1. Introduction

Ice formation on aircraft surfaces represents a critical safety hazard, significantly impairing aerodynamic performance by increasing drag and reducing lift. This phenomenon, known as icing, occurs when supercooled water droplets in the atmosphere freeze in contact with an aircraft during flight. The presence of ice can lead to increased fuel consumption, reduced engine performance, and even catastrophic failure of aircraft control systems. Consequently, the development of effective de-icing and anti-icing technologies is crucial to aviation safety and operational efficiency.

The primary technologies currently in use include pneumatic systems, electro-thermal heating elements, fluid-based anti-icing, and hybrid ice protection technologies [

1,

2,

3].

Pneumatic systems work by inflating rubber boots on leading edges to break the ice. They can be manually or automatically activated, and their effectiveness relies on timely activation to prevent ice buildup [

4]. Electro-thermal heating elements, embedded in critical areas of the aircraft surface, melt and remove ice by utilizing electrical heating elements. While efficient, they consume a significant amount of power and often require continuous activation [

5].

Fluid-based anti-icing involves spraying glycol-based solutions onto aircraft surfaces, preventing ice formation by lowering the freezing point. However, their efficacy is limited to specific flight conditions, and they require regular re-application [

6]. Hybrid ice protection technologies integrate pneumatic, electro-thermal, and fluid-based methods to create a comprehensive solution. Although these systems are effective due to the combination of techniques, their complexity and energy demands can be prohibitive [

7].

Despite advancements in pneumatic, electro-thermal, fluid-based, and hybrid anti-icing systems, these solutions are often limited by manual activation, high energy consumption, or complexity. As a result, there is a growing demand for automated, predictive, and energy-efficient ice detection and removal systems. Our research aims to address this gap by developing an innovative smart ice control system using machine learning models to predict ice formation. This system should work as an interpreter for the signal coming from a graphene-based sensor [

8,

9,

10], as well as a provider of local heating only when necessary.

Supercooling is crucial to the method of detecting ice formation because the freezing process is exothermic and releases heat, causing a temperature rise in the surrounding area. Substantial heat is released in a short time during a freezing event on the airplane wing surface, and this thermal anomaly can be detected using thermocouples without prior knowledge of the precise freezing point. The developed device detects the presence of ice and activates melting via the same graphene-based resistance system.

This research is significant for several reasons. First, using machine learning algorithms allows for accurate detection and prediction of ice formation patterns, reducing false positives and enabling timely de-icing actions. By leveraging supervised and unsupervised machine learning algorithms, as well as neural networks, the goal is to optimize the de-icing process in real-time while reducing power consumption. Machine learning techniques such as decision trees, support vector machines, and neural networks are effective for this purpose, providing robust models for classification and prediction tasks [

11,

12,

13].

The smart ice control system presented in this research lays the foundation for further exploration into predictive ice detection and control. Future developments could include enhanced integration with avionics for seamless communication between the ice control system and other critical flight systems, adaptive learning algorithms that continuously refine the system’s ice detection and removal capabilities based on in-flight data, and the extension of this technology to other industries where ice formation poses a challenge, such as wind turbines and power lines. Ultimately, this research advances predictive ice detection and control, contributing to safer and more efficient operations in aviation and beyond.

2. Experimental Setup and Methodology

2.1. Concept of Investigation and Sensor Preparation

The methodology employed in this study is based on one fundamental principle of thermodynamics [

14]. The freezing process of water doesn’t always commence immediately when the temperature (T) drops below its freezing point (T

) but often begins at a significantly lower temperature, a phenomenon known as supercooling [

15].

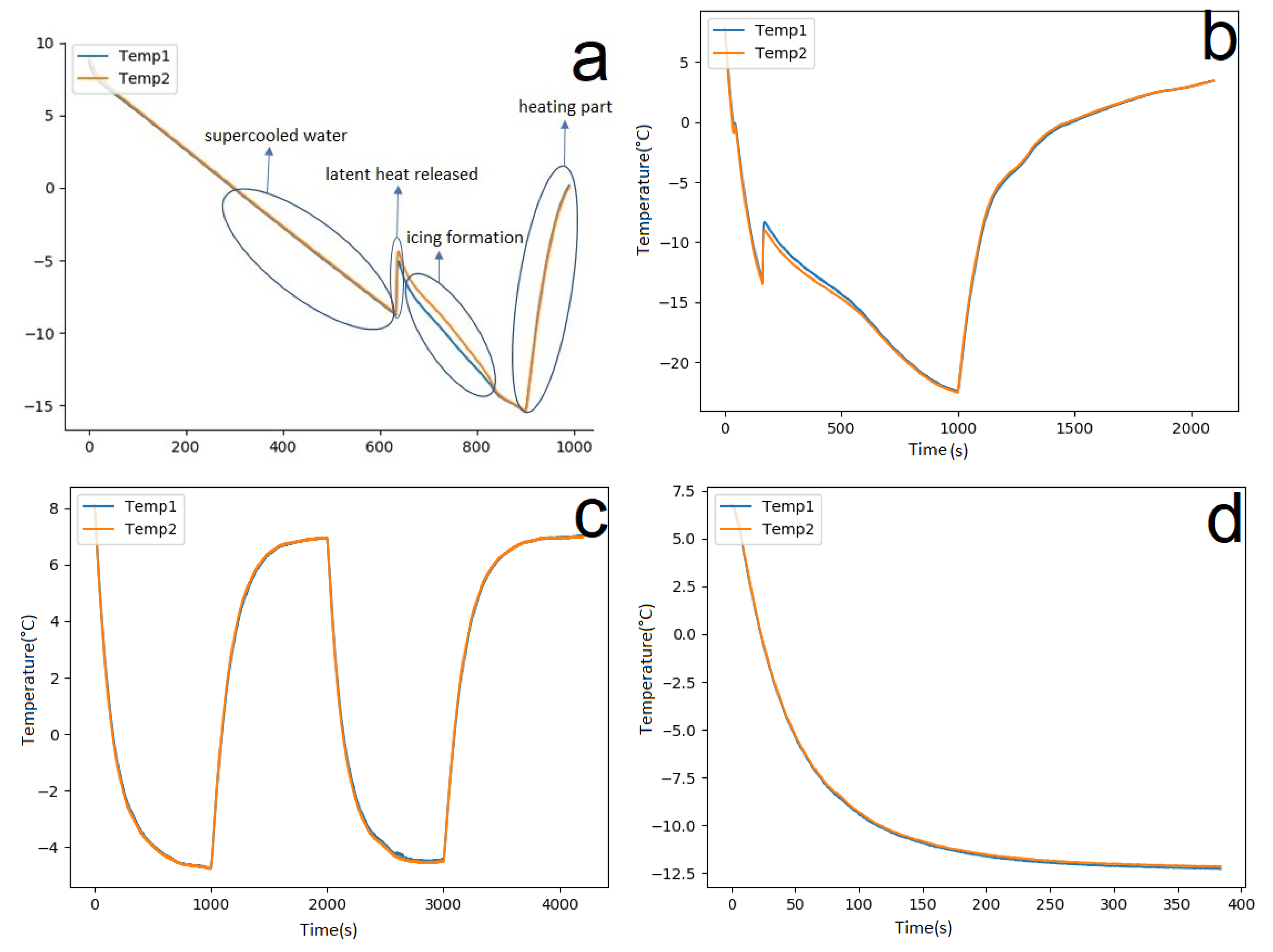

In fact, water freezing is an exothermic process, releasing heat that influences its surroundings. During icing events on aircraft wings, a significant amount of heat is released over a short period. By using thermocouples to measure the temperature of the wing surface, the instant heat release can be captured without prior knowledge of the freezing point. Our device detects ice formation and melts it by sending a current through a graphene resistor.

In the temperature profiles captured via thermocouples, "Temp1" and "Temp2" indicate ice detection in the so-called "passive method." The term "passive" is used because no active electrical signal is sent through the sensing area; instead, the system observes variations in terms of resistance and sharp changes in temperature, which allow for the analysis of the events occurring on the surface. These temperature changes are different from those caused by evaporation or external temperature fluctuations. Indeed, temperature changes due to freezing are much abrupter than by the other aforementioned mechanisms. By monitoring the temperature profiles, the onset and development of ice formation can be detected, providing critical data for understanding and mitigating ice accretion on aircraft surfaces. For wet (glaze) ice, the stagnation region remains at 0

C due to the latent heat released during freezing. For dry (rime) ice, the temperature peaks below freezing. A characteristic temperature profile can be measured using thermocouples isolated from the ice accretion area by prepreg composite materials [

17].

Prepregs are composite materials consisting of reinforcement fibers pre-impregnated with a thermoplastic or thermoset resin matrix. Cured under high temperature and pressure, they exhibit unique properties such as high strength, uniformity, and lightweight nature. The prepreg used in this project is Fibre Glast Prepreg, which is shipped between layers of backing cloth to prevent sticking. It is partially cured for handling and typically stored in cool conditions.

First, it is necessary to prepare the shape required for the experiment, which is a square of 11 cm. The prepreg is partially cured, which means that it is in B-stage. It can be trimmed, pleated, and formed using a knife or a pair of scissors. To obtain a glossy finished component, it is necessary to have a flawless mold, which has been waxed and coated with PVA.

Then, it is necessary to peel off the backing cloth from one side and adapt this side to the mold. The prepreg surface is very sticky, so it is important to place the material carefully into the mold. Once the layer is fixed over the mold, it should not be moved anymore.

Two sheets of Teflon have been used as a mold, and the layers of prepreg have been placed in the middle to ensure a smooth surface. It is possible to continue placing layers on top of each up to a total thickness of 1/4 inch (0.654 cm) at a single time. The prepreg structure used in this work is multilayer; thermocouples and graphene strips have been placed between the layers.

After the first layer is fixed on the mold, the second cloth is peeled off, and another piece of graphene each 0.5 cm is placed over the first layer, the setup prepared is composed of three layers, between the second and the third layer are placed 2 thermocouples.

Once the layers and the thermocouples are placed in the mold, the prepreg must be compressed in order to allow bonding, remove any trapped air between the layers, and squeeze out any excess resin. To do this, the prepreg has been compressed with 2 steel plates. The resin will naturally become thinner as the temperature is raised, and there will be resin flow prior to a full cure of the resin.

Heat and pressure are essential to completely cure the prepreg. While required pressure can be achieved using a press, an autoclave with temperature and pressure controls is ideal. Generally, an oven is needed to manage temperature ramp-up, ramp-down, and maintain uniform temperature throughout the curing process.

All curing cycles start with a temperature ramp-up and conclude with a ramp-down. The variation lies in the target temperature and the duration needed for a complete cure. Temperature is maintained throughout the cycle and then reduced at a rate of less than 5C/min to at least 150C before the part is removed from the oven.

After curing, the part cools at room temperature and is then removed from the mold. If the prepreg is not sturdy or remains sticky, adjustments to curing time or temperature may be necessary.

Figure 1 illustrates the preparation and setup of the sensor and system. Part (a) shows a clear view of the sensor preparation after the stage of compression, detailing the arrangement of cables, thermocouples, graphene resistance, and prepreg layers. Part (b) presents the flow diagram of the system, depicting the sequence from temperature sensing to ice detection and the activation of the graphene resistance for temperature control.

Figure 2 illustrates the synchronized temperature profiles from two sensors, "Temp1" and "Temp2," showing the progression of ice formation and melting over time. Key stages, such as supercooled water formation, latent heat release, and icing development, are annotated to highlight crucial temperature changes that indicate the presence of ice. The heating phase, where applied heat melts the formed ice, is evident in the gradual temperature rise. This collective view of the temperature profiles helps demonstrate the effectiveness of ice detection using dual thermocouples and shows how the system accurately identifies and manages icing events through distinct temperature patterns.

2.2. Experimental Setup

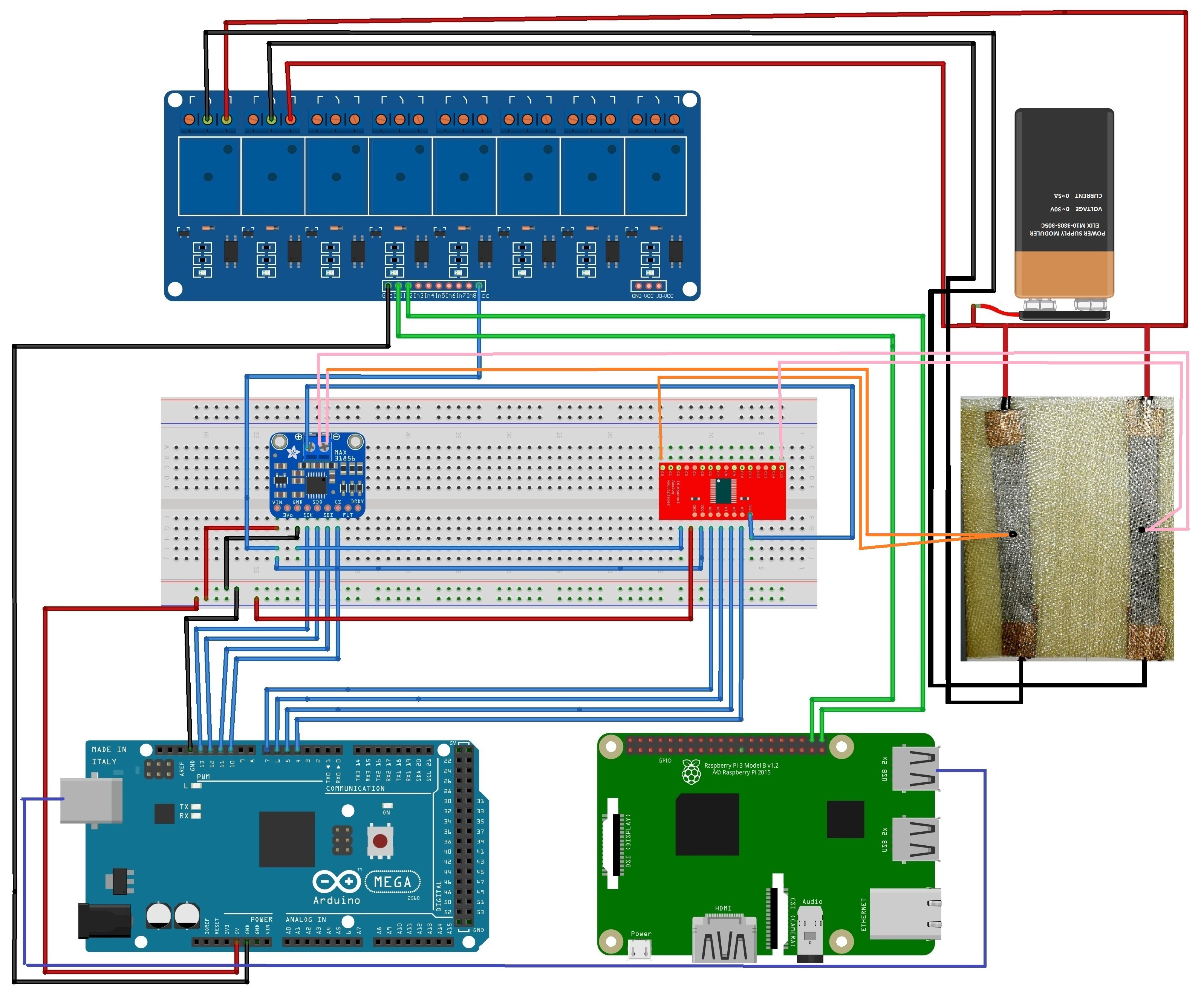

The central objective of this work is the development of a smart ice detection and control device capable of autonomous operation to minimize operator intervention. This system leverages existing technologies while ensuring simplicity, cost-effectiveness, and a streamlined design. Compatibility between Arduino (an open-source electronics platform for building digital devices) and Raspberry Pi (a small single-board computer for various programming tasks) was assessed to identify the optimal configuration for data collection and system management. It was determined that both Arduino uno and Raspberry Pi 3b+ could function complementarily, with Arduino handling data collection (specifically temperature data), while Raspberry Pi manages the system and hosts machine learning models.

Raspberry Pi was selected for its comprehensive computer-like functionality and versatility, including a powerful microprocessor, large memory, and versatile I/O ports, making it ideal for managing the system and implementing predictive ice detection algorithms. Arduino, serving as a microcontroller, acquires temperature data and communicates it to Raspberry Pi via a serial port. The thermocouple amplifier that was used offers optimal sensitivity and a broad temperature range, enabling effective data collection during ice formation studies.

Figure 3.

Schematic of the smart ice detection and control system, illustrating the connections between the Arduino Mega 2560, Raspberry Pi, relays, temperature sensors, and graphene resistance heating element.

Figure 3.

Schematic of the smart ice detection and control system, illustrating the connections between the Arduino Mega 2560, Raspberry Pi, relays, temperature sensors, and graphene resistance heating element.

An eight-channel relay module acts as a switch, activating heating elements during passive de-icing methods. For experiments requiring more than two thermocouples, a CD74HC4067 multiplexer is incorporated to extend data collection capabilities. An Adafruit MAX31856 was used to amplify the signal coming from the sensing area.

The sensing area was composed of Graphene strips GS50-type produced by NANESA SRL (Arezzo, Italy). In fact, graphene is a unique material known as a zero-gap semiconductor because its conduction and valence bands meet at the Dirac points. This property allows it to conduct electrical charges through both electrons and holes, providing ambipolar conduction. In terms of thermal properties, graphene relies on phonons for heat conduction, as with other semiconductors, and achieves the highest thermal conductivity in its single-layer form. Mechanically, graphene is incredibly strong yet lightweight and flexible, making it highly resistant to mechanical stress. Its optical properties include high transparency despite its ability to absorb a fraction of incident light. These electro-thermal properties make graphene an innovative, versatile material suitable for applications requiring excellent conductivity and durability. The electrical and mechanical properties of graphene make it ideal for conducting current in the ice mitigation process. Graphene’s high thermal conductivity enables rapid heating to melt detected ice accumulations. Graphene is embedded between two Prepreg sheets

Section 2.1.

Red and green LEDs provide visual indicators of the system state, while an I2C LCD screen displays operational messages. The final configuration integrates all components within a metallic enclosure for organized port access and visual indicators.

3. Machine Learning for Ice Detection and Control

Machine learning algorithms can effectively detect and control ice formation by leveraging a combination of Python programming tools and neural network architectures. Python, a high-level programming language, offers a rich ecosystem of open-source libraries suitable for scientific computing and data analysis. This versatility enables the development of sophisticated machine-learning models using libraries like NumPy, Pandas, SciPy, and sci-kit-learn. In fact, machine learning (ML) algorithms are broadly classified into supervised, unsupervised, semi-supervised, and reinforcement learning, each with unique applications depending on the nature of the problem being solved. Supervised learning relies on labeled data to train predictive models, while unsupervised learning seeks patterns in unlabeled datasets to identify clusters and relationships. Semi-supervised learning combines elements of both approaches and reinforcement learning enables models to improve through a feedback loop of rewards and penalties.

3.1. Python Programming and Libraries

Python’s high-level, object-oriented programming facilitates concise and efficient code writing, while its extensive modules and packages provide robust tools for data analysis and visualization. Key libraries used in this project include:

SciPy: An open-source library for scientific computing, offering modules for optimization, linear algebra, signal processing, and special functions.

NumPy: A numerical computing library that adds support for multi-dimensional arrays and high-level mathematical functions.

Pandas: A data manipulation library designed for numerical tables and time series.

Matplotlib: A plotting library that integrates with NumPy to provide an API for embedding plots in applications.

scikit-learn: A machine learning library featuring algorithms for classification, regression, clustering, and model evaluation.

A supervised machine learning approach using labeled training data is highly effective for ice detection tasks. Various algorithms such as Logistic Regression, Random Forests, Support Vector Machines (SVMs), and Artificial Neural Networks (ANNs) excel in binary classification and regression tasks, making them suitable for this application. In our research, we will use and compare these methods to determine the most efficient algorithm for predicting ice formation.

Among these, the K-means algorithm, which is an unsupervised clustering method, will be used to group data based on proximity to k randomly selected centroids. It uses distance measurements like Euclidean, Manhattan, Chebyshev, and Minkowski to determine cluster membership.

Logistic Regression, a supervised binary classification model, will be employed to predict discrete outcomes based on independent variables using a probability function. This model is particularly effective in situations where the outcome variable is binary, such as detecting the presence or absence of ice.

Decision Trees, which are hierarchical models used for classification and regression tasks, will be used to organize decision rules into nodes and split data based on criteria such as information gain and Gini index, creating a tree-like structure that is easy to interpret.

Random Forests, an ensemble learning method, will enhance the performance of decision trees by building multiple trees and averaging their predictions. This approach reduces overfitting and improves accuracy.

Support Vector Machines (SVMs), which excel in classification and regression problems by maximizing the geometric margins between classes, will be used for their effectiveness in high-dimensional spaces.

Artificial Neural Networks (ANNs), inspired by biological neurons, will be used for their capability to learn data patterns through interconnected layers. These networks, consisting of input, hidden, and output layers, can be adapted for various tasks, including classification, regression, and clustering.

Advanced neural network architectures will further extend the capabilities of ANNs to tackle more complex tasks. Convolutional Neural Networks (CNNs) will process multi-dimensional input through convolutional, pooling, and fully connected layers, making them highly effective for image classification and object detection. Recurrent Neural Networks (RNNs), which maintain hidden states through time, will be useful for processing sequential data. Long Short-Term Memory (LSTM), an advanced form of RNN, will incorporate memory cells to learn long-term dependencies, enhancing its ability to model temporal sequences.

In conclusion, our study will employ and compare these machine learning algorithms to determine the most effective approach for detecting and controlling ice formation, ensuring aircraft safety and operational efficiency.

3.2. Data Collection and Ice Detection Using Machine Learning Algorithms

This section presents the application of machine learning algorithms to detect ice formation based on the experimental data collected. The study focuses on supervised and unsupervised learning approaches to analyze data from both active and passive methods. The collected data, formatted in comma-separated files and graphical images, undergo machine learning processing.

The data was collected according to the experimental setups detailed in

Section 2.2. In the method used, real-time temperature measurements were taken to observe graphical patterns indicative of ice formation, such as the notch-type peak points visible, as well as a camera positioned for validation. "No ice" and "ice" presence were recorded and labeled with "0" = noIce, "1"=Ice.

Table 1 contains a sample of the data collected through the data collection.

The dataset was processed to be ready for the machine learning algorithms and other ice detection algorithms. The first processing technique applied is the conversion of the time string to double. Missing data or anomaly data that are observed are removed from the data set programmatically.

The data set is transformed by combining every five consecutive temperature data points into a single point. The modal class for the five data points is considered the target class for the combined point.

The ice detection algorithm is evaluated using data collected during ice formation experiments and in real-time scenarios. For collected data, the algorithms are assessed in the Jupyter Notebook environment on a Windows operating system. The evaluation employs machine learning techniques with 5-fold cross-validation, which involves dividing the dataset into training and testing subsets. The dataset is split into a 1:5 ratio for testing and training. Here are key terms used in performance evaluation:

True Positive (TP): The relevant class correctly detected by the model (ice formation).

True Negative (TN): The irrelevant class correctly identified (non-ice formation).

False Positive (FP): The irrelevant class mistakenly detected as relevant.

False Negative (FN): The relevant class mistakenly detected as irrelevant.

3.3. Metrics

We introduce some useful definitions based on the key terms for performance evaluation:

Precision: Measures the portion of correctly detected relevant data points out of all detected relevant points.

Recall: Measures the correctly detected relevant data points among all existing relevant points.

F1 Score: Balances precision and recall.

Accuracy: Indicates the proportion of correctly detected relevant and irrelevant data points among all data.

Table 1.

Sample data collected using the passive method.

Table 1.

Sample data collected using the passive method.

| s/n |

Time |

T (°C) |

T (°C) |

| 1 |

18:42:55.632 |

6.732 |

6.760 |

| 2 |

18:42:55.797 |

6.621 |

6.683 |

| 3 |

18:42:56.009 |

6.348 |

6.487 |

| 4 |

18:42:56.216 |

6.041 |

6.213 |

| 5 |

18:42:56.430 |

5.704 |

5.830 |

| 6 |

18:42:56.590 |

5.406 |

5.545 |

| 7 |

18:42:56.798 |

5.028 |

5.214 |

| 8 |

18:42:57.007 |

4.686 |

4.852 |

| 9 |

18:42:57.213 |

4.363 |

4.529 |

| 10 |

18:42:57.420 |

4.040 |

4.239 |

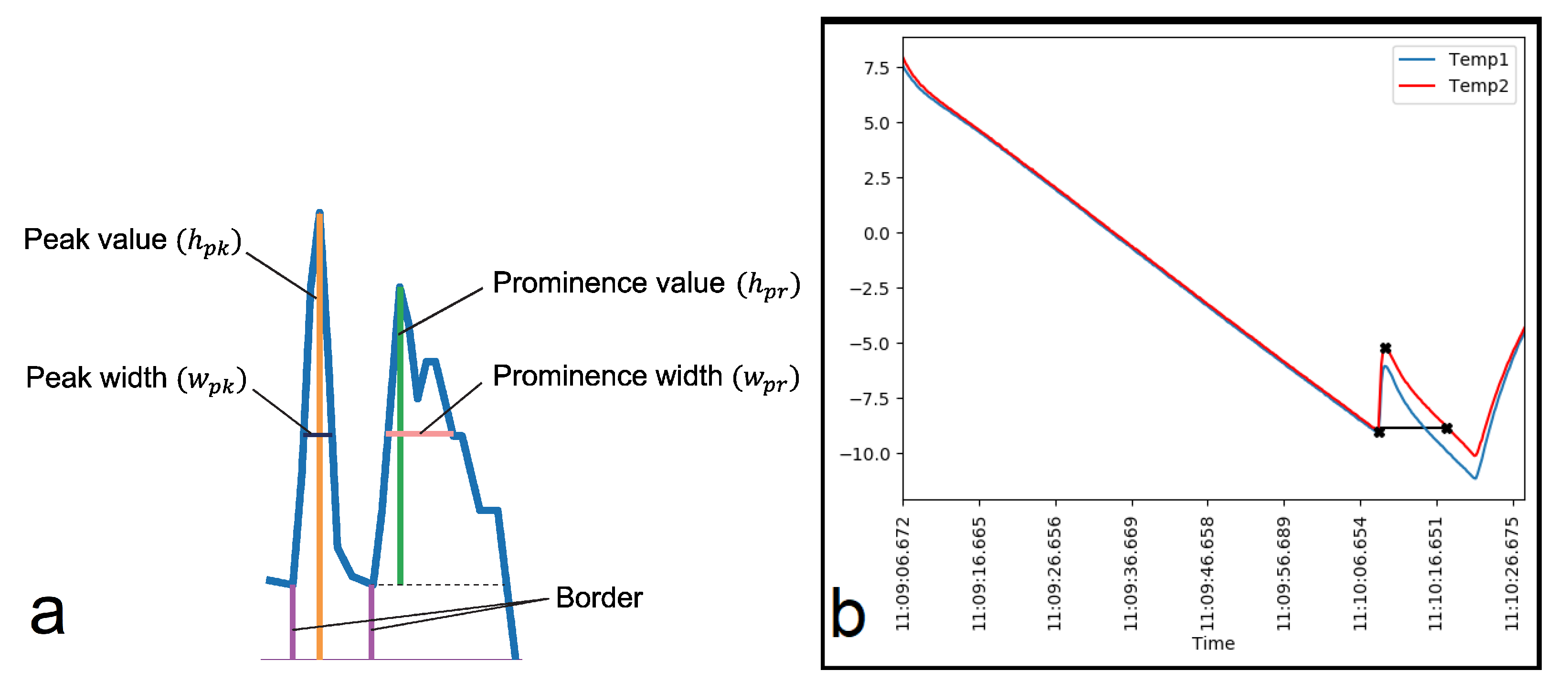

3.4. Peak Identification for Ice Detection

Ice detection relies on peak identification in the method used. Peak characteristics like maximum and minimum heights, widths, and prominence are considered to minimize false positives.

Figure 4 defines peak properties, while

Table 2 summarizes the values obtained.

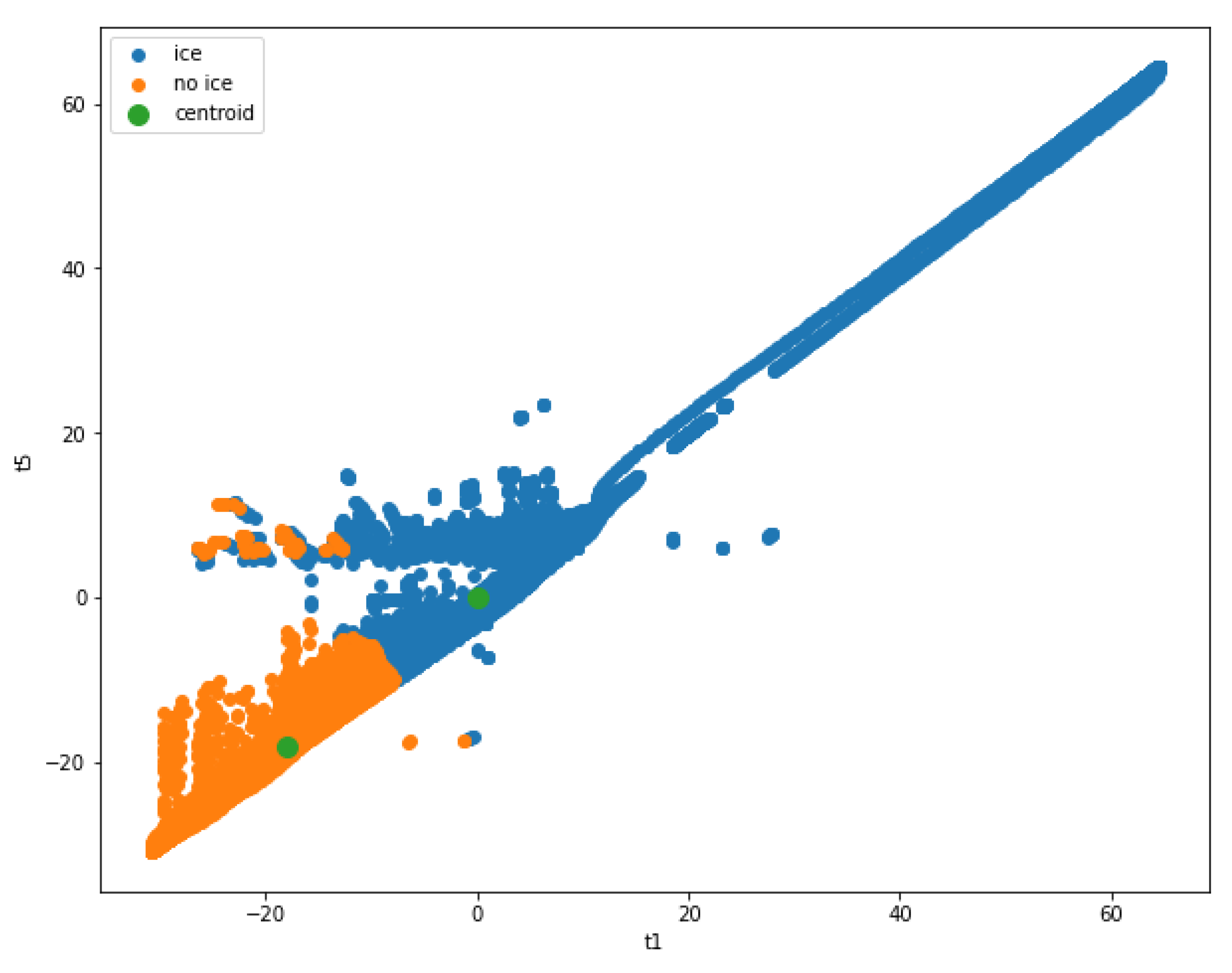

3.5. Unsupervised Learning Approach

Unsupervised learning aims to identify ice detection patterns based on clustering. The K-means algorithm is used, where the k value is set to 2, representing two clusters: one for ice and one for no-ice. Each cluster has a centroid, which is the central point of the data points within that cluster. The algorithm classifies the data into ice and no-ice clusters by computing the Euclidean distance between each data point and the centroids. The Euclidean distance

between a data point

t and a centroid

c is calculated using the following equation:

In this equation, represents the individual data points, and represents the coordinates of the centroid. The distance helps determine the proximity of each data point to the centroids. Based on this distance, each data point is assigned to the nearest centroid, thereby classifying it into either the ice or no-ice cluster.

Table 3 provides a sample of the fitted data used for clustering, and

Figure 5 visualizes the k-means classification, showing how data points are grouped based on their proximity to the centroids.

3.6. Supervised Learning Approach

The supervised learning approach involves labeling data points to identify those resulting in ice formation. The algorithms used include k-nearest neighbors (KNN), logistic regression, random forests, support vector machines (SVMs), and multilayer perceptrons.

Logistic regression models classify data based on probabilistic thresholds.

Table 4 shows the logistic parameters obtained, and Equation

6 defines the logistic function.

4. Results

This section outlines the experimental and non-experimental results collected during the project. Experimental results obtained from ice formation experiments discussed above, include graphs and values. Non-experimental results consist of the performance evaluation of ice detection models developed in Python using the Jupyter Notebook environment.

Figure 5 shows the results obtained from the k means algorithm. The first temperature is plotted against the last temperature, and the centroid computed by the k means algorithm is used to classify the data points. The plot shows that the data points indicating ice detection are well separated from the data points indicating no ice detection. However, there are false detection points indicated by the colors overlapping on each other.

Figure 5.

Ice detection using k-mean algorithm

Figure 5.

Ice detection using k-mean algorithm

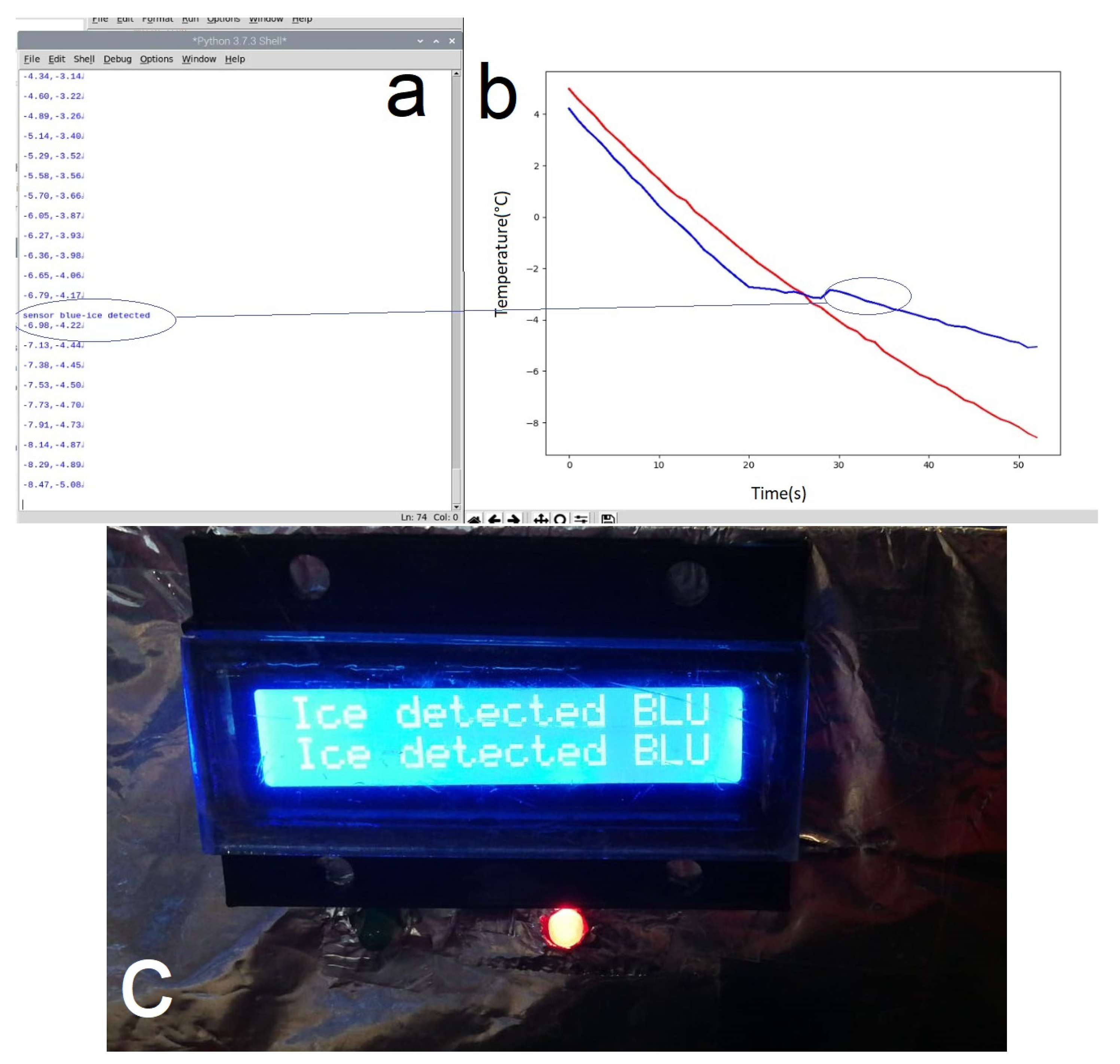

When the system detects the presence of ice, the program gives a message indicating which thermocouple is affected by ice and the corresponding temperature measured. This is illustrated in

Figure 6. Part (a) shows the Python output with the detected ice event. Part (b) presents the temperature profile graph with the red and blue lines representing the two different thermocouples, highlighting the ice detection point circled in the graph. Part (c) displays the LCD screen showing the ice detection message and the blue LED indicator turned on.

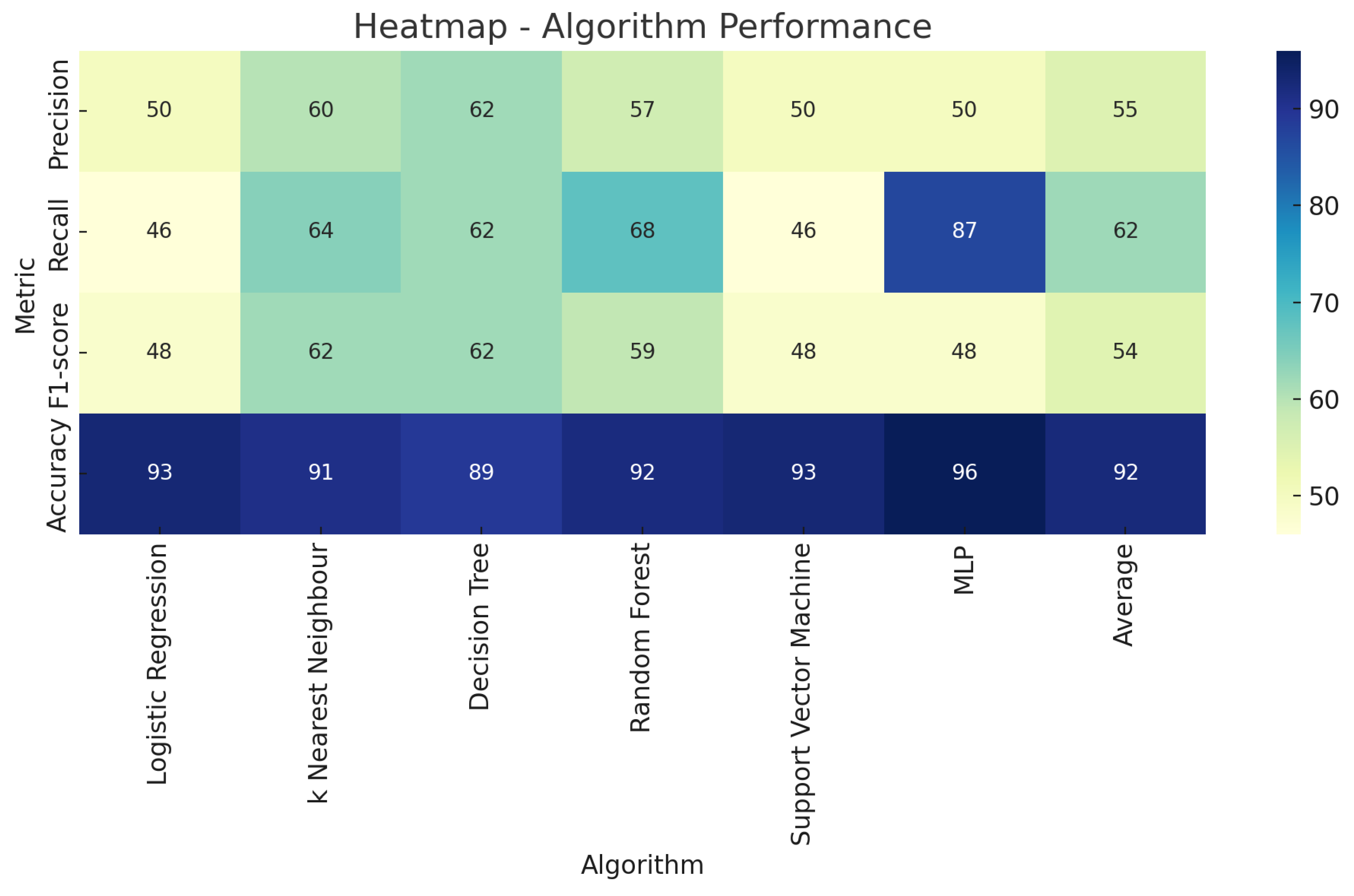

4.1. Performance Evaluation of Ice Detection Algorithm

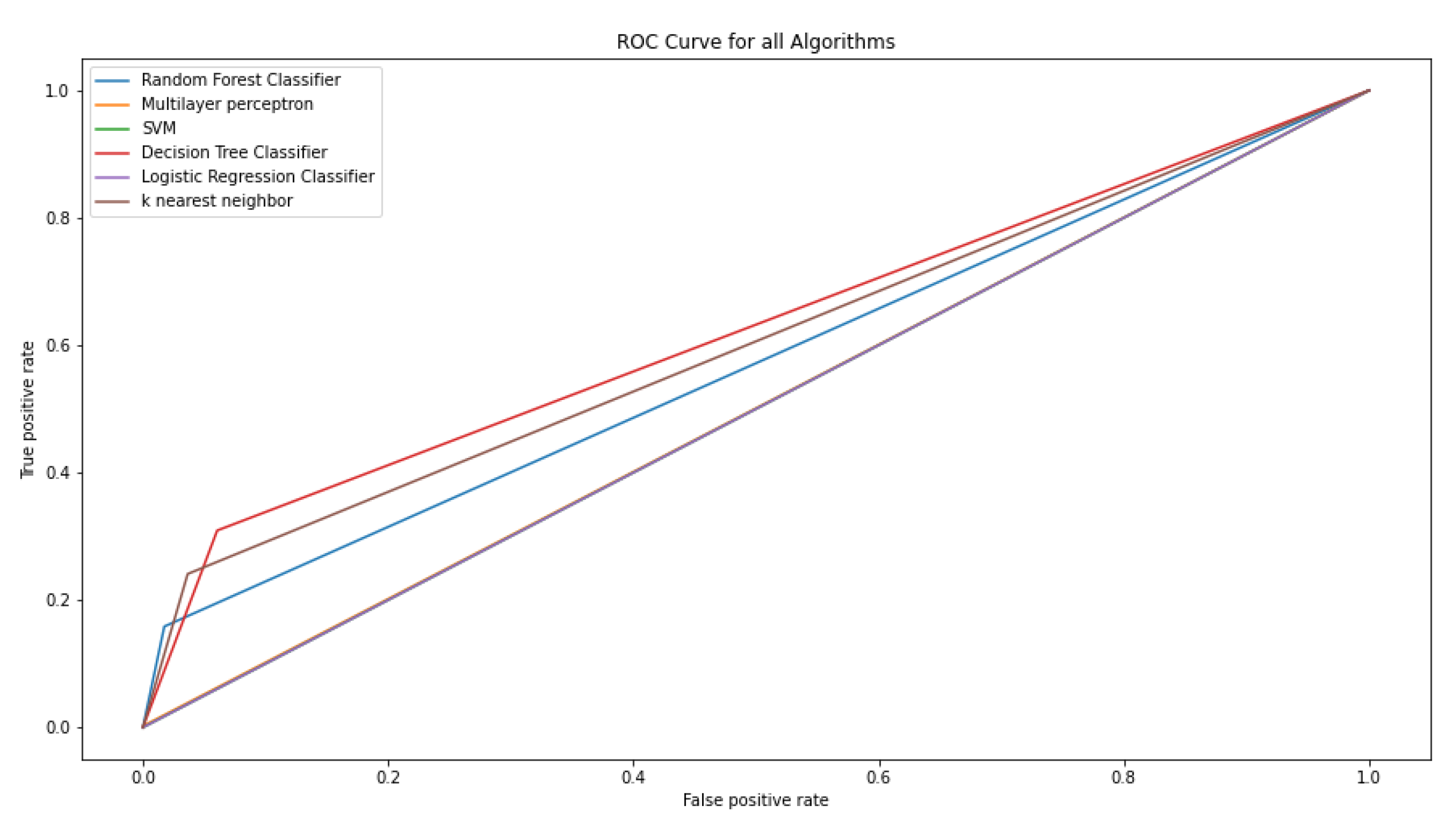

Figure 7 shows the heatmap representing the performance metric, which includes precision, recall, f1 score, and accuracy obtained from each of the classifiers. From the map, it is possible to see that the Multi-layer perceptron has the highest accuracy. However, it is necessary to focus on the detection of the relevant class which is given by precision and recall. Therefore, in order to find a balance between precision and recall, the focus is set on the f1 score. The k nearest neighbor and decision tree algorithm has the highest f1 score. Thus, the algorithms that are effective in detecting ice are the k nearest neighbor (KNN) and the decision tree algorithm. The Receiver Operating Characteristic (ROC) curve, which is a graphical plot illustrating the diagnostic ability of a binary classifier system as its discrimination threshold is varied, is shown for all classifier models in

Figure 8.

5. Discussion

The results of this project demonstrate the feasibility and effectiveness of using machine learning algorithms to develop a smart system for detecting and controlling ice formation on aircraft surfaces. Several key findings emerged from the experimental evaluation of the passive and active detection methods, which were tested using supervised and unsupervised learning models.

The unsupervised k-means clustering algorithm was able to distinguish between ice and no-ice conditions, but some false positives were noted due to overlapping clusters. This indicates that while k-means can provide a general classification, the precision could be improved by refining the clustering criteria or supplementing it with additional features.

Supervised learning algorithms, particularly k-nearest neighbors (k-NN) and decision trees showed the highest precision, achieving up to 62% accuracy in predicting ice formation. Labeling of training data provided better-defined patterns, resulting in more accurate predictions. However, further improvements could involve tuning hyperparameters and increasing the volume of labeled training data.

The integration of Raspberry Pi and Arduino platforms with machine learning algorithms proved advantageous due to their low cost and flexibility. The inclusion of indicator LEDs and an I2C LCD provided valuable real-time feedback to visually confirm the predictions. Despite this success, challenges were noted in managing the active heating process and maintaining consistent temperature measurements across different environmental conditions.

Overall, the results indicate that machine learning models can effectively predict ice formation patterns, and combining these models with a robust hardware platform like Raspberry Pi allows for cost-effective ice detection and control. However, further research should explore additional detection methods, refine the training datasets, and develop enhanced user interfaces to increase system precision and adaptability.

6. Conclusion

The project began with the identification of goals and deliverables. The primary objective was to develop a low-cost, smart system capable of predicting and mitigating ice formation by heating a resistance. This involved utilizing machine learning techniques and artificial neural networks. The work was conducted in three phases: research, implementation, and integration. In the research phase, various single-board computers were evaluated for their specifications, pricing, and suitability for the system. Interface boards, multiplexers, and alternatives to Arduino were also explored. During the phase of implementation, sensors, single-board computers, and Python code were implemented and evaluated. Various challenges were encountered and resolved, such as determining suitable heating elements and active detection systems. Ultimately, relay boards were chosen over MOSFETs due to their higher current support and safety. In the integration phase, the smart device was designed using background research on machine learning, neural networks, and data science. Block diagrams were created to depict the complete system architecture and the interconnection of components. Techniques for peak identification, machine learning, and neural networks were carefully analyzed for implementation details. The most challenging task was building the physical device and developing all required algorithms. Interfacing the Raspberry Pi with the Arduino Mega and other components required special attention. Some hardware components had existing libraries, but custom code based on datasheets was also implemented. Due to architecture differences with 64-bit notebooks, the primary code development was done on the Raspberry Pi.

Two separate datasets, one for each detection method, were created to ensure accurate model training. Various machine learning algorithms, including k-nearest neighbors and decision trees, were developed and evaluated.

The evaluation phase involved training models and validating their accuracy. The smart system was tested by visually confirming the physical formation of ice on the prepreg and comparing this to predictions displayed on the Raspberry Pi. Additional features, such as an I2C LCD screen and indicator LEDs, were added to provide real-time feedback.

Overall, the project was successful in developing an efficient, low-cost smart device for ice detection and control using Raspberry Pi and Arduino platforms. Among the tested models, k-nearest neighbors and decision trees achieved the highest accuracy, with 60% and 62% precision, respectively.

While the smart system proved effective, there is still significant potential for future improvements. Implementing a graphene network for localized ice detection and expanding the dataset for more accurate machine-learning model training are key areas for development. Additionally, enhancing the user interface and exploring alternative detection methods could further refine the system’s precision and adaptability.

7. Patents

International patent n WO2022162068A1/ EP4036565A1

Author Contributions

Conceptualization, C.S.I., P.D.D, and D.F.; methodology, C.S.I., P.D.D, and D.F.; software, P.Q. and D.F.; validation, H.M., C.S.I. and D.F., P.D.D.; formal analysis, D.F.; investigation, D.F., P.D.D; resources, D.F.; data curation, D.F.; writing—original draft preparation, D.F., and H.M.; writing—review and editing, D.F., C.S.I and H.M.; visualization, D.F., H.M., and P.Q.; supervision, C.S.I.; project administration, C.S.I.; funding acquisition, C.S.I. All authors have read and agreed to the published version of the manuscript.

Funding

This study was conducted within the scope of the Graphene Flagship Spearhead project GICE: Graphene-Based Heater Mat for Electrothermal Ice Protection System. The Graphene Flagship represents a Future and Emerging Technology research endeavor supported by the European Commission.

Data Availability Statement

All system protocols are publicly accessible and can be found at the Université Libre de Bruxelles.

Acknowledgments

This investigation followed preliminary feasibility analyses and the development of novel technology. We would like to extend our gratitude to Patrick Hendrick, director of the ATM, for his constant support. We also thank the entire team of the ATM, including Olivier Berten and Bilal Outirba, for their invaluable help throughout the entire process of testing the smart device inside the wind tunnel.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| ATM |

Aero-Thermo-Mechanics |

| ULB |

Université Libre de Bruxelles |

| CREST |

Centre for Research and Engineering in Space Technologies |

| GOPS |

(3-glycidyloxypropyl)trimethoxysilane |

| PEDOT |

Poly(3,4-ethylenedioxythiophene) |

| PSS |

Poly(styrenesulfonate) |

| PVDF |

Polyvinylidene fluoride or polyvinylidene difluoride |

| LMS |

Least Mean Squares |

| MEMS |

micro electro-mechanical systems |

| AI |

Artificial Intelligence |

| ANN |

Artificial Neural Network |

| CPU |

Central Processing Unit |

| DR |

Decision Tree |

| GPIO |

General Purpose Input/Output |

| GPU |

Graphics Processing Unit |

| GUI |

Graphical User Interface |

| IDE |

Integrated Development Environment |

| IDLE |

Integrated Development and Learning Environment |

| I2C |

Inter-Integrated Circuit |

| KNN |

K-nearest Neighbors |

| LR |

Logistic Regression |

| ML |

Machine Learning |

| NN |

Neural Network |

| OS |

Operating System |

| PID |

Process Identifier |

| PWM |

Pulse Width Modulation |

| SBC |

Single-Board Computer |

| SPI |

Serial Peripheral Interface |

| SVM |

Support Vector Machine |

References

- Thomas, S. K., Cassoni, R. P., & MacArthur, C. D. (1996). Aircraft anti-icing and de-icing techniques and modeling. Journal of Aircraft, 33(5), 841-854. [CrossRef]

- Oleskiw, M. M. (2001). A review of 65 years of aircraft in-flight icing research at NRC. Canadian Aeronautics and Space Journal, 47(3), 259-268 . Retrieved from https://www.researchgate.net/publication/44057561_A_Review_of_65

_Years_of_Aircraft_In-Flight_Icing_Research_at_NRC?enrichId=rgreq-6d26a23f3d0ebb54b837ce6448d588a5-XXX&enrichSource=Y292ZXJQYWdlOzQ0MDU3NTYxO0FTOjExNzc3ODQ1OTY2NDM4NUAxNDA1MD-

kxOTgxNjc0&el=1_x_2&_esc=publicationCoverPdf.

- Goraj, Z. (2004). An overview of the deicing and anti-icing technologies with prospects for the future. In 24th International Congress of the Aeronautical Sciences, Yokohama, Japan. Retrieved from https://citeseerx.ist.psu.edu/document?repid=rep1&type=pdf&doi=c3071c51eccd93d0e9e584f3aca23acf0be9d0c0.

- Smith, J., Johnson, A., & Lee, P. Advanced Pneumatic De-icing Systems. Journal of Aerospace Engineering 2020, 34, 456–470. [Google Scholar]

- Johnson, T. Efficiency of Electro-Thermal De-icing Elements. Proceedings of the International Conference on Aviation Safety 2019, 12, 123–136. [Google Scholar]

- Miller, R., & Davis, S. Performance of Fluid-Based De-icing Systems in Adverse Conditions. Aircraft Design Journal 2018, 27, 195–210. [Google Scholar]

- Nguyen, L., Roberts, J., & Sanchez, E. Hybrid Ice Protection Systems: Combining Electro-Thermal and Fluid-Based Techniques. International Journal of Aerospace Science 2021, 45, 98–112. [Google Scholar]

- Dongo, P.D. (Microgravity Research Centre, Université libre de Bruxelles, Campus Solbosch, CP165/62, Avenue P.Héger, 1050 Brussels, Belgium); Machrafi, H. (Thermodynamics of Irreversible Phenomena, Université de Liège, Allée du 6-Août, 19, 4000, Belgium); Minetti, C.; Amato, A.; Queeckers, P.; Iorio, C.S. A heat-pulse method for detecting ice formation on surfaces. Received 3 August 2020, Revised 12 December 2020, Accepted 12 December 2020, Available online 17 December 2020, Version of Record 12 January 2021.

- Farina, D. (University, City, State, Country); Mazio, M. (University, City, State, Country); Machrafi, H. (University, City, State, Country); Queeckers, P. (University, City, State, Country); Iorio, C.S. (University, City, State, Country). Environmental Chamber Characterization of an Ice Detection Sensor for Aviation Using Graphene and PEDOT:PSS. Micromachines 2024, 15, 504. [Google Scholar] [CrossRef] [PubMed]

- Farina, D. (University, City, State, Country); Mazio, M. (University, City, State, Country); Machrafi, H. (University, City, State, Country); Queeckers, P. (University, City, State, Country); Iorio, C.S. (University, City, State, Country). Wind Tunnel Characterization of a Graphene-Enhanced PEDOT:PSS Sensing Element for Aircraft Ice Detection Systems. Micromachines 2024, 15, 198. [Google Scholar] [CrossRef] [PubMed]

- Das, K., and Behera, R. N. A survey on machine learning: concept, algorithms and applications. International Journal of Innovative Research in Computer and Communication Engineering 2017, 5, 1301–1309. [Google Scholar]

- Mahesh, B. Machine learning algorithms-a review. International Journal of Science and Research (IJSR) 2020, 9, 381–386. [Google Scholar]

- Pandey, D., Niwaria, K., and Chourasia, B. (2019). Machine learning algorithms: A review. Machine Learning, 6(02).

- Riehm, M., Gustavsson, T., & Bogren, J. (2009). Innovative sensor systems for detection of ice formation and freezing point temperature measurements.

- Politovich, M.K. (American Meteorological Society, City, State, Country). Aircraft Icing Caused by Large Supercooled Droplets. Journal of Applied Meteorology (1988-2005) 1989, 28, 856–868. Available online: http://www.jstor.org/stable/26185238 (accessed on 20 May 2024). [CrossRef]

- Trenberth, K.E. (2011). Attribution of climate variations and trends to human influences and natural variability. WIREs Climate Change, 2(6).

- Dershowitz, A., & Hansman, R.J. (1991). A passive infrared ice detection technique for helicopter applications.

- Das, K., & Behera, R.N. (2017). A survey on machine learning: concept, algorithms and applications. International Journal of Innovative Research in Computer and Communication Engineering, 5(2).

- Dey, A. (2016). Machine learning algorithms: A review. International Journal of Computer Science and Information Technologies, 7(3).

- Reddy, Y.C.A.P., Viswanath, P., & Reddy, B.E. Semi-supervised learning: a brief review. International Journal of Engineering and Technology 2018, 7, 81–85. [Google Scholar]

- Ranaudo, R.J., Mikkelsen, K.L., McKnight, R.C., & Perkins, P.J. Jr. (1984). Performance degradation on a typical twin engine commuter type aircraft in measured natural icing conditions. 22nd Aerospace Sci. Meeting, Reno.

- Staudemeyer, R.C., & Morris, E.R. (2019). Understanding LSTM: a tutorial into Long Short-Term Memory Recurrent Neural Networks.

- Grantz. Heavy ice accumulation on aircraft surfaces. Retrieved from http://training.deicinginnovations.com/?attachment_id=1579.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).