1. Introduction

The reduction of fossil fuel usage in the future electricity grid is an important measure to alleviate global warming and strive to maintain temperature increases within acceptable thresholds in the future. This process is destined to happen through the advancement of pertinent renewable technologies and their widespread adoption, facilitated by initiatives such as new installations, the overhaul or decommissioning of antiquated fossil fuel-based power plants, and the establishment of a new grid architecture centered around renewable, distributed generation. This evolution may also usher in novel roles, such as those of prosumers, contributing to the diversification of the energy landscape.

It is widely acknowledged that the optimal functioning of renewable-based generation systems necessitates one or more renewable sources (e.g., Photo Voltaic (PV) panels, Wind Turbines (WTs)) integrated with storage solutions, efficient power conversion units, and complemented by digital technologies (including circuitry and software) for control and seamless interaction with relevant entities. In this scenario, the effectiveness of the deployed solutions in supporting or impeding the decarbonization of the electricity grid depends on their technological maturity.

Crucially, ensuring the expected quality of service from these systems is imperative, as any compromise in this regard could lead to significant systemic failures with far-reaching consequences. This risk becomes more pronounced in the context of small to mid-size installations, where larger penetration, cost constraints, and supply chain heterogeneity may introduce challenges not as prevalent in larger counterparts. As such, meticulous attention to the robustness and reliability of these renewable energy solutions is paramount for achieving a sustainable and decarbonized electricity grid.

While the existing scientific literature compiles a substantial number of publications focusing on specific components or aspects relevant to the topic, there is a notable lack of articles addressing the entire technological mix and beyond (i.e., namely, the conversion, monitoring and communication systems).

For instance, [

1] addresses renewable-based energy systems and presents a review of Machine Learning (ML) techniques for health monitoring. Thus, for instance, the relevant time-scales considered by the reviewed algorithms are larger than those considered by the contribution we propose. Further, the scope addressed is quite different from that of this paper because it reviews ML techniques aiming at health monitoring, while we propose a survey on anomalies and faults in renewable-based power systems not focusing on specific algorithms. In [

2] energy systems are still addressed nor the survey is focused on renewable-based systems. Rather, the Authors address Artificial Intelligence (AI) techniques for prognostic maintenance which is somehow related to anomalies and faults but it is not the main target. Power systems are addressed by the review in [

3] however only related to the electric part, while the article we propose reviews anomalies and faults that affect, e.g., also the communication systems in renewable-based power systems. In this regard, [

3] does not specifically consider anomalies and faults, nor renewable energy and generally targets ML applications in power systems. Renewable-based power systems are also addressed in [

4], however with the scope being restricted to those with a dominance of inverter and targeting cybersecurity instead of anomalies and faults in general. A survey on fault diagnosis in micro-grids can be found in [

5], thus it does not generally address power systems, renewable energy, and anomalies and faults; also it is not recent since it dates back to 2016. The same authors have already proposed a similar contribution in 2014 [

6], addressing faults and fault diagnosis. However, also this case move away from the focus we propose since only the electrical part is addressed therein. In [

7] a systematic review of faults that may arise in smart-grid is presented. But, the focus is not on renewable-based power systems. The paper [

8] does not focus on a unique system and addresses PV and WT renewable generation. However, for instance it does not include the hydrogen-related technologies, as instead this paper does, and in particular, electrolyzers and Fuel Cells (FCs). This is a major point, since hydrogen is identified as one of the main technologies for storing renewable generation and that will strongly support its diffusion in the future power systems. Furthermore, [

8] restrict its review to monitoring of fault conditions and not on the possible anomalies and faults that may instead happen. In [

9], the review targets fault detection methodologies and datasets in district heating substations, in [

10] the review addresses fault location and detection techniques in power distribution systems with distributed generation. In both cases the target system is more specific and the scope is not the same as with respect to what is proposed in this paper, and with the renewable generation not being considered at all.

Summarizing, the analyzed literature is either too specific, by restricting the investigation on particular instances of power systems (e.g., PV systems, district heating substations), with peculiar implemented software (e.g., AI) and hardware (e.g., inverter) technologies, and aim (e.g., fault location), and do not broadly gather the main renewable-based technologies in one self-consistent article with the focus on the possible anomalies and faults that may affect them. In particular, a substantial gap regards hydrogen technologies, monitoring and conversion systems, where reviews that considers them even within similar frameworks to that identified by this paper are basically missing.

The paper is organized according to the standard format of this journal, and the rest is as follows.

Section 2 reports some clarifications regarding the terms “anomaly” and “fault” as used in the specific context addressed and more broadly in the scientific/technical community, and the survey outcomes. In particular,

Section 2.2 addresses PV systems,

Section 2.3 addresses WTs,

Section 2.4 addresses electrolyzers,

Section 2.5 addresses FCs,

Section 2.6 addresses Battery Systems (BSs),

Section 2.7 addresses DC/x conversion systems,

Section 2.8 addresses monitoring systems, and

Section 2.9 addresses communication systems.

Section 3 concludes the paper.

2. Materials and Methods

The present article elucidates the primary causes of anomalous behaviors and malfunctions in specific systems, along with the accessibility of data for their characterization. To achieve this objective, technical-scientific literature and technical documentation (e.g., datasheets provided by manufacturers) for each relevant component has been systematically examined. This process aimed to identify the most prevalent types of malfunctions and the availability of simulated and/or experimental data for their characterization. In instances where such data was not readily available, a thorough exploration of mathematical models and/or empirical/simulative methodologies suitable for fault characterization has been conducted. To enhance the usability of the obtained results, they have been organized into tables.

2.1. Caveats

Before presenting the outcomes of the survey, some clarifications are needed regarding the terms “anomaly” and “fault”. In the scientific/technical literature, their meaning is debated and there is no unique understanding about. This is well reflected in how the subject is addressed by, e.g., IEEE and NASA, two prominent institution in the technical field. In the first case, IEEE Std 1044-2009 [

11] reports that <<

[...] The word `anomaly’ may be used to refer to any abnormality, irregularity, inconsistency, or variance from expectations. It may be used to refer to a condition or an event, to an appearance or a behavior, to a form or a function. The 1993 version of IEEE Std 1044 characterized the term `anomaly’ as a synonym for error, fault, failure, incident, flaw, problem, gripe, glitch, defect, or bug, essentially deemphasizing any distinction among those words. Such usage may be common practice in everyday conversation where the inherent ambiguity is mitigated by the richness of direct person-to-person communication, but it is not conducive to effective communication by other (especially asynchronous) methods [...]>>.

On the contrary, in the second case, NASA SP-2016-6105 [

12] reports that an anomaly is <<

[...] The unexpected performance of intended function.>> while a fault is <<

[...] A physical or logical cause, which explains a failure[...]>> and relies on how the question is addressed in [

13].

The existence of heterogeneous positions regarding the meaning attributed to the terms “anomaly” and “fault” is an element of ambiguity that, e.g., affects the definition of possible taxonomies aiming at the establishment of pertaining structured knowledge.

However, by considering that the surveyed literature makes no difference about the two terms and use both interchangeably [

14], in what follows, the same convention is kept without any further discussion. Yet, in a broad sense, this identifies a possible gap in the literature that could be filled by a specific contribution on the topic from interested fellows.

2.2. Anomalies and Faults in PV Systems

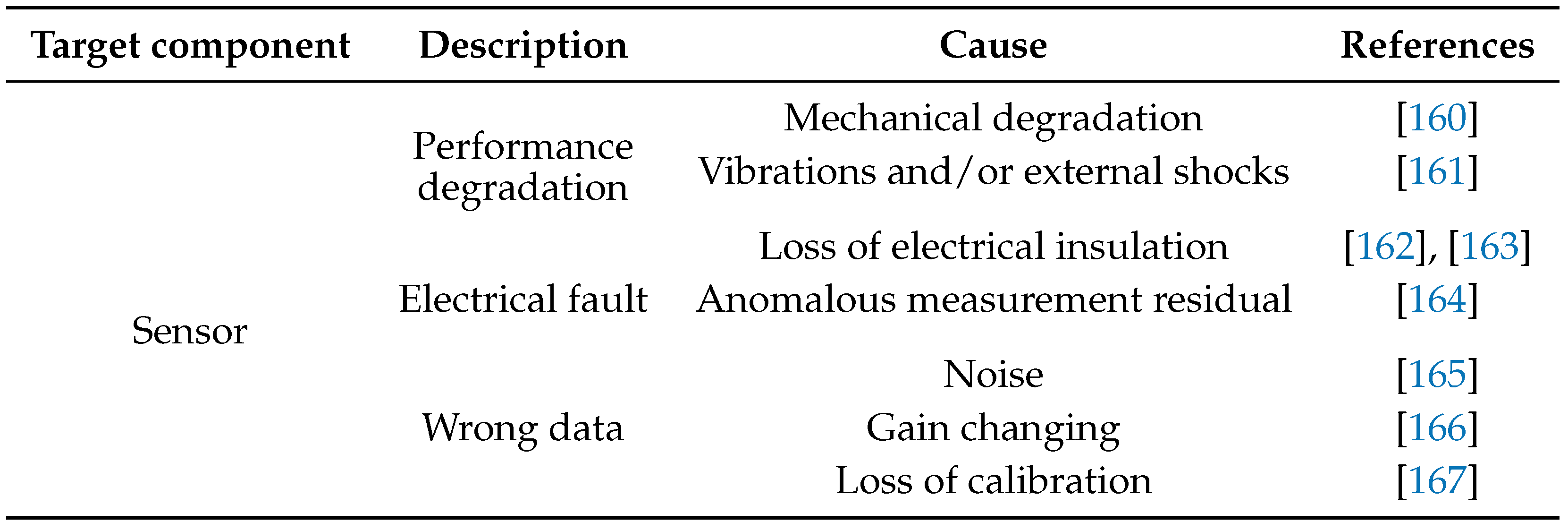

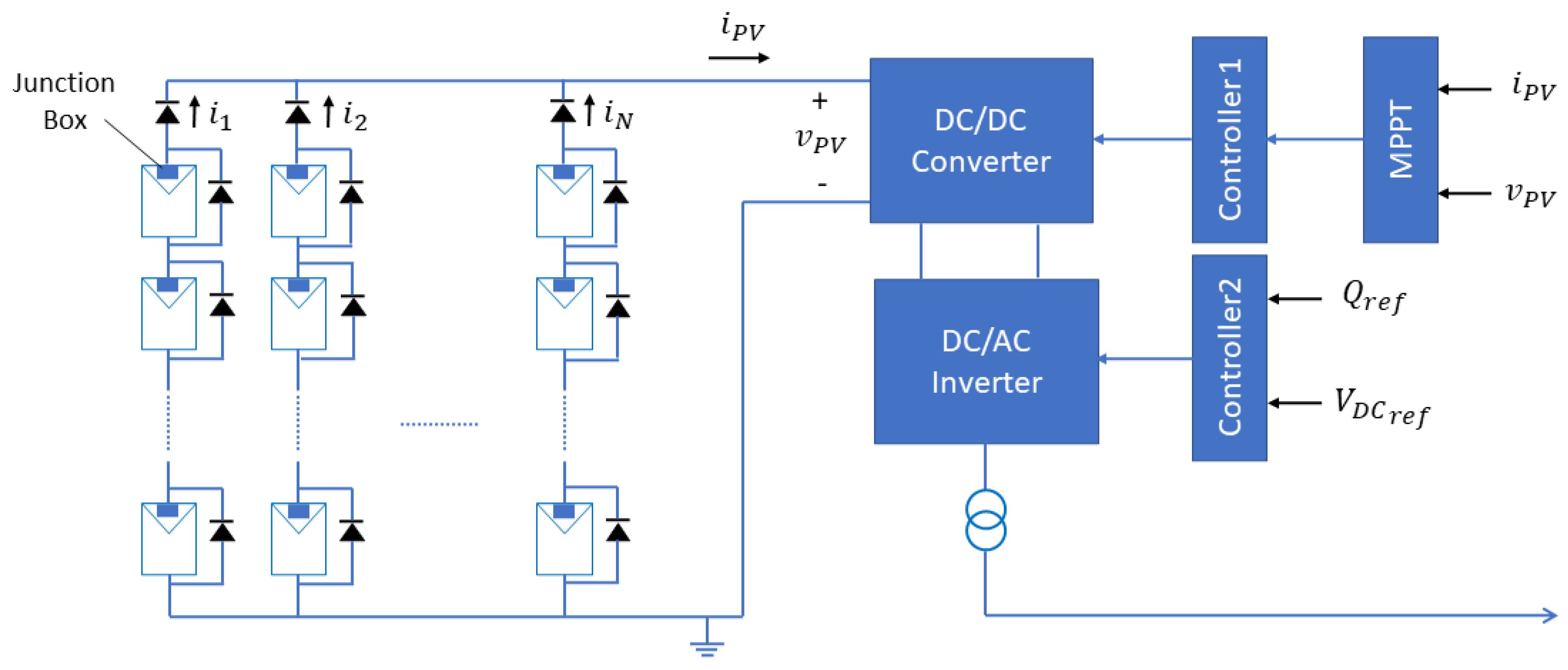

The survey focused on articles related to PV systems (as shown in

Figure 1), composed by several PV modules organized in strings in diverse configurations. The DC power generated by the photovoltaic array is directed towards the DC/DC converter. The voltage and current readings are continuously monitored and adjusted within the Maximum Power Point Tracking (MPPT) to maximize the output power. Subsequently, the output from the DC/DC converter is sent to the DC/AC inverter and then to the grid (for grid-connected PV systems). Prior to entering the grid, the inverter’s output is directed through a low-pass filter leaving only the fundamental frequency of the utility grid (typically 50 Hz or 60 Hz). Filtered signal then passes through a step-up transformer before being injected into the utility grid. Sometimes, an electricity storage is also paired, whilst this is neglected since it is separately addressed in the following sections.

2.2.1. Research Highlights

The analyzed literature encompasses a diverse array of instances, wherein anomalies/faults can be attributed to varied and heterogeneous origins. Broadly, an absence of uniform taxonomy emerges among different authors, potentially stemming from the intricate interplay of contributing factors, more realistically manifesting in a domino effect. Authors of [

16] groups PV anomalies and faults in three categories: internal, external, and electrical.

The internal faults are localized inside the PV module (e.g. under the protective glass, on the strings, on PV cells, etc.). The main internal faults are short circuit, bridging, fault to bypass diode and open circuit [

17,

18,

19]. The main causes of these type of faults are manufacturer’s defects, subpar fabrication quality, packaging inadequacies, and improper wiring and have a dramatic impact on PV system. In particular: short circuit entails the failure to supply power to the DC load or the power conditioning unit; bridging results in a complete absence of power output; bypass diode fault manifests as an incapacity to mitigate hotspot events; open circuit fault leads to the incapability of delivering power to the DC load or the power conditioning unit leading to a partial blackout or to a not homogeneity in the power production [

16].

The external anomalies and faults are located outside the PV module and usually are due to the environmental condition, natural disasters but also to wrong packaging, installation, etc. Since PV systems are located outdoors, they frequently encounter environmental stress as high temperatures, rain, snow, and the PV system does not operate under Standard Test Conditions (STCs), thus failing to achieve their nominal power. Since variations in solar irradiation directly impact the power generation of PV systems [

20], with the consequent uncertainties that must be carefully considered [

21], certain areas of PV arrays could yield higher power output compared to others (mismatch) due to non-uniform shading from physical obstructions like trees, buildings, and overhead power lines, etc. [

22,

23]. Additionally, environmental factors such as dust accumulation, bird and leaf droppings could lead to a partial shading condition [

24,

25]. Furthermore, natural disasters like lightning and storms [

26] can have dramatic consequences on the PV modules. Some of the faults listed before are temporary because they are reversible (e.g., partial shading, dust accumulation, etc.). Permanent mismatch faults, instead, are irreversible and can be related to poor soldering, module degradation, glass breakage, and structural defects due to improper manufacturing processes or environmental conditions like heavy snow loads or frequent temperature fluctuations [

27,

28]. Since the external anomalies and faults are very diverse the severity of the related damages vary as well, going from a non homogeneous power production to a complete blackout [

16].

The electrical faults are related to the perturbations to variables as voltage, current, power, etc. The main electrical faults are the ground faults, line-to-line fault, and arc fault [

29,

30]. These faults can have dramatic consequences as electrocution of operators or great damage to the equipment as a fire [

16]. Finally, other faults can affect other parts of the PV system as MPPT [

31], inverter [

32].

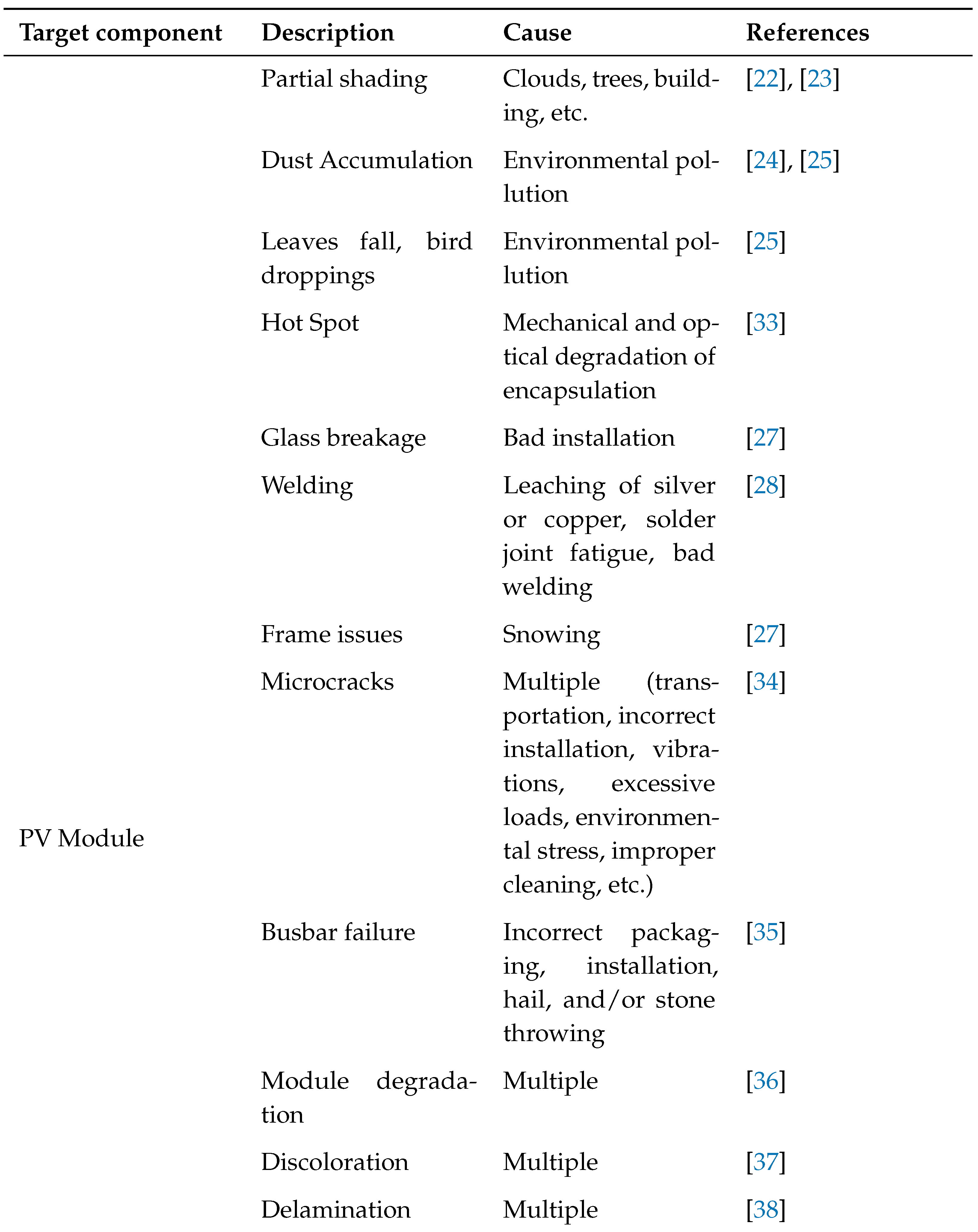

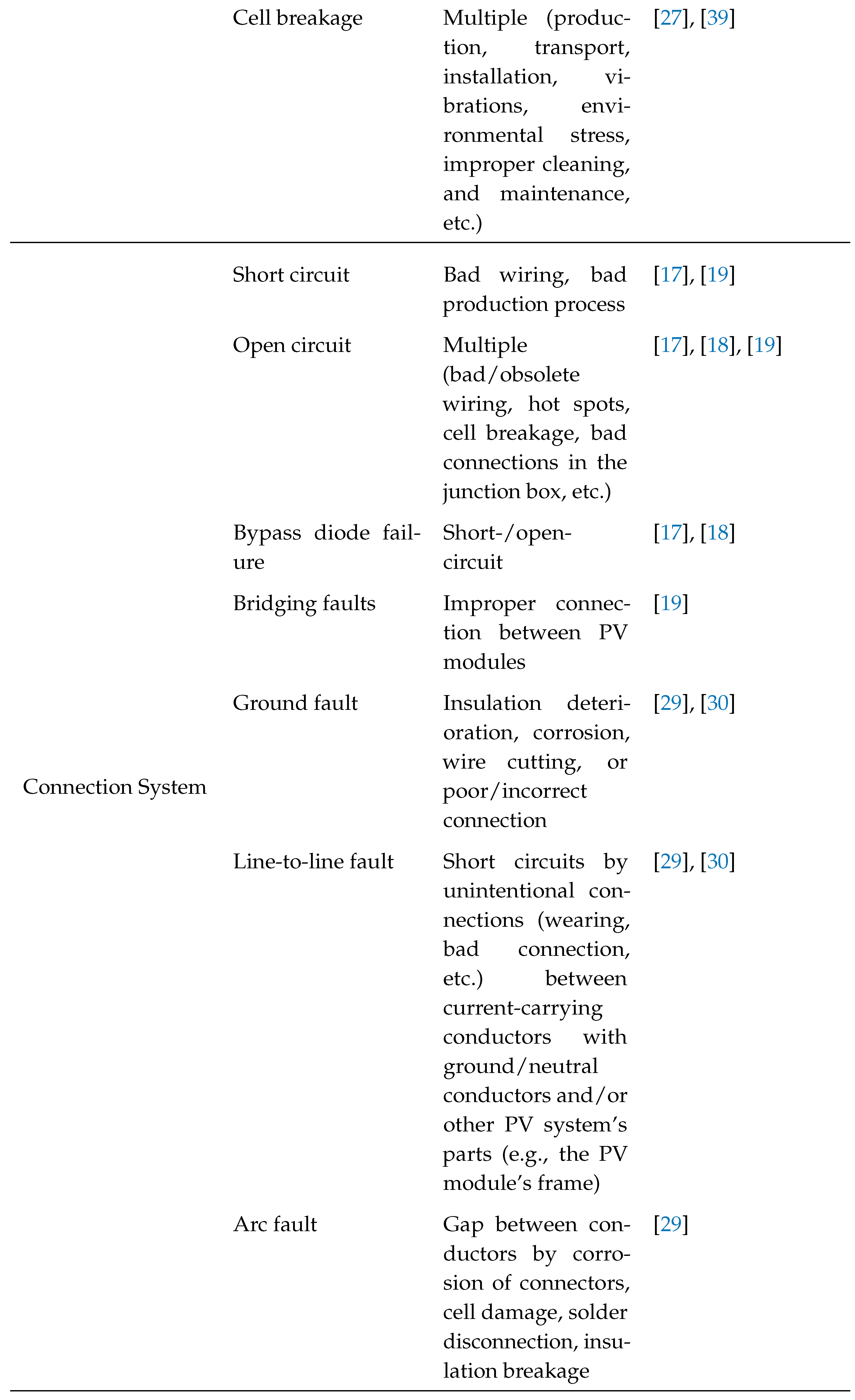

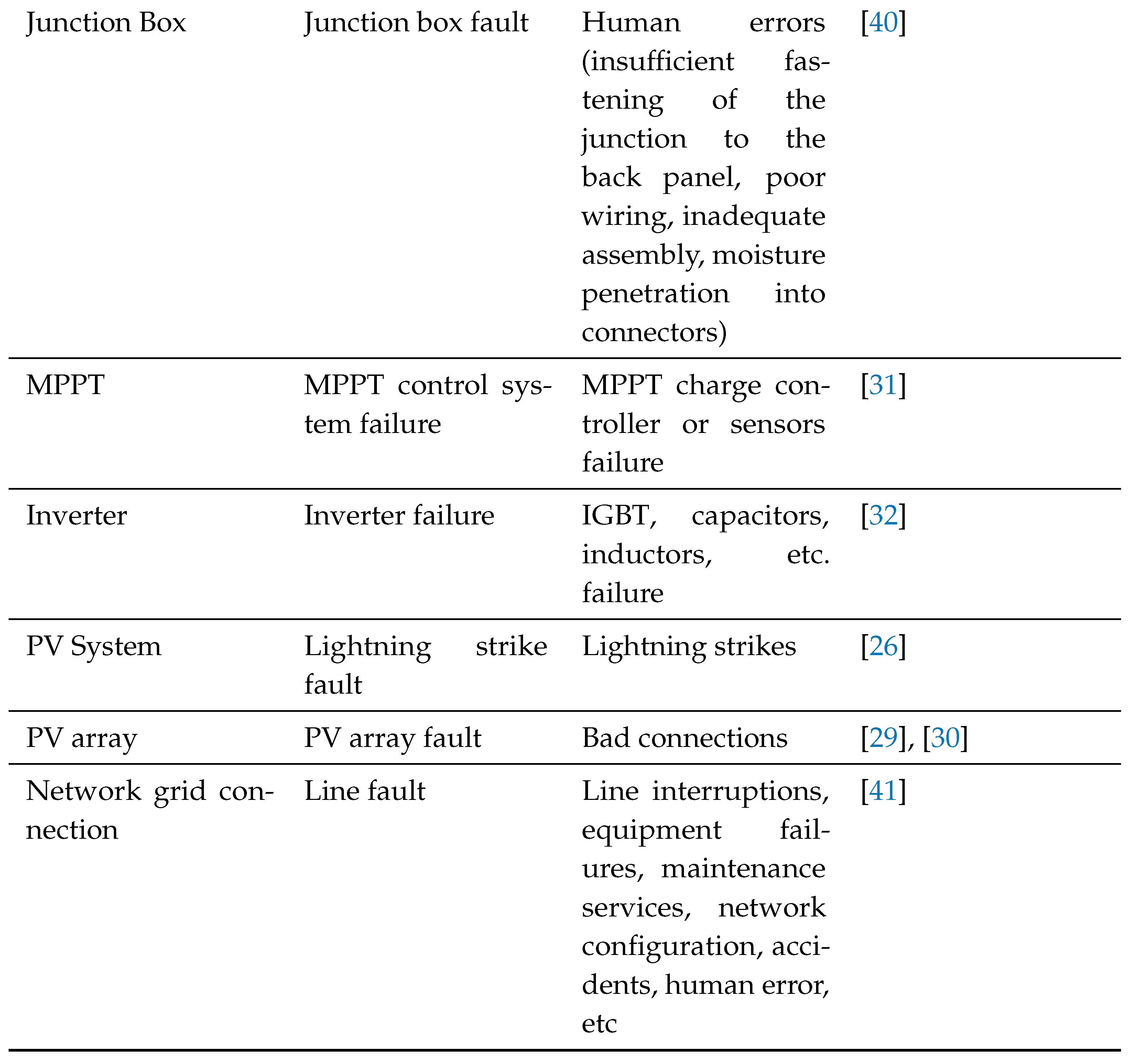

The results of the survey are presented in

Table 1, where the first column specifies the target component, of the system at hand, subject to anomaly/fault, the second column reports a description of the anomaly/fault considered, the third column specifies causal factors, and the fourth column compiles bibliographic references. All similar tables, i.e., related to literature findings about the other systems addressed by this paper, are organized with equal column names.

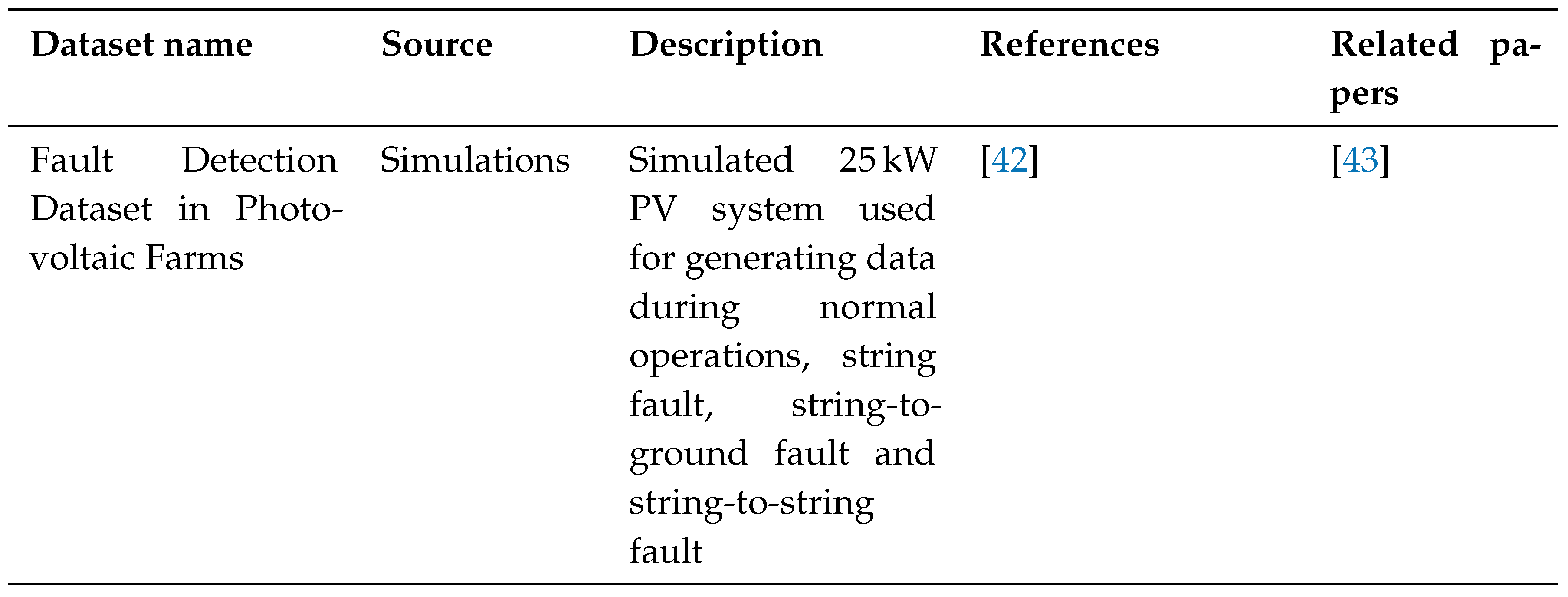

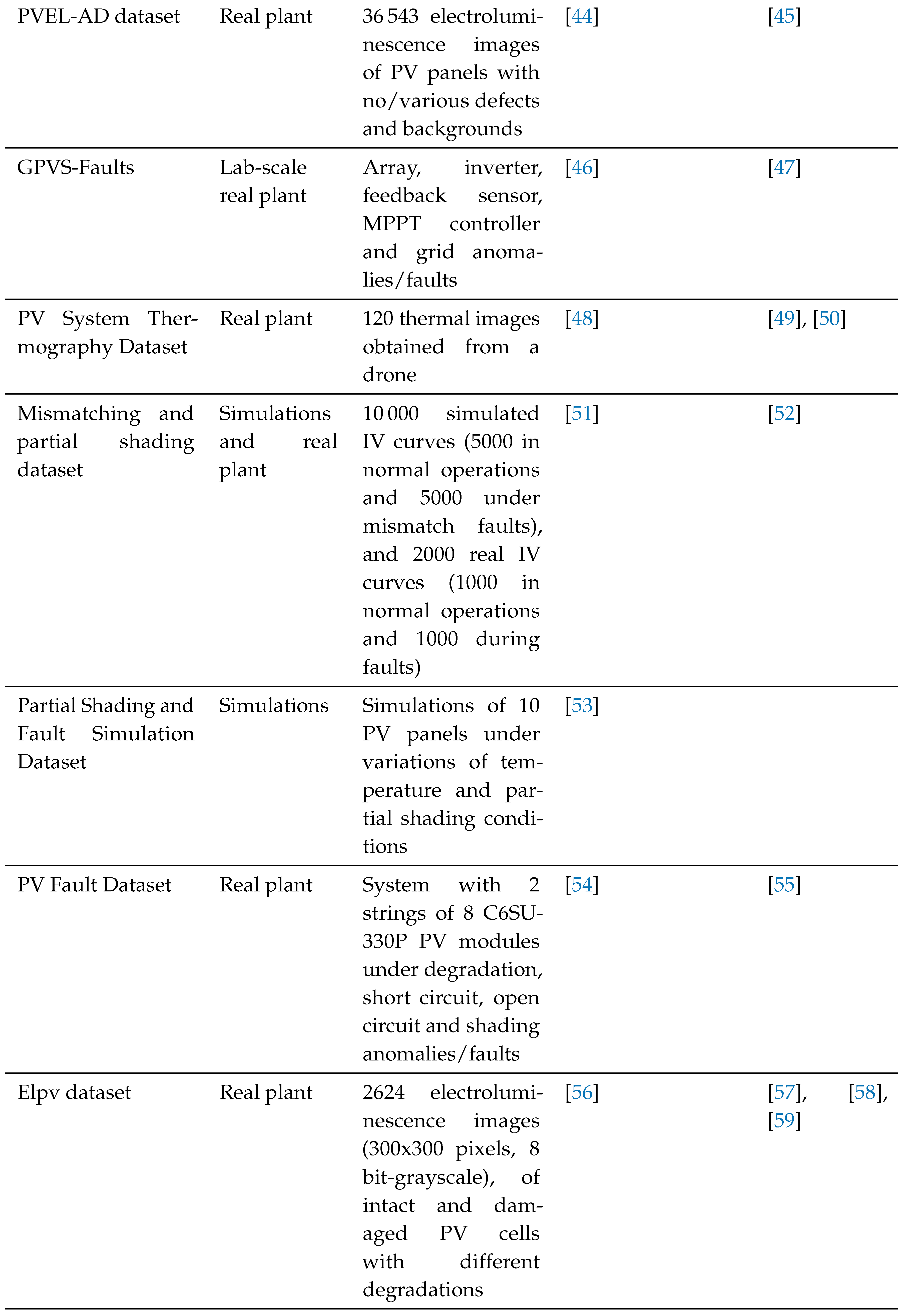

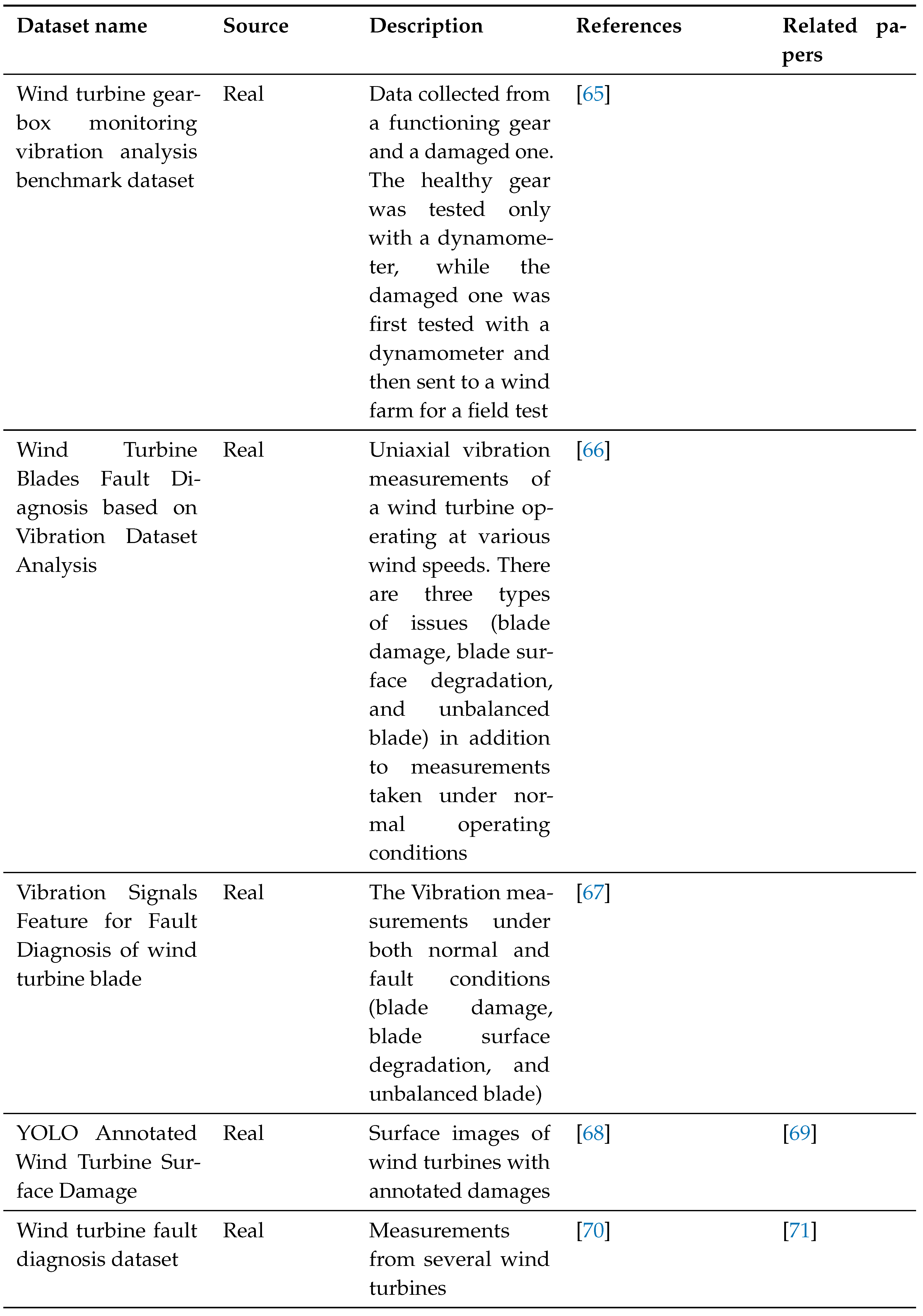

The literature also offers several datasets, summarized in

Table 2, obtained from experimental measurements of real plants or simulated through mathematical models and, in some cases, the anomalies are also simulated. The first column reports the dataset name as specified in the referred online resource, the second column allows to specify, e.g., whether the provided data are from real plants/systems, simulations, lab-scale installation or others, the third column describes the dataset, the fourth column reports the bibliografic reference and the fifth column reports possible other references of papers that the authors of the dataset ask to cite. Also in this case, all other tables related to the datased of the other systems addressed by this paper, are organized with equal column names.

2.3. Anomalies and Faults in Wind Turbines

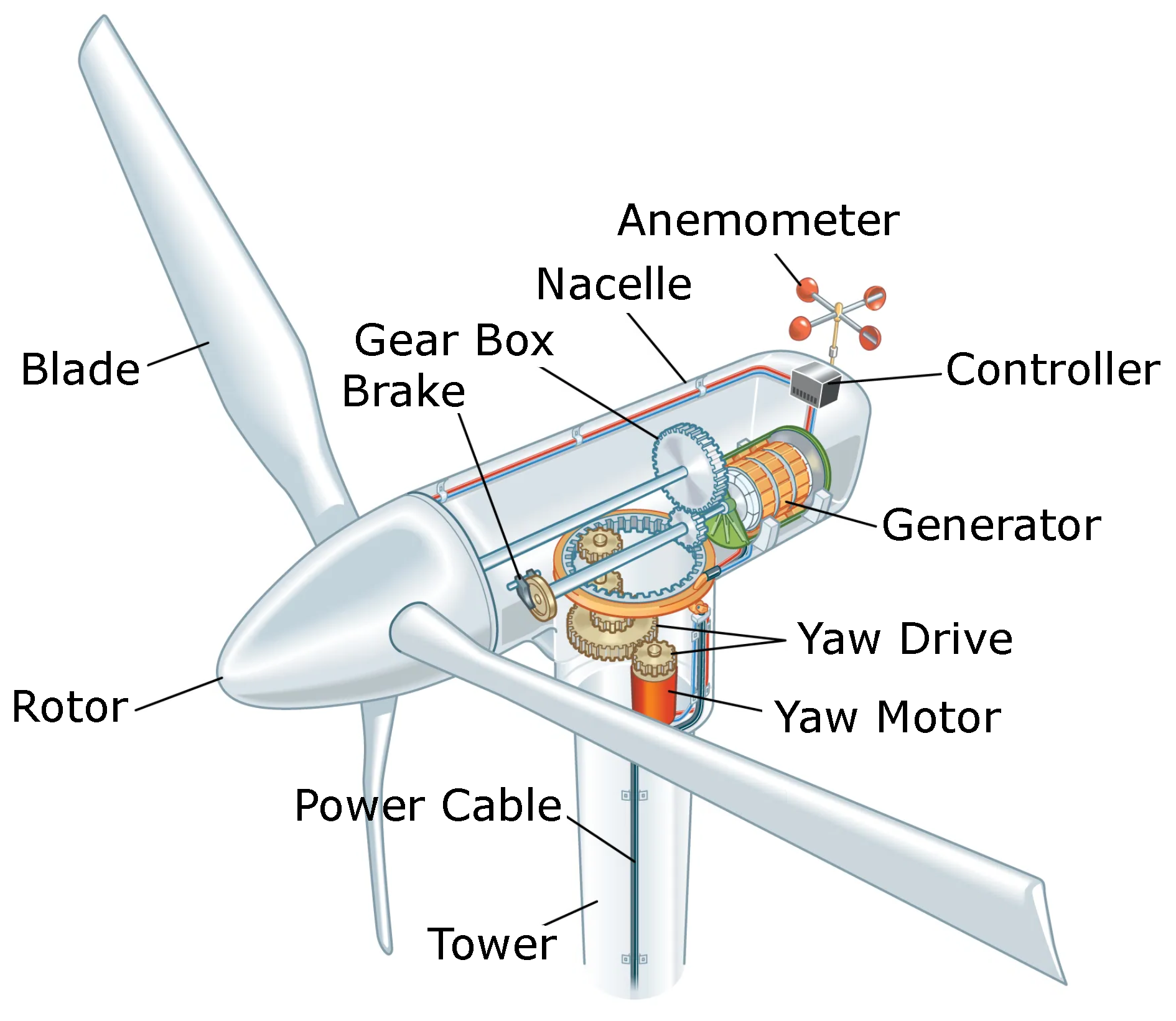

The surveyed literature targets WTs as depicted in

Figure 2. The blades transform the kinetic energy of the wind in a rotation movement applied to the rotor and, through a generator, in electricity. There are two main types of WTs, Vertical-Axis Wind Turbines (VAWTs) and Horizontal-Axis Wind

Turbines (HAWTs) as the one described in

Figure 2. HAWTs are the most common and usually consist of two or three blades, or a disc containing several blades. On the other hand, VAWTs are designed with blades that rotate around a vertical axis, thus being able to harness wind blowing from any direction.

2.3.1. Research Highlights

In [

62] authors present several statistics of anomalies of different constituting components of the WT. Some of them have a higher median failure rate (electrical components, control system, pitch system, blades, hub), while others have a higher median downtime (transmission, system, shafts, bearings, structure). Failure rates for offshore installations are generally higher than those for onshore installations, even because they are under more critical operating conditions (e.g., higher wind speed, corrosive action of sea salt, etc.). Downtime in offshore installations, given logistical difficulties, is generally higher than that in onshore installations.

In general, technical-scientific literature provides numerous works on WT diagnostic systems [

63,

64] but provides few details about the different type of faults and anomalies that can occur in WTs, except for the already mentioned work on the statistics [

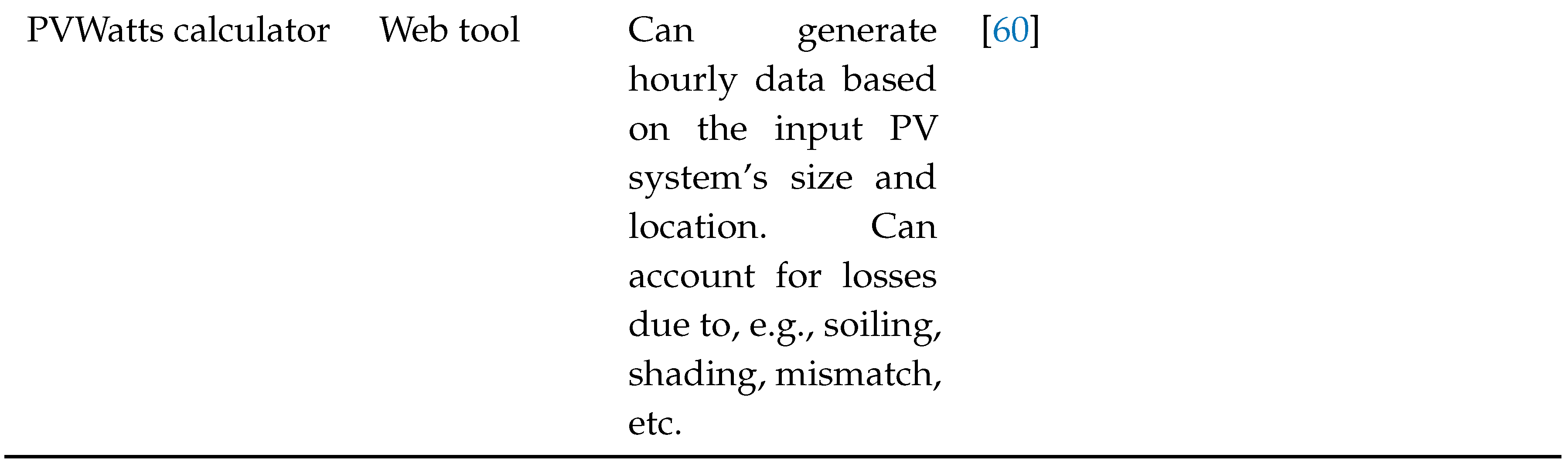

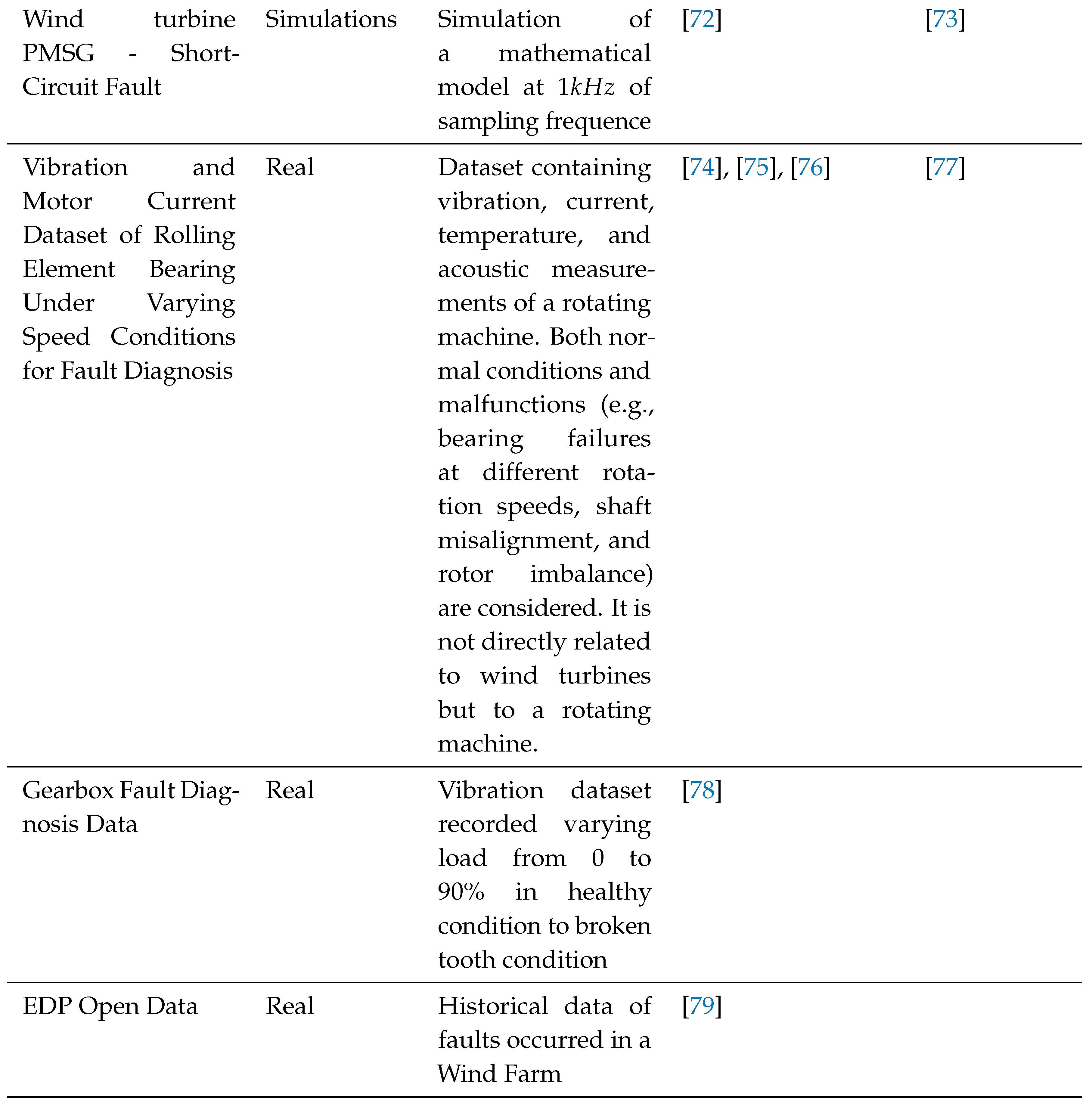

62]. Moreover, there are several datasets containing the real and simulated data related to the WTs and are listed in

Table 3.

2.4. Anomalies and Faults in Electrolysers

In the recent years, the water electrolysis is the most considered way for the eco-friendly hydrogen production, in particular, whereas energy input for the process is achieved by renewable sources. The basic reaction of water electrolysis is expressed in (

1) [

80].

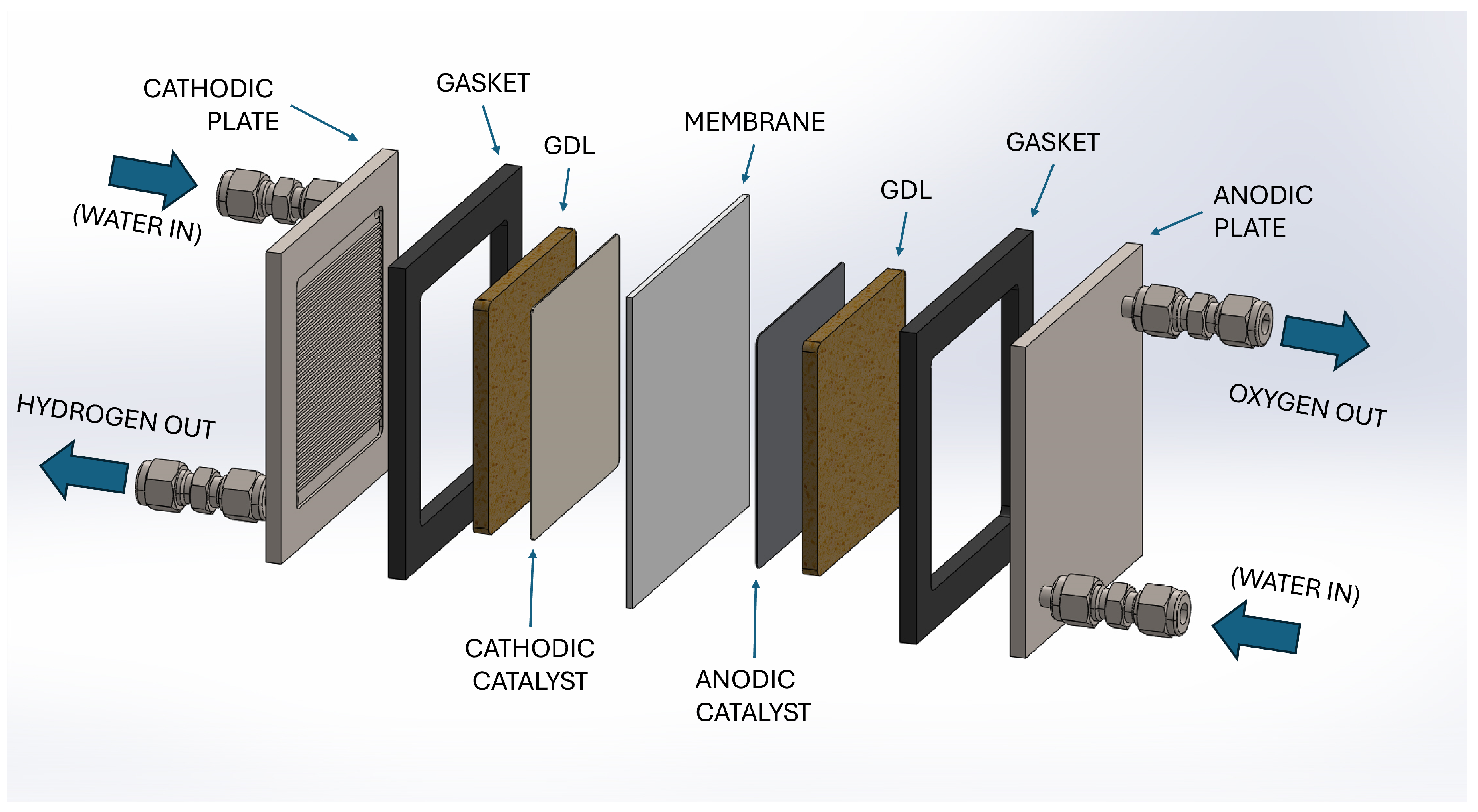

The electrolyser is the device in which the process is host, the main part of which is the electrolytic cell, in which the electro-chemical reaction takes place. A typical electrolytic cell representation is reported in

Figure 3. From an overall point of view, the cell is composed by two bipolar plates (anodic and cathodic), in which the water is fed and at which the electrical potentials are applied. The crucial component of the cell, that characterizes the cell typology, is the electrolytic membrane, that separates the anodic zone from cathodic zone, allowing the selective cross-over of a specific ion through it. Moreover, the Gas Distribution Layer (GDL) aims to allow an uniform access to the gas from the anodic or cathodic plates towards the membrane. The GDLs terminate with a catalytic layer, devoted to promote the chemical reactions hosted at anodic or chatodic sides. The nature of the catalyst depends on the typology of reaction to be promoted: for example, in a Polymeric Electrolyte Membrane (PEM) electrolyzer, at the anodic side, catalysts based on ruthenium and iridium are widely used [

81] to promote the water splitting in H

+ protons and OH

- anions, while at cathodic side platinum nanoparticles (dispersed on carbon supports) are mainly employed to promote the protons reduction to hydrogen [

82].

2.4.1. Research Highlights

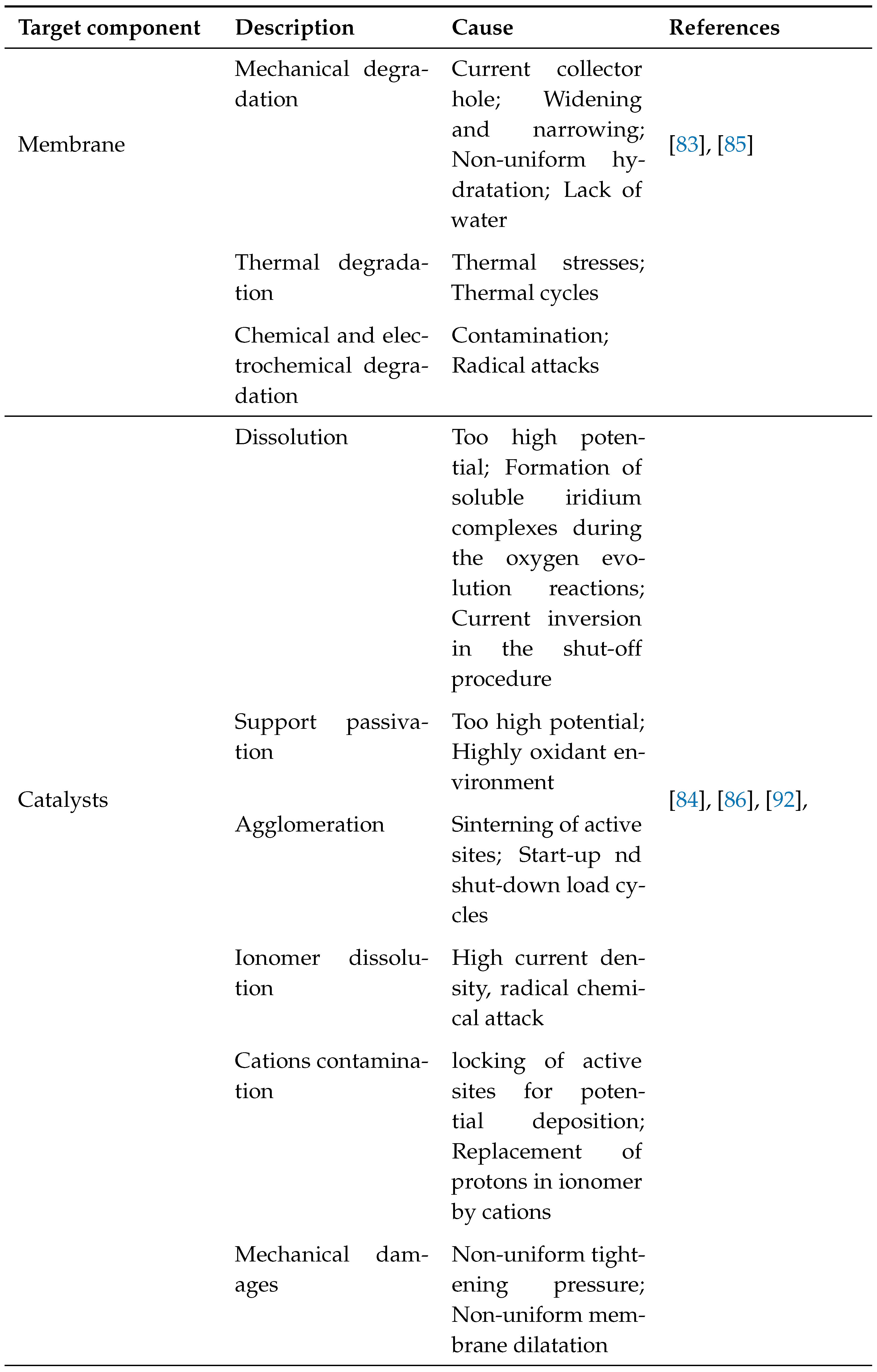

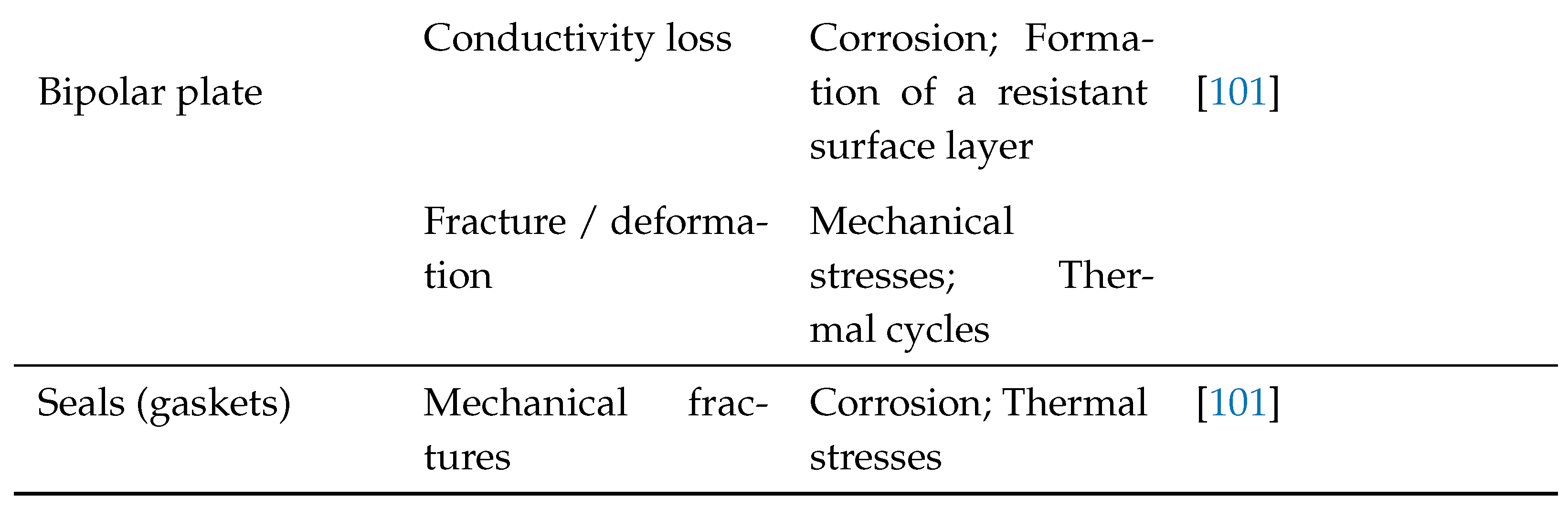

The survey’s outcome is summarized in

Table 4. Notably, the analysis reveals that predominant failure causes are associated with the membrane and catalyst, with occurrences of failures in bipolar plates and current collectors being comparatively infrequent. Membranes failures are typically associated to aging and cracking mainly due to fabrication defects or due to thermal, mechanical and chemical stresses in normal and severe operating conditions. Mechanical failures, including cracking, perforation or pinholes, are due to abnormal stresses or other mechanical factors, such as temperature, humidity, start-up and shut-down cycles, operating conditions fluctuation and warm-up/cool-down procedures [

83]. Temperature anomalies could increase membrane failure rate up to 2 order of magnitude when operating T increases from 55°C to 150°C [

80]. Impurities could also result in membrane degradation [

84,

85], often due to catalyst corrosion [

86]. Moreover, radical attacks are responsible for membrane degradation [

80]: the phenomenon is more promoted for low current density [

87,

88], since a faster membrane thinning could be observed [

89]. It is however worth noting that temperature effect is more severe with respect to the operative current density [

88]. Catalyst degradation is a very slow process, thus is not responsible for sudden cell failure. Among typical catalyst deactivation mechanisms, most common are particles dissolution and migration, sintering, catalytic layer detachment and support passivation [

90]. A more common phenomenon is the catalytic particle dissolution and the consequent penetration in the membrane lattice, affecting its functionality [

80,

86]. Another mechanism is the catalyst passivation, due to the oxidation of the catalytic support at the anodic side, thus reducing the electron flux between support and the anodic plate. One of the most common deactivation mechanism is the catalyst sintering, since high temperature could cause the catalytic particle agglomeration, resulting in a reduced catalytic activity [

91]. Finally, catalytic poisoning due to impurities in the water or metallic dissolution in bipolar plates are responsible for a (more or less) transitory catalytic deactivation, since impurities occupy active sites [

92]. Diverse diagnostic approaches are deployed, with the most cutting-edge methodologies involving statistical techniques grounded in neural networks. These, however, necessitate extensive historical or synthetic device data, leading to prolonged characterization times. In contrast, conventional methods relying on electrical and electrochemical measurements, while more practicable, exhibit a more confined capacity for fault identification.

The investigation on possible empirical dataset pertaining to electrolyser failures highlighted a consistent lack in this regard. For this reason,

Table 5 actually compiles only mathematical models that can be used to achieve synthetic datasets anyway.

2.5. Anomalies and Faults in Fuel Cells

A FC is a device able to generate electricity by exploiting electrochemical potential of oxidation-reduction reactions. In a general overview, reactants are basically a fuel and an oxidant: in particular in the case the fuel is the hydrogen, and the oxidant is oxygen (or air), the reaction, summarized in (

2), is able to generate electrical power and heat, by resulting in water as the only side-product.

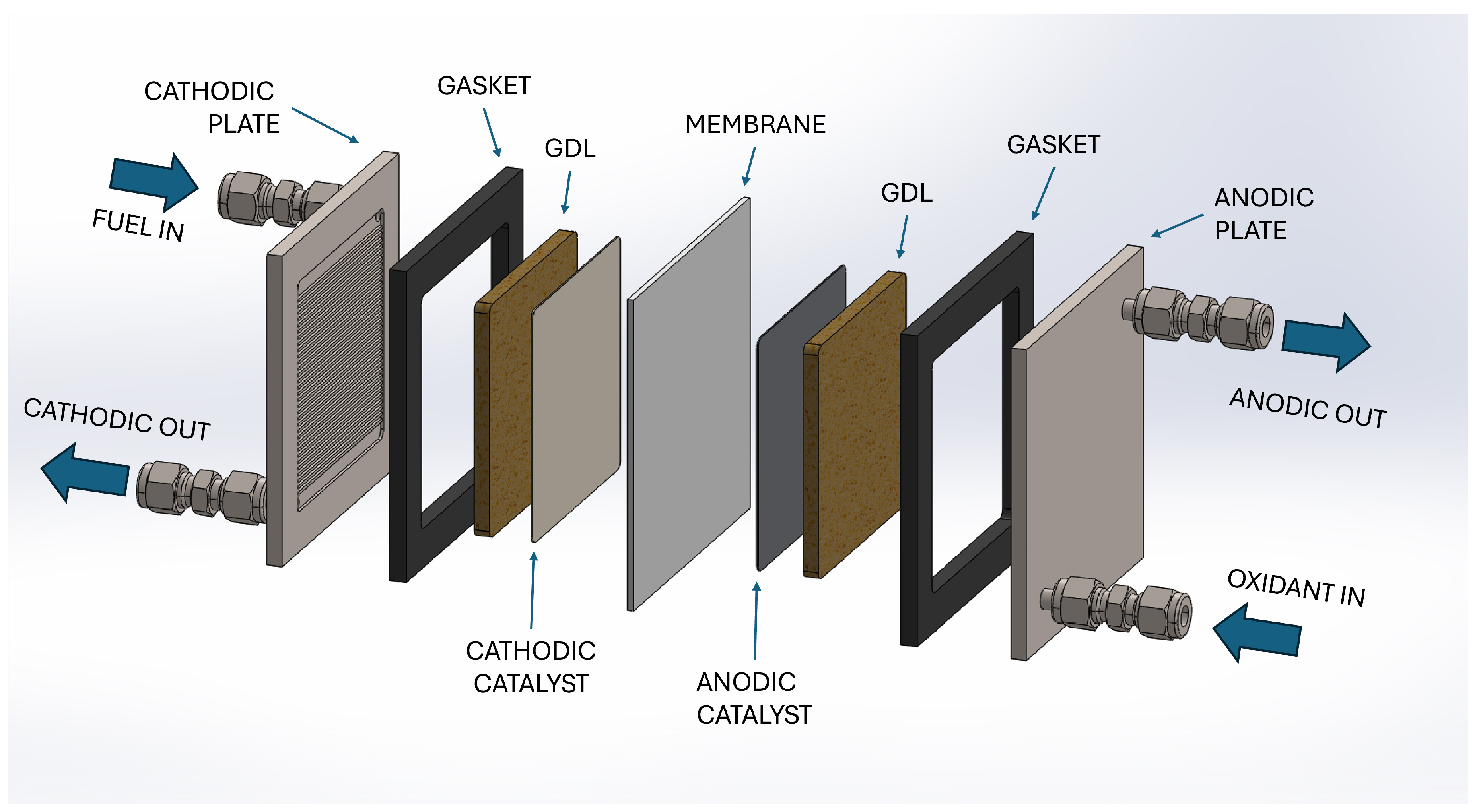

Of course, depending on the employed FC typology, methane, ethanol, carbon monoxide or other hydrocarbons can be used as fuels, and carbon dioxide can be used as oxidant. In a global point of view, a FC is an electrolytical cell (similar to cells used in electrolysis) able to intercept electrons involved in the oxidation-reduction reactions, thus forcing electrons flux in an electrical circuit, thus generating electrical power. FC elements are reported in

Figure 4. Main components of the cell are the same already described for the electrolyzer: fuel is fed to the cathodic plate, while oxidant is fed to anodic plate: bipolar plates also act as electrical collector. Reagents are delivered to the catalytic layers through dedicated gas distribution layer; on the catalytic surface, the chemical reactions take place, which mechanism strictly depends on the cell typology. The membrane separating anodic and cathodic sides act as a selective barrier, aiming the cross-over of only a selected ion depending on the hosted process: in the case of PEM-FC, membrane only allow the proton (H

+) crossing.

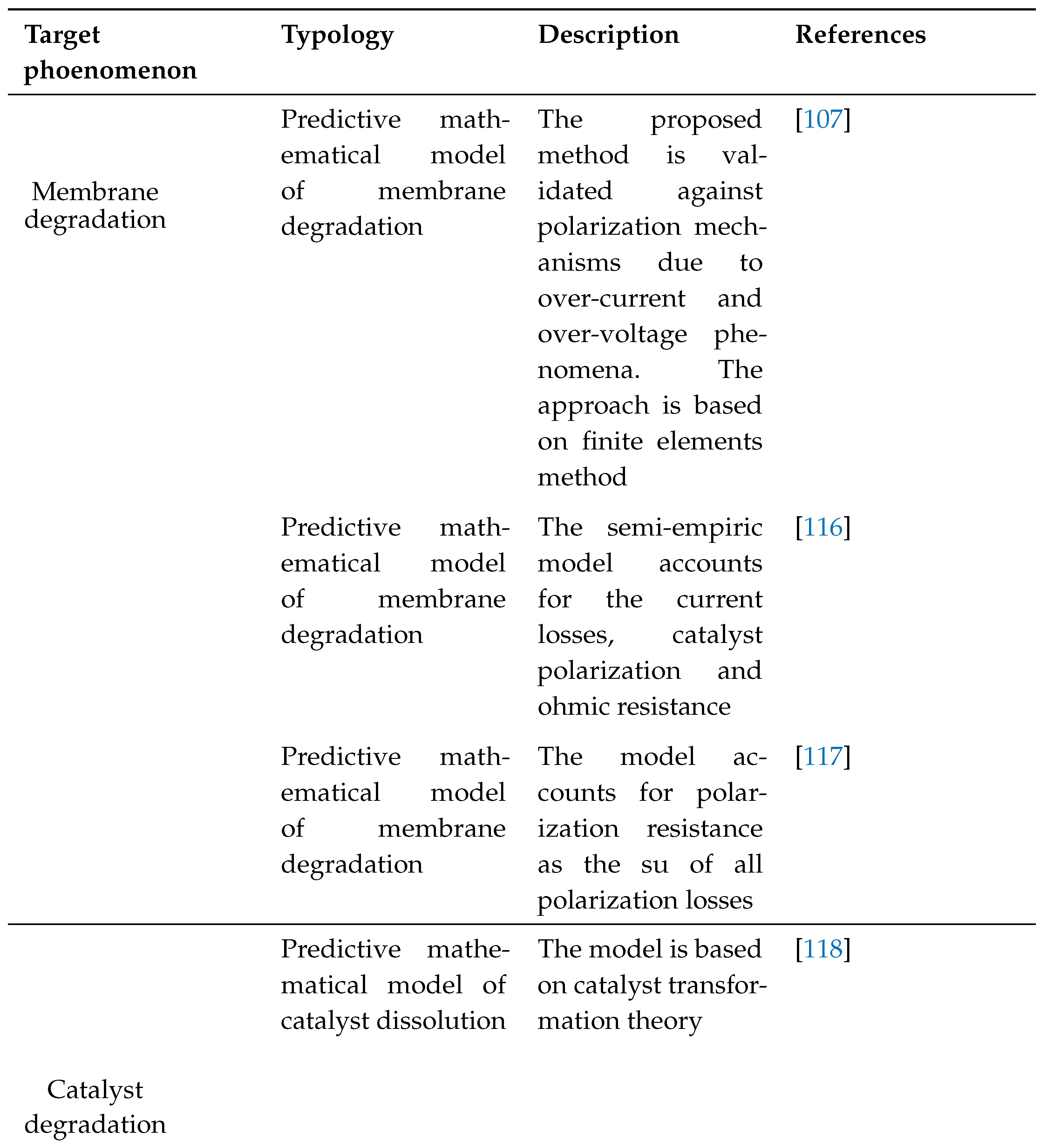

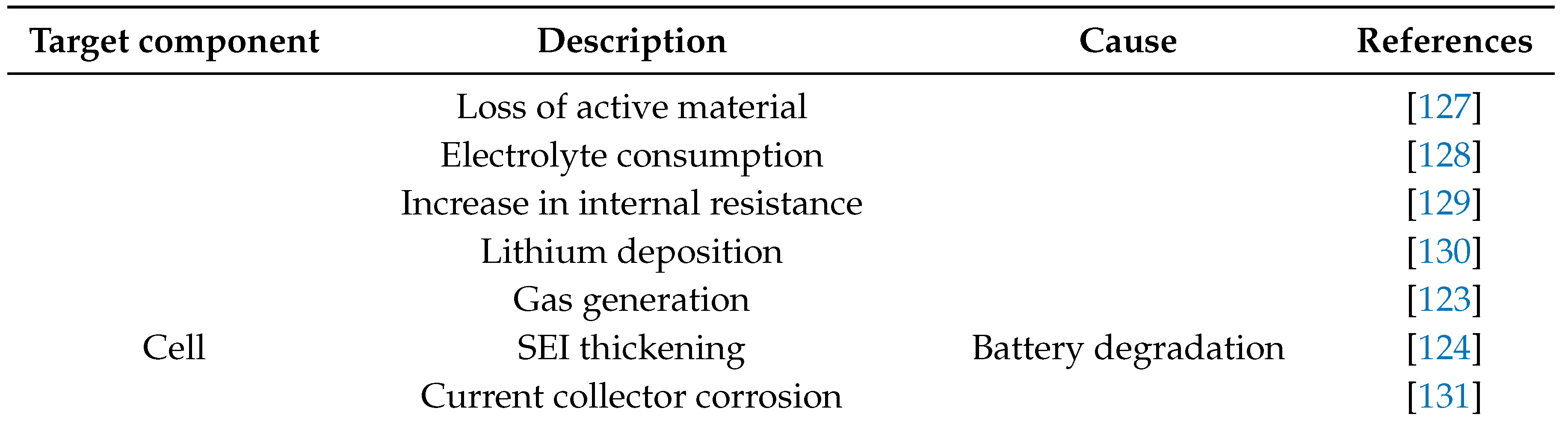

2.5.1. Research Highlights

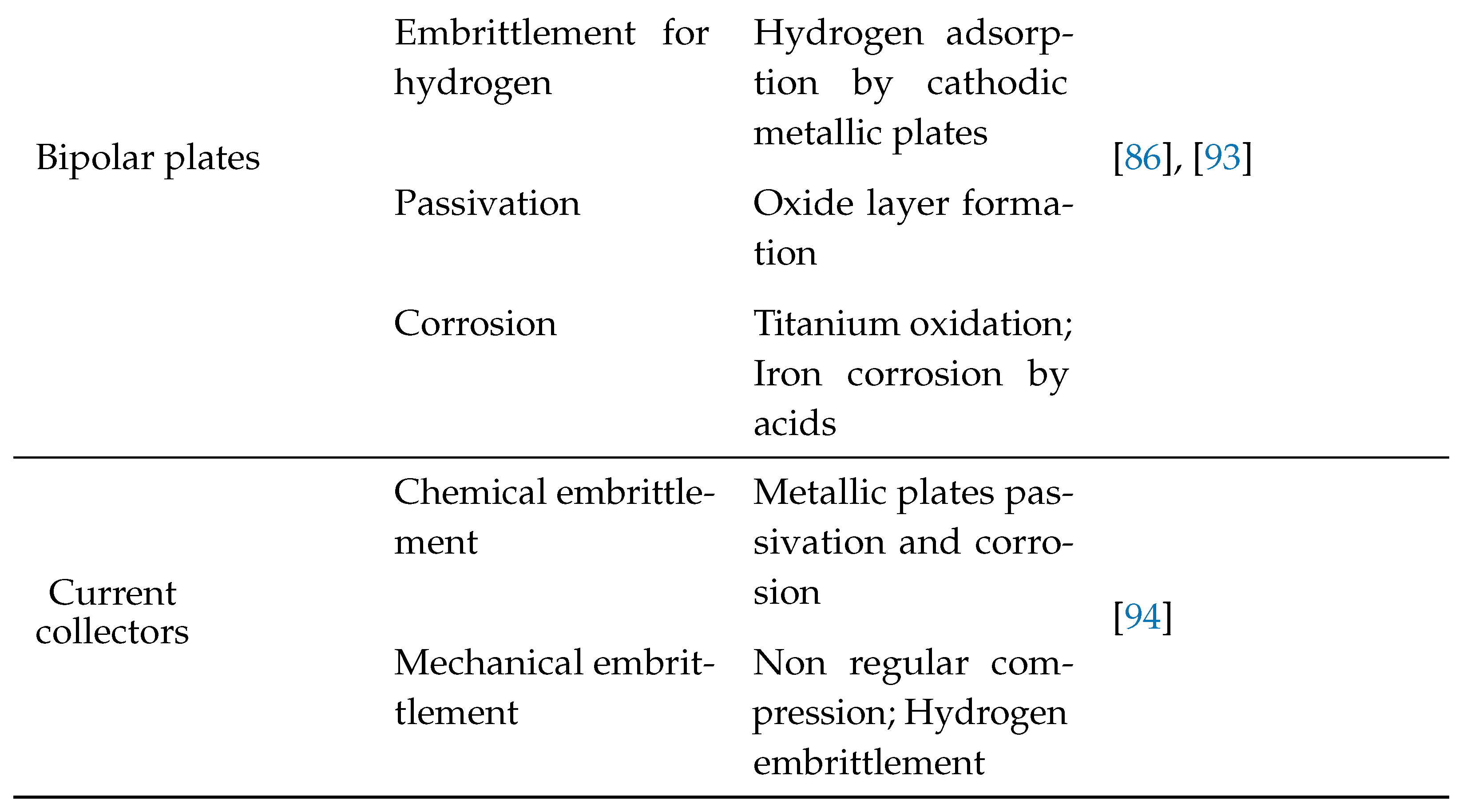

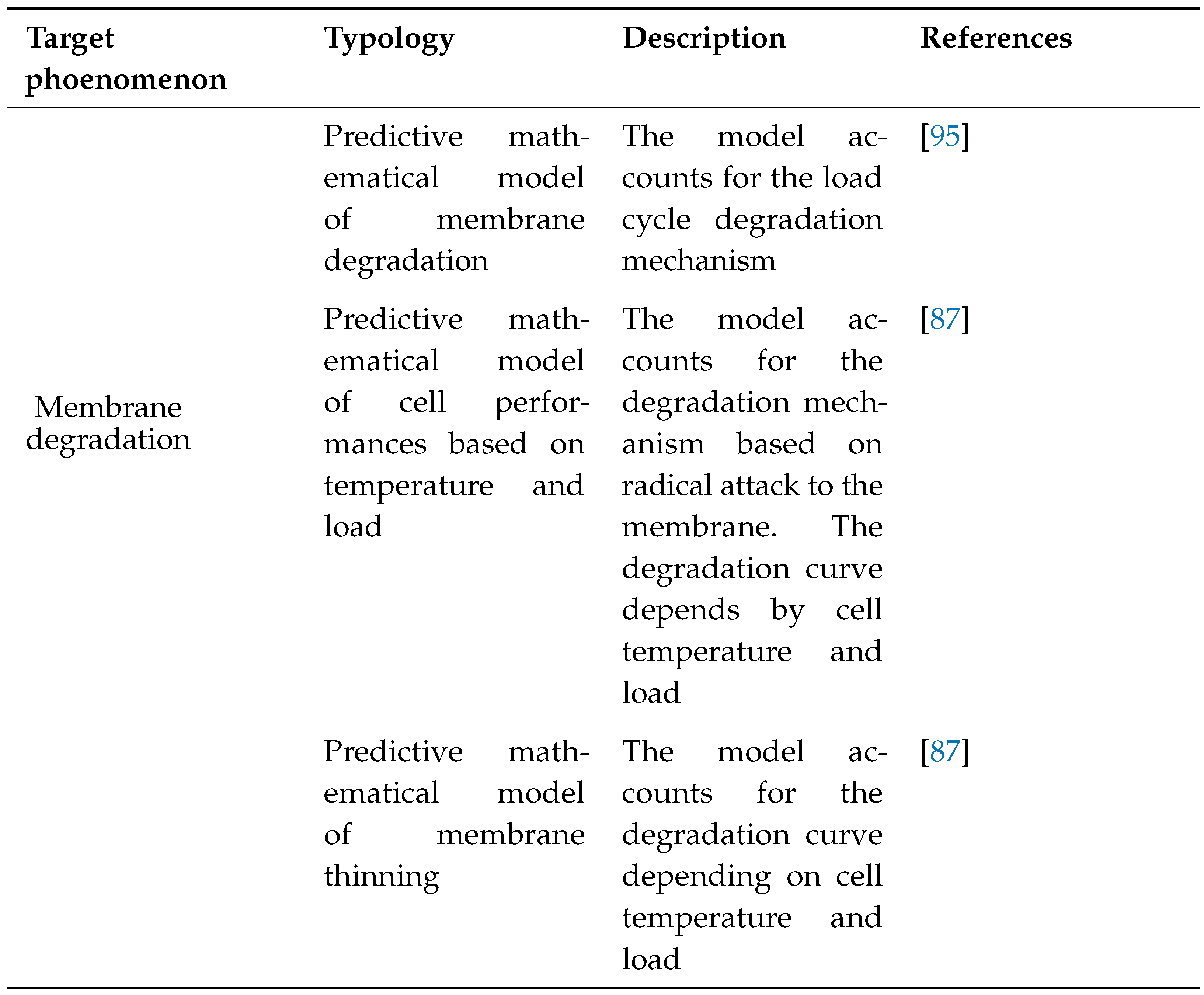

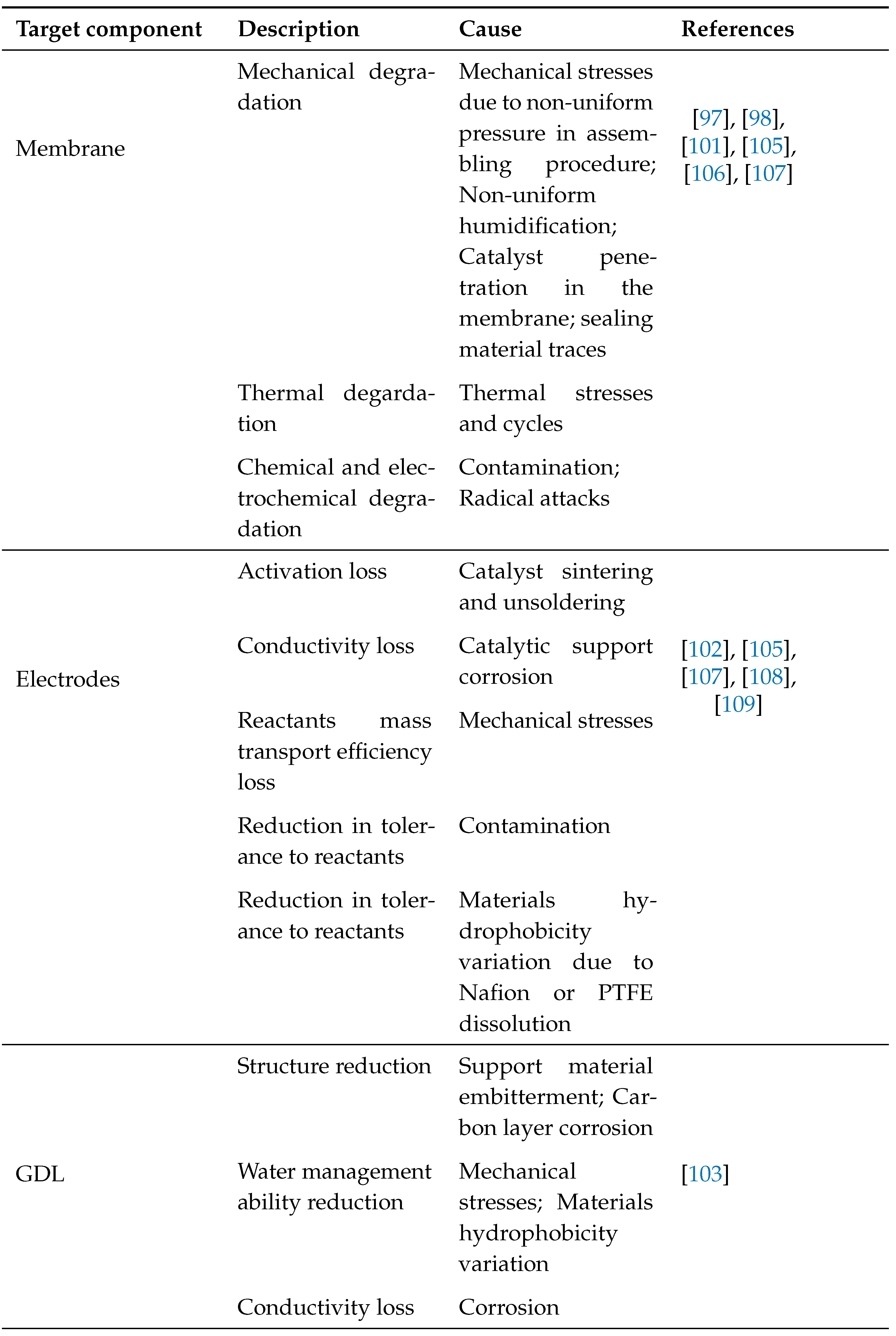

The survey’s outcome is summarized in

Table 6 and shows that the most fragile components are the membrane and the catalyst, accounting for 95% of malfunctions. As mentioned for the electrolyzers, membranes can suffer for cracking or perforation due to uncontrolled humidity or temperature in the process, that originates to tensile, mechanical and thermal stresses responsible for the failure of the component [

96,

97], causing the reactants crossover and in turn the uncontrolled fuel combustion [

98]. It is worth to underline that such events are more frequent in the early period of the cell lifetime [

99]. Membrane degradation can moreover be originated by peroxyl and hydroxyl radicals attack, particularly in low current conditions: under such conditions, PEM membrane could release fluorides, thus undergoing to a weakening that leads to the membrane failure [

100,

101]. The second reason for FC failure is catalyst degradation: it could occur for particle sintering [

102], carbon monoxide poisoning [

103] or carbon support oxidation [

104]: these failure mechanisms are responsible for a more or less severe activity reduction of the device, rather than a real cell service interruption. Some phenomena such as corrosion or mechanical stresses could occur also at the GDL [

103] and bipolar plates [

101] causing conductivity loss and structure deformation or fracture. GDL can also suffer for embrittlement of the support material due to severe operating conditions as well as to the contact with hydrogen. Finally, non-adequate operating conditions, in terms of temperature or pressure, as well as factory defects, can be responsible for sealing failure originates by mechanical fractures [

101].

Unfortunately, it was not possible to obtain experimental data on faults associated with FCs. Conversely, several methods for FC failure prediction were explored in the available literature, both stochastic [

110,

111] and neural network based [

112,

113]. Their usage is strictly connected to the achieving of instrument typical data through a long training phase. Analytic methods require the knowledge of specific FC parameters, not easy to achieve [

113]. Several techniques for on-line failure analysis and characterization are available in the literature: among them, the most viable are the Electrochemical Impedance Spectrometry (EIS) [

108], the V/P characteristic curve analysis [

114], and the cell voltage measuring [

115]. Several mathematical models able to describe the degradation mechanism are reported in

Table 7.

2.6. Anomalies and Faults in Battery Systems

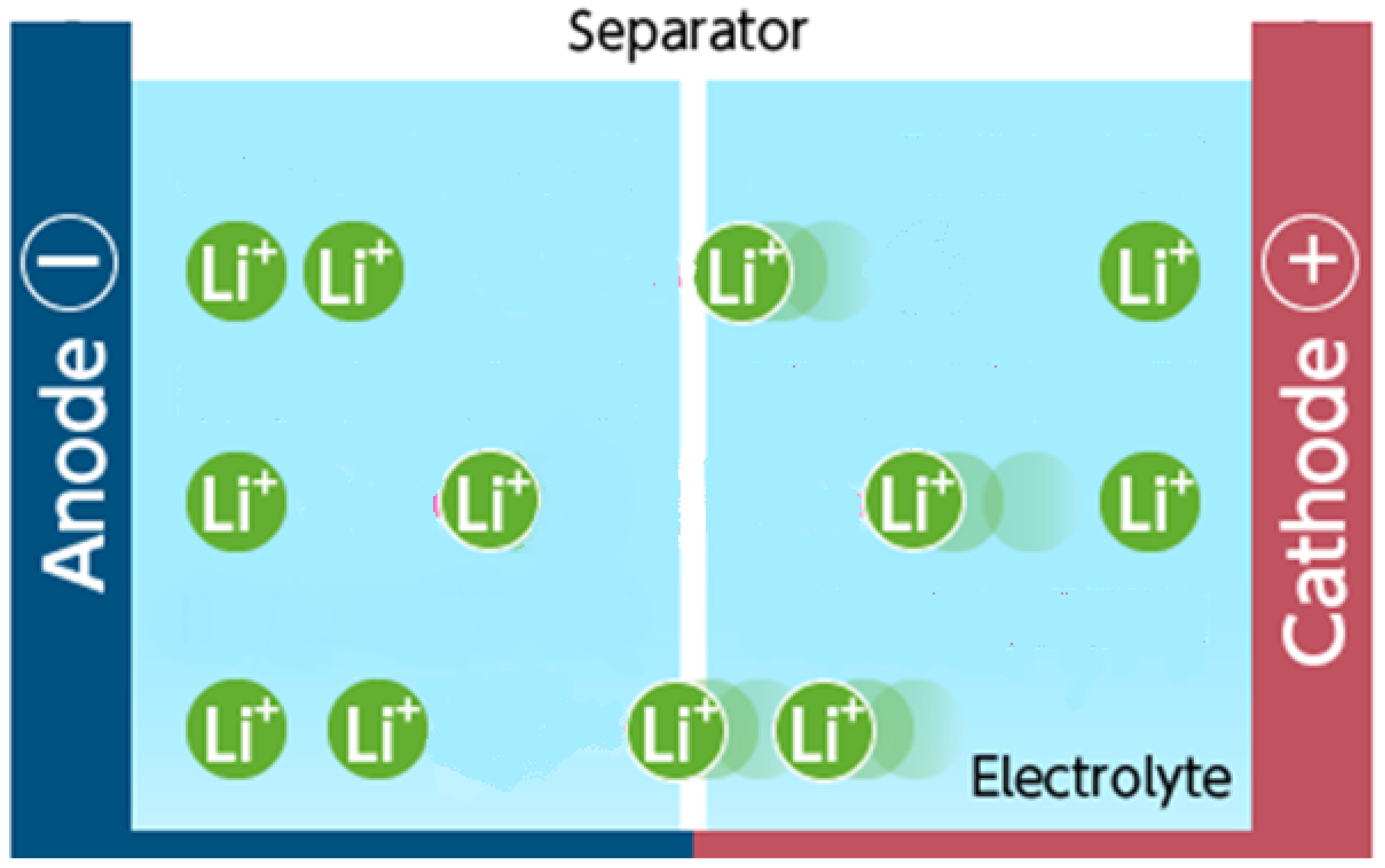

The survey focused on the currently most widespread BSs technology [

121] that is Lithium-ion (Li-ion) technology. The

Figure 5 shows a sketch of a Li-Ion battery cell. It has four main components: positive electrode, negative electrode, electrolyte and separator. The separator aims to isolate the electrodes to avoid internal short circuit. Moreover, it is made up of porous material to allow, with the electrolyte, the ions movement between the electrodes.

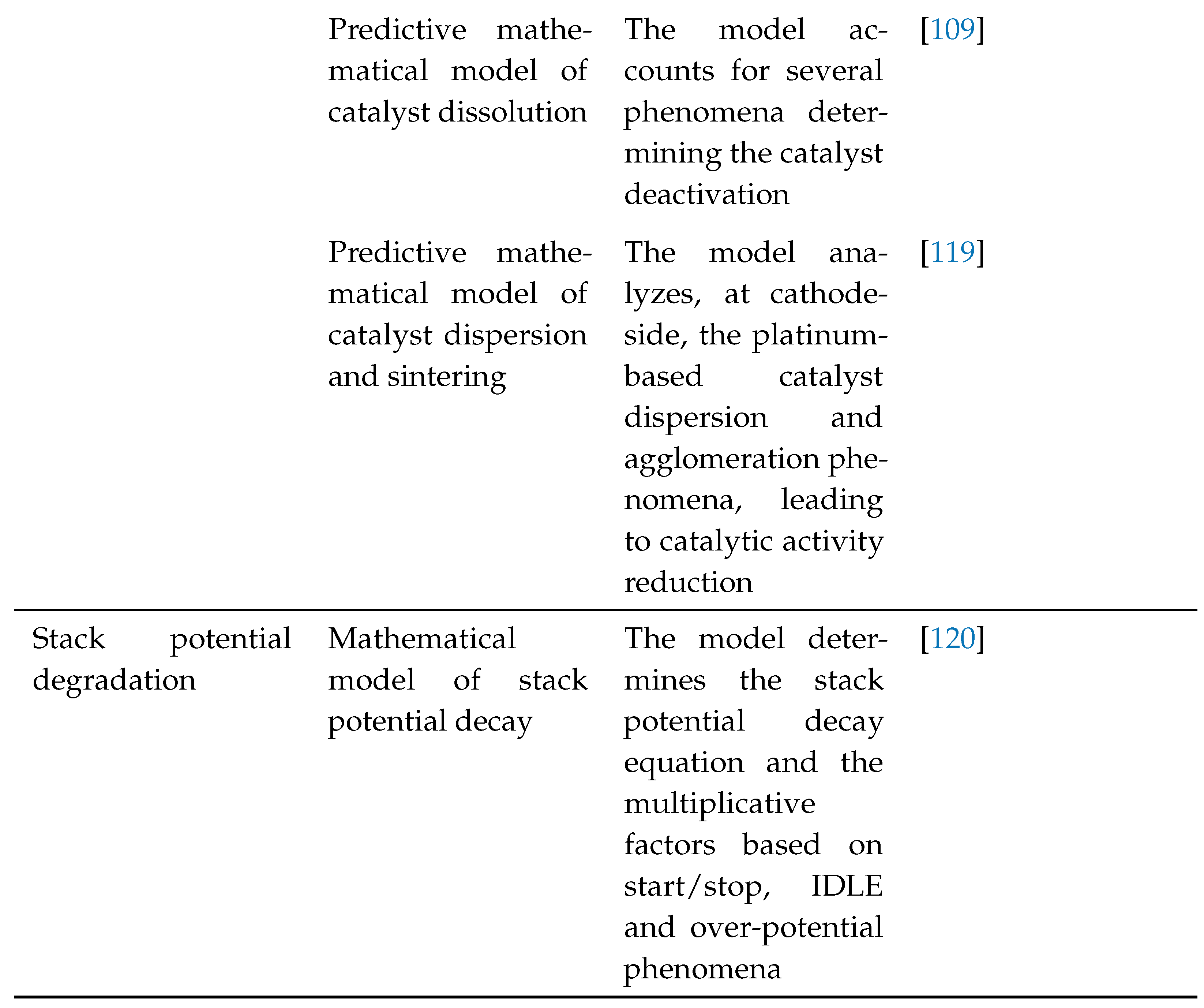

2.6.1. Research Highlights

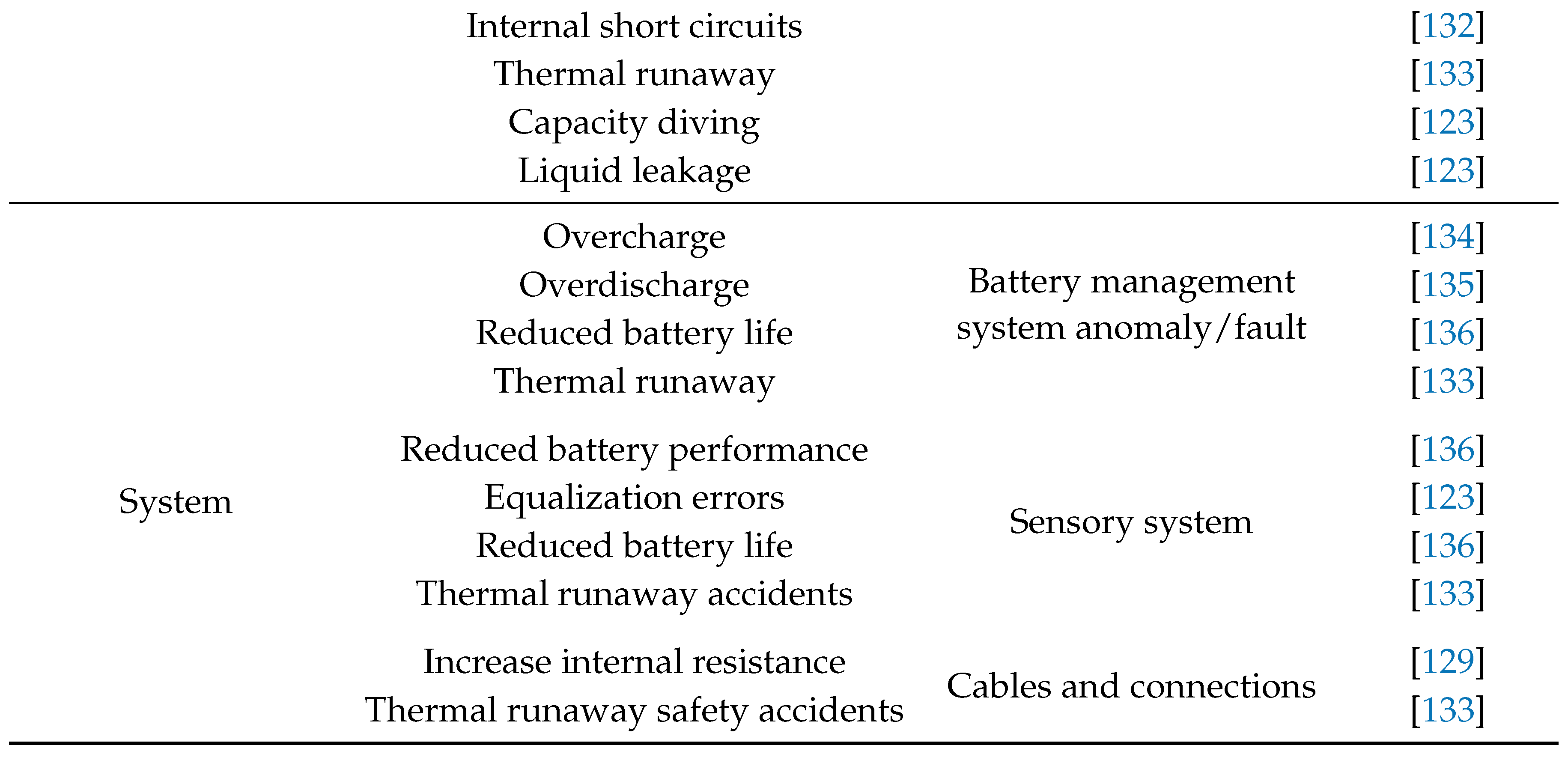

The survey’s findings are gathered in

Table 8. The outcomes shown in

Table 8 highlight that the BS faults can be classified into two types [

123]: cell fault and system fault. The cell faults are mainly caused by Battery degradation phenomena and include the following anomalies/faults: loss of active material; electrolyte consumption; increase in internal resistance; lithium deposition; gas generation; Solid Electrolyte Interphase (SEI) thickening. A passivation layer called SEI is formed on electrode surfaces from decomposition products of electrolytes. The SEI allows Li

+ transport and blocks electrons in order to prevent further electrolyte decomposition and ensure continued electrochemical reactions [

124]; current collector corrosion; internal short circuit (can cause explosion and is mainly caused by overload); thermal runaway; capacity diving; liquid leakage. The system faults are mainly caused by battery management system anomaly/fault [

125,

126], sensory system anomaly/fault, cables and connections anomaly/fault. They can be classified as: overcharge (can provoke the reaction of the positive electrode with the electrolyte, resulting in heat generation, pressure increase, and subsequent fire); overdischarge; reduced battery life; thermal runaway; reduced battery performance; equalization errors; thermal runaway accident; increase in internal resistance; thermal runaway safety accident.

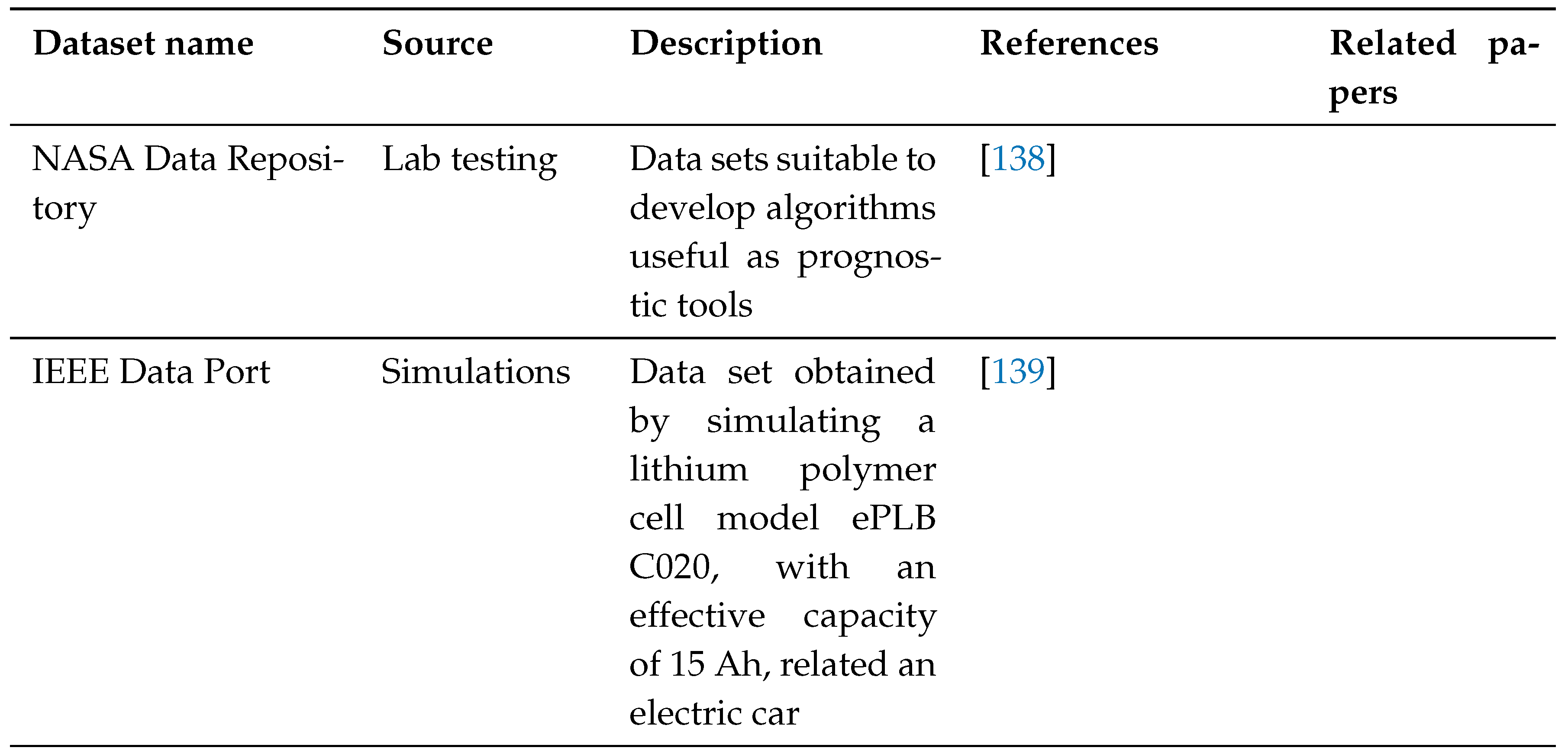

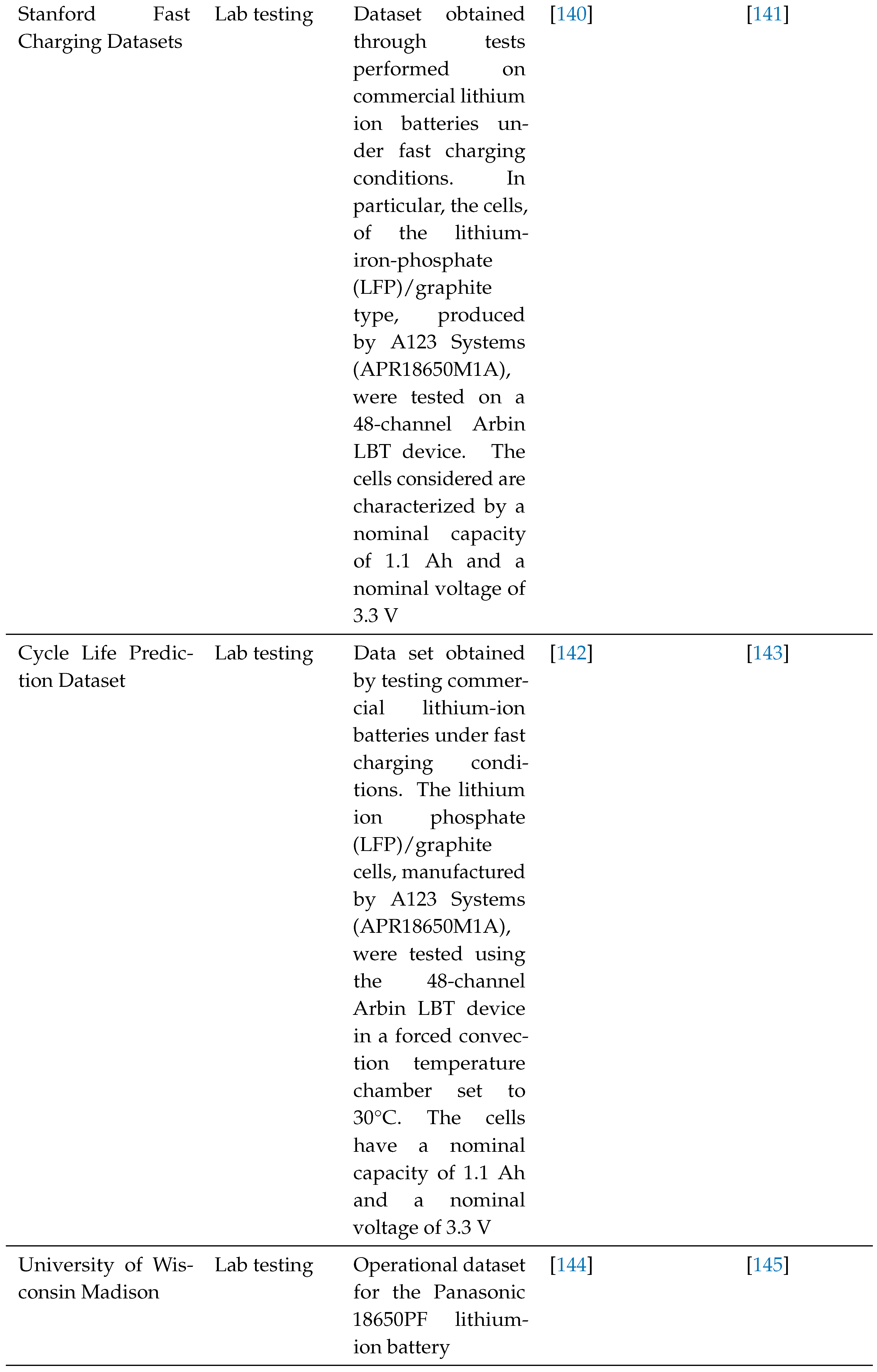

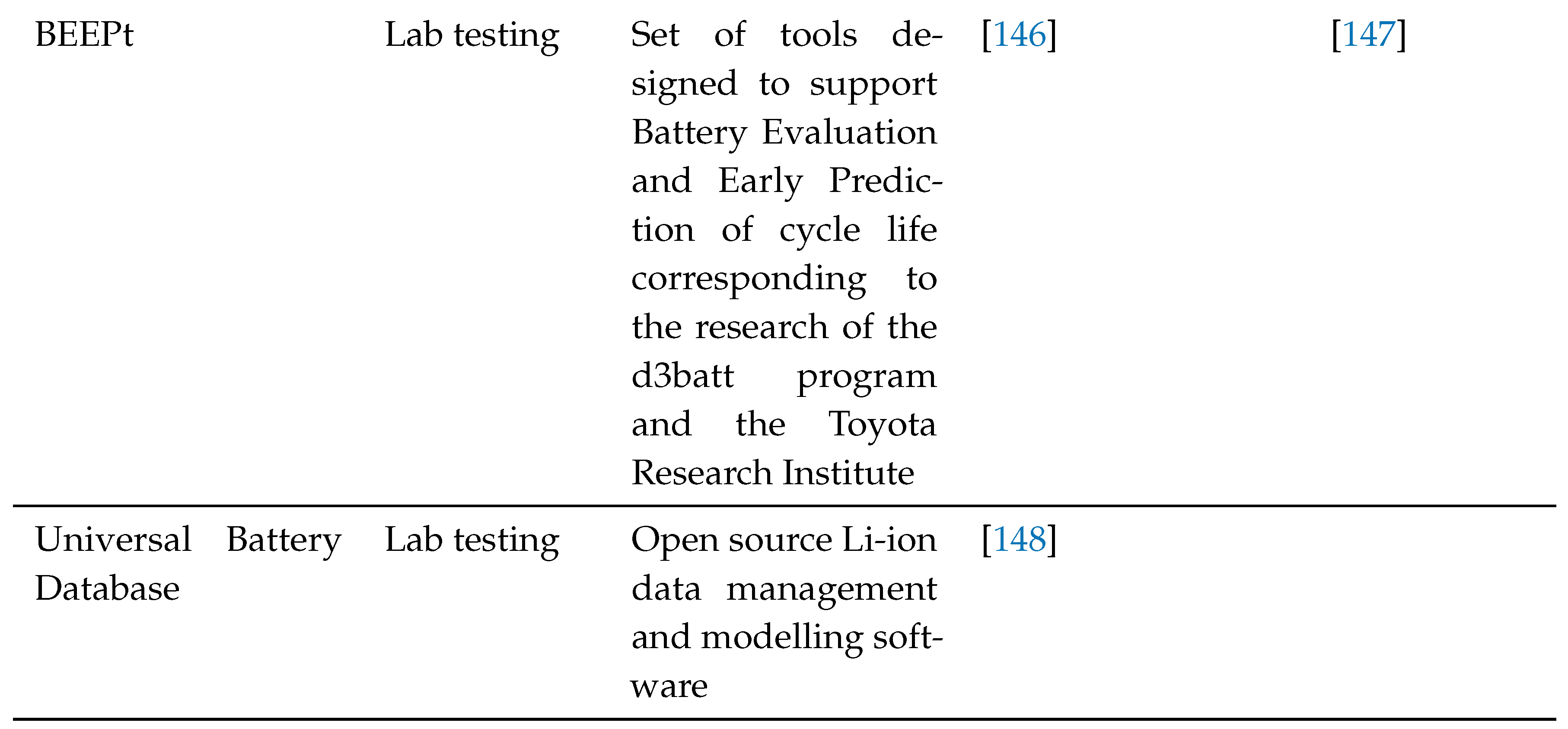

The

Table 9 highlights the main dataset on faults in Li-ion BSs.

2.7. Anomalies and Faults in DC/x Conversion Systems

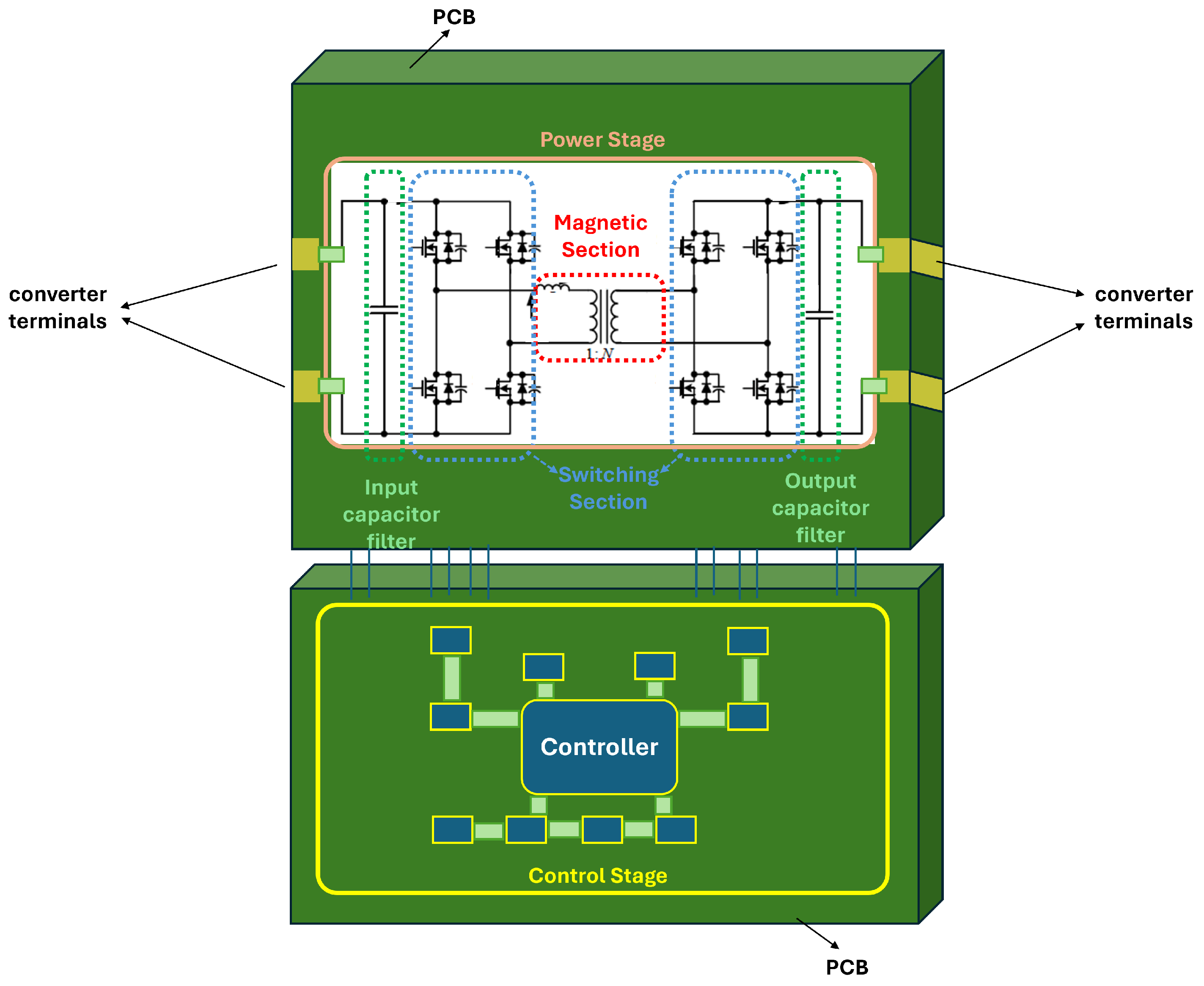

A power electronics converter is a circuit adequately interfacing a power source with an electricity absorbing system, such as a load, a storage or a sinking busbar of the main grid. They are constituted by different stages (

Figure 6), including an input and an output filter, a switching stage and a magnetic section. The switching section represents the converter core which can be realized by Metal–Oxide–Semiconductor Field-Effect Transistor (MOSFET) or IGBT devices. A gate driver circuit turns on/off the converter switching devices according to Pulse-Width Modulation/Modulated (PWM) technique assuring its functioning mode.

These converters can be employed as interfaces between a DC voltage source to obtain a DC output voltage of different magnitude or as a DC/AC conversion system. They can be designed and realized to assure unidirectional or bidirectional power flows.

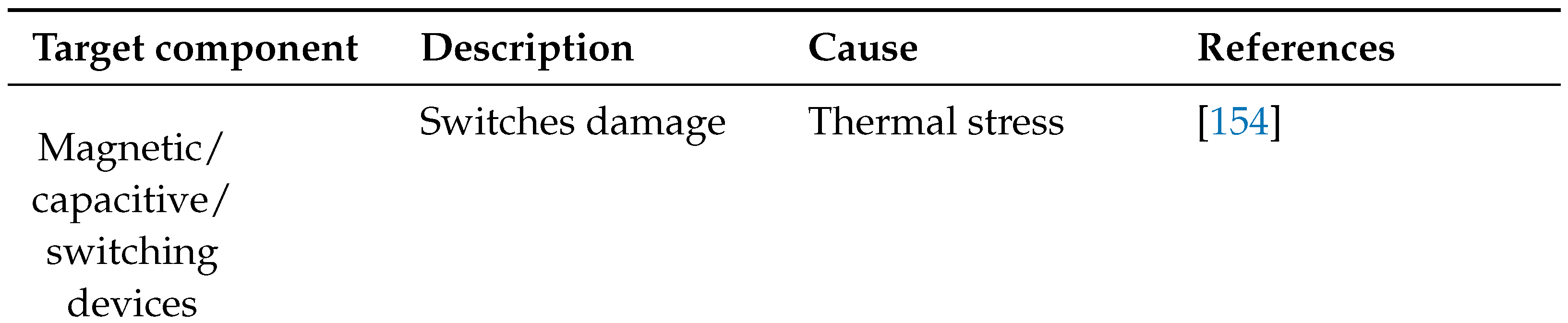

2.7.1. Research Highlights

The conducted study highlights the converter is subjected to operating conditions that can vary over time, its devices are subjected to electrical, thermal, mechanical or combined (electro-thermal, etc.) stresses. In addition, aging phenomena can impact the converter performances. These factors can cause anomalies and/or failures to the power stage devices, the control stage, switching components driving circuit, and at the converter inputs and outputs terminals.

The sector literature focused the attention mainly on the physics of the failure and/or anomaly of the individual components, also reporting the converters most damaged/fault devices.

In switching devices, overcurrent and overvoltage conditions can cause the component overtemperature. In particular, the action of thermal stress can have significant effects on secondary breakdown phenomena which lead to the destruction of the switching device. During design phases of such equipment it is essential to consider the safe operating area of these components and appropriate heat sinks. It must be kept in mind that the value of the junction temperature depends on the ambient temperature as reported in (

3):

where

is the switching device junction temperature,

is the ambient temperature,

is the losses power, and

is the thermal ambient-junction resistance.

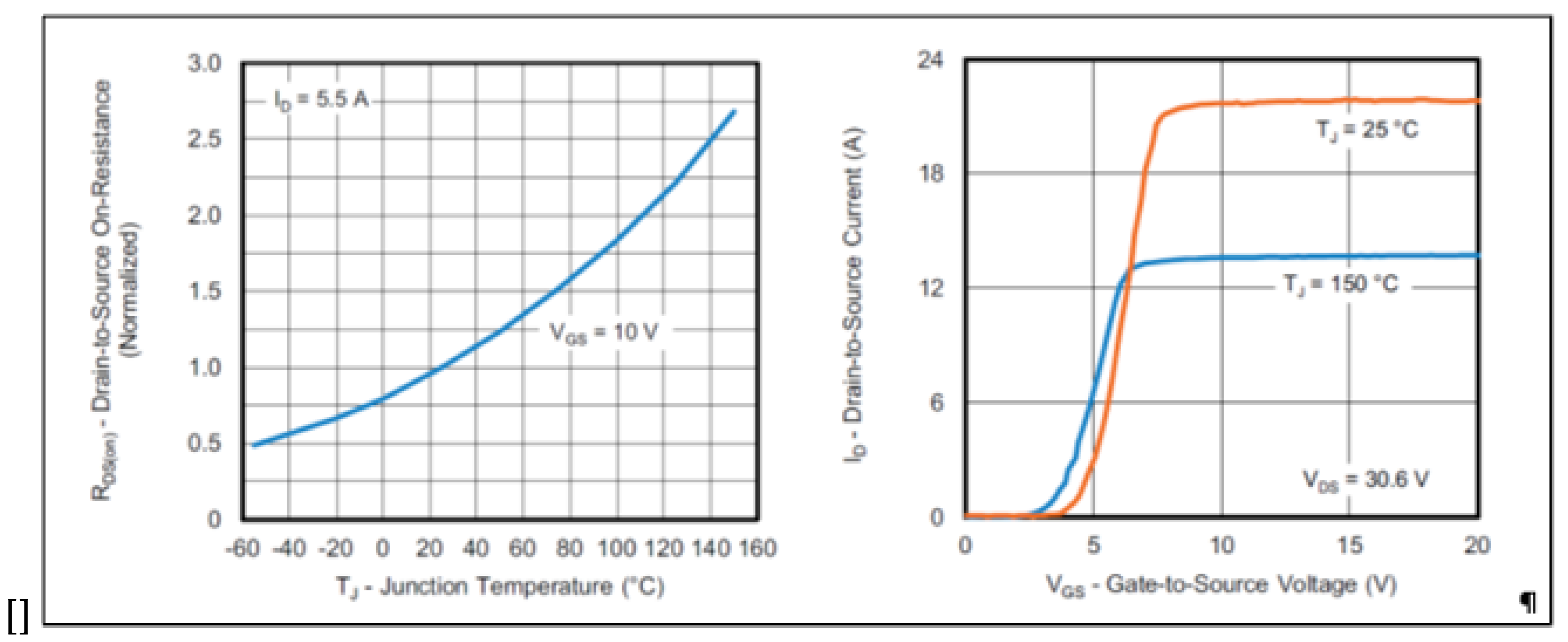

Also the switch Drain-Source resistance, and Gate-Source voltage depend on the junction temperature. The Drain-Source resistance increases to the junction temperature growth (

Figure 7(a)) while, in

Figure 7(b), the Gate-Source voltage decreases for rising junction temperature values.

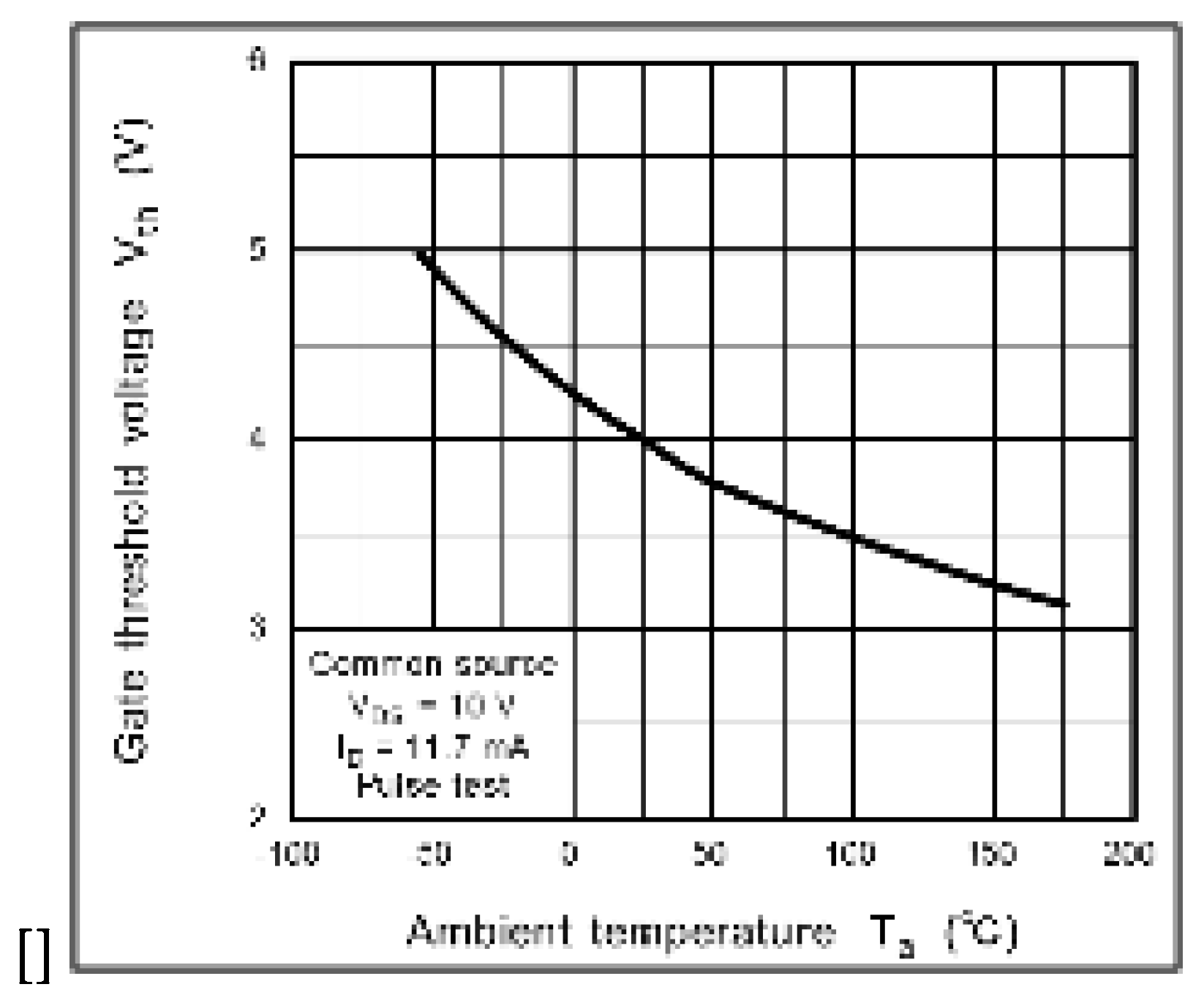

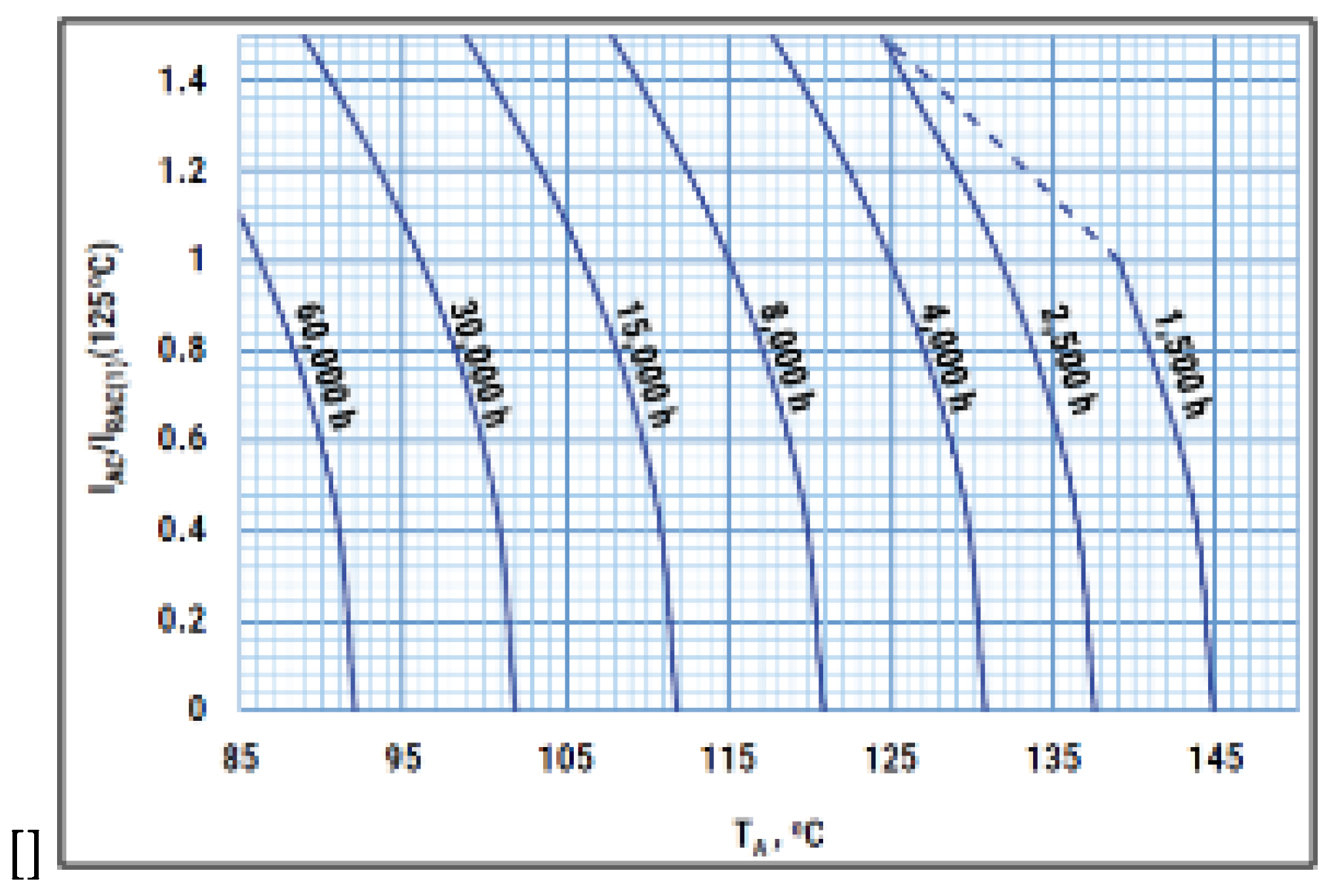

The graph reported in

Figure 8 underlines that the switch threshold voltage (

) can decrease to the ambient temperature increase. Given the temperatures that have characterized the latest heat wave phenomena, the threshold voltage

could drop causing the unwanted switching on of the switching device with harmful consequences for the individual component and also for the interface converter of which it is part.

Furthermore, it must be underlined that temperature also represents a stressful agent for the materials that make up the switching devices. The use of materials characterized by different behavior in terms of thermal expansion and compression can, in fact, cause cracks with the consequent failure of the component.

A further cause of anomalies and failures in switching devices are electrostatic discharges. In detail, their action can cause the gate oxide to break without obvious malfunctions for the component immediately, but leading to breakage after a period of time from the event. The adoption of protections and the possibility of monitoring the gate charge can avoid the failure.

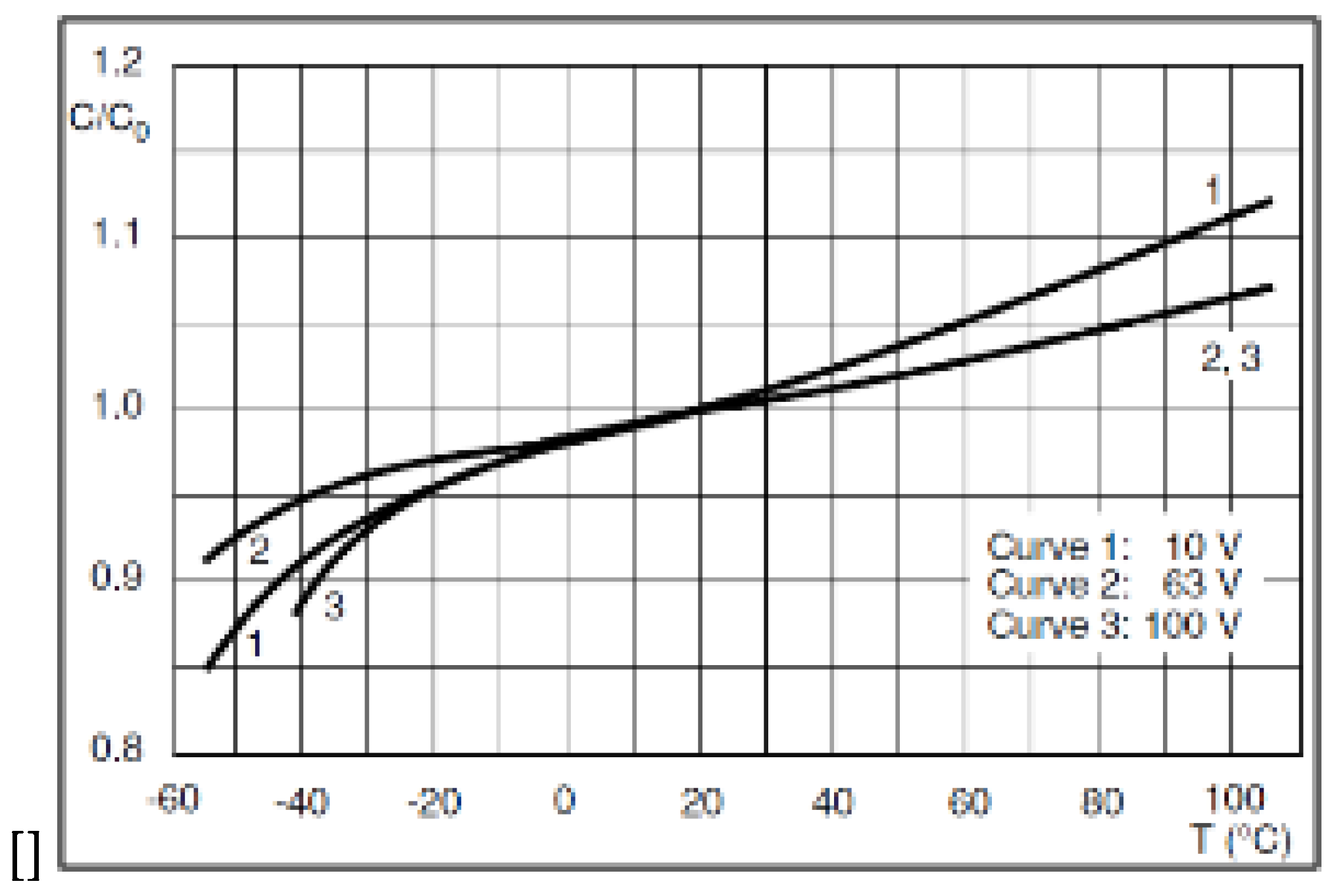

With reference to capacitive components it is necessary to underline that electrolytic, ceramic and film capacitors are used in interface converters. The capacity of these devices varies with temperature as shown in

Figure 9.

The graphs represented in

Figure 10 also highlight the halving of the operational life (expressed in hours) of a condenser for every 10°C increase in temperature.

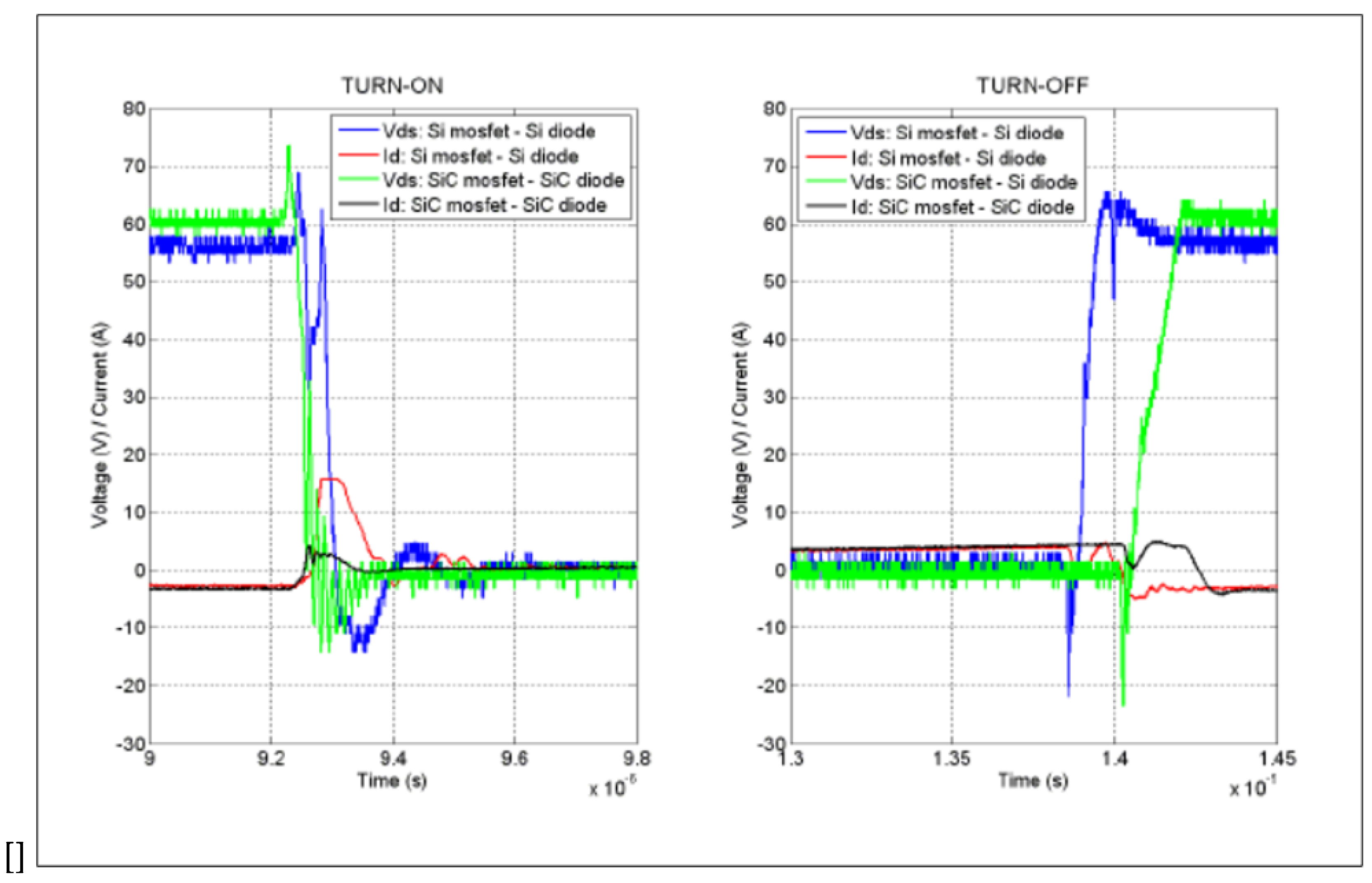

The converter output voltage is obtained by appropriately driving the switching on and off of the switching devices present in the circuit. This function is carried out by appropriate integrated circuits (drivers). They may exhibit anomalous behavior when negative voltages are applied to their inputs or outputs.

In particular, the switching on and off phases (

Figure 11) of mosfet and igbt are characterized by voltage and current transients which, in the presence of parasitic components (capacitances and inductances), can cause the presence of negative voltages at the driver terminals.

The analysis of anomalies and faults occurring in power converters has made it possible to identify the most delicate devices in the power and circuit control stage and the main causes of damages and malfunctions. They are schematically synthesized in

Table 10.

It is appropriate, in any case, to highlight that it was not possible to find datasets relating to the anomalies and failures of either the interface converters or the switching, capacitive and inductive devices of the power stage, nor of the components of the control stage.

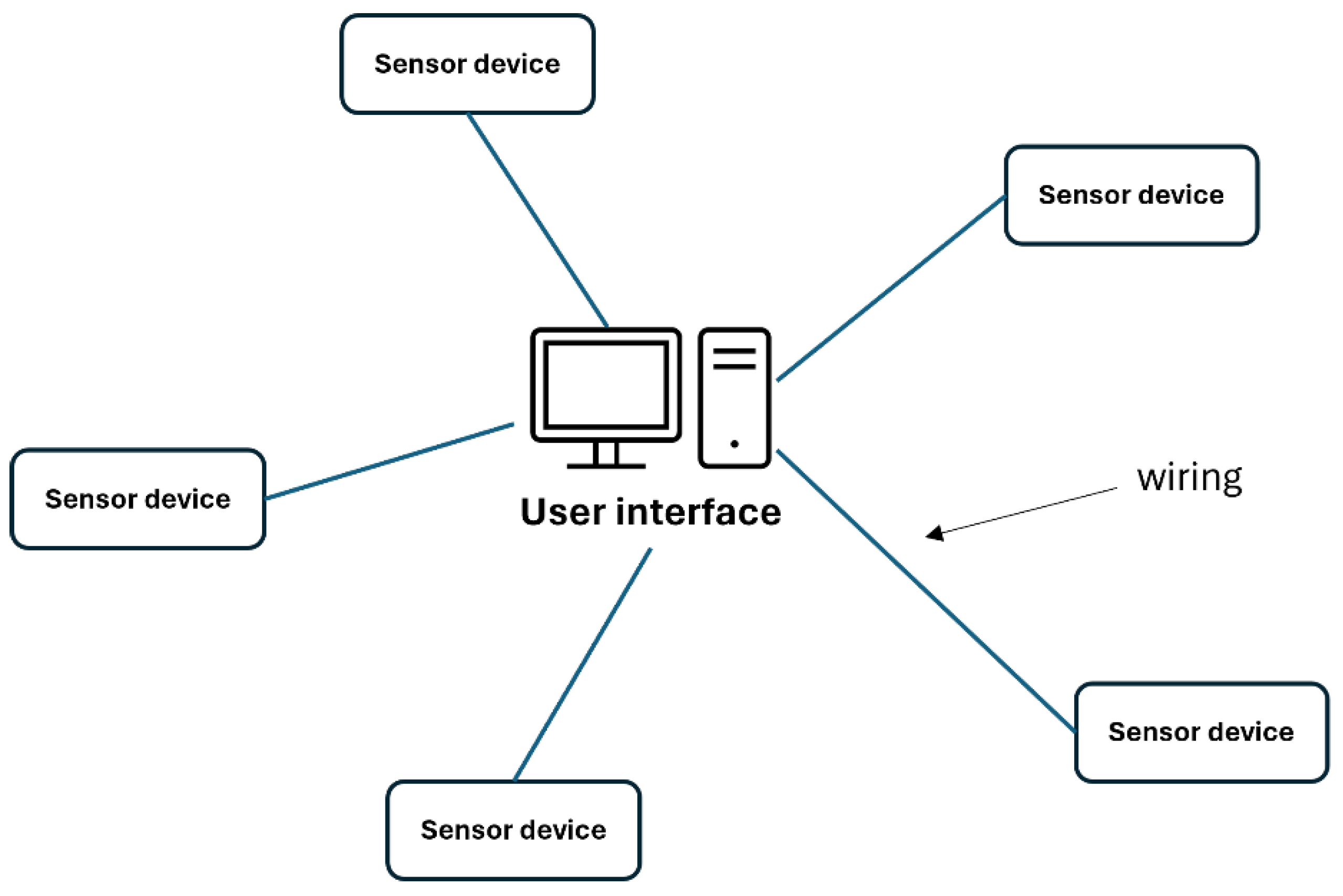

2.8. Anomalies and Faults in Monitoring Systems

A monitoring system can be seen as a set of sensors, wiring and user interface as shown in the following

Figure 12.

A software layer is used to manage the data transmitted by the sensors and to give a suitable visualization to the user. The main component that is affected by failures is the sensor so the survey is focused on this.

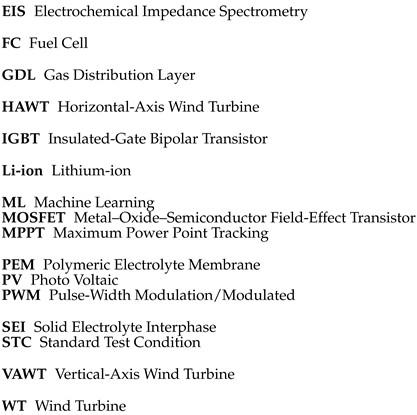

2.8.1. Research Highlights

The surveyed literature is organized in Table 7. It is highlighted that the main anomalies and faults associated with monitoring system can be listed [

159] as mechanical faults regarding to the mechanical structure of the apparatus (e.g. degradation of materials [

160], vibrations, external shocks [

161]), electrical faults that affect the electrical properties of the device (e.g. loss of insulation [

162,

163], anomalous measurement residual [

164] due to blackout or overloading of the device) and other faults, that can affect the measurement due for example to noise [

165], reading errors (value read by the device different from the actual one due to a change in gain) [

166], calibration losses or performance degradation [

167].

The study highlighted that the failures of monitoring equipment strongly depend on the operating conditions of the environment in which they are inserted. The most common are reading errors due to incorrect sensor calibration, performance degradation, or electrical faults; mechanical failures are less frequent.

For all type of faults, it was not possible to find simulated and/or experimental data or information regarding faults and anomalies relating to measurement systems for the specific sector of electricity networks (smart meters).

Table 11.

Main contributions on anomalies/faults in monitoring systems.

Table 11.

Main contributions on anomalies/faults in monitoring systems.

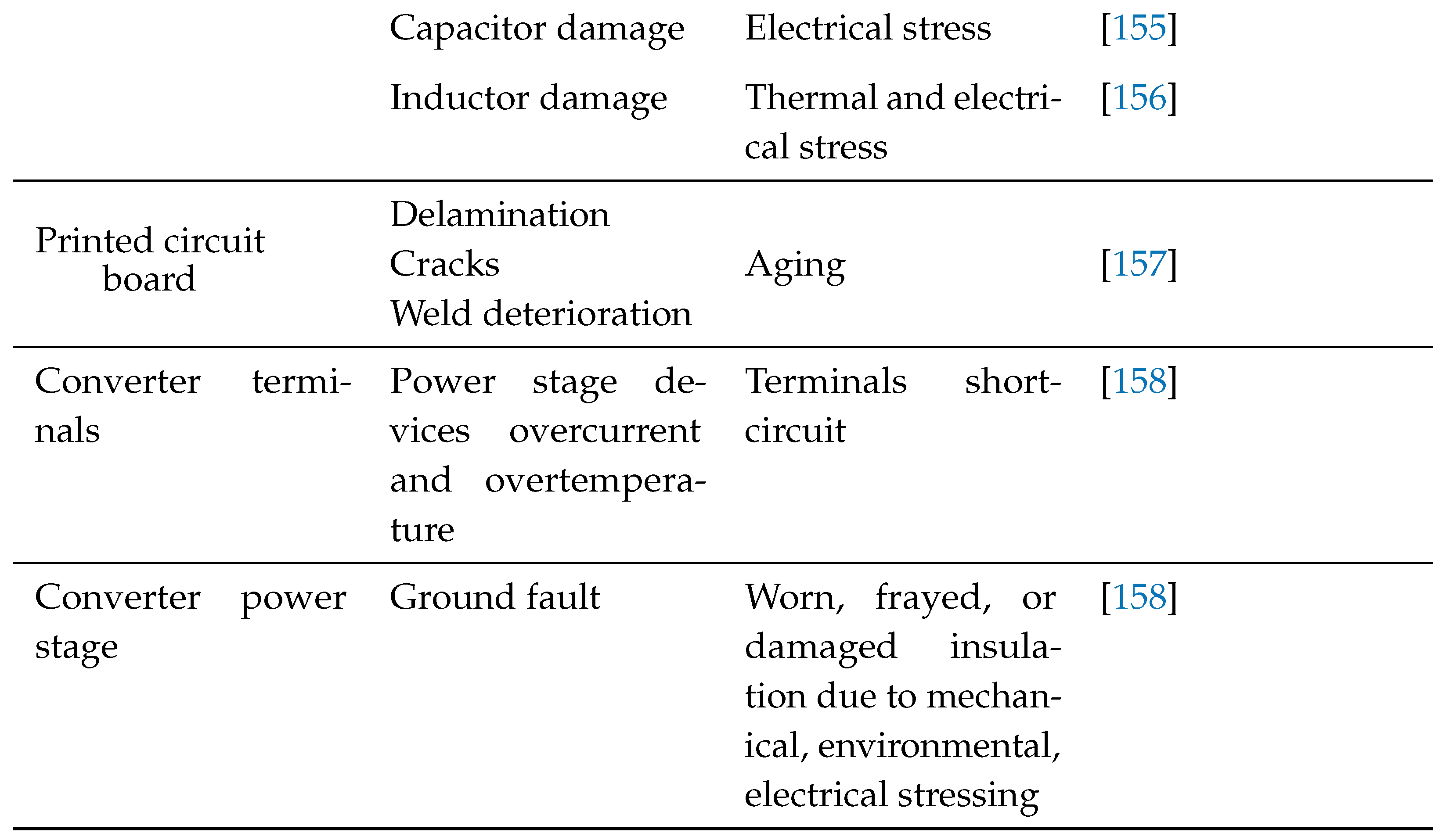

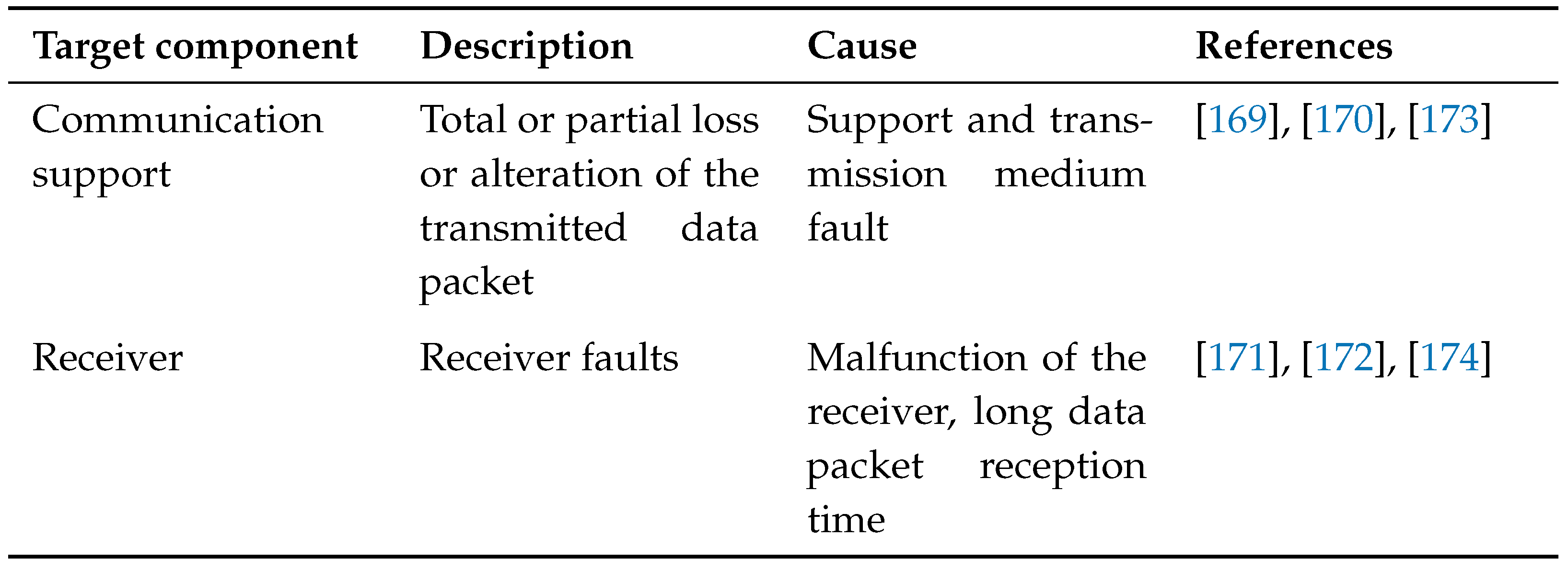

2.9. Anomalies and Faults in Communication Systems

The main aim of a communication system is to send and receive data. This system consists of a sender, a receiver and a communication support in order to obtain the data transmission between them. The following

Figure 13 shows the principle scheme of a communication system.

The data are packaged in a message by means of a suitable protocol. Therefore, the causes of failure are attributable to multiple subsystems as described in the following paragraph.

2.9.1. Research Highlights

The surveyed literature is organized in

Table 12. The study has highlighted that the main anomalies and faults associated with communication systems can be classified [

168] into failures of the communication support regarding to the support and transmission medium (e.g. fiber breakage, excessive bending, connectors or splice breakage [

169,

170]), receiver failure involving a malfunction of the receiver, such as a high data packet reception time [

171,

172] and data integrity that affect the integrity of the transferred data, degrading the accuracy and reliability of the transmission, and caused by alteration or loss of part of the transmitted data packet [

173]. These last are, generally, recognized by the receiver using checksum [

174]. The survey has highlighted that failures due to the support medium are more frequent than the other two types.

For all type of faults it was not possible to find simulated/experimental datasets but only methods for fault diagnostics (

Table 12).

3. Conclusions

This paper presents a survey on anomalies and faults in renewable-based power systems and may impact their reliability, by addressing several heterogeneous technologies that are therein deployed. Tables related to the literature findings and possible datasets are also reported for reference. In both cases, the survey shows that some aspects are covered by very old articles/references and it is not possible to find up-to-date material. This is a gap that should be filled maybe orienting the study to the specific scope this paper addresses. Furthermore, the survey also highlights a lack of datasets for some technologies, namely electrolyzers, FCs, DC/x conversion systems, monitoring and communication systems. In the case of electrolyzers and FCs, suitable tables report mathematical models that can reproduce the target anomaly/fault phoenomenon and can output synthetic data for further analysis/investigation. And this is another gap that should be filled.

In general, with regards to similar paper, this paper includes many technologies and does not restrict itself to specific ones. For instance, beyond technologies specific to the power domain, also monitoring and communication systems in renewable-based power systems are surveyed. This can help other fellows in orienting their research effort via a self-consistent reference.

Author Contributions

Conceptualization, A. Buonanno, A. Ricca, R. Ciavarella, G. Adinolfi, V. Sorrentino, M. Valenti; methodology, A. Buonanno, A. Ricca, R. Ciavarella, G. Adinolfi, V. Sorrentino, M. Valenti; investigation, V. Mariani, A. Buonanno, A. Ricca, R. Ciavarella, G. Adinolfi, V. Sorrentino, M. Valenti; data curation, A. Buonanno, A. Ricca, R. Ciavarella, G. Adinolfi, V. Sorrentino; writing—original draft preparation, V. Mariani, A. Buonanno, A. Ricca, R. Ciavarella, G. Adinolfi, V. Sorrentino; writing—review and editing, V. Mariani, A. Buonanno, A. Ricca, R. Ciavarella, G. Adinolfi, V. Sorrentino; visualization, V. Mariani, A. Buonanno, A. Ricca, R. Ciavarella, G. Adinolfi, V. Sorrentino; supervision, M. Valenti; project administration, M. Valenti, G. Graditi; funding acquisition, M. Valenti, G. Graditi. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Research Fund for the Italian Electrical System through the project “Accordo di Programma 2022–2024—Project 2.3” between ENEA and the Ministry of the Environment and Energetic Safety (MASE).

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

References

- Ren, B.; Chi, Y.; Zhou, N.; Wang, Q.; Wang, T.; Luo, Y.; Ye, J.; Zhu, X. Machine learning applications in health monitoring of renewable energy systems. Renewable and Sustainable Energy Reviews 2024, 189, 114039. [Google Scholar] [CrossRef]

- Afridi, Y.S.; Ahmad, K.; Hassan, L. Artificial intelligence based prognostic maintenance of renewable energy systems: A review of techniques, challenges, and future research directions. International Journal of Energy Research 2022, 46, 21619–21642. [Google Scholar] [CrossRef]

- Ibrahim, M.S.; Dong, W.; Yang, Q. Machine learning driven smart electric power systems: Current trends and new perspectives. Applied Energy 2020, 272, 115237. [Google Scholar] [CrossRef]

- Tuyen, N.D.; Quan, N.S.; Linh, V.B.; Van Tuyen, V.; Fujita, G. A Comprehensive Review of Cybersecurity in Inverter-Based Smart Power System Amid the Boom of Renewable Energy. IEEE Access 2022, 10, 35846–35875. [Google Scholar] [CrossRef]

- Hare, J.; Shi, X.; Gupta, S.; Bazzi, A. Fault diagnostics in smart micro-grids: A survey. Renewable and Sustainable Energy Reviews 2016, 60, 1114–1124. [Google Scholar] [CrossRef]

- Hare, J.; Shi, X.; Gupta, S.; Bazzi, A. A review of faults and fault diagnosis in micro-grids electrical energy infrastructure. 2014 IEEE Energy Conversion Congress and Exposition (ECCE), 2014, pp. 3325–3332. [CrossRef]

- Labrador Rivas, A.E.; Abrão, T. Faults in smart grid systems: Monitoring, detection and classification. Electric Power Systems Research 2020, 189, 106602. [Google Scholar] [CrossRef]

- Jaen-Cuellar, A.Y.; Elvira-Ortiz, D.A.; Osornio-Rios, R.A.; Antonino-Daviu, J.A. Advances in Fault Condition Monitoring for Solar Photovoltaic and Wind Turbine Energy Generation: A Review. Energies 2022, 15. [Google Scholar] [CrossRef]

- Neumayer, M.; Stecher, D.; Grimm, S.; Maier, A.; Bücker, D.; Schmidt, J. Fault and anomaly detection in district heating substations: A survey on methodology and data sets. Energy 2023, 276, 127569. [Google Scholar] [CrossRef]

- Gururajapathy, S.S.; Mokhlis, H.; Illias, H.A. Fault location and detection techniques in power distribution systems with distributed generation: A review. Renewable and Sustainable Energy Reviews 2017, 74, 949–958. [Google Scholar] [CrossRef]

- IEEE Std 1044-2009. IEEE Standard Classification for Software Anomalies 2010. pp. 1–23. [CrossRef]

- NASA SP-2016-6105. NASA Systems Engineering Handbook; NASA - National Aeronautics and Space Administration, 2016.

- Avizienis, A.; Laprie, J.C.; Randell, B.; Landwehr, C. Basic concepts and taxonomy of dependable and secure computing. IEEE Transactions on Dependable and Secure Computing 2004, 1, 11–33. [Google Scholar] [CrossRef]

- Tipton, C.I.W. Survey of Fault Detection and Classification in Power Conversion Electronics. Technical Report AD1115443, DEVCOM Army Research Laboratory, Adelphi, United States, 2020. https://apps.dtic.mil/sti/citations/AD1115443.

- Hong, Y.Y.; Pula, R.A. Methods of photovoltaic fault detection and classification: A review. Energy Reports 2022, 8, 5898–5929. [Google Scholar] [CrossRef]

- Osmani, K.; Haddad, A.; Lemenand, T.; Castanier, B.; Alkhedher, M.; Ramadan, M. A critical review of PV systems’ faults with the relevant detection methods. Energy Nexus 2023, 12, 100257. [Google Scholar] [CrossRef]

- Jiang, L.; Maskell, D. Automatic fault detection and diagnosis for photovoltaic systems using combined artificial neural network and analytical based methods. 2015 International Joint Conference on Neural Networks (IJCNN), 2015, pp. 1–8. [CrossRef]

- Chine, W.; Mellit, A.; Pavan, A.; Lughi, V. Fault diagnosis in photovoltaic arrays. 2015 International Conference on Clean Electrical Power, 2015, pp. 67–72. [CrossRef]

- Kumar, S.S.; Selvakumar, A.I. Detection of the faults in the photovoltaic array under normal and partial shading conditions. 2017 Innovations in Power and Advanced Computing Technologies (i-PACT), 2017, pp. 1–5. [CrossRef]

- Buonanno, A.; Caputo, G.; Balog, I.; Fabozzi, S.; Adinolfi, G.; Pascarella, F.; Leanza, G.; Graditi, G.; Valenti, M. Machine Learning and Weather Model Combination for PV Production Forecasting. Energies 2024, 17. [Google Scholar] [CrossRef]

- Buonanno, A.; Caliano, M.; Di Somma, M.; Graditi, G.; Valenti, M. A Comprehensive Tool for Scenario Generation of Solar Irradiance Profiles. Energies 2022, 15. [Google Scholar] [CrossRef]

- Nguyen, X.H. Matlab/Simulink Based Modeling to Study Effect of Partial Shadow on Solar Photovoltaic Array. Environmental Systems Research 2015, 4. [Google Scholar] [CrossRef]

- Hu, Y.; Cao, W.; Ma, J.; Finney, S.J.; Li, D. Identifying PV Module Mismatch Faults by a Thermography-Based Temperature Distribution Analysis. IEEE Transactions on Device and Materials Reliability 2014, 14, 951–960. [Google Scholar] [CrossRef]

- Li, X.; Yang, Q.; Lou, Z.; Yan, W. Deep Learning Based Module Defect Analysis for Large-Scale Photovoltaic Farms. IEEE Transactions on Energy Conversion 2019, 34, 520–529. [Google Scholar] [CrossRef]

- Mustafa, R.J.; Gomaa, M.R.; Al-Dhaifallah, M.; Rezk, H. Environmental Impacts on the Performance of Solar Photovoltaic Systems. Sustainability 2020, 12. [Google Scholar] [CrossRef]

- Hetita, I.; Zalhaf, A.S.; Mansour, D.E.A.; Han, Y.; Yang, P.; Wang, C. Modeling and Protection of Photovoltaic Systems During Lightning Strikes: A Review. Renewable Energy 2022. [Google Scholar] [CrossRef]

- Köntges, M.; Kurtz, S.; Packard, C.; Jahn, U.; Berger, K.A.; Kato, K.; Friesen, T.; Liu, H.; Van Iseghem, M. Review of Failures of Photovoltaic Modules. Report T13-01:2014, IEA-PVPS, 2014. https://iea-pvps.org/key-topics/review-of-failures-of-photovoltaic-modules-final/.

- Itoh, U.; Yoshida, M.; Tokuhisa, H.; Takeuchi, K.; Takemura, Y. Solder Joint Failure Modes in the Conventional Crystalline Si Module. Energy Procedia 2014, 55, 464–468. [Google Scholar] [CrossRef]

- Alam, M.K.; Khan, F.; Johnson, J.; Flicker, J. A Comprehensive Review of Catastrophic Faults in PV Arrays: Types, Detection, and Mitigation Techniques. IEEE Journal of Photovoltaics 2015, 5, 982–997. [Google Scholar] [CrossRef]

- Zhao, Y. Fault Analysis in Solar Photovoltaic Arrays. Master thesis, Northeastern University Boston, Massachusetts, 2010.

- Badr, M.M.; Hamad, M.S.; Abdel-Khalik, A.S.; Hamdy, R.A. Fault Detection and Diagnosis for Photovoltaic Array Under Grid Connected Using Support Vector Machine. 2019 IEEE Conference on Power Electronics and Renewable Energy (CPERE), 2019, pp. 546–553. [CrossRef]

- Chan, F.; Calleja, H. Reliability: A New Approach in Design of Inverters for PV Systems. 2006 IEEE International Power Electronics Congress, 2006, pp. 1–6. [CrossRef]

- Ma, M.; Liu, H.; Zhang, Z.; Yun, P.; Liu, F. Rapid diagnosis of hot spot failure of crystalline silicon PV module based on I-V curve. Microelectronics Reliability 2019, 100-101, 113402. [Google Scholar] [CrossRef]

- Bdour, M.; Dalala, Z.; Al-Addous, M.; Radaideh, A.; Al-Sadi, A. A comprehensive evaluation on types of microcracks and possible effects on power degradation in photovoltaic solar panels. Sustainability 2020, 12. [Google Scholar] [CrossRef]

- Colvin, D.J.; Schneller, E.J.; Davis, K.O. Impact of Interconnection Failure on Photovoltaic Module Performance. Progress in Photovoltaics: Research and Applications 2021, 29, 524–532. [Google Scholar] [CrossRef]

- Kim, J.; Rabelo, M.; Padi, S.; Yousuf, H.; Cho, E.C.; Yi, J. A review of the degradation of photovoltaic modules for life expectancy. Energies 2021, 14. [Google Scholar] [CrossRef]

- Bouaichi, A.; Merrouni, A.; El Hassani, A.; Naimi, Z.; Ikken, B.; Ghennioui, A.; Benazzouz, A.; El Amrani, A.; Messaoudi, C. Experimental evaluation of the discoloration effect on PV-modules performance drop. Energy Procedia 2017, 119, 818–827. [Google Scholar] [CrossRef]

- Hasan, A.A.; Ahmed Alkahtani, A.; Shahahmadi, S.A.; Nur, E. Alam, M.; Islam, M.A.; Amin, N. Delamination and Electromigration-Related Failures in Solar Panels – A Review. Sustainability 2021, 13. [Google Scholar] [CrossRef]

- Popovich, V. Breakage issues in silicon solar wafers and cells. Photovoltaics International 2011, 12, 49–57. [Google Scholar]

- Kalejs, J. Junction Box Wiring and Connector Durability Issues in Photovoltaic Modules. International Society for Optical Engineering (SPIE), 2014, Vol. 9179, p. 91790S. [CrossRef]

- National Academies of Sciences, Engineering, and Medicine. Enhancing the Resilience of the Nation’s Electricity System; The National Academies Press: Washington, DC, 2017. [Google Scholar] [CrossRef]

- Ghoneim, S.S.M.; Rashed, A.E.; Elkalashy, N.I. Fault Detection Dataset in Photovoltaic Farms. https://www.kaggle.com/datasets/amrezzeldinrashed/fault-detection-dataset-in-photovoltaic-farms, 2020. Accessed: Jan. 12, 2024.

- Ghoneim, S.S.M.; Rashed, A.E.; Elkalashy, N.I. Fault Detection Algorithms for Achieving Service Continuity in Photovoltaic Farms. Intelligent Automation & Soft Computing 2021, 30, 467–479. [Google Scholar] [CrossRef]

- Su, B.; Zhou, Z.; Chen, H. Photovoltaic Cell Aanomaly Detection Dataset. https://ieee-dataport.org/documents/photovoltaic-cell-anomaly-detection-dataset, 2022. Accessed: Jan. 12, 2024.

- Su, B.; Zhou, Z.; Chen, H. PVEL-AD: A Large-Scale Open-World Dataset for Photovoltaic Cell Anomaly Detection. IEEE Transactions on Industrial Informatics 2023, 19, 404–413. [Google Scholar] [CrossRef]

- Bakdi, A.; Bounoua, W.; A., G.; Mekhilef, S. GPVS-Faults: Experimental Data for fault scenarios in grid-connected PV systems under MPPT and IPPT modes. https://data.mendeley.com/datasets/n76t439f65/1, 2020. Accessed: Jan. 12, 2024.

- Bakdi, A.; Bounoua, W.; A., G.; Mekhilef, S. Real-time fault detection in PV systems under MPPT using PMU and high-frequency multi-sensor data through online PCA-KDE-based multivariate KL divergence. International Journal of Electrical Power & Energy Systems 2021, 125, 106457. [CrossRef]

- Wang, Q.; Paynabar, K.; Pacella, M. Online automatic anomaly detection for photovoltaic systems using thermography imaging and low rank matrix decomposition. https://tandf.figshare.com/articles/dataset/Online_automatic_anomaly_detection_for_photovoltaic_systems_using_thermography_imaging_and_low_rank_matrix_decomposition/15123655/1, 2021. Accessed: Jan. 12, 2024.

- Wang, Q.; Paynabar, K.; Pacella, M. Online automatic anomaly detection for photovoltaic systems using thermography imaging and low rank matrix decomposition. Journal of Quality Technology 2022, 54, 503–516. [Google Scholar] [CrossRef]

- Gabriel, M. Photovoltaic system thermography. https://www.kaggle.com/datasets/marcosgabriel/photovoltaic-system-thermography, 2023. Accessed: Jan. 12, 2024.

- Piliougine, M.; Spagnuolo, G. Mismatching and partial shading identification in photovoltaic arrays by an artificial neural network ensemble. https://zenodo.org/record/4781151, 2022. Accessed: Jan. 12, 2024.

- Piliougine, M.; Spagnuolo, G. Mismatching and partial shading identification in photovoltaic arrays by an artificial neural network ensemble. Solar Energy 2022, 236, 712–723. [Google Scholar] [CrossRef]

- Sood, K.; Ruppert, N.; Mahto, R. Partial Shading and Fault Simulation Dataset of Photovoltaics Module. 2022. Accessed: Jan. 12, 2024. [CrossRef]

- Lazzaretti, A.E.; Costa, C.H.d.; Rodrigues, M.P.; Yamada, G.D.; Lexinoski, G.; Moritz, G.L.; Oroski, E.; Goes, R.E.d.; Linhares, R.R.; Stadzisz, P.C.; Omori, J.S.; Santos, R.B.d. A Monitoring System for Online Fault Detection and Classification in Photovoltaic Plants. https://github.com/clayton-h-costa/pv_fault_dataset, 2020. Accessed: Jan. 12, 2024.

- Lazzaretti, A.E.; Costa, C.H.d.; Rodrigues, M.P.; Yamada, G.D.; Lexinoski, G.; Moritz, G.L.; Oroski, E.; Goes, R.E.d.; Linhares, R.R.; Stadzisz, P.C.; Omori, J.S.; Santos, R.B.d. A Monitoring System for Online Fault Detection and Classification in Photovoltaic Plants. Sensors 2020, 20. [Google Scholar] [CrossRef] [PubMed]

- ELPV-Dataset. https://github.com/zae-bayern/elpv-dataset, 2018. Accessed: Jan. 12, 2024.

- Buerhop-Lutz, C.; Deitsch, S.; Maier, A.; Gallwitz, F.; Berger, S.; Doll, B.; Hauch, J.; Camus, C.; Brabec, C.J. A Benchmark for Visual Identification of Defective Solar Cells in Electroluminescence Imagery. European PV Solar Energy Conference and Exhibition (EU PVSEC), 2018. [CrossRef]

- Deitsch, S.; Christlein, V.; Berger, S.; Buerhop-Lutz, C.; Maier, A.; Gallwitz, F.; Riess, C. Automatic classification of defective photovoltaic module cells in electroluminescence images. Solar Energy 2019, 185, 455–468. [Google Scholar] [CrossRef]

- Deitsch, S.; Buerhop-Lutz, C.; Sovetkin, E.; Steland, A.; Maier, A.; Gallwitz, F.; Riess, C. Segmentation of photovoltaic module cells in uncalibrated electroluminescence images. Machine Vision and Applications, 32. [CrossRef]

- NREL - National Renewable Energy Laboratory, U.S. Department of Energy, Office of Energy Efficiency and Renewable Energy. PVWatts Calculator. https://pvwatts.nrel.gov/pvwatts.php, n.a. Accessed: Jan. 12, 2024.

- Badurek, C.A. Wind turbine. https://www.britannica.com/technology/wind-turbine, 2024. Encyclopedia Britannica. Accessed March 11, 2024.

- Dao, C.; Kazemtabrizi, B.; Crabtree, C. Wind turbine reliability data review and impacts on levelised cost of energy. Wind Energy 2019, 22, 1848–1871. [Google Scholar] [CrossRef]

- Sivankutty, S.; Mary, S.A.J. Fault Diagnosis and Control Techniques for Wind Energy Conversion System: A Systematic Review. 2022 Third International Conference on Intelligent Computing Instrumentation and Control Technologies (ICICICT), 2022, pp. 700–704. [CrossRef]

- Liu, W.Y.; Gu, H.; Gao, Q.W.; Zhang, Y. A review on wind turbines gearbox fault diagnosis methods. Journal of Vibroengineering 2021, 23, 26–43. [Google Scholar] [CrossRef]

- Sheng, S. Wind Turbine Gearbox Condition Monitoring Vibration Analysis Benchmarking Datasets. https://data.openei.org/submissions/738, 2014. [CrossRef]

- Ogaili, A.A.F.; Abdulhady, J.A.; Hamzah, M.N. Wind Turbine Blades Fault Diagnosis based on Vibration Dataset Analysis. https://data.mendeley.com/datasets/5d7vbdp8f7/4, 2023. Accessed: Jan. 12, 2024.

- Ogaili, A.A.F.; Abdulhady, J.A. Vibration Signals Feature for Fault Diagnosis of wind turbine blade. https://data.mendeley.com/datasets/2kx995rscj/2, 2023. Accessed: Jan. 12, 2024.

- Foster, A.; Best, O.; Gianni, M.; Khan, A.; Collins, K.; Sharma, S. YOLO Annotated Wind Turbine Surface Damage. https://www.kaggle.com/datasets/ajifoster3/yolo-annotated-wind-turbines-586x371, 2021. Accessed: Jan. 12, 2024.

- Foster, A.; Best, O.; Gianni, M.; Khan, A.; Collins, K.; Sharma, S. Drone Footage Wind Turbine Surface Damage Detection. 2022 IEEE 14th Image, Video, and Multidimensional Signal Processing Workshop (IVMSP), 2022, pp. 1–5. [CrossRef]

- Xiaoqiang, W.; Ziang, X. Data for: Wind turbine fault diagnosis based on ReliefF-PCA and DNN. https://data.mendeley.com/datasets/v9wnr4bft9/1, 2021. Accessed: Jan. 12, 2024. [CrossRef]

- Wen, X.; Xu, Z. Wind turbine fault diagnosis based on ReliefF-PCA and DNN. Expert Systems with Applications 2021, 178, 115016. [Google Scholar] [CrossRef]

- Sá, B.A.; Barros, C.M.V.; Siebra, C.A.; Barros, L.S. Wind turbine PMSG - Short-Circuit Fault. https://www.kaggle.com/datasets/brunoadonis/wind-turbine-pmsg-short-circuit-fault-mcsa, 2019. Accessed: Jan. 12, 2024.

- Sá, B.A.; Barros, C.M.V.; Siebra, C.A.; Barros, L.S. A Multilayer Perceptron-Based Approach for Stator Fault Detection in Permanent Magnet Wind Generators. 2019 IEEE PES Innovative Smart Grid Technologies Conference - Latin America (ISGT Latin America), 2019, pp. 1–6. [CrossRef]

- Wonho, J.; Seong-Hu, K.; Sung-Hyun, Y.; Jaewoong, B.; Yong-Hwa, P. Vibration and Motor Current Dataset of Rolling Element Bearing Under Varying Speed Conditions for Fault Diagnosis: Subset1. https://data.mendeley.com/datasets/vxkj334rzv/7. Accessed: Jan. 12, 2024. [CrossRef]

- Wonho, J.; Seong-Hu, K.; Sung-Hyun, Y.; Jaewoong, B.; Yong-Hwa, P. Vibration and Motor Current Dataset of Rolling Element Bearing Under Varying Speed Conditions for Fault Diagnosis: Subset2. https://data.mendeley.com/datasets/x3vhp8t6hg/7. Accessed: Jan. 12, 2024. [CrossRef]

- Wonho, J.; Seong-Hu, K.; Sung-Hyun, Y.; Jaewoong, B.; Yong-Hwa, P. Vibration and Motor Current Dataset of Rolling Element Bearing Under Varying Speed Conditions for Fault Diagnosis: Subset3. https://data.mendeley.com/datasets/j8d8pfkvj2/7. Accessed: Jan. 12, 2024. [CrossRef]

- Wonho, J.; Seong-Hu, K.; Sung-Hyun, Y.; Jaewoong, B.; Yong-Hwa, P. Vibration, acoustic, temperature, and motor current dataset of rotating machine under varying operating conditions for fault diagnosis. Data in Brief 2023, 48, 109049. [Google Scholar] [CrossRef]

- Pandya, Y. Gearbox Fault Diagnosis Data. https://data.openei.org/submissions/623, 2018. Accessed: Jan. 12, 2024.

- de Portugal, E.E. EDP Open data. [https://www.edp.com/en/innovation/open-data/data]. Accessed: Jan. 12, 2024.

- Kheirrouz, M.; Melino, F.; Ancona, M.A. Fault detection and diagnosis methods for green hydrogen production: A review. International Journal of Hydrogen Energy 2022, 47, 27747–27774. [Google Scholar] [CrossRef]

- Kokoh, K.B.; Mayousse, E.; Napporn, T.W.; Servat, K.; Guillet, N.; Soyez, E.; Grosjean, A.; Rakotondrainibé, A.; Paul-Joseph, J. Efficient multi-metallic anode catalysts in a PEM water electrolyzer. International Journal of Hydrogen Energy 2014, 39, 1924–1931. [Google Scholar] [CrossRef]

- Yu, H.; Bonville, L.; Jankovic, J.; Maric, R. Microscopic insights on the degradation of a PEM water electrolyzer with ultra-low catalyst loading. Applied Catalysis B: Environmental 2020, 260, 118194. [Google Scholar] [CrossRef]

- Zhang, S.; Yuan, X.; Wang, H.; Merida, W.; Zhu, H.; Shen, J.; Wu, S.; Zhang, J. A review of accelerated stress tests of MEA durability in PEM fuel cells. International Journal of Hydrogen Energy 2009, 34, 388–404. [Google Scholar] [CrossRef]

- Siracusano, S.; Baglio, V.; Van Dijk, N.; Merlo, L.; Aricò, A. Enhanced performance and durability of low catalyst loading PEM water electrolyser based on a short-side chain perfluorosulfonic ionomer. Applied Energy 2017, 192, 477–489. [Google Scholar] [CrossRef]

- Millet, P.; Ranjbari, A.; De Guglielmo, F.; Grigoriev, S.A.; Auprêtre, F. Cell failure mechanisms in PEM water electrolyzers. International Journal of Hydrogen Energy 2012, 37, 17478–17487. [Google Scholar] [CrossRef]

- Grigoriev, S.A.; Dzhus, K.A.; Bessarabov, D.G.; Millet, P. Failure of PEM water electrolysis cells: Case study involving anode dissolution and membrane thinning. International Journal of Hydrogen Energy 2014, 39, 20440–20446. [Google Scholar] [CrossRef]

- Chandesris, M.; Médeau, V.; Guillet, N.; Chelghoum, S.; Thoby, D.; Fouda-Onana, F. Numerical modelling of membrane degradation in PEM water electrolyzer: Influence of the temperature and current density. 6th International Conference on Fundamentals and Development of Fuel Cells, FDFC2015, 2015.

- Kuhnert, E.; Heidinger, M.; Sandu, D.; Hacker, V.; Bodner, M. Analysis of PEM Water Electrolyzer Failure Due to Induced Hydrogen Crossover in Catalyst-Coated PFSA Membranes. Membranes 2023, 13, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Li, N.; Araya, S.S.; Kær, S.K. Investigating low and high load cycling tests as accelerated stress tests for proton exchange membrane water electrolysis. Electrochimica Acta 2021, 370, 137748. [Google Scholar] [CrossRef]

- Spöri, C.; Kwan, J.T.H.; Bonakdarpour, A.; Wilkinson, D.P.; Strasser, P. The Stability Challenges of Oxygen Evolving Catalysts: Towards a Common Fundamental Understanding and Mitigation of Catalyst Degradation. Angewandte Chemie International Edition 2017, 56, 5994–6021. [Google Scholar] [CrossRef]

- Renda, S.; Ricca, A.; Palma, V. Precursor salts influence in Ruthenium catalysts for CO2 hydrogenation to methane. Applied Energy 2020, 279, 115767. [Google Scholar] [CrossRef]

- Hu, Y.; Xu, X.; Wang, W. A new cavity profile for a diaphragm compressor used in hydrogen fueling stations. International Journal of Hydrogen Energy 2017, 42, 24458–24469. [Google Scholar] [CrossRef]

- Ghaedamini, M.; Baharlou-Houreh, N.; Afshari, E.; Shokouhmand, H.; Jahantigh, N. Experimental investigation on the heat and water transfer enhancement in a membrane-based air-to-air humidifier at insulation condition. International Journal of Hydrogen Energy 2022, 47, 17010–17021. [Google Scholar] [CrossRef]

- Carmo, M.; Fritz, D.L.; Mergel, J.; Stolten, D. A comprehensive review on PEM water electrolysis. International Journal of Hydrogen Energy 2013, 38, 4901–4934. [Google Scholar] [CrossRef]

- Choi, S.R.; Lim, M.; Kim, D.Y.; An, W.Y.; Lee, S.W.; Choi, S.; Bae, S.J.; Yim, S.D.; Park, J.Y. Life prediction of membrane electrode assembly through load and potential cycling accelerated degradation testing in polymer electrolyte membrane fuel cells. International Journal of Hydrogen Energy 2022, 47, 17379–17392. [Google Scholar] [CrossRef]

- Singh, Y.; Orfino, F.; Dutta, M.; Kjeang, E. 3D Failure Analysis of Pure Mechanical and Pure Chemical Degradation in Fuel Cell Membranes. Journal of The Electrochemical Society 2017, 164, F1331–F1341. [Google Scholar] [CrossRef]

- Alavijeh, A.S.; Bhattacharya, S.; Thomas, O.; Chuy, C.; Yang, Y.; Zhang, H.; Kjeang, E. Effect of hygral swelling and shrinkage on mechanical durability of fuel cell membranes. Journal of Power Sources 2019, 427, 207–214. [Google Scholar] [CrossRef]

- Panha, K.; Fowler, M.; Yuan, X.Z.; Wang, H. Accelerated durability testing via reactants relative humidity cycling on PEM fuel cells. Applied Energy 2012, 93, 90–97. [Google Scholar] [CrossRef]

- Yuan, X.Z.; Zhang, S.; Ban, S.; Huang, C.; Wang, H.; Singara, V.; Fowler, M.; Schulze, M.; Haug, A.; Friedrich, K.A.; Hiesgen, R. Degradation of a PEM fuel cell stack with Nafion® membranes of different thicknesses. Part II: Ex situ diagnosis. Journal of Power Sources 2012, 205, 324–334. [Google Scholar] [CrossRef]

- Healy, J.; Hayden, C.; Xie, T.; Olson, K.; Waldo, R.; Brundage, M.; Gasteiger, H.; Abbott, J. Aspects of the chemical degradation of PFSA ionomers used in PEM fuel cellsx. Fuel Cells 2005, 5, 302–308. [Google Scholar] [CrossRef]

- Shi, S.; Sun, X.; Lin, Q.; Chen, J.; Fu, Y.; Hong, X.; Li, C.; Guo, X.; Chen, G.; Chen, X. Fatigue crack propagation behavior of fuel cell membranes after chemical degradation. International Journal of Hydrogen Energy 2020, 45, 27653–27664. [Google Scholar] [CrossRef]

- Ferreira, P.J.; la O’, G.J.; Shao-Horn, Y.; Morgan, D.; Makharia, R.; Kocha, S.; Gasteiger, H.A. Instability of Pt/C Electrocatalysts in Proton Exchange Membrane Fuel Cells. Journal of The Electrochemical Society 2005, 152. [Google Scholar] [CrossRef]

- Hassan, A.; Paganin, V.A.; Ticianelli, E.A. Investigation of carbon supported PtW catalysts as CO tolerant anodes at high temperature in proton exchange membrane fuel cell. Journal of Power Sources 2016, 325, 375–382. [Google Scholar] [CrossRef]

- Kangasniemi, K.H.; Condit, D.A.; Jarvi, T.D. Characterization of Vulcan Electrochemically Oxidized under Simulated PEM Fuel Cell Conditions. Journal of The Electrochemical Society 2004, 151, E125. [Google Scholar] [CrossRef]

- Brik, K.; Ammar, F.B.; Djerdir, A.; Miraoui, A. Causal and Fault Trees Analysis of Proton Exchange Membrane Fuel Cell Degradation. Journal of Fuel Cell Science and Technology 2015, 12. [Google Scholar] [CrossRef]

- Shi, L.; Setzler, B.P.; Yan, Y. Understanding the Ebalance for water management in hydroxide exchange membrane fuel cells. Journal of Power Sources 2022, 536, 231514. [Google Scholar] [CrossRef]

- Singh, R.; Sui, P.C.; Wong, K.H.; Kjeang, E.; Knights, S.; Djilali, N. Modeling the Effect of Chemical Membrane Degradation on PEMFC Performance. Journal of The Electrochemical Society 2018, 165, F3328–F3336. [Google Scholar] [CrossRef]

- Araya, S.S.; Zhou, F.; Sahlin, S.L.; Thomas, S.; Jeppesen, C.; Kaer, S.K. Fault characterization of a proton exchange membrane fuel cell stack. Energies 2019, 12. [Google Scholar] [CrossRef]

- Jahnke, T.; Futter, G.A.; Baricci, A.; Rabissi, C.; Casalegno, A. Physical Modeling of Catalyst Degradation in Low Temperature Fuel Cells: Platinum Oxidation, Dissolution, Particle Growth and Platinum Band Formation. Journal of The Electrochemical Society 2020, 167, 013523. [Google Scholar] [CrossRef]

- Rama, P.; Chen, R.; Andrews, J. Failure analysis of polymer electrolyte fuel cells. SAE Technical Papers 2008, pp. 776–790. [CrossRef]

- Wang, H.; Li, H.; Yuan, X.Z. PEM Fuel Cell Failure Mode Analysis; Vol. 1, CRC Press, 2011. [CrossRef]

- Dhimish, M.; Zhao, X. Enhancing reliability and lifespan of PEM fuel cells through neural network-based fault detection and classification. International Journal of Hydrogen Energy 2023, 48, 15612–15625. [Google Scholar] [CrossRef]

- Mao, L.; Jackson, L. Comparative study on prediction of fuel cell performance using machine learning approaches. International MultiConference of Engineers and Computer Scientists (IMECS), 2016, Vol. 1, pp. 52–57.

- Lin, Z.; Wang, C.H.; Liu, Y. The Fault Analysis and Diagnosis of Proton Exchange Membrane Fuel Cell Stack. Advanced Materials Research 2011, 197-198, 705–710. [Google Scholar] [CrossRef]

- Li, Z.; Outbib, R.; Giurgea, S.; Hissel, D.; Giraud, A.; Couderc, P. Fault diagnosis for fuel cell systems: A data-driven approach using high-precise voltage sensors. Renewable Energy 2019, pp. 1435–1444. [CrossRef]

- Sarbast, V.A. Modeling of Proton Exchange Membrane Fuel Cell Performance Degradation and Operation Life. Master thesis, University of Victoria, Canada, 2021.

- Wang, P.; Liu, H.; Chen, J.; Qin, X.; Lehnert, W.; Shao, Z.; Li, R. A novel degradation model of proton exchange membrane fuel cells for state of health estimation and prognostics. International Journal of Hydrogen Energy 2021, 46, 31353–31361. [Google Scholar] [CrossRef]

- Ao, Y.; Chen, K.; Laghrouche, S.; Depernet, D. Proton exchange membrane fuel cell degradation model based on catalyst transformation theory. Fuel Cells 2021, 21, 254–268. [Google Scholar] [CrossRef]

- Bernhard, D.; Kadyk, T.; Kirsch, S.; Scholz, H.; Krewer, U. Model-assisted analysis and prediction of activity degradation in PEM-fuel cell cathodes. Journal of Power Sources 2023, 562. [Google Scholar] [CrossRef]

- Yue, M.; Jemei, S.; Gouriveau, R.; Zerhouni, N. Review on health-conscious energy management strategies for fuel cell hybrid electric vehicles: Degradation models and strategies. International Journal of Hydrogen Energy 2019, 44, 6844–6861. [Google Scholar] [CrossRef]

- Ciavarella, R.; Graditi, G.; Valenti, M.; Pinnarelli, A.; Barone, G.; Vizza, M.; Menniti, D.; Sorrentino, N.; Brusco, G. Modeling of an energy hybrid system integrating several storage technologies: The DBS technique in a nanogrid application. Sustainability, 13. [CrossRef]

- Working of Lithium-ion Battery. https://robu.in/working-of-lithium-ion-battery/.

- Zou, B.; Zhang, L.; Xue, X.; Tan, R.; Jiang, P.; Ma, B.; Song, Z.; Hua, W. A Review on the Fault and Defect Diagnosis of Lithium-Ion Battery for Electric Vehicles. Energies, 16. [CrossRef]

- Wang, A.; Kadam, S.; Li, H.; Shi, S.; Qi, Y. Review on modeling of the anode solid electrolyte interphase (SEI) for lithium-ion batteries. npj Computational Materials, 4. [CrossRef]

- G., G.; R., C.; M., V. An innovative BESS management for dynamic frequency restoration. 2017 17th IEEE International Conference on Environment and Electrical Engineering and 2017 1st IEEE Industrial and Commercial Power Systems Europe, EEEIC/I and CPS Europe 2017, 2017. [CrossRef]

- R., C.; G., G.; M., V.; T., S. Innovative Frequency Controls for Intelligent Power Systems. International Symposium on Power Electronics, Electrical Drives, Automation and Motion (SPEEDAM 2018), 2018. [CrossRef]

- Birkl, C.R.; Roberts, M.R.; McTurk, E.; Bruce, P.G.; Howey, D.A. Degradation diagnostics for lithium ion cells. Journal of Power Sources, 341. [CrossRef]

- Jung, R.; Metzger, M.; Haering, D.; Solchenbach, S.; Marino, C.; Tsiouvaras, N.; Stinner, C.; Gasteiger, H.A. Consumption of Fluoroethylene Carbonate (FEC) on Si-C Composite Electrodes for Li-Ion Batteries. The Electrochemical Society, 163. [CrossRef]

- Ibraheem, R.; Strange, C.; Reis, G.d. Capacity and Internal Resistance of lithium-ion batteries: Full degradation curve prediction from Voltage response at constant Current at discharge. Journal of Power Sources, 556. [CrossRef]

- Li, Z.; Huang, J.; Liaw, B.Y.; Metzler, V.; Zhang, J. A review of lithium deposition in lithium-ion and lithium metal secondary battery. Journal of Power Sources, 254. [CrossRef]

- Gabryelczyk, A.; Ivanov, S.; Bund, A.; Lota, G. Corrosion of aluminium current collector in lithium-ion batteries: A review. Journal of Energy Storage, 43. [CrossRef]

- Wang, H.; Simunovic, S.; Maleki, H.; Howard, J.N.; Hallmark, J.A. Internal Configuration of Prismatic Lithium-Ion Cells at the Onset of Mechanically Induced Short Circuit. J. Power Sources, 306.

- Tran, M.K.; Mevawalla, A.; Aziz, A.; Panchal, S.; Xie, Y.; Fowler, M. A Review of Lithium-Ion Battery Thermal Runaway Modeling and Diagnosis Approaches. Processes 2022, 10. [Google Scholar] [CrossRef]

- Li, H.; Fu, L.; Long, X.; Liu, L.; Zeng, Z. A study on overcharge behavior of high-power type lithium-ion battery with Li(Ni1/3Mn1/3Co1/3)O2 as cathode material. Journal of Thermal Analysis and Calorimetry. [CrossRef]

- Magne-Tang, N.; Decaux, C.; Thivel, P.X.; Lefrou, C. Exploring the Discharge Performance of Li-ion Batteries Using Ohmic Drop Compensation. Batteries, 9. [CrossRef]

- Han, X.; Lu, L.; Zheng, Y.; Feng, X.; Li, Z.; Li, J.; Ouyang, M. A review on the key issues of the lithium ion battery degradation among the whole life cycle. eTransportation, 1, 100005. [CrossRef]

- Surya, S.; Mohan, K.; Chhetri, A.; Williamson, S. Software Tools and Datasets for Battery Management System Applications. TechRxiv. Preprint. [CrossRef]

- Saha, B.; Goebel, K. Battery Data Set. https://www.nasa.gov/intelligent-systems-division/discovery-and-systems-health/pcoe/pcoe-data-set-repository/, 2007. NASA Prognostics Data Repository, NASA Ames Research Center, Moffett Field, CA.

- Luzi, M. Automotive Li-ion Cell Usage Data Set. https://ieee-dataport.org/documents/automotive-li-ion-cell-usage-data-set, 2018. IEEE Dataport.

- Attia, P.M.; Grover, A.; Jin, N.; Severson, K.A.; Markov, T.M.; Liao, Y.H.; Chen, M.H.; Cheong, B.; Perkins, N.; Yang, Z.; Herring, P.K.; Aykol, M.; Harris, S.J.; Braatz, R.D.; Ermon, S.; Chueh, W.C. Automotive Li-ion Cell Usage Data Set. https://data.matr.io/1/projects/5d80e633f405260001c0b60a, 2018.

- Attia, P.M.; Grover, A.; Jin, N.; Severson, K.A.; Markov, T.M.; Liao, Y.H.; Chen, M.H.; Cheong, B.; Perkins, N.; Yang, Z.; Herring, P.K.; Aykol, M.; Harris, S.J.; Braatz, R.D.; Ermon, S.; Chueh, W.C. Closed-loop optimization of fast-charging protocols for batteries with machine learning. Nature, pp. 397–402. [CrossRef]

- Severson, K.A.; Attia, P.M.; Jin, N.; Perkins, N.; Jiang, B.; Yang, Z.; Chen, M.H.; Aykol, M.; Herring, P.K.; Fraggedakis, D.; Bazant, M.Z.; Harris, S.J.; Chueh, W.C.; Braatz, R.D. Cycle Life Prediction Dataset. https://data.matr.io/1/projects/5c48dd2bc625d700019f3204, 2019.

- Severson, K.A.; Attia, P.M.; Jin, N.; Perkins, N.; Jiang, B.; Yang, Z.; Chen, M.H.; Aykol, M.; Herring, P.K.; Fraggedakis, D.; Bazant, M.Z.; Harris, S.J.; Chueh, W.C.; Braatz, R.D. Data-driven prediction of battery cycle life before capacity degradation. Nature Energy, pp. 383–391. [CrossRef]

- Kollmeyer, P. Panasonic 18650PF Li-ion Battery Data. https://data.mendeley.com/datasets/wykht8y7tg/1, 2018. Mendeley Data.

- Zhao, R.; Kollmeyer, P.J.; Lorenz, R.D.; Jahns, T.M. A compact unified methodology via a recurrent neural network for accurate modeling of lithium-ion battery voltage and state-of-charge. 2017 IEEE Energy Conversion Congress and Exposition (ECCE), 2017, pp. 5234–5241. [CrossRef]

- Herring, P.; Gopal, C.B.; Aykol, M.; Montoya, J.H.; Anapolsky, A.; Attia, P.M.; Gent, W.; Hummelshøj, J.S.; Hung, L.; Kwon, H.K.; Moore, P.; Schweigert, D.; Severson, K.A.; Suram, S.; Yang, Z.; Braatz, R.D.; Storey, B.D. Battery Evaluation and Early Prediction (BEEP). https://github.com/TRI-AMDD/beep, 2020. Git repository.

- Herring, P.; Gopal, C.B.; Aykol, M.; Montoya, J.H.; Anapolsky, A.; Attia, P.M.; Gent, W.; Hummelshøj, J.S.; Hung, L.; Kwon, H.K.; Moore, P.; Schweigert, D.; Severson, K.A.; Suram, S.; Yang, Z.; Braatz, R.D.; Storey, B.D. BEEP: A Python library for Battery Evaluation and Early Prediction. SoftwareX 2020, 11, 100506. [Google Scholar] [CrossRef]

- Buteau, S. Universal Battery Database. https://github.com/Samuel-Buteau/universal-battery-database, 2020. Git repository.

- VISHAY INTERTECHNOLOGY. E Series Power MOSFET. https://www.vishay.com/docs/92295/siha11n80ae.pdf, 2019. Rev. A.

- Toshiba Electronic Devices & Storage Corporation. MOSFETs Silicon Carbide N-Channel MOS. https://www.vishay.com/docs/92295/siha11n80ae.pdf, 2022. Rev. 2.

- VISHAY INTERTECHNOLOGY. Aluminum Electrolytic Capacitors SMD (Chip), Very Low Z. https://www.vishay.com/docs/28395/150crz.pdf, 2024.

- KEMET Electronics Corporation. Surface Mount Hybrid Aluminum Polymer Capacitors. https://content.kemet.com/datasheets/KEM_A4098_A780.pdf, 2024.

- Bogónez-Franco, P.; Sendra, J.B. EMI comparison between Si and SiC technology in a boost converter. International Symposium on Electromagnetic Compatibility - EMC EUROPE, 2012, pp. 1–4. [CrossRef]

- Graditi, G.; Adinolfi, G. Temperature influence on photovoltaic power optimizer components reliability. International Symposium on Power Electronics Power Electronics, Electrical Drives, Automation and Motion, 2012, pp. 1113–1118. [CrossRef]

- Hu, Y.; Shi, P.; Li, H.; Yang, C. Health Condition Assessment of Base-Plate Solder for Multi-Chip IGBT Module in Wind Power Converter. IEEE Access 2019, 7, 72134–72142. [Google Scholar] [CrossRef]

- Khalil, M.; Soulatiantork, P. Reliability assessment of PV inverters. 14th IMEKO TC10 Workshop Technical Diagnostics New Perspectives in Measurements, Tools and Techniques for system’s reliability, maintainability and safety, Milan, Italy, June 27-28, 2016.

- Hu, Z.; Ge, X.; Xie, D.; Zhang, Y.; Yao, B.; Dai, J.; Yang, F. An Aging-Degree Evaluation Method for IGBT Bond Wire with Online Multivariate Monitoring. Energies 2019, 12. [Google Scholar] [CrossRef]

- Faults in LVDC microgrids with front-end converters. Technical Application Papers N. 14, ABB S.p.A., 2021. https://library.e.abb.com/public/d772a7b5e0d0428fbc66ea24fe04be65/1SDC007113G0201_QT14%202021_EN.pdf.

- Kullaa, J. Detection, identification, and quantification of sensor fault in a sensor network. Mechanical Systems and Signal Processing 2013, 40, 208–221. [Google Scholar] [CrossRef]

- Jiang, L.; Djurdjanovic, D.; Ni, J.; Lee, J. Sensor Degradation Detection in Linear Systems. Engineering Asset Management, 2006, pp. 1252–1260. [CrossRef]

- Hau, F.; Baumgärtner, F.; Vossiek, M. Influence of vibrations on the signals of automotive integrated radar sensors. 2017 IEEE MTT-S International Conference on Microwaves for Intelligent Mobility (ICMIM), 2017, pp. 159–162. [CrossRef]

- Huang, Y.; Gertler, J.; McAvoy, T.J. Sensor and actuator fault isolation by structured partial PCA with nonlinear extensions. Journal of Process Control 2000, 10, 459–469. [Google Scholar] [CrossRef]

- Zhang, X.; Parisini, T.; Polycarpou, M.M. Sensor bias fault isolation in a class of nonlinear systems. IEEE Transactions on Automatic Control 2005, 50, 370–376. [Google Scholar] [CrossRef]

- Liu, L.; Zhao, F.; Yi, L.; Peng, M.; Lu, B.; Wang, T.; Shen, J. Fault Test Analysis of Abnormal Remaining Amount of Smart Meter. 2023 Panda Forum on Power and Energy (PandaFPE), 2023, pp. 1366–1370. [CrossRef]

- Lei, Z.Q.; Li, G.J.; Egelhoff, W.F.; Lai, P.T.; Pong, P.W.T. Review of Noise Sources in Magnetic Tunnel Junction Sensors. IEEE Transactions on Magnetics 2011, 47, 602–612. [Google Scholar] [CrossRef]

- Grouz, F.; Sbita, L.; Boussak, M. Current sensors gain faults detection and isolation based on an adaptive observer for PMSM drives. 10th International Multi-Conferences on Systems, Signals & Devices 2013 (SSD13), 2013, pp. 1–6. [CrossRef]

- Yang, Q.; Wang, J. Multi-Level Wavelet Shannon Entropy-Based Method for Single-Sensor Fault Location. Entropy 2015, 17, 7101–7117. [Google Scholar] [CrossRef]

- Abrahamsen, F.E.; Ai, Y.; Cheffena, M. Communication Technologies for Smart Grid: A Comprehensive Survey. Sensors 2021, 21. [Google Scholar] [CrossRef] [PubMed]

- Xinyu, D.; Yin, H.; Yang, H.; Yue, H.; Xiaoyong, Q.; Yu, J.; Jie, Q.; Lin, L. Demonstration of chaotic-laser based WDM-PON secure optical communication and real-time online fiber-fault detection and location. 2015 Opto-Electronics and Communications Conference (OECC), 2015, pp. 1–3. [CrossRef]

- Chun-Kit, C.; Tong, F.; Lian-Kuan, C.; Keang-Po, H.; Lam, D. Fiber-fault identification for branched access networks using a wavelength-sweeping monitoring source. IEEE Photonics Technology Letters 1999, 11, 614–616. [Google Scholar] [CrossRef]

- Gardner, F. A BPSK/QPSK Timing-Error Detector for Sampled Receivers. IEEE Transactions on Communications 1986, 34, 423–429. [Google Scholar] [CrossRef]

- Yuan, W.; Shi, Q.; Wu, N.; Guo, Q.; Huang, X. Gaussian Message Passing Based Passive Localization in the Presence of Receiver Detection Failures. 2018 IEEE 87th Vehicular Technology Conference (VTC Spring), 2018, pp. 1–5. [CrossRef]

- Li, F.; Luo, B. Preserving data integrity for smart grid data aggregation. 2012 IEEE Third International Conference on Smart Grid Communications (SmartGridComm), 2012, pp. 366–371. [CrossRef]

- Kim, H.; Hwang, I.; Lee, J.; Yeom, H.Y.; Sung, H. Concurrent and Robust End-to-End Data Integrity Verification Scheme for Flash-Based Storage Devices. IEEE Access 2022, 10, 36350–36361. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).