1. Introduction

According to World Bank, waste generation is rapidly increasing worldwide, and it is estimated to reach 3.5 Gt/year by 2050 [

1]. In the field of solid waste management, the established scenario until today has been sanitary landfilling. However, this practice remains environmentally harmful due to greenhouse gasses emissions (GHG) and polluting agents affecting ground and aerial contamination [

2]. Incineration for electricity production and anaerobic digestion with biogas production are two practices dating back to the industrial revolution, but innovative WtE methods such as gasification and pyrolysis have emerged in recent decades, producing solid, gaseous, and liquid fuels [

3]. This has created the need for large-scale processing, especially for waste with increased areal density, such as that of municipal solid waste (MSW). Moreover, the concept of sustainability introduced the participation of various stakeholders in decision making combined with different, often self-conflicting criteria. Multi-criteria decision analysis (MCDA) belongs to the broader scientific field of operational research and allows the synthesis of conflicting views concerning the three pillars of sustainability, namely the financial, the social and the environmental [

4].

Along the scientific literature, many methods of MCDA have been used up to date, to comparatively analyze different WtE technologies. According to Vlachokostas et al. (2021) [

4] the most widely used is Analytic Hierarchy Process (AHP), Simple Additive Models (SAM) and Preference Ranking Organization Method for Enrichment of Evaluations (PROMETHEE). The majority of MCDA studies involve the 3 established criteria (social, environmental, economic) and in many cases the addition of a fourth, namely the technological. Kheybari et al. 2019 [

5] expands the set of selected criteria for MCDA to include technical aspects like technical maturity, reliability, cleaning systems, energy efficiency, skilled personnel etc. Thengane (2019) [

6] included volume reduction, safety, user friendliness and scalability potential among the technical criteria as well as community acceptance and employment among the socio-political. Integrating sustainability criteria with a robust MCDA methodological scheme equips researchers with a user-friendly method adjusted for niche-specific sustainability issues (waste management, etc.).

The objective of this research is twofold: Firstly, to propose a complete MCDA methodological scheme comprised of clear and manageable steps for the selection of WtE technologies in the context of sustainability and secondly, to comparatively analyze various technology rankings produced by the MCDA method, using alternative scenarios and location specific data for the case of Greece. For this purpose, the PROMETHEE method was chosen as one of the most preferred techniques in similar problems taking also into account that it allows sensitivity analysis in a tractable and flexible way for the user. The alternative scenarios being examined involve variations in weighting factors of selected criteria and data from different sources (public, experts, scientific literature). Apart from environmental and economic criteria, public preference and experts’ opinions produce evident data and valuable conclusions that can be used by local authorities in decision making processes, to avoid “Not In My Back Yard” (NIMBY) syndrome and technical issues of scalability, especially for innovative and newly incorporated technologies. In the second section the basic structure and components of the developed methodological framework are meticulously described. In the third section the applicability of the methodology is presented, and the main results are critically discussed for the case study of Greece. In the final section important conclusions are summarized and future challenges are considered.

2. Materials and Methods

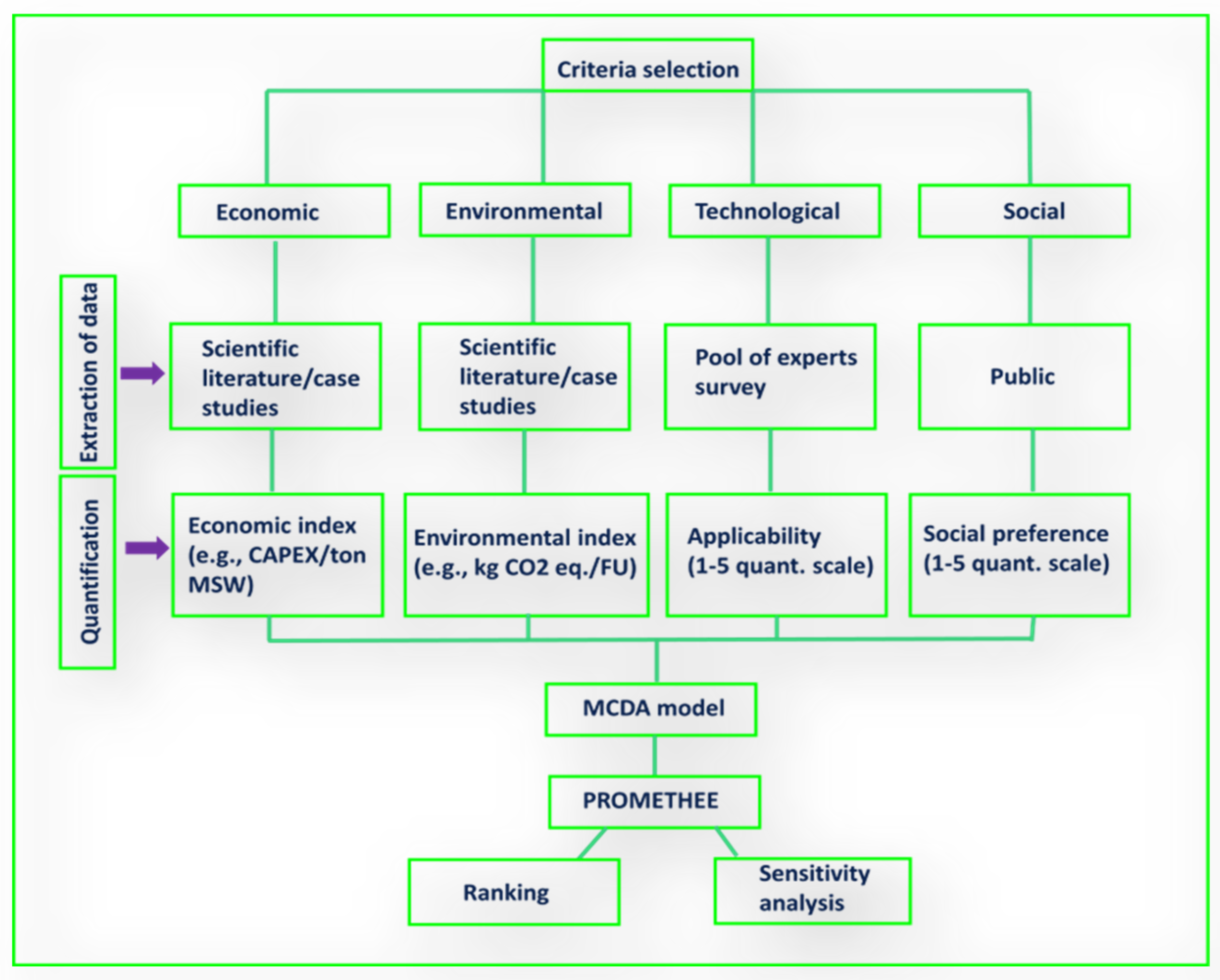

The Materials The general methodological scheme developed and demonstrated for the purpose of this study comprises of 6 consecutive steps as depicted in

Figure 1. Firstly, the strategic scope of the MCDA analysis must be defined. This is crucial towards the efficient realization of sustainability’s assessment of the technological mixture (i.e., combination of different technologies) under consideration. As a second step, the researcher defines the set of alternatives that will be compared (third step) based upon the selected criteria that represent the three pillars of sustainability. The majority of MCDA methods require quantitative data (fourth step). When the data model is complete, application in selected software (fifth step) yields various rankings/solutions according to the number of scenarios. Sensitivity analysis is considered a useful technique in MCDA, especially in the context of sustainability. Alteration of each criterion’s weight often leads to different solutions that must be taken into consideration to have a broader and clearer understanding of various parameters (criteria, alternatives, stakeholders, etc.) and the way that these interrelate and interact to produce a well-defined result.

2.1. PROMETHEE Method

PROMETHEE method for MCDA was originally developed by J.P Brans and Ph. Vincke in 1985 and it is based on the outranking approach, using pairwise comparison between alternatives (actions), and utilizing preference functions [

7]. Three main steps comprise the PROMETHEE method [

8]:

Calculation of preference degrees for each pair of alternatives

Calculation of unicriterion flows

Calculation of global flows

Preference degrees are scores between 0 and 1 that indicate how much an alternative is preferred compared to another. Preference degree of 1 indicates total preference while preference degree of 0 means no preference at all. This is accomplished by using preference functions of various forms (usual, linear, level, u-shape, gaussian, etc.). Preference threshold p is the difference of two alternatives beyond of which, the decision maker shows clear preference to an alternative over another, while indifference threshold q is the difference of two alternatives, beneath of which, the decision maker shows indifference to either [

8]. For each pair of alternatives

, a unicriterion preference degree

is calculated, based on criterion

where

is the number of criteria. Let

be the performance of action

on criterion

. Linear function can be shown in Equation (1) [

8].

The global preference degree π

ij indicates the global preference of action c

i on action c

j according to all criteria, where w

m is the weight of each criterion Equation (2) [

8].

The next step in the PROMETHEE method is the calculation of unicriterion flows, which is the summarization of the total pairwise preference degrees. Unicriterion flows consist of the positive, negative, and net flows. The positive flow indicates how an alternative is preferred over all other alternatives, for a certain criterion, using a score between 0 and 1. The negative flow, on the contrary, indicates how all other alternatives are preferred to this alternative, using a score between 0 and 1. The net flow is produced by the substruction of the negative flow, from the positive and it is indicated by a score between -1 and 1 [

8].

Lastly, for the calculation of global flows, that takes into consideration all the criteria simultaneously, the decision maker must specify the weight of each alternative, i.e., the relative importance of the alternative in comparison to all the others. As in unicriterion flows, positive and negative flows return values between 0 and 1 and net flows between -1 and 1. Global net flows produce the final result in the form of ranking. By denoting Φ

+(c

i) and Φ

-(c

j) the positive and negative flows of action c

i, respectively, the global flows are produced by Equations (3) and (4) [

8].

One of the main advantages of PROMETHEE software is the capability for implementing sensitivity analysis. It allows the decision maker to produce dynamic results (rankings) while changing various parameters, e.g., weight. Additionally, this method requires fewer inputs compared to other techniques and it has a clear and easy-to-use structure [

9].

2.1. Criteria and Data Collection

Sustainability encompasses environmental, economic, social, and technological criteria, forming a framework for their integration into an efficient management strategy [

10]. Various frameworks exist in the scientific literature, such as the 3E model (Energy, Economic, Environmental) [

11]. For the case of Greece, four criteria were analyzed: economic, environmental, technological, and social. A thorough study of the scientific literature was needed for the economic and environmental criteria, and the design of two surveys, specially customized to assess public preference and experts opinion, for the social and technological criterion respectively. Criteria selection was accompanied by the proper selection of the corresponding index for each criterion, in order to provide the MCDA model with the necessary quantitative data. Several case studies were studied, concerning either real case scenarios of WtE plants or model applications.

Figure 3 depicts the applied framework used for the scope of this study.

Figure 2.

Detailed MCDA methodological framework for the selection of the opti mal WtE technology.

Figure 2.

Detailed MCDA methodological framework for the selection of the opti mal WtE technology.

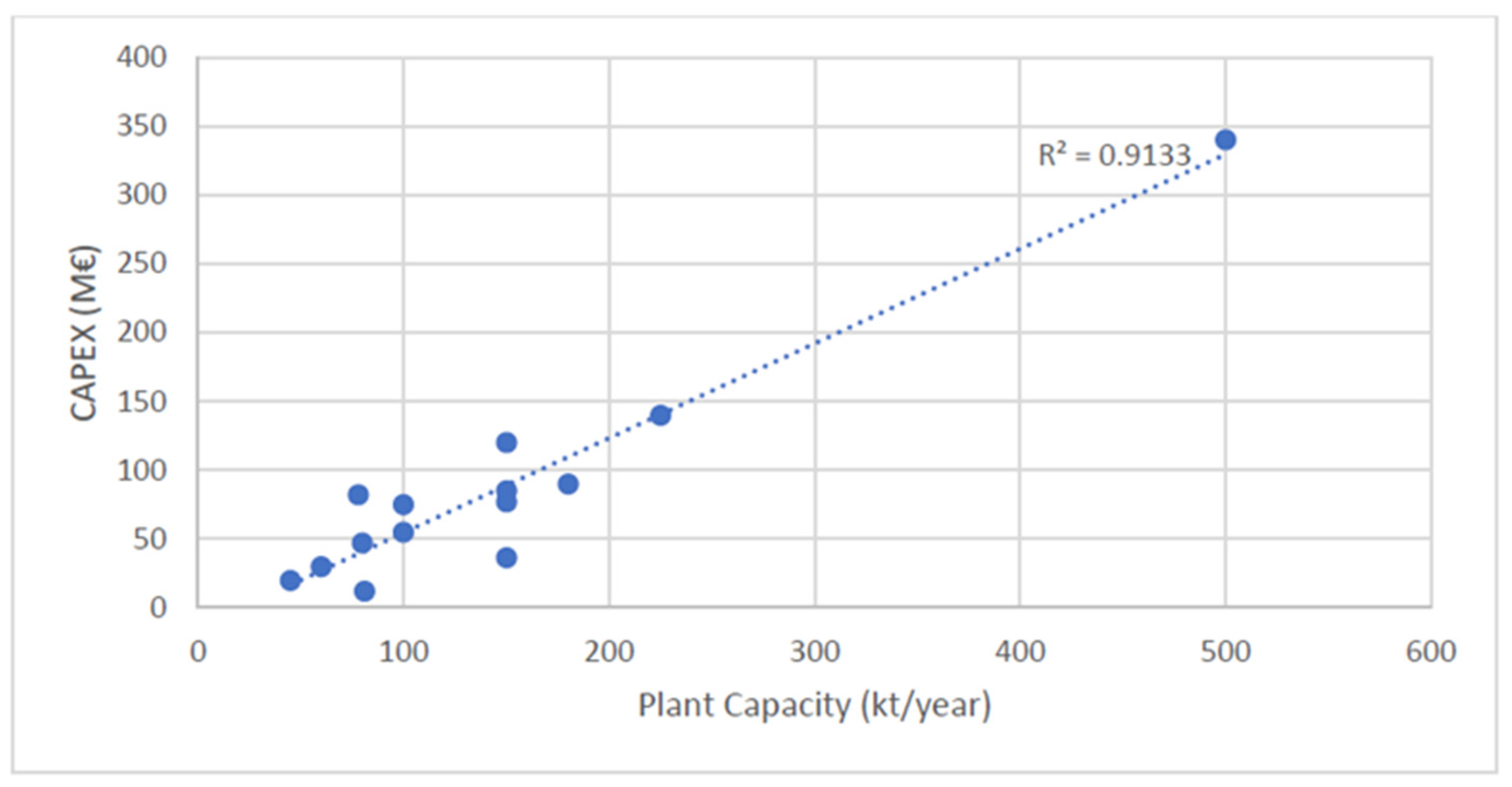

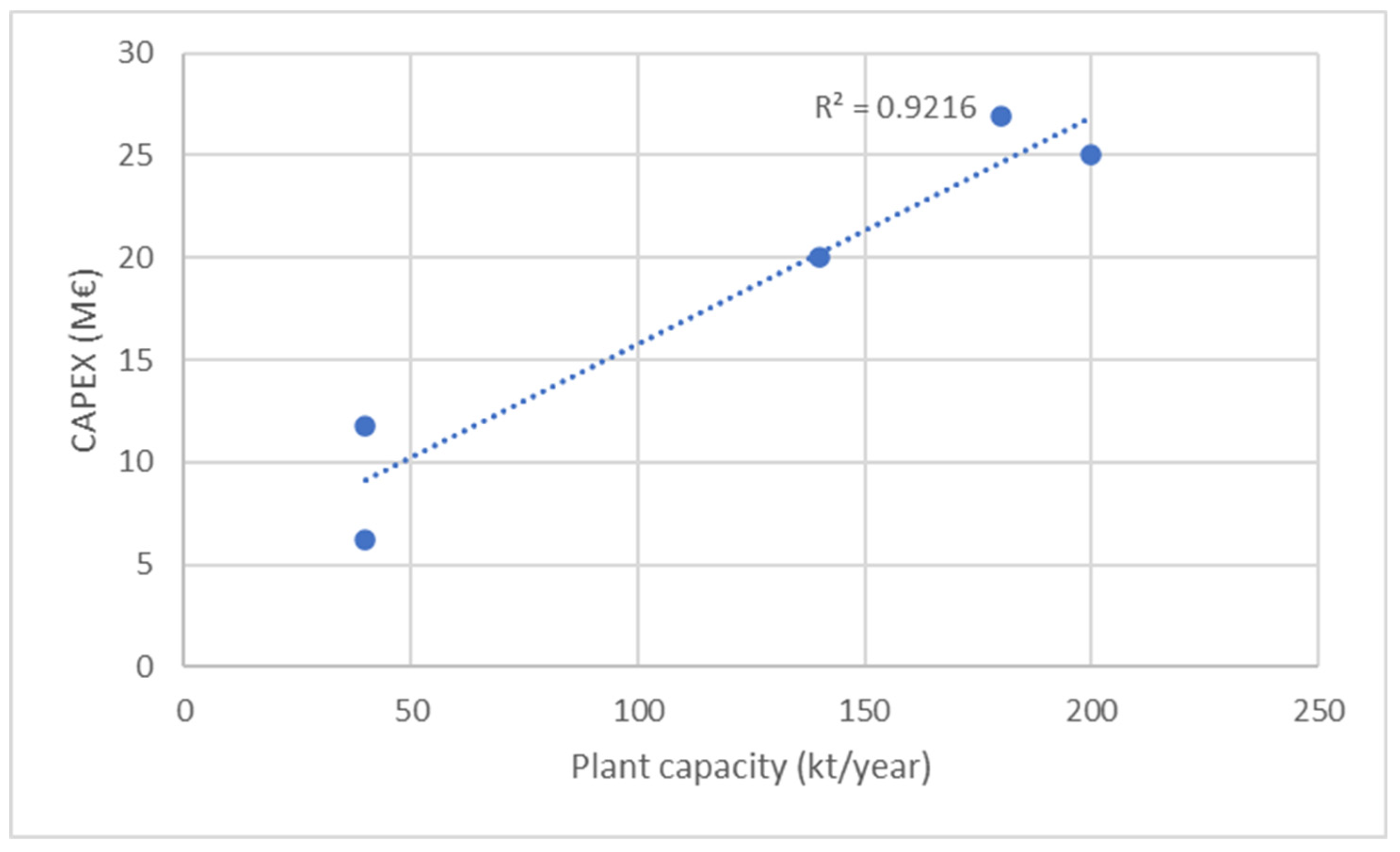

2.2.1. Economic Criterion

Capital Expenditure (CAPEX) mainly consists of construction costs, equipment and installation, land use and preparation, loan interest, etc. External costs are another factor that is usually taken into consideration in sustainability issues and is consisted of direct and/or indirect consequences of a plant operation in stakeholders not directly related to the plant owner or operator, e.g., costs related to healthcare from harmful emissions in the area, or social costs related to the mechanization of labor and the concurrent job loss [

12]. For the purpose of this study, CAPEX/ton of feedstock for the 4 types of plants (incineration, gasification, pyrolysis, and anaerobic digestion) was chosen, as an indicator, mainly due to the greater availability of data in the scientific literature. Especially in the case of incineration and anaerobic digestion plants, data analysis was conducted based on data from the scientific literature, that reveal a strong positive linear correlation between CAPEX (M€) and plant capacity (kt/year), as it is shown in

Figure 4, with R

2 = 0.9133 and 0.9216 respectively [

12,

13,

14,

15,

16].

Figure 3.

Correlation of CAPEX and plant capacity for incineration of MSW.

Figure 3.

Correlation of CAPEX and plant capacity for incineration of MSW.

Figure 4.

Correlation of CAPEX and plant capacity for anaerobic digestion of organic waste.

Figure 4.

Correlation of CAPEX and plant capacity for anaerobic digestion of organic waste.

2.2.2. Environmental Criterion

According to ISO 14040, LCA (Life Cycle Assessment) is a methodical process of gathering and analyzing material and energy inputs and outputs, as well as the related environmental effects that are directly related to the operation of a system of goods or services over the course of its life cycle, and has been widely used during the last decades, as an environmental support system [

17]. The assessment covers the entire life cycle of the product or activity, including, for example, extraction and processing of raw materials, manufacturing, distribution, use, maintenance, recycling, and final disposal, as well as transportation between the aforementioned stages. Through the comparison of environmental burdens of various options, it provides a valuable tool in decision making and management [

18]. Conducted through dedicated software, LCA provides a plethora of environmental indicators that stem from the defined system. The most widely known Life Cycle Impact Assessment Methodologies, currently used especially in Europe, are IPCC GWP (carbon print), CML-IA (midpoint), ReCiPe (midpoint and endpoint) and Ecoindicator 99 (endpoint) [

19]. The results of the LCA though are affected by parameters that are up to the researcher’s assumptions such as system boundaries, functional unit, availiability and accuracy of data, type of waste, etc. Moreover, geographical and seasonal variability of the composition of waste adds more uncertainty to the expected results.

Table 1 highlights the variability of LCA results of selected studies, taking into account also the work of Mayer et al. (2019) [

20], and Dastjerdi et al. (2021) [

21].

For the scope of the present study, Global Warming Potential (GWP) was chosen as an indicator to be gathered and analyzed from various LCA papers in, mainly for the plethora of this type of data in scientific literature. GWP is used to compare the amount of thermal energy absorbed by a gas without directly measuring its concentration in the atmosphere and It’s defined as the ratio of the impact on Earth’s energy balance from 1 kg of a GHG to the impact from 1 kg of CO

2 [

34]. In recent years, due to heightened efforts to combat climate change, GWP has gained prominence as a quantified metric that aids researchers in understanding the overall impact of human activities.

2.2.3. Environmental Criterion

For the successful implementation of any waste management system within the framework of sustainability, social consensus is required. This is also evident in the last decade’s literature which indicates an increase of the social criteria incorporation in the MCDA for WtE technologies [

4]. According to [

35], the factors influencing information collection concern how easily this data can be quantified, and temporal or geographical constraints. For the needs of this research, a questionnaire was implemented as a tool, and distributed in electronic format through email and social networks. 225 responds were received. The questionnaire’s structure revolved around three axes. The first focused on public knowledge about the four examined technologies, the second involved the preference for constructing a unit near the respondent’s place of residence, and the third sought public opinion on the advantages/disadvantages of WtE technologies and the degree of trust in auditing and pollution control procedures. An additional objective was to facilitate the quantification of results, primarily regarding public preference. For this reason, five qualitative choices were presented as responses, corresponding to those used in the PROMETHEE model (qualitative 5-point scale). Subsequently, in each technology, a preference grade was assigned in a quantitative 5-point scale. Ultimately, four performance evaluations emerged, using weighted average method, corresponding to the four technologies introduced into the model. It is worth noting that during the last decade, social considerations are being increasingly incorporated in MCDA studies, despite the difficulties of the quantification of public preference. Public consensus is considered crucial in sustainable waste management [

4].

2.2.4. Technological Criterion

The fourth criterion considered is the technological one, which concerns the degree to which these technologies can be realistically applied in Greece, with unit capacity characterized as large (>150 kt/year). For this purpose, an additional questionnaire was structured, concerning the opinion of experts on these technologies, and distributed via email and social networks. The questionnaire’s structure is as follows: The first axis concerns experts’ opinions on ranking technologies based on economic and environmental criteria. Its purpose is to verify and enrich literature research. The second axis focuses on the primary concern, the realistic application of technologies. The third and final axis revolves around respondents’ judgment regarding the reasons for hindering the development of such units in Greece. As it was in the questionnaire for the public, the type of responses in this survey were given in a qualitative 1-5 scale and subsequently converted into a quantitative scale, using weighted average method. This questionnaire targeted a specific sample of 15 experts from academia, public, and private sector, whose opinions hold significant weight, particularly due to the interdisciplinary nature required to thoroughly examine the subject.

2.3. Current State of MSW Management in Greece

Greece is an exceptional case study to demonstrate the applicability of the proposed methodological scheme. The need to promote WtE technological options is imperative, not only for MSW, but also for other types of waste (agricultural, industrial, sewage, etc.). Currently, the main MSW management method used in Greece is landfilling, as 80% of MSW ends up in landfills [

36] The legislative framework for waste management in Greece follows closely the corresponding European framework. Over the last years, all relevant EU Directives have been transposed into national law. It should be noted that, in 2021, law 4819/2021 imposed a landfilling fee for the unprocessed MSW and the remnants of MSW management facilities. This legislation paves the way for the implementation of the Pay-As-You-Throw (PAYT) system, in compliance with the “polluter pays” principle. The final target of MSW management is the reduction of MSW landfill disposal down to 10% by 2035 [

37]. EU Waste Framework Directives are also incorporated in the National Waste Management Plan (NWMP). According to the NWMP, organic waste represents more than 40% of the total generated MSW in Greece, most of which will be separated at source in the near future, due to the installation of urban brown bins for biodegradable waste collection exclusively. This provides a great opportunity for the implementation of organic waste treatment facilities, with anaerobic digestion being at the forefront of biowaste valorization technologies. Optimal decision making in bio-WtE can increase the value of biowaste to bioproducts and improve the efficiency of bioenergy production [

4].

It should be underlined that in Greece’s co-capital, Thessaloniki, the estimation of local MSW production ranges about 180.000 t/a [

38], hence providing a viable application of a potential MSW management facility, as it fits the typical capacity of large scale WtE units, that starts in the range of 150 kt/a [

39].

The location of a MSW management facility is of critical importance, especially to the viability of the project, since it influences economic and social factors [

40]. No MSW incineration facility exists in Greece so far, and the only operational unit is a medical waste incineration facility in Attica. The unlikelihood of a MSW incineration unit construction in Greece is due to the lack of economic viability as well as social acceptance (ΝIMBY syndrome), despite the significant energy recovery [

41]. A WtE incineration facility can be promoted as a preferable option in contrast to landfilling, only under specific conditions of minimizing external costs of health impacts [

38].

As for implementation of WtE technologies in Greece, only hypothetical case studies exist regarding MSW gasification, such as a MSW plasma gasification plant in Greece by [

42], and biomass gasification in the region of Messenia, Greece [

43]. Concerning pyrolysis, no MSW pyrolysis units exist in Greece, but up-to-date information presented by [

44] shows future plans for an innovative pyrolysis-anaerobic digestion biomass residues processing plant. In any case, there is still effort to be realized towards implementing waste prevention principle, which seeks to reduce the total volume of waste and reduce the harmful effects on health and the environment through re-use, recovering of materials and circular economy, taking into account economic costs and social predisposition.

2.4. Selection of Waste-to-Energy Technologies

2.4.1. Incineration

During the process of incineration, MSW are combusted in a chamber, in a temperature range between 900-950°C. The process is exothermic, and it is used to heat up water for steam generation. Electricity production is usually carried by turbines that use the generated steam for energy production [

45]. Volume and mass reduction of MSW may reach up to 90% [

46]. Apart from energy production and waste management, incineration of MSW may be useful for other sectors like road construction, recovery of ferrous materials and cement industry, mainly through the utilization of fly and bottom ash [

47].

2.4.2. Gasification

Gasification is another example of technology that belongs to thermal treatment methods. The organic compound is partially oxidated in the presence of a gasifying agent (air, oxygen, steam). The main product is syngas, a gaseous fuel comprised of CO

2, CH

4, CO, H

2, etc. Typical operating temperatures are 1000–1600 °C when the agent is pure oxygen and 550– 900 °C when air is used [

48]. Advantages of gasification as WtE technology, are among others, reduction of polluting emissions, significant reduction of waste volume and mass, co-generation compatibility, etc. [

45].

2.4.3. Pyrolysis

Pyrolysis is a relatively novel thermal treatment WtE technology, that usually operates in 3 distinct temperature ranges, always in absence of oxygen. In ranges between 400–800 °C, it mainly produces oil, char and gaseous products that depend upon the process temperature, heating time and residence time [

49]. At ranges close to 500 °C, the main products are tar, wax, and pyrolysis oil, and at higher temperatures (>700 °C) the main product is pyrolysis gas. Usually, the type of waste that is best suited for pyrolysis, is plastics, tires, electric waste, etc. [

47]. Compared to incineration and gasification, pyrolysis shows the least production of SO

2 and NO

x [

50].

2.4.4. Anaerobic Digestion

Anaerobic digestion belongs to the biochemical processes. It involves several stages of biodegradation of bio-waste by methanogenic bacteria, in absence of oxygen. Initially, simple molecules and organic components are produced. The second stage is the hydrolysis of these products into acetic acid, hydrogen, and volatile fatty acids (VFA). The third stage is the conversion of H

2 and organic acids into CH

4 and CO

2 [

51] Biogas is composed mainly by 25-50% CO

2, 50-75% CH

4, and 1-15% other gaseous products (NH

3, H

2S, water vapor, etc.) [

52]. Eliminating contaminants, and especially H

2S is of crucial importance due to the fact that they may produce corrosion problems and influence negatively the process [

53].

3. Results

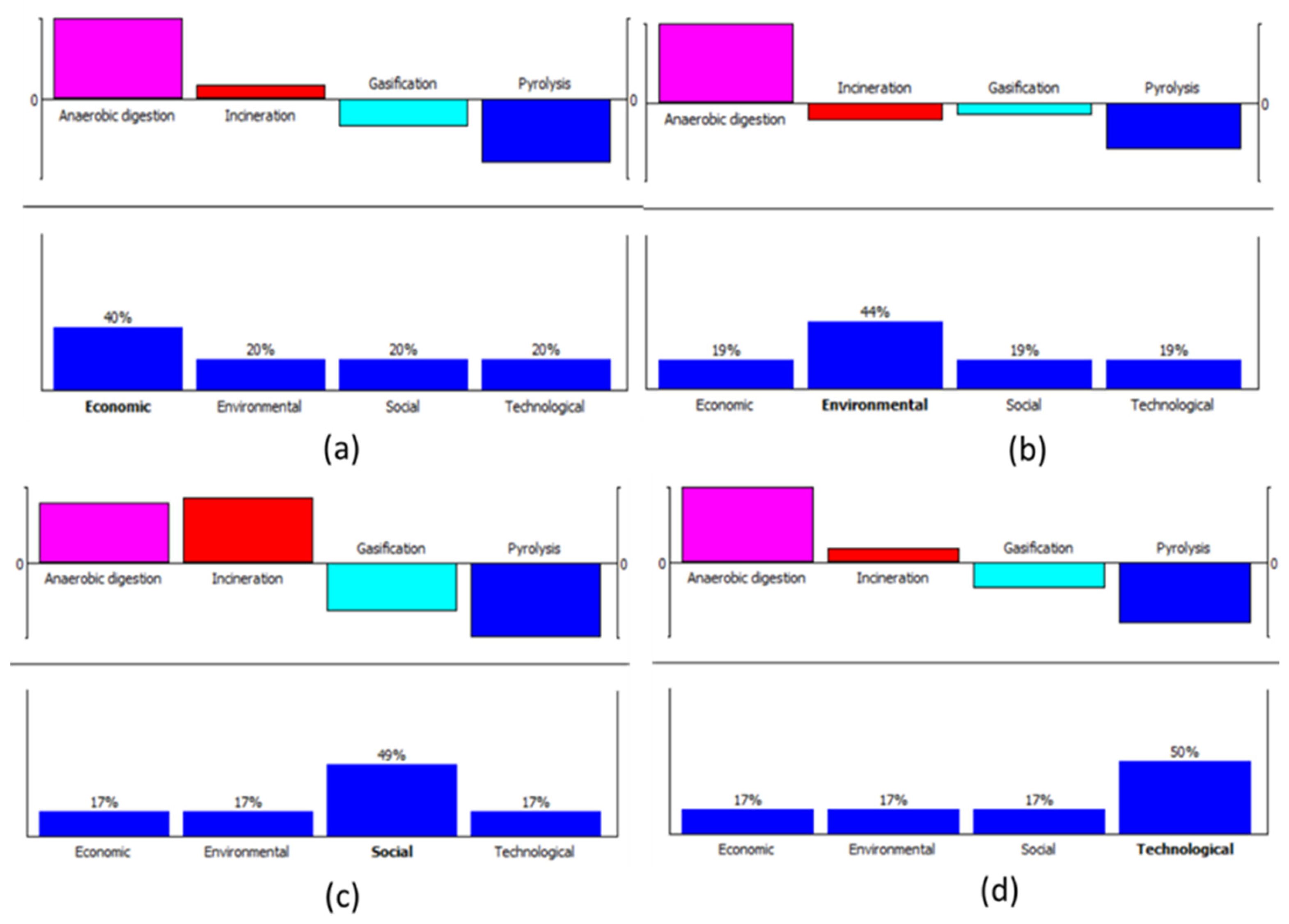

Results were obtained for 2 different scenarios. In Scenario 1, CAPEX (€/t) and GWP (kg CO

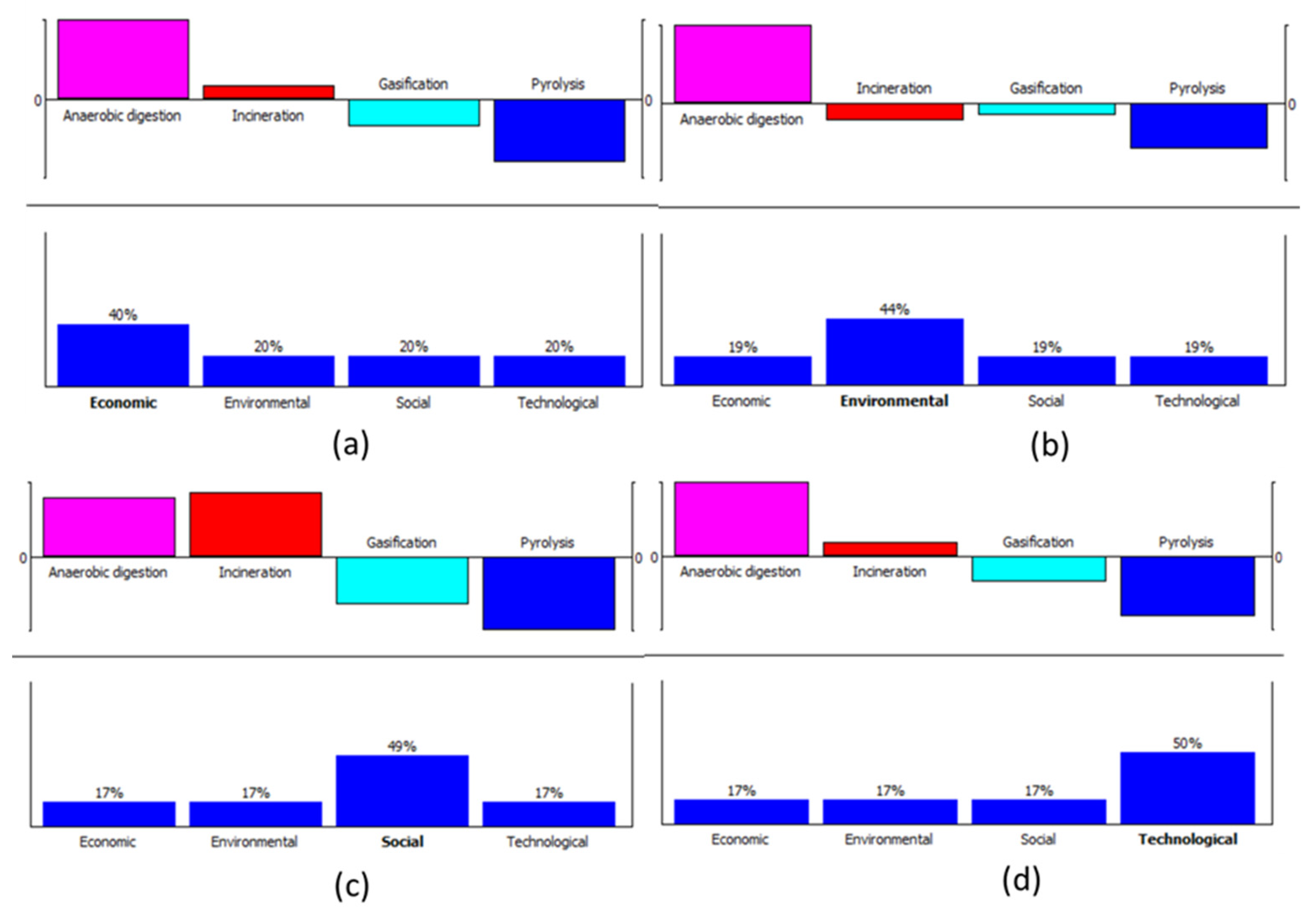

2 eq./t feedstock) are extracted by calculating the mean values reported in the literature for the 4 WtE processes similar technological characteristics and by considering particular type of feedstock (MSW for thermal technologies and organic waste for Anaerobic Digestion) and the same functional unit (1 kg of feedstock). Regarding social preference, the overall grade of each of the 4 WtE technologies is produced by calculating the normal weighted average for each technology in the 1-5 qualitative scale based on the answers of the public. The same method is used for the technological criterion also, based on the experts’ answers for the applicability of each technology in Greece (in 1-5 qualitative scale). In Scenario 2, data concerning the economic and environmental dimension are based on the experts’ responses to the respected questionnaire. More specifically, the experts were asked to comparatively rank the 4 WtE technologies (given the same plant capacity) (i) from the least to the most expensive and (ii) from the most to least environmentally friendly, respectively. Both of the above criteria were normalized using the weighted average method for each technology. The social preference in Scenario 2, is the same as in Scenario 1. In Scenarios 1 and 2, economic and environmental criteria were set to minimize in PROMETHEE, while social and technological were set to maximize. Overall, 4 sub-scenaria were examined for each of the 2 scenarios, by implementing sensitivity analysis according to various weights of the criteria (

Figure 6 and Figure 7).

Table 2 summarizes the collected data from scientific literature and from the data analysis of the survey’s responses, that were used as input in PROMETHEE. In the CAPEX and GWP columns, the values in parentheses account for Scenario 2.

3.1. Scenario 1

Results for Scenario 1 are depicted in

Figure 6. Rankings of the four technologies, in

Figure 6a–d, are produced by adjusting the weights of the four criteria, economic, environmental, social, and technological, to 40%, 44%, 49%, and 50% respectively. Sensitivity analysis showed that anaerobic digestion remains the most preferable technology in all of the four cases. Whether emphasis is given in the economic or technological criterion, total ranking remains the same among the rest of the technologies. Incineration with energy recovery ranks second, gasification third, and fourth comes pyrolysis. Considering environmental performance among the thermochemical processes, gasification seems to be the most preferable option compared to incineration and pyrolysis. Considering social preference, by increasing the corresponding weight percentage, a clear tendency towards incineration is observed. Result diagrams in

Figure 6, overall, agree with the data shown in

Table 1. Anaerobic digestion appears to be the least expensive, most environmentally friendly, and the most applicable compared to the rest. Among the thermochemical processes, gasification and pyrolysis rank lower in investment costs (most expensive) but higher in environmental performance. Considering the social criterion, it is shown that the public is generally positively inclined towards energy valorization of waste, in Greece, with minimal differences among the selected technologies. From data analysis on the responses, about 56% of the responders consider WtE implementation as necessary and 40% hold a positive stance. As far as knowledgeability of the technologies, most of the responders have a clear understanding of incineration and anaerobic digestion (33% and 44% respectively), compared to gasification and pyrolysis (23% and 27%, respectively). Among the benefits of WtE technologies, reduction in waste volume, environmental pollution and decarbonization rank to the top of the responses (57%, 54%, and 44% respectively). Considering the disadvantages, 32% replied that there would be none, 30% would argue that they pose a threat to public health due to harmful emissions and 30% would emphasize aesthetic degradation of landscape. Finally, 60 % of the responders show little or very little trust in anti-pollution control and auditing procedures, while 40% are generally positively inclined.

Figure 5.

Sensitivity analysis of scenario 1 by adjusting the weight of (a) economic criterion, (b) environmental criterion, (c) social criterion, (d) technological criterion.

Figure 5.

Sensitivity analysis of scenario 1 by adjusting the weight of (a) economic criterion, (b) environmental criterion, (c) social criterion, (d) technological criterion.

3.2. Scenario 2

Results in Scenario 2 are depicted in Figure 7. In Figure 7a–d, emphasis is given to the economic, environmental, social, and technological criterion, respectively. Results in this scenario differ slightly from Scenario 1, nevertheless weight percentages in sensitivity analysis, for each of the four cases, remained the same as Scenario 1. Experts’ ratings on the technologies economic and environmental performance, are generally in accordance with the collected data is Scenario 1, further validating the research method that was implemented. Sensitivity analysis produced the following results. Whether emphasis is given to the economic, environmental, and technological criterion, anaerobic digestion ranks first, as in Scenario 1. However, public preference, as it is shown in Figure 7c, favors incineration with energy recovery as the optimum choice, over anaerobic digestion. Among thermochemical processes, gasification is preferred in comparison to incineration and pyrolysis, as the weight of the environmental criterion increases. As in Scenario 1, the increase in the weight of the social criterion to 49% favors incineration over anaerobic digestion. Finally, an increase in the weight of the technological criterion to 50%, as shown in Figure 7d ranks incineration as second, gasification as third and pyrolysis last.

Figure 6.

Sensitivity analysis of scenario 2 by adjusting the weight of (a) economic criterion, (b) environmental criterion, (c) social criterion, (d) technological criterion.

Figure 6.

Sensitivity analysis of scenario 2 by adjusting the weight of (a) economic criterion, (b) environmental criterion, (c) social criterion, (d) technological criterion.

4. Discussion

Anaerobic digestion appears to be the cheapest and most realistic option compared to the thermochemical processes, while gasification and pyrolysis are more expensive and early in their large-scale implementation for Greece, according to experts’ opinion. Incineration represents a middle choice in terms of cost and realistic large-scale application, with a significant portion of the cost attributed to anti-pollution technology. Additionally, a strong correlation is noted between the investment cost and the capacity of anaerobic digestion and incineration units

Figure 3. Anaerobic digestion and incineration are more widespread, with the former developing in recent years, even in Greece. Furthermore, in these two technologies, social consensus seems to be achieved. Public predisposition towards incineration and anaerobic digestion is generally positive compared to the other two, for which there appear to be limited data. An important preference criterion and a key factor in the NIMBY syndrome, is the level of trust in pollution control procedures, while at the same time, the general attitude towards energy production from waste is positive. In conclusion, the public perception of the technologies under consideration is characterized as positive.

Matters of technological hysteresis in Greece should be addressed, in order to implement these technologies in large-scale application. Most cases of large-scale application of gasification, pyrolysis, and a combination (thermoselect method) come from Japan, in widely known commercial plants. Italy also, utilizes pyrolysis, although not in large scale, but many plants involve mass-burning of MSW. With the exception of Finland (Metso Lahti), gasification is not widely used in Europe [

54].

Additionally, there is a notable gap in LCA studies related to energy production from MSW on a large scale, as revealed by the literature review done by the authors. This fact poses a future challenge in the research field. However, expert responses generally align with the ranking derived from the processing of data in PROMETHEE in Scenario 1, indicating incineration with energy recovery as the most polluting process, anaerobic digestion as the most environmentally friendly, and gasification and pyrolysis in the middle.

Multicriteria analysis identified anaerobic digestion as the optimal choice in most cases. Incineration and gasification differ minimally in the produced rankings, with the former maintaining a slight lead over the latter, except when the weight of the social criterion increases. If greater emphasis were to be placed on environmental protection, Refuse Derived Fuel (RDF) gasification could be combined with anaerobic digestion, provided the appropriate technology is developed, while if emphasis is placed on social consensus, the combination of incineration and anaerobic digestion becomes preferable. These conclusions are also confirmed by the scenario analysis based on expert opinions.

The combination of anaerobic digestion with incineration or gasification is reinforced by the fact that biochemical processes only affect the biodegradable fraction of waste, while materials with high calorific value, such as plastic, paper, etc., could undergo thermochemical processing if they arise as RDF from mechanical processing, a process that can be integrated into a comprehensive waste management framework, including recycling. Co-generation of electricity and heat is also considered a sustainable practice in the field of energy production from waste, achieving greater efficiency cumulatively.

Finally, the importance of establishing a methodological framework for multicriteria analysis for waste-to-energy methods, with specific and clear stages, should be emphasized. This framework should serve as a useful tool in the research process, avoiding gaps where critical aspects of the subject under consideration are overlooked.

Author Contributions

Conceptualization, Christos Vlachokostas.; Methodology, Christos Mertzanakis.; Investigation, Christos Mertzanakis; data curation, Christos Mertzanakis, Charalambos Toufexis; Writing—original draft preparation, Christos Mertzanakis, Charalambos Toufexis; Writing—review and editing, Alexandra V. Michailidou; Supervision, Christos Vlachokostas; All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- S. Kaza, L. C. Yao, P. Bhada-Tata, and F. Van Woerden, “What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050.,” 2018.

- M. Abdallah, A. Shanableh, M. Arab, A. Shabib, M. Adghim, and R. El-Sherbiny, “Waste to energy potential in middle income countries of MENA region based on multi-scenario analysis for Kafr El-Sheikh Governorate, Egypt,” J Environ Manage, vol. 232, pp. 58–65, Feb. 2019. [CrossRef]

- N. B. Klinghoffer and M. J. Castaldi, “Gasification and pyrolysis of municipal solid waste (MSW),” in Waste to Energy Conversion Technology, Elsevier Ltd., 2013, pp. 146–176. [CrossRef]

- C. Vlachokostas, A. V. Michailidou, and C. Achillas, “Multi-Criteria Decision Analysis towards promoting Waste-to-Energy Management Strategies: A critical review,” Renewable and Sustainable Energy Reviews, vol. 138. Elsevier Ltd., Mar. 01, 2021. [CrossRef]

- S. Kheybari, F. M. Rezaie, S. A. Naji, and F. Najafi, “Evaluation of energy production technologies from biomass using analytical hierarchy process: The case of Iran,” J Clean Prod, vol. 232, pp. 257–265, Sep. 2019. [CrossRef]

- S. K. Thengane, “Assessment of Different Technologies for Managing Yard Waste Using Analytic Hierarchy Process,” Process Integration and Optimization for Sustainability, vol. 3, no. 2, pp. 255–272, Jun. 2019. [CrossRef]

- J. P. Brans and Ph. Vincke, “Note—A Preference Ranking Organisation Method,” Manage Sci, vol. 31, no. 6, pp. 647–656, Jun. 1985. [CrossRef]

- A. Ishizaka and P. Nemery, Multi-Criteria Decision Analysis: Methods and Software. Chichester: Wiley, 2013.

- H. Taherdoost, “Using PROMETHEE Method for Multi-Criteria Decision Making: Applications and Procedures,” Iris Journal of Economics & Business Management, vol. 1, no. 1, May 2023. [CrossRef]

- N. H. Afgan and M. G. Carvalho, “Multi-criteria assessment of new and renewable energy power plants,” 2002. [Online]. Available: www.elsevier.com/locate/energy.

- S. T. Tan, W. S. Ho, H. Hashim, C. T. Lee, M. R. Taib, and C. S. Ho, “Energy, economic and environmental (3E) analysis of waste-to-energy (WTE) strategies for municipal solid waste (MSW) management in Malaysia,” Energy Convers Manag, vol. 102, pp. 111–120, Jul. 2015. [CrossRef]

- J. Aleluia and P. Ferrão, “Assessing the costs of municipal solid waste treatment technologies in developing Asian countries,” Waste Management, vol. 69, pp. 592–608, Nov. 2017. [CrossRef]

- I. Katsanevakis, A. Malamakis, G. Perkoulidis, and T. Tsatsarelis, “Evaluation of Municipal Solid Waste by energy point of view and the perspectives of application in Region of Central Macedonia,” Thessaloniki, 2010.

- Langen and J. Mitchinson, “PROCESSING OF MUNICIPAL SOLID WASTE BEFORE ANAEROBIC DIGESTION - QUALITIES, CAPEX AND OPEX OF CASE STUDIES,” in 15th European Biosolids and Organic Resources Conference, 2010.

- P. Mckendry, “Overview of Anaerobic Digestion and Power and Gas to Grid Plant CAPEX and OPEX Costs Citation: McKendry P (2019) Overview of Anaerobic Digestion and Power and Gas to Grid Plant CAPEX and OPEX Costs,” International Journal of Bioprocessing and Biotechniques Review Article McKendry P. Int J Bioprocess Biotech, vol. 02, p. 109, 2018.

- M. A. Satiada and A. Calderon, “Comparative analysis of existing waste-to-energy reference plants for municipal solid waste,” Cleaner Environmental Systems, vol. 3, Dec. 2021. [CrossRef]

- “International Standard ISO 14040 (2006) Environmental Management—Life Cycle Assessment—Principle and Framework,” 2006.

- M. M. V. Leme, M. H. Rocha, E. E. S. Lora, O. J. Venturini, B. M. Lopes, and C. H. Ferreira, “Techno-economic analysis and environmental impact assessment of energy recovery from Municipal Solid Waste (MSW) in Brazil,” Resour Conserv Recycl, vol. 87, pp. 8–20, 2014. [CrossRef]

- J. M. Fernández-González, A. L. Grindlay, F. Serrano-Bernardo, M. I. Rodríguez-Rojas, and M. Zamorano, “Economic and environmental review of Waste-to-Energy systems for municipal solid waste management in medium and small municipalities,” Waste Management, vol. 67, pp. 360–374, Sep. 2017. [CrossRef]

- F. Mayer, R. Bhandari, and S. Gäth, “Critical review on life cycle assessment of conventional and innovative waste-to-energy technologies,” Science of the Total Environment, vol. 672. Elsevier B.V., pp. 708–721, Jul. 01, 2019. [CrossRef]

- B. Dastjerdi, V. Strezov, M. A. Rajaeifar, R. Kumar, and M. Behnia, “A systematic review on life cycle assessment of different waste to energy valorization technologies,” Journal of Cleaner Production, vol. 290. Elsevier Ltd., Mar. 25, 2021. [CrossRef]

- A. U. Zaman, “Life cycle assessment of pyrolysis-gasification as an emerging municipal solid waste treatment technology,” International Journal of Environmental Science and Technology, vol. 10, no. 5, pp. 1029–1038, Sep. 2013. [CrossRef]

- H. A. Arafat, K. Jijakli, and A. Ahsan, “Environmental performance and energy recovery potential of five processes for municipal solid waste treatment,” J Clean Prod, vol. 105, pp. 233–240, Oct. 2015. [CrossRef]

- S. Evangelisti, C. Tagliaferri, R. Clift, P. Lettieri, R. Taylor, and C. Chapman, “Life cycle assessment of conventional and two-stage advanced energy-from-waste technologies for municipal solid waste treatment,” J Clean Prod, vol. 100, pp. 212–223, Aug. 2015. [CrossRef]

- Z. A. Coventry, R. Tize, and A. T. Karunanithi, “Comparative life cycle assessment of solid waste management strategies,” Clean Technol Environ Policy, vol. 18, no. 5, pp. 1515–1524, Jun. 2016. [CrossRef]

- H. K. Jeswani and A. Azapagic, “Assessing the environmental sustainability of energy recovery from municipal solid waste in the UK,” Waste Management, vol. 50, pp. 346–363, Apr. 2016. [CrossRef]

- S. N. M. Menikpura, J. Sang-Arun, and M. Bengtsson, “Assessment of environmental and economic performance of Waste-to-Energy facilities in Thai cities,” Renew Energy, vol. 86, pp. 576–584, Feb. 2016. [CrossRef]

- C. Aracil, P. Haro, D. Fuentes-Cano, and A. Gómez-Barea, “Implementation of waste-to-energy options in landfill-dominated countries: Economic evaluation and GHG impact,” Waste Management, vol. 76, pp. 443–456, Jun. 2018. [CrossRef]

- A. Ramos, C. A. Teixeira, and A. Rouboa, “Assessment study of an advanced gasification strategy at low temperature for syngas generation,” Int J Hydrogen Energy, vol. 43, no. 21, pp. 10155–10166, May 2018. [CrossRef]

- Z. Zhou et al., “Environmental performance evolution of municipal solid waste management by life cycle assessment in Hangzhou, China,” J Environ Manage, vol. 227, pp. 23–33, Dec. 2018. [CrossRef]

- V. Chhabra, A. Parashar, Y. Shastri, and S. Bhattacharya, “Techno-economic and life cycle assessment of pyrolysis of unsegregated urban municipal solid waste in India,” Ind Eng Chem Res, vol. 60, no. 3, pp. 1473–1482, Jan. 2021. [CrossRef]

- A. S. Ouedraogo, R. S. Frazier, and A. Kumar, “Comparative life cycle assessment of gasification and landfilling for disposal of municipal solid wastes,” Energies (Basel), vol. 14, no. 21, Nov. 2021. [CrossRef]

- J. Wang et al., “Life cycle assessment of the integration of anaerobic digestion and pyrolysis for treatment of municipal solid waste,” Bioresour Technol, vol. 338, Oct. 2021. [CrossRef]

- “Climate Change 1995: The Science of Climate Change,” 1996.

- G. Assefa and B. Frostell, “Social sustainability and social acceptance in technology assessment: A case study of energy technologies,” Technol Soc, vol. 29, no. 1, pp. 63–78, Jan. 2007. [CrossRef]

-

OECD Environmental Performance Reviews: Greece 2020. in OECD Environmental Performance Reviews. OECD, 2020. [CrossRef]

- Directive (EU) 2018/ of the European Parliament and of the Council of 30 May 2018 amending Directive 1999/31/EC on the landfill of waste,” 2018.

- C. Vlachokostas, C. Achillas, A. V. Michailidou, G. Tsegas, and N. Moussiopoulos, “Externalities of energy sources: The operation of a municipal solid waste-to-energy incineration facility in the greater Thessaloniki area, Greece,” Waste Management, vol. 113, pp. 351–358, Jul. 2020. [CrossRef]

- ISWA, “White Book on Energy-from-Waste (EfW),” Rotterdam, NL, 2022.

- M. G. Silva, A. L. Przybysz, and C. M. Piekarski, “Location as a key factor for waste to energy plants,” Journal of Cleaner Production, vol. 379. Elsevier Ltd., Dec. 15, 2022. [CrossRef]

- I. Manousaki and F. Konstandakopoulou, “Environmental appraisal of alternative municipal solid waste management scenarios: the case of Chania, Greece,” 2018.

- A. Zitouni-Petrogianni and E. Voutsas, “Modeling, Optimization and Cost Analysis of Municipal Solid Waste Treatment with Plasma Gasification,” Environmental Processes, vol. 8, no. 2, pp. 747–767, Jun. 2021. [CrossRef]

- S. Alatzas, K. Moustakas, D. Malamis, and S. Vakalis, “Biomass potential from agricultural waste for energetic utilization in Greece,” Energies (Basel), vol. 12, no. 6, 2019. [CrossRef]

- V. P. Aravani and V. G. Papadakis, “Technoeconomic assessment for the viable exploitation of biomass residues by an innovative pyrolysis-anaerobic digestion processing plant,” Environ Res, vol. 243, Feb. 2024. [CrossRef]

- D. Moya, C. Aldás, G. López, and P. Kaparaju, “Municipal solid waste as a valuable renewable energy resource: A worldwide opportunity of energy recovery by using Waste-To-Energy Technologies,” in Energy Procedia, Elsevier Ltd., 2017, pp. 286–295. [CrossRef]

- R. P. Singh, V. V. Tyagi, T. Allen, M. H. Ibrahim, and R. Kothari, “An overview for exploring the possibilities of energy generation from municipal solid waste (MSW) in Indian scenario,” Renewable and Sustainable Energy Reviews, vol. 15, no. 9. pp. 4797–4808, Dec. 2011. [CrossRef]

- A. Kumar and S. R. Samadder, “A review on technological options of waste to energy for effective management of municipal solid waste,” Waste Management, vol. 69. Elsevier Ltd., pp. 407–422, Nov. 01, 2017. [CrossRef]

- J. Dong, Y. Tang, A. Nzihou, Y. Chi, E. Weiss-Hortala, and M. Ni, “Life cycle assessment of pyrolysis, gasification and incineration waste-to-energy technologies: Theoretical analysis and case study of commercial plants,” Science of the Total Environment, vol. 626, pp. 744–753, Jun. 2018. [CrossRef]

- L. Lombardi, E. Carnevale, and A. Corti, “A review of technologies and performances of thermal treatment systems for energy recovery from waste,” Waste Management, vol. 37, pp. 26–44, Mar. 2015. [CrossRef]

- A. T. Sipra, N. Gao, and H. Sarwar, “Municipal solid waste (MSW) pyrolysis for bio-fuel production: A review of effects of MSW components and catalysts,” Fuel Processing Technology, vol. 175. Elsevier B.V., pp. 131–147, Jun. 15, 2018. [CrossRef]

- W. Rulkens, “Sewage sludge as a biomass resource for the production of energy: Overview and assessment of the various options,” Energy and Fuels, vol. 22, no. 1, pp. 9–15, Jan. 2008. [CrossRef]

- K. C. Surendra, D. Takara, A. G. Hashimoto, and S. K. Khanal, “Biogas as a sustainable energy source for developing countries: Opportunities and challenges,” Renewable and Sustainable Energy Reviews, vol. 31. Elsevier Ltd., pp. 846–859, 2014. [CrossRef]

- C. A. Sevillano, A. A. Pesantes, E. Peña Carpio, E. J. Martínez, and X. Gómez, “Anaerobic digestion for producing renewable energy-the evolution of this technology in a new uncertain scenario,” Entropy, vol. 23, no. 2. MDPI AG, pp. 1–23, Feb. 01, 2021. [CrossRef]

- D. Panepinto and M. Zanetti, “Technical and environmental comparison among different municipal solid waste management scenarios,” Sustainability (Switzerland), vol. 13, no. 6, Mar. 2021. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).