Submitted:

24 May 2024

Posted:

27 May 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

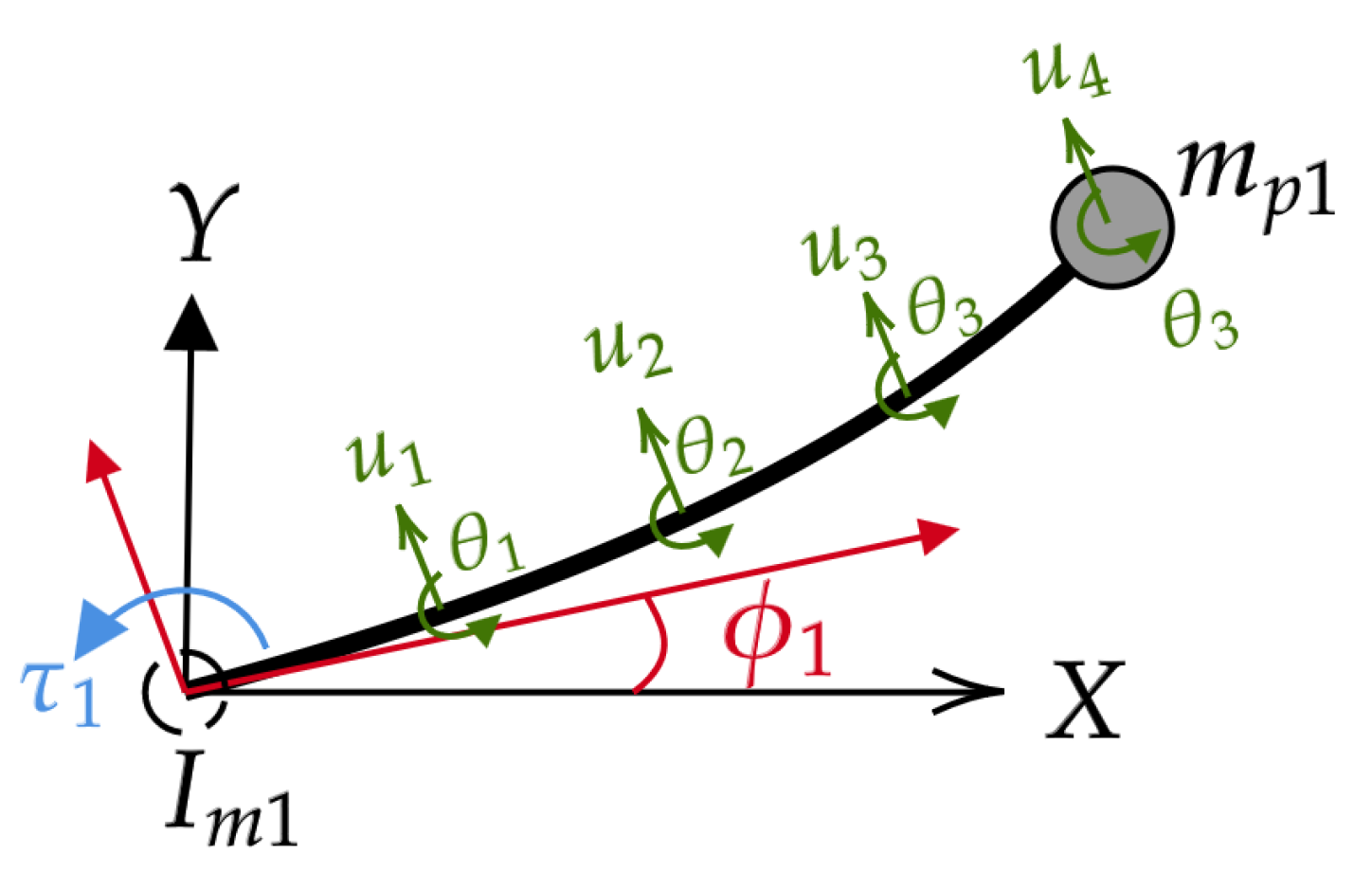

2.1. Flexible-Link Manipulator Dynamics

2.2. Parameter Identification Approach

3. Case Study: One-Link Flexible Manipulator

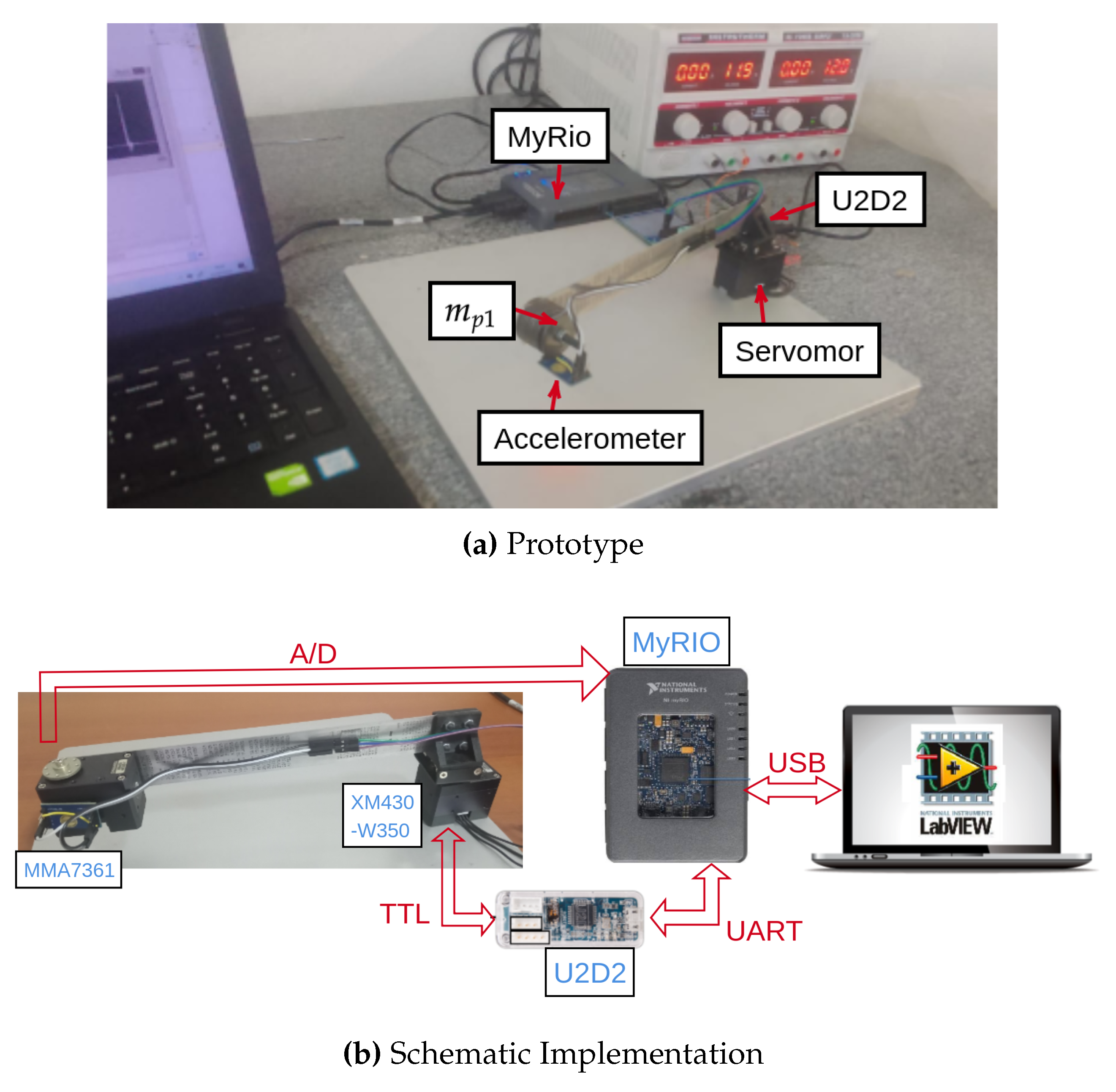

3.1. Testbed

3.2. Numerical Model

4. Results and Discussion

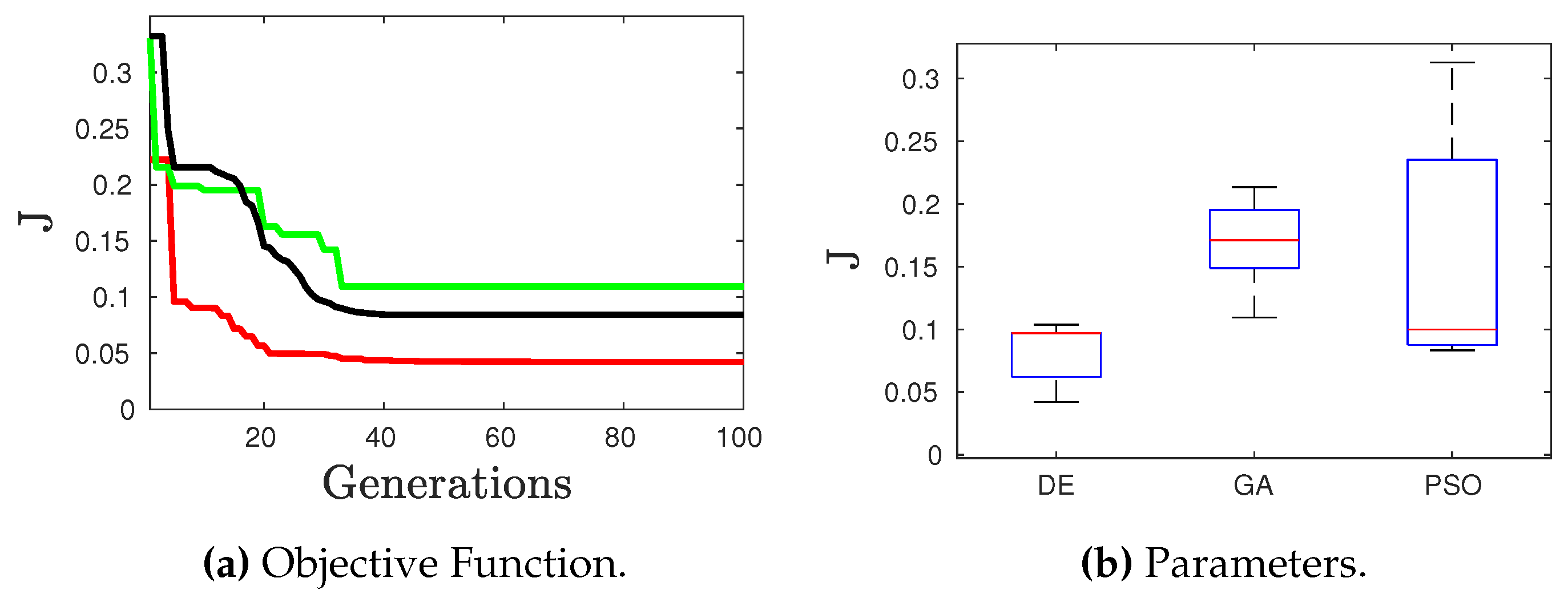

- The parameters used by the DE algorithm [27] are: population size =100, weighting factor F=0.5, crossover probability , 100 generations and strategy for the generation of candidates.

- The parameters used by the GA algorithm [28] are: =100, selection rate =0.5, crossover rate , mutation rate 0.2 and 100 generations.

- The parameters used by the PSO algorithm [29] are: number of particles =100, inertia weigth w=1.4, , 2.5 and 100 iterations.

- Stopping criteria considered was the maximum number of generations/iterations.

- The study cases were run 10 times, and the average values were obtained.

- To establish a fair comparison among the evolutionary algorithms. The seeds were used to initialize the random generator for each simulation.

- The aforementioned case studies, using DE, GA, and PSO, were run 10 times to obtain the upcoming average values.

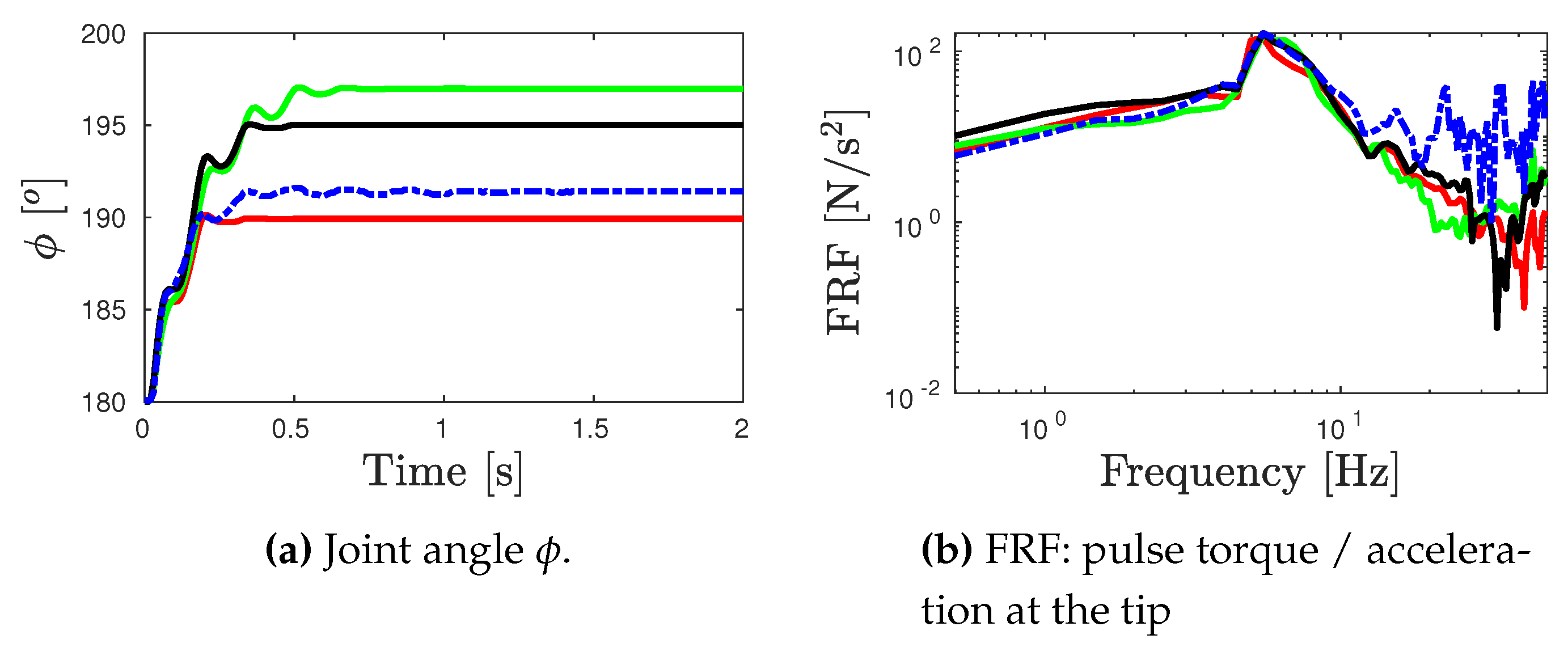

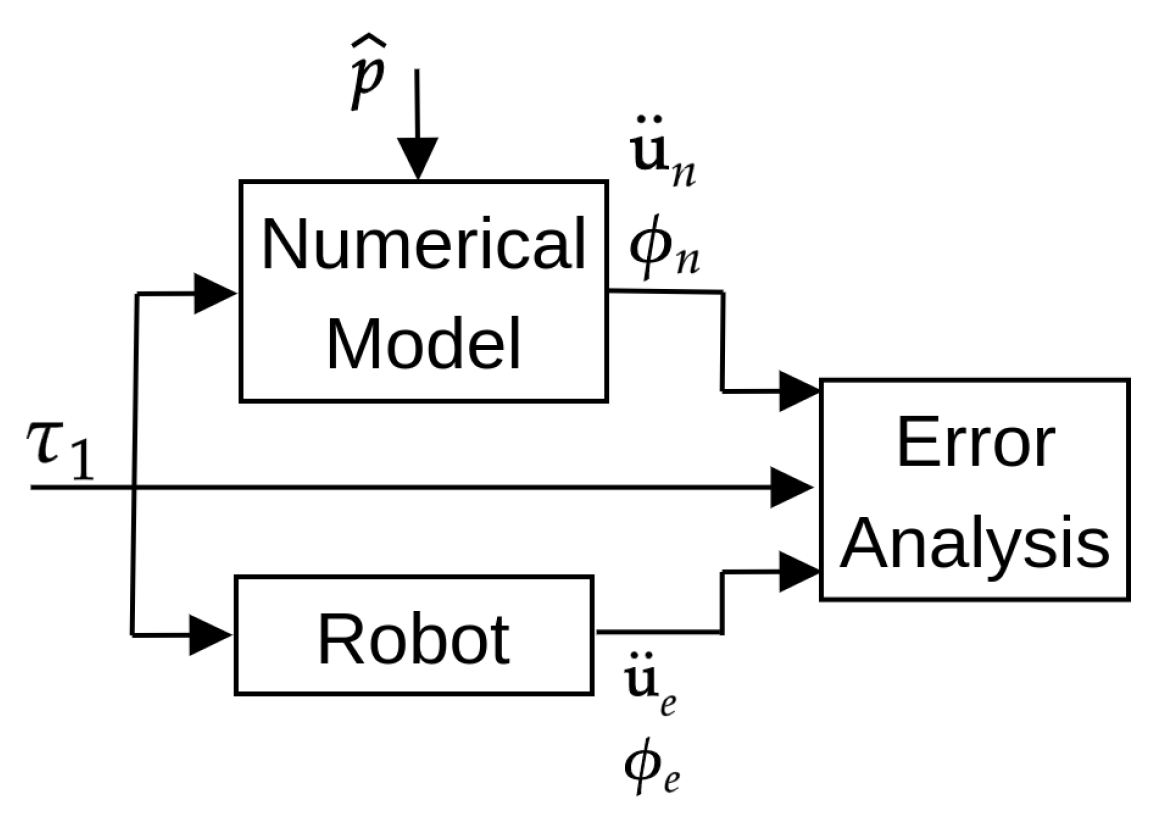

Model Validation

- The identified parameters considered in the numerical model were obtained for the best case of DE, and these parameters are presented in Table 2.

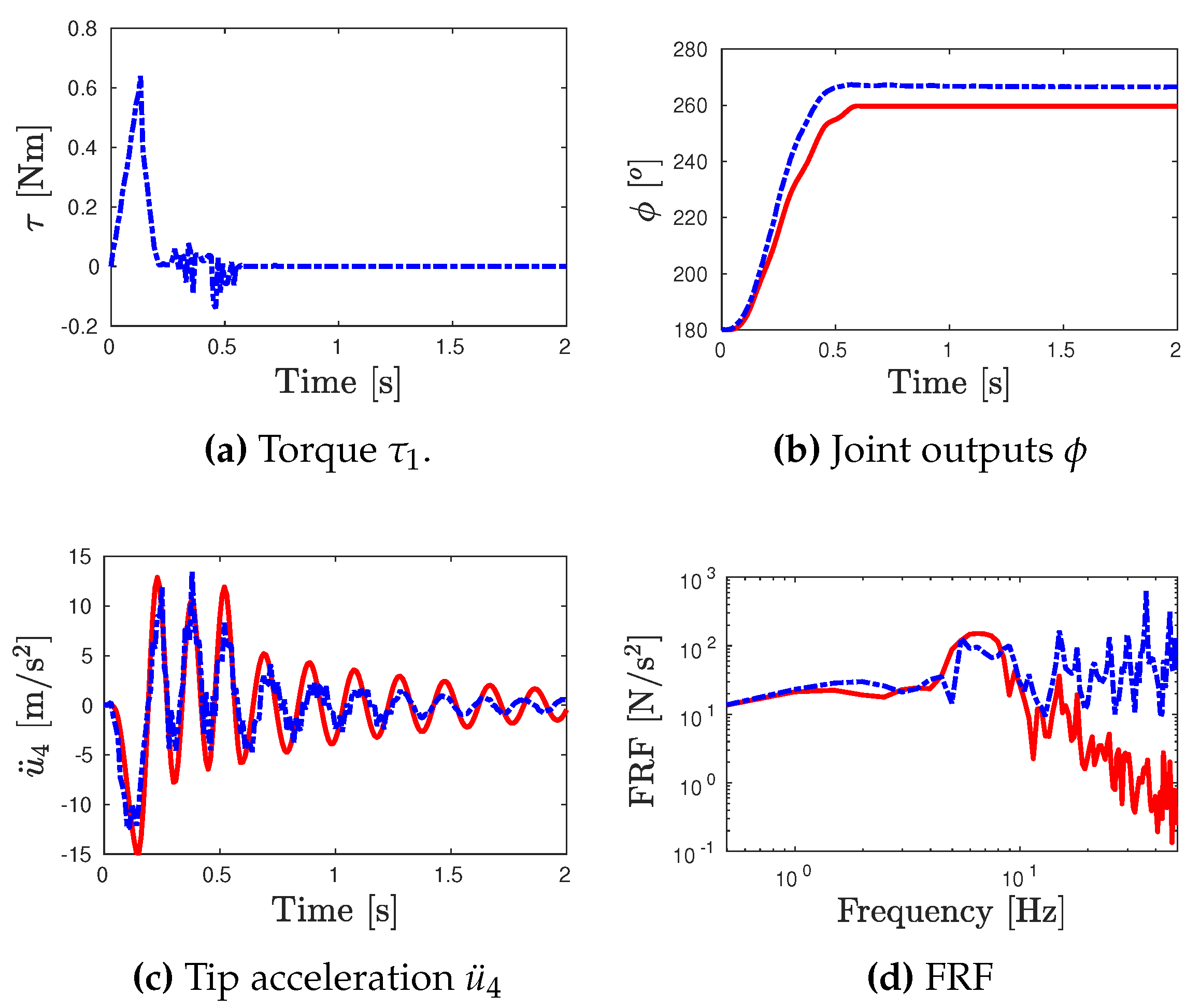

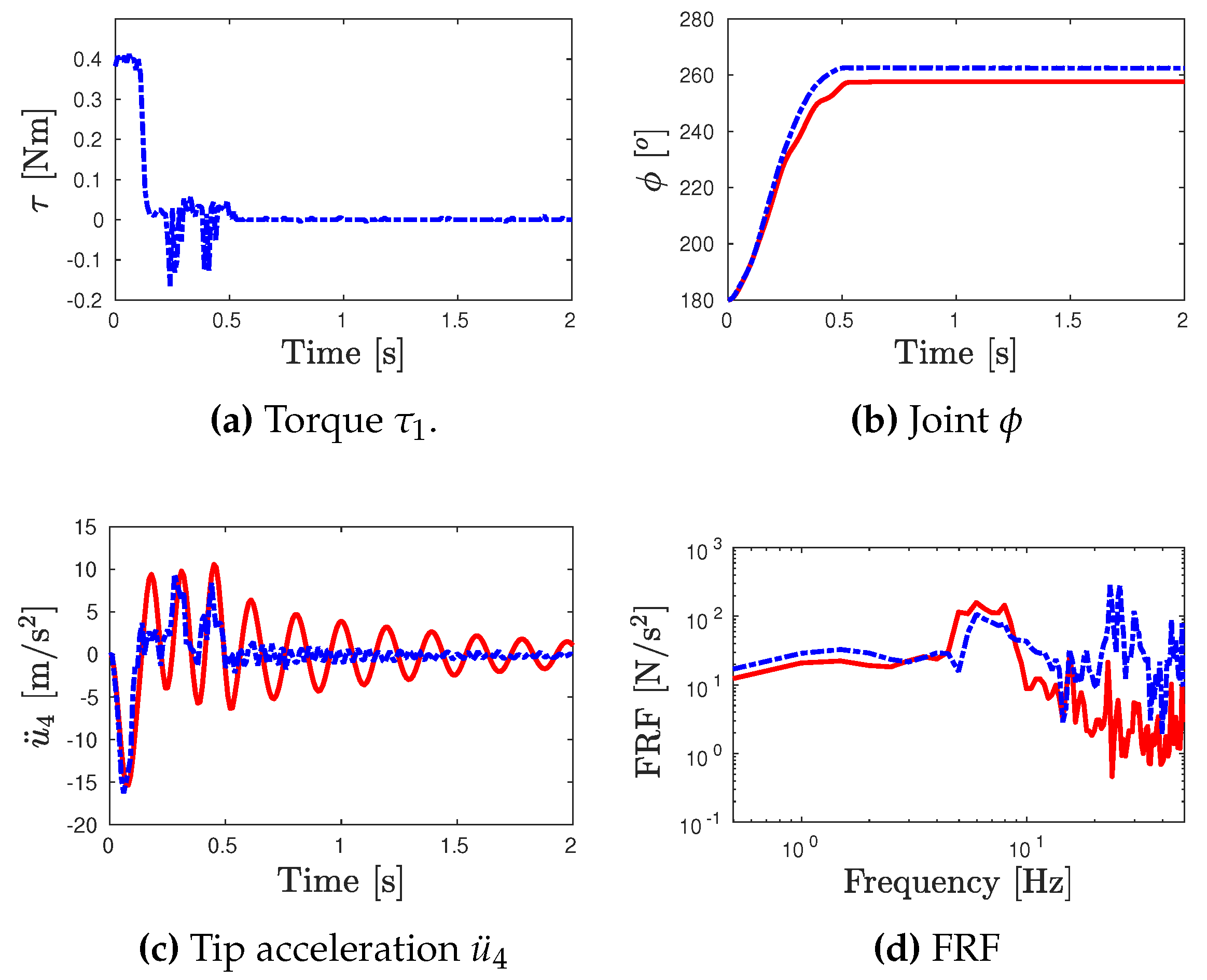

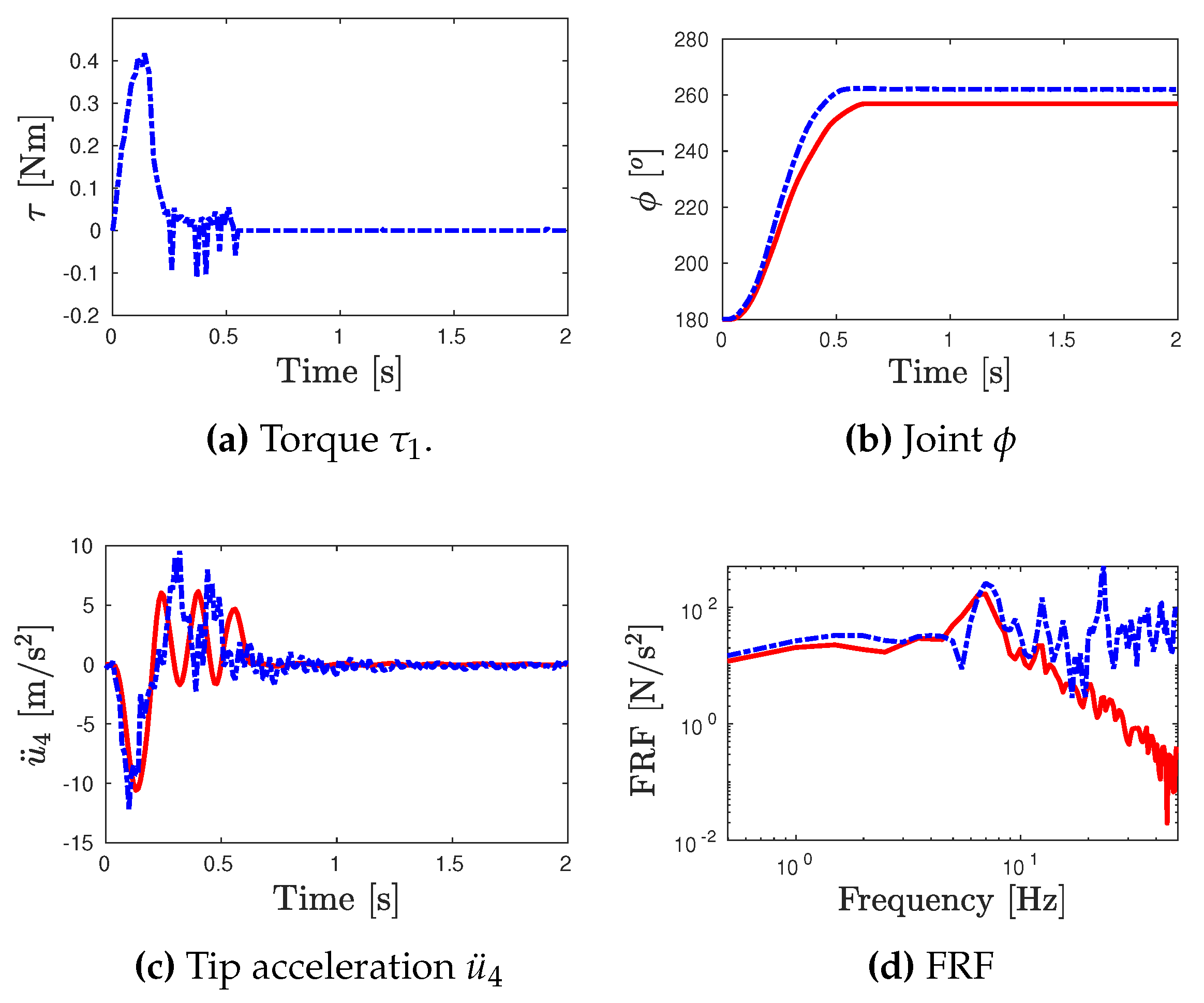

- The numerical and experimental outputs of link’s tip acceleration for the corresponding test inputs are presented in Figure 7c, Figure 8c and Figure 9c. Moreover, the frequency response functions (toque input/link’s tip acceleration) for the numerical and experimental outputs are also computed in Figure 7d, Figure 8d and Figure 9d.

- For the error analysis, the error between the numerical model and experimental outputs in terms of the joint angle and the FRFs are estimated based on the Normalized Root Mean Square Error (RMSE) according to the expressions of Eq. (7).where 2s and 15Hz. The Root Mean Square (RMS) outputs are presented in Table 3.

5. Conclusions

Acknowledgments

References

- Cordier, J.; Friconneau, J.; Gargiulo, L.; Grisolia, C.; Palmer, J.; Perrot, Y.; Samaille, F. Articulated inspection arm for ITER, a demonstration in the Tore Supra tokamak. 20th IEEE/NPSS Symposium onFusion Engineering, 2003. IEEE, 2003, pp. 197–200.

- Zhang, Y.; Lu, M. A review of recent advancements in soft and flexible robots for medical applications. The International Journal of Medical Robotics and Computer Assisted Surgery 2020, 16, e2096. [Google Scholar] [CrossRef]

- Sąsiadek, J. Space robotics and its challenges. Aerospace Robotics: Selected Papers from I Conference on Robotics in Aeronautics and Astronautics. Springer, 2013, pp. 1–8.

- Li, B.; Li, X.; Gao, H.; Wang, F.Y. Advances in Flexible Robotic Manipulator Systems—Part I: Overview and Dynamics Modeling Methods. IEEE/ASME Transactions on Mechatronics 2024. [Google Scholar] [CrossRef]

- Lara-Molina, F.A.; Gonçalves, R.S. Reliability-based optimization of flexible manipulators. Journal of Vibration Engineering & Technologies 2023, 11, 3147–3162. [Google Scholar]

- Lismonde, A.; Sonneville, V.; Brüls, O. A geometric optimization method for the trajectory planning of flexible manipulators. Multibody System Dynamics 2019, 47, 347–362. [Google Scholar] [CrossRef]

- Lara-Molina, F.A.; Dumur, D.; Assolari Takano, K. Multi-objective optimal design of flexible-joint parallel robot. Engineering Computations 2018, 35, 2775–2801. [Google Scholar] [CrossRef]

- Sayahkarajy, M.; Mohamed, Z.; Mohd Faudzi, A.A. Review of modelling and control of flexible-link manipulators. Proceedings of the Institution of Mechanical Engineers, Part I: Journal of Systems and Control Engineering 2016, 230, 861–873. [Google Scholar] [CrossRef]

- Wu, J.; Wang, J.; You, Z. An overview of dynamic parameter identification of robots. Robotics and computer-integrated manufacturing 2010, 26, 414–419. [Google Scholar] [CrossRef]

- Urrea, C.; Pascal, J. Design, simulation, comparison and evaluation of parameter identification methods for an industrial robot. Computers & electrical engineering 2018, 67, 791–806. [Google Scholar]

- Yazdizadeh, A.; Khorasani, K.; Patel, R.V. Identification of a two-link flexible manipulator using adaptive time delay neural networks. IEEE Transactions on Systems, Man, and Cybernetics, Part B (Cybernetics) 2000, 30, 165–172. [Google Scholar] [CrossRef]

- Liu, K.; Sun, X. System identification and model reduction for a single-link flexible manipulator. Journal of Sound and vibration 2001, 242, 867–891. [Google Scholar] [CrossRef]

- Ziaei, K.; Wang, D.W. Application of orthonormal basis functions for identification of flexible-link manipulators. Control Engineering Practice 2006, 14, 99–106. [Google Scholar] [CrossRef]

- Zhu, C.; Wang, J.; Chen, Z.; Liu, B. Dynamic characteristic parameters identification analysis of a parallel manipulator with flexible links. Journal of Mechanical Science and Technology 2014, 28, 4833–4840. [Google Scholar] [CrossRef]

- Pappalardo, C.M.; Lök, Ş.İ.; Malgaca, L.; Guida, D. Experimental modal analysis of a single-link flexible robotic manipulator with curved geometry using applied system identification methods. Mechanical Systems and Signal Processing 2023, 200, 110629. [Google Scholar] [CrossRef]

- Perry, M.; Koh, C.; Choo, Y. Modified genetic algorithm strategy for structural identification. Computers & Structures 2006, 84, 529–540. [Google Scholar]

- Trinh, T.N.; Koh, C.G. An improved substructural identification strategy for large structural systems. Structural Control and Health Monitoring 2012, 19, 686–700. [Google Scholar] [CrossRef]

- Tam, J.H.; Ong, Z.C.; Ismail, Z.; Ang, B.C.; Khoo, S.Y.; Li, W.L. Inverse identification of elastic properties of composite materials using hybrid GA-ACO-PSO algorithm. Inverse Problems in Science and Engineering 2018, 26, 1432–1463. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, G.; Wang, X.; Ni, P. Output-only structural parameter identification with evolutionary algorithms and correlation functions. Smart Materials and Structures 2020, 29, 035018. [Google Scholar] [CrossRef]

- Zhou, H.; Zhang, G.; Wang, X.; Ni, P.; Zhang, J. A hybrid identification method on butterfly optimization and differential evolution algorithm. Smart Structures and Systems, An International Journal 2020, 26, 345–360. [Google Scholar]

- Xu, X.; Lin, P. Parameter identification of sound absorption model of porous materials based on modified particle swarm optimization algorithm. PloS One 2021, 16, e0250950. [Google Scholar] [CrossRef]

- Yoshikawa, T.; Hosoda, K. Modeling of flexible manipulators using virtual rigid links and passive joints. The International Journal of Robotics Research 1996, 15, 290–299. [Google Scholar] [CrossRef]

- Theodore, R.J.; Ghosal, A. Comparison of the assumed modes and finite element models for flexible multilink manipulators. The International journal of robotics research 1995, 14, 91–111. [Google Scholar] [CrossRef]

- Jonker, J.B.; Aarts, R.G. A perturbation method for dynamic analysis and simulation of flexible manipulators. Multibody System Dynamics 2001, 6, 245–266. [Google Scholar] [CrossRef]

- Usoro, P.B.; Nadira, R.; Mahil, S.S. A Finite Element/Lagrange Approach to Modeling Lightweight Flexible Manipulators. Journal of Dynamic Systems, Measurement, and Control 1986, 108, 198–205. [Google Scholar] [CrossRef]

- Lara-Molina, F.A. Modeling of Flexible-Link Manipulators Under Uncertain Parameters Based on Stochastic Finite Element Method. Journal of Mechanisms and Robotics 2022, 14, 061002. [Google Scholar] [CrossRef]

- Storn, R.; Price, K. Differential evolution–a simple and efficient heuristic for global optimization over continuous spaces. Journal of global optimization 1997, 11, 341–359. [Google Scholar] [CrossRef]

- Holland, J.H. Genetic algorithms. Scientific american 1992, 267, 66–73. [Google Scholar] [CrossRef]

- Kennedy, J.; Eberhart, R. Particle swarm optimization. Proceedings of ICNN’95-international conference on neural networks. ieee, 1995, Vol. 4, pp. 1942–1948.

| Parameter | Units | Lower limit () | Upper limit () |

|---|---|---|---|

| E | Pa | 20 × 109 | 100 × 109 |

| kg m2 | 1 × 10−3 | 0.2 | |

| v | Nm /(rad/s) | 1 × 10 −5 | 0.3 |

| N m | 1 × 10−3 | .2 | |

| - | 1 × 10−3 | 4 | |

| - | 1 × 10−7 | 2 × 10−4 |

| Parameter | DE | GA | PSO |

|---|---|---|---|

| E [Pa] | 5.7002e+10 | 6.0665e+10 | 5.6597e+10 |

| [kg m2] | 0.0053 | 0.0073 | 0.0048 |

| v [Nm /(rad/s)] | 6.3016e-04 | 1.0000e-05 | 1.0802e-05 |

| [N m] | 0.1071 | 0.0589 | 0.0902 |

| 1.8240 | 0.2020 | 0.8055 | |

| 7.6275e-05 | 1.1754e-04 | 3.7784e-05 |

| Torque Input | ||

|---|---|---|

| Triangular | 2.8556 | 1.7092 |

| Rectangular | 5.0235 | 1.5390 |

| Sinusoidal | 6.0896 | 1.5093 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).