Submitted:

31 May 2024

Posted:

31 May 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

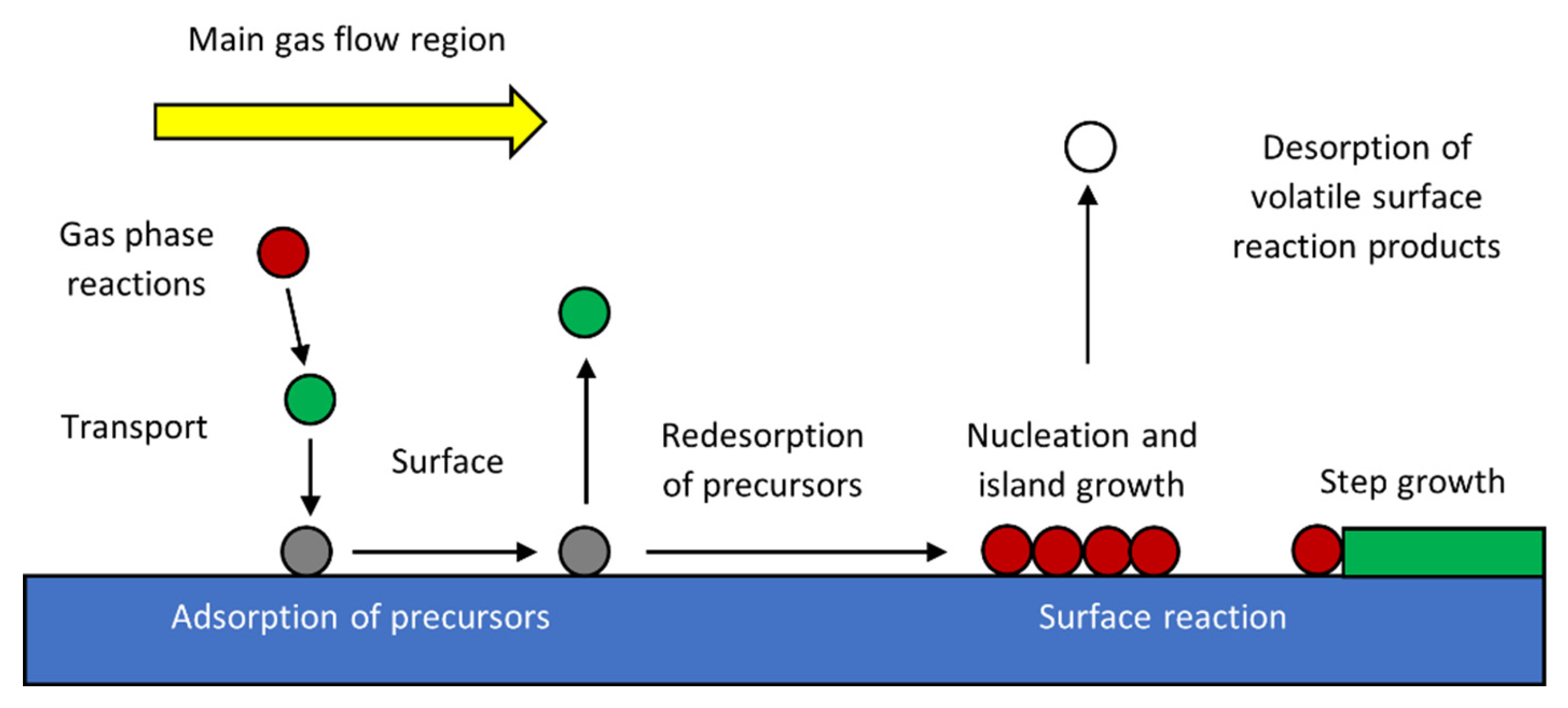

2. Fundamentals of CVD

- -

- production of a chemical compound of the applied element with high volatility (easily evaporating),

- -

- transport of gas (vapor) from the forming compound to the place of deposition without its disintegration,

- -

- the chemical reaction necessary to produce a coating on the surface of the product.

- the process temperature, which affects the mobility of atoms,

- supersaturation,

- process duration,

- pressure in the chamber,

- gas flow rate (laminar or turbulent),

- spatial position of the substrate in the chamber,

- substrate surface preparation.

- -

- operating conditions (atmospheric pressure CVD (APCVD), low pressure CVD (LPCVD), and ultrahigh vacuum CVD (UHVCVD)),

- -

- physical characteristics of vapor (aerosol-assisted CVD (AACVD) and direct liquid injection CVD (DLICVD)),

- -

- substrate heating (hot wall CVD, and cold wall CVD).

3. Heat Transfer Modeling

3.1. Continuum-Based Approaches

3.1.1. Finite Element Analysis

3.1.2. Computational Fluid Dynamics (CFD)

3.2. Molecular Dynamics (MD) Simulations

3.3. Lattice Boltzmann Method (LBM)

4. Mass Transport Modeling

4.1. Diffusion-Based Models

4.1.1. Fick’s Laws of Diffusion

4.1.2. Boundary Layer Approaches

4.2. Kinetic Monte Carlo (KMC) Simulations

4.3. Multi-Scale Modeling Techniques

4.4. Machine Learning and Data-Driven Approaches

5. Combined Heat and Mass Transfer Modeling

5.1. Coupled Heat and Mass Transfer Equations

5.2. Phase Change Phenomena

5.3. Surface Reaction Kinetics

| Title | Advantages | Disadvantages | Gaps and Limitations |

|---|---|---|---|

| Surface Kinetics of Titanium Isopropoxide in High Vacuum Chemical Vapor Deposition [134] | The authors developed a surface kinetic model for TTIP and water, including first- and second-order reactions. | The kinetic model and simulations are computationally intensive, needing significant resources. | Including different CVD processes and precursors would enhance the findings’ generalizability. |

| The study uses 363 data points across various deposition parameters, like substrate temperature and precursor rates. | The study focuses specifically on the HV-CVD process using TTIP and water. | Testing under varying precursor concentrations and temperatures would better assess the model’s capabilities. | |

| The findings have significant practical relevance for optimizing HV-CVD processes in the semiconductor and thin-film industries. | Although the model is validated against a substantial dataset, the study could benefit from additional experimental validation under various conditions to further confirm the robustness and accuracy of the model. | Optimizing computational efficiency would make the kinetic model more accessible for industrial use. | |

| Surface Kinetic Mechanisms of Epitaxial Chemical Vapour Deposition of 4H Silicon Carbide Growth by Methyltrichlorosilane-H₂ Gaseous System [135] | The article provides an in-depth analysis of the kinetic mechanisms at play during the CVD process. By dissecting both gas-phase and surface reactions, it offers a granular understanding of the factors influencing SiC growth, which is crucial for optimizing deposition conditions. | The complexity of the reactions and the detailed kinetic modeling may pose challenges for readers who are not well-versed in chemical kinetics and CVD processes. | Including various precursors and carrier gases would broaden understanding of the CVD process for SiC and other materials. |

| Focusing on the efficient MTS-H₂ system, it highlights chlorine’s role in enhancing deposition rates and film quality. | While the study is thorough in its theoretical analysis, it could benefit from more extensive experimental validation. | Testing dynamic conditions like varying temperatures and gas flow rates would better evaluate kinetic mechanisms and their impact. | |

| The insights gained from this study can directly impact the semiconductor industry, particularly in the production of high-quality SiC epitaxial layers. | Focusing on the MTS-H₂ system may limit applicability to other precursor systems or deposition processes. | Examining long-term stability and performance of SiC layers under different conditions would provide insights into their practical applications in high-stress environments like power electronics and aerospace. | |

| A Review on Sustainable Manufacturing of Ceramic-Based Thin Films by Chemical Vapor Deposition (CVD): Reactions Kinetics and the Deposition Mechanisms [130] | The review comprehensively covers CVD aspects like reaction kinetics, deposition mechanisms, and parameter effects on ceramic thin film quality and efficiency. | The detailed discussion on reaction kinetics and deposition mechanisms might be complex for readers without a strong background in chemical engineering or materials science. | Extending the research to include other types of materials and their respective CVD processes would provide a more holistic view and increase the applicability of the findings across different industries. |

| Emphasizing sustainable practices, the article discusses optimizing CVD to reduce waste and energy use. | While the review is comprehensive, it could benefit from more extensive experimental data to validate the theoretical aspects discussed. | Investigating how temperature, pressure, and precursor flow rates affect CVD could optimize the process under various conditions. | |

| The article provides detailed insights into the methodological aspects of CVD, making it a valuable resource for researchers and practitioners aiming to improve the efficiency and sustainability of their processes. | The focus on ceramic-based thin films may limit the applicability of the findings to other materials. | A lifecycle analysis of the CVD process would offer a complete view of its sustainability. | |

| Chemical Vapor Deposition of Two-Dimensional Magnetite Nanosheets and Raman Study of Heat-Induced Oxidation Reaction [138] | The use of CVD for synthesizing high-quality Fe3O4 nanosheets is a significant advancement, offering a controlled and scalable method for producing two-dimensional materials with desirable properties. | The study emphasizes Fe3O4 nanosheet synthesis and initial characterization, less on practical device integration. | Investigating nanosheet stability under various conditions would provide insights into durability and reliability. |

| The combination of Raman spectroscopy, X-ray diffraction, and atomic force microscopy provides a thorough characterization of the nanosheets, ensuring a detailed understanding of their structural and chemical properties. | While the study details the oxidation process, it could benefit from a deeper exploration of the conditions affecting the oxidation rate and the stability of the resulting α-Fe2O3 phase. | Exploring dynamic CVD conditions like varying gas compositions and flow rates would deepen understanding of synthesis parameters. | |

| The findings have potential applications in spintronic devices and other advanced technologies, where the magnetic properties of these nanosheets could be exploited. | Challenges and optimizations for large-scale CVD nanosheet production are not extensively addressed. | Functional testing in device applications would enhance the study’s practical relevance and showcase real-world potential. | |

| Chemical Vapor Deposition of Elemental Crystallogen Thin Films [139] | The study offers a thorough examination of CVD techniques, providing detailed insights into reaction kinetics, deposition mechanisms, and the influence of various process parameters. | Focusing on elemental crystallogens may limit generalizability to other CVD materials. | Including a wider range of materials would enhance the findings’ generalizability and applicability across CVD processes. |

| Focusing on elemental crystallogens, it addresses crucial materials for semiconductor and microelectronics industries. | While the study is detailed, more extensive experimental validation under varying conditions would strengthen the reliability of the results. | Testing under varying temperatures and pressures would provide a comprehensive understanding of the deposition process. | |

| The article outlines strategies for optimizing CVD conditions to enhance film quality, valuable for manufacturing applications. | Optimization strategies may need sophisticated equipment and precise control, challenging in large-scale production. | Studying long-term stability and performance under operational conditions would offer valuable insights for practical applications. |

6. Challenges and Opportunities in CVD Modeling Including Heat and Mass Transfer Aspects

- o

- Modeling heat and mass transfer for CVD processes requires addressing complex interactions between different phases (gas and solid), necessitating advanced modeling techniques and considerable computational resources.

- o

- o Achieving accurate modeling of flow fields is essential but challenging, as it requires accounting for heat transfer contributions from multiple phases.

- o

- The significant computational demands of accurate simulations present a major challenge, requiring the use of advanced hardware and optimization techniques, such as GPU acceleration.

- o

- Ensuring the accuracy and applicability of numerical models is challenging and necessitates extensive validation against experimental data, which can be resource-intensive. Without proper validation, the predictive power of these models is limited.

- o

- Incorporating advanced techniques such as fuzzy logic and artificial intelligence into CVD modeling can improve predictive capabilities. However, these methods require sophisticated implementation and validation, posing additional challenges.

- o

- Advanced simulation tools such as CFD facilitate the creation and validation of numerical models without requiring physical prototypes, potentially streamlining the design process and lowering costs.

- o

- CFD and other advanced modeling techniques provide significant opportunities for optimizing the design and performance of heat exchangers, which are crucial components in CVD processes.

- o

- Methods such as fuzzy logic-based models can effectively predict heat transfer coefficients, offering valuable tools for optimizing industrial processes and enhancing model accuracy.

- o

- Incorporating AI and machine learning into CVD modeling enhances predictive capabilities and optimizes process parameters by uncovering patterns not evident through traditional methods.

- o

- Real-time monitoring and control in CVD processes ensure optimal conditions, enhancing product quality and reducing material waste.

- o

- Collaboration among material science, engineering, and computer science researchers can create more accurate CVD models, addressing the complex challenges of these processes.

- o

- Using dimpled surfaces can enhance heat transfer and reduce flow resistance, making CVD processes more efficient.

- o

- CVD processes involve multiscale phenomena, and parallel programming efficiently simulates these models by distributing tasks across multiple processors, allowing simultaneous solving of molecular dynamics and continuum mechanics equations.

- o

- CVD processes often involve solving large PDE systems for heat, mass, and momentum transfer. Parallel programming reduces computation time by dividing the domain into sub-domains and solving them concurrently, which is crucial for real-time process optimization and control.

- o

- Parallel programming distributes computational demands, enabling high-resolution simulations to capture detailed CVD process features like intricate temperature gradients and concentration profiles.

- o

- Conducting parametric studies on CVD outcomes is computationally intensive. Parallel programming allows simultaneous simulations with different parameters, drastically reducing time and crucially optimizing process parameters and product quality.

- o

- In advanced manufacturing, real-time control and monitoring of CVD processes are vital. Parallel computing enables real-time simulations and adjustments, ensuring the process stays within desired parameters and reduces defects.

- o

- As CVD models grow in complexity and size, scaling simulations across multiple processors is crucial. Parallel programming provides the scalability to handle larger models without exponentially increasing computation time.

- o

- CVD processes often involve coupled phenomena, like fluid flow and chemical reactions. Parallel programming allows simultaneous solving of these models, ensuring more accurate and realistic simulations.

7. Conclusions

8. Future Directions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Alsmadi, M.M.; Farahneh, S. Enhancing the efficacy of thin films via chemical Vapor deposition techniques. Int. J. Electron. Devices Netw. 2023, 4, 01–04. [Google Scholar] [CrossRef]

- Christensen, T.M. Chemical Vapor Deposition. Underst. Surf. Thin Film Sci. 2022, 209–224. [Google Scholar] [CrossRef]

- Jeong, J.-I.; Yang, J.-H. Trend and Prospect of Thin Film Processing Technology. J. Korean Magn. Soc. 2011, 21, 185–192. [Google Scholar] [CrossRef]

- Ogle, J.; Lahiri, N.; Jaye, C.; Tassone, C.J.; Fischer, D.A.; Louie, J.; Whittaker-Brooks, L.; Ogle, J.; Lahiri, N.; Louie, J.; et al. Semiconducting to Metallic Electronic Landscapes in Defects-Controlled 2D π-d Conjugated Coordination Polymer Thin Films. Adv. Funct. Mater. 2021, 31, 2006920. [Google Scholar] [CrossRef]

- Masi, M.; Cavallotti, C.; Boccalari, D.; Castellana, F. Preliminary design of a novel high throughput CVD reactor for photovoltaic applications. Cryst. Res. Technol. 2014, 49, 614–619. [Google Scholar] [CrossRef]

- Martinu, L.; Poitras, D. Plasma deposition of optical films and coatings: A review. J. Vac. Sci. Technol. 2000, 18, 2619–2645. [Google Scholar] [CrossRef]

- Medvedovski, E.; Chinski, F.A.; Stewart, J. Wear- and Corrosion-Resistant Boride-Based Coatings Obtained through Thermal Diffusion CVD Processing. Adv. Eng. Mater. 2014, 16, 713–728. [Google Scholar] [CrossRef]

- Sun, L.; Yuan, G.; Gao, L.; Yang, J.; Chhowalla, M.; Gharahcheshmeh, M.H.; Gleason, K.K.; Choi, Y.S.; Hong, B.H.; Liu, Z. Chemical vapour deposition. Nat. Rev. Methods Prim. 2021, 1. [Google Scholar] [CrossRef]

- Rong, W.; Ronghui, M. Modeling of heat and mass transfer in a cold wall CVD reactor for large area poly-SiC film deposition. Collect. Tech. Pap. - 9th AIAA/ASME Jt. Thermophys. Heat Transf. Conf. Proc. 2006, 4, 2806–2817. [Google Scholar] [CrossRef]

- Memon, N.; Jaluria, Y. Flow Structure and Heat Transfer in a Stagnation Flow CVD Reactor. J. Heat Transf. Asme 2011, 133, 082501. [Google Scholar] [CrossRef]

- Panickar, R.; Sobhan, C.B.; Chakravorti, S. Substrate temperature optimization for diamond thin film synthesis using hot-filament chemical vapor deposition. 2019 8th Int. Conf. Model. Simul. Appl. Optim. ICMSAO 2019 2019. [Google Scholar] [CrossRef]

- Elers, K.E.; Blomberg, T.; Peussa, M.; Aitchison, B.; Haukka, S.; Marcus, S. Film Uniformity in Atomic Layer Deposition. Chem. Vap. Depos. 2006, 12, 13–24. [Google Scholar] [CrossRef]

- Ylilammi, M. Mass Transport in Atomic Layer Deposition Carrier Gas Reactors. J. Electrochem. Soc. 1995, 142, 2474–2479. [Google Scholar] [CrossRef]

- Fauzi, F.B.; Ismail, E.; Ani, M.H.; Bakar, S.N.S.A.; Mohamed, M.A.; Majlis, B.Y.; Din, M.F.M.; Abid, M.A.A.M. A critical review of the effects of fluid dynamics on graphene growth in atmospheric pressure chemical vapor deposition – CORRIGENDUM. J. Mater. Res. 2018, 33, 1308–1308. [Google Scholar] [CrossRef]

- Abegunde, O.O.; Akinlabi, E.T.; Oladijo, O.P.; Akinlabi, S.; Ude, A.U.; Abegunde, O.O.; Akinlabi, E.T.; Oladijo, O.P.; Akinlabi, S.; Ude, A.U. Overview of thin film deposition techniques. AIMS Mater. Sci. 2019 2174 2019, 6, 174–199. [Google Scholar] [CrossRef]

- Chemical vapour deposition (CVD) : Advances, Technology and Applications; Choy, K.-L., Ed.; 2019; ISBN 1000691071.

- Ohring, M. The Materials Science of Thin Films; Elsevier Inc., 2013; ISBN 012524990X.

- Chemical Vapour Deposition An Integrated Engineering Design for Advanced, Materials; Yan, X.-T. Chemical Vapour Deposition An Integrated Engineering Design for Advanced Materials; Yan, X.-T., Xu, Y., Eds.; Springer, 2010; ISBN 1447125509.

- Pierson, H.O. Handbook of chemical vapor deposition (CVD) : principles, technology, and applications; Second Edition.; Noyes Publications, 1999; ISBN 0815514328.

- Smith, D.L. Thin-film deposition : principles and practice; McGraw-Hill, 1995; ISBN 9780071139137.

- Sharma, S. Phase evolution of boron nitride and carbide during chemical vapor deposition, 2024.

- Schalk, N.; Tkadletz, M.; Mitterer, C. Hard coatings for cutting applications: Physical vs. chemical vapor deposition and future challenges for the coatings community. Surf. Coatings Technol. 2022, 429, 127949. [Google Scholar] [CrossRef]

- Vardanyan, E.L.; Nazarov, A.Y.; Ramazanov, K.N.; Gabitashvili, S.O.; Nagimov, R.S. Influence of reaction gases on phase compounds and mechanical properties of coatings based on intermetallics of Ti-Al systems. J. Phys. Conf. Ser. 2018, 1121, 012031. [Google Scholar] [CrossRef]

- Koh, J.H.; Woo, S.I. Computer Simulation Study on Atmospheric Pressure CVD Process for Amorphous Silicon Carbide. J. Electrochem. Soc. 1990, 137, 2215–2222. [Google Scholar] [CrossRef]

- Moreno-Bárcenas, A.; Perez-Robles, J.F.; Vorobiev, Y. V.; Ornelas-Soto, N.; Mexicano, A.; García, A.G. Graphene synthesis using a CVD reactor and a discontinuous feed of gas precursor at atmospheric pressure. J. Nanomater. 2018, 2018. [Google Scholar] [CrossRef]

- Regolini, J.L.; Bensahel, D.; Mercier, J.; D’Anterroches, C.; Perio, A. Epitaxial Silicon Layers Made by Reduced Pressure/Temperature CVD. MRS Online Proc. Libr. 1988 1291 2011, 129, 609–613. [Google Scholar] [CrossRef]

- Heil, S.B.S.; Langereis, E.; Roozeboom, F.; van de Sanden, M.C.M.; Kessels, W.M.M. Low-Temperature Deposition of TiN by Plasma-Assisted Atomic Layer Deposition. J. Electrochem. Soc. 2006, 153, G956. [Google Scholar] [CrossRef]

- Luo, J.K.; Fu, Y.Q.; Le, H.R.; Williams, J.A.; Spearing, S.M.; Milne, W.I. Diamond and diamond-like carbon MEMS. J. Micromechanics Microengineering 2007, 17. [Google Scholar] [CrossRef]

- Liu, Y.; Yu, S.; Shi, Q.; Ge, X.; Wang, W. Multilayer Coatings for Tribology: A Mini Review. Nanomater. 2022, Vol. 12, Page 1388 2022, 12, 1388. [Google Scholar] [CrossRef]

- Alamgir, A.; Bogatov, A.; Jõgiaas, T.; Viljus, M.; Raadik, T.; Kübarsepp, J.; Sergejev, F.; Lümkemann, A.; Kluson, J.; Podgursky, V. High-Temperature Oxidation Resistance and Tribological Properties of Al2O3/ta-C Coating. Coatings 2022, 12. [Google Scholar] [CrossRef]

- Azadi, M.; Rouhaghdam, A.S.; Ahangarani, S. Mechanical Behavior of TiN/TiC-n Multilayer Coatings and Ti(C,N) Multicomponent Coatings Produced by PACVD. Strength Mater. 2016, 48, 279–289. [Google Scholar] [CrossRef]

- Osmond, L.; Cook, I.; Slatter, T. Tribological Properties of Multilayer CVD Coatings Deposited on SiAlON Ceramic Milling Inserts. J. Manuf. Mater. Process. 2023, Vol. 7, Page 67 2023, 7, 67. [Google Scholar] [CrossRef]

- Kashani, H.; Heydarzadeh Sohi, M.; Kaypour, H. Microstructural and physical properties of titanium nitride coatings produced by CVD process. Mater. Sci. Eng. A 2000, 286, 324–330. [Google Scholar] [CrossRef]

- Wu, L.; Qiu, L.; Du, Y.; Zeng, F.; Lu, Q.; Tan, Z.; Yin, L.; Chen, L.; Zhu, J. Structure and Mechanical Properties of PVD and CVD TiAlSiN Coatings Deposited on Cemented Carbide. Cryst. 2021, Vol. 11, Page 598 2021, 11, 598. [Google Scholar] [CrossRef]

- Cheng, H.E.; Wen, Y.W. Correlation between process parameters, microstructure and hardness of titanium nitride films by chemical vapor deposition. Surf. Coatings Technol. 2004, 179, 103–109. [Google Scholar] [CrossRef]

- Wagner, J. Chemical Vapor Deposition of Titanium Nitride based Hard Coatings, 2007.

- Saringer, C.; Tkadletz, M.; Thurner, J.; Czettl, C.; Schalk, N. Influence of deposition parameters on microstructure and mechanical properties of chemical vapor deposited Ti1-xAlxN coatings. Int. J. Refract. Met. Hard Mater. 2023, 113, 106203. [Google Scholar] [CrossRef]

- Zhu, M.; Achache, S.; Boulet, P.; Virfeu, A.; Pierson, J.F.; Sanchette, F. Effects of deposition parameters on the microstructure and mechanical properties of Ti(C,N) produced by moderate temperature chemical vapor deposition (MT-CVD) on cemented carbides. Vacuum 2022, 195, 110650. [Google Scholar] [CrossRef]

- Fraga, M.; Pessoa, R. Progresses in synthesis and application of sic films: From CVD to ALD and from MEMS to NEMS. Micromachines 2020, 11. [Google Scholar] [CrossRef] [PubMed]

- Wejrzanowski, T.; Skibinski, J.; Lewandowska, A.K.; Kurzydlowski, K.J. Modeling Of Heat And Mass Transfer In An SiC CVD Reactor As A Tool To Design Modern Materials For High Power Electronics Applications. WIT Trans. Eng. Sci. 2015, 91, 213–219. [Google Scholar] [CrossRef]

- Allendorf, M.D.; Besmann, T.M.; Kee, R.J.; Swihart, M.T. Chapter 3:Modeling CVD Processes. Chem. Vap. Depos. 2008, 93–157. [Google Scholar] [CrossRef]

- Baillet, F.; Chaussende, D.; Charpentier, L.; Pernot, E.; Pons, M.; Madar, R. Heat Transfer Modeling of a New Crystal Growth Process. Mater. Sci. Forum 2003, 433–436, 103–106. [Google Scholar] [CrossRef]

- Xia, H.X.; Xiang, D.; Mou, P.; Zhang, H. Analysis and Modeling of Wafer Thermal Transfer in a PECVD Reactor. Appl. Mech. Mater. 2013, 376, 3–12. [Google Scholar] [CrossRef]

- Stupple, D.J.; Kemp, V.; Oldfield, M.J.; Watts, J.F.; Baker, M.A. Modelling of Heat Transfer in an Aluminum X-ray Anode Employing a CVD Diamond Heat Spreader. J. Heat Transf. Asme 2018, 140, 124501. [Google Scholar] [CrossRef]

- Huang, W.; Chiu, W.K.S. Heat and Mass Transfer in a CVD Optical Fiber Coating Process by Propane Precursor Gas. Numer. Heat Transf. Part A-applications 2006, 50, 147–163. [Google Scholar] [CrossRef]

- Kleimanov, R.; Korshunov, A.; Kondrateva, A.; Karaseov, P.; Mishin, M.; Enns, Y.; Komarevtsev, I. Numerical Simulation of CVD Reactor for Oxide Semiconductor Layer Deposition. Springer Proc. Phys. 2022, 268, 229–234. [Google Scholar] [CrossRef]

- Bernard, C.; Blanquet, E.; Pons, M. Chemical vapor deposition of thin films and coatings: Evaluation and process modeling. Surf. Coatings Technol. 2007, 202, 790–797. [Google Scholar] [CrossRef]

- Houston, P.; Sime, N. Numerical modelling of MPA-CVD reactors with the discontinuous Galerkin finite element method. J. Phys. D 2017, 50, 295202. [Google Scholar] [CrossRef]

- Sime, N. Numerical modelling of chemical vapour deposition reactors, 2016.

- Cheimarios, N.; Kokkoris, G.; Boudouvis, A.G. Multiscale Modeling in Chemical Vapor Deposition Processes: Models and Methodologies. Arch. Comput. Methods Eng. 2021, 28, 637–672. [Google Scholar] [CrossRef]

- Zhou, X.; Hsieh, S.-J. Thermal analysis of fused deposition modeling process using infrared thermography imaging and finite element modeling. Thermosense Therm. Infrared Appl. XXXIX 2017, 10214, 1021409. [Google Scholar] [CrossRef]

- Khanafer, K.; Al-Masri, A.; Deiab, I.; Vafai, K. Thermal analysis of fused deposition modeling process based finite element method: Simulation and parametric study. Numer. Heat Transf. Part A-applications 2022, 81, 94–118. [Google Scholar] [CrossRef]

- Gabrielli, A.; Battarra, M.; Mucchi, E. A Critical Analysis of Finite-Element Modeling Procedures for Radial Bearing Stiffness Estimation. Math. Probl. Eng. 2021, 2021, 1–18. [Google Scholar] [CrossRef]

- Lisik, Z.; Turczynski, M.; Ruta, L.; Raj, E. Verification of Thermo-Fluidic CVD Reactor Model. J. Phys. Conf. Ser. 2014, 494, 012020. [Google Scholar] [CrossRef]

- Aranganadin, K.; Hsu, H.Y.; Lin, M.C. Design and Simulation of a Microwave Plasma Enhanced Chemical Vapor Deposition System Operated at 2.45 GHz Using the Multiphysics Modeling based on a Finite Element Method. 2023 24th Int. Vac. Electron. Conf. IVEC 2023 2023, 1–2. [Google Scholar] [CrossRef]

- Lee, Y.H.; Kim, T.H.; Kim, K.H.; Choi, S. Two-dimensional computational fluid dynamics modeling of slip-flow heat transfer in the hot filament chemical vapor deposition process. Surf. Coat. Technol. 2023, 456, 129291–129291. [Google Scholar] [CrossRef]

- Libreros, N.S.; Mercado, N.M.; Ochoa, G.V.; Forero, J.D.; Obregon, L.G. Critical Review of the Theoretical, Experimental and Computational Fluid Dynamics Methods for Designing Plate Fin Heat Exchangers. J. Eng. Sci. Technol. Rev. 2019, 12, 126–133. [Google Scholar] [CrossRef]

- Tran, H.T.; Lee, C.H.; Liu, J. Chemical Vapor Deposition Processes: Reduced-Order Modeling. Ref. Modul. Mater. Sci. Mater. Eng. 2014, 1–4. [Google Scholar] [CrossRef]

- Passos, M.F.; Binelli, A.R.R.; Jardini, L.A.; Dias, C.G.B.T.; Filho, R.M. CFD study of chemical vapor deposition reactor for synthesis of PHEMA. Chem. Eng. Trans. 2015, 43, 1459–1464. [Google Scholar] [CrossRef]

- Da Silva, R.C.; De Morais, P.J.D.; Carvalho, A.; De Rossi, W.; Motta, C.C. Numerical simulation on modified chemical vapor deposition (MCVD) thermal flow field. Sbfot. IOPC 2022 - Sbfot. Int. Opt. Photonics Conf. 5. [CrossRef]

- Zhou, X.; Wu, Y.; Yang, X.; Huang, C. Numerical Analysis of an Inline Metal-Organic Chemical Vapour Deposition Process Based on Sliding-Mesh Modelling. THE Coatings 2020, 10, 1198. [Google Scholar] [CrossRef]

- Park, K.S.; Choi, M.; Chung, J.D. Unsteady heat and mass transfer for multi-component particle deposition in the modified chemical vapor deposition. 2023. [Google Scholar] [CrossRef]

- Peng, L.; Dong, H.; Li, S.; Wang, Z.; Meng, X.; Wang, Y.; Liu, T.; Li, X.; Ji, J. Numerical Simulation Study on Flow and Heat Transfer of the Tungsten Crucible CVD Reactor. ACS omega 2022, 7, 42044–42055. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Zhang, Y.; Ragui, K.; Hou, C.; Zang, J.; Huang, Y.; Skripov, P.; Pavlenko, A.; Chen, L.; Zhang, Y.; et al. Molecular Dynamics Method for Supercritical CO2 Heat Transfer: A Review. Energies 2023, 16, 2902–2902. [Google Scholar] [CrossRef]

- Hong, S. Quantum molecular dynamics simulations of chemical vapor deposition synthesis of MoS 2 crystal assisted by H 2 partial pressures. 2020; 11282, 1128215. [Google Scholar] [CrossRef]

- Karmakar, T.; Finney, A.R.; Salvalaglio, M.; Yazaydin, A.O.; Perego, C. Non-Equilibrium Modeling of Concentration-Driven processes with Constant Chemical Potential Molecular Dynamics Simulations. Acc. Chem. Res. 2023, 56, 1156–1167. [Google Scholar] [CrossRef] [PubMed]

- Martins, I.T.; Alvariño, P.F.; Cabezas-Gómez, L. Dimensional lattice Boltzmann method for transport phenomena simulation without conversion to lattice units. 2023. [Google Scholar] [CrossRef]

- Prinz, F.; Elcner, J.; Pokorny, J.; Jicha, M. Lattice Boltzmann simulation of the laminar-turbulent transition in a constricted tube. Nucleation Atmos. Aerosols 2023, 2672. [Google Scholar] [CrossRef]

- Delavar, M.A.; Wang, J. Lattice Boltzmann method and its applications. Handb. HydroInformatics Vol. I Class. Soft-Computing Tech. 2023; 289–319. [Google Scholar] [CrossRef]

- Abaszadeh, M.; Safavinejad, A.; Amiri Delouei, A.; Amiri, H. Analysis of radiative heat transfer in two-dimensional irregular geometries by developed immersed boundary–lattice Boltzmann method. J. Quant. Spectrosc. Radiat. Transf. 2022, 280. [Google Scholar] [CrossRef]

- Rahman, A.; Nag, P.; Molla, M.M.; Hassan, S. Magnetic field effects on natural convection and entropy generation of non-Newtonian fluids using multiple-relaxation-time lattice Boltzmann method. Int. J. Mod. Phys. C 2021, 32. [Google Scholar] [CrossRef]

- Huang, J.; Wang, L.; Yang, X. An efficient thermal lattice Boltzmann method for simulating three-dimensional liquid–vapor phase change. Comput. Fluids 2024, 273, 106214. [Google Scholar] [CrossRef]

- Wang, L.; Liu, Z.; Rajamuni, M. Recent progress of lattice Boltzmann method and its applications in fluid-structure interaction. 2022; 237, 2461–2484. [Google Scholar] [CrossRef]

- Korba, D.; Wang, N.; Li, L. Accuracy of interface schemes for conjugate heat and mass transfer in the lattice Boltzmann method. Int. J. Heat Mass Transf. 2020, 156. [Google Scholar] [CrossRef]

- Qin, F.; Fei, L.; Zhao, J.; Kang, Q.; Derome, D.; Carmeliet, J. Lattice Boltzmann modelling of colloidal suspensions drying in porous media accounting for local nanoparticle effects. J. Fluid Mech. 2023, 963. [Google Scholar] [CrossRef]

- Łach, Ł.; Svyetlichnyy, D.; Straka, R. Heat flow model based on lattice Boltzmann method for modeling of heat transfer during phase transformation. Int. J. Numer. Methods Heat Fluid Flow 2020, 30, 2255–2271. [Google Scholar] [CrossRef]

- Svyetlichnyy, D.S. Development of the Platform for Three-Dimensional Simulation of Additive Layer Manufacturing Processes Characterized by Changes in State of Matter: Melting-Solidification. Mater. 2022, Vol. 15, Page 1030 2022, 15, 1030. [Google Scholar] [CrossRef] [PubMed]

- Svyetlichnyy, D.; Krzyzanowski, M.; Straka, R.; Lach, L.; Rainforth, W.M. Application of cellular automata and Lattice Boltzmann methods for modelling of additive layer manufacturing. Int. J. Numer. Methods Heat Fluid Flow 2018, 28, 31–46. [Google Scholar] [CrossRef]

- Łach, Ł.; Svyetlichnyy, D. 3D Model of Carbon Diffusion during Diffusional Phase Transformations. Mater. 2024, Vol. 17, Page 674 2024, 17, 674. [Google Scholar] [CrossRef] [PubMed]

- Shinde, V.M.; Deivendran, B.; Kumar, H.; Eswara Prasad, N. Investigation of transport processes in a commercial hot wall CVD reactor with multi-substrates for high-quality pyrocarbon deposition. Surf. Coatings Technol. 2021, 425, 127685. [Google Scholar] [CrossRef]

- Huang, W.; Chiu, W.K.S. A Mass Transport Model for CVD Coating of Optical Fibers. Am. Soc. Mech. Eng. Heat Transf. Div. HTD 2008, 374, 305–310. [Google Scholar] [CrossRef]

- Krumdieck, S.P.; Cave, H.M.; Baluti, S.; Jermy, M.; Peled, A. Expansion transport regime in pulsed-pressure chemical vapor deposition. Chem. Eng. Sci. 2007, 62, 6121–6128. [Google Scholar] [CrossRef]

- La Via, F.; Camarda, M.; La Magna, A. Mechanisms of growth and defect properties of epitaxial SiC. Appl. Phys. Rev. 2014, 1. [Google Scholar] [CrossRef]

- Blanquet, E.; Chaussende, D.; Nishizawa, S.-I.; Pons, M. High temperature silicon carbide chemical vapor deposition processes: From pure thermodynamic to mass transport modeling. Eur. Conf. Comput. Fluid Dyn. ECCOMAS CFD 2006.

- Nakamura, Y.; Sato, S.; Ohnishi, N. Proper orthogonal decomposition method of constructing a reduced-order model for solving partial differential equations with parametrized initial values. Partial Differ. Equations Appl. Math. 2024, 9, 100654. [Google Scholar] [CrossRef]

- Pons, M.; Bernard, C.; Madar, R. Numerical modelling for CVD simulation and process optimization: coupled thermochemical and mass transport approaches. Surf. Coatings Technol. 1993, 61, 274–281. [Google Scholar] [CrossRef]

- Fishman, N.; Klarner, L.; De Bortoli, V.; Mathieu, E.; Hutchinson, M. Diffusion Models for Constrained Domains. Trans. Mach. Learn. Res. 2023. [Google Scholar]

- Yang, L.; Zhang, Z.; Song, Y.; Hong, S.; Xu, R.; Zhao, Y.; Zhang, W.; Cui, B.; Yang, M.H. Diffusion Models: A Comprehensive Survey of Methods and Applications. ACM Comput. Surv. 2023, 56. [Google Scholar] [CrossRef]

- Paul, A.; Laurila, T.; Vuorinen, V.; Divinski, S. V. Fick’s Laws of Diffusion. Thermodyn. Diffus. Kirkendall Eff. Solids 2014, 115–139. [Google Scholar] [CrossRef] [PubMed]

- Poirier, D.R.; Geiger, G.H. Fick’s Law and Diffusivity of Materials. Transp. Phenom. Mater. Process. 2016, 419–461. [Google Scholar] [CrossRef] [PubMed]

- Donev, A.; Fai, T.G.; Vanden-Eijnden, E. A reversible mesoscopic model of diffusion in liquids: from giant fluctuations to Fick’s law. J. Stat. Mech. Theory Exp. 2014, 2014, 04004. [Google Scholar] [CrossRef]

- Andreucci, D.; Cirillo, E.N.M.; Colangeli, M.; Gabrielli, D. Fick and Fokker–Planck Diffusion Law in Inhomogeneous Media. J. Stat. Phys. 2019, 174, 469–493. [Google Scholar] [CrossRef]

- Gavriil, G.; Kanavouras, A.; Coutelieris, F.A. Can Fick law-based models accurately describe migration within a complete food product life cycle? J. Food Process. Preserv. 2018, 42. [Google Scholar] [CrossRef]

- Philipse, A.P. Continuity, Gradients and Fick’s Diffusion Laws. 2018; 70. [Google Scholar] [CrossRef]

- Sibatov, R.T.; Sun, H. Dispersive Transport Described by the Generalized Fick Law with Different Fractional Operators. Fractal Fract. 2020, 4, 42. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, W.; Cheng, G.; Li, J. Effect of Boundary Layers on Polycrystalline Silicon Chemical Vapor Deposition in a Trichlorosilane and Hydrogen System. Chinese J. Chem. Eng. 2011, 19, 1–9. [Google Scholar] [CrossRef]

- Aghajani, H.; Hosseini, N.; Mirzakhani, B. Deposition kinetics and boundary layer theory in the chemical vapor deposition of β-SiC on the surface of C/C composite. Mater. Phys. Mech. 2020, 75, 34–47. [Google Scholar] [CrossRef] [PubMed]

- Boi, F.; Song, J.; Guo, X.; Zhang, L.; Guo, J.; He, Y.; Wang, S.; Wen, J. Possible interplay of tangential and perpendicular modes in the growth of Fe-filled carbon nanotubes. CrysteEngComm 2023, 25, 761–769. [Google Scholar] [CrossRef]

- Lukashov, V. V.; Turgambaeva, A.E.; Igumenov, I.K. Analytical Model of the Process of Thermal Barrier Coating by the MO CVD Method. Coatings 2021, Vol. 11, Page 1390 2021, 11, 1390. [Google Scholar] [CrossRef]

- Sayevand, K.; Machado, J.A. Accurate splitting approach to characterize the solution set of boundary layer problems. Comput. Methods Differ. Equations 2019, 7, 206–223. [Google Scholar]

- Timms, R.; Purvis, R. A boundary layer analysis for the initiation of reactive shear bands. Proc. R. Soc. A Math. Phys. Eng. Sci. 2019, 475, 20180899. [Google Scholar] [CrossRef] [PubMed]

- Kouroudis, I.; Gößwein, M.; Gagliardi, A. Utilizing Data-Driven Optimization to Automate the Parametrization of Kinetic Monte Carlo Models. J. Phys. Chem. A 2023, 127, 5967–5978. [Google Scholar] [CrossRef] [PubMed]

- Pineda, M.; Stamatakis, M. Kinetic Monte Carlo simulations for heterogeneous catalysis: Fundamentals, current status, and challenges. J. Chem. Phys. 2022, 156, 120902. [Google Scholar] [CrossRef] [PubMed]

- Cheimarios, N.; To, D.; Kokkoris, G.; Memos, G.; Boudouvis, A.G. Monte Carlo and Kinetic Monte Carlo Models for Deposition Processes: A Review of Recent Works. Front. Phys. 2021, 9. [Google Scholar] [CrossRef]

- Chen, S.; Gao, J.; Srinivasan, B.M.; Zhang, G.; Sorkin, V.; Hariharaputran, R.; Zhang, Y.W. An all-atom kinetic Monte Carlo model for chemical vapor deposition growth of graphene on Cu(1 1 1) substrate. J. Phys. Condens. Matter 2020, 32, 155401. [Google Scholar] [CrossRef]

- Papanikolaou, K.G.; Stamatakis, M. Toward the accurate modeling of the kinetics of surface reactions using the kinetic Monte Carlo method. Front. Nanosci. 2020, 17, 95–125. [Google Scholar] [CrossRef]

- Rodgers, W.J.; May, P.W.; Allan, N.L.; Harvey, J.N. Three-dimensional kinetic Monte Carlo simulations of diamond chemical vapor deposition. J. Chem. Phys. 2015, 142, 214707. [Google Scholar] [CrossRef] [PubMed]

- Osman, H.R.; Mitra, S. A Basic Monte Carlo Model of Initiated Chemical Vapor Deposition Using Kinetic Theory. MRS Proc. 2014, 1704, 35–40. [Google Scholar] [CrossRef]

- Heiber, M.C. Excimontec v1.0: An Open-Source Software Tool for Kinetic Monte Carlo Simulations of Organic Electronic Devices. J. Open Source Softw. 2020, 5, 2307. [Google Scholar] [CrossRef]

- Edward, S.; Johnson, H.T. Atomistic Multi-Lattice Kinetic Monte Carlo (KMC) Modeling of Hyperthermal Oxidation of Multi-Layer Graphene. AIAA Sci. Technol. Forum Expo. AIAA SciTech Forum 2022, 2022; AIAA 2022-1610. [Google Scholar] [CrossRef]

- Agarwal, A.; Hengartner, N.W.; Gnanakaran, S.; Voter, A.F. Computing long time scale biomolecular dynamics using quasi-stationary distribution kinetic Monte Carlo (QSD-KMC). J. Chem. Phys. 2019, 151, 074109–074109. [Google Scholar] [CrossRef]

- Momeni, K.; Ji, Y.; Zhang, K.; Robinson, J.A.; Chen, L.Q. Multiscale framework for simulation-guided growth of 2D materials. npj 2D Mater. Appl. 2018, 2, 27. [Google Scholar] [CrossRef]

- Geiser, J. Multiscale Modeling of Chemical Vapor Deposition (CVD) Apparatus: Simulations and Approximations. Polym. 2013, Vol. 5, Pages 142-160 2013, 5, 142–160. [Google Scholar] [CrossRef]

- Xie, Y.; Stearrett, R. Machine Learning based CVD Virtual Metrology in Mass Produced Semiconductor Process. 2021.

- Costine, A.; Delsa, P.; Li, T.; Reinke, P.; Balachandran, P. V. Data-driven assessment of chemical vapor deposition grown MoS2 monolayer thin films. J. Appl. Phys. 2020, 128, 235303. [Google Scholar] [CrossRef]

- Yoshihara, N.; Tahara, Y.; Noda, M. Machine learning method for determining chemical vapor deposition conditions for large-area graphene growth. Asia-Pacific J. Chem. Eng. 2023, 18. [Google Scholar] [CrossRef]

- Zeng, Q.; Gao, Y.; Guan, K.; Liu, J.; Feng, Z. Machine learning and a computational fluid dynamic approach to estimate phase composition of chemical vapor deposition boron carbide. J. Adv. Ceram. 2021, 10, 537–550. [Google Scholar] [CrossRef]

- Khosravi, M.; Zeraati, M. Predictive modeling of the length of prepared CNT by CVD through ANN-MPSO and GEP. J. Part. Sci. Technol. 2019, 5, 145–159. [Google Scholar] [CrossRef]

- Dritsas, E.; Trigka, M. Efficient Data-Driven Machine Learning Models for Cardiovascular Diseases Risk Prediction. Sensors 2023, Vol. 23, Page 1161 2023, 23, 1161. [Google Scholar] [CrossRef]

- Koronaki, E.D.; Gkinis, P.A.; Beex, L.; Bordas, S.P.A.; Theodoropoulos, C.; Boudouvis, A.G. Classification of states and model order reduction of large scale Chemical Vapor Deposition processes with solution multiplicity. Comput. Chem. Eng. 2019, 121, 148–157. [Google Scholar] [CrossRef]

- Kuvyrkin, G.N.; Zhuravskii, A. V.; Savel′eva, I.Y. Mathematical Modeling of Chemical Vapor Deposition of Material on a Curvilinear Surface. J. Eng. Phys. 2016, 89, 1374–1379. [Google Scholar] [CrossRef]

- An, L.; Lei, X.; Qi, X.; Fang, M.; Liu, Y. Heat and mass transfer characteristics of three-dimensional bell-shaped polysilicon chemical vapor deposition reactor. J. Therm. Anal. Calorim. 2020, 141, 323–335. [Google Scholar] [CrossRef]

- Reznik, S. V.; Mikhailovskii, K. V.; Prosuntsov, P. V. Heat and Mass Transfer in the Chemical Vapor Deposition of Silicon Carbide in a Porous Carbon–Carbon Composite Material for a Heat Shield. J. Eng. Phys. 2017, 90, 291–300. [Google Scholar] [CrossRef]

- Raji, K.; Sobhan, C.B. A computational model for predicting the mass transport in a CVD reactor for carbon nanotube synthesis. Fourth Int. Conf. Smart Mater. Nanotechnol. Eng. 2013, 8793, 455–463. [Google Scholar] [CrossRef]

- Leone, S.; Kordina, O.; Henry, A.; Nishizawa, S.I.; Danielsson, Ö.; Janzén, E. Gas-Phase Modeling of Chlorine-Based Chemical Vapor Deposition of Silicon Carbide. Cryst. Growth Des. 2012, 12, 1977–1984. [Google Scholar] [CrossRef]

- Geiser, J.; Arab, M. Simulation of chemical vapor deposition: four-phase model. Spec. Top. Rev. Porous Media - An Int. J. 2012, 3, 55–68. [Google Scholar] [CrossRef]

- Jamshidi, R.; Yaghmaee, M.S.; Sarani, A.; Hosseini, S.I.; Ahmadizadeh, Y.; Shokri, B. Thermodynamics Modeling of Gas Phase Processes in Polycrystalline Diamond Deposition During Thermal Plasma Chemical Vapor Deposition. Adv. Stud. Theor. Phys 2012, 6, 201–215. [Google Scholar]

- Vignoles, G.L. Modeling of chemical vapor infiltration processes. Adv. Compos. Manuf. Process Des. 2015, 415–458. [Google Scholar] [CrossRef]

- Fashu, S.; Yang, J.; Yang, L.; Wang, N. Phase-field modelling of 2D island growth morphology in chemical vapor deposition. Eur. Phys. J. E 2020, 43, 57. [Google Scholar] [CrossRef]

- Sabzi, M.; Mousavi Anijdan, S.H.; Shamsodin, M.; Farzam, M.; Hojjati-Najafabadi, A.; Feng, P.; Park, N.; Lee, U. A Review on Sustainable Manufacturing of Ceramic-Based Thin Films by Chemical Vapor Deposition (CVD): Reactions Kinetics and the Deposition Mechanisms. Coatings 2023, 13, 188–188. [Google Scholar] [CrossRef]

- Jansen, A.P.J. Modeling Surface Reactions I. Lect. Notes Phys. 2012, 856, 121–153. [Google Scholar] [CrossRef]

- Badran, I.; Shi, Y. A kinetic study of the gas-phase reactions of 1-methylsilacyclobutane in hot wire chemical vapor deposition. Phys. Chem. Chem. Phys. 2018, 20, 75–85. [Google Scholar] [CrossRef] [PubMed]

- Reinke, M.O. Surface Kinetics of Titanium Isopropoxide in Chemical Vapor Deposition of Titanium Dioxide and Barium Titanate, EPFL, 2016.

- Reinke, M.; Kuzminykh, Y.; Hoffmann, P. Surface Kinetics of Titanium Isopropoxide in High Vacuum Chemical Vapor Deposition. J. Phys. Chem. C 2015, 119, 27965–27971. [Google Scholar] [CrossRef]

- Song, B.; Gao, B.; Han, P.; Yu, Y. Surface Kinetic Mechanisms of Epitaxial Chemical Vapour Deposition of 4H Silicon Carbide Growth by Methyltrichlorosilane-H2 Gaseous System. Materials (Basel). 2022, 15, 3768–3768. [Google Scholar] [CrossRef] [PubMed]

- Muneshwar, T.; Cadien, K. Surface reaction kinetics in atomic layer deposition: An analytical model and experiments. J. Appl. Phys. 2018, 124, 095302. [Google Scholar] [CrossRef]

- Konar, R.; Nessim, G.D. A mini-review focusing on ambient-pressure chemical vapor deposition (AP-CVD) based synthesis of layered transition metal selenides for energy storage applications. Mater. Adv. 2022, 3, 4471–4488. [Google Scholar] [CrossRef]

- Xiang, Y.; An, N.; Zhang, G.; Wang, L.; Chen, X. Chemical Vapor Deposition of Two-Dimensional Magnetite Nanosheets and Raman Study of Heat-Induced Oxidation Reaction. J. Nanoelectron. Optoelectron. 2024, 19, 564–571. [Google Scholar] [CrossRef]

- Tomasini, P. Chemical Vapor Deposition of Elemental Crystallogen Thin Films. ECS J. Solid State Sci. Technol. 2024, 13, 043014. [Google Scholar] [CrossRef]

- Zhao, Z.; Dong, F.; Wang, Y.; Sun, J.; Ye, H.; Wang, R.; Zhang, J. Growth of few-layer WTe2 by a salt-assisted double-tube chemical vapor deposition method with high infrared photosensitivity. Nanoscale 2023, 15, 11955–11962. [Google Scholar] [CrossRef]

- Filho, P.I.O.; Carmalt, C.J.; Angeli, P.; Fraga, E.S. Mathematical Modeling for the Design and Scale-Up of a Large Industrial Aerosol-Assisted Chemical Vapor Deposition Process under Uncertainty. Ind. Eng. Chem. Res. 2020, 59, 1249–1260. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.H.; Sim, Y.; Wang, J.; Kwon, S.Y. Metal-organic chemical vapor deposition of 2D van der Waals materials - The challenges and the extensive future opportunities. APL Mater. 2020, 8, 30901. [Google Scholar] [CrossRef]

- Jiang, X.; Chen, F.; Zhao, S.; Su, W. Recent progress in the CVD growth of 2D vertical heterostructures based on transition-metal dichalcogenides. CrystEngComm 2021, 23, 8239–8254. [Google Scholar] [CrossRef]

- Dong, J.; Zhang, L.; Wu, B.; Ding, F.; Liu, Y. Theoretical Study of Chemical Vapor Deposition Synthesis of Graphene and Beyond: Challenges and Perspectives. J. Phys. Chem. Lett. 2021, 12, 7942–7963. [Google Scholar] [CrossRef]

- Wang, Q.; Shi, R.; Zhao, Y.; Huang, R.; Wang, Z.; Amini, A.; Cheng, C. Recent progress on kinetic control of chemical vapor deposition growth of high-quality wafer-scale transition metal dichalcogenides. Nanoscale Adv. 2021, 3, 3430–3440. [Google Scholar] [CrossRef]

| Title | Advantages | Disadvantages | Gaps and Limitations |

|---|---|---|---|

| Numerical Modelling of MPA-CVD Reactors with the Discontinuous Galerkin Finite Element Method [48] | High accuracy in solving complex PDEs. | Resource and time-intensive. | The model’s focus on axisymmetric scenarios may not account for all plasma distribution perturbations, limiting its applicability to reactors with non-axisymmetric features. |

| Integrating multiple physical phenomena (e.g., gas dynamics, electromagnetic fields, plasma chemistry) into a single model offers a holistic view of reactor processes. | Complex implementation requiring numerical modeling expertise. | Although robust in simulations, the model requires further real-world validation to ensure alignment with experimental data. | |

|

Applying the model to various reactor geometries demonstrates its versatility and potential for optimizing reactor design and operation. |

The model’s assumptions and simplifications may not fully capture all real-world reactor interactions. | The need for extensive computational resources and specialized expertise may limit the adoption of these simulations in routine industrial processes. | |

| Thermal Analysis of Fused Deposition Modeling Process Using Infrared Thermography Imaging and Finite Element Modeling [51] | Integrating infrared thermography with FEM provides detailed thermal analysis during the FDM process. | The study primarily focuses on a specific material, typically acrylonitrile butadiene styrene (ABS). | Including more materials would enhance the study’s applicability and relevance. |

|

The authors present a robust framework for coupling different scales. The findings offer valuable insights for optimizing FDM process parameters, such as printing speed and layer thickness, to reduce thermal-induced defects and enhance the mechanical properties of printed parts. Validating FEM simulations with infrared thermography strengthens the model’s credibility. |

Finite element modeling is computationally intensive and resource-demanding, limiting accessibility in some settings. Real-time integration requires specialized equipment and expertise, not always available in all settings. |

Further investigation is needed to scale the approach to larger, more complex parts and different FDM printers. The study focuses on immediate thermal effects; examining long-term stability and performance under varied conditions would provide a more comprehensive understanding. |

|

| Thermal Analysis of Fused Deposition Modeling Process Based Finite Element Method: Simulation and Parametric Study [52] | FEM allows high-resolution simulation of temperature distribution and gradients in FDM. | FEM simulations are resource-intensive, requiring significant expertise, which may limit their use by small to medium-sized enterprises. | More comprehensive experimental validation of the simulation results is needed. |

| A parametric study shows how print speed, layer thickness, and extrusion temperature affect the thermal profile. | The study focuses on a specific thermoplastic commonly used in FDM. | Incorporating dynamic variables like environmental temperatures and humidity would improve the study. | |

|

The findings provide valuable guidelines to enhance the quality of FDM-produced parts in the additive manufacturing industry. |

Although valuable, the simulations have limited experimental validation. |

The scalability to larger and more complex prints is not fully addressed. |

|

| Verification of Thermo-Fluidic CVD Reactor Model [54] | The article’s main strength is verifying the numerical model with experimental data. | ANSYS CFX simulations are computationally intensive and resource-demanding. | The findings are specific to certain reactor configurations and conditions. |

| Using ANSYS CFX offers a high-fidelity approach to modeling thermo-fluidic phenomena in CVD reactors. | The study is specific to the modeled CVD reactor’s conditions and configurations. |

Incorporating dynamic variables like temperature fluctuations and varying gas compositions would improve real-world relevance. |

|

| The study tackles practical challenges in CVD reactor operation, like managing heat and mass transfer under varying conditions. | The study’s experimental validation is limited despite its focus on model verification. | More extensive experimental data is needed to validate the model under diverse conditions. | |

| Modelling of Heat Transfer in an Aluminum X-Ray Anode Employing a CVD Diamond Heat Spreader [44] | Using CVD diamond as a heat spreader innovatively manages thermal loads in X-ray anodes. | The numerical simulations are resource-intensive, requiring significant expertise. | Including different anode materials and configurations would enhance the study’s relevance. |

| Numerical modeling offers detailed insights into thermal behavior, identifying critical heat buildup areas and showing effective mitigation by the CVD diamond heat spreader. The findings have practical implications for X-ray equipment design and operation. |

The study focuses on aluminum X-ray anodes with CVD diamond heat spreaders. The experimental validation is somewhat limited in scope. |

Incorporating dynamic conditions like varying power loads and environmental temperatures would improve the study. Investigating long-term performance and durability under continuous operation would provide valuable insights. |

| Title | Advantages | Disadvantages | Gaps and Limitations |

|---|---|---|---|

| Two-Dimensional Computational Fluid Dynamics Modeling of Slip-Flow Heat Transfer in the Hot Filament Chemical Vapor Deposition Process [56] | The use of two-dimensional CFD modeling provides a high-resolution analysis of heat transfer in the HFCVD process. | While two-dimensional modeling provides valuable insights, it simplifies the reactor’s real-world three-dimensional nature, potentially overlooking complex interactions and flow characteristics. | Extending the modeling to three dimensions would capture more complex flow and heat transfer phenomena. |

| The study’s emphasis on slip-flow heat transfer is relevant for HFCVD processes operating under low-pressure conditions where slip-flow effects are significant. | Despite being two-dimensional, CFD simulations are computationally intensive and require significant resources and expertise. | Extensive experimental validation is needed to corroborate the CFD results. | |

| Insights from the CFD simulations can improve HFCVD reactor design and operation. | The study may have limited experimental validation. | Incorporating dynamic operating conditions, like transient temperature changes and varying gas compositions, would provide a more realistic representation of the HFCVD process. | |

| CFD Study of Chemical Vapor Deposition Reactor for Synthesis of PHEMA [59] | CFD provides detailed insights into fluid dynamics and heat transfer within the CVD reactor. | CFD simulations are computationally intensive, requiring substantial resources and expertise. | Expanding the study to include different polymers and reactor designs would enhance the generalizability of the findings. |

| The study’s findings can optimize key process parameters like temperature, pressure, and gas flow rates, improving the quality and efficiency of PHEMA synthesis. | The study focuses on a specific polymer (PHEMA) and reactor design. | Incorporating dynamic operating conditions, like fluctuating temperatures and varying gas compositions, would better represent the CVD process. | |

|

The research has significant practical implications for the chemical and materials engineering industries. |

The extent of experimental validation is limited. | Investigating the long-term performance and stability of synthesized PHEMA under different environmental conditions would provide valuable insights. | |

| Numerical Simulation on Modified Chemical Vapor Deposition (MCVD) Thermal Flow Field [60] | CFD allows high-resolution analysis of thermal and flow fields within the MCVD reactor. | CFD simulations are computationally intensive, requiring significant resources and expertise. | Including different materials and MCVD reactor configurations would enhance the generalizability of the findings. |

| The study provides insights into optimizing process parameters like heat flux, gas flow rates, and rotation speed. | The study is specific to the MCVD process used for optical fiber preform manufacturing. |

Incorporating dynamic operating conditions, like transient temperature changes and varying gas compositions, would provide a more realistic representation of the MCVD process. |

|

| The findings are applicable to the optical fiber manufacturing industry, where precise control over the deposition process is essential. | The extent of experimental validation is limited. |

Investigating the long-term performance and stability of the deposition process under continuous operation would provide valuable insights. |

|

| Unsteady Heat and Mass Transfer for Multi-Component Particle Deposition in the Modified Chemical Vapor Deposition [62] | Emphasizing multi-component particle deposition is crucial for real-world applications, where multiple materials are often deposited simultaneously. | The simulations are computationally intensive, requiring significant resources and expertise. | Including different CVD processes and materials would enhance the generalizability of the findings. |

| Examining unsteady heat and mass transfer provides insights into transient behaviors during MCVD. | The study is focused on the MCVD process, which may limit the generalizability to other CVD methods. | Incorporating dynamic operating conditions, like varying gas compositions and temperature fluctuations, would better represent the deposition process. | |

| Computational simulations provide detailed analysis of the deposition process, helping identify optimal conditions and predict parameter effects on deposition quality. | The scope of experimental validation is limited. | Investigating the long-term stability and performance of the deposited layers under continuous operation would provide valuable insights. | |

| Numerical Simulation Study on Flow and Heat Transfer of the Tungsten Crucible CVD Reactor [63] | CFD provides detailed analysis of flow and heat transfer within the tungsten crucible CVD reactor. | CFD simulations are computationally intensive, requiring substantial resources and expertise. | Including different materials and CVD reactor designs would enhance the generalizability of the findings. |

| The study addresses practical challenges in the CVD process, applicable to industrial settings. | The study focuses on a tungsten crucible CVD reactor, which may limit the generalizability to other CVD reactors or materials. |

Incorporating dynamic operating conditions, like transient temperature changes and varying gas compositions, would better represent the deposition process. |

|

| The article investigates various process parameters, like gas flow rates, temperature distributions, and reactor geometry. | The scope of experimental validation is limited. |

Investigating the long-term stability and performance of the deposition process under continuous operation would provide valuable insights. |

| Title | Advantages | Disadvantages | Gaps and Limitations |

|---|---|---|---|

| Quantum Molecular Dynamics Simulations of Chemical Vapor Deposition Synthesis of MoS2 Crystal Assisted by H2 Partial Pressures [65] | Applying quantum molecular dynamics to study the CVD process is innovative, offering atomic-level insights not easily accessible through experiments, aiding in understanding sulfurization mechanisms. | QMD simulations are resource-intensive, requiring significant expertise. | Including other materials synthesized via CVD would enhance the study’s generalizability and provide broader insights into optimizing CVD processes. |

| By investigating the role of H2 partial pressures, the study addresses a critical factor in the CVD process. Understanding how H2 influences the sulfurization of MoO3 is essential for optimizing the synthesis of high-quality MoS2 crystals. | The study’s focus on MoS2 synthesis may limit its generalizability to other materials or processes. | Incorporating dynamic conditions, such as varying H2 concentrations and temperatures, would offer a more comprehensive understanding of the CVD process. | |

| The article thoroughly analyzes how different H2 environments affect the sulfurization process, providing valuable insights for optimizing CVD conditions for MoS2 synthesis. | Although insightful, the study offers limited discussion on experimental validation. | Investigating the long-term stability and performance of synthesized MoS2 crystals under various conditions would provide insights into their practical applications. | |

| Non-Equilibrium Modeling of Concentration-Driven Processes with Constant Chemical Potential Molecular Dynamics Simulations [66] | Introducing CμMD simulations marks a significant advancement in molecular dynamics. | CμMD simulations are computationally demanding. | Expanding experimental validation to more conditions and systems would strengthen the findings. |

| The study’s detailed analysis of concentration-driven processes shows the versatility of CμMD simulations across various systems. | Implementing CμMD simulations requires expertise in molecular dynamics and non-equilibrium thermodynamics. | Including varied dynamic conditions in simulations would offer a more comprehensive understanding of non-equilibrium processes. | |

| The findings have broad applicability in material science, chemistry, and biology. | Experimental validation is crucial to confirm the simulations’ accuracy and applicability. | Investigating long-term stability under constant chemical potential conditions would provide valuable practical insights. |

| Title | Advantages | Disadvantages | Gaps and Limitations |

|---|---|---|---|

| Lattice Boltzmann Method and Its Applications [69] | The article provides a comprehensive overview of LBM, covering its theoretical foundations and practical applications. | LBM’s computational intensity is a primary challenge, particularly for large-scale simulations. Discussing strategies for optimizing efficiency and managing resources would enhance the article. | The article lacks extensive coverage of scalability challenges and solutions for very large or complex systems. |

| The article lacks extensive coverage of scalability challenges and solutions for very large or complex systems. | Expanding the discussion to include fields like biomedical engineering and material science would broaden the article’s scope beyond hydroinformatics. | While LBM excels in steady-state simulations, it faces challenges in dynamic and transient processes. | |

| The authors clearly explain the LBM methodology, making it accessible to readers of varying expertise levels. | Focusing primarily on theoretical and computational aspects, the article would benefit from more discussions on experimental validations and real-world case studies. | Highlighting more interdisciplinary applications of LBM would increase the article’s appeal to a wider audience. | |

| Analysis of Radiative Heat Transfer in Two-Dimensional Irregular Geometries by Developed Immersed Boundary–Lattice Boltzmann Method [70] | Combining the immersed boundary method (IBM) with the lattice Boltzmann method (LBM) enhances the accuracy of radiative heat transfer simulations in irregular geometries. | The hybrid IB-LBM approach is computationally intensive, potentially limiting its practical use for large-scale problems or users with limited resources. | Expanding to three-dimensional geometries would improve the findings’ generalizability. |

| Addressing two-dimensional irregular geometries, the study tackles a common challenge in heat transfer simulations. | Focusing on two-dimensional geometries may not capture the full complexity of three-dimensional systems. | Evaluating the method under dynamic conditions would provide a more comprehensive assessment of its capabilities. | |

| The article thoroughly analyzes simulation results, detailing how various parameters affect radiative heat transfer in irregular geometries. | The article relies mainly on numerical simulations, with limited experimental validation. | Discussing strategies to optimize IB-LBM computational efficiency, such as parallel computing or algorithmic improvements, would enhance practical accessibility. | |

| An Efficient Thermal Lattice Boltzmann Method for Simulating Three-Dimensional Liquid–Vapor Phase Change [72] | The article presents an advanced thermal LBM for three-dimensional liquid-vapor phase change simulations. | Despite efficiency improvements, the thermal LBM still demands significant computational resources. | Expanding the study to include different types of phase change phenomena and fluid flow scenarios would enhance the generalizability of the findings. |

| A major strength is the focus on computational efficiency, making the optimized thermal LBM feasible for large-scale simulations. | Focusing on liquid-vapor phase change may limit the findings’ generalizability to other phase change or fluid flow problems. | Investigating the method’s performance under dynamic and transient conditions, such as varying heat fluxes and pressure changes, would provide a more comprehensive understanding of its capabilities. | |

| The article thoroughly analyzes simulation results, including comparisons with existing methods. | More extensive experimental validation would enhance the article. | Further optimizing computational efficiency through parallel computing or algorithmic improvements would make the thermal LBM more practical for large-scale simulations. | |

| Accuracy of Interface Schemes for Conjugate Heat and Mass Transfer in the Lattice Boltzmann Method [74] | The study compares multiple interface schemes, highlighting their accuracy and computational efficiency. | Evaluating multiple interface schemes through extensive simulations is computationally demanding. | Expanding the study to include a wider range of heat and mass transfer problems would enhance the generalizability of the findings. |

| Addressing conjugate heat and mass transfer, the article focuses on a crucial aspect of thermal and fluid dynamics simulations, relevant for material and phase interactions. | The study’s insights on conjugate heat and mass transfer may not apply to other heat and mass transfer problems. | Testing interface schemes under dynamic conditions, like varying heat fluxes and pressure changes, would offer a more comprehensive understanding. | |

| Combining theoretical analysis with numerical simulations strengthens the study’s conclusions. | More extensive experimental validation would enhance the article. | Optimizing the computational efficiency of interface schemes would improve their accessibility for practical applications. | |

| Lattice Boltzmann Modelling of Colloidal Suspensions Drying in Porous Media Accounting for Local Nanoparticle Effects [75] | The study uses the lattice Boltzmann method to model the complex drying of colloidal suspensions involving multiphase flows and nanoparticle interactions. | Including nanoparticle effects makes LBM simulations computationally intensive. | Including various porous materials and drying conditions would enhance the findings’ generalizability. |

| Incorporating local nanoparticle effects like viscosity changes, surface tension variations, and drying rate reductions, the model offers detailed simulations. | The study’s insights on colloidal suspensions in porous media may not apply to other drying processes or materials. | Investigating the method’s performance under dynamic and transient conditions, such as varying temperatures and humidity levels, would provide a more comprehensive understanding of its capabilities. | |

| The article comprehensively analyzes how different parameters affect the drying process. | More extensive experimental validation would enhance the article. | Studying the long-term stability of dried colloidal structures under different environments would offer practical application insights. |

| Title | Advantages | Disadvantages | Gaps and Limitations |

|---|---|---|---|

| Fick’s Law and Diffusivity of Materials [90] | The chapter thoroughly covers Fick’s first and second laws of diffusion. | The chapter focuses on theoretical aspects with limited experimental validation. | Expanding the discussion to cover a wider range of materials, including non-metallic systems, would enhance the applicability of the principles discussed. |

| The discussion includes practical applications in materials processing, valuable for engineers and scientists in metallurgy, ceramics, and materials science. | Detailed insights into metallurgical applications are provided, but diffusivity in other materials may not be comprehensively covered. | Exploring interdisciplinary applications, such as in biological systems or environmental engineering, would show Fick’s law’s broader utility. | |

| The authors provide clear explanations of complex concepts, accessible to both students and professionals. | The mathematical treatment may be challenging for readers without a strong background in mathematics or transport phenomena. | Incorporating modern diffusivity measurement techniques and recent advancements would provide an up-to-date perspective. | |

| A Reversible Mesoscopic Model of Diffusion in Liquids: From Giant Fluctuations to Fick’s Law [91] | The study introduces a reversible mesoscopic model with thermal fluctuations, offering a more accurate view of diffusion in liquids and challenging the traditional irreversible model based solely on Fick’s law. | The accurate mesoscopic model is computationally intensive, requiring significant resources and limiting its use for large-scale or real-time simulations. | Extending the model to include diffusion in other states of matter and complex fluids would enhance its generalizability. |

| The authors present a strong theoretical framework linking microscopic fluctuations to macroscopic diffusion behavior. | The model is specifically tailored for diffusion in liquids, which may limit its generalizability to other states of matter such as gases or solids. | Testing under dynamic conditions, like varying temperature and pressure, would clarify the model’s capabilities and limitations. | |

| Using Lagrangian numerical methods, the study captures the stochastic nature of particle movements and thermal fluctuations, essential for accurate mesoscopic diffusion modeling. | The study could benefit from more extensive experimental validation despite strong theoretical and numerical development. | Optimizing computational efficiency would make the model more practical for real-world applications. | |

| Fick and Fokker–Planck Diffusion Law in Inhomogeneous Media [92] | The study thoroughly explores Fick’s law and the Fokker–Planck equation in inhomogeneous media. | The study’s mathematical models and equations are highly complex. | Expanding the study to include a broader range of applications and different types of diffusion processes would enhance the generalizability of the findings. |

| Integrating Fick’s law with the Fokker–Planck equation provides a comprehensive diffusion modeling framework for inhomogeneous media. | Despite robust theoretical insights, the article lacks extensive experimental validation. | Testing diffusion models under dynamic conditions, like time-varying gradients and external fields, would provide a more comprehensive understanding. | |

| The authors use rigorous mathematical methods to derive and validate their models. | Focusing on inhomogeneous media may limit the results’ generalizability to other diffusion processes. | Simplifying the complex mathematical models without losing accuracy would make the findings more accessible. | |

| Continuity, Gradients and Fick’s Diffusion Laws [94] | The article thoroughly explores continuity, gradients, and Fick’s laws. | While the theoretical coverage is extensive, the article could benefit from more practical examples and applications. | The article could broaden its scope to include interdisciplinary applications of Fick’s laws. |

| The author explains complex concepts clearly and concisely. | The advanced mathematical treatment may be challenging for readers without a strong math or physics background. | The discussion is primarily focused on linear systems. Addressing Fick’s laws in dynamic and non-linear systems would enhance the discussion. | |

| The article places Fick’s laws in historical context, highlighting their evolution and significance in diffusion theory. | The article focuses on theory and lacks discussion on experimental validation. | Including recent advancements in diffusion would complement the historical perspective. | |

| Dispersive Transport Described by the Generalized Fick Law with Different Fractional Operators [95] | Using fractional calculus to generalize Fick’s law for dispersive transport is innovative, addressing traditional models’ limitations in disordered systems. | The fractional differential equations and their solutions are mathematically complex, which might limit the accessibility of the study to researchers who are not well-versed in advanced mathematical techniques. | Incorporating diverse experimental data would validate and demonstrate the models’ robustness across various scenarios. |

| The article presents a detailed theoretical framework, linking fractional derivatives to observable ToF experiment phenomena. | Robust theoretical models need more extensive experimental validation to confirm their real-world accuracy and applicability. | Testing fractional models under dynamic conditions, like varying temperature or electric fields, would deepen understanding of their practical applicability. | |

| The findings have broad implications for studying charge transport in disordered systems like amorphous semiconductors, organic bulk heterojunction cells, and perovskite solar cells, making the study relevant in materials science and electronics. | Focusing on Riemann–Liouville derivatives, the study could explore other fractional operators or hybrid models for a more comprehensive understanding of dispersive transport phenomena. | Simplifying or optimizing fractional models would make them more accessible for industrial use with limited computational resources. |

| Title | Advantages | Disadvantages | Gaps and Limitations |

|---|---|---|---|

| Deposition Kinetics and Boundary Layer Theory in the Chemical Vapor Deposition of β-SiC on the Surface of C/C Composite [97] | The study provides valuable insights into optimizing CVD parameters for β-SiC coatings on C/C composites. | The study primarily focuses on experimental observations. Integrating computational modeling could provide a more comprehensive understanding of the deposition mechanisms and boundary layer dynamics. | Extending the study to include different materials and substrates would enhance the generalizability and applicability of the findings across various industrial applications. |

| The use of XRD and FESEM allows for a detailed analysis of the coating’s phase composition and microstructure, which is crucial for understanding the deposition process and improving the quality of the coatings. | The research is specific to β-SiC on C/C composites. Expanding the scope to other materials and composites would increase the findings’ generalizability. | Investigating dynamic conditions like fluctuating temperatures and precursor flow rates would better represent the CVD process. | |

| The findings are significant for industries like aerospace and electronics that rely on high-quality β-SiC coatings. | The study does not address the environmental impact of the CVD process, such as the emissions and by-products generated during deposition. Including this analysis would provide a more holistic view of the process’s sustainability. | Examining the long-term stability and performance of β-SiC coatings under operational conditions would provide insights into their practical applications and durability. | |

| Possible Interplay of Tangential and Perpendicular Modes in the Growth of Fe-Filled Carbon Nanotubes [98] | The study’s exploration of tangential and perpendicular growth modes offers new insights into Fe-CNT formation mechanisms. | Replicating the study’s precise CVD parameter control may be challenging. | Including other metal-filled CNTs would offer a broader understanding of growth mechanisms. |

| The article comprehensively analyzes nanotube structures using various characterization techniques. | The detailed insights on Fe-CNTs may not apply to other filled carbon nanotubes or nanomaterials. | Studying Fe-CNT growth under varying temperatures and gas compositions would reveal the process’s sensitivity to environmental changes. | |

| Understanding Fe-CNT growth mechanisms has significant implications for nanotechnology and materials science applications. | Scaling up the synthesis and analysis methods for large-scale Fe-CNT production may be difficult. | Evaluating Fe-CNTs’ long-term stability and performance in practical applications would provide insights into their durability and limitations. | |

| Analytical Model of the Process of Thermal Barrier Coating by the MO CVD Method [99] | The article provides a robust analytical framework for understanding the deposition process in MO CVD. By integrating diffusion combustion reactions and convection conditions, the model offers a detailed mechanism for the growth of TBCs. | The model’s computational intensity may limit its industrial use without significant resources. | Including different coatings and precursors would enhance the model’s generalizability. |

| The study’s focus on 7YSZ coatings, widely used in aerospace and energy industries, enhances its practical relevance. | The model is tailored specifically for MO CVD processes and 7YSZ coatings. | Testing under dynamic conditions like varying temperatures and flow rates would better assess its capabilities. | |

| Model predictions validated against experimental data strengthen the proposed approach’s credibility and practical applicability. | Although the model is compared with experimental data, the scope of this validation is somewhat limited. | Examining long-term stability and performance under operational conditions would provide insights into practical applications and durability. | |

| Numerical Simulation of CVD Reactor for Oxide Semiconductor Layer Deposition [46] | The use of detailed numerical simulations to model the CVD reactor processes is a significant strength. | The simulations require significant computational resources, limiting accessibility to advanced research facilities. | Expanding the study to include different types of semiconductor materials and reactor configurations would enhance the generalizability of the findings and provide broader insights into the CVD process. |

| The study tackles practical CVD challenges like substrate temperature stability and uniform layer deposition. | The study focuses on a specific CVD reactor and material system (oxide semiconductors with gold nanoparticles). | Testing under dynamic conditions like varying temperatures and gas flow rates would better reveal the reactor’s capabilities and limitations. | |

| Combining fluid dynamics, heat transfer, and materials science offers a comprehensive approach to CVD reactor design. | While the simulations are thorough, the study would benefit from more extensive experimental validation to confirm the accuracy and applicability of the simulated results under real-world conditions. | Optimizing computational efficiency would make simulations more practical for industrial use. | |

| Accurate Splitting Approach to Characterize the Solution Set of Boundary Layer Problems [100] | Using fractional calculus for boundary layer problems offers a novel perspective on differential equations. | The complex mathematical models may limit accessibility for non-specialists. | Expanding the approach to include a wider range of differential equations and boundary conditions would enhance its generalizability and applicability. |

| The modified truncated Chebyshev series and operational matrix technique ensure high accuracy, crucial for practical applications. | Focusing on specific boundary layer problems may limit the approach’s generalizability. | Simplifying the mathematical techniques while maintaining accuracy would broaden accessibility. | |

| Detailed methodology, including stability and error analysis, makes the findings robust and reliable. | More empirical data is needed to enhance the method’s practical applicability. | Testing under dynamic and transient conditions would provide a comprehensive understanding of the method’s capabilities. |

| Title | Advantages | Disadvantages | Gaps and Limitations |

|---|---|---|---|

| An All-Atom Kinetic Monte Carlo Model for Chemical Vapor Deposition Growth of Graphene on Cu(111) Substrate [105] | The all-atom kMC model accurately captures atomic interactions and surface dynamics in graphene growth. | The all-atom kMC model is computationally intensive, requiring significant resources and time. | Including substrates like Ni(111) or SiC would broaden the findings’ generalizability and deepen understanding of graphene growth. |

| The model includes factors like hydrogen partial pressures, surface diffusion, and carbon-copper interactions. | The study focuses on the Cu(111) substrate, though it’s not the only one used for graphene growth. | Testing under dynamic conditions, like varying temperature and pressure, would better evaluate the model’s capabilities and limitations. | |

| The findings have significant implications for the optimization of industrial graphene production. | Despite detailed theoretical insights, the study lacks extensive experimental validation. | Increasing the extent of experimental validation through systematic comparison with empirical data would help confirm the model’s accuracy and enhance its practical applicability in industrial settings. | |