1. Introduction

The food and wood processing industries frequently use flammable powder sub-stances which can explode under certain conditions. In order to ensure work safety, it is necessary to apply the principles of explosion prevention in these industries.

When designing explosion prevention, it is necessary to know the properties of the materials being handled. Effective explosion protection measures rely on safety character-istics. These are experimentally determined values that help in the prevention of an explo-sive atmosphere like the minimum explosive concentration (MEC) or the limiting oxygen concentration (LOC), below which a flame cannot propagate. This is called primary ex-plosion protection. If it is not possible to stay below these values the determination of the minimum ignition energy (MIE) and the minimum ignition temperature (MIT) help to avoid ignition by avoiding ignition sources exceeding these values (so-called secondary explosion protection). If it is neither possible to avoid an explosive atmosphere nor to eliminate the possibility of ignition sources explosion characteristics like the maximum explosion pressure (pmax) and the maximum rate of pressure rise (dp/dt)max are used to mitigate the consequences of an explosion (so-called ternary or constructive explosion protection). The food industry frequently uses natural substances. Various types of the same processed food may have different composition. This can have a significant impact on the achieved safety characteristics. It is therefore necessary to know the characteristics of each kind/type of food. During their processing, it is thus necessary to design explosion protection in accordance with the changing safety characteristics. Only then, explosion prevention measures protect technology, people and the environment during the entire technological process. A typical example of the food processed in large quantities and in a wide variety of species are peppers (Capsicum L.).

There are five commercially cultivated species of chili (C. chinense, C. annuum, C. pubescens, C. baccatum, and C. frutescens) and around 25 wild and semi-cultivated spe-cies. Peppers (C. annuum L.) are classified as hot or sweet. [

1]

Bell peppers can be of different colours (red, green, orange, and yellow), depending on their ripening stages and capacity to synthesize chlorophylls or carotenoids. Besides their exotic flavour, bell peppers are an important source of vitamins (provitamins A, E, and C) and various bioactive compounds (phenolic compounds and carotenoids) beneficial for the health of consumers [

2].

The consumers appreciate them for their exotic colours (green, red, yellow, and or-ange), flavour, and texture. Furthermore, they are usually consumed fresh, but are also frequently used to enhance food dishes or other food products. Moreover, they can be pro-cessed in commercial products, such as sauces, puree, and powders, among others [

2].

According to the literature, bell peppers show high levels of water (dry up to 8 %, fresh up to 90 %) and carbohydrates (approx. 50 %) with low protein (ca. 10 %) and fat content (up to 5 %), which makes them a low-calorie food. Additionally, bell peppers con-tain some nutritionally important compounds, such as vitamins (B, A, D, C, E, and K) and minerals (potassium, sodium, magnesium, calcium, and phosphorus) [

2]. Authors of [3-5] investigated the average content of components in Capsicum annuum and Capsicum chinense.

Generally, peppers are consumed raw (bell pepper) or in powdered form as a spice (chili pepper) or as a colorant (paprika). Pepper fruits range from sweet, large and thick, like green bell peppers, up to thin and hot varieties, like cayenne. The fruits can be of dif-ferent colours, from green, yellow and orange, corresponding to distinct stages of matura-tion and capacities of synthetizing carotenoids or chlorophylls. Regarding flavour, this vegetable ranges from the sweet (non-pungent) varieties, such as paprika, to the hot spe-cies, such as chilies or cayenne [

6].

Among the different pepper-derived products used in the industry, such as oleoresin and other enriched extracts, one of the most important is the powder, called paprika, with the 70% of its production used as spice in meat products, soups, sauces and snacks. The total world supply of paprika powder is approximately 60,000 tons per annum, in con-trast to the 1400 tons of paprika oleoresin produced. [

1,

6,

7]

2. Materials and Methods

The following red coloured pepper powder samples were used in this research:

Type I – sweet bell pepper (Capsicum annuum)

Type II – Hungarian wax pepper (Capsium annuum)

Type III – Serrano chilli pepper – 25 000 Scoville heat units (Capsicum chinense)

Type IV – Cayenne chilli pepper – 50 000 Scoville heat units (Capsicum chinense)

All pepper samples were dried in a laboratory oven at a temperature of 70 °C for 24 hours. The samples were milled on a knife mill, the average particle size (median) of the samples used for measurement was 71 µm (

Table 1).

3.1. Explosion Characteristics

A 365 liter explosion chamber (KV-150M2 at Slovak University of Technology in Bratislava, OZM Research manufacturer, redesigned at Faculty of Materials Science and Technology in Trnava) and a 20L sphere (at Faculty of Safety Engineering - VSB Technical University of Ostrava, Kuehner AG manufacturer) were used to determine the explosion characteristics. The measurement was based on the EN 14034 Standard [

8]. The conditions of the explosion characteristics measurement are listed in

Table 2.

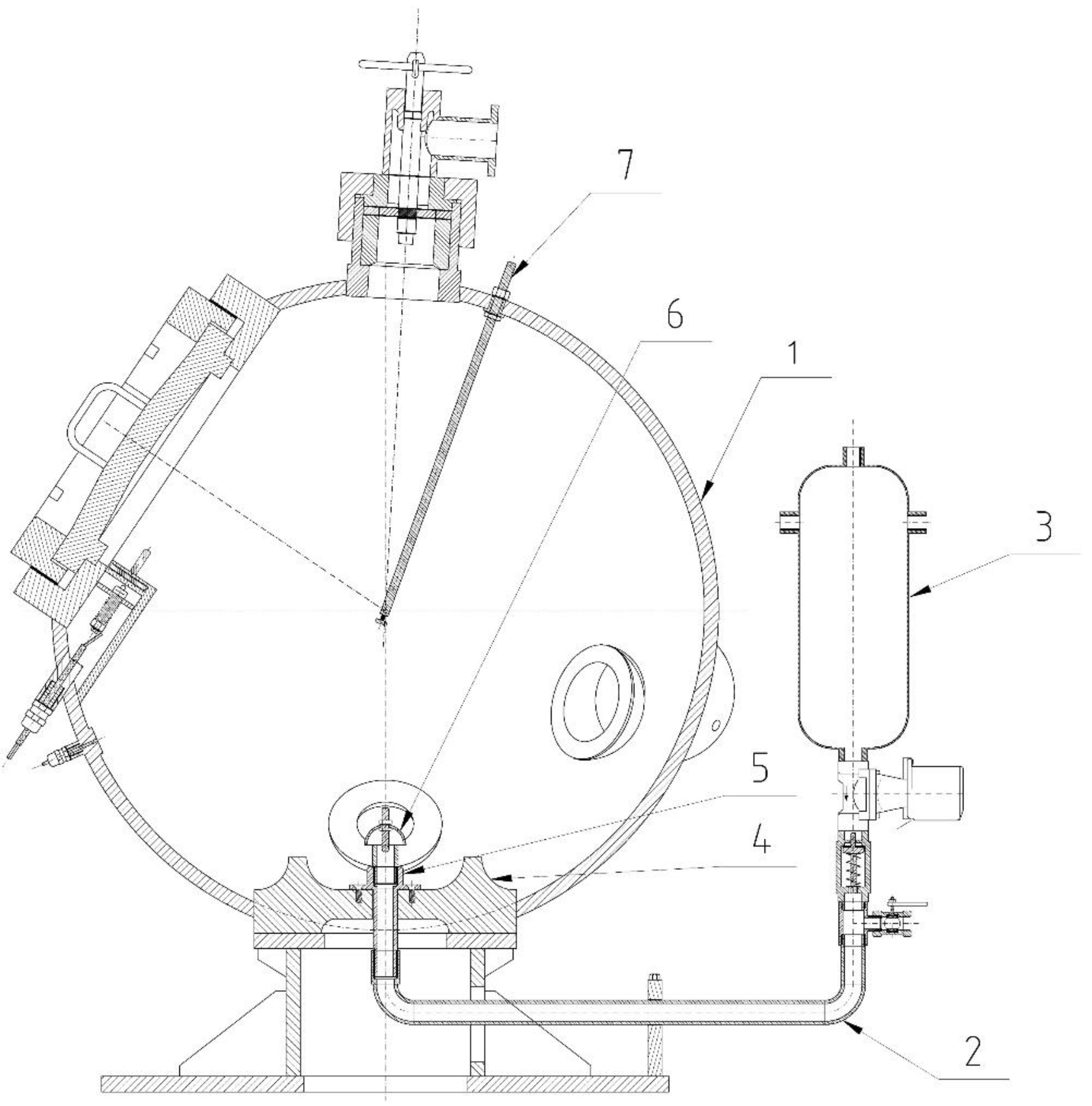

The specific design solution of the KV150M2 chamber dispersing system is shown in

Figure 3 and

Figure 4.

Figure 3.

Cross-section of KV-150M2 explosion chamber (1 – spherical explosion chamber, 2 – dispersing tube, 3 – pressure vessel, 4 – dispersing plate, 5 + 6 – disperser, 7 – igniter rod) [

9].

Figure 3.

Cross-section of KV-150M2 explosion chamber (1 – spherical explosion chamber, 2 – dispersing tube, 3 – pressure vessel, 4 – dispersing plate, 5 + 6 – disperser, 7 – igniter rod) [

9].

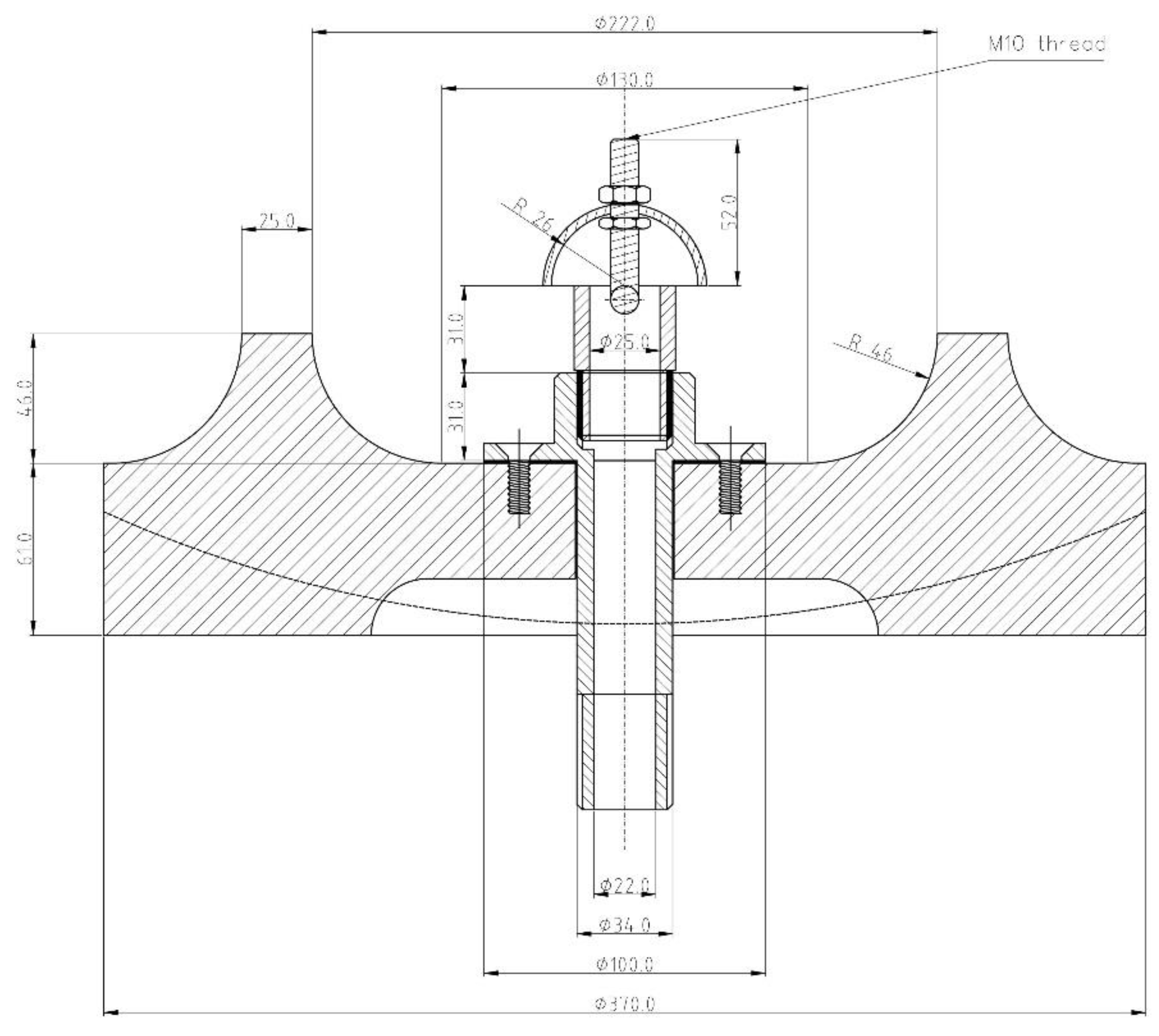

Figure 4.

Cross-section of disperser [

10].

Figure 4.

Cross-section of disperser [

10].

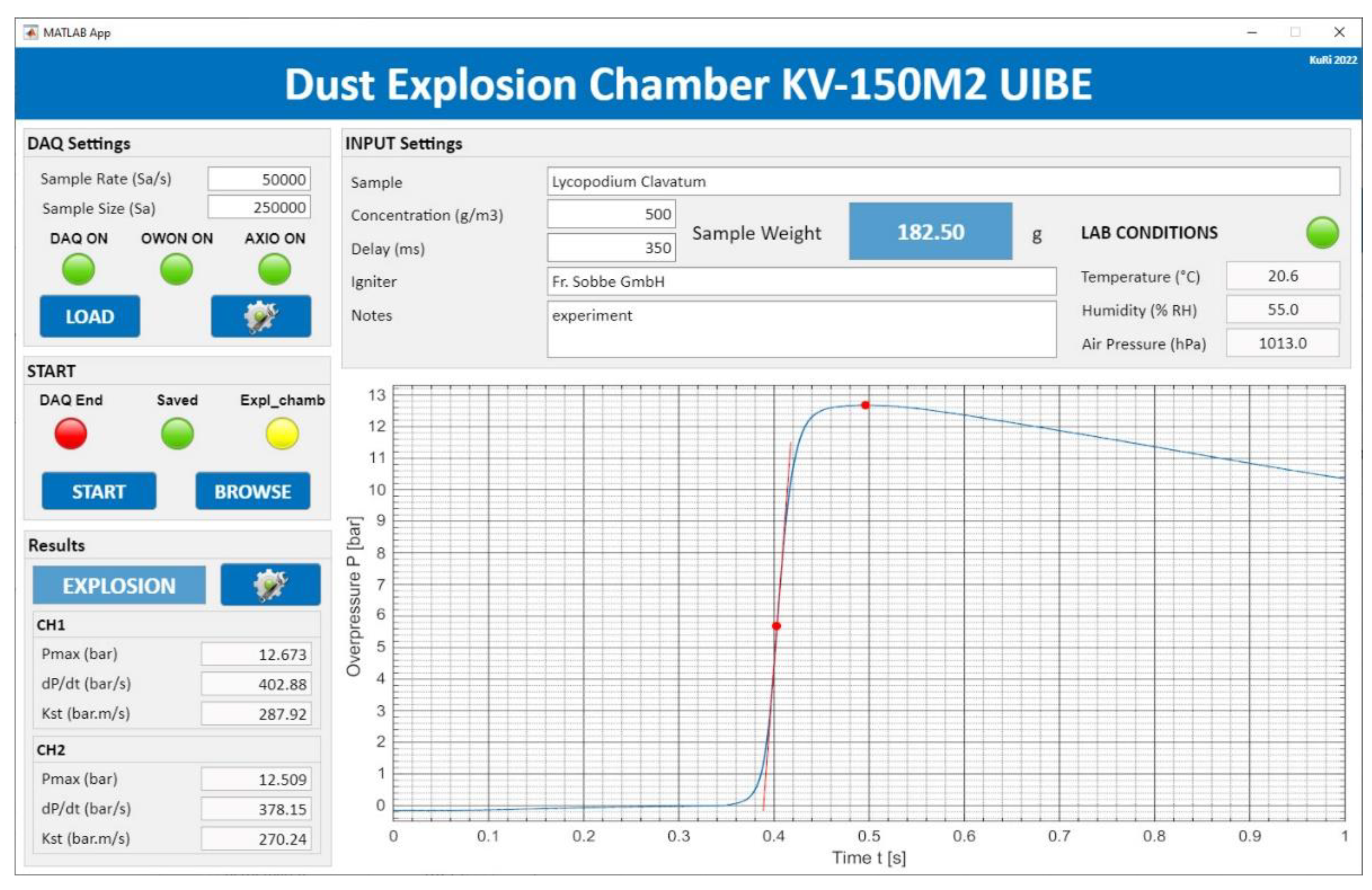

Figure 5.

MATLAB application layout for evaluation of dust explosion in KV-150M2 chamber.

Figure 5.

MATLAB application layout for evaluation of dust explosion in KV-150M2 chamber.

3.2. Minimum Ignition Energy

The minimum initiation energy was measured using a standard MIKE 3 apparatus (manufacturer Cesana AG, Bettingen, Switzerland). The measurement was carried out in accordance with the requirements of the European EN 13821 Standard [

11] and the American ASTM E 2019 [

12] Standard (see

Table 3). For all combinations, the dust was tested at least 10 times. When ignition occurred, the ignition energy was lowered and all combinations were checked again. All tests were performed with an inductance of 1 mH in the circuit.

3.3. Minimum Ignition Temperature of Dust Layer

The ignition temperature of dust layer from hot surface was measured using the device (Classic CZ manufacturer) in accordance with the requirements of the EN ISO/IEC 80079 Standard [

13]. The temperature of the dust layer (100 mm diameter, 5 mm height) was measured by two K-type thermocouples located in the dust layer. The temperature of the dust layer and the hot plate were recorded at a rate of 1 Hz.

3. Results and Discussion

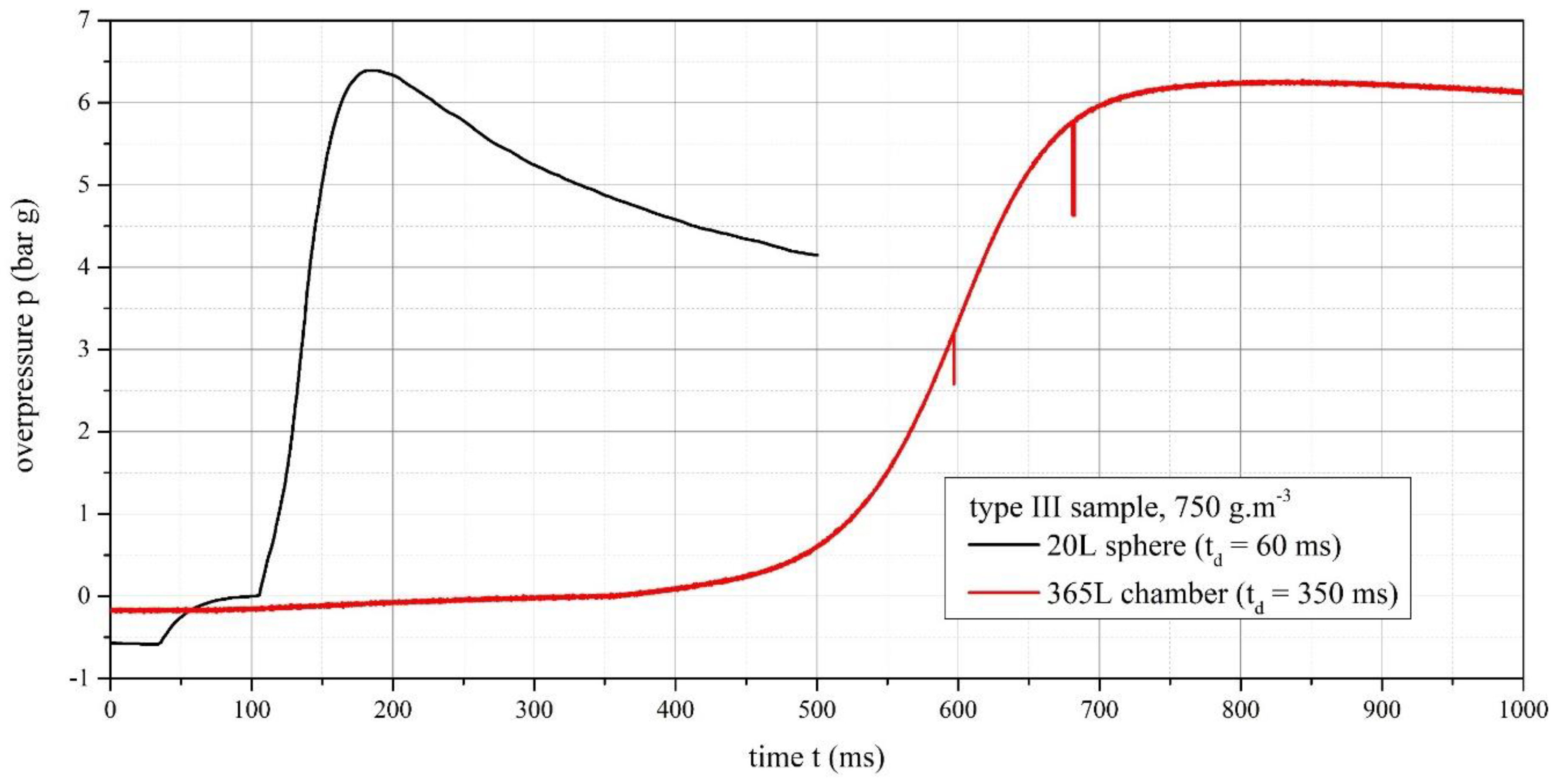

The measurement in a 20L sphere was carried out at the Technical University of Ostrava, Faculty of Safety Engineering. The measurement was performed twice at each concentration.

The highest values of the pressure and the rate of pressure rise at individual concentrations are shown in

Table 4. An example of the recording of a pressure curve in the 20Lsphere is illustrated in

Figure 6.

The maximum values of the explosion characteristics were measured for individual pepper samples at different concentration values. The results of the measurements indicate that the composition of different types of pepper influences the explosion characteristics. The maximum value of the explosion pressure was achieved with Type II pepper (Pmax = 6.9 bar @ 500 g/m3) and the highest value of the explosion constant was achieved with Type I pepper (Kst = 51 bar.m/s @ 1500 g/m3). The explosion pressure reached a value of 6.3 - 6.9 bar (10% difference). The explosion constant was in the range of 37 51 bar.m/s (difference 27.5%).

The important fact is that each type of pepper reached its maximum explosion characteristics at different concentration values. This result is important in terms of explosion prevention. Though the same type of food product (pepper powder) is concerned, explosion characteristics significantly depend on the type of the pepper used. In the food industry, it is therefore necessary to take into account also the specific type of food dust when designing explosion prevention.

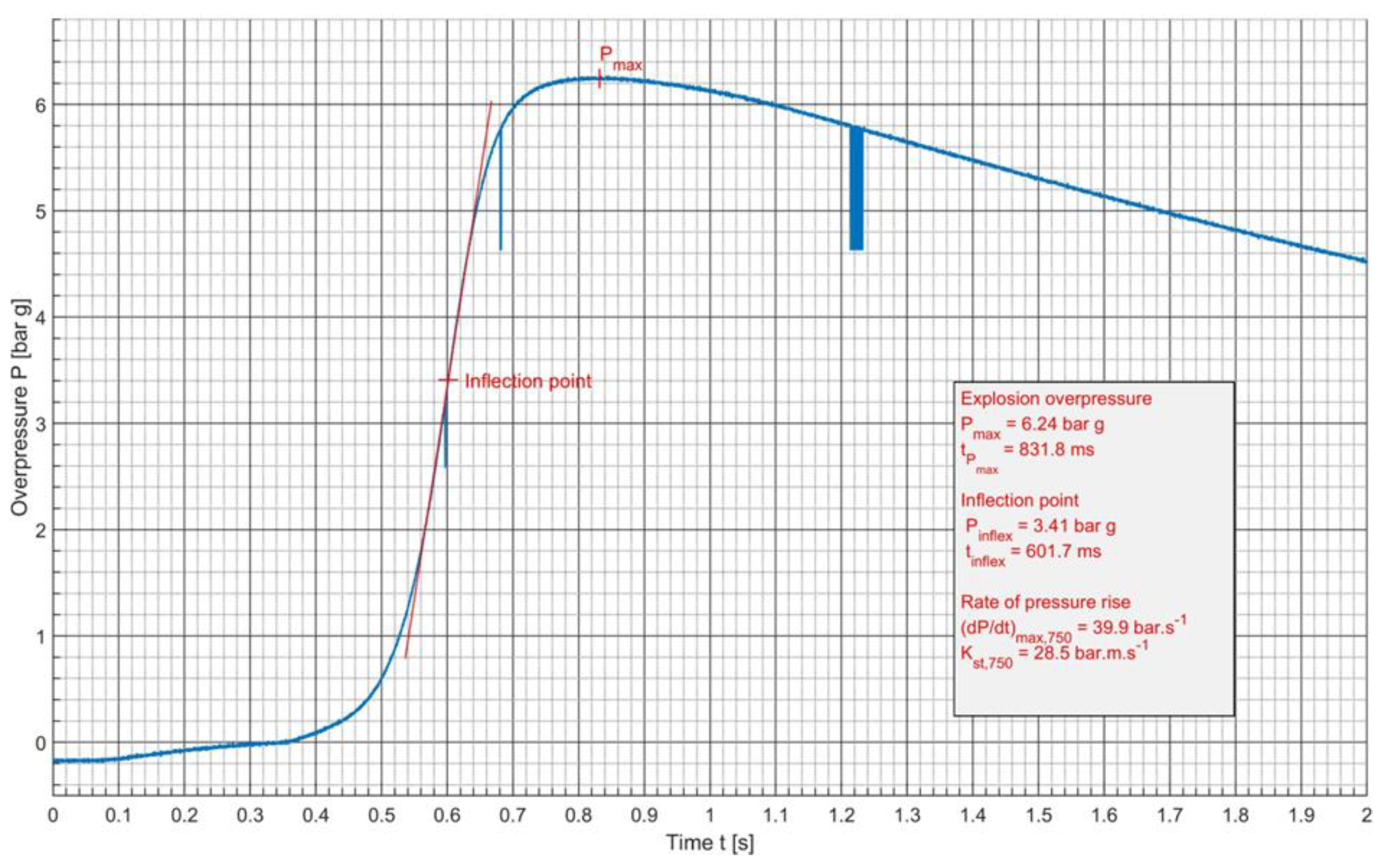

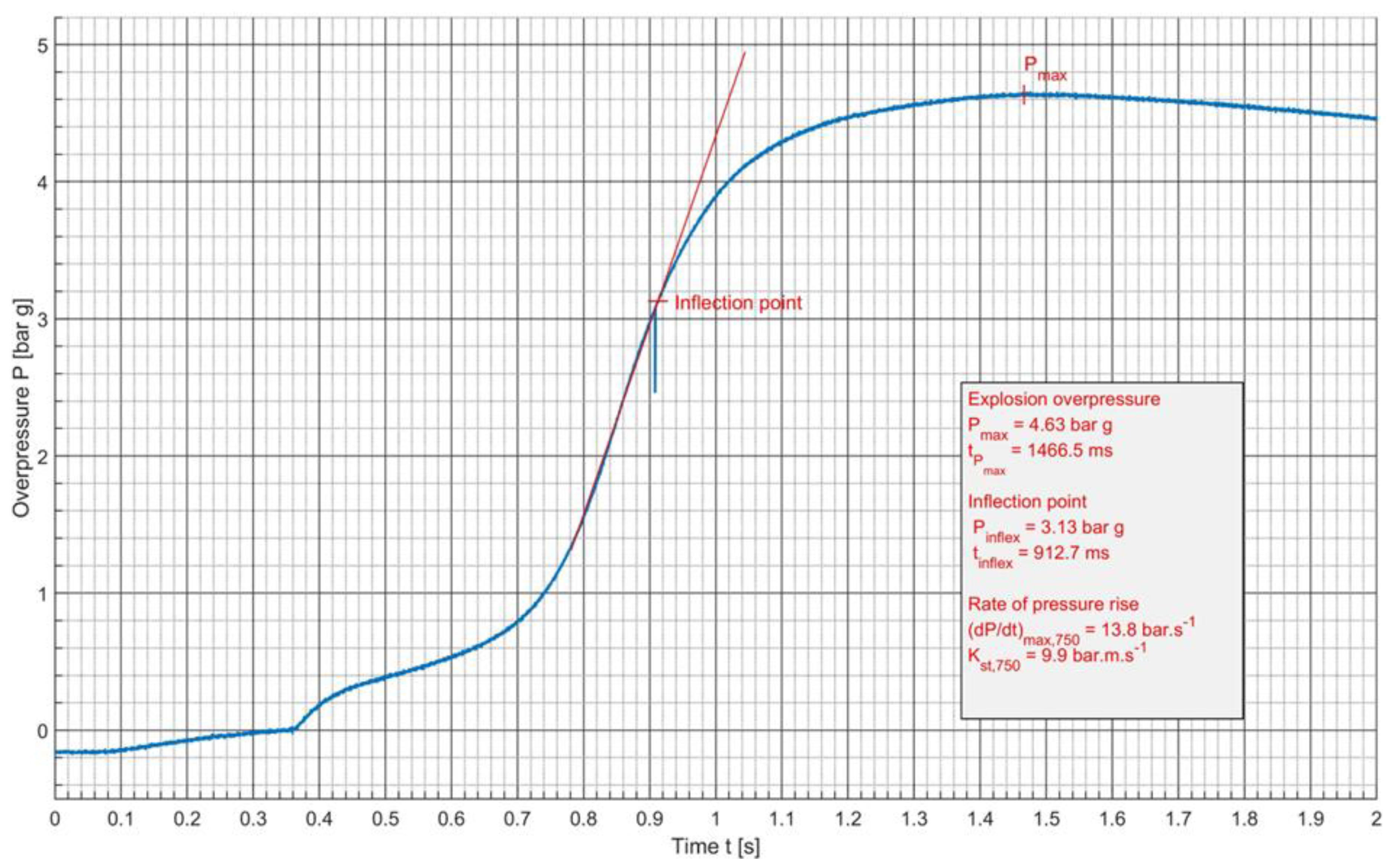

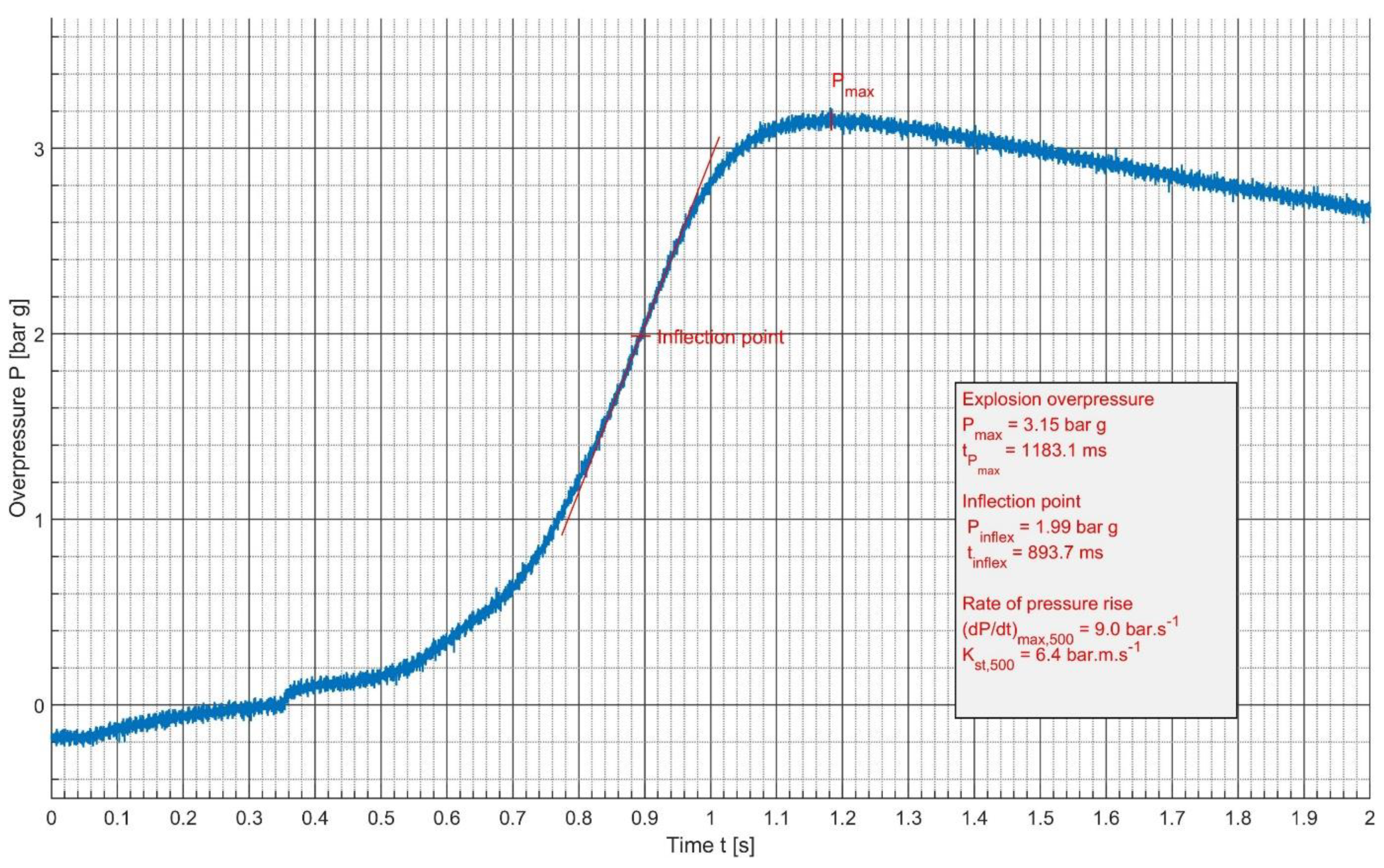

The measurement of explosion characteristics at the same concentrations was also carried out in the explosion chamber KV-150M2 at the Slovak University of Technology. The results (highest values) are listed in

Table 5 and selected pressure records are shown in

Figure 7,

Figure 8 and

Figure 9.

The maximum value of the explosion pressure was achieved using Type IV sample (Pmax = 6.38 bar @ 1000 g/m3), while the highest value of the explosion constant (Kst = 38.9 bar.m/s @ 1250 g/m3) was achieved using Type I sample.

In the 365L sphere, the maximum explosion characteristics were achieved at different concentrations, similarly to those in the 20L sphere. The maximum explosion pressure achieved in the 365L chamber was in the range of 5.94 - 6.38 bar (6.9%), while the explosion constant was in the range of 28.5 - 38.9 bar.m/s (26.4%).

This section may be divided by subheadings. It should provide a concise and precise description of the experimental results, their interpretation, as well as the experimental conclusions that can be drawn.

Comparison of the explosion characteristics of peppers in the 20L and 365L chambers indicates that the characteristics also significantly depend on the used test equipment. The explosion characteristics depend on the parameters of the dispersing system and the ignition mechanism. The explosion characteristics in devices of different volumes can also be influenced by the properties of the sample, such as particle agglomeration or stickiness to the walls of the dispersing device since the sample contains oils.

In the 20L sphere, the sample is dispersed in the dispersion nozzle from the pressure vessel with the air. In this case, the friction and stickiness of the sample have an effect on the dispersion process.

In the 365L chamber, the sample is placed directly on the dispersion plate. The sample is dispersed by a stream of compressed air from a pressure vessel. Friction of the sample in the dispersing system is thus eliminated.

The mechanism of action of the ignition cloud also has a significant impact on the explosion characteristics. The value of the explosion pressure is similar in both devices (approx. 5.9 - 6.3 bar in the 365L sphere, 6.3 - 6.9 bar in the 20L sphere - difference up to 10%). The higher values of the explosion constant in the 20L sphere are due to the fact that, after the igniter in this sphere is activated, the hot particles of the cloud are dispersed throughout the entire volume of the 20L sphere [

14,

15]. Therefore, the sample particles are ignited in the entire volume of the 20L sphere. In the 20L sphere, a greater proportion of the sample particles is ignited by the ignition cloud simultaneously. Propagation of particle burning is thus faster, which also increases the rate of pressure rise during explosions.

In the 365L sphere, the hot particles of the igniter are dispersed in about 1/3 – 1/2 of the chamber volume. The particles in this cloud are ignited, while the remaining particles are ignited by the propagation of the flame in the sphere. [

16]

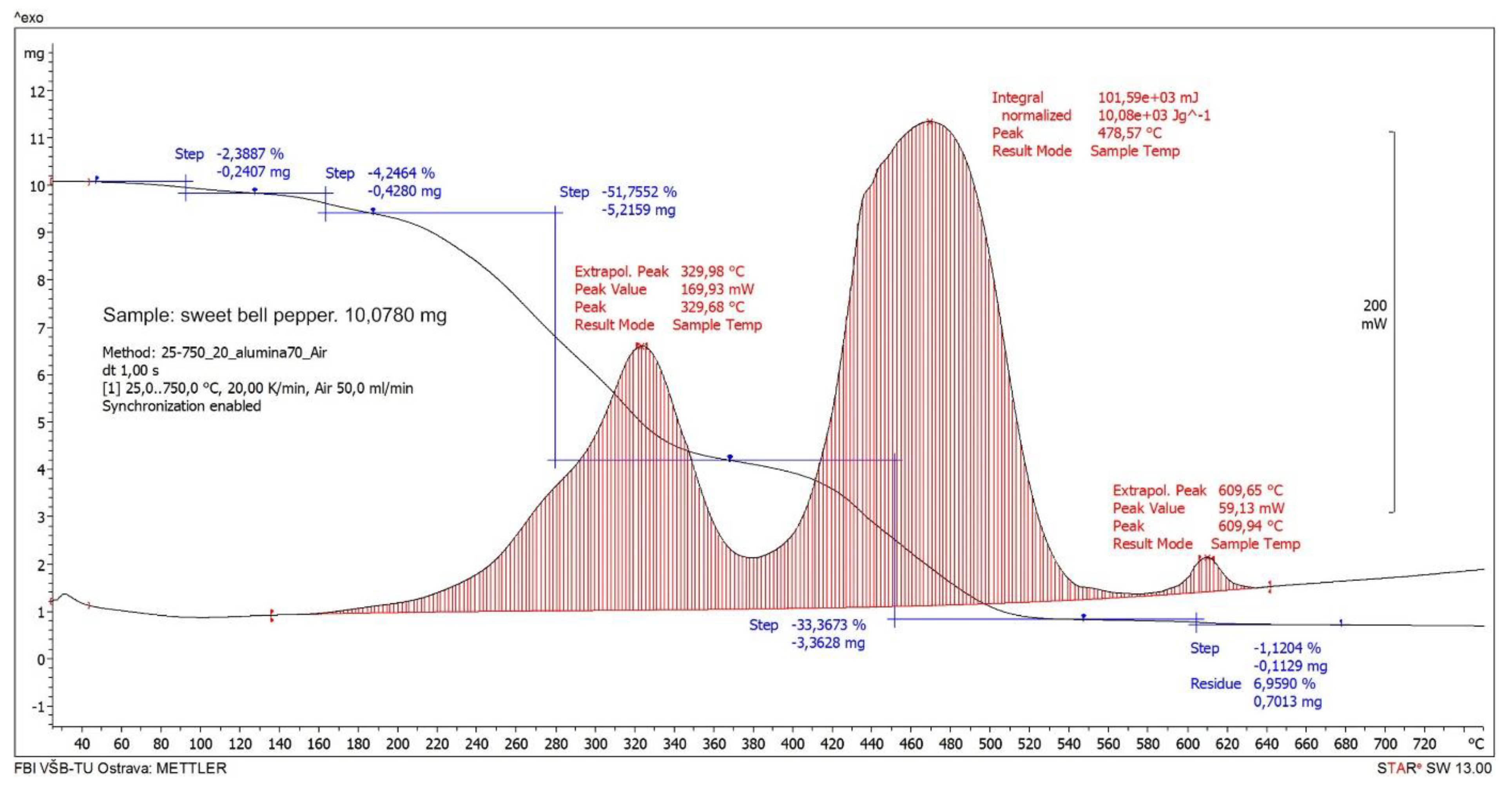

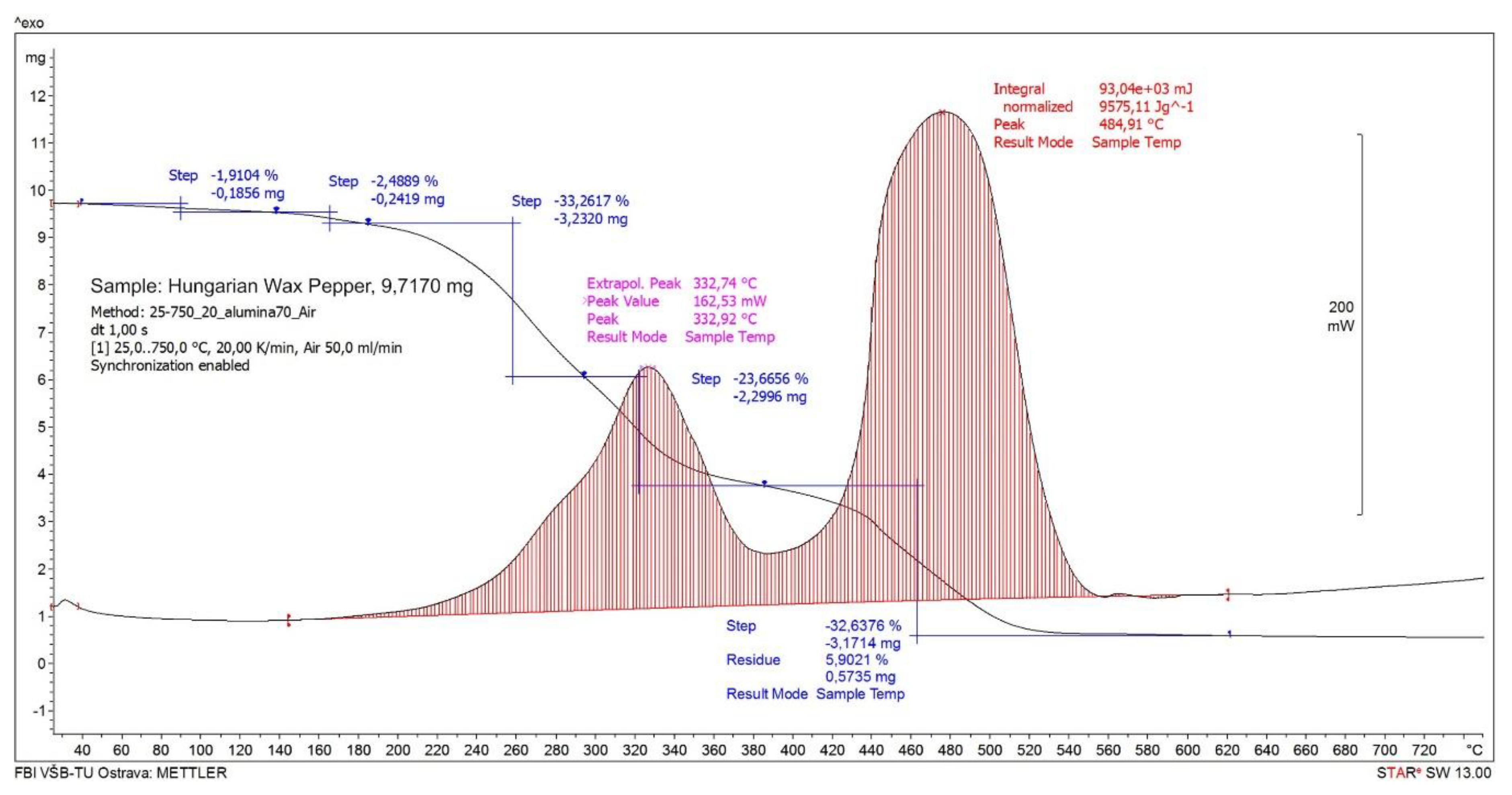

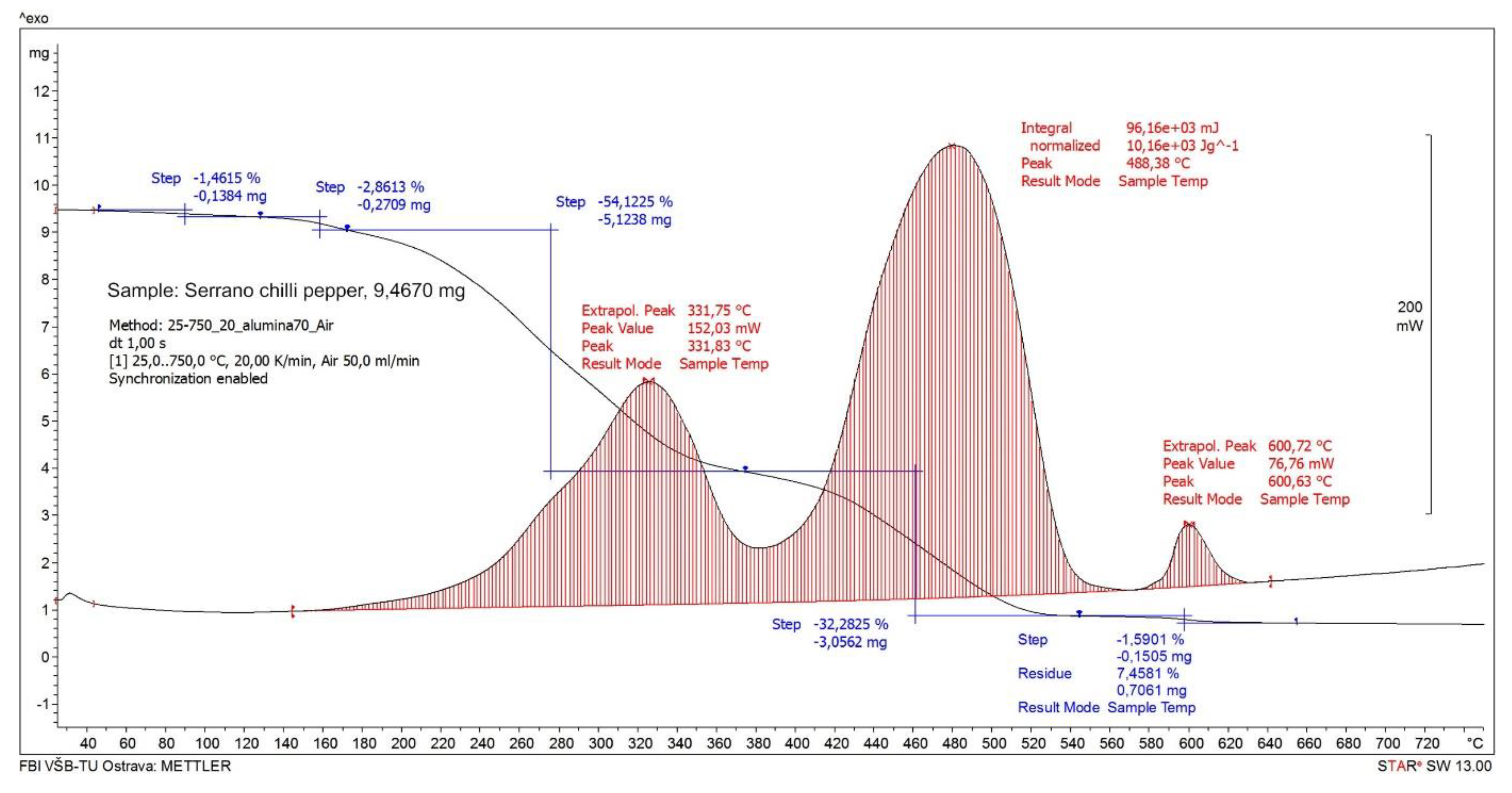

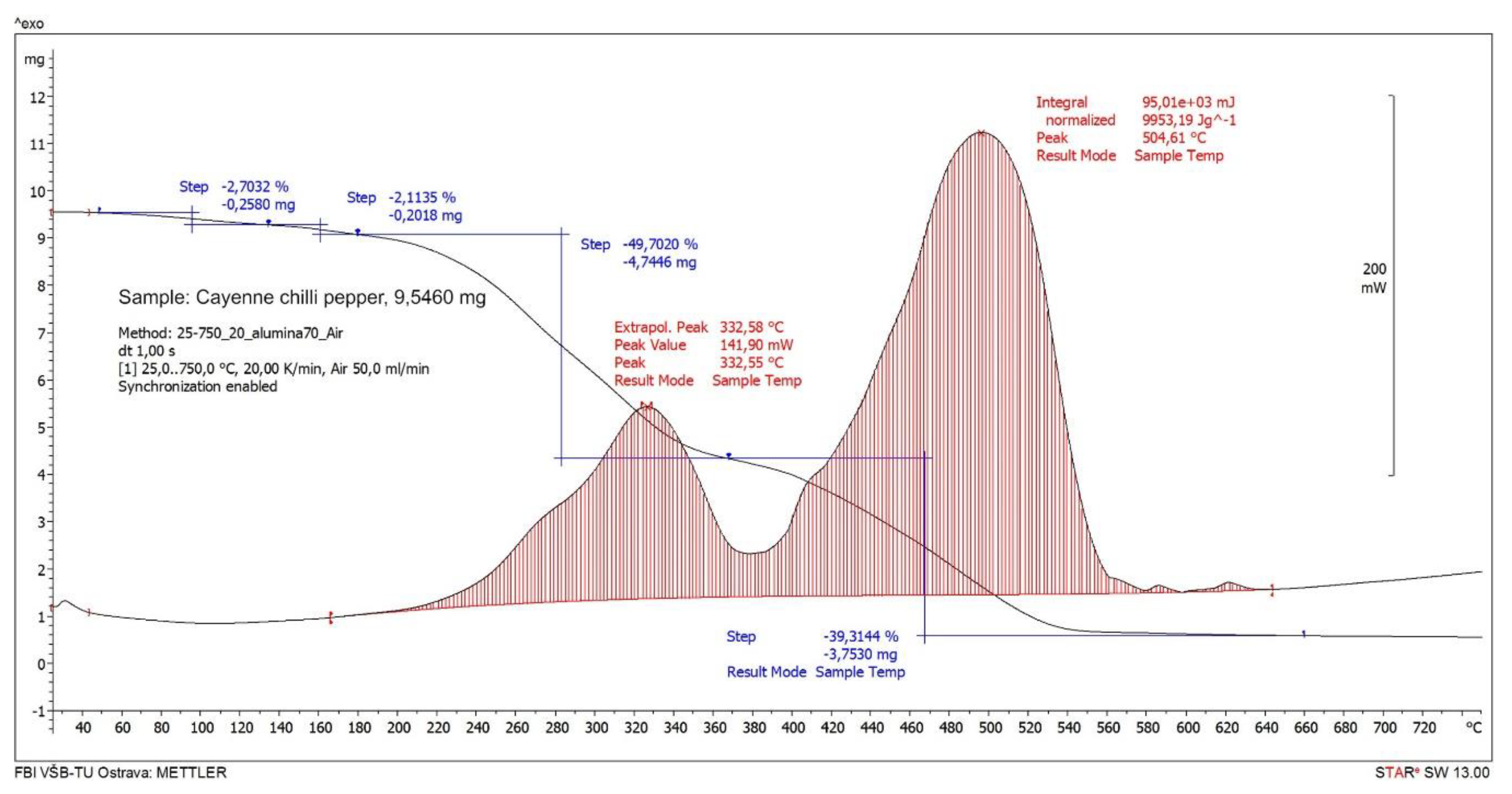

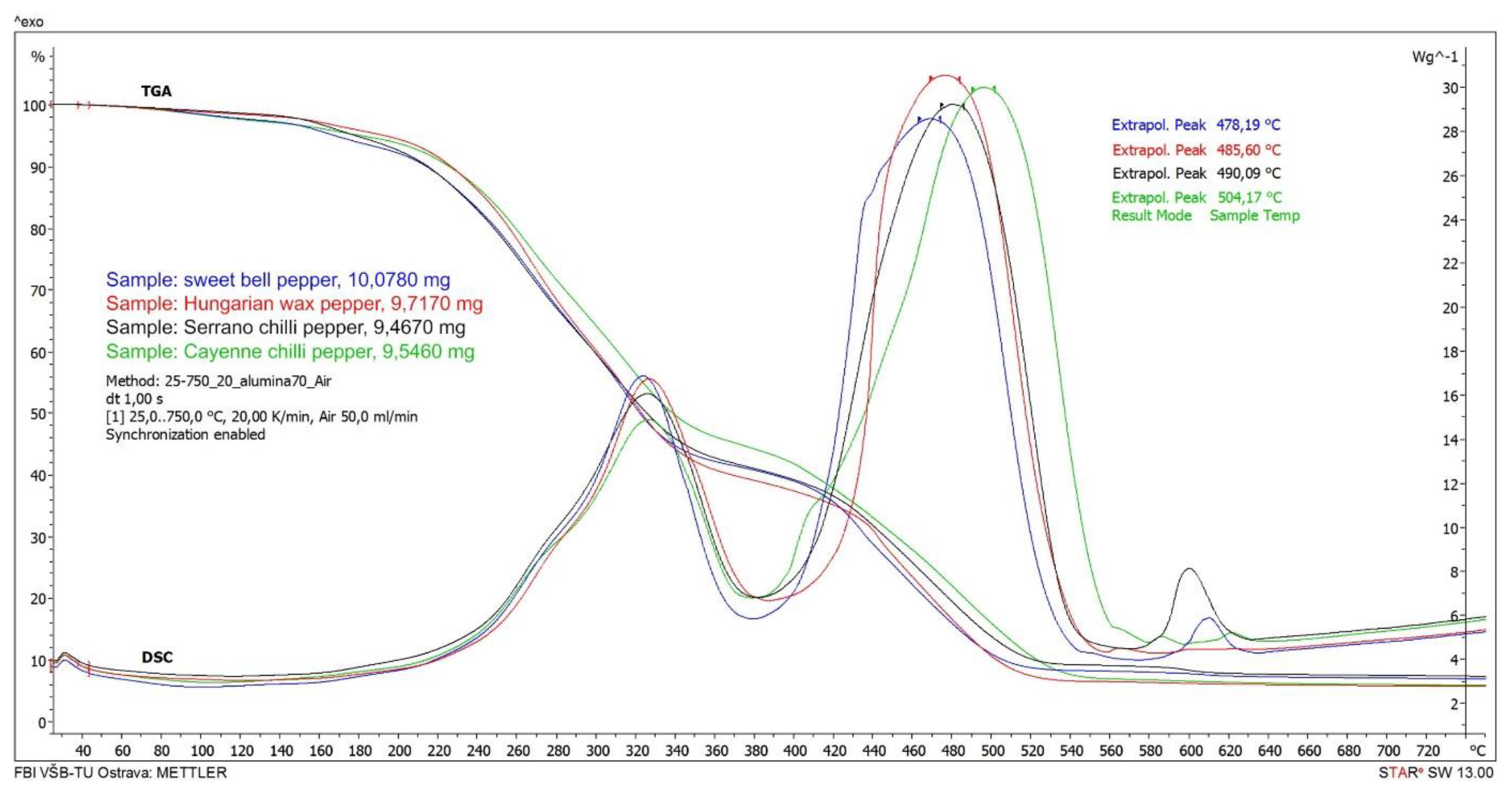

The thermal analysis was performed on a METTLER TOLEDO TGA-DSC2 in air atmosphere and a temperature range of 25 to 750 °C, with a temperature rise of 20 °C/min. The paprika powder samples at a weight of about 10 mg were placed in a corundum ceramic crucible.

TA for each type of pepper was performed only once. For better comparison,

Figure 14 illustrates the thermal decomposition curves of all four types of peppers tested in separate figures.

Figure 10.

TG/DSC of Type I sample.

Figure 10.

TG/DSC of Type I sample.

Figure 11.

TG/DSC of Type II sample.

Figure 11.

TG/DSC of Type II sample.

Figure 12.

TG/DSC of Type III sample.

Figure 12.

TG/DSC of Type III sample.

Figure 13.

TG/DSC of Type IV sample.

Figure 13.

TG/DSC of Type IV sample.

Figure 14.

Comparison of TG/DSC records of pepper samples.

Figure 14.

Comparison of TG/DSC records of pepper samples.

The thermal decomposition was carried out in two main phases. Initially, free water was released, then bound water and other volatile compounds with increasing temperature. Between 160 and 200 °C, the rate of mass loss increased. The highest proportion of volatile substances was recorded for sweet peppers, at more than 6.5 %. The TGA results do not correspond to the data in

Table 1. Above 200 °C, decomposition of the protein fraction and fats began, followed by the polysacharides. The decomposition was mainly due to carbonisation; some of the gaseous products were oxidised in the air, so that, from 180 °C onwards, the decomposition took an exothermic colour. The exothermic maxima were around 330 °C. The heat evolution decreased as carbonisation continued. The minimum rate of mass loss was around 390 °C, where the minimum heat development in the phase of thermal decomposition also fell. From about 400 °C the oxidation of the resulting carbonaceous residue began as the most energy productive phase of decomposition. The maxima of heat evolution were between 478 and 504 °C and ranged from 93 to 101 J. In two pepper samples, a faint exothermic maximum was found at 600 °C, which could be related to the oxidation of the C-residue with a more ordered, thermally stable graphitic structure. The unburnable residue at 750 °C was between 6 and 7.5 %.

Pepper samples were tested to determine the minimum ignition temperature of dust layer from a hot surface. Carbonization of the sample with visible smouldering was considered as ignition. The results are shown in the

Table 6.

The minimum ignition temperatures of the pepper samples were measured in the range of 320-340 °C. Despite the fact that the samples ignited at different temperatures (with a difference of max. 20 K), we can conclude that the samples showed similar minimum ignition temperature.

The results of the minimum initiation energy measurement are presented in

Table 7.

The measured MIE results suggest that the type of pepper has no influence on the MIE energy range values. The reason is that the minimum value of the quantity is determined. The sample type does not yet have a significant impact on the values of the achieved safety characteristics.

5. Conclusion

Based on the evaluation of the safety characteristics of different pepper samples, we can conclude that the type of pepper has a significant influence on certain safety characteristics.

Different types of pepper achieve different values of explosion characteristics. In this article, the maximum explosion pressure and the rate of pressure rise (explosion constant) were compared at selected concentrations. Depending on the type of sample, the maximum explosion pressure and rate of pressure rise were achieved at the concentrations from 500 to 1500 g/m3.

These results are important for explosion prevention. They illustrate that all types of samples should always be considered when designing explosion prevention in the industry. Therefore, explosion prevention must meet the the entire range of concentrations.

The explosion characteristics are also influenced by the mechanism of action of the ignition cloud. Two explosive devices with different volumes were used. Higher explosion characteristics were achieved in the device of a smaller volume (20L). It was probably caused by the action of a cloud of ignition particles, so called overdriving. [

17,

18]

Different types of pepper have no effect on the safety characteristics used for secondary explosion protection, the minimum ignition temperature of dust layer and the minimum initiation energy.

Finally, food dust of partially different composition can reach different safety characteristics. It is therefore necessary to take this fact into account when designing explosion prevention.

Author Contributions

L.K., Z.S. and R.K. conceived and designed the experiments; L.K, Z.S., R.K., S.H.S, M.M., and B.F. performed the experiments and analyzed the data; R.K. and Z.S. managed all the experiments and writing process as the corresponding authors. All authors discussed the results and commented on the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Slovak Research and Development Agency under the Contract No. APVV-21-0187.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Krishna De, A. (Ed.). 2003. Capsicum: The genus Capsicum (1st ed.). CRC Press. [CrossRef]

- Anaya-Esparza L. M., Mora Z. V., Vázquez-Paulino O., Ascencio F., Villarruel-López A. 2021. Bell Peppers (Capsicum annum L.) Losses and Wastes: Source for Food and Pharmaceutical Applications. Molecules, 26(17):5341. PMID: 34500773; PMCID: PMC8434037 . [CrossRef]

- Sharma, J., Sharma, P., Sharma, B. and Chaudhary, P. 2017. Estimation of Proximate Composition of Selected Species of Capsicum (Capsicum annuum and Capsicum chinense) Grown in India, Int. J. Pure App. Biosci. 5(3): 369-372. [CrossRef]

- Imran, M., Butt, M.S., Suleria, H.A.R. 2019. Capsicum annuum Bioactive Compounds: Health Promotion Perspectives. In: Mérillon, JM., Ramawat, K. (eds) Bioactive Molecules in Food. Reference Series in Phytochemistry. Springer, Cham. [CrossRef]

- Akhtar A., Asghar W., Khalid N. 2021. Phytochemical constituents and biological properties of domesticated capsicum species: a review. Bioactive Compounds in Health and Disease 2021; 4(9): 201-225. [CrossRef]

- Baenas N., Belović M., Ilic N., Moreno D. A., García-Viguera C. 2019. Industrial use of pepper (Capsicum annum L.) derived products: Technological benefits and biological advantages, Food Chemistry, Volume 274, Pages 872-885, ISSN 0308-8146. [CrossRef]

- ZakiI N.; HakmaouiI A.; OuatmaneI A.; Fernandez-TrujilloII J.P. 2013. Quality characteristics of Moroccan sweet paprika (Capsicum annuum L.) at different sampling times, Food Sci. Technol 33 (3). [CrossRef]

- EN 14034-1: 2004+ A1: 2011 Determination of explosion characteristics of dust clouds.

- Kuracina R., Szabová Z., Bachratý M., Mynarz M., Škvarka M.. 2021a. A new 365-litre dust explosion chamber: design and testing. Powder Technol., 386, pp. 420-427, 10.1016/j.powtec.2021.03.061, ISSN 0032-5910.

- Kuracina R., Szabová Z., Škvarka M. 2021b. Study into parameters of the dust explosion ignited by an improvised explosion device filled with organic peroxide, Process Saf. Environ. Protect., 155 (2021) (2021), pp. 98-107, 10.1016/j.psep.2021.09.011, ISSN 0957-5820.

- EN 13821 Potentially explosive atmospheres - Explosion prevention and protection - Determination of minimum ignition energy of dust/air mixtures.

- ASTM E 2019 Standard Test Method for Minimum Ignition Energy of a Dust Cloud in Air.

- EN ISO/IEC 80079-20-2: 2016 Explosive atmoshperes – Part 20-2: Material characteristics – Combustible dusts test methods.

- Krietsch A., Kwangvitayanon Y., Schmidt M., Klippel A., Schröder V. 2014. Validation of the New Ignition Source “Exploding Wire” for Dust Explosion Testing in the 20-L-Sphere vol. 159, Symposioum series No, Edinburgh, p. 24.

- Spitzer S. H., Jankuj V., Hecht K. J., Krietsch A. 2023. Igniting volume of four ignition sources, Process Safety and Environmental Protection, Volume 170, Pages 1200-1207, ISSN 0957-5820. [CrossRef]

- Spitzer S., Askar E., Krietsch A., Schröder V. 2021. Comparative study on standardized ignition sources used for explosion testing J. Loss Prev. Process. Ind., 71, Article 104516, 10.1016/j.jlp.2021.104516, ISSN 0950-4230.

- Kuracina R., Szabová Z., Kosár L., Sahul M. 2023. Study into influence of different types of igniters on the explosion parameters of dispersed nitrocellulose powder, Journal of Loss Prevention in the Process Industries, Volume 83, 105017, ISSN 0950-4230. [CrossRef]

- Going, J. E., Chatrathi, K., and Cashdollar, K. L. Flammability limit measurements for dusts in 20-L and 1-m3 vessels. Journal of Loss Prevention in the Process Industries, 13(3-5):209–219, 2000. [CrossRef]

- Chawla, N., Amyotte, P. R., and Pegg, M. J. A comparison of experimental methods to determine the minimum explosible concentration of dusts. FUEL, 75(6):654–658, 1996. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).