3.2. Hardened State Properties

Table 5 shows the experimental results obtained in the tests in the hardened state of the SCC. Considering the results of the compressive strengths, the obtained values reveal that values higher than 34 (±2) MPa at 7 days are attained. Since HES cement is used, it is recognized that a more rapid hydration is provided. Besides, higher cohesion than conventional cement (ordinary Portland) is also reached [

61,

62].

It is recognized that all studied concrete compositions are commonly classified as structural concrete according to ABNT NBR 8953:2015. Excepting the sample with 5% rubber (SCC/20SF/30MGR/5R), all other samples indicate the group II class, which has compressive strength ≥ 55 MPa being considered high strength concrete, at 28 days. In a previous investigation developed by Aïtcin [

63], it is classified as high-performance concrete, i.e. class I (between 50 and 75 MPa).

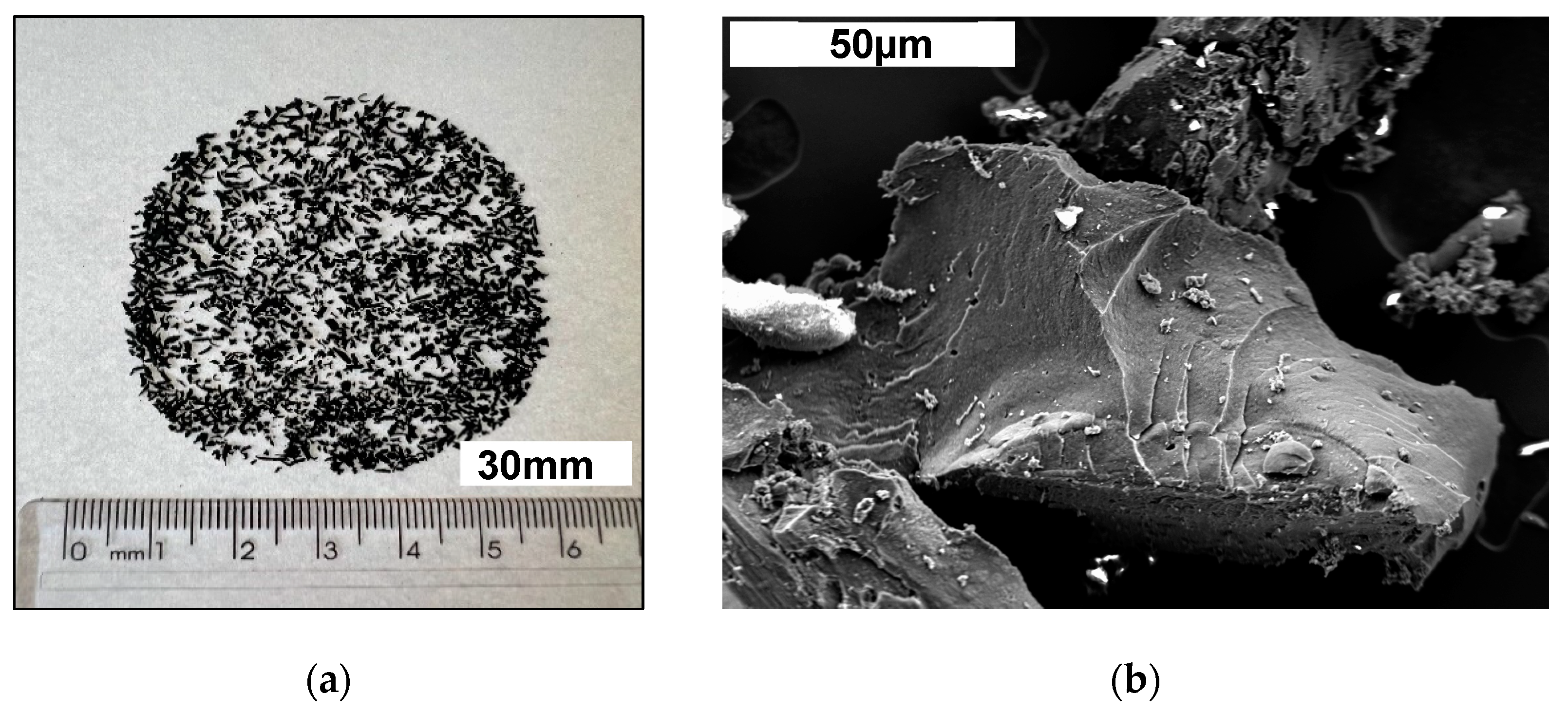

Regarding the addition of the MGR content into the mixture, a low increase in the compressive strength of the SCC/20SF/30MGR mixture is observed when the SCC/20SF sample is compared. The MGR consumption of 105 kg/m3 for the SCC/20SF/30MGR mixture evidences that no substantial modification is verified, even with the decrease in cement consumption (350 kg/m3). This seems to be compensated by the MGR content, resulting in a slight increase (of about of 2.5%) in the compressive strength when the SCC/20SF sample is compared. This correlates with the reduction of the pores of the cement paste, since the MGR portion fills these voids, providing more cohesion of the paste and increasing the packaging of the concrete.

However, the values obtained for the SCC/10SF and SCC/10SF/30MGR samples are very close. The MGR consumption of 105 kg/m3 for the SCC/10SF/30MGR sample has not affected the compressive strength when the SCC/10SF sample is compared. This has occurred probably due to the sand portion is replaced with the MGR content. Interesting that a cement consumption of 366 kg/m3 is maintained.

The compressive strengths of the group with HESF consumption of 10 kg/m

3 (SCC/10SF, SCC/10SF/30MGR, SCC/10SF/30MGR/2.5R) have shown higher values than the group with HESF consumption of 20 kg/m

3 (SCC/20SF, SCC/20SF/30MGR, SCC/20SF/30MGR/5R). This indicated that the increase of the fiber rate has no affect this property, according to previous studies [

22,

23,

24].

For the sample of the group with HESF consumption of 10 kg/m3, the cement consumption is kept constant (366 kg/m3), and the sand portion is replaced with both the rubber and MGR residues contents. This has provided a compressive strength higher than the group with 20 kg/m3 of HESF and cement consumption of 365 kg/m3 (the SCC/20SF sample), 350 kg/m3 (the SCC/20SF/30MGR sample) and 345 kg/m3 (the SCC/20SF/30MGR/5R sample).

It is also found that the compressive strength is strongly affected in mixtures containing rubber residue, i.e. the SCC/10SF/30MGR/2.5R and SCC/20SF/30MGR/5R samples. The lowest compressive strength is that of the SCC/20SF/30MGR/5R sample. It corresponds to a decrease of about 36% when the SCC/20SF sample is compared. The SCC/10SF/30MGR/2.5R mixture has shown a 14.5% reduction in the compressive strength when compared with the SCC/10SF sample. The decrease in compressive strength with the increase of rubber content is also previously reported [

16,

37,

39,

64,

65,

66]. This occurrence is attributed to two main reasons: (a) firstly, the cracks are rapidly initiated at neighboring the rubber particles and concrete paste, and (b) the rubber particles are weakly adhered to the paste, behaving like voids in the concrete matrix [

16,

64].

Regarding the tensile strength, this property is less affected than the compressive strength for all mixtures examined. Considering the rubber compositions, a decrease of about 13% is verified for the SCC/10SF/30MGR/2.5R sample when the SCC/10SF is compared. Similarly when the SCC/20SF/30MGR/5R and the SCC/20SF samples are also compared. In previous studies this behavior is also reported [

16,

23,

64,

65]. From this point, it is important to remark the decision to rubber content be adopted in the proposed mixture examined in the present investigation. Although it is recognized that rubber potentially decreases compressive behavior, certain improvements in tensile strength can be attained [61-62; 64-66]. Based on this previous perspective the rubber contents were considered to prepare other mixtures containing rubber contents.

Table 6 shows, at 28 days of age, the static moduli of elasticity of the SCC/20SF and SCC/20SF/30MGR samples are very similar. Similarly, this also occurs when the SCC/10SF and the SCC/10SF/30MGR samples are compared. Comparing the mixtures without residues, the SCC/20SF and SCC/10SF samples have revealed a decrease or difference of about of 2.5%. When the rubber compositions are considered, the decreases are ~22% for the SCC/20SF/30MGR/5R when compared to the SCC/20SF sample; and of about 6% for the SCC/10SF/30MGR/2.5R sample when the SCC/10SF sample is considered.

Aslani and Kelin [

23] have found that with the increase of the steel fiber content in a SCC, an increase of the elasticity modulus is attained. On the other hand, Hilal [

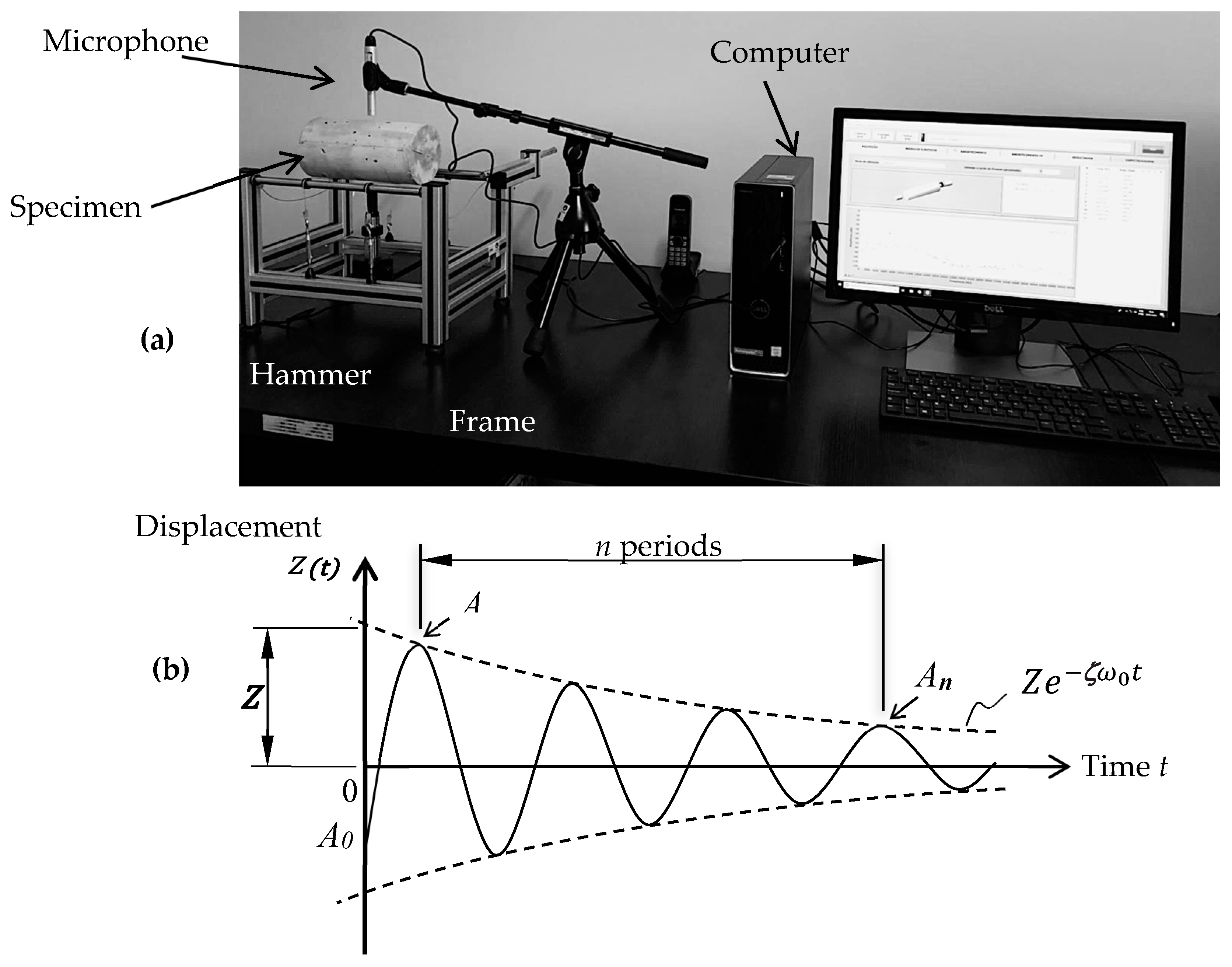

16] has also found that the static elastic modulus has decreased with the increase of the rubber content, similar to that observed for both the tensile and compressive strengths. Based on the fact that the dynamic longitudinal modulus is lower than the flexional, the longitudinal dynamic modulus is considered. The non-destructive method (IET) presents values of the longitudinal dynamic elasticity moduli higher than the static moduli, at 28 days of age, as shown in

Table 6 and

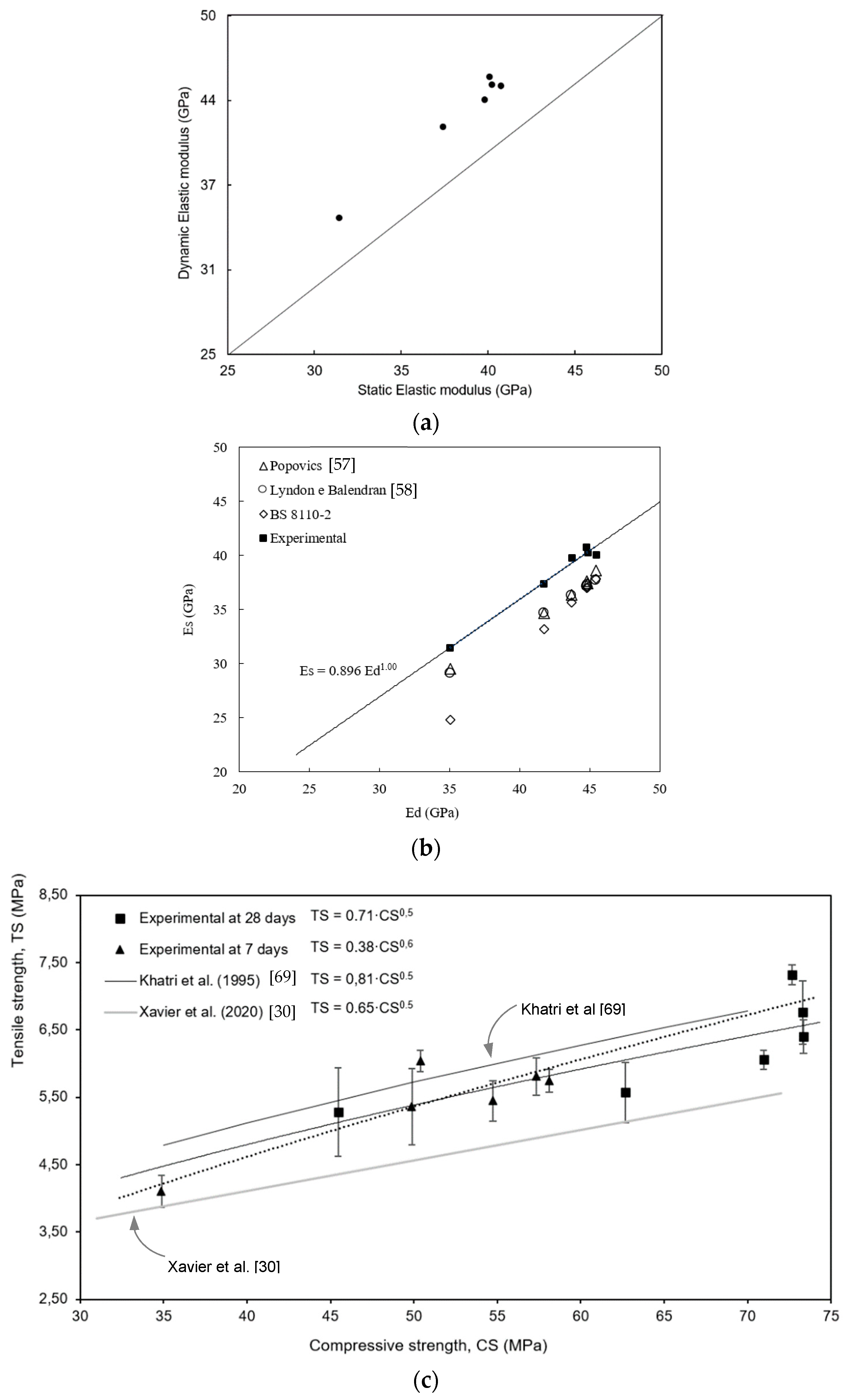

Figure 4 (a).

This fact is associated with the IET method, which consists in determining the natural vibration frequencies of the concrete specimen, in the free-free condition, through excitation by a slight mechanical impact. This mechanical excitation applied to the specimen produces very low stress levels during the determination of these parameters; therefore, the formation of microcracking and creep effect is not provided. For these reasons, it can be considered that the dynamic modulus is associated only with elastic phenomena of the material and is closer to the initial tangent modulus. This corresponds to the elastic behavior of the concrete obtained at the beginning of the stress strain curve [

54,

55]. The values of dynamic moduli are usually higher than static moduli due to the period of time characteristic of the vibration used in dynamic methods is regularly less than 1 millisecond (ms). With this, the occurrence of annelastic mechanisms with a relaxation time higher than 1 ms is prevented [

67].

The IET method has some advantages when compared to the static method. The non-destructive test has reproducibility in a short period using the same sample. Therefore, a smaller amount of samples is required and less susceptibility to experimental errors due to the number of variables is provided [

68].

Figure 4 (b) shows the results of some empirical data realted with the attained static (Ec) and dynamic (Ed) and compared with previously reported results of Popovics [

58], Lyndon and Baladran [

57], and prescribed into BS 8110-2:1985 [

56]. It is observed that the experimental values of dynamic (Ed) and static moduli (Es) of the SCC compositions examned, the follow correlation is attained, i.e., Es = 0.896 x Ed

1.0 associated with R² = 0.99. It is observed that the experimental values are overestimating those previously reported [

56,

57,

58]. The variability of the results is justified by the multiphase nature of the concrete, which influences the mechanims that it deforms.

Figure 4 (c) shows the correlation considering an exponential dependence of the tensile property with the compressive strength at 7 days (expressed by TS = 0.38 x CS

0.6) and at 28 days (expressed by TS = 0.71 x CS

0.5). Khatri et al. [

69] and Xavier et al. [

30] have reported similar correlations when silica fume/furnace slag/fly ash and MGR contents are used, respectively. The equations proposed in this present study of both the experimental results at 7 and 28 days, are located between the upper and lower limits proposed.

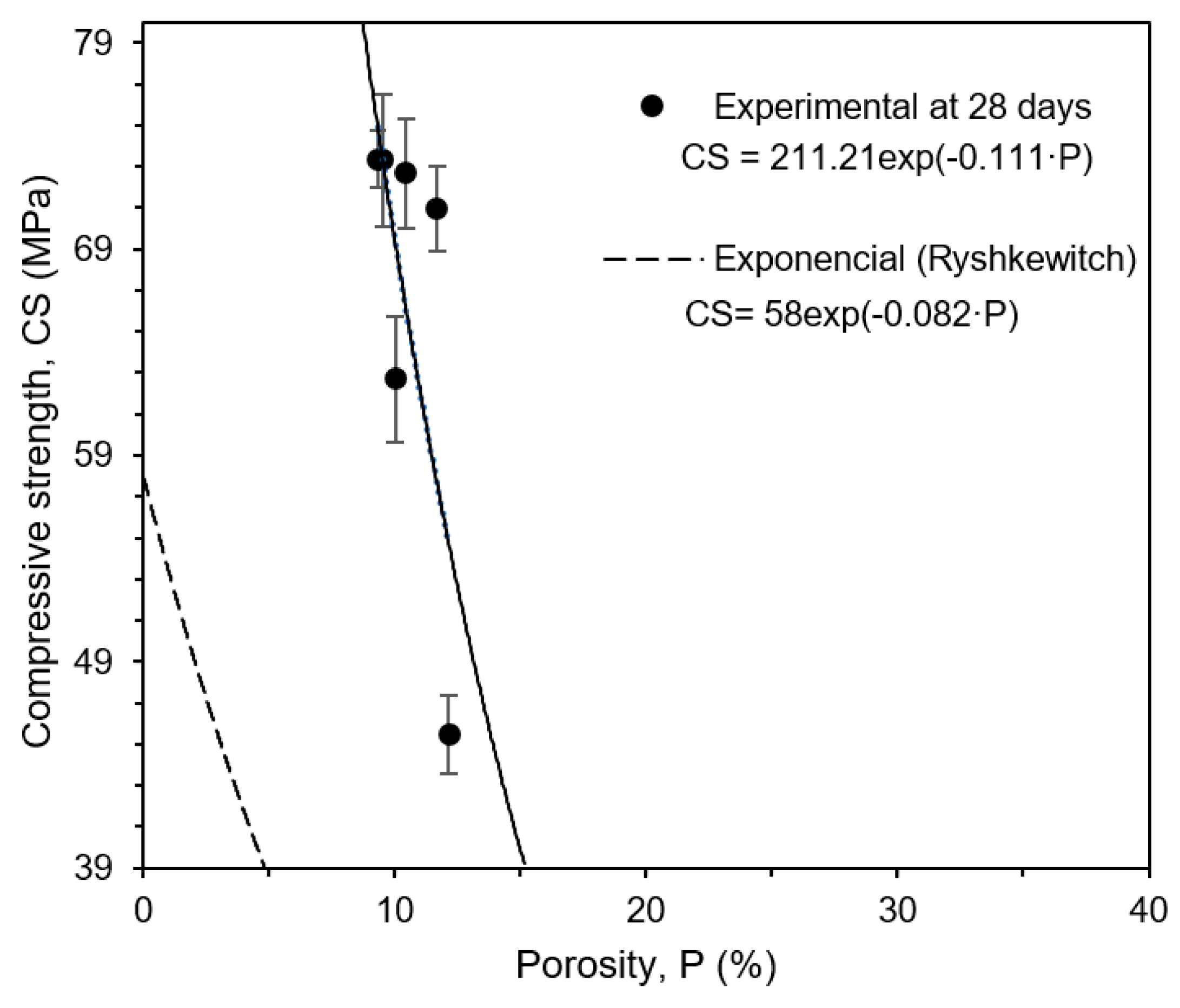

The experimental results at 28 days of compressive strength as a function of porosity is shown in

Figure 5. The Ryshkewitch’s equations are described, CS = 58exp (

– 0.082 P), and the experimental results at 28 days, CS = 211.21 exp (

– 0.111 P). Similar trends are observed.

Table 6 shows the values obtained in the experimental tests of the damping factor of the SCC samples examined. The damping factor of the studied SCC is higher than steel and cast iron. The damping rate of the steel is reported between 0.001 and 0.002 [

70] and the corresponding value to the cast iron is of about 0.0023 [

71]. Regarding to the SCC/20SF sample (with a consumption of HESF being of 20 kg/m

3) and the SCC/10SF (with HESF consumption of 10 kg/m

3), it is observed that with the increase of HESF consumption, the damping factor is of about 9% increased, as shown in

Table 6. However, there is a decrease in this property for the SCC/20SF/30MGR and SCC/10SF/30MGR samples when the SCC/20SF and SCC/10SF samples are compared, i.e. of about 6% and 2%, respectively.

With regard to the SCC/20SF/30MGR/5R and the SCC/10SF/30MGR/2.5R samples, a slight increase of 1.34% is observed when the SCC/20SF/30MGR/5R and the SCC/20SF samples are compared. When the SCC/10SF/30MGR/2.5R sample is compared with the SCC/10SF samples, the observed difference is of about 2.6%.

Considering those samples containing both MGR content and rubber residue portions, i.e. 2.5 and 5%, the two highest reached values (0.35% and 0.38%, respectively) of damping factors are associated with these mentioned samples, i.e. designated as the SCC/10SF/30MGR/2.5R and the SCC/20SF/30MGR/5R samples. This suggests that a better energy dissipation capacity is provided when the modified concrete is subjected under a dynamic load, as previously reported [

12,

39,

72].

The rubber portion, when incorporated into the concrete, certain voids into the paste are prevalent, and consequently the resulting porosity is increased. The experimental results of the specific mass, voids index and water absorption by immersion, measured accordingly to ABNT NBR 9778:2009, are shown in

Table 7. The observation of the attained values shown in

Table 7 clarifies that both the HESF and rubber contents provides the highest values of both the water absorption and voids (porosity).

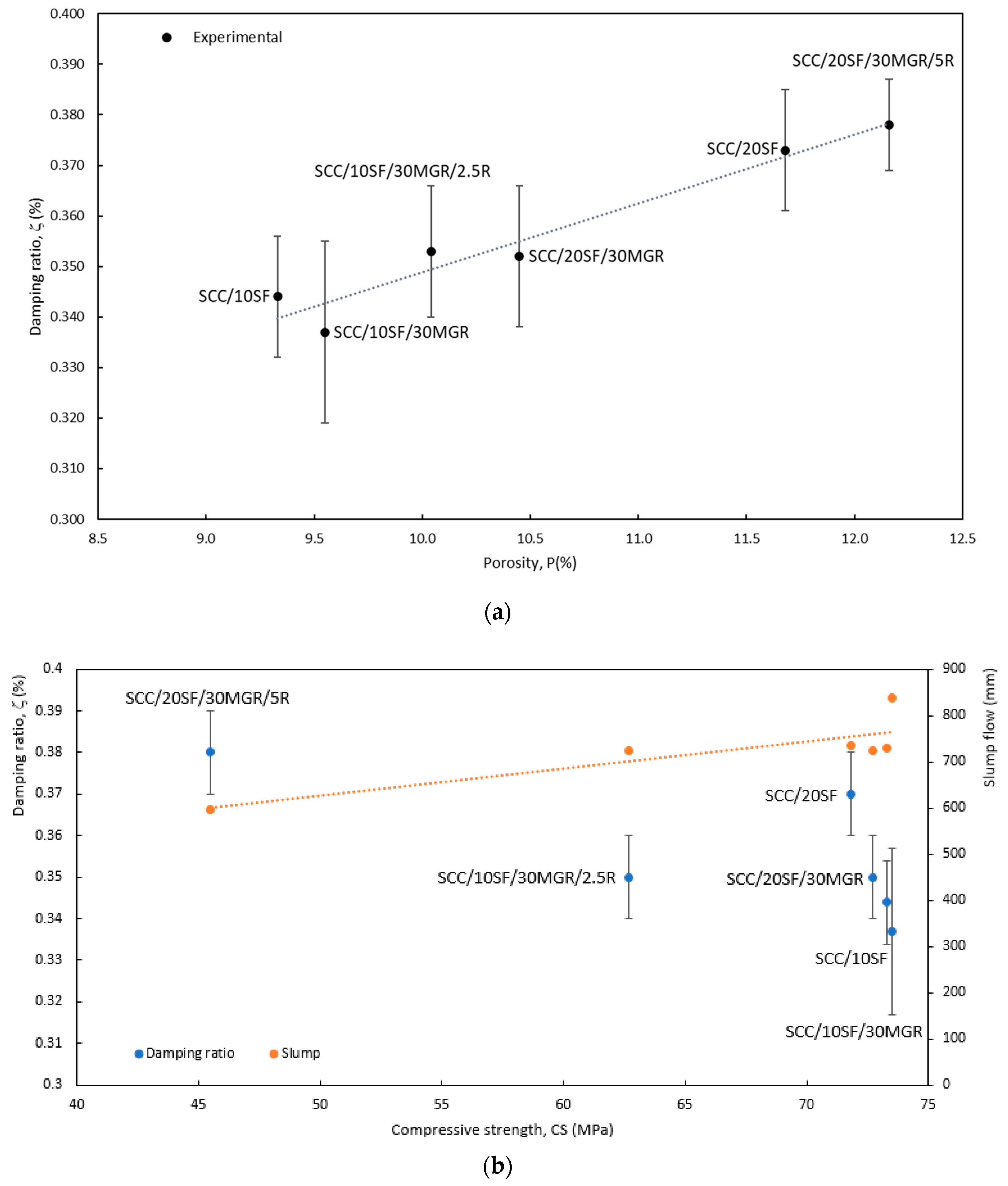

Figure 6(a) shows the influence of porosity in relation to the damping rate. Thakare et al. [

72] have also found that the air entrapped in fresh mortars is increased with rubber fibers incorporation. Based on these previous assertions and attained experimental observations, it is induced that a SCC containing rubber residue has the porosity increases, associated with decreasing in the compressive strength, the tensile strength and the dynamic modulus. On the other hand, it is clarified that the damping has appreciably increased.

Li et al. [

12] have concluded that the SCC damping rate increases linearly with the rubber content. This suggests that a better energy dissipation capacity is attained when subjected to dynamic load. Najim and Hall [

39] have also found that the damping coefficient increases with the increase of rubber content in the mixture.

Based on aforementioned results, it is considered interesting to analyze the concatenated effects of the MGR and HESF contents up on two main important properties of a SCC, i.e. slump (fresh property) and compressive strength (hardened property). Besides, considering the fact that, at under certain determined condition, the damping should also be considered, both slump flow and damping are evaluated. The experimental variations of slump flow and damping ratio as a function of the compressive strength are demonstrated in

Figure 6(b). This due to the slump flow and damping seems to be competitive properties mainly when the MGR and HESF contents are increased.

Considering that a design of mixture requires compressive strength in a magnitude between 70 and 75 MPa, the HESF content has no substantial effect on the slump flow results. However, the MGR content clarifies that slump flow can slightly be improved mainly the HESF portion is increased. This is observed when the same magnitude of compressive strength (between 70 and 75 MPa) is considered. Also considering this same range of compressive behavior, the damping results reveal that the 30 MGR content has a deleterious effect. Interesting, the HESF content demonstrates a positive effect on the damping.

For instance, the SCC/20SF has a damping considerably higher (~9%) than SCC/10SF sample. Similarly, when analyzing the SCC/10SF/30MGR and SCC/20SF/30MGR samples, the damping results reveal that, although, 30MG content is present in both mixtures, the sample with higher steel fiber content (

i.e. SCC/20SF/30MGR) has evidenced higher damping (~7%) than other one. On the other hand, when the SCC/20SF is compared with the SCC/20SF/30MGR, and the SCC/10SF with the SCC/10SF/30MGR, the effect of the MGR content is indicated. It is revealed a deleterious effect of the MGR content up on the damping results, i.e. it decreases of about 6%. Additionally, when lower range of the compressive strength is acceptable in a certain design mixture, for instance between 40 and 50 MPa, it is induced that the slump flow and damping ratio are competitive properties. The highest damping ratio is that of the SCC/20SF/30MGR/5R samples, while their corresponding slump flow result is the lowest attained result. The increase of the damping is intimately associated with 20SF content and the considerable decrease (~20 %) of their slump flow is attributed to rubber content, as also shown in Fig 6(b). It is previously reported that rubber content, depending of some limited characteristics and condition, in a general way, the rubber content provides a deleterious effect on mechanical behavior [61-65; 72-77]. Also, it is reported that the steel fiber content (up to certain limits) improves the damping behavior [

78], as also observed in this study.

When the SCC/20SF/30MGR/5R and the SCC/10SF/30MGR/2.5R samples are compared, it is remarked that the SF content increases damping results while rubber content decreases the slump flow. Associated to this a considerable and substantial decrease of the compressive strength (~38%) is observed. This is also associated with double rubber content in the SCC/20SF/30MGR/5R sample, as also depicted in

Figure 6(b). Summarizing, it is worth noting that the rubber addition induces to certain worsening in the compressive strength of concrete.

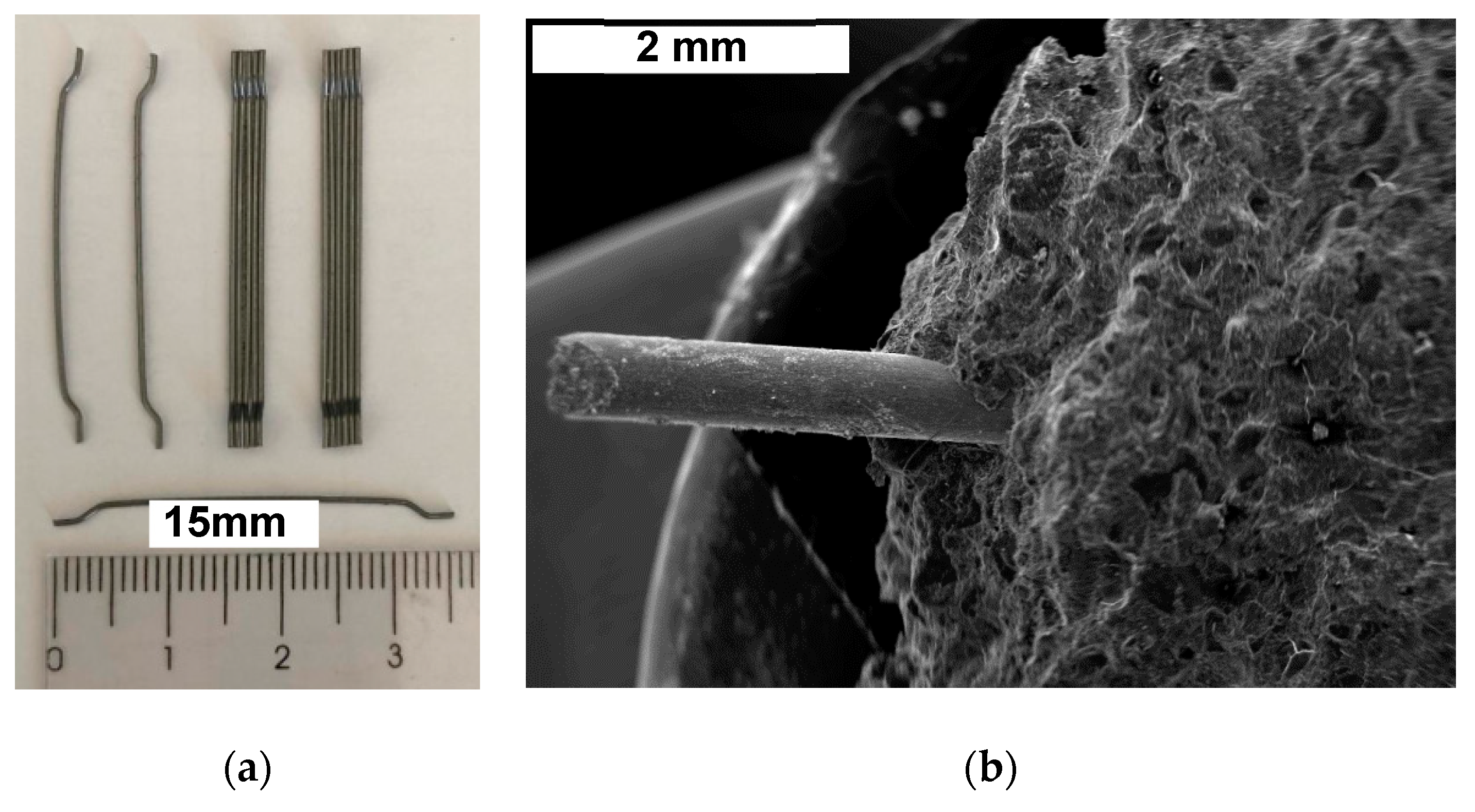

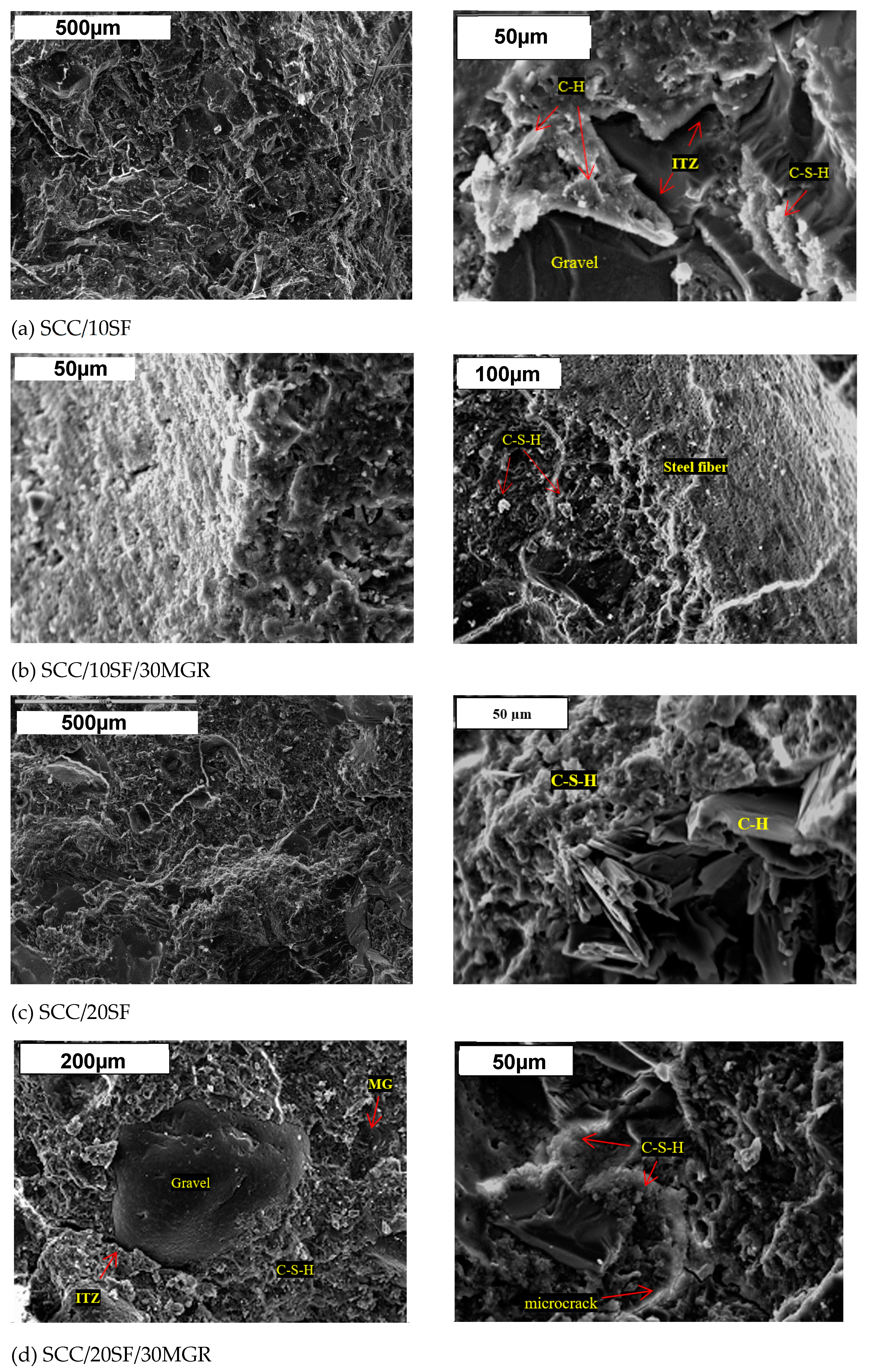

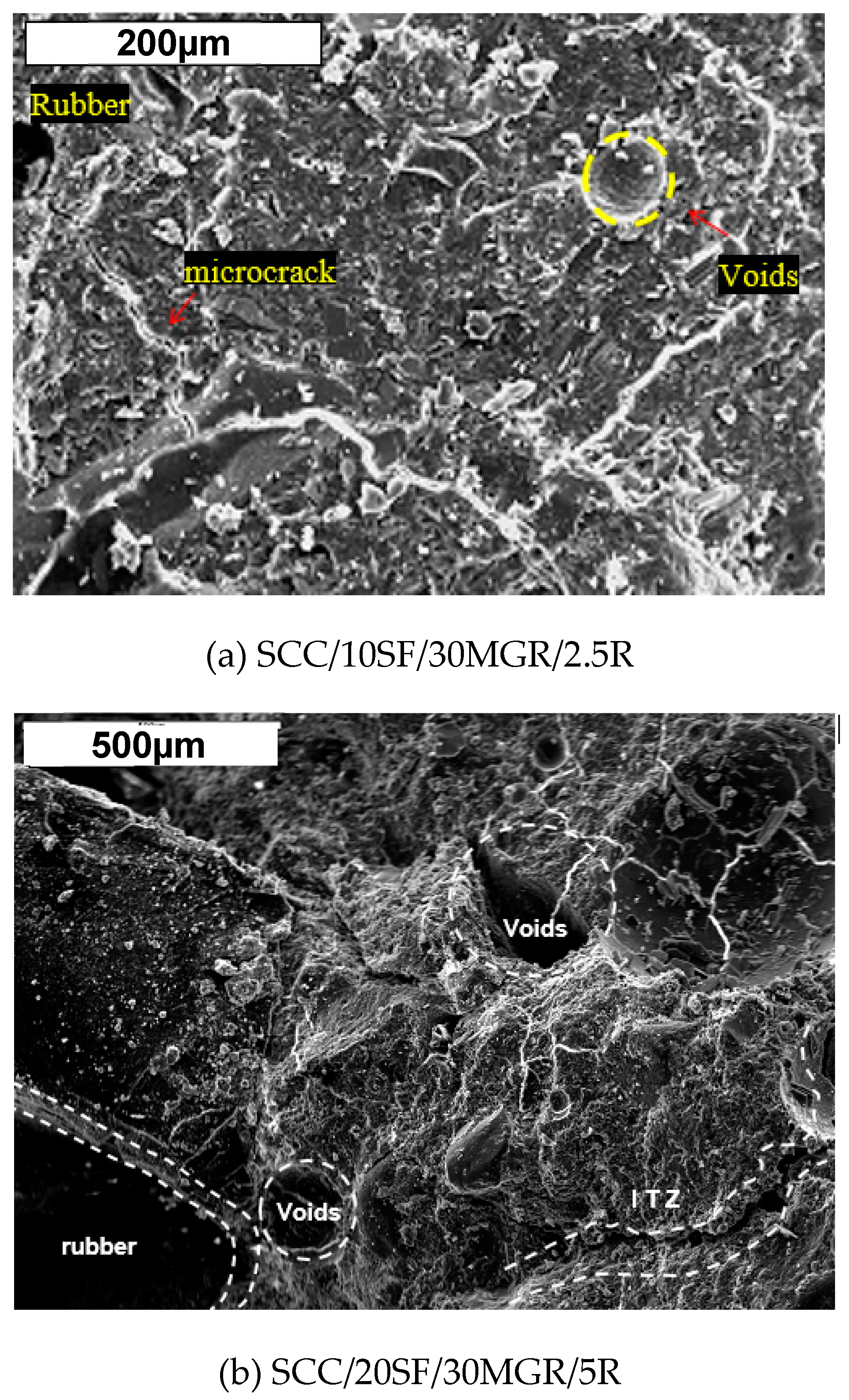

In the next section, the micrographs of the reinforced concretes using SEM technique demonstrate that the concrete with rubber content, various microcracks are constituted. Also, it is shown that HESF has an interface with cement paste without “voids”, as forwardly described and discussed.