1. Introduction and Objectives

Water measurement in water distribution networks is essential to make a rational use of water. The importance of controlling the use of water, especially irrigation water, is even greater during periods of drought, such as the one we are currently experiencing in southern Spain.

Traditional irrigation systems, where water is distributed through canals and irrigation ditches, do not often have gauging elements, partly due to the use of weirs, with low modular limits. On the contrary, long-throated flumes have a design that allows them to reach high modular limits, above 80% (Domínguez et al., 1984), which makes them ideal for use in open flow channel.

It has always been intended to design a measuring flume for free flow with characteristics like those of the Venturi in pressurized conduits. Perhaps the prototype that achieved the greatest similarity was the so-called Parshall measuring flume (Parshall, 1945), which has been in use during the second half of the 20th century. However, its different models did not meet the requirement of satisfying the laws of similarity, so that for each one a different flow equation was required with experimentally obtained parameters that are only valid for that structure.

The first works on modular or critical-flow flumes did not appear until the last quarter of the 20th century (Bos, 1978; Ackers et al., 1978). The term "modular" assumes that a critical regime occurs in the throat section, so that the flow rate could be obtained by simply reading the head upstream.

Although other design procedures of modular flumes have been proposed previously (e.g. Wahl et al., 2005, based mainly on the WinFlume program (Bautista et al., 2020, in its latest version), the methodology presented in this paper directly provides the parameters of the control section with a more accurate procedure than. for example, that of Vantakhah and Mahdvi (2012).

The main objective of this communication is to provide a quick and automated design using a spreadsheet that allows to obtain directly the dimensions of the narrowed section of a long throat channel, side slope and bottom width, choosing previously the modular limit, the sill height and the throat length more in accordance with the characteristics of the channel where the flume is going to be installed and that guarantees the flow measurement in the desired flows range.

2. Material and Methods

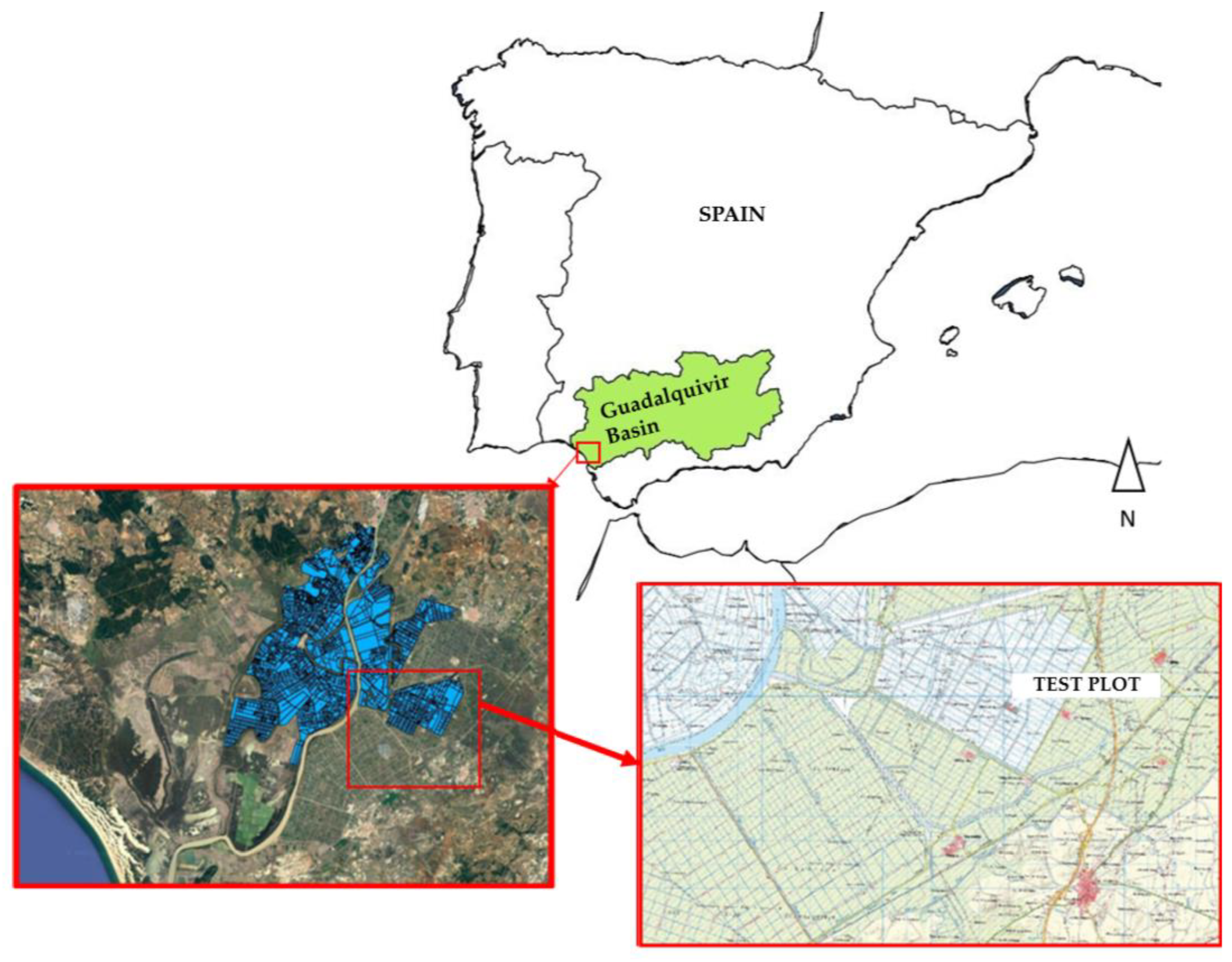

Rice is grown under anaerobic conditions by means of flood irrigation that maintains a constant water depth during most of the crop cycle. Thus, water requirements reach a very high volume of about 12,000 m

3/ha. The described procedure has been applied in the design of a flume to measure the flow in a drainage channel of a 15 ha plot of land cultivated with rice and located in the marshes (“marismas”) of the Guadalquivir valley, southwestern Spain (see

Figure 1). Its control will allow us to establish practices to reduce the high-water consumption. The drained discharge varies depending on the inflow, crop growth phase and drying periods (Ishfaq et al., 2020) so that to measure it requires the use of a device that is able to cover a wide range of flow rates, which in this case has been estimated between Q

m = 0.02 y Q

M = 0.05 m

3/s. The characteristics of the trapezoidal section drainage channel are as follows: b

c = 0.4 m; z

c = 1.1798 (θ/2 = 49.71º) (see

Figure 2); S (slope) = 0.002; n = 0.025 (Manning's roughness coefficient).

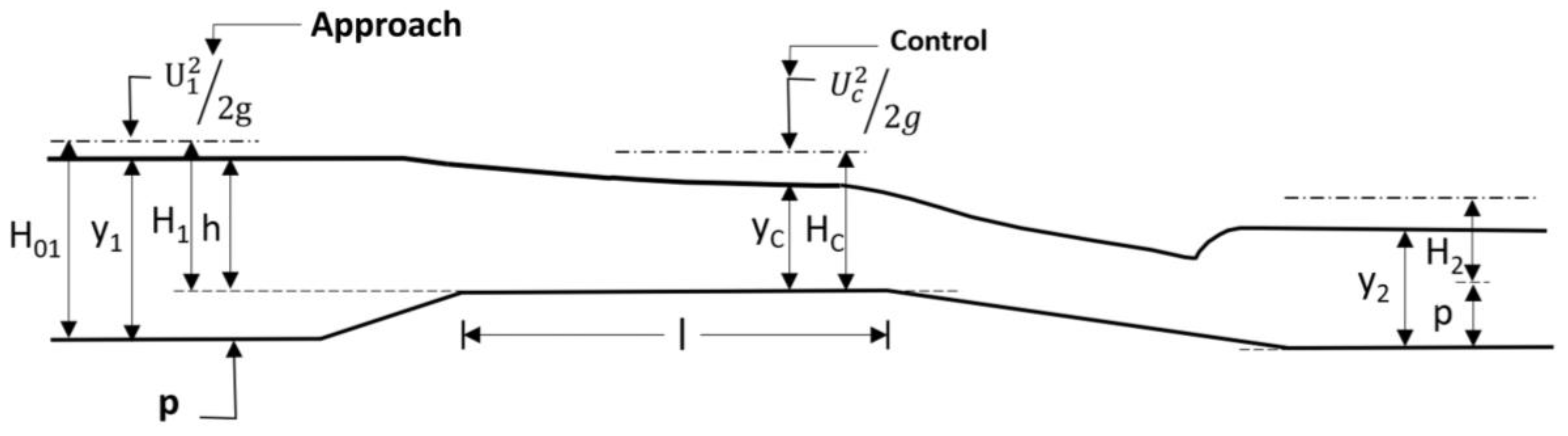

The long-throated flume consists of a convergent-divergent structure that interposed in a subcritical permanent free flow can impose the critical depth, y

c, in the throat section (see

Figure 2). The acceptance of uniform flow in both the upstream section and the narrowed section facilitates the theoretical development and, hence, the throat must be of sufficient length in relation to the upstream head to be able to accept uniform flow in the throat. It should also not be too long since energy losses would increase proportionally.

Channel narrowing, whether due to bed elevation by a sill, wall approach (convergence of side walls and bottom contraction), or both, causes an increase in upstream head, resulting in energy losses ∆H = H2 - H1 through the flume, which should be sufficient to produce a critical regime in the throat. The limit of utilization depends on the ratio (H2/H1) called the submergence ratio, which should not exceed the modular limit, L. With proper design of the convergence and divergence sections, especially the latter, few energy losses will occur, and L will be high, which characterizes these flumes (Domínguez et al., 1984).

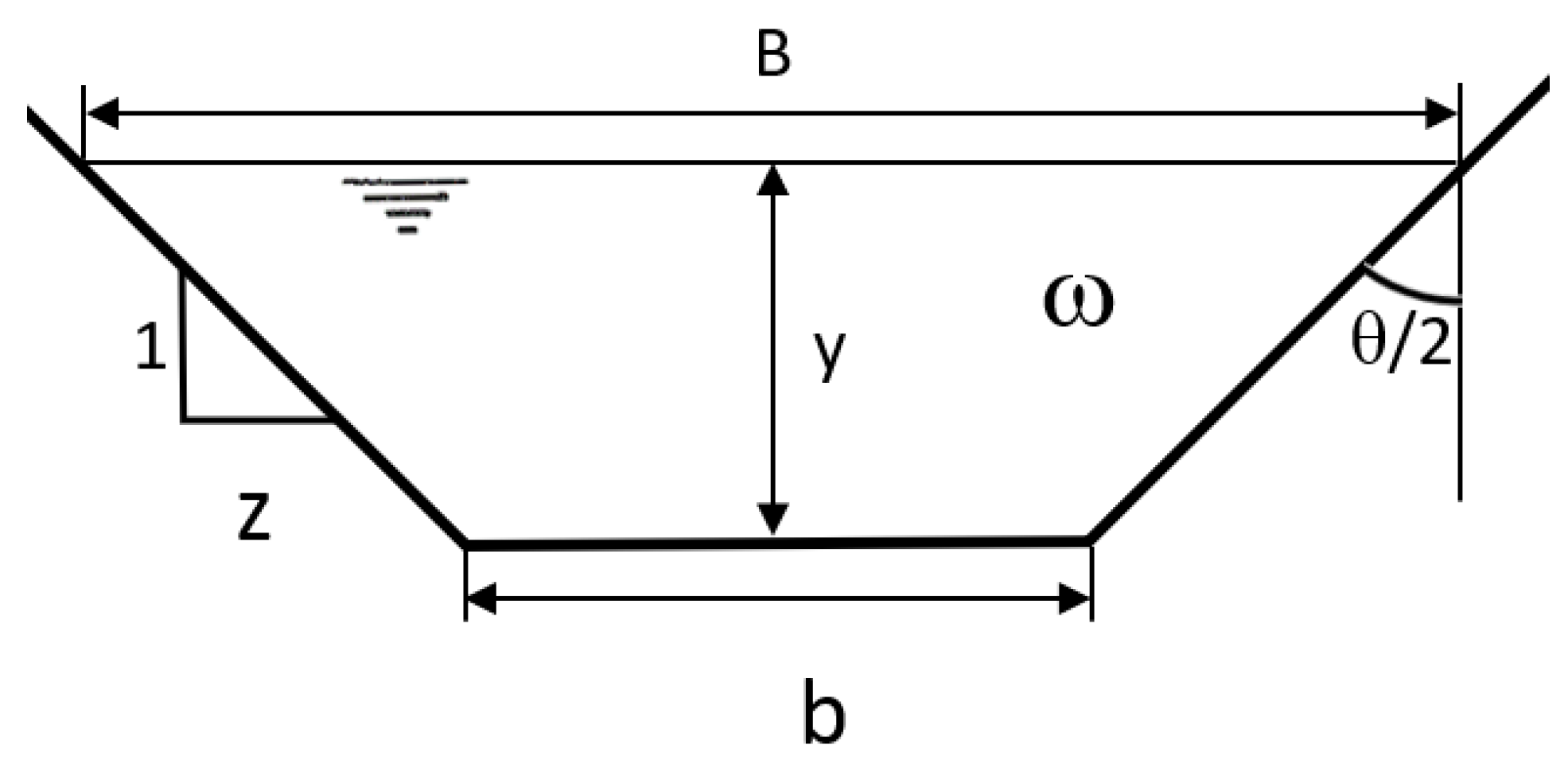

The geometrical shape of the throat can be diverse, with trapezoidal, rectangular, parabolic and circular sections being common. The procedure to be presented has been particularized for the trapezoidal section but it can be generalized to any other cross-section shape.

The design of the trapezoidal shaped control section is very complex since it is necessary to calculate two parameters, b

t and z

t (see

Figure 3). For this purpose, Domínguez et al., 1984) started from the flow interval to be measured (Q

M; Q

m) and, applying Manning's equation (1), obtained the hydraulic depths, y

M, y

m, with which they would circulate through the channel. Neglecting the velocity head in a first approximation, H

1 = h = y

1-p (see

Figure 2), they had a pair of initial values (Q

M, H’

M) and (Q

m, H’

m) with which to proceed to calculate b

t and z

t. Each narrowed section design is made for different values of p ranging from zero to a maximum of 15% of the hydraulic depth in the upstream section, y

1M.

where ω is the channel cross-sectional area (m

2), R is the hydraulic radius (m) and S is the channel slope

However, when the long-throated flume is installed, the upstream head H

1 > H’

1, i.e., the energy values are higher than those considered by these authors. An estimate of the energy value upstream can be made by considering that downstream of the flume the uniform flow that existed in the channel without the flume is restored and, therefore, the actual upstream head would be H

1 = (H

2/L) with L being the modular limit. Consequently, the values of H with which the design would start would be:

In a first approximation, we start from the assumption of frictionless flow, H=H

1=H

c, and the flow rate is obtained as follows:

where C

g is the shape coefficient which is calculated as:

with

with

.

The final expression C

g (C

H) is practically impossible to obtain analytically so it is easier to fit an equation to the pairs of values (C

g, C

H) which, representing these values, is observed to be of linear type:

The fit gives us the values of m and n. Combining equations (3) and (6) leads to the expression:

which, particularized for the pairs of values (Q, H’) results in:

Solving this system of equations gives us the values of

and

For viscous flow, the values of m and n remain unchanged, while the new values of b

t and z

t are obtained using the flow equation where a new coefficient, C

d, is introduced (3'):

where C

d is the discharge coefficient obtained from (10) (Bos, 1978):

being

l the throat length calculated from (11):

Following the same procedure as before, but now for the pair of values (Q, H), the values of bottom width, b

t, and side slope, z

t, of the throat section are obtained:

Finally, the application of the complete discharge equation (3’’) (Domínguez et al., 1984) would serve to verify the design:

where C

v is the approach velocity coefficient calculated as (12) and (13):

with ω

1 = approach section area

The calculation of the flow rate is made by applying equation (3'') after measuring the upstream gaged head h. However, the coefficients Cg and Cd depend on H so, initially, the calculations are started with H=h. Once the first value of the flow rate, Q', is obtained, the next value is calculated, Hn, as , and so on until the flow rate value is repeated, which will occur in very few iterations.

A solution widely used because it is constructively very easy to realize consists in keeping the side slope of the approach section in the throat section: z

t = z

c. Under this assumption, there is only one unknown to be calculated, b

t, which can be obtained using a single pair of values (Q

M, H

M):

In this situation, when the circulating flow rate is Qm equation (14) for (Qm, Hm) must also be fulfilled, which allows Hm to be calculated while keeping the same value of bt. The ratio (Hm2/Hm1) must be less than L to accept the proposed design. However, for lower values of L, within the range considered, it is possible that no solution to the problem can be found since higher head losses are required and the narrowing is only achieved by raising the sill, p, which now can no longer be equal to zero.

3. Results and Discussion

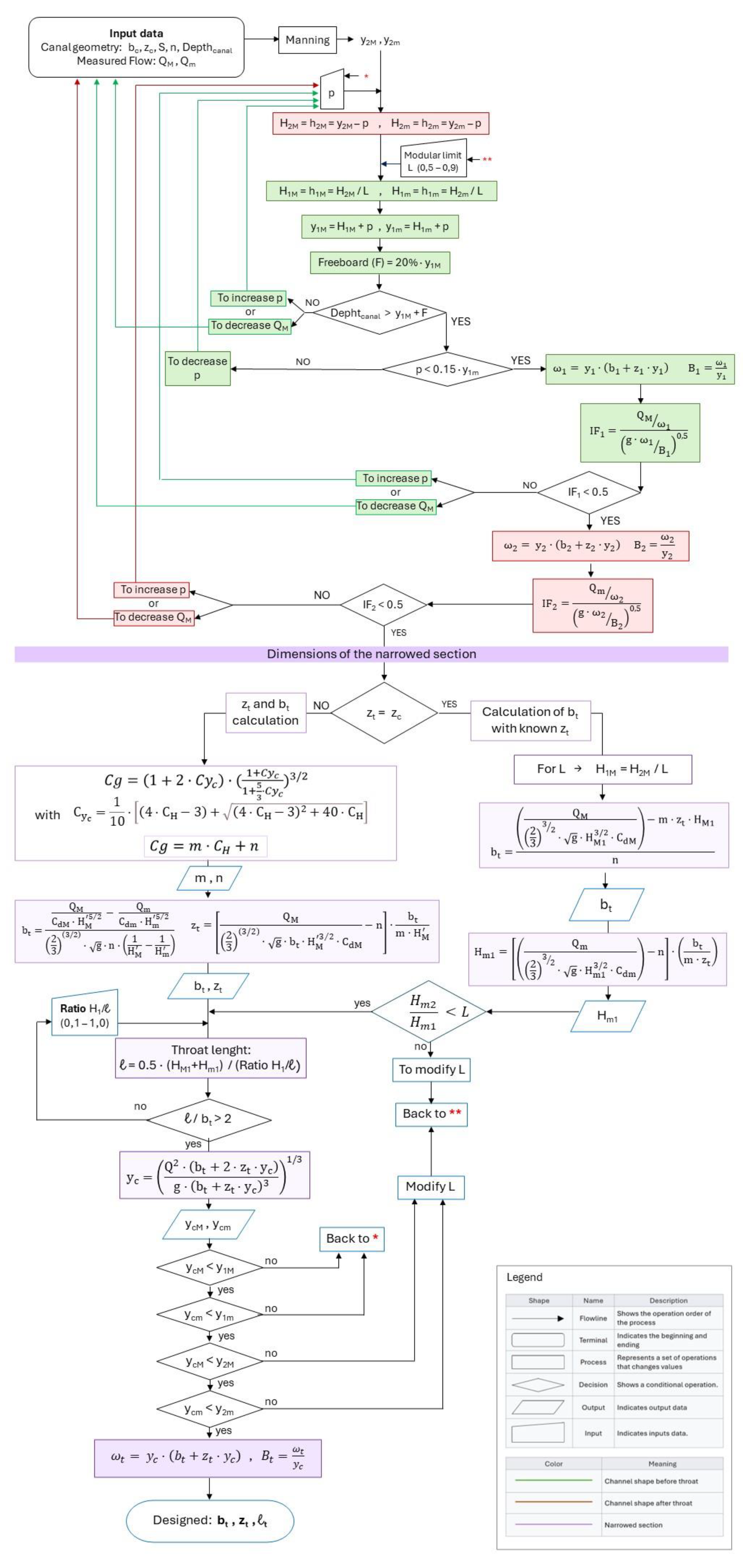

The calculation process has been developed on an Excel spreadsheet following the process shown in the flow chart (see

Figure 4). The design recommendations were taken from Wahl et al. (2000, 2005). The preliminary results of this work have been presented at a scientific conference (Roldán-Cañas et al, 2023).

The design steps for the narrowed section starts with the choice of the flow rate range to be measured, in our case Qm=0.02 and QM=0.05 m3/s. Next, a value of the sill height p is selected, which in this example has varied between 0 and 0.015 m. Later, the water levels downstream are calculated using Manning's equation and then, the values of the energy are obtained. For a given value of the modular limit, L, whose variation has been set between 0.5 and 0.9, the energy and depth values upstream of the flume are then calculated so that the maximum value of sill height, p, must be less than 15% of the depth in the approach section, y1M. Subsequently, a freeboard of 0.2 y1M is adopted and a check is made to see if the canal bank is overcome. If any of these assumptions is not met, p must be decreased or the maximum flow that can be measured would be less than QM. It is also checked that the Froude number, F, be less than 0.5 in the approach section for both QM and Qm. Otherwise, p would have to be increased or QM would have to be decreased.

Next, bt and zt are calculated using equations (8') and (9') and the throat length, l, is obtained using (11) so that the ratio (H/l) is kept between 0.1 and 1.0 and l be greater than twice the bottom width, bt, to ensure that the uniform flow is achieved in the throat. Finally, it is verified that the critical regime is reached at the throat. Otherwise, it would be necessary to go back to the beginning and increase p. A 1:3 ratio is adopted for the upstream ramp and a softer 1:6 ratio for the downstream ramp due to the higher risk of boundary layer separation.

For each combination of p, L and H/l, the values of b

t and z

t that meet all the requirements of the flow chart shown in

Figure 4 are obtained. In total, 300 (6x5x10) possible different sizes of narrowed sections have been designed in which a critical regime could be reached in the throat when the flow rate is between Q

M and Q

m.

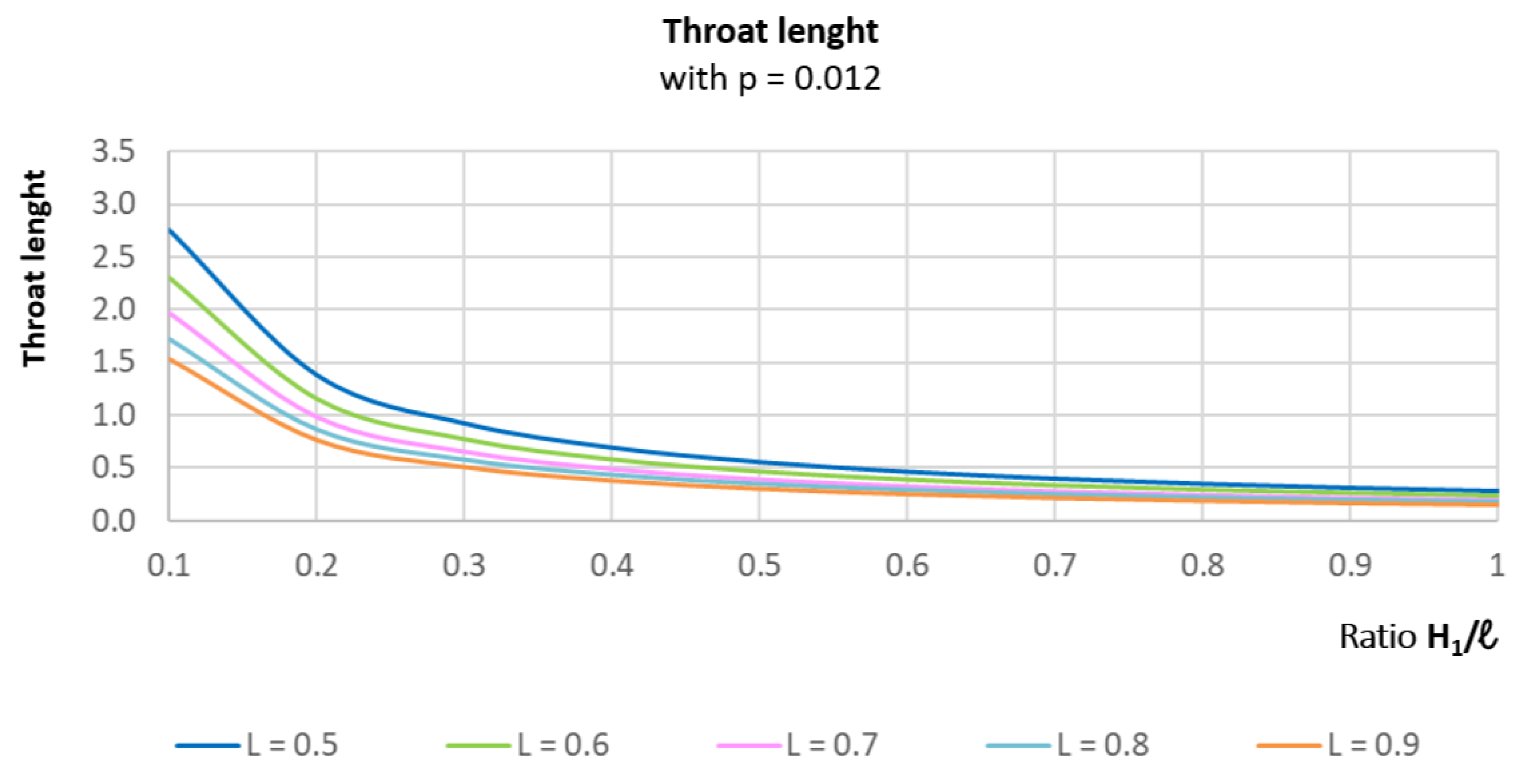

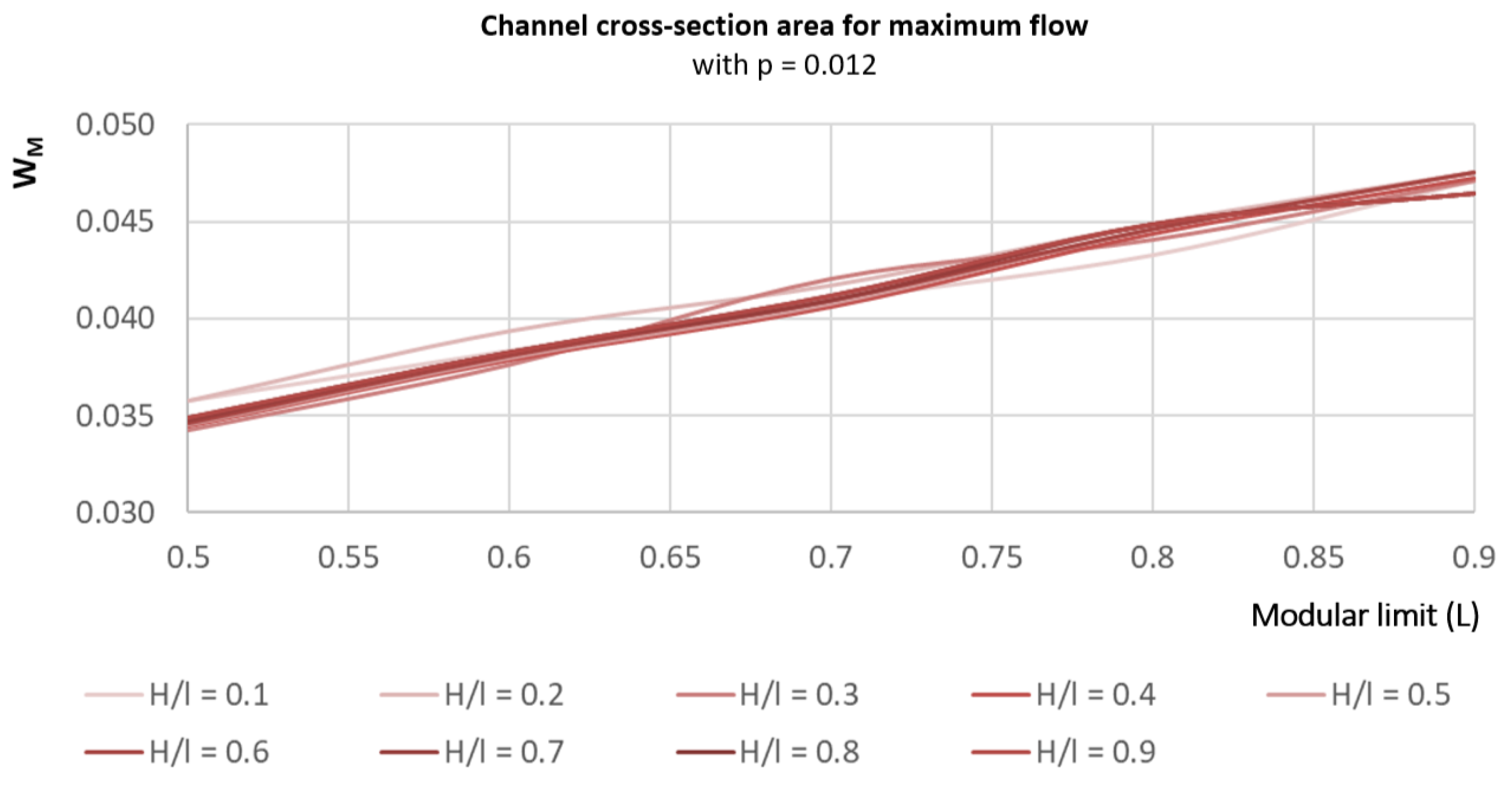

Some of the results obtained are presented graphically. Thus, for example,

Figure 5 shows the relationship between the throat length, l, and the ratio H/l for p=0.012 and for all values of L. The higher the L, i.e. the lower the head losses, the throat length is reduced accordingly, although from H/l > 0.5 onwards the throat length remains practically constant. The influence of p is small, although the higher the sill height, the shorter the throat length (not shown in this figure).

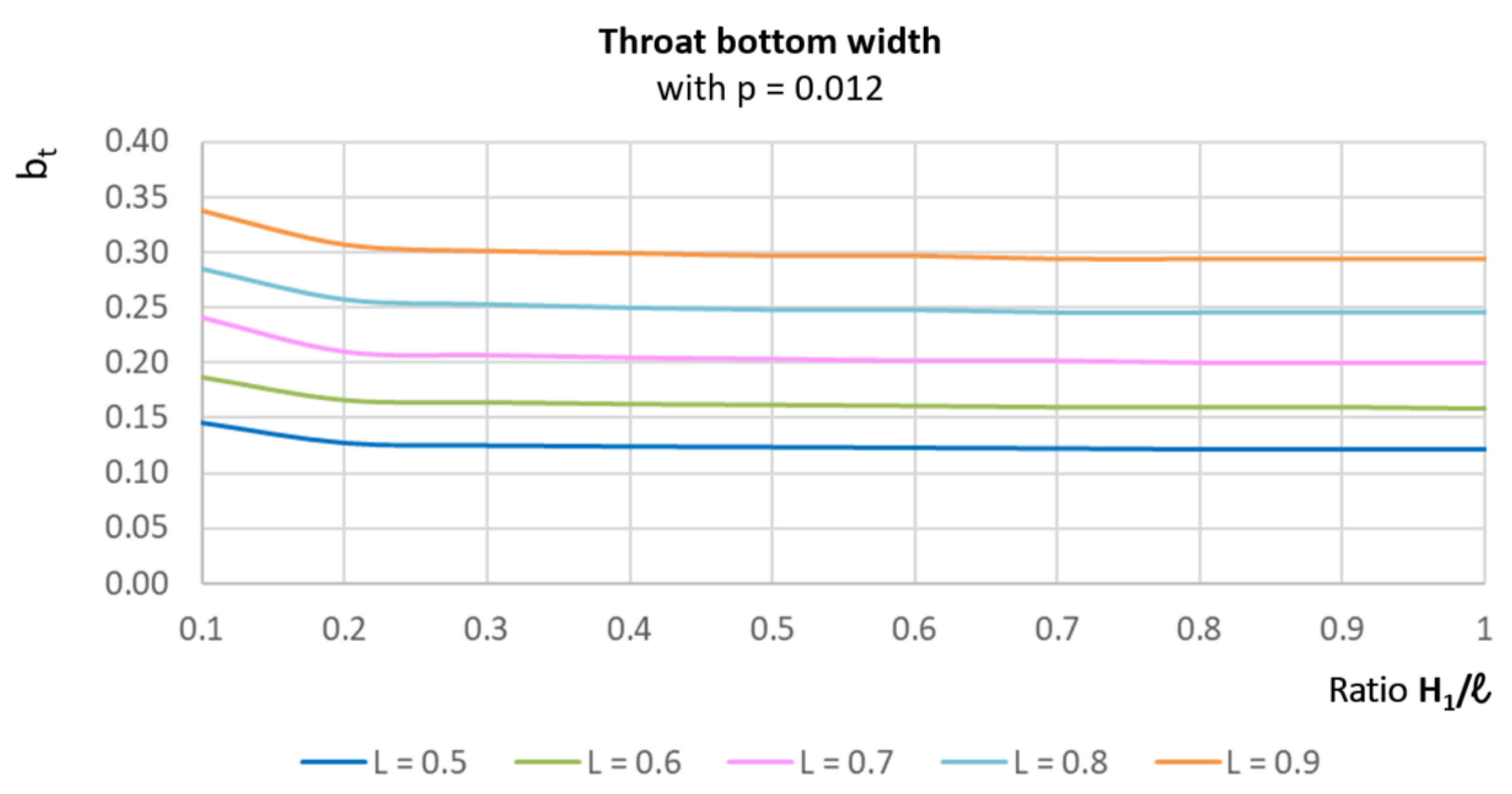

Figure 6 shows the relationship between b

t and H/l for p=0.012 and for all values of L. Obviously, the value of b

t is higher as L increases and that when H/l>0.2, b

t decreases slightly, although it tends to be constant. Below H/l < 0.2, the variation of b

t is very pronounced, evidence of the non-uniformity of the flow. It has also been found that, at higher p, the value of b

t increases (not shown in the figure) as is logical.

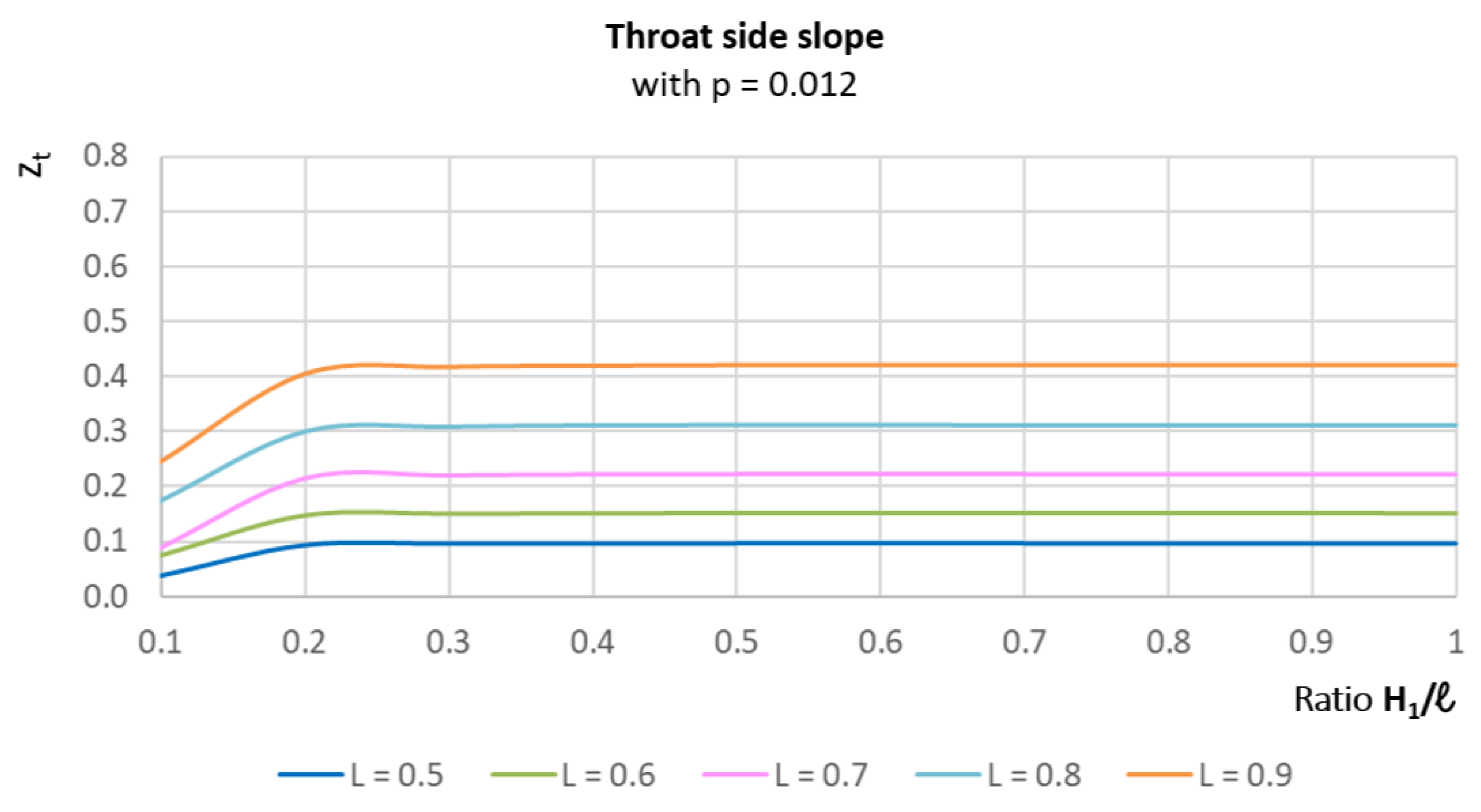

The relationship between z

t and H/l is shown in

Figure 7 for p=0.012. In this case, a large variation of z

t also appears for values of H/l<0.2 and, thereafter, z

t rises and remains practically constant. At higher L the value of z

t increases which implies that the throat section becomes larger since the head losses are smaller. It has also been found that increasing p obviously decreases the value of z

t (not shown in the figure).

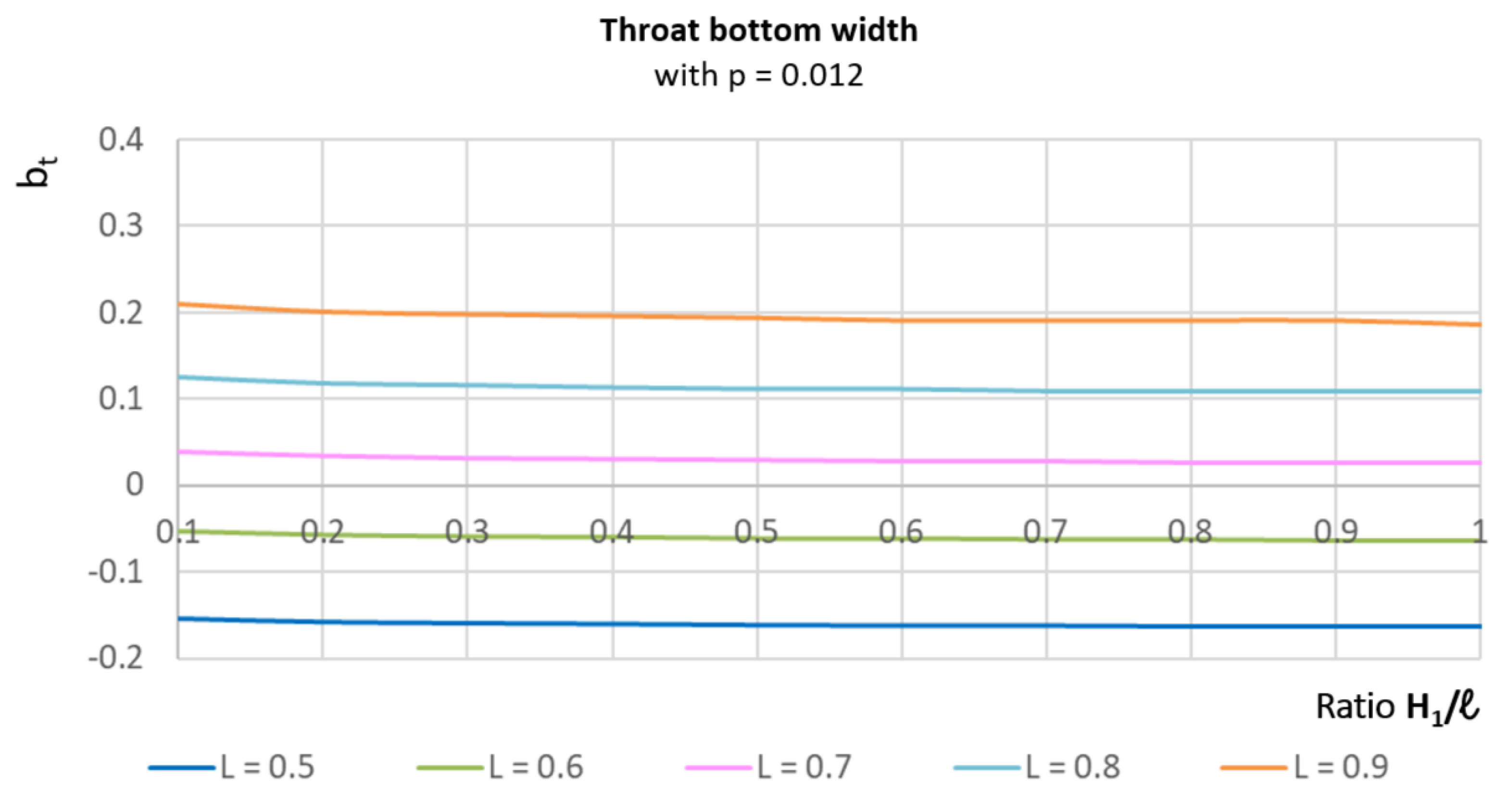

Figure 8 presents the relationship between b

t and H/l, for different values of L when the side slope of the channel is maintained at the throat, z

c=z

t. It is not possible to find a feasible solution if L<0.7. When L≥0.7, all solutions are possible designs. In all cases, b

t decreases slightly with increasing H/l since a higher contraction is required when the throat length decreases.

The joint effect of b

t, z

t and p is studied in

Figure 9, where the relationship between the channel cross-section area for maximum flow, w

M, and the modular limit for different values of H/l is shown, being p = 0.012. It is observed that for a larger L, the size of the narrowed section increases as expected, although there are no big differences when H/l varies the larger L is. Nor have large differences been found when varying the value of p (not shown in the figure).

4. Application

The design of a long-throated flume located in the drainage channel of the rice plot using the methodology developed in this paper is the subject of this application.

The characteristics of this trapezoidal section earthen channel are as follows:

Channel bottom width: bc = 0.4 m

Channel side slope: zc = 1.1798 (θ/2 = 49.71º)

S (channel slope) =0.002

n = 0.025 (Manning's roughness coefficient)

Channel depth: 0.89 m

Flow rate range to be measured: Qm=0.02 and QM=0.05 m3/s

The input parameters for the design, adopted according to the channel characteristics, have been:

A high value is adopted for the modular limit since no great head losses are available in the channel. Then:

Modular limit: L= 0.8

The sill height is set at the minimum value so that the height upstream of the flume is not too high and reaches the pipes draining from the plot to the canal. Then:

Sill height: p= 0

The length of the throat is adopted by setting a value for the ratio H/l which must be at least 0.5 to ensure uniform flow through the throat. A higher value only implies higher head losses. Then:

Ratio H/l = 0.5

Applying the designed spreadsheet, the following throat section parameters are obtained:

Throat bottom width, bt = 0.18 m

Side slope, zt = 0.5317 (θ/2 = 28°)

In case the obtained value of bt is extremely small, the value of the threshold p should be increased.

5. Conclusions

A new analytical design of a long-throated flume interposed in a channel has been proposed based on the range of flows to be measured and on the channel characteristics.

An example has been used to demonstrate the accuracy of the developed method where the throat section has been considered to be trapezoidal. However, the analytical procedure is the same for any geometrical shape of the narrowed section.

All the results found after generating a large number of throat cross-sections demonstrate the reliability of the method used. Each user can choose the modular limit, as well as the sill height and the throat length most suited to the characteristics of the channel where the flume is to be installed, which will automatically provide them with the dimensions of the throat cross-section.

The consistency of the results obtained demonstrates the accuracy and feasibility of the procedure presented for designing the throat section of a long-throated flume.

The whole process has been implemented in an Excel spreadsheet that allows to modify the input data and to quickly check the accuracy of the results obtained.

Author Contributions

Conceptualization, María Fátima Moreno-Pérez and José Roldán-Cañas; Data curation, María Fátima Moreno-Pérez and Francisco Javier Pérez-Ardoy; Formal analysis, María Fátima Moreno-Pérez, Francisco Javier Pérez-Ardoy and José Roldán-Cañas; Funding acquisition, María Fátima Moreno-Pérez and José Roldán-Cañas; Investigation, María Fátima Moreno-Pérez and José Roldán-Cañas; Methodology, María Fátima Moreno-Pérez and José Roldán-Cañas; Project administration, María Fátima Moreno-Pérez, Francisco Javier Pérez-Ardoy and José Roldán-Cañas; Resources, María Fátima Moreno-Pérez; Software, María Fátima Moreno-Pérez; Supervision, María Fátima Moreno-Pérez; Validation, María Fátima Moreno-Pérez, Francisco Javier Pérez-Ardoy and José Roldán-Cañas; Visualization, María Fátima Moreno-Pérez and Francisco Javier Pérez-Ardoy; Writing – original draft, María Fátima Moreno-Pérez; Writing – review & editing, María Fátima Moreno-Pérez and José Roldán-Cañas.

Data Availability Statement

Acknowledgments

We gratefully acknowledge the support received from the Spanish Ministry of Science and Innovation, through grant RTC2019-007133-2 (2020-2023). We are also grateful for the collaboration of the Comunidad de Regantes de la Sección II de las Marismas del Guadalquivir (Irrigation district of Guadalquivir Marshes). We also acknowledge financial support from the Spanish Ministry of Science and Innovation, the Spanish State Research Agency, through the Severo Ochoa and María de Maeztu Program for Centers and Units of Excellence in R&D (Ref. CEX2019-000968-M).

Glossary of symbols used

| Symbol |

Short description (units, if applicable) |

| bc

|

channel bottom width (m) |

| bt

|

throat bottom width (m) |

| Cd

|

discharge coefficient |

| Cg

|

shape coefficient |

| Cv

|

approach velocity coefficient |

| IF1

|

Froude number in the channel approach section |

| g |

acceleration of gravity (m/s2) |

| H/l |

head/throat section length |

| H |

sill referenced energy head (m) |

| h |

upstream gaged head (m) |

|

energy head when flow rate is QM for frictionless flow (m) |

|

m

|

energy head when flow rate is Qm for frictionless flow (m) |

| H0

|

specific energy head (m) |

| H1

|

upstream energy head (m) |

| H2/H1

|

submergence ratio |

| H2

|

downstream energy head (m) |

| Hc

|

critical energy head at throat section |

| HM

|

energy head when flow rate is QM for viscous flow (m) |

| Hm

|

energy head when flow rate is Qm for viscous flow (m) |

| Hn

|

new value of the energy head in the iterative process for flow rate calculation |

| L |

modular limit |

| l |

length of the throat (m) |

| m, n |

regression line fit coefficients |

| n |

Manning's roughness coefficient |

| p |

sill height (m) |

| pc

|

channel depth (m) |

| Q |

channel flow rate (m3/s) |

| Q’ |

new value of flow rate in the iterative process for flow rate calculation (m3/s) |

| QM

|

maximum flow rate (m3/s) |

| Qm

|

minimum flow rate (m3/s) |

| R |

hydraulic radius (m) |

| S |

channel slope |

| U1

|

velocity in the approach section of the channel (m/s) |

| Uc

|

critical velocity in the throat section (m/s) |

| y1

|

upstream hydraulic depth (m) |

| y1M

|

upstream hydraulic depth when flow rate is QM (m) |

| y1m

|

upstream hydraulic depth when flow rate is Qm (m) |

| y2

|

downstream hydraulic depth (m) |

| y2M

|

downstream hydraulic depth when flow rate is QM (m) |

| y2m

|

downstream hydraulic depth when flow rate is Qm (m) |

| yc

|

critical hydraulic depth in the throat section (m) |

| zc

|

channel side slope |

| zt

|

throat side slope |

| ΔH (=H2-H1) |

energy losses through the flume |

| θ/2 |

channel angle slope |

| ω |

channel cross-sectional area (m2) |

| ω1

|

flume approach section area (m2) |

| ωM

|

throat section area when flow rate is QM (m2) |

Glossary of subscripts used

| Subscript |

Short description |

| 1 |

upstream flume |

| 2 |

downstream flume |

| c |

channel |

| M |

maximum flow rate |

| m |

minimum flow rate |

| t |

throat |

References

- Ackers. P.; White, W.R.; Perkins, J.A.; Harrison, A.J.M. 1978. Weirs and flumes for flow measurement. John Wiley, New York.

- Bos, M.G (ed). 1978. Discharge measurement structures. International Institute for Land Reclamation and Improvement. Publication nº 20, Wageningen.

- Bos, M.G.; Replogle, J.A.; Clemmens, A.J. 1984. Flow measuring flumes for open channel systems. John Wiley, New York, 321 pp.

- Bautista, E.; Schlegel, J.L. Wahl, T.L.; Clemmens, A.J. Replogle, J.A. 2020. WinFlume 2.0. Software for design and calibration of long-throated flumes and broad-crested weirs for open-channel water flow measurement. Software and user manual. USDA-Agricultural Research Service (Maricopa, AZ) and USDI-Bureau of Reclamation (Denver, CO), USA.

- Domínguez, J.; Losada A.; Roldán, J. Alcaide, M.1984. Curvas de gasto para aforo modular. Instituto Nacional de Investigaciones Agrarias, Madrid, 81 pp.

- Ishfaq, M, Farroq, M., Zulfiqar, U., Hussain, S., Akbar, N., Nawaz, A., Anjum, S.A. 2020. Alternate wetting and drying: A water-saving and ecofriendly rice production system. Agricultural Water Management, 241: 106363. https://doi.org/10.1016/j.agwat.2020.106363. [CrossRef]

- Parshall, R.L. 1945. Improving the distribution of water to farmers by use of the Parshall measuring flume. Soil Conservation Service. Bull. 488. U.S. Department of Agriculture and Colorado Agricultural Experiment Station. Fort Collins, Colorado. [CrossRef]

- Roldán-Cañas, J.; Pérez Ardoy, F.J.; Moreno-Pérez, M.F. 2023. Design of a long-throated flume in a recirculating water channel of a rice field. Hydraulic Measurements & Experimental Methods Conference. EWRI. ASCE. Fort Collins, Colorado | June 25–29, 2023.

- Vantakhah, A.R. y Mahdvi, A. 2012. Simplified procedure for design of long.throated flumes and weirs. Flow Measurement and Instrumentation, 26:79-84. [CrossRef]

- Wahl, T.L.; Replogle, J.A.; Wahlin, B.T.; Higgs, J.A. 2000. New developments in design and application of long-throated flumes. Joint conference on Water Resources Engineering and Water Resources Planning and Management. Minneapolis, Minnesota. [CrossRef]

- Wahl, T.L.; Clemmens, A.J.; Replogle, J.A.; Bos, M.G. 2005. Simplified design of flumes and weirs. Irrigation and Drainage, 54:231-247. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).