1. Introduction

Mineral resources are an indispensable material basis for the survival and development of human society. It is not only an important source of people's means of living, but also an extremely important means of social production [

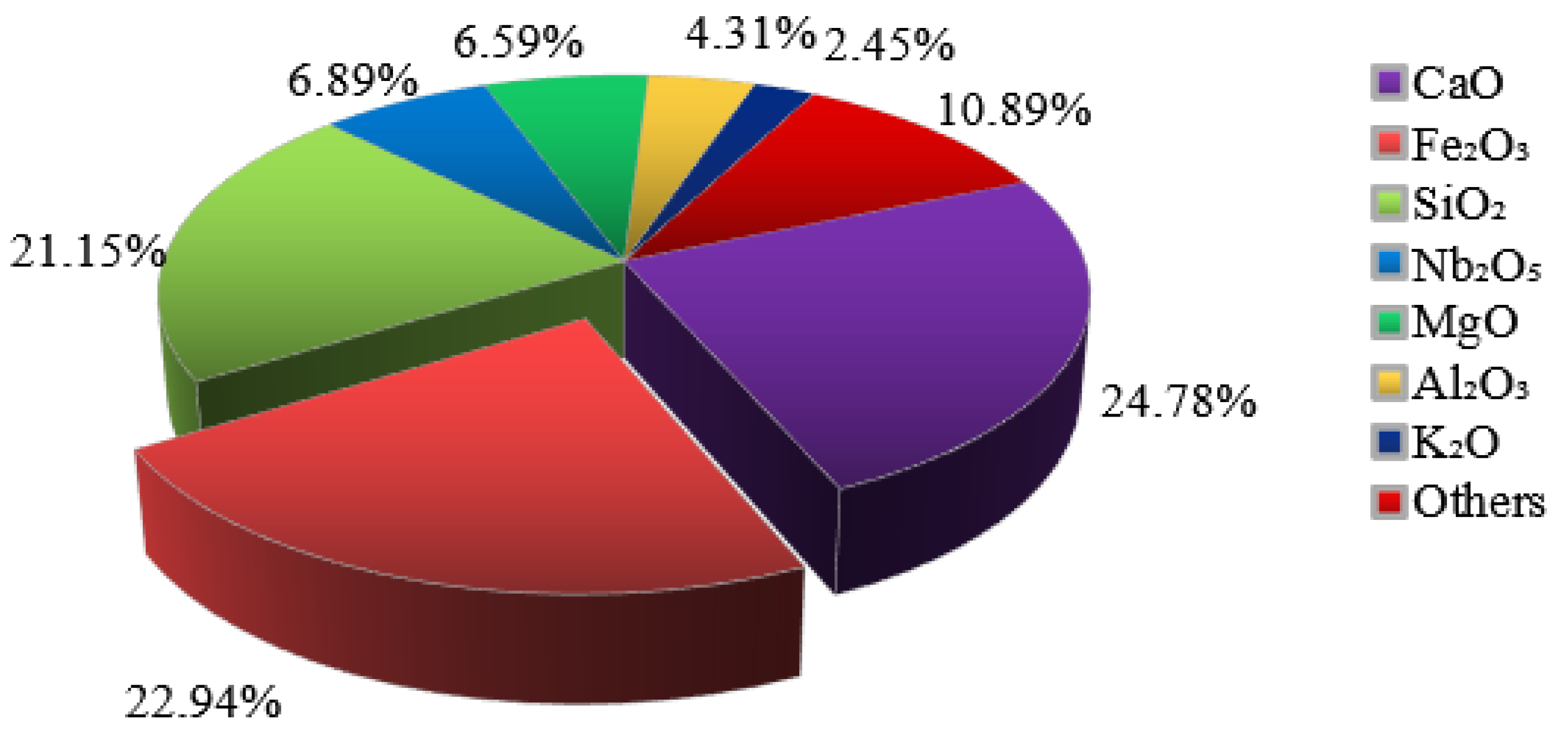

1]. Most iron ore resources are of low grade and must be crushed, ground and sorted to obtain concentrate before they can be smelted. Normally, iron tailings are waste residue formed after iron ore is crushed, ground, and beneficiated. It is mainly composed of silicate minerals such as quartz, calcite, and hornblende. Iron tailings is a composite mineral raw material. In addition to containing a small amount of metal components, its main mineral component is gangue minerals; its chemical components are mainly oxides of iron, silicon, magnesium, calcium, and aluminum, with accompanying There is a small amount of phosphorus, sulfur, etc. With the rapid development of the steel industry, iron tailings account for an increasing proportion of industrial solid waste. The two major characteristics of iron ore resources are the symbiosis of many poor ores and multi-components, which results in a large number of tailings and a large number of associated valuable components. According to statistics, about 3 tons of tailings will be produced for every 1 ton of iron concentrate produced [

2]. Taking 2021 as an example, China produced a total of 543 million tons of iron tailings that year, accounting for 41.8% of the country's total tailings emissions that year. Iron ore resources are relatively concentrated in distribution. More than half of the iron ore deposits are located in Anshan, Bayan Obo, Panzhihua, and other metallogenic belts. Over the years, they have also created huge tailings stocks in many areas. Reports show that as of the end of 2021, China’s cumulative stockpiles of tailings and waste rock have reached more than 70 billion tons, of which iron tailings account for the largest proportion [

3].

Figure 1 shows the main components of iron tailings.

The large accumulation of iron tailings has brought environmental, safety, and economic impacts [

4]. Iron tailings generally have small particle sizes and lack organic matter fixation. Harmful components such as heavy metal ions and residual chemicals are easily released and migrated by being mixed into rainwater runoff and dust, thereby destroying the local soil structure and polluting the atmosphere and water environment. The accumulation of large amounts of iron tailings not only occupies land and causes harm to the ecological environment, but also causes the valuable components in the tailings to not be effectively utilized, which also causes a waste of resources to a certain extent. There are also huge safety risks in tailings ponds. Mining countries such as the United States and South Africa mostly use "conservative" techniques such as the downstream method and the midline method to build dams [

5]. In China, the upstream method is often used to build tailings ponds. The mine bank is in the shape of a valley, which is a source of danger with high potential energy. The upstream dam construction process is more sensitive to heavy rains and vibrations, and the risk of dam failure is greater. Once a dam failure occurs, debris flows will occur, which may cause harm to the safety of residents and facilities downstream. serious threat. On the other hand, with the increasing reduction of high-grade ore bodies and the continued demand for mineral resources, fine-grained tailings and the construction of high tailings dams have become a future trend, and tailings dam seepage has also become a hidden danger [

6]. Therefore, it is urgent to find a suitable comprehensive utilization approach for iron tailings [

7].

In summary, iron tailings, as an important part of industrial solid waste, can easily cause environmental pollution in soil, water, and dust. There is an urgent need to achieve low-cost harmless treatment and highly comprehensive utilization processing and utilization [

8]. Specifically, it includes the recovery of valuable elements from part of the tailings after comprehensive consideration of reprocessing costs, market prices of recyclable components, etc., after technical and economic evaluation, and batching and modification according to the properties of the iron tailings for use. Construction materials, filling materials, chemical products, and agricultural products. Based on the current research background of comprehensive utilization of iron tailings, this article first analyzes the basic characteristics of iron tailings, then analyzes the impact of iron tailings on the environment, and finally puts forward suggestions for the treatment and prevention and control strategies of iron tailings. provide a basis for future research.

2. Impact of Iron Tailings on Various Environmental Factors

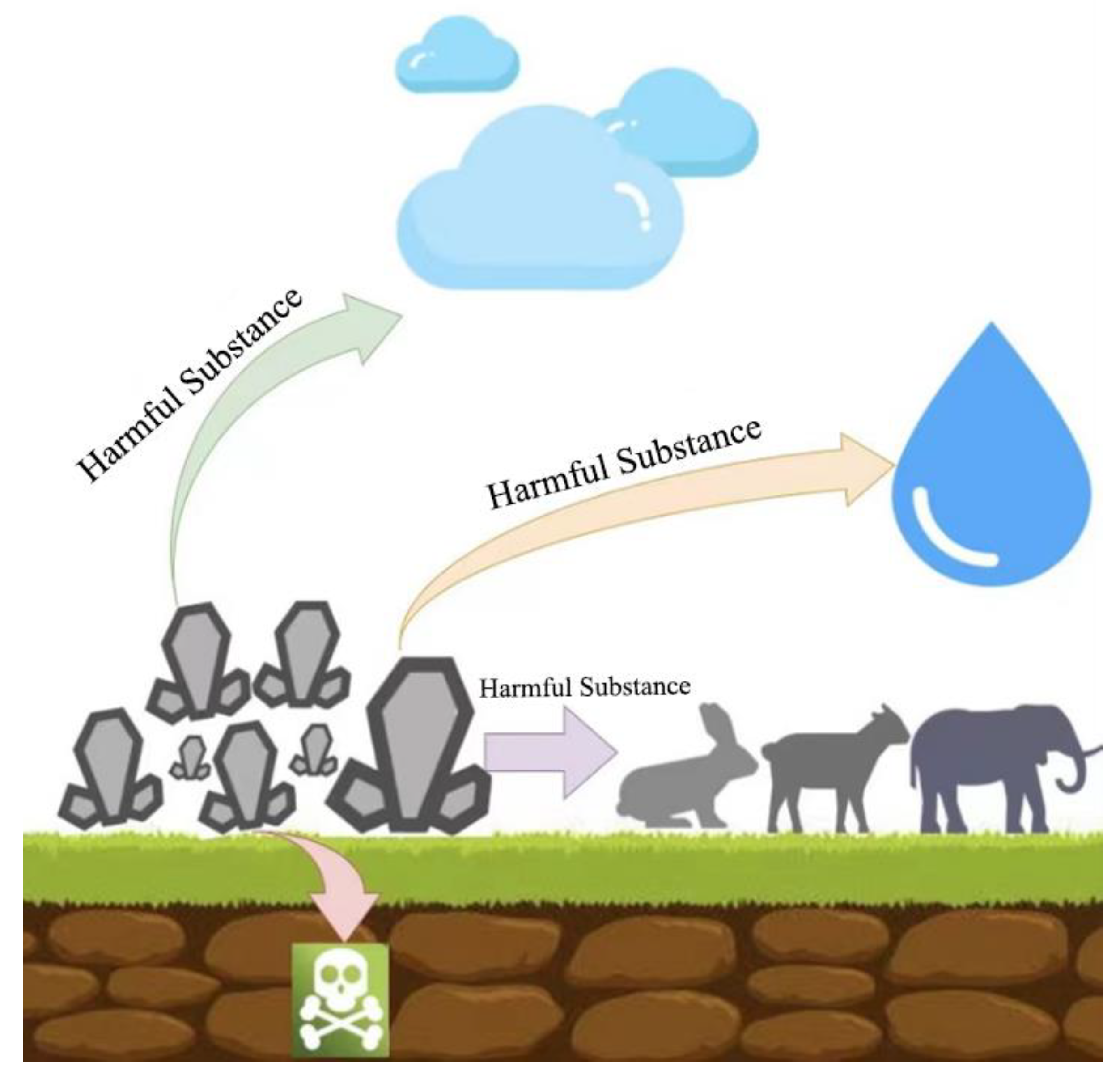

The impact of iron tailings on the environment is mainly reflected in soil pollution, water pollution, air pollution, and biodiversity loss [

9]. Tailings contain a large amount of metal elements and impurities. When the tailings are piled or discharged into the soil, the harmful substances in them will penetrate the soil, causing soil pollution. This not only causes damage to the soil ecosystem, but also affects agricultural production.

Table 1 shows the concentrations and background values of heavy metals in tailings in China.

At the same time, harmful substances in tailings may penetrate water bodies through rainfall or water sources, pollute water sources, and cause harm to aquatic organisms such as rivers and lakes [

10]. In addition, the open-air stacking and processing of tailings may release harmful gases such as sulfur dioxide and nitrogen oxides, causing pollution to the atmosphere. For example, a dam break in a tailing reservoir will be a disaster for surrounding residents [

11]; tailings The particle size is relatively fine, and sandstorms can easily form during dry seasons, which can have a serious impact on the ecological environment of surrounding areas, such as affecting crop harvests and causing various respiratory diseases. In addition, tailings dumps occupy land areas, destroy the original ecological environment, and cause loss of biodiversity.

Figure 2 shows the various impacts of iron tailings on the ecological environment.

2.1. Impact on the Water Environment

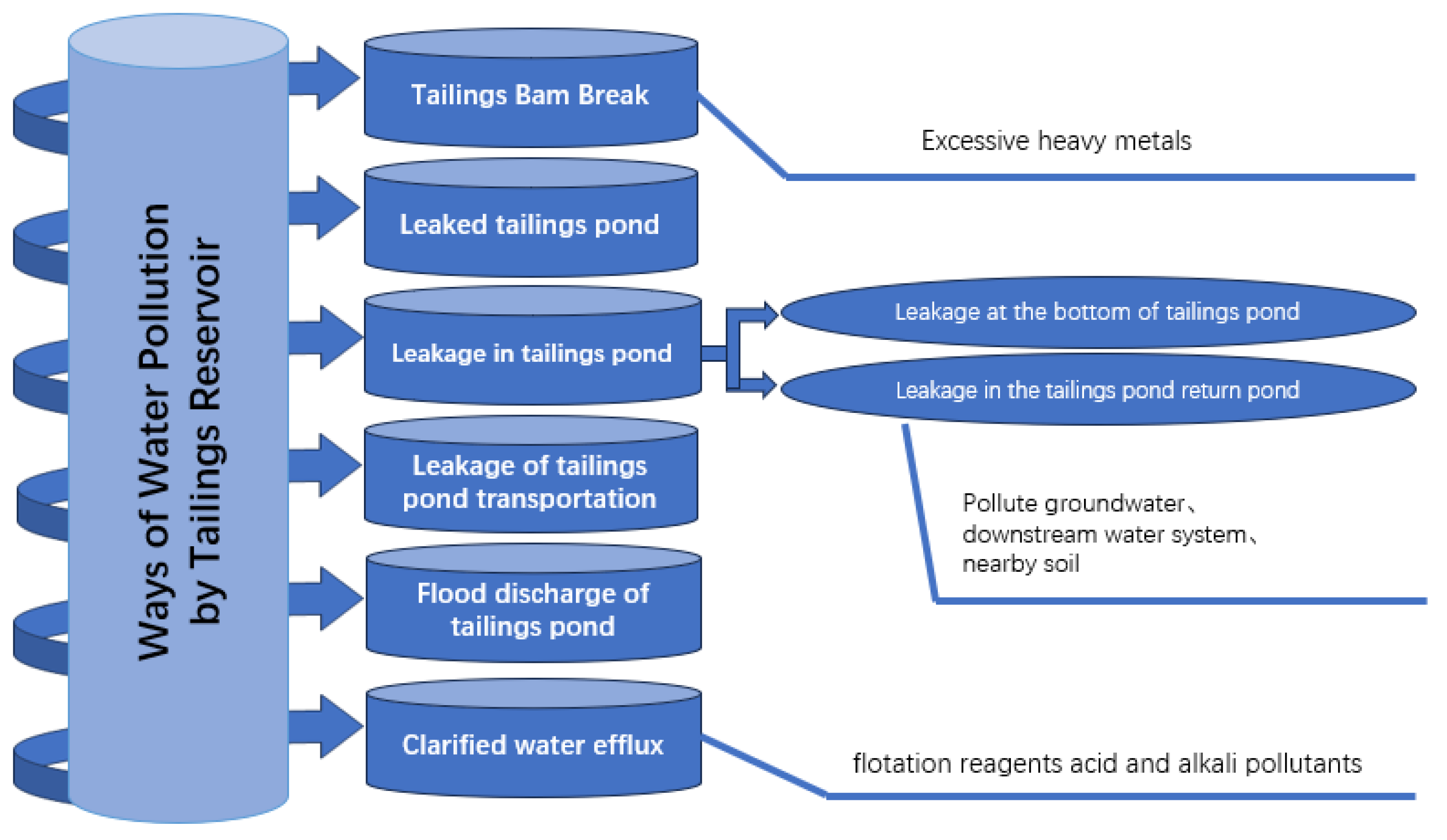

Iron tailings contain a certain amount of heavy metals and harmful substances. When the tailings are piled or handled improperly, these substances may seep into groundwater or nearby water bodies, causing water pollution. The accumulation of heavy metals may cause toxic effects on aquatic life and disrupt the balance of aquatic ecosystems. In addition, the acidic substances in iron tailings may also cause acidification of water bodies, further affecting the survival and reproduction of aquatic organisms [

12]. The following are some important aspects of the impact of mineral extraction on surface and groundwater.

2.1.1. Surface Subsidence and Water Area Changes

Mineral mining will cause the surface to collapse, forming seasonal or perennial water accumulation areas, and changing the original surface runoff distribution [

13]. To ensure the safety and smooth progress of mining, the water in the mine needs to be drained out and injected into the river in time, which increases the water volume of the river, enhances the erosion ability of the river, causes the river channel to deepen and widen, and also changes the shape of surface runoff. Mineral mining may also cut off underground aquifers, disrupt the natural state and distribution of groundwater, create funnel areas where water levels drop, and impact or even cause rivers, lakes, and swamps around mining areas to dry up.

2.1.2. Water Pollution

The water discharged from mines contains suspended solids, mineral components, heavy metal elements, and toxic substances, which affects the quality of water bodies around the mining area [

14]. Industrial wastewater generated during mineral processing is discharged into rivers. If it is not treated or treated incompletely, it will cause pollution to rivers, lakes, and swamps. The degree and scope of pollution depend on the concentration of pollutants in the industrial wastewater and the amount of water in the river. The accumulation of pollutants will have an impact on aquatic communities. As water circulation and water body self-purification progress, pollutants will spread to a larger area, but the concentration will gradually decrease. Therefore, the farther away from the mining area or sewage outlet, the water quality will deteriorate. The smaller the impact.

Figure 3 shows how tailings pollute reservoirs.

To reduce the impact of mineral mining on surface and groundwater, a series of prevention and treatment measures need to be taken, including rational planning of mining areas, strengthening water resources management, wastewater treatment, and monitoring, etc. [

16]. In the mining industry, tailings are often stored in artificial ponds that are prone to rupture, as happened in southeastern Brazil in November 2015. The Fundao fault dumped approximately 40 million cubic meters of very fine iron-rich tailings material into the Doce River Basin, some of which reached the adjacent continental shelf. Part of the spilled material remained suspended in the water column after reaching the ocean, and zeta potential measurements (pH and salt dependence) were performed to verify the flocculation tendency of the suspension. Surface sediment samples were collected on the continental shelf before failure representing the transport of tailings through rivers and subsequently on the continental shelf and were used as controls. The final experimental results showed that although the continental shelf sediments before the input of iron ore tailings materials were typical naturally weathered sediments containing clay minerals, the sediments contaminated by iron ore tailings sludge had an impact on their apparent zeta potential patterns. Obvious ferric hydroxide influence. The results can therefore be used to predict the transport and deposition of iron oxyhydroxide nanoparticles as well as sediments contaminated with iron ore tailings sludge in this and other similar environments.

2.2. Impact on the Atmospheric Environment

Dust and gas emissions may be generated during the stacking or processing of iron tailings. The fine particles and harmful gases (such as sulfur dioxide, nitrogen oxides, etc.) in the tailings may be blown by the wind into the surrounding environment, causing air pollution [

17]. These pollutants are potentially harmful to air quality and human health. The following are the impacts of mineral resource development on the atmospheric environment:

2.2.1. Dust Pollution

A large amount of dust will be generated during the mineral mining process, and this dust will be suspended in the air, causing air pollution [

18]. Dust pollution not only affects air quality but also causes damage to surrounding vegetation and ecosystems.

2.2.2. Exhaust Gas Emissions

Mineral mining and processing generate waste gases, including greenhouse gases and harmful gases. The burning of coal and oil releases large amounts of greenhouse gases such as carbon dioxide (CO

2), which intensifies the greenhouse effect and leads to climate change [

19]. In addition, the combustion process also releases acidic gases such as sulfur dioxide (SO

2), which in turn triggers acid rain and causes damage to soil and water bodies. The impact of the development of these mineral resources on the atmospheric environment will not only directly affect the growth and development of animals and plants, but also hurt, harm human health and cause diseases. At the end of 2015, an iron ore tailings dam ruptured in Anchietta, southeastern Brazil, causing a pelletizing plant to cease production [

20]. A statistical analysis of the spatiotemporal patterns of PM10, PM2.5, SO

2, NO

2, and O3 from 2012 to 2018 was conducted to determine the trend of air quality since the shutdown of the pellet plant. By presenting the analysis of short- and long-term exposures and local air quality standard (AQS) exceedances, as well as a study of directional patterns of pollutants associated with prevailing winds. Anchieta's air quality has improved significantly since 2016, while the pelletizing plant was also shut down. Thereafter, depending on the monitoring station, the annual mean value of PM10 decreased and the annual mean value of SO

2 decreased, which resulted in a significant reduction in AQS threshold exceedances for these pollutants.

2.2.3. Influence of Gangue Mountain

The solid waste generated after mineral mining is piled on the surface to form gangue mountains, which may contain more carbon and sulfur substances. Under the action of oxidation, waste rock mountains will release large amounts of CO

2, CO, H2S, and other harmful gases, further aggravating air pollution. The former ferromanganese alloy plant has been out of operation for 25 years and the remaining tailings are still affecting the environmental quality of the Sibenik Bay in Croatia. Laura, et al. [

21] in the recently collected tailings and dust collected from the factory roof during production, The main manganese mineral phases were found to be rhodonite and manganese oxides. The same type of manganese mineral phase was recently found in sediments collected from Sibenik Bay. Detailed chemical and phase analysis of the dust samples revealed that the effects of the tailings were visible in the sediments, but through analysis, the concentrations of the identified potentially toxic elements were within legal limits and the mine tailings are still exposed to weathering and should therefore be additionally monitored. Analysis confirmed that Sibenik Bay in Rhodia is still affected by tailings pollution, and that the current impact may be caused by the transport of tailings materials by wind and sea [

22]. This study provides future insights into the conditions in the deeper parts of the tailings mine and the real threats they pose to the environment and the Krka Estuary, which is a sensitive and easily changeable environment.

2.3. Impact on Soil Environment

Soil is the loose material layer covering the land surface. It has fertility characteristics and can grow green plants. It is one of the most important elements in the ecosystem. Harmful substances and acidic substances in iron tailings may seep into the soil, causing soil pollution and acidification, which will affect the fertility and biodiversity of the soil and reduce the agricultural production capacity of the soil [

23]. Soil contamination may also negatively impact plant growth and ecosystem recovery. During the development and utilization of mineral resources, the impact on soil is mainly reflected in the following three aspects.

2.3.1. Soil Erosion

Soil erosion refers to the process in which soil or rock materials are worn, denuded, or dissolved, and detached from the surface under the action of wind and water [

24]. During the mining of mineral resources, activities such as stripping, clearing the ground, and transporting soil, stone, and slag deposits over large areas can intensify the process of soil erosion. Severe soil erosion can lead to thinning of the soil layer, loss of soil nutrients, and even desertification. Especially in areas with relatively fragile ecological environments, the impact of soil erosion is more significant.

Geochemical and mineralogical properties of iron ore tailings constrain direct plant-stabilized soil formation Key physicochemical and mineralogical properties of magnetite iron (Fe) tailings were characterized to identify constraints on in situ soil formation and direct plant development. Potential limiting factors for stability [

25]. Tailings of varying ages and undisturbed local native soil samples were collected from a magnetite mine in Western Australia after four years of age under field conditions. The aging process reduced the biotite minerals in the tailings but increased hematite and magnetite. However, aged tailings lack goethite and contain discrete sharp iron-containing minerals that are not physically combined with other minerals such as silicon/aluminum-containing minerals [

26]. In contrast, iron minerals in native soils are tightly aggregated with silicon/aluminum-rich phyllosilicates and have highly eroded edges. The lack of unstable organic matter and the persistence of alkali-salt conditions may have hindered the biological weathering of iron minerals and the formation of secondary iron minerals in the tailings. However, there are indications that a native pioneer plant, Marena brevifolia, can promote the biological weathering of iron-containing minerals in tailings [

27]. Therefore, ecological engineering inputs such as organic carbon accumulation and the introduction of functional microorganisms and pioneer plants to accelerate biological weathering of iron-containing minerals should be used as priorities to initiate in situ soil formation in iron ore tailings.

2.3.2. Soil Acidification

Soil acidification is the process in which acidic substances make soil acidic. During the mining process of mineral resources, the mining of sulfide deposits will lead to acidification of the soil environment [

28]. In addition, acidic gases produced during the later processing and utilization of minerals, such as SO

2 produced by coal combustion, can also lead to the formation of acid rain, which in turn triggers soil acidification. Soil acidification will reduce soil pH, affect the soil's ability to absorb nutrients, lead to nutrient loss, and reduce soil productivity.

2.3.2. Soil Pollution

Soil pollution occurs when pollutants accumulate in the soil, surpassing its self-purification ability [

29]. Various forms of soil pollution arise from mineral resource development, including heavy metal pollution, organic matter pollution, solid waste pollution, and nuclear pollution. Heavy metals like mercury, cadmium, and lead, produced during mineral mining and processing, organic matter pollution from the petrochemical industry, solid waste from mining processes, and nuclear pollution from the nuclear industry all contribute to soil pollution. This pollution adversely affects plant growth, as pollutants can remain on or in plants and harm animals and humans through the food chain, leading to diseases. The extensive expansion of mining activities results in significant land occupation, severe environmental pollution, and high ecological risks, necessitating the development of cost-effective tailings resource utilization technologies. Experiments conducted in Anshan Iron Mine, Liaoning, examined the effects of amendments, plants, microorganisms, and plant-microorganism complexes in the sustainable utilization of iron tailings [

30]. The results demonstrated that comprehensive tailings utilization technologies could reduce bulk density and pH value, increase moisture content and porosity, and improve fertility levels, providing an ideal growing environment for plants. Different utilization methods also promoted the growth of soil bacteria, fungi, and actinomycetes populations to varying degrees. These findings offer valuable insights for improving tailings management and mitigating the long-term impacts of mining activities.

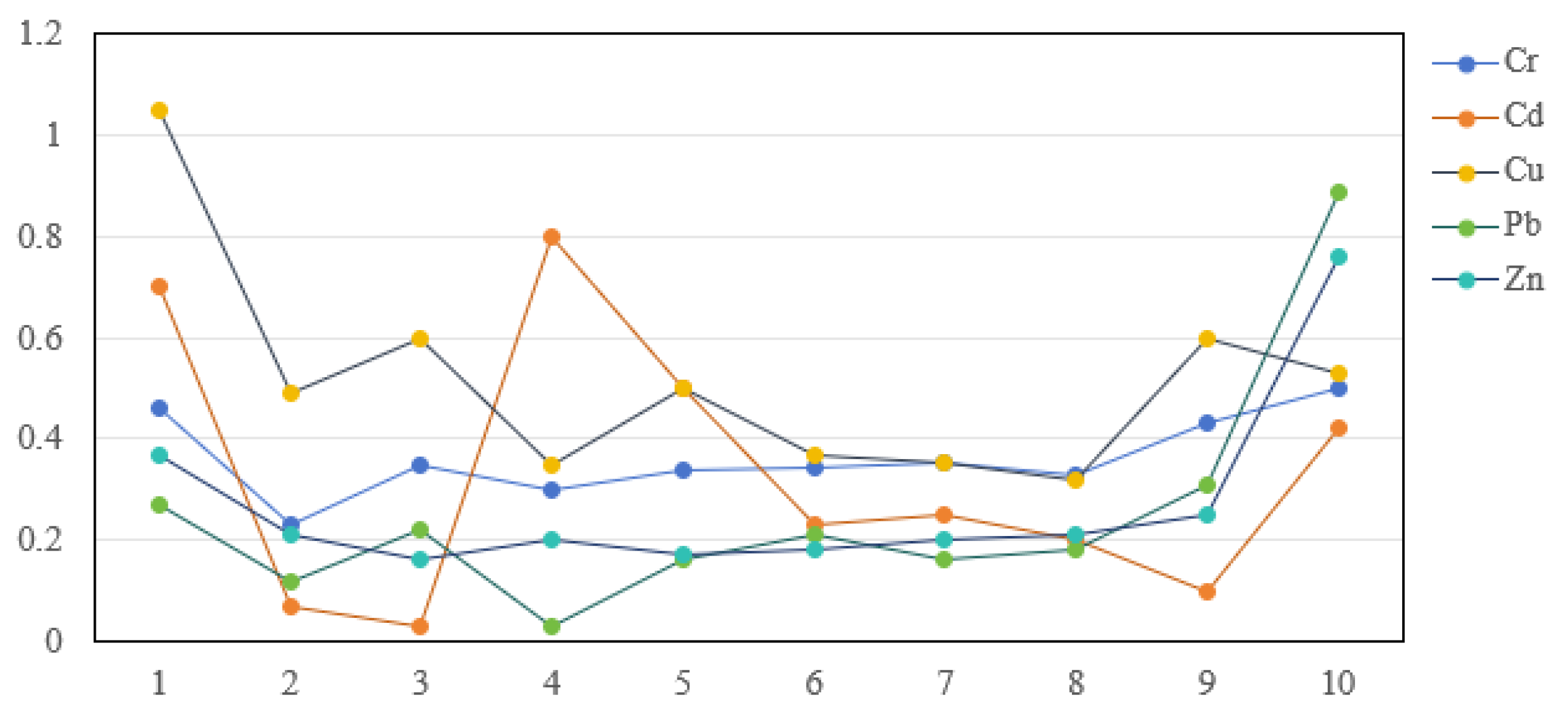

Figure 4 shows the pollution degree of heavy metals such as Cr and Cd to the ecological environment.

The high toxicity of heavy metals to humans has garnered significant attention, and the migration and transformation patterns of heavy metals are closely related to soil safety [

31]. Investigating the migration and transformation of heavy metals in tailings can provide a reliable basis for pollution control and ecosystem restoration. Heavy metal speciation plays a crucial role in risk assessment. The research focused on Anshan tailings, encompassing field investigations and laboratory studies. The main form of heavy metals in Anshan tailings is in a residual state, but they exhibit strong migration and transformation capabilities both vertically and horizontally. Their tendency to shift from stable to unstable forms increases their bioavailability and potential bioavailability [

32]. The study also examined the impact of ores on soil quality, toxic metal concentrations, and geological accumulation conditions. Soil and mineral samples from Itakpe, Kogi State in Nigeria were collected, classifying the iron load in farmland soil as "extremely contaminated" based on the site accumulation index value. The soil samples were found to be "severely contaminated" with lead, "moderately contaminated" with manganese and zinc, and "not contaminated" with cadmium and copper. The distribution of metals in soil samples, soil quality, and mineral-rich soils were found to be influenced by geology and human activities. Additionally, the levels of toxic metals in farmland soils may have increased due to mine tailings or anthropogenic activities. It is recommended to conduct rigorous ongoing environmental impact assessments, environmental monitoring, environmental audits, and environmental awareness activities [

33].

2.4. Impact on the ecological environment

The discharge of iron tailings can hurt, harm the environment and wildlife. Harmful substances can accumulate and poison organisms, leading to damage to their physiological functions and reproductive capabilities, which in turn affects biodiversity. Additionally, the discharge of iron tailings can destroy animal habitats, reduce their food and resources, and negatively impact animal populations. Li, et al. [

34] conducted a study on the physical and chemical properties, heavy metal pollution status, and bacterial community structure of soil near an iron tailings pond in Linze County, Gansu Province, China. The study found that the tailings-related soil had poor quality, with alkaline pH and low organic matter content. The dominant bacteria phyla were Actinobacteria, Proteobacteria, and Deinococcus, while Blastococcus, Arthrobacter, and Marblebacterium were dominant at the genus level. The study concluded that the iron tailings pond in northwest China was heavily polluted with various heavy metals, leading to a significant reduction in soil bacterial richness and diversity. This research provides a basis for further research and ecological restoration of iron tailings ecosystems in northwest China [

35]. The impact of the SAMARCO iron tailings spill on the dam and the Atlantic Doce River was assessed by examining the presence of toxic metals. The spill resulted in a large amount of waste deposited along the Dorsey Basin and a significant increase in suspended sediment loads. The risk of adverse impacts, not only from dam failures but also from iron ore mining and artisanal gold mining, is a real concern. Heavy rainfall can lead to increased erosion, mobilization, and transportation of contaminated particles, which can sustain high inputs of suspended particulate matter (SPM) and metals in the future, posing a threat to ecosystem services.

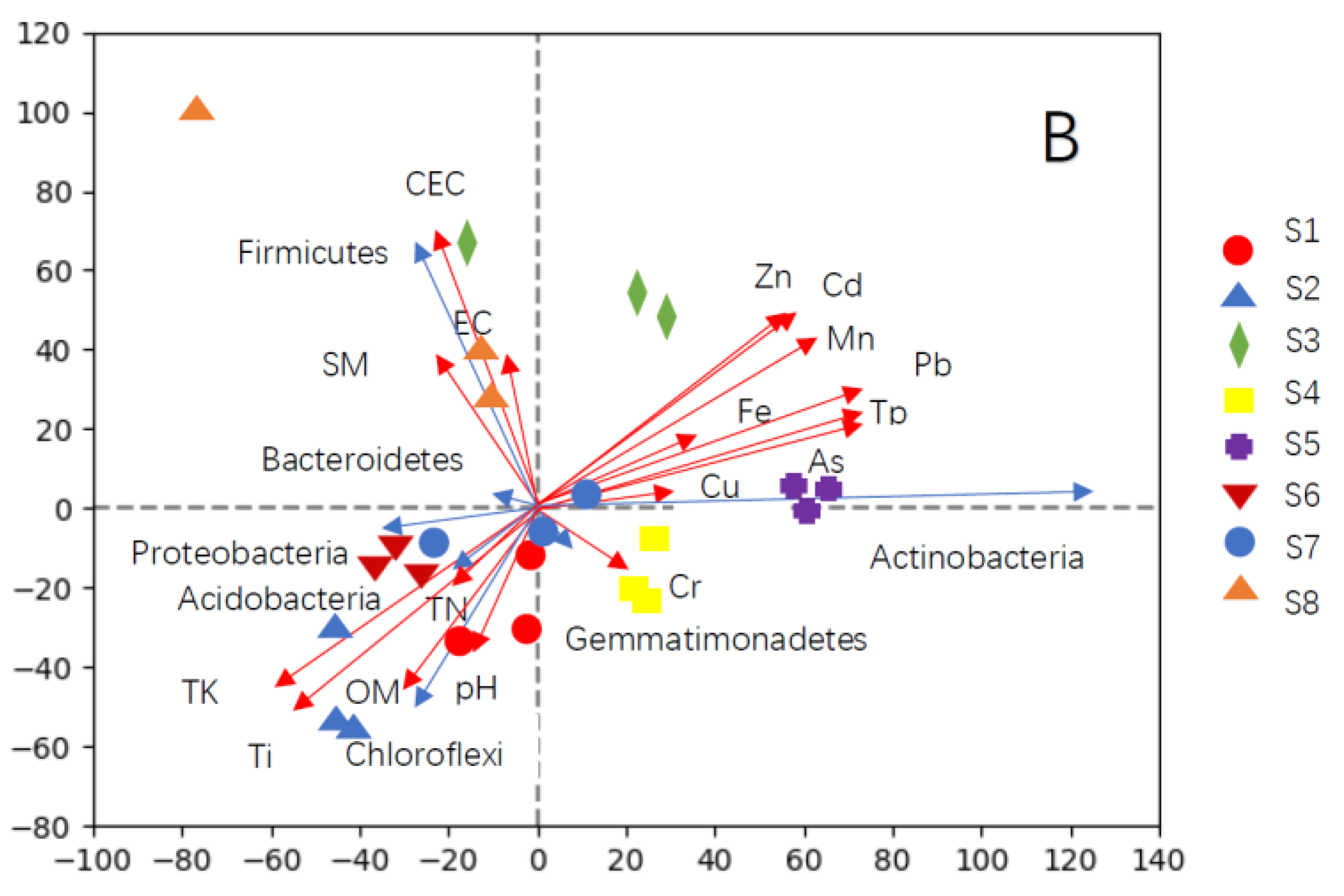

Figure 5 shows the correlation between environmental factors and bacterial communities.

Iron tailings containing toxic metals pose significant risks to ecosystems and human health due to the dispersion of particles containing high concentrations of toxic metals such as lead (Pb), arsenic (As), and zinc (Zn) through wind and water. Iron tailings are particularly susceptible to erosion by wind and water before vegetation cover is established, especially in semi-arid environments, which can persist for decades or even longer without intervention. Robert, et al. [

36] observed severe erosion in the top 2 meters of the tailings at the Humboldt Smelter Super Mine, with a noticeable redox gradient in the top 0.5 meters. The mineral composition transformation revealed the conversion of ferrous iron sulfides to ferrihydrite and gypsum, forming schwertmannite and jarosite. When the tailings are exposed to air, oxidative weathering releases arsenic, lead, and zinc from parent sulfides such as arsenopyrite, galena, and sphalerite, and these elements are incorporated into adsorbed complexes of secondary minerals, carbonates, (hydr)oxides, and (hydroxy)sulfates. This process is accompanied by an increase in acidity, leading to severe damage to the ecosystem in the region [

37].

3. Treatment and Prevention Strategies for Iron Tailings

With the unprecedented pace of mining and mineral processing over the past decade, the world has become increasingly concerned about the fate of tailings and the consequences of the release of pollutants through dust, leakage from tailings dams, breach of dam walls, or direct discharge of tailings into waterways. irreversible consequences [

38]. The more low-grade ore that may be mined in the future, the more extreme weather events that global climate change will produce, and the risks associated with tailings management may increase. A review of alternative tailings management methods that can improve environmental, social, and economic outcomes identified the three more effective approaches: pasty and concentrated tailings, tailings reuse, recycling and reprocessing, and active proactive management [

39]. In the future, models can be constructed to optimize the environmental, social, and economic outcomes of tailings management throughout the value chain by integrating ore body characteristics, mine planning, processing, disposal, reprocessing, recycling, and reuse [

40]. To reduce the negative impact of iron tailings on the environment, a series of measures need to be taken. To reduce the adverse impact of iron tailings on the environment, a series of measures need to be taken [41-43].

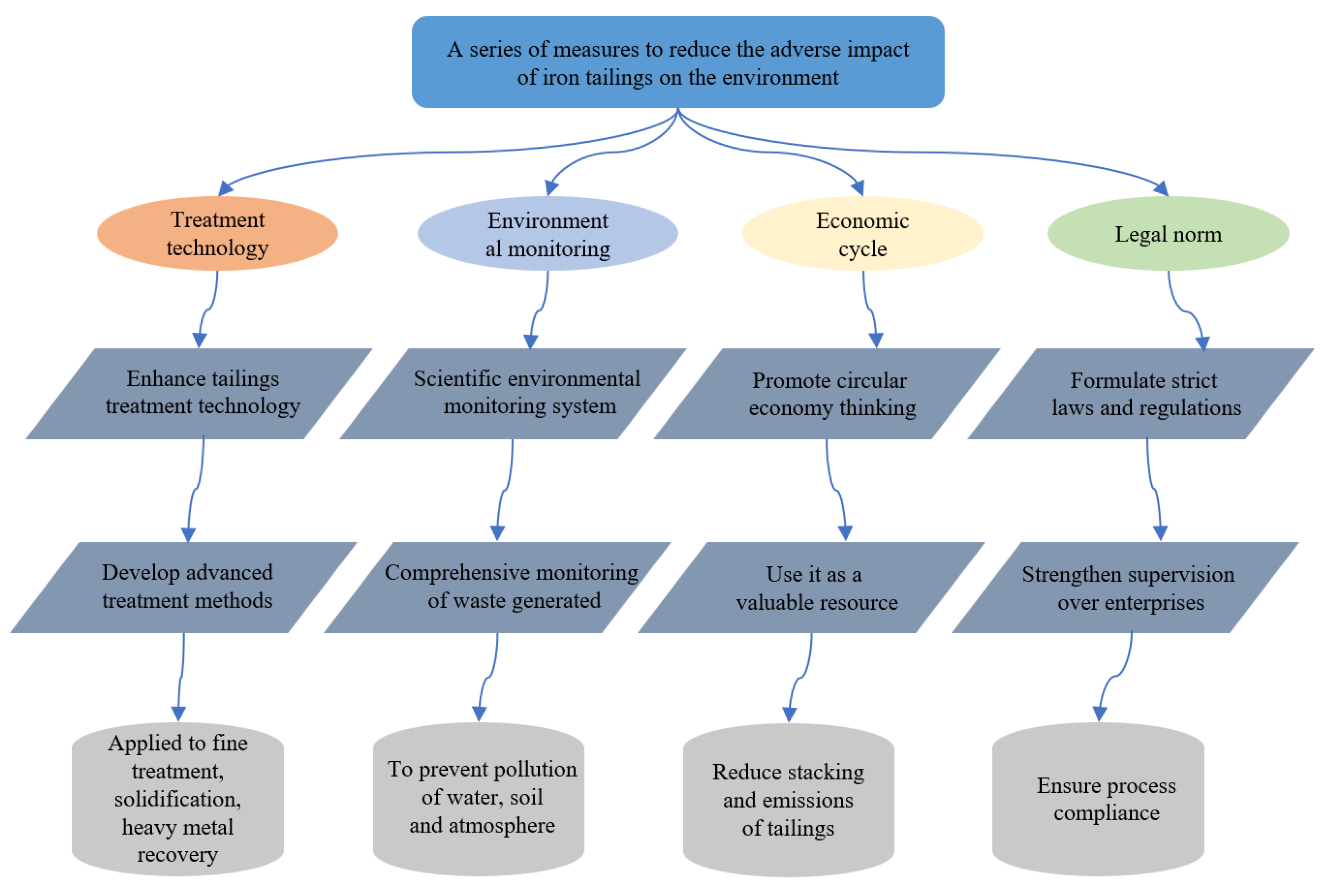

Figure 6 shows what can be done for iron tailings.

3.1. Improve Processes to Reduce the Generation of Pollutants

In the process of resource development and utilization, the application of production equipment and process technology is crucial. Its progress and upgrading can not only improve resource recovery efficiency, but also achieve energy conservation and emission reduction, and reduce environmental pollution. For example, in the ore beneficiation process, the pre-selection process of ultra-fine crushing and coarse-grained tailing can improve the processing capacity and economic benefits of lean ores. In coal mining, improving the management of the goaf roof and using filling or semi-filling methods to fill the goaf and abandoned tunnels with waste rock can not only reduce surface subsidence but also reduce waste rock emissions. With the development and application of new equipment and new processes, resource development and utilization efficiency and economic benefits have been improved, and environmental pollution has also been reduced, enabling the production process to achieve sustainable development. Technological innovation is an important way to achieve green production [

44]. Mining and environmental problems that exist to ensure the environmental safety of technogenetic systems, mathematical methods can be used to conduct complex geoecological evaluations of environmental objects, revealing the migration patterns of heavy metal compounds and arsenic from tailings to components of ecological zones, reducing approach to negative impacts on mountain systems [

45]. Snow samples, industrial soils, plants, and industrial effluents were analyzed by using an ICPMC Elan DRC II Perkin Elmer mass spectrometer (USA). By using graphics software such as ESRI's Q-GIS and ArcGIS to build a digital mapping model of environmental pollution, the mining process methods can be improved through the reported data.

Wei, et al. [

46] comprehensively studied the strength and leaching performance of four types of high-calcium geopolymer-stabilized tailings under the combined action of dry-wet cycles and acid rain. Through unconfined compression tests, apparent integrity tests and compression The mercury test evaluates the strength and durability of stabilized tailings and compares the results to determine which material is superior. By analyzing the relationship between the characteristics of different properties of the permeate, the chemical properties of the soil, and the ion leaching concentration, we can evaluate the leaching durability of stabilized tailings and understand the erosion and leaching mechanisms of the soil [

47]. The study found that the good stability in long-term complex erosion environments and the low dosage and low price of the new binder indicate that the stabilized material is green, low-carbon and sustainable.

3.2. Figures, Tables and Schemes

The extremely fine particle size, angular particle morphology, and inert mineral components are the main reasons why iron tailings are difficult to comprehensively utilize in large quantities [

48]. Re-selecting and recovering valuable metals from iron tailings is difficult and more expensive. The tailings are still discharged after secondary recovery. The appropriate particle size and gradation of iron tailings replacement aggregates need to be explored. The utilization of iron tailings the characteristics of low water absorption and multi-angular accumulation of pores have great research prospects in the production of building materials such as thermal insulation, heat insulation, and sound insulation wall panels. Iron tailings can also help reduce the firing temperature, which can be used to prepare fired bricks and fired cement; Based on agricultural applications, a large number of experiments have been conducted to identify species that can survive in iron tailings mining areas, so that they can evolve attributes suitable for survival or combine with nutrients to achieve ecological reclamation of iron tailings areas [

49]. In countries such as Brazil, iron tailings are also used to produce non-toxic pigments to provide the additional aesthetic value of iron tailings. Adhering to the concept of environmental protection, the above approach is how to consume iron tailings stockpiles in large quantities without affecting the application performance of iron tailings products provides a reference basis [

50].

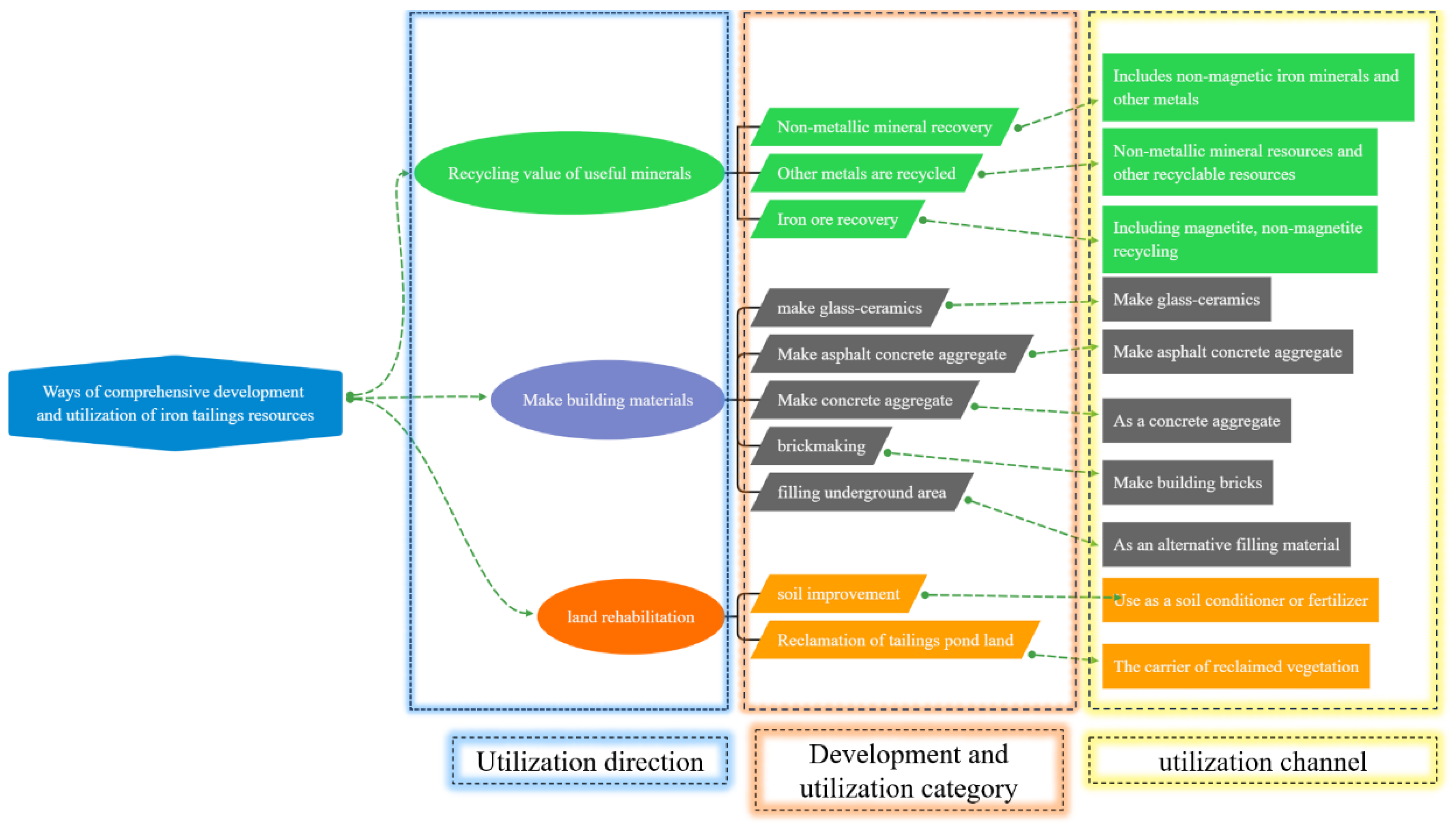

Figure 7 shows the comprehensive development and utilization approach of iron tailings resources.

Researchers have conducted a lot of research on the comprehensive utilization of iron tailings. Thejas, et al. [

51] discussed the environmental pollution caused by improper disposal of iron tailings and the reuse methods of iron tailings in the construction field. Simply put, improper disposal of iron tailings can cause water pollution, air pollution, and soil pollution. Researchers have also given methods to deal with waste iron tailings, which can be used to build bricks. The methods of using waste iron tailings to make bricks can be divided into three categories: firing, cementing and geotechnical polymerization. The strength of bricks built using these processes is up to standard and is particularly outstanding in the geopolymerization process. Reusing iron tailings in the construction field can reduce the loss of natural resources. The intensive development of mineral deposits in pristine mineral areas has led to the accumulation of large amounts of waste from the processing of mineral raw materials, which has hurt, harmed the environment. Reshma, et al. [

52] used the co-precipitation method to recover iron and cobalt from iron ore tailings and waste lithium-ion batteries respectively, prepared cobalt ferrite nanoparticles, and characterized them and photo/acoustic catalytic degradation of Congo red. The samples were characterized by XRD, UV-DRS, SEM/TEM, and specific surface area testing. The results show that the sample can effectively degrade Congo red dye under the action of visible light and ultrasonic power, and the most likely degradation pathway is proposed. Recyclability tests show that the magnetic catalyst is quite stable, effective, and easy to separate using external magnets. This study raises the possibility of large-scale application of synthetic value-added materials in iron tailings for environmental protection. Gao, et al. [

53] constructed a sustainable framework from a life cycle perspective, including environmental, social, and quantitative indicators from three aspects of the economy to evaluate the case. It developed a comprehensive framework from three aspects: environmental sustainability assessment, social and economic sustainability assessment, and overall sustainability assessment. The newly designed framework of this study has the potential to improve the sustainability of tailings treatment technology to promote Circular economic development of tailings utilization.

3.3. Human Monitoring to Help Restore the Ecological Environment

By constructing a model for iron tailings or using organisms in the iron tailings ecology as monitoring indicators, we can help restore the ecological environment [

54]. Building models can help researchers predict the impact of iron tailings on the ecological environment and provide a scientific basis for formulating corresponding prevention and control measures. The model can provide decision support for the environmental protection department by simulating and predicting the migration and accumulation process of iron tailings based on the physical, chemical, and biological properties of iron tailings [

55]. In addition, models can be used to evaluate the effectiveness of different control measures and provide guidance for monitoring and evaluation. A method to use organisms in iron tailings ecology as monitoring indicators. Organisms in the iron tailings ecology have strong adaptability, and they can be used as indicator species of environmental quality to reflect the impact of iron tailings on the ecosystem [

56]. By monitoring biological population structure, biodiversity, and ecological functions, the impact of iron tailings on the ecological environment can be assessed and corresponding restoration measures can be guided. In addition, some specific organisms such as metal hyperaccumulators and microorganisms in iron tailings can also be used as monitoring indicators to monitor the accumulation and transformation process of iron tailings through their physiological and biochemical characteristics.

Grazielle, et al. [

57] established a multivariable classification model using water quality monitoring data from the Guarazo River Basin in Minas Gerais, Brazil, where the iron ore tailings protective structure ruptured in 2015. Affected and unaffected areas were assessed and chemical, physical and microbial variables were monitored by applying multivariate classification techniques to the data and building classification models using PLS-DA and LDA. The resulting model does this by discerning whether sites affected by tailings exhibit characteristics comparable to unaffected areas, thereby providing insights into the restoration of the assessed ecosystems. Its research results can provide decision-makers with action and policy support, as well as monitor environmental restoration in fractured and degraded areas. After the collapse of the Findan Dam in Brazil, 60 million cubic meters of iron-rich tailings were released, affecting a large area and requiring detailed characterization and monitoring for agricultural and environmental purposes. Rafaella, et al. [

58] used proximal sensors to collect iron tailings data. They collected composite samples in fully affected, partially affected, and non-impacted areas (natural soils) and used principal component analysis of sample elemental composition to distinguish affected from non-impacted areas and predict agronomic and environmental importance attributes. This study resulted in a large data set that provides a reliable basis for further field investigations across multiple scientific disciplines, aiming to identify hotspots of contamination, digital mapping of soil and property changes, and pedological, agricultural, and environmental issues. Reliable characterization, and planning of specific environmental and agricultural restoration practices.

Helio, et al. [

59] conducted a study on the genotoxicity and mutagenicity of earthworms exposed to the Brumadinho tailings area compared to a reference area. They exposed the earthworms to different concentrations of iron ore waste and found that higher concentrations resulted in increased DNA damage and micronuclei formation. The earthworms also experienced a decrease in body weight with higher concentrations of mining waste. This suggests that soil contaminated with iron slag can cause DNA damage and metabolic changes in exposed earthworms. Further research in mining areas is needed to confirm and expand on these findings. Siqueira, et al. [

60] assessed the ecotoxicological effects of the collapse of the Vale iron ore dam in Brumadinho, Brazil. They collected tailings from three areas and conducted acute ecotoxicity tests on Eisenia spp. and Daphnia, as well as chronic reproduction tests on Nodida and Chlorella. The bioassays revealed high metal concentrations, particularly for iron, manganese, and nickel, exceeding the limits set by Brazilian law. Chronic effects on the reproduction of aquatic and soil organisms were more severe than acute effects, indicating the long-term impact of the tailings on the ecosystem. Rodolfo, et al. [

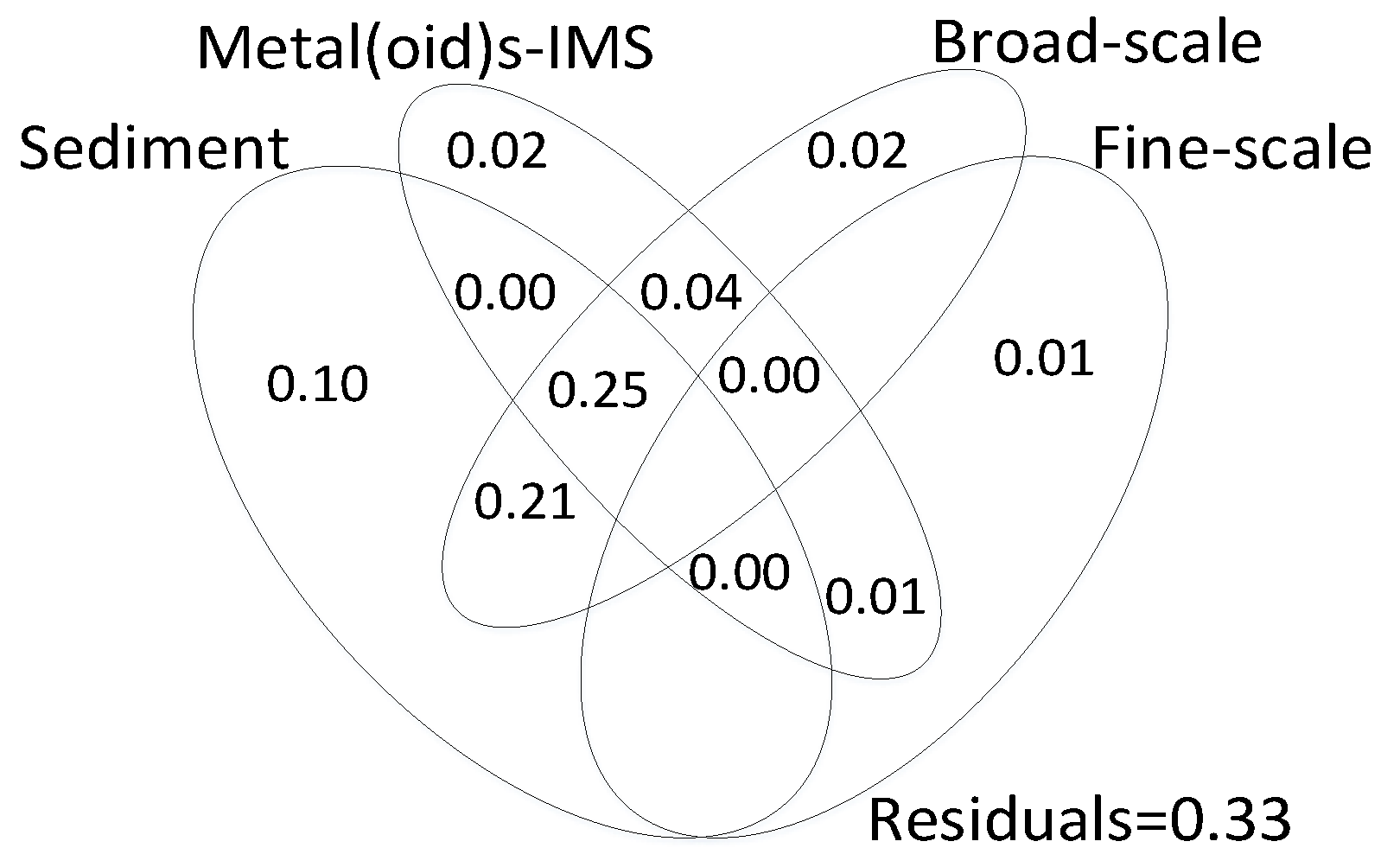

61] investigated the factors influencing the macrobenthic structure in the Algasto-Abroljos Coast Marine Reserve. They considered the IMS index, sediment variables, organic pollutants, and metal concentrations. The study found that mine tailings increased sediment influx, burying benthic macrofauna in mud and causing long-term changes in macrofauna. The tailings mud significantly reduced species richness and diversity, favoring opportunistic species.

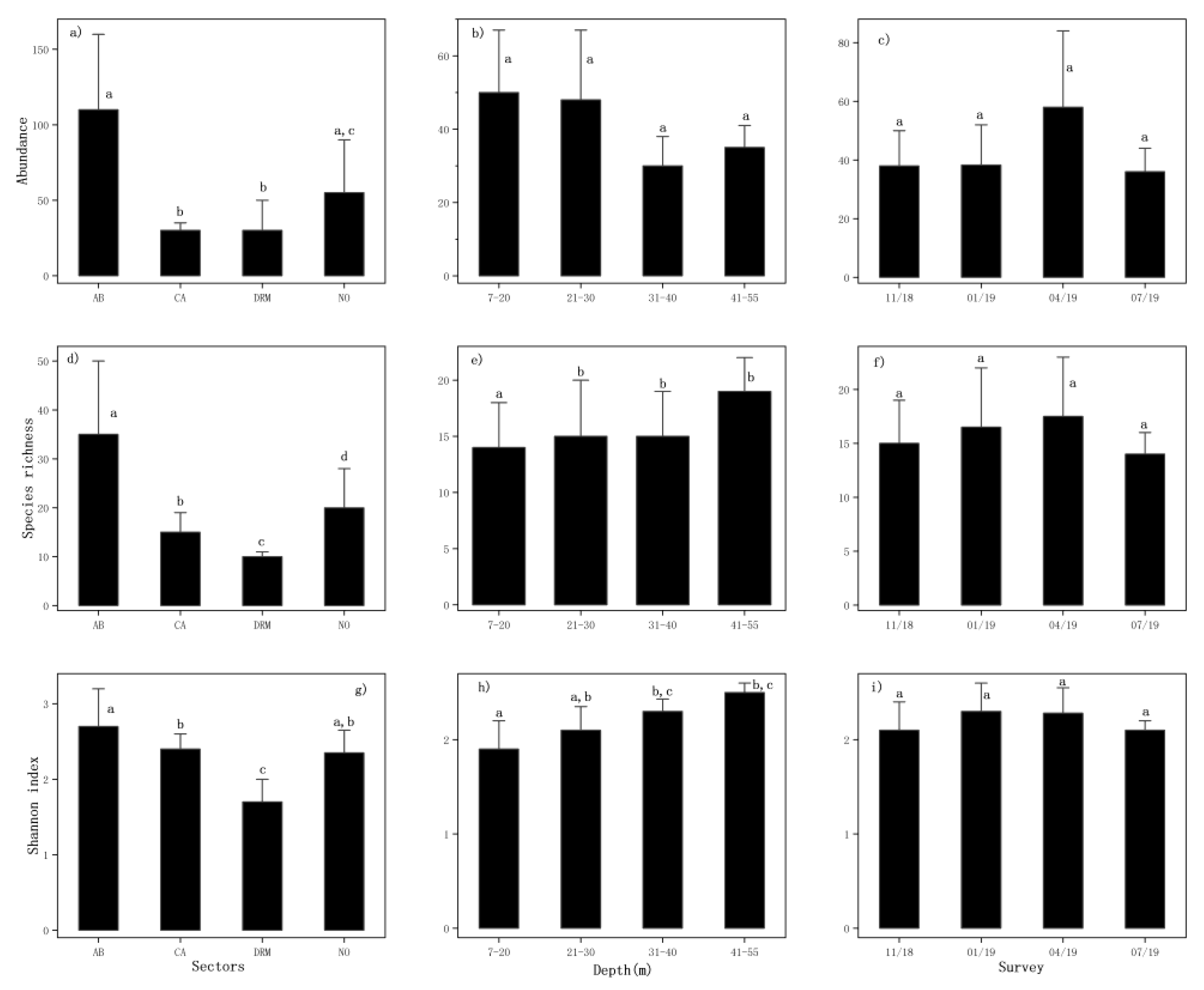

Figure 8 and

Figure 9 show the findings of Rodolfo et al.

Mud quality, IMS index, and metal concentrations were related to the Findan Dam breach, and a macrofauna community dominated by resistant taxa was formed in the affected area. Studies have shown that nearly four years after the disaster, tailings slurry, and its accumulation resulted in declines in species abundance, richness, diversity, and that long-term monitoring is necessary to assess the impact of the Findan dam failure [

62]. Additionally, these results provide support for management plans to restore this important marine ecology.

3.4. Ecological Restoration and Reconstruction of Ecosystem Functions

Microorganisms and herbs are important tools that can help restore the ecological environment of damaged iron tailings areas. By using microorganisms to degrade pollutants and planting absorptive herbs to purify the soil, the ecological environment in iron tailings areas can be effectively expanded. This approach can also promote the restoration and protection of local ecosystems, providing more sustainable resources for the future.

The research conducted by Cui, et al. [

63] focused on testing soil utilization technologies in the tailings area. They used amendments, plants, and microorganisms in various combinations to study their effects on the sustainable utilization of iron tailings. The results showed that these treatments improved the physical and chemical properties of the tailings, creating a more favorable environment for plant growth. Ouyang, et al. [

64] investigated the transformation pathways of iron minerals and associated arsenic forms in iron-rich tailings. They found that dissimilatory iron-reducing bacteria played a crucial role in the dissolution and reduction of iron minerals. The release of iron promoted the oxidative dissolution of pyrite and arsenopyrite, leading to the precipitation of oxides and carbonates [

65]. The released arsenic was fixed by ferrihydrite and newly formed hydrous iron oxide. This research provided insights into the microbial-mediated transformation of iron minerals and pollutant migration in tailings. The ability of resident microorganisms to tolerate high concentrations of metals is important for the recovery and reconstruction of mining areas, as highlighted by Marques, et al. [

66]. They studied the colonization of iron ore tailings by microorganisms and observed the presence of heterotrophic and phototrophic species. The presence of living organisms in these artificially constructed niches is promising for initiating the process of primary succession and restoring the ecosystem. Overall, these studies emphasize the role of microorganisms in the restoration of tailings areas and the importance of effective soil utilization technologies. They provide valuable insights into the processes and strategies for ecological restoration and management of mining sites [

67].

Common herbs such as Chinese cabbage and amaranth have been found to have the ability to absorb heavy metals in tailings, thus purifying the soil. Zhang, et al. [

68] conducted a study on the prevention and management of local soil pollutants, focusing on the vertical and horizontal migration characteristics of five heavy metals in Anshan tailings: copper, zinc, lead, cadmium, and chromium. They found that these heavy metals have different migration trends in the vertical direction, posing a threat to groundwater. They also found that amaranth, as a dominant species, can effectively remove heavy metals from tailings. In another study by Zhou and Li [

69] the preparation of iron-based biochar (T-BC) was explored as a means of soil remediation. They used iron tailings waste and biomass as raw materials and found that T-BC could adsorb and immobilize heavy metals in contaminated soil [

70]. The addition of T-BC resulted in a reduction in the concentrations of cadmium and lead in the edible parts of Chinese cabbage. Paspalum densifera, a tropical herb, was studied by Souza, et al. [

71] in terms of its potential for restoring iron ore mining sites. They found that the deposition of solid particulate iron matter (SPMFe) on the leaves of Paspalum plants resulted in an increase in leaf iron concentration and a reduction in net photosynthesis. However, the plants exhibited efficient energy dissipation mechanisms and a reduction in lipid peroxidation, suggesting their ability to cope with excessive irradiation and reactive oxygen species. The study also indicated that an increase in atmospheric carbon dioxide concentration had a positive impact on the efficiency of photosynthesis in Paspalum species. These studies highlight the potential of common herbs in the remediation of tailings areas and the importance of understanding the migration and transformation of heavy metals in soil. They provide valuable insights into the strategies and techniques for restoring and managing mining sites [

72].

The Guarquez River in southeastern Brazil experienced significant damage due to the release of iron tailings caused by the rupture of the Findan Dam. This event altered the characteristics of the Yellow River Delta, leading to a decline in physical habitat diversity and ecological biodiversity. To restore and manage the impacted ecosystem, a river restoration project was implemented to reconstruct geomorphological features, and natural habitats, and enhancing the recovery of biota. Tatiana, et al. [

73] conducted a study as part of this restoration project, where 203 wooden structures were installed. The effectiveness of the project was evaluated using a before-and-after and impact-control design, with control and reference reaches established upstream of each restored reach. Four activities were carried out in total. After 14 months of installing the wooden structures, the hydraulic retention capacity of the restored river section was found to be improved compared to the control section. This improvement was beneficial for sediment accumulation, which strengthened the formation of natural tailings barriers and promoted the enrichment of substrate types. Additionally, there was an increase in the total abundance of benthic macroinvertebrate communities. The river restoration approach employed in this study proved to be effective in accelerating ecological resilience and aiding in the recovery from the severe impacts of the dam failure. Furthermore, this technology was innovative, low-cost, and easily replicable. In conclusion, the river restoration project implemented in the Guarquez River successfully reconstructed geomorphological features, restored natural habitats, and enhanced the recovery of biota. This study demonstrates the potential of such restoration approaches in mitigating the impacts of dam failures and promoting the resilience and recovery of damaged ecosystems.

4. Summary and Outlook

4.1. Summary

The impact of iron tailings on the environment and its prevention and control measures is an important research field. This article summarizes the main impact of iron tailings on the environment and the current prevention and control measures by reviewing relevant literature. The study found that the discharge of iron tailings can have acidic and metallic effects on surface water and groundwater, posing potential threats to aquatic ecosystems and groundwater resources. To prevent and control this impact, a series of measures can be taken, such as using recycling methods to promote surface water runoff and preventing water from seeping into the tailings; and using solidification technology to treat the tailings to reduce the release of harmful substances. These measures help mitigate the negative impact of iron tailings on the environment and protect water resources and the health of ecosystems.

4.2. Outlook for Future Research

This study is based on exploring the impact of iron tailings on the environment and its prevention and control strategies. However, there are still some limitations in the impact and prevention of iron tailings on the environment. Future research can obtain more accurate information through field surveys and experimental studies. data and conduct deeper analysis. Future research can be carried out from the following aspects:

(1) Explore new prevention and control technologies: At present, the prevention and control of iron tailings mainly focuses on recycling and solidification treatment. Future research can explore new prevention and control technologies, such as biological remediation, chemical remediation, etc., to improve the control effect and reduce costs.

(2) Study the environmental effects of tailings treatment: In addition to studying the direct impact of tailings on the environment, we can also further study the environmental effects of tailings after treatment, including the impact of solidified tailings on soil and plants to comprehensively assess the feasibility and environmental benefits of tailings treatment.

(3) Explore ways to utilize sustainable development: Tailings, as a resource, can achieve sustainable development through rational utilization. Future research can explore high-value utilization of tailings, such as using tailings to produce building materials, soil conditioners, etc., to improve the utilization efficiency of tailings and reduce environmental risks.

Author Contributions

Y.B.: Writing – original draft, Writing – review & editing, Conceptualization, Investigation. W.L.: Data curation, Formal analysis, Methodology. A.Y.: Funding acquisition, Resources, Supervision. B.G.: Software, Validation. H.L.: Software, Writing – review & editing. Z.L.: Visualization.

Funding

This project is supported by National Natural Science Foundation of China (52074126), Natural Science Foundation of Hebei Province (E2022209110) and Science and Technology Research and Development Project of Hebei Provincial Education Department (QN2024226).

Data Availability Statement

The data used to support the findings of this study are available from

the corresponding author upon request.

Acknowledgments

Thank you for Hebei Engineering Research Center of Iron ore optimization and Iron pre-process intelligence, Hebei Key Laboratory of Data Science and Application, The Key Laboratory of Engineering Computing in Tangshan City, and Tangshan Intelligent Industry and Image Processing Technology Innovation Center.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Lee, J. K.; Shang; J. Q., Wang, H.; Zhao, C. In-situ study of beneficial utilization of coal fly ash in reactive mine tailings. Journal of environmental management. 2014, 135, 73–80. [Google Scholar] [CrossRef]

- Hu, D.; Hou, W.; Xiang, C.; Lu, D.; Yang, Q.; Li, J.; Wang, J. Waste heat utilization performance verification of Heat Exchanger Only Thermal Management System for fuel cell vehicle. Journal of Cleaner Production. 2023, 139479. [Google Scholar] [CrossRef]

- Giri, S. K.; Das, N. N.; Pradhan, G. C. Magnetite powder and kaolinite derived from waste iron ore tailings for environmental applications. Powder technology. 2011, 214(3), 513–518. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, L.; Wang, Q.; Han, D.; Li, Z. Iron ore tailings, phosphate slags, and lithium slags as ternary supplementary cementitious materials for concrete: Study on compression strength and microstructure. Materials Today Communications. 2023, 36, 106644. [Google Scholar] [CrossRef]

- Zago, G. P.; Giudici, R.; Soares, J. B. Exploring Alternatives to Polyacrylamide: A Comparative Study of Novel Polymers in the Flocculation and Dewatering of Iron Ore Tailings. Polymers. 2023, 15(14), 3019. [Google Scholar] [CrossRef]

- Jing, C.; Wang, N.; Shi, W.; Meng, X.; Guo, C. Experimental study on iron ore tailings sand and municipal solid waste incineration fly ash used in semi-rigid base of asphalt pavement. Construction and Building Materials. 2023, 393, 131981. [Google Scholar] [CrossRef]

- da Silva, H. E.; Benvindo-Souza, M.; e Silva, D. D. M.; Antoniosi Filho, N. R. Genotoxic and mutagenic evaluation in Eisenia foetida annelids exposed to iron ore tailings from the region of Brumadinho, MG, Brazil. Environmental Toxicology and Pharmacology. 2023, 102, 104247. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Sun, H.; Bai, J.; Li, L. Innovative methodology for comprehensive utilization of iron ore tailings: Part 1. The recovery of iron from iron ore tailings using magnetic separation after magnetizing roasting. Journal of Hazardous Materials. 2010, 174, 71–77. [Google Scholar] [CrossRef] [PubMed]

- González-Díaz, E.; García, S.; Soto, F.; Navarro, F.; Townley, B.; Caraballo, M. A. Geochemical, mineralogical and geostatistical modelling of an IOCG tailings deposit (El Buitre, Chile): Implications for environmental safety and economic potential. Journal of Geochemical Exploration. 2022, 239, 106997. [Google Scholar] [CrossRef]

- Yin, M.; Sun, J.; He, H.; Liu, J.; Zhong, Q.; Zeng, Q.; Chen, D. Uranium re-adsorption on uranium mill tailings and environmental implications. Journal of hazardous materials. 2021, 416, 126153. [Google Scholar] [CrossRef]

- Wang, L.; Wang, P.; Chen, W. Q.; Wang, Q. Q.; Lu, H. S. Environmental impacts of scandium oxide production from rare earths tailings of Bayan Obo Mine. Journal of cleaner production. 2020, 270, 122464. [Google Scholar] [CrossRef]

- Thejas, H. K.; Hossiney, N. A short review on environmental impacts and application of iron ore tailings in development of sustainable eco-friendly bricks. Materials Today: Proceedings. 2022, 61, 327–331. [Google Scholar]

- Achterberg, E. P.; Herzl, V. M.; Braungardt, C. B.; Millward, G. E. Metal behaviour in an estuary polluted by acid mine drainage: the role of particulate matter. Environmental Pollution. 2003, 121(2), 283–292. [Google Scholar] [CrossRef] [PubMed]

- Guo, P.; Zhao, Z.; Li, Y.; Zhang, Y.; He, T.; Hou, X.; Li, S. Co-utilization of iron ore tailings and coal fly ash for porous ceramsite preparation: Optimization, mechanism, and assessment. Journal of Environmental Management. 2023, 348, 119273. [Google Scholar] [CrossRef] [PubMed]

- Qin, J.; Zhao, H.; Dai, M.; Zhao, P.; Chen, X.; Liu, H.; Lu, B. Speciation distribution and influencing factors of heavy metals in rhizosphere soil of Miscanthus floridulus in the tailing reservoir area of dabaoshan iron polymetallic mine in northern guangdong. Processes. 2022, 10(6), 1217. [Google Scholar] [CrossRef]

- Grilo, C. F.; Chassagne, C.; Quaresma, V. D. S.; Van Kan, P. J. M.; Bastos, A. C. The role of charge reversal of iron ore tailing sludge on the flocculation tendency of sediments in marine environment. Applied geochemistry. 2022, 117, 104606. [Google Scholar] [CrossRef]

- Parente, C. E.; Carvalho, G. O.; Lino, A. S.; Sabagh, L. T.; Azeredo, A.; Freitas, D. F.; Malm, O. First assessment of atmospheric pollution by trace elements and particulate matter after a severe collapse of a tailings dam, Minas Gerais, Brazil: An insight into biomonitoring with Tillandsia usneoides and a public health dataset. Environmental Research. 2023, 233, 116435. [Google Scholar] [CrossRef] [PubMed]

- Mafessoli, M.; Marques, S. F. V.; Scheuermann Filho, H. C.; Consoli, N. C. Response of artificially cemented iron ore tailings for dry stacking disposal over a wide range of stresses. Indian Geotechnical Journal. 2023, 53(4), 904–915. [Google Scholar] [CrossRef]

- Carvalho, J. V. D. A.; Wagner, A. C.; Scheuermann Filho, H. C.; Chaves, H. M.; Silva, J. P. S.; Delgado, B. G.; Consoli, N. C. Evaluation of strength parameters for application in cemented iron ore tailings stacks. Indian Geotechnical Journal. 2023, 53(4), 775–788. [Google Scholar] [CrossRef]

- Galvão, E. S.; Feroni, R. D. C.; Silveira, A. B. Trends in air quality and hospital admissions due to respiratory diseases since the standstill of an industrial plant in Brazil. Environmental Science and Pollution Research. 2020, 27, 24452–24465. [Google Scholar] [CrossRef]

- Huljek, L.; Strmić Palinkaš, S.; Fiket, Ž.; Fajković, H. Environmental Aspects of Historical Ferromanganese Tailings in the Šibenik Bay, Croatia. Water. 2021, 13(21), 3123. [Google Scholar] [CrossRef]

- Liu, P.; Liu, J.; Bi, J. Experimental and theoretical study of dynamic mechanical behavior of concrete subjected to triaxial confining and impact loads. Journal of Building Engineering. 2023, 64, 105715. [Google Scholar] [CrossRef]

- Freitas, J. C. E.; De Resende, C. F.; de Paula Pimenta, M.; Frattini, L. M.; Reis, P. R. C.; Miranda, J. B.; Peixoto, P. H. P. Assessing the ecophysiological effects of iron mining tailings on velvet bean: implications for growth limitations based on mineral composition and physicochemical properties of tailings-soil substrates. Brazilian Journal of Botany. 2023, 46(3), 715–729. [Google Scholar] [CrossRef]

- Song, Y.; Liu, R.; Yang, L.; Xiao, X.; He, G. Effects of Moss-Dominated Biocrusts on Soil Microbial Community Structure in an Ionic Rare Earth Tailings Area of Southern China. Toxics. 2022, 10(12), 782. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.; Liu, Y.; Southam, G.; Robertson, L.; Chiu, T. H.; Cross, A. T.; Huang, L. Geochemical and mineralogical constraints in iron ore tailings limit soil formation for direct phytostabilization. Science of the total environment. 2019, 651, 192–202. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Chen, H.; Li, Y. Rhizosphere soil keystone taxa of Robinia pseudoacacia and Juniperus sabina in an iron tailings matrix and their effects on soil enzyme activity. Plant and Soil. 2023, 490(1), 681–692. [Google Scholar] [CrossRef]

- da Silva, A. P. V.; Silva, A. O.; de Lima, F. R. D.; Benedet, L.; de Jesus Franco, A.; de Souza, J. K.; Carneiro, M. A. C. Potentially toxic elements in iron mine tailings: Effects of reducing soil pH on available concentrations of toxic elements. Environmental Research. 2022, 215, 114321. [Google Scholar] [CrossRef] [PubMed]

- Espinoza, S. E.; Quiroz, I. A.; Magni, C. R.; Yáñez, M. A.; Martínez, E. E. Long-term effects of copper mine tailings on surrounding soils and sclerophyllous vegetation in Central Chile. Water, Air, & Soil Pollution. 2022, 233, 288. [Google Scholar]

- Wang, Q.; Sun, Q.; Wang, W.; Liu, X.; Song, L.; Hou, L. Effects of different native plants on soil remediation and microbial diversity in jiulong iron tailings area, Jiangxi. Forests. 2022, 13(7), 1106. [Google Scholar] [CrossRef]

- Cui, X.; Geng, Y.; Li, T.; Zhao, R.; Li, X.; Cui, Z. Field application and effect evaluation of different iron tailings soil utilization technologies. Resources, Conservation and Recycling. 2021, 173, 105746. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, H.; Cui, Z. Migration and speciation of heavy metal in salinized mine tailings affected by iron mining. Water Science and Technology. 2017, 76(7), 1867–1874. [Google Scholar] [CrossRef]

- Hindersmann, B.; Achten, C. Urban soils impacted by tailings from coal mining: PAH source identification by 59 PAHs, BPCA and alkylated PAHs. Environmental Pollution. 2018, 242, 1217–1225. [Google Scholar] [CrossRef] [PubMed]

- Itodo, A. U.; Egbegbedia, L. A.; Eneji, I. S.; Asan, A. A. Iron ore deposit and its tailing impact on the toxic metal level of neighboring agricultural soils. Asian J Environ Ecol. 2017, 2(4), 1–16. [Google Scholar] [CrossRef]

- Li, S.; Wu, J.; Huo, Y.; Zhao, X.; Xue, L. Profiling multiple heavy metal contamination and bacterial communities surrounding an iron tailing pond in Northwest China. Science of the Total Environment. 2021, 752, 141827. [Google Scholar] [CrossRef] [PubMed]

- Hatje, V.; Pedreira, R. M. A.; De Rezende, C. E.; Schettini, C. A. F.; De Souza, G. C.; Marin, D. C.; Hackspacher, P. C. The environmental impacts of one of the largest tailing dam failures worldwide. Sci Rep 2017, 7, 10706. [Google Scholar] [CrossRef] [PubMed]

- Root, R. A.; Hayes, S. M.; Hammond, C. M.; Maier, R. M.; Chorover, J. Toxic metal (loid) speciation during weathering of iron sulfide mine tailings under semi-arid climate. Applied Geochemistry. 2015, 62, 131–149. [Google Scholar] [CrossRef] [PubMed]

- Sun, B.; Guo, Z.; Ren, F.; Pan, X.; Lyu, C.; Qiao, X.; Hou, Q. Enhanced photocatalyst with TiO2-anchored iron tailings structure for highly efficient degradation of doxycycline hydrochloride. Journal of Cleaner Production. 2023, 427, 139241. [Google Scholar] [CrossRef]

- Edraki, M.; Baumgartl, T.; Manlapig, E.; Bradshaw, D.; Franks, D. M.; Moran, C. J. Designing mine tailings for better environmental, social and economic outcomes: a review of alternative approaches. Journal of Cleaner Production. 2014, 84, 411–420. [Google Scholar] [CrossRef]

- Dos Santos, G. R.; Maia, L. C.; Lobo, F. A.; da Fonseca Santiago, A.; da Silva, G. A. A model based on a multivariate classification for assessing impacts on water quality in a DOCE river watershed after the Fundão tailings dam failure. Environmental Pollution. 2023, 334, 122174. [Google Scholar] [CrossRef]

- Wei, M.; Li, Y.; Yu, B.; Wei, W.; Liu, L.; Xue, Q. Low-carbon treatment of zinc contaminated iron tailings using high-calcium geopolymer: Influence of wet-dry cycle coupled with acid attack. Journal of Cleaner Production. 2022, 338, 130636. [Google Scholar] [CrossRef]

- Freitas, J. C. E.; De Resende, C. F.; de Paula Pimenta, M.; Frattini, L. M.; Reis, P. R. C.; Miranda, J. B.; Peixoto, P. H. P. Assessing the ecophysiological effects of iron mining tailings on velvet bean: implications for growth limitations based on mineral composition and physicochemical properties of tailings-soil substrates. Brazilian Journal of Botany. 2023, 46(3), 715–729. [Google Scholar] [CrossRef]

- Yaghoobian, S.; Zonoozi, M. H.; Saeedi, M. Performance evaluation of Fe-based water treatment sludge for dewatering of iron ore tailings slurry using coagulation-flocculation process: Optimization through response surface methodology. Journal of Environmental Management. 2022, 316, 115240. [Google Scholar] [CrossRef] [PubMed]

- Deng, J.; Ning, X. A.; Shen, J.; Ou, W.; Chen, J.; Qiu, G.; He, Y. Biomass waste as a clean reductant for iron recovery of iron tailings by magnetization roasting. Journal of Environmental Management. 2022, 317, 115435. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Luo, S. H.; Zhang, L.; Wang, Q.; Huang, X.; Zhang, Y.; Duan, X. Study on preparation and performance of iron tailings-based porous ceramsite filter materials for water treatment. Separation and Purification Technology. 2021, 276, 119380. [Google Scholar] [CrossRef]

- Filatova, M. Y.; Krupskaya, L. T.; Kocharyan, Y. G.; Leonenko, A. V.; Romashkina, E. A. Mining and environmental problems of Dalnegorsk, Primorye territory, and ways to solve them. In IOP Conference Series: Earth and Environmental Science. 2022, (Vol. 1061, No. 1, p. 012002). IOP Publishing.

- Wei, M.; Li, Y.; Yu, B.; Wei, W.; Liu, L.; Xue, Q. Low-carbon treatment of zinc contaminated iron tailings using high-calcium geopolymer: Influence of wet-dry cycle coupled with acid attack. Journal of Cleaner Production. 2022, 338, 130636. [Google Scholar] [CrossRef]

- de Freitas, V. A. A.; Breder, S. M.; Silvas, F. P. C.; Rouse, P. R.; de Oliveira, L. C. A. Use of iron ore tailing from tailing dam as catalyst in a fenton-like process for methylene blue oxidation in continuous flow mode. Chemosphere. 2019, 219, 328–334. [Google Scholar] [CrossRef]

- Behura, R.; Sakthivel, R.; Das, N. Synthesis of cobalt ferrite nanoparticles from waste iron ore tailings and spent lithium ion batteries for photo/sono-catalytic degradation of Congo red. Powder technology. 2021, 386, 519–527. [Google Scholar] [CrossRef]

- Qiu, J.; Yang, L.; Sun, X.; Xing, J.; Li, S. Strength characteristics and failure mechanism of cemented super-fine unclassified tailings backfill. Minerals. 2017, 7(4), 58. [Google Scholar] [CrossRef]

- Onitiri, M. A.; Akinlabi, E. T. Effects of particle size and particle loading on the tensile properties of iron-ore-tailing-filled epoxy and polypropylene composites. Mechanics of Composite Materials. 2017, 52, 817–828. [Google Scholar] [CrossRef]

- Li, Y.; Liu, L.; Deng, Y.; Chen, Y.; Li, Y.; Wu, J. Unlocking the potential of iron ore tailings in controlled low-strength material: Feasibility, performance, and evaluation. Journal of Cleaner Production. 2023, 423, 138772. [Google Scholar] [CrossRef]

- Behura, R.; Sakthivel, R.; Das, N. Synthesis of cobalt ferrite nanoparticles from waste iron ore tailings and spent lithium ion batteries for photo/sono-catalytic degradation of Congo red. Powder technology. 2021, 386, 519–527. [Google Scholar] [CrossRef]

- Gao, Z.; Li, Y.; Qian, H.; Wei, M. Environmental, economic, and social sustainability assessment: A case of using contaminated tailings stabilized by waste-based geopolymer as road base. Science of the Total Environment. 2023, 888, 164092. [Google Scholar] [CrossRef] [PubMed]

- Wan, R.; Kong, D.; Kang, J.; Yin, T.; Ning, J.; Ma, J. The experimental study on thermal conductivity of backfill material of ground source heat pump based on iron tailings. Energy and Buildings. 2018, 174, 1–12. [Google Scholar] [CrossRef]

- Knights, B. D. H.; Satyro, J. C.; Dias, R. A.; de Araújo Freitas, A. C. Performance improvements provided by Mintek's FloatStar™ advanced control system on reverse flotation of iron ore. Journal of the Southern African Institute of Mining and Metallurgy. 2012, 112(3), 203–209. [Google Scholar]

- Yan, D.; Zhao, F.; Sun, O. J. Assessment of vegetation establishment on tailings dam at an iron ore mining site of suburban Beijing, China, 7 years after reclamation with contrasting site treatment methods. Environmental management. 2013, 52, 748–757. [Google Scholar] [CrossRef]

- Dos Santos, G. R.; Maia, L. C.; Lobo, F. A.; da Fonseca Santiago, A.; da Silva, G. A. A model based on a multivariate classification for assessing impacts on water quality in a DOCE river watershed after the Fundão tailings dam failure. Environmental Pollution. 2023, 334, 122174. [Google Scholar] [CrossRef]

- de Sá, R. T. S.; Prianti, M. T. A.; Andrade, R.; Silva, A. O.; Batista, É. R.; Dos Santos, J. V.; Ribeiro, B. T. Detailed characterization of iron-rich tailings after the Fundão dam failure, Brazil, with inclusion of proximal sensors data, as a secure basis for environmental and agricultural restoration. Environmental Research. 2023, 228, 115858. [Google Scholar] [CrossRef] [PubMed]

- da Silva, H. E.; Benvindo-Souza, M.; e Silva, D. D. M.; Antoniosi Filho, N. R. Genotoxic and mutagenic evaluation in Eisenia foetida annelids exposed to iron ore tailings from the region of Brumadinho, MG, Brazil. Environmental Toxicology and Pharmacology. 2023, 102, 104247. [Google Scholar] [CrossRef]

- Siqueira, D.; Cesar, R.; Lourenço, R.; Salomão, A.; Marques, M.; Polivanov, H.; Castilhos, Z. C. Terrestrial and aquatic ecotoxicity of iron ore tailings after the failure of VALE SA mining dam in Brumadinho (Brazil). Journal of Geochemical Exploration. 2022, 235, 106954. [Google Scholar] [CrossRef]

- Nascimento, R. L.; Alves, P. R.; Di Domenico, M.; Braga, A. A.; de Paiva, P. C.; Orlando, M. T. D. A.; de Lourdes Longo, L. The Fundão dam failure: Iron ore tailing impact on marine benthic macrofauna. Science of the Total Environment. 2022, 838, 156205. [Google Scholar] [CrossRef]

- Osipova, N. V. Model of stabilization of the quality of iron-ore concentrate in the process of magnetic separation with the use of extreme regulation. Metallurgist. 2018, 62(3), 303–309. [Google Scholar] [CrossRef]

- Cui, X.; Geng, Y.; Li, T.; Zhao, R.; Li, X.; Cui, Z. Field application and effect evaluation of different iron tailings soil utilization technologies. Resources, Conservation and Recycling. 2021, 173, 105746. [Google Scholar] [CrossRef]

- Ouyang, B.; Lu, X.; Li, J.; Liu, H. Microbial reductive transformation of iron-rich tailings in a column reactor and its environmental implications to arsenic reactive transport in mining tailings. Science of the total environment. 2019, 670, 1008–1018. [Google Scholar] [CrossRef] [PubMed]

- Jin, J.; Qin, Z.; Lü, X.; Liu, T.; Zhang, G.; Shi, J.; Li, D. Rheology control of self-consolidating cement-tailings grout for the feasible use in coal gangue-filled backfill. Construction and Building Materials. 2022, 316, 125836. [Google Scholar] [CrossRef]

- Marques, A. R.; Couto, F. R.; Silva, V. D. C.; Fonseca, P. V.; Paiva, P. R. P.; Pontes, P. P.; Ferreira, Â. D. M. Biological re-colonization of sub-aerial boundaries of an ‘artificial construction-niche’contaminated by iron mine tailings: laboratory bioassays. Environmental Earth Sciences. 2017, 76, 1–14. [Google Scholar] [CrossRef]

- Puiatti, G. A.; Elerate, E. M.; de Carvalho, J. P.; Luciano, V. A.; de Carvalho Teixeira, A. P.; Lopes, R. P.; Teixeira de Matos, A. Reuse of iron ore tailings as an efficient adsorbent to remove dyes from aqueous solution. Environmental Technology. 2017, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Yang, H.; Cui, Z. Evaluation and analysis of soil migration and distribution characteristics of heavy metals in iron tailings. Journal of cleaner production. 2018, 172, 475–480. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, L. Effect of a passivator synthesized by wastes of iron tailings and biomass on the leachability of Cd/Pb and safety of Pak Choi (Brassica chinensis L.) in contaminated soil. Processes. 2021, 9, 1866. [Google Scholar] [CrossRef]

- Gu, X.; Liu, B.; Li, Z.; Wang, H.; Liu, J.; Nehdi, M. L.; Zhang, Y. Mechanical grinding kinetics and particle packing novel characterization of iron ore tailings as inert filler for cement mortar. Journal of Building Engineering. 2023, 78, 107558. [Google Scholar] [CrossRef]

- de Souza, A. E.; Rios, C. O.; de Araújo, T. O.; Siqueira-Silva, A. I.; Souza, J. P.; Pereira, E. G. Is a C4 tropical grass still an option in the revegetation of iron ore tailings in face of climate change? Theoretical and Experimental Plant Physiology. 2021, 33(4), 397–409. [Google Scholar] [CrossRef]

- Freitas, J. C. E.; De Resende, C. F.; de Paula Pimenta, M.; Frattini, L. M.; Reis, P. R. C.; Miranda, J. B.; Peixoto, P. H. P. Assessing the ecophysiological effects of iron mining tailings on velvet bean: implications for growth limitations based on mineral composition and physicochemical properties of tailings-soil substrates. Brazilian Journal of Botany. 2023, 46(3), 715–729. [Google Scholar] [CrossRef]

- Furley, T. H.; Calado, S. L. M.; Mendes, L. B.; Chagas, K. R.; Andrade, D. P.; Covre Barbiero, D.; Niencheski, L. F. H. Short-term hydromorphological and ecological responses of using woody structures for river restoration in a tailing-impacted tropical river. Integrated Environmental Assessment and Management. 2023, 19(3), 648–662. [Google Scholar] [CrossRef] [PubMed]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).