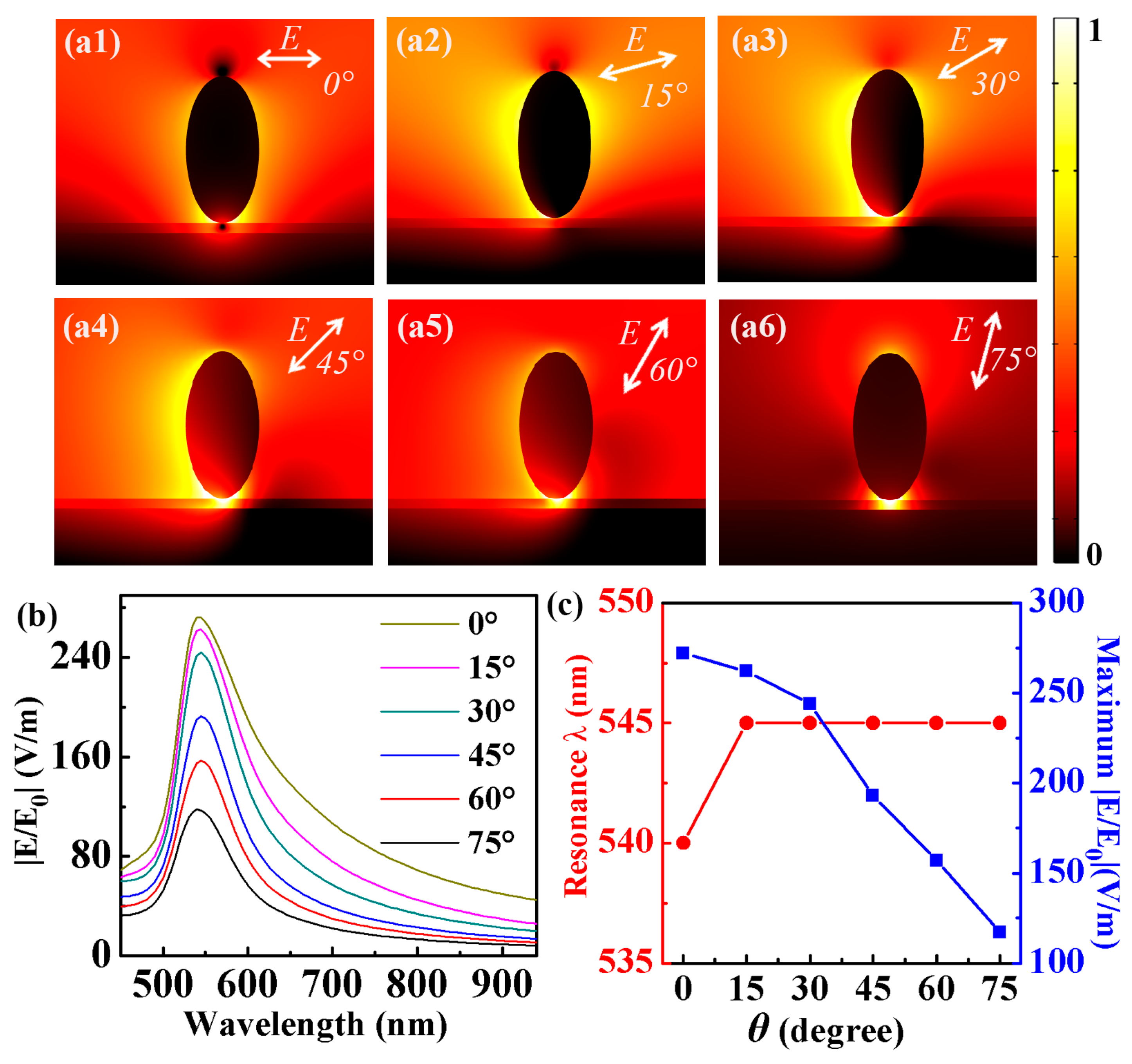

3.5. Electric Field Distribution of NPOM Structure at the Polarization Angles 0°

4. Conclusion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Abbreviation | Definition |

| SERS | Surface-enhanced Raman scattering |

| GENP | gold ellipsoidal nanoparticles |

| MNP | metal nanoparticles |

| NPOM | nanoparticle-on-mirror |

References

- Yanglin, Z.; Kaiwen, Z.; Jinyan, N.; Tao, X.; Shenghao, W. Plasmonics in Organic Solar Cells: Toward Versatile Applications. ACS Appl. Electron. Mater. 2023, 5, 631–641. [Google Scholar]

- Bipasha, B.; Pekham, C.; Najirul, H.; Swarbhanu, G.; Mitali, S.; Aslam, K.; Manirul, I. AgNPs Embedded in Porous Polymeric Framework: A Reusable Catalytic System for the Synthesis of α-Alkylidene Cyclic Carbonates and Oxazolidinones via Chemical Fixation of CO2. Catalysts 2023, 13, 1467. [Google Scholar] [CrossRef]

- Shan, F.; Zhang, X.Y.; Fu, X.C.; Zhang, L.J.; Su, D.; Wang, S.J.; Wu, J.Y.; Zhang, T. Investigation of simultaneously existed Raman scattering enhancement and inhibiting fuorescence using surface modifed gold nanostars as SERS probes. Sci. Rep. 2017, 7, 6813. [Google Scholar] [CrossRef] [PubMed]

- Battulga, M.; Johannes, Z.; Hannes, P.; Christian, W.; Dmitry, S.; Markus, C.S.; Thomas, A.K.; Calin, H. Hybrid Multilayered Plasmonic Nanostars for Coherent Random Lasing. J. Phys. Chem. C 2016, 120, 23707–23715. [Google Scholar]

- Yeshchenko, O.A.; Bondarchuk, I.S.; Malynych, S.Z.; Galabura, Y.; Chumanov, G.; Luzinov, I. Surface plasmon modes of sandwich-like metal–dielectric nanostructures. Plasmonics 2015, 12, 655–665. [Google Scholar] [CrossRef]

- Shan, F.; Zhang, X.Y.; Wu, J.Y.; Zhang, T. Hot spots enriched plasmonic nanostructure-induced random lasing of quantum dots thin film. Chin. Phys. B 2018, 27, 047804. [Google Scholar] [CrossRef]

- Armstrong, R.E.; Liempt, J.C.; Zijlstra, P. Effect of film thickness on the far- and near-field optical response of nanoparticle-on-film systems. J. Phys. Chem. C 2019, 123, 25801–25808. [Google Scholar] [CrossRef]

- Zhu, S.Q.; Zhang, T.; Guo, X.L.; Zhang, X.Y. Self-assembly of large-scale gold nanoparticle arrays and their application in SERS. Nanoscale Research Letters 2014, 9, 114. [Google Scholar] [CrossRef]

- Hu, P.; Zheng, L.; Zhan, L.; Li, J.; Zhen, S.; Liu, H.; Luo, L.; Xiao, G.; Huang, C. Metal-enhanced fluorescence of nano-core–shell structure used for sensitive detection of prion protein with a dual-aptamer strategy. Analytica Chimica Acta 2013, 787, 239–245. [Google Scholar] [CrossRef]

- Hiroyuki, N.; Akito, M.; Sadahiro, M.; Tsunenobu, O.; Hitoshi, K.; Hidetoshi, O. Highly Controlled Plasmonic Emission Enhancement from MetalSemiconductor Quantum Dot Complex Nanostructures. J. Phys. Chem. C 2013, 117, 2455–2459. [Google Scholar]

- Jiang, N.; Zhuo, X.; Wang, J. Active Plasmonics: Principles, Structures, and Applications. Chem. Rev. 2018, 118, 3054–3059. [Google Scholar] [CrossRef] [PubMed]

- Nielsen, M.G.; Bozhevolnyi, S.I. Highly confined gap surface plasmon modes in metal strip-gap-film configurations. J. Opt. Soc. Am. B 2015, 32, 462–467. [Google Scholar] [CrossRef]

- Kim, M.; Lee, J.; Nam, J. Plasmonic photothermal nanoparticles for biomedical applications. Adv. Sci. 2019, 6, 1900471. [Google Scholar] [CrossRef]

- Langer, J. Present and future of surface-enhanced Raman scattering. ACS Nano 2020, 14, 28–117. [Google Scholar] [CrossRef] [PubMed]

- Ratchford, D.C. Plasmon-induced charge transfer: Challenges and outlook. ACS Nano 2019, 13, 13610–13614. [Google Scholar] [CrossRef] [PubMed]

- Kim, W.; Kim, N.; Park, J.W.; Kim, Z.H. Nanostar probes for tip-enhanced spectroscopy. Nanoscale 2016, 8, 987–994. [Google Scholar] [CrossRef] [PubMed]

- Guo, Q.; Ma, X.; Xie, Y.; Tan, W.; Zhang, H. Green synthesis and formation mechanism of Ag nanofowers using lcysteine and the assessment of Ag nanofowers as SERS substrates. Colloids Surf A 2017, 530, 53–57. [Google Scholar]

- Khurana, K.; Jaggi, N. Localized surface plasmonic properties of Au and Ag nanoparticles for sensors: A review. Plasmonics 2021, 16, 981–999. [Google Scholar] [CrossRef]

- Vasanthan, D.; Jong, K.L.; Jin, W.O. Distinguishable Plasmonic Nanoparticle and Gap Mode Properties in a Silver Nanoparticle on a Gold Film System Using Three-Dimensional FDTD Simulations. Nanomaterials 2018, 8, 582. [Google Scholar] [CrossRef]

- Tanya, H.; Stephen, R.E.; Sumeet, M. Interaction of metallic nanoparticles with dielectric substrates: Effect of optical constants. Nanotechnology 2013, 24, 035201. [Google Scholar]

- Médéric, L.; David, M.; Priyamvada, V.; Gillibert, R.; Boujday, S.; Knoll, W.; Dostalek, J.; Chapelle, M.L. Plasmonic Properties of Gold Nanostructures on Gold Film. Plasmonics 2020, 15, 1653–1660. [Google Scholar]

- Vasanthan, D.; Hyun, L.; Minjun, K.; Thanh, M.N.; Jong, P.S.; Jong, M.L.; Lee, D.; Kim, K.H.; Oh, J.W. Unveiling facet effects in metallic nanoparticles to design an efficient plasmonic nanostructure. Current Applied Physics 2022, 44, 22–28. [Google Scholar]

- Jubb, K.M.; Jiao, Y.; Eres, G.; Retterer, S.T.; Gu, B. Elevated gold ellipse nanoantenna dimers as sensitive and tunable surface enhanced Raman spectroscopy substrates. Nanoscale 2016, 8, 5641–5648. [Google Scholar] [CrossRef]

- Near, R.; Tabor, C.; Duan, J.; Pachter, R.; El-Sayed, M. Pronounced effects of anisotropy on plasmonic properties of nanorings fabricated by electron beam lithography. Nano Lett 2012, 12, 2158–2164. [Google Scholar] [CrossRef] [PubMed]

- Hatab, N.A.; Hsueh, C.; Gaddis, A.L.; Retterer, S.T.; Li, J.H.; Eres, G.; et al. Freestanding optical gold bowtie nanoantenna with variable gap size for enhanced Raman spectroscopy. Nano Lett 2010, 10, 4952. [Google Scholar] [CrossRef] [PubMed]

- Vladimir, L.; Ronen, A.; Alket, A.; Ahmet, A.K.; Kai, C.; Thomas, H.J.; Shyamsunder, E.; Hatice, A. Angle-and polarization-dependent collective excitation of plasmonic nanoarrays for surface enhanced infrared spectroscopy. Optics Express. 2011, 19, 11202–11212. [Google Scholar]

- Oleg, A.Y.; Anastasiya, V.T.; Viktor, V.K.; Randal, J.K.; Michael, H.; Anatoliy, O.P. Angle and polarization dependent coupling of surface plasmon and gap modes in plasmonic gap metasurfaces. Optical Materials 2022, 132, 112884. [Google Scholar]

- Jiang, M.; Wang, G.; Xu, W.; Ji, W.; Zou, N.; Ho, H.P.; Zhang, X. Two-dimensional arbitrary nano-manipulation on a plasmonic metasurface. Optics Letters. 2018, 43, 1602–1605. [Google Scholar] [CrossRef]

- Palik, E.D. Handbook of optical constants of solids; Academic Press: Orlando, 1985. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).