1. Introduction

Numerous techniques have been developed for the densification of metal and ceramic powders and the controlled development of their microstructure. Among these methods that involve pressure and temperature for powder sintering are Hot Pressing (HP), Hot Isostatic Pressing (HIP), and Spark Plasma Sintering (SPS) [

1,

2]. SPS offers distinct advantages by incorporating electric current during sintering, leading to high heating rates due to Joule heating of the conductive dies [

3]. The interest in SPS as a preferred powder synthesis method has grown, attributed to its rapid heating rates (hundreds of °C min

-1), lower sintering temperatures, shorter dwell times, capability to fabricate nanostructured bulk materials, and the control it provides over processing parameters, influencing grain growth and stoichiometry [

4,

5].

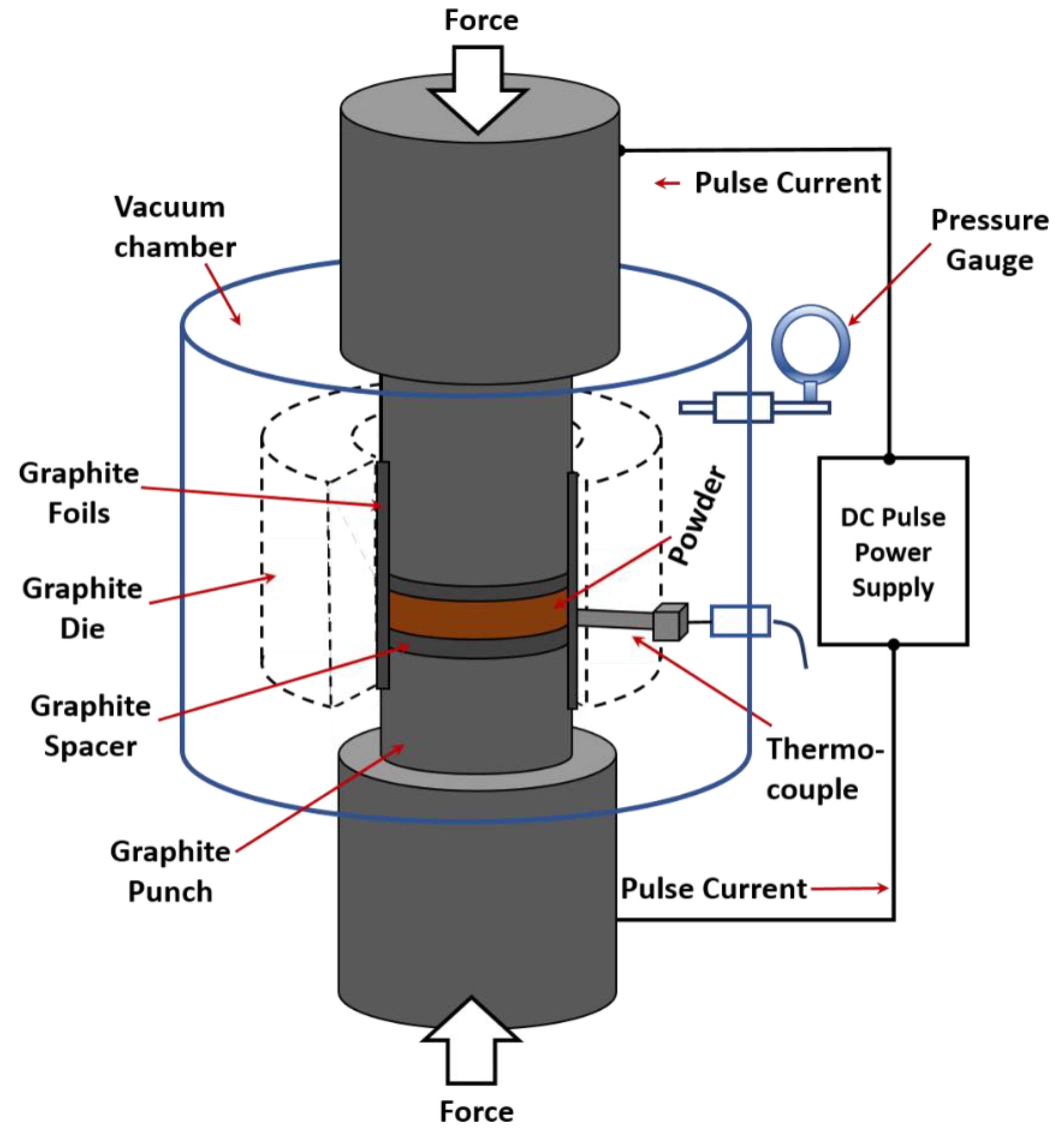

A schematic illustrating a typical SPS apparatus is presented in

Figure 1. Key controls in the process include (a) dc current, (b) heating rate, (c) temperature, and (d) applied pressure [

3,

4,

6]. Throughout an SPS sintering cycle, Joule heating from the dc current simultaneously raises the temperature of the powder and die, ensuring a swift temperature increase to the required sintering temperature [

7]. This effectively limits grain growth by internally generating heat [

1], in contrast to conventional methods relying on external heating by conduction and/or radiation [

8]. Mechanical pressure is applied to remove pores, further enhancing the densification process [

1,

4]. Despite the numerous advantages of SPS, some researchers have reported issues such as non-uniform densities and microstructures [9-11]. Density variations, with the core exhibiting higher density than the outer regions, have been observed [

12]. Additionally, the microstructure obtained through SPS has been likened to that of HP, characterized by typically round-shaped grains [

12]. These reported challenges are often linked to the characteristics of the mould/dies used during synthesis, which impose limitations on plastic deformation [

1,

12].

Spark Plasma Texturing (SPT) is a variation of SPS, introducing the concept of edge-free sintering wherein the sample undergoes unrestricted deformation during the pressure stage [

1,

12]. The objective of SPT extends beyond mere densification, aiming to achieve a specific texture or alignment of grains within the material [

13]. Essentially, SPT represents a two-stage SPS process, with modifications to the sintering parameters and die configurations utilized in each stage [

1]. In the initial phase of SPT, the sample undergoes pre-sintering within a smaller die, employing only half of the necessary temperature and pressure required for bulk synthesis. This pre-sintering step results in a sample with sufficient mechanical strength. Subsequently, the pre-sintered sample is transferred into a larger-diameter die for the second stage, facilitating edge-free deformation during the subsequent synthesis to the required temperature and pressure. The utilization of a larger die in the second stage of SPS serves multiple purposes, including the elimination of die-wall interaction [

12], removal of residual pores, and the promotion of grain refinement and deformation [

1,

13,

14].

SPT has never been employed in the sintering of metallic powder albeit a few reported studies exist for ceramics. This work explores for the first time the sintering of Al7075 aerospace alloy by SPT and compares the evolving microstructure and mechanical properties to conventional SPS sintered Al7075. It is noteworthy that spark plasma texturing is not hot deformation which has been previously explored on recycled material by SPS.

2. Experimental Procedure

2.1. Materials and Process Methods

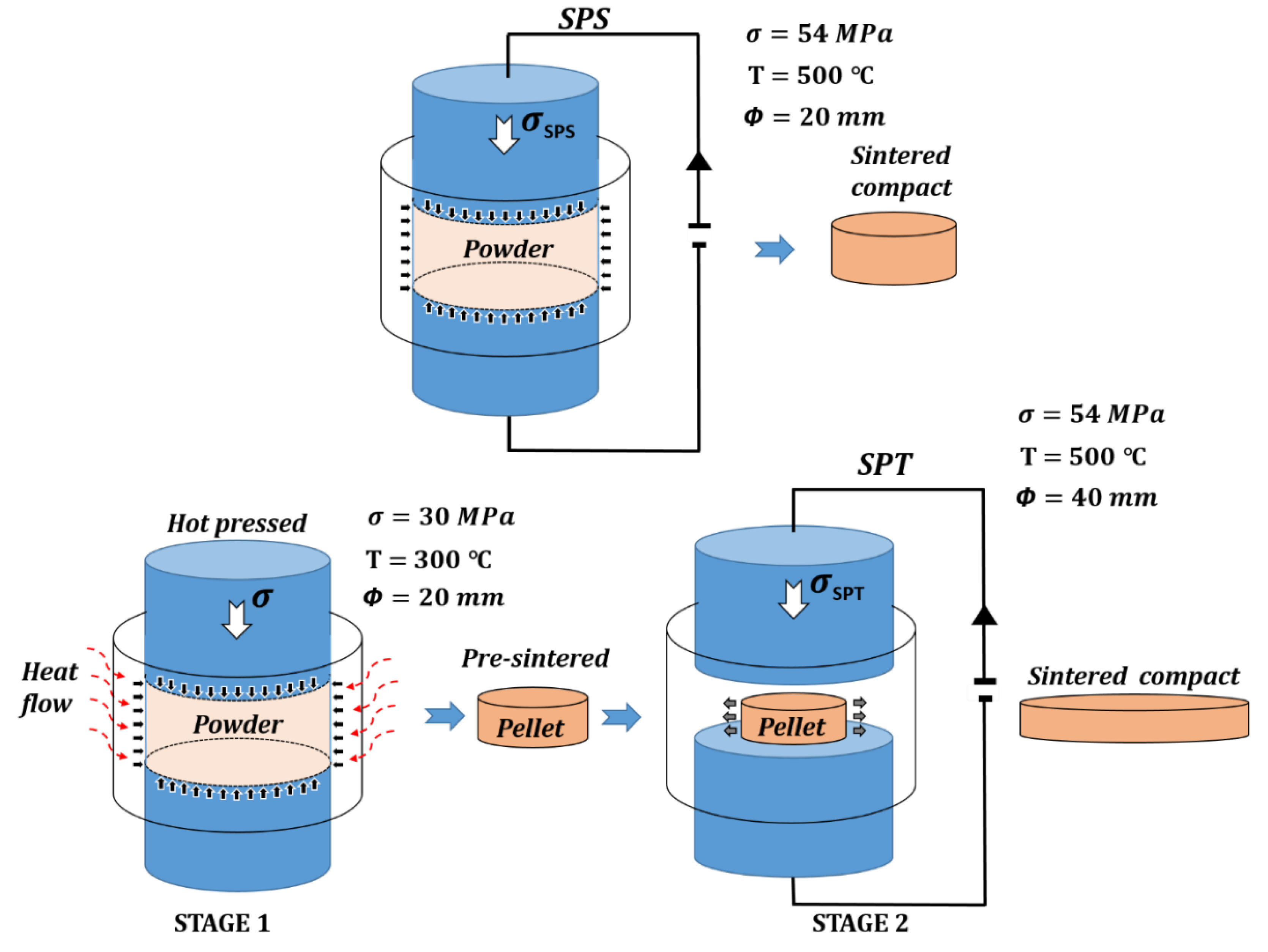

Commercially available Al7075 powder (Alfa Aesar, -40+325 mesh, 99.8%) was synthesized by powder metallurgy SPS and SPT (HP D25 Furnace; FCT Systeme GmbH, Germany) methods. Details of the SPS and SPT sintering techniques and parameters are shown schematically in

Figure 2. For SPS, the Al7075 powder were synthesized using a 20 mm graphite die, pressure 54 MPa (16 kN) and temperature 500 °C. For SPT, a two-stage sintering with intermediate sintering parameter and a second stage larger-diameter mould was employed. In the first stage, a hot press was employed with sintering pressure 30 MPa and temperature 300 °C in a 20 mm graphite mould. For the second stage, the hot pressed pre-sintered compact in stage one was then transferred into a 40 mm graphite die and sintered to requisite sintering temperature of 500 °C using a pressure of 54 MPa using SPS. It is noteworthy that the hot press was employed in the first stage as the SPS default temperature that can be picked up by a pyrometer is 400 °C, which is too close to the requisite sintering temperature 500 °C. The large-diameter configuration in the second stage is referred to as edge-free SPT.

Phase analysis of the sintered compacts was performed with a Bruker D2 Phaser X-ray diffractometer using CuKα radiation. XRD data were collected over the range with a step size of 0.02°. The Archimedes method was employed to measure the bulk density of the samples using distilled water as the immersing medium. The mechanical properties (hardness and reduced elastic modulus) were evaluated by nanoindentation (Nano Test Vantage, Micro Materials, UK) at room temperature in the load control mode, using a Berkovich pyramidal diamond tip at a strain rate of 1mm/s and 500 mN. Vickers macrohardness test was further undertaken using Vickers-Armstrong hardness testing system. Surface morphology of the indented bulk sample was extracted directly using an optical profiler (Contour Elite X, Bruker) equipped with vision 64® analysis software. Microstructural and morphological characterization of the sintered samples polished surface were undertaken using optical microscopy (Leica Microsystems CMS, GmbH). Samples were etched in a 5wt.% NaOH solution at 80 C for a minute, followed by a thorough rinse in deionized water. Subsequently, then were immersed in a 70 vol.% HNO3 solution for 30 seconds and again rinsed in deionized water.

3. Results

3.1. Temperature-Time-Pressure-Punch Displacement Curve

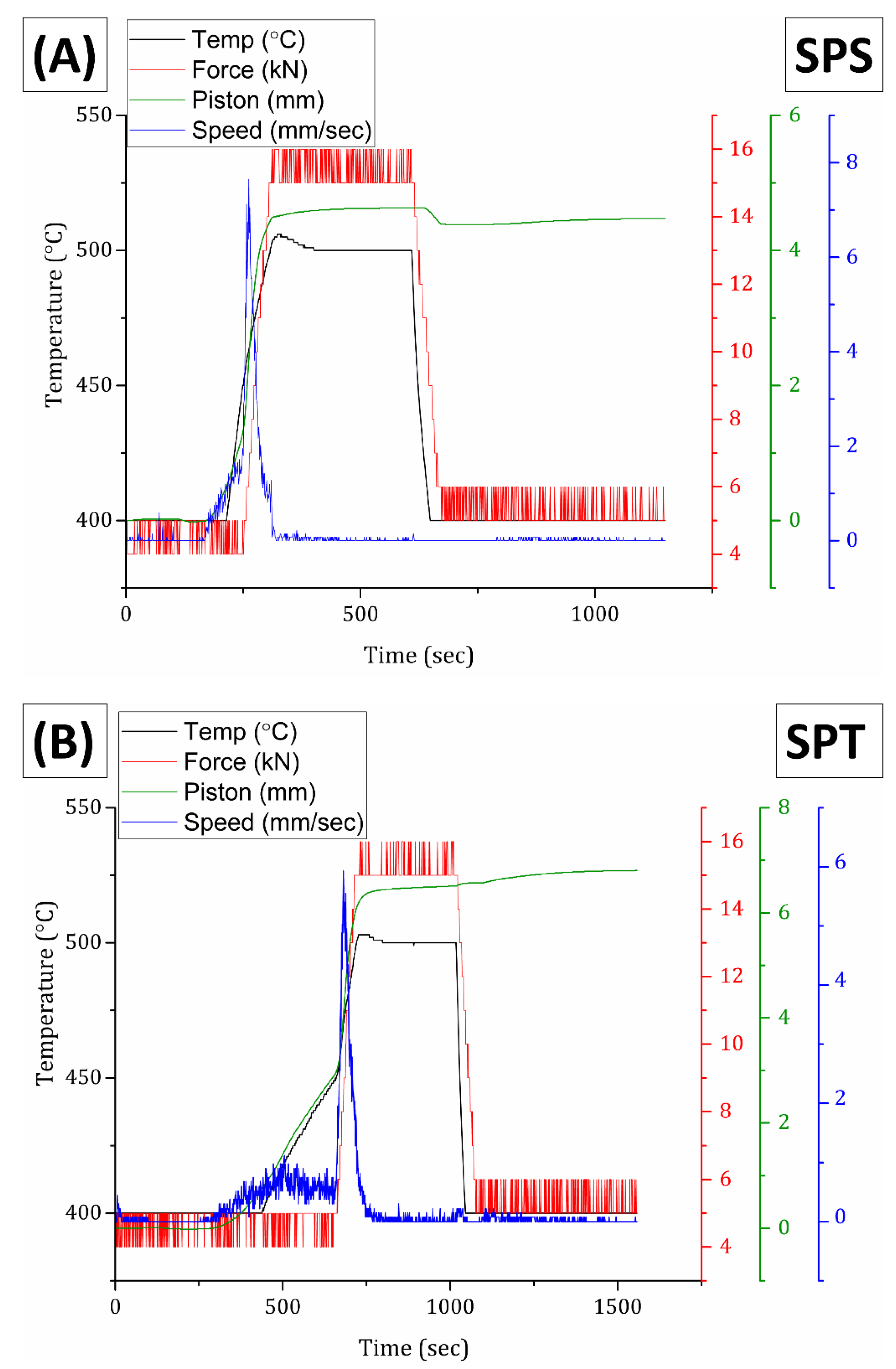

The sintering profile recorded for the samples during SPS and SPT synthesis is shown in

Figure 3. It is noteworthy that punch displacement also known as piston movement is recorded as the difference between shrinkage and thermal expansion during synthesis. Comparing the sintering profiles, for SPS the total piston movement was ~ 4.6 mm, sintering speed ~ 8 mm/s, and sintering time ~ 1000 s. Whilst for SPT, the total piston movement was ~ 7 mm, sintering speed ~ 6 mm/s, and sintering time ~ 1500 s.

3.2. Powder Morphology and Optical Images of the Sintered Compacts

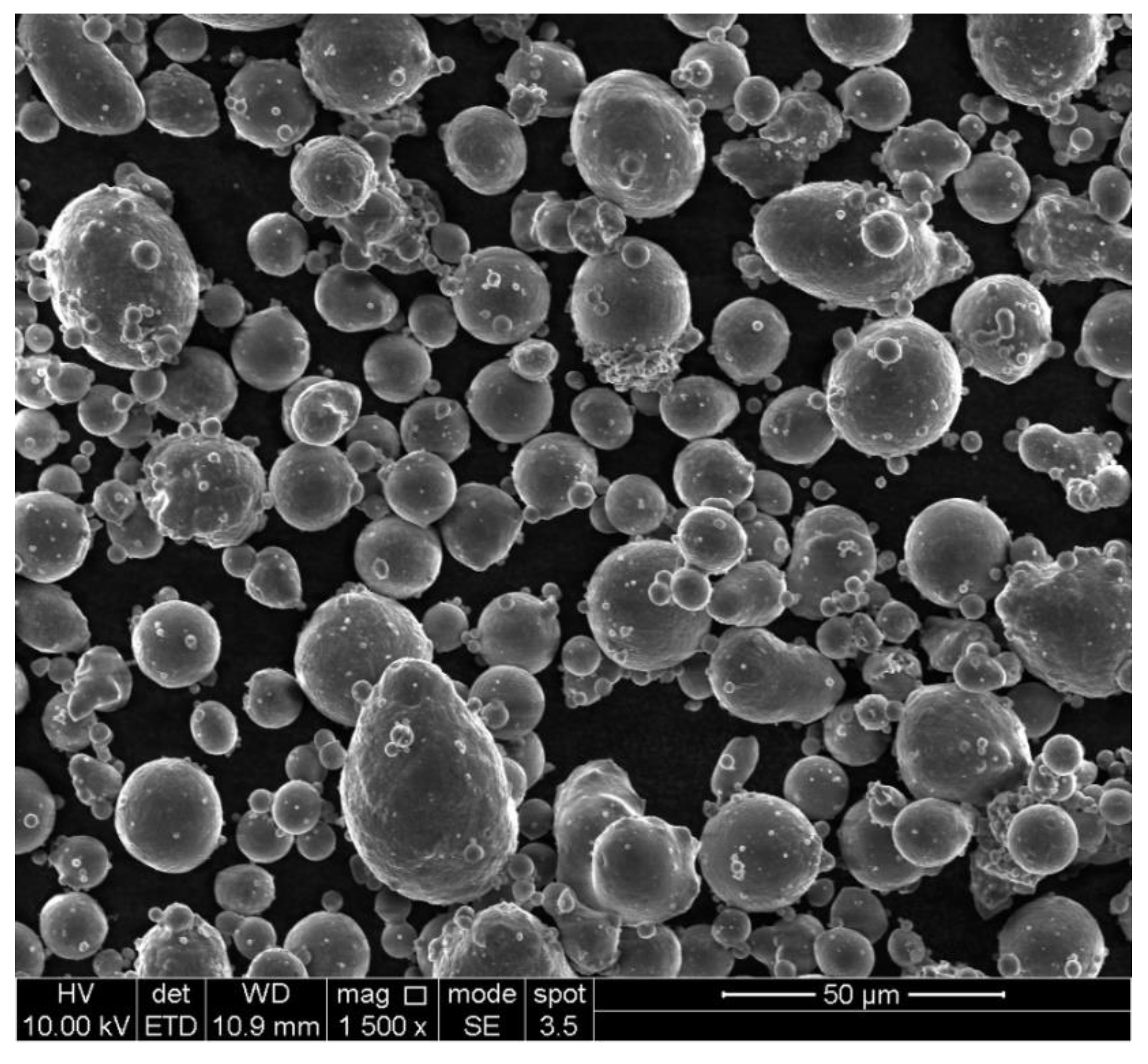

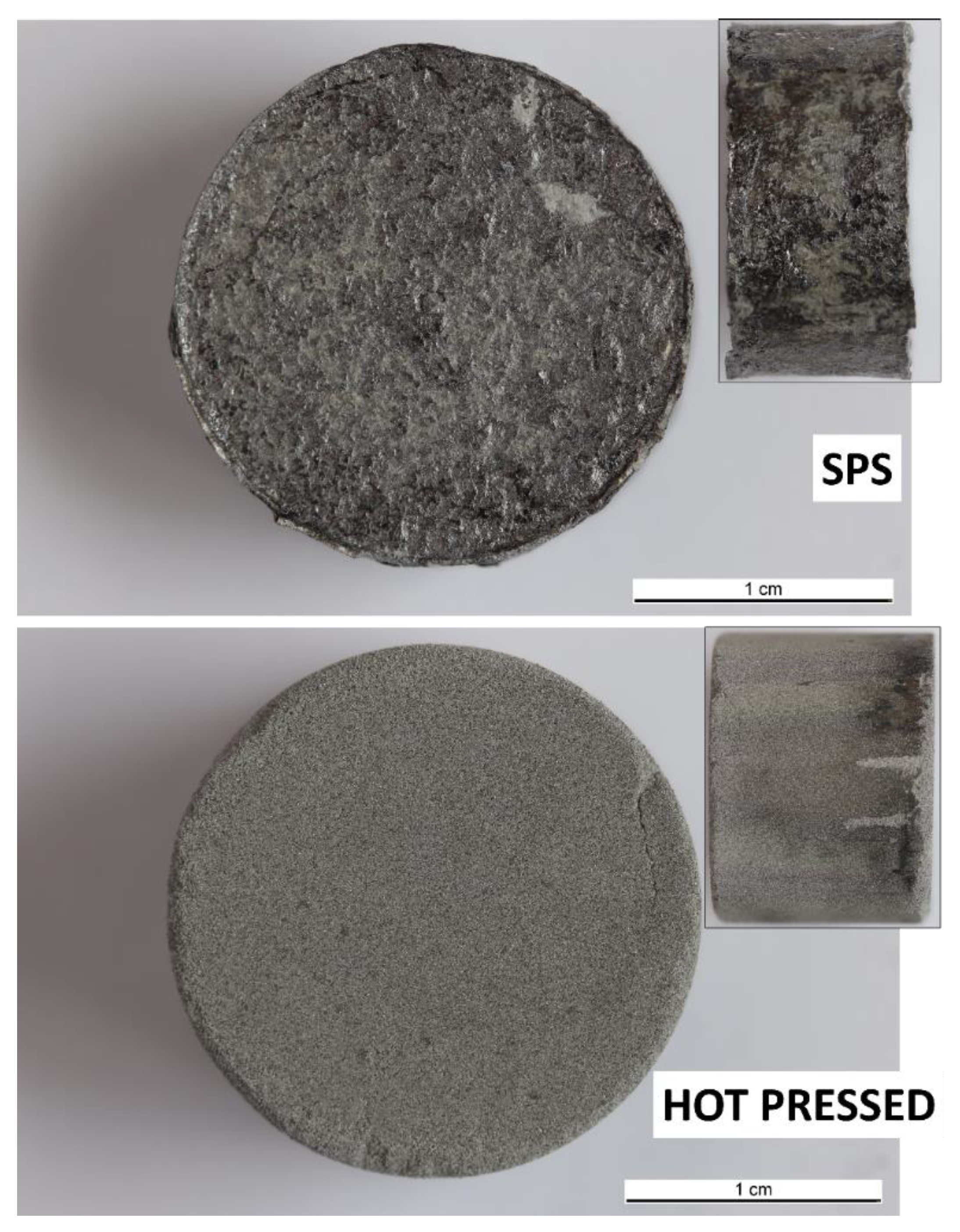

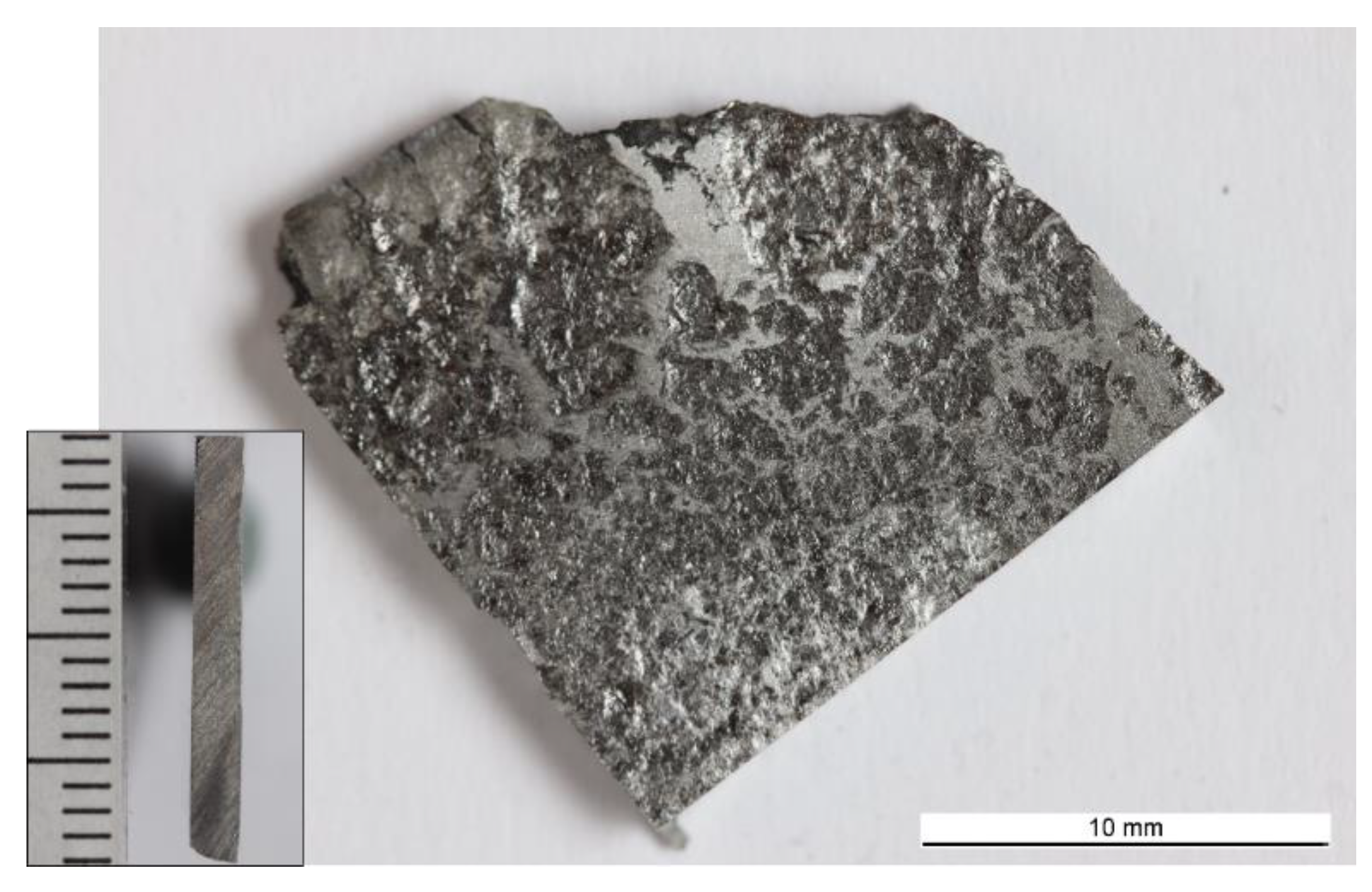

Figure 4 shows the morphology of the starting Al7075 alloy powder used in the bulk synthesis by SPS and SPT. The optical images of the resulting bulk SPS, hot pressed pellet, and bulk SPT samples following synthesis are presented in

Figure 5 and

Figure 6.

3.3. Density Measurement and X-ray Diffraction

The relative densities following Archimedes method (taken into account the theoretic density of Al7075 is 2.81 g/cm

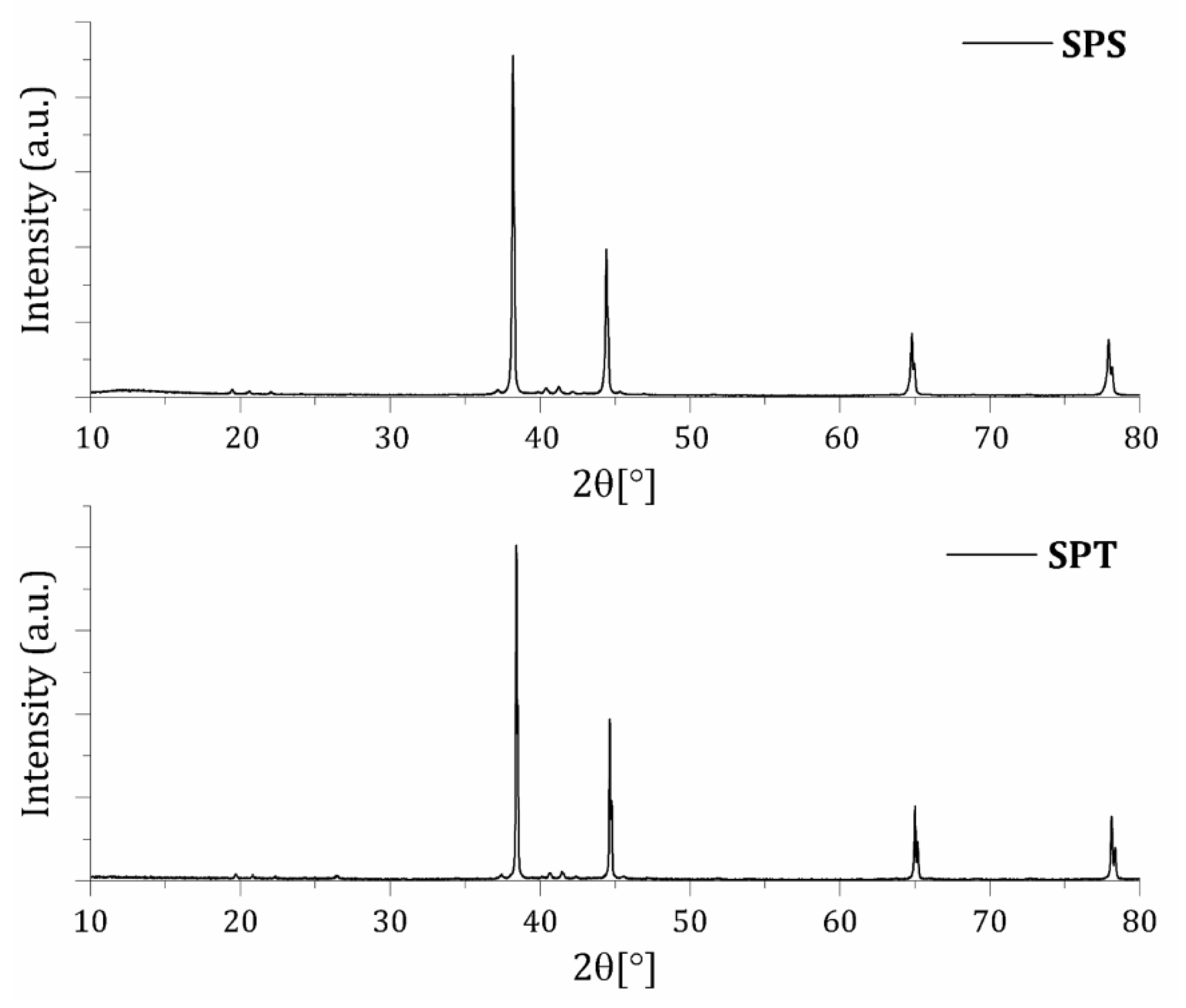

3) for the SPS, hot press, and SPT compact are 95%, 81%, and 99%, respectively. The X-ray diffraction patterns of Al7075 synthesized by SPS and SPT are presented in

Figure 7. As shown in

Figure 7, there are no observable differences in diffraction pattern in relation to in phase formation and intensities, suggesting the absence of crystallographic orientation.

3.4. Optical Micrographs of the Sintered Compact

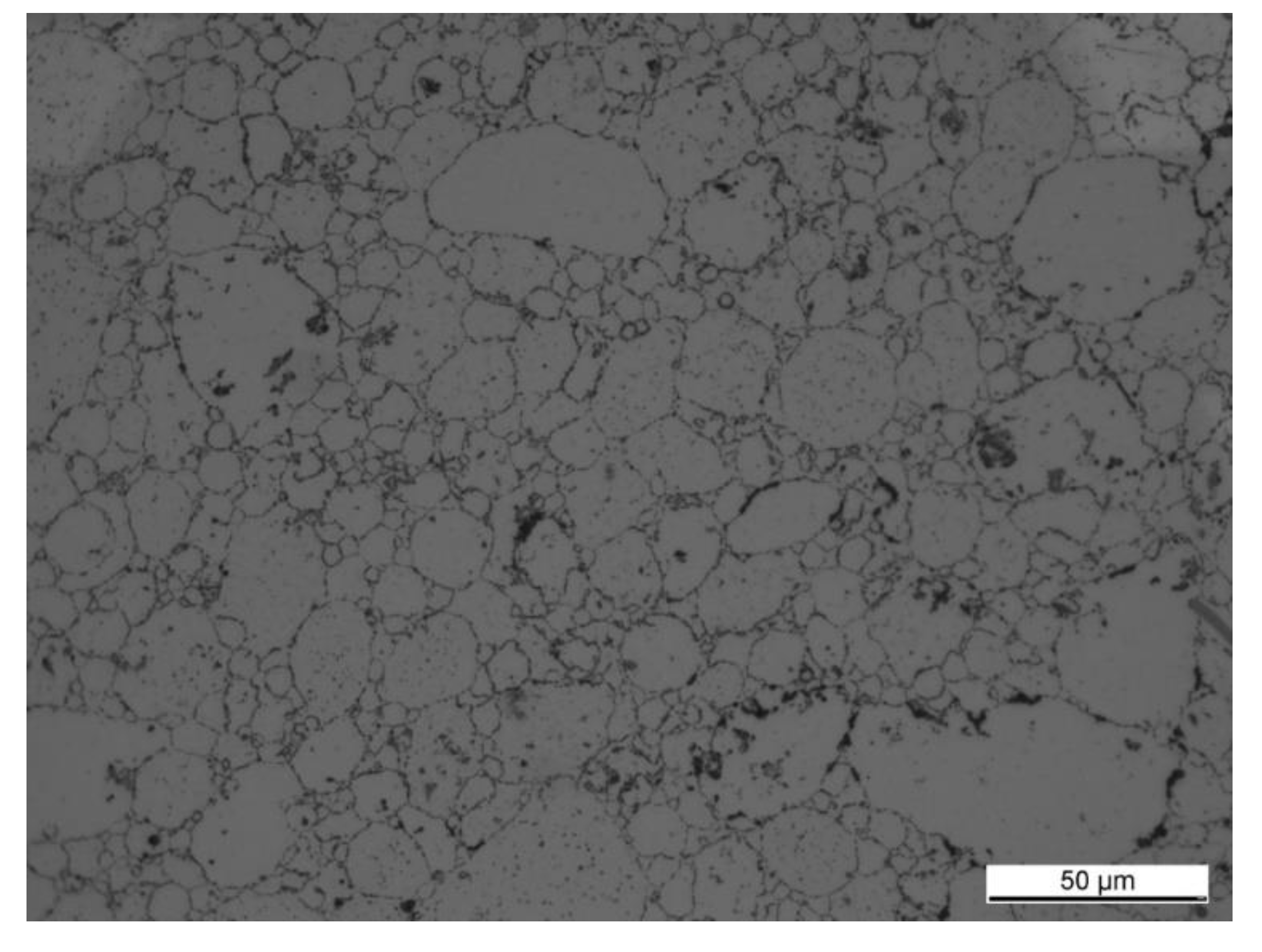

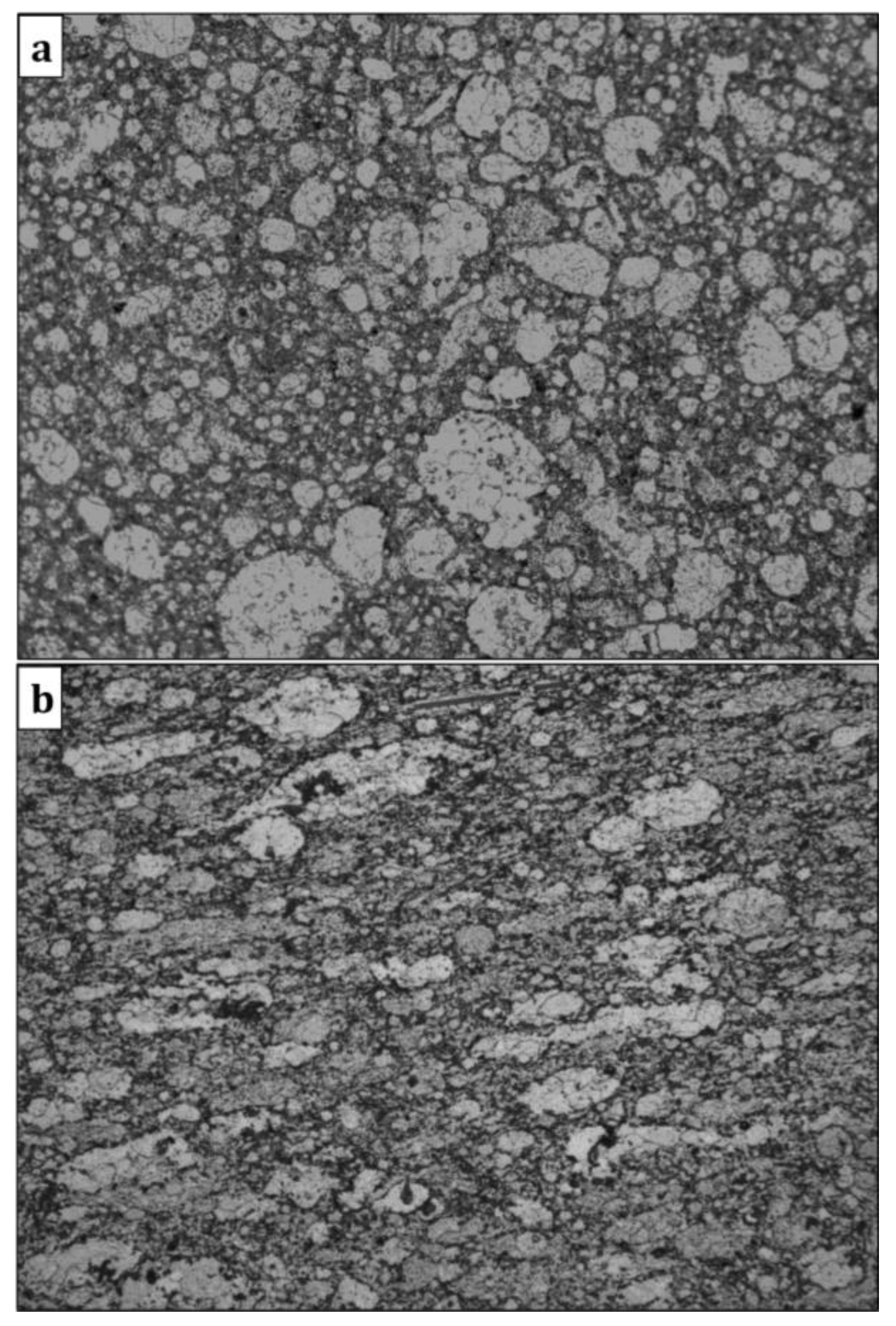

Figure 8 presents the unetched microstructure of the SPSed compact whilst

Figure 9 is a low-magnification (20 x) optical microstructure of the etched metallographic Al7075 alloy fabricated by SPS and SPT. Nearly equiaxed shape grains (

Figure 9(a)) was obtained by SPS, indicating grain growth in the pressing direction during synthesis. Whilst the grains (

Figure 9(b)) are elongated longitudinally as well as perpendicular to the loading direction by SPT. In general, the microstructure obtained by both SPS AND SPT is heterogeneous due to the simultaneous presence of very large and fine grains. The observed heterogeneous microstructure is in good agreement with observations reported elsewhere [

17].

3.5. Mechanical and Surface Properties

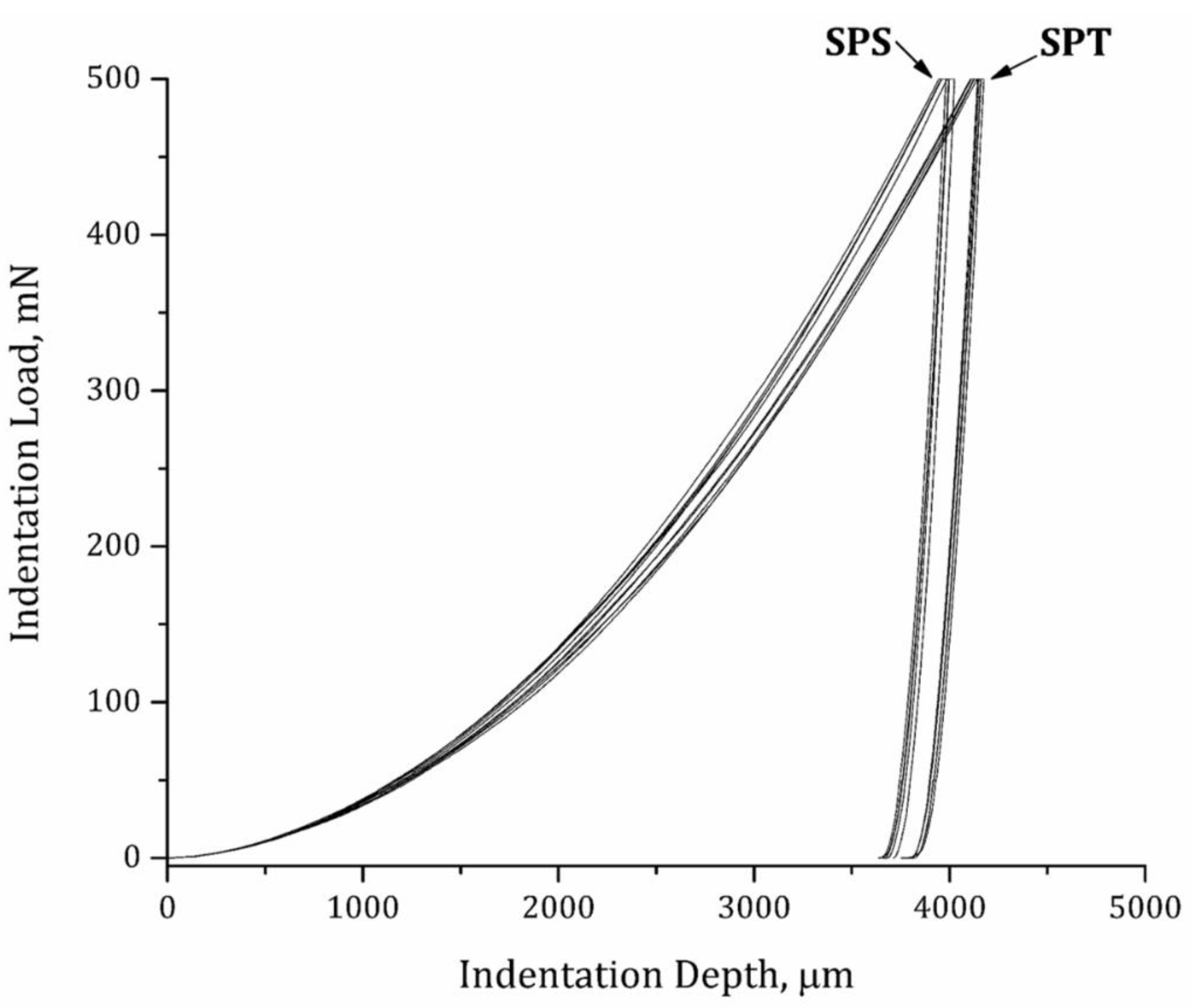

The loading-unloading curves acquired for the SPSed and SPTed Al7075 compacts are shown in

Figure 10. The loading curve for the SPS AND SPT are quite similar except for the unloading curve wherein the elastic recovery is slightly different. Macro hardness was also undertaken to get an insight of the overall bulk hardness and not just grain-scale nanohardness. The extracted nanomechanical properties, that is, nanohardness and reduced modulus as well as Vickers macrohardness are summarized in

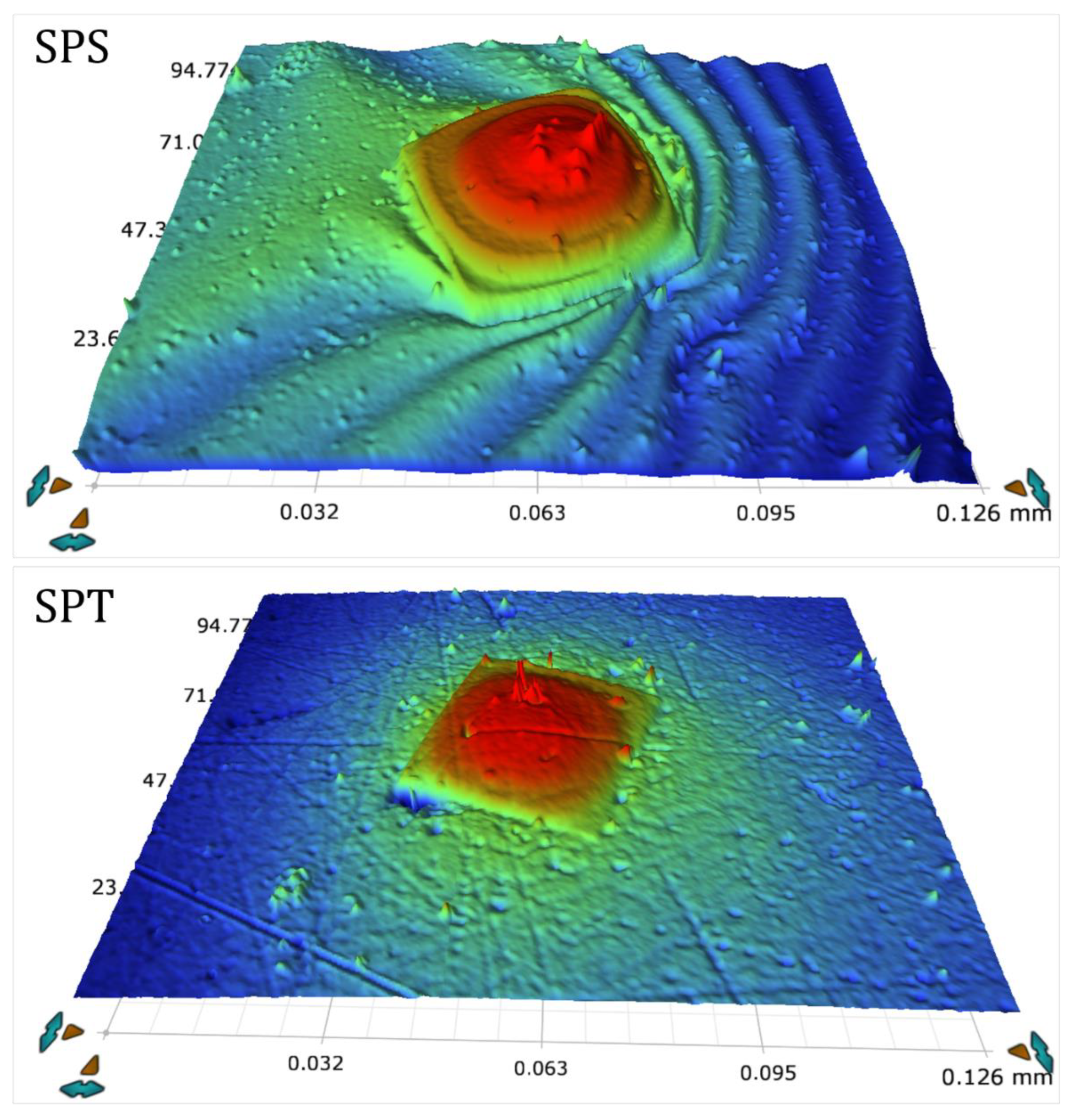

Table 1. The extracted 3D surface profile around the indent from the SPSed and SPTed compact is presented in

Figure 11.

4. Discussion

Upon the application of external pressure to a powder compact in a mould, there would be particle rearrangement and breaking of powder agglomerates as recorded by the piston movement within the first 500 secs for the SPSed and SPTed sintering profile. This is then followed by necking – closing of pores between powder particle – and subsequent plastic deformation of the interconnecting powder particles leading to densification. For the SPSed compact, the initial particle rearrangement – marked by piston movement – was reached at about ~250 secs and the total piston movement during the plastic deformation stage was about ~4.25 mm. Whilst for the SPTed compact, the initial particle rearrangement, – marked by piston movement – was reached at about ~500 secs and the total piston movement during the plastic deformation stage was about ~7 mm. the sintering cycle for the SPSed compact took about ~1000 secs whilst the SPTed compact took ~1500 secs. The differences in the extent of piston movement at various stages of the sintering cycle is due to the absence of lateral constraint imposed by the walls of the mould during SPT. As such, this allowed the SPTed compact to deform in the radial direction as compared to the SPSed compact which does not undergo radial deformation due to restriction imposed by the walls of the mould. The influence of edge-free deformation observed during SPT in this work is consistent with observations already reported elsewhere [

1,

12]. The difference in the extent of densification is linked to complete removal of pores and agglomerates due edge-free deformation during SPT which allowed for extended deformation. The extended deformation during the sintering cycle implies that grain growth is impeded as well as ensuring the growth of elongated grains longitudinally during SPT.

The result of the nanohardness test showed slight differences in hardness and reduced modulus for the SPSed and SPTed compact albeit the absence of crystallographic orientation as confirmed by XRD. The observed differenced may be linked to differences in the size of the grain in the bulk for the SPSed and SPTed compact. As nanoindentation data is extracted at grain scale, according to Bo et al.[

18] when the indent size is smaller than the grain size, the hardness increases. On the other hand, the hardness decreases when the indent size is larger than the grain size as the surrounding grains will also deform. 3D surface profile revealed extensive elastic recovery around the indent in the SPSed sample with no recovery observed for the SPTed sample. The observed elastic recovery in the SPSed compact in contrast to SPT may be linked to microstructural changes induced by the manufacturing processes as the alignment of the grains by SPT may allow for less recovery. However, the Vickers macrohardness – which encompass multiple grains – was higher for the SPTed Al7075 sample. This higher macrohardness which is consistent with observation reported elsewhere [

17] is linked to the fact that elongated grains can hinder the movement of dislocations more effectively. The longer grain boundaries stemming from grain elongation provide more barriers for dislocations, making it more difficult for them to move freely.

The result obtained in this work clearly shows that spark plasma texturing (SPT) allows fully dense, fine, and elongated grains to be obtained due to edge-free deformation, resulting in a good balance of hardness and ductility. This approach can further be extended to titanium alloys which undergoes deformation-assisted phase transformation for enhanced mechanical properties.

5. Conclusions

In this work, we report the microstructure and mechanical properties of spark plasma textured (SPT) Al7075 for the first time. The main conclusions are as follows:

It was found that the microstructure synthesized by SPT process resulted in fine and large elongated grain structure.

The SPT compact was fully-dense due to complete removal of necking, pores, and agglomerates that accompanied the edge-free deformation process.

The enhanced macrohardness observed for the SPTed sample is due to the elongated grain structure.

SPT offers a new, sustainable and inexpensive method for directional metal and ceramic processing.

References

- Pinho, R.; Tkach, A.; Zlotnik, S.; Costa, M.E.; Noudem, J.; Reaney, I.M.; Vilarinho, P.M. Spark plasma texturing: A strategy to enhance the electro-mechanical properties of lead-free potassium sodium niobate ceramics. Applied Materials Today 2020, 19, 100566. [Google Scholar] [CrossRef]

- Liu, Y.; Zhu, J.; Dai, B. Transparent MgAl2O4 ceramics prepared by microwave sintering and hot isostatic pressing. Ceramics International 2020, 46, 25738–25740. [Google Scholar] [CrossRef]

- Yamanoglu, R. Pressureless Spark Plasma Sintering: A Perspective from Conventional Sintering to Accelerated Sintering Without Pressure. Powder Metallurgy and Metal Ceramics 2019, 57, 513. [Google Scholar] [CrossRef]

- Hungría, T.; Galy, J.; Castro, A. Spark Plasma Sintering as a Useful Technique to the Nanostructuration of Piezo-Ferroelectric Materials. Advanced Engineering Materials 2009, 11, 615–631. [Google Scholar] [CrossRef]

- Munir, Z.A.; Anselmi-Tamburini, U.; Ohyanagi, M. The effect of electric field and pressure on the synthesis and consolidation of materials: A review of the spark plasma sintering method. Journal of Materials Science 2006, 41, 763–777. [Google Scholar] [CrossRef]

- Guillon, O.; Gonzalez-Julian, J.; Dargatz, B.; Kessel, T.; Schierning, G.; Räthel, J.; Herrmann, M. Field-Assisted Sintering Technology/Spark Plasma Sintering: Mechanisms, Materials, and Technology Developments. Advanced Engineering Materials 2014, 16, 830–849. [Google Scholar] [CrossRef]

- Chawake, N.; Pinto, L.; Srivastav, A.; Akkiraju, K.; Murty, B.; Kottada, R.S. On Joule Heating During Spark Plasma Sintering of Metal Powders. Scripta Materialia 2014, 93, 52–55. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Fedorov, S.V.; Hamdy, K. Materials, properties, manufacturing methods and cutting performance of innovative ceramic cutting tools − a review. Manufacturing Rev. 2019, 6, 19. [Google Scholar] [CrossRef]

- Li, X.Y.; Zhang, Z.H.; Cheng, X.W.; Huo, G.J.; Zhang, S.Z.; Song, Q. The Development and Application of Spark Plasma Sintering Technique in Advanced Metal Structure Materials: A Review. Powder Metallurgy and Metal Ceramics 2021, 60, 410. [Google Scholar] [CrossRef]

- Elissalde, C.; Maglione, M.; Estournès, C. Tailoring Dielectric Properties of Multilayer Composites Using Spark Plasma Sintering. Journal of the American Ceramic Society 2007, 90, 973–976. [Google Scholar] [CrossRef]

- Orrù, R.; Licheri, R.; Locci, A.M.; Cincotti, A.; Cao, G. Consolidation/synthesis of materials by electric current activated/assisted sintering. Materials Science and Engineering: R: Reports 2009, 63, 127–287. [Google Scholar] [CrossRef]

- Noudem, J.G.; Kenfaui, D.; Chateigner, D.; Gomina, M. Toward the enhancement of thermoelectric properties of lamellar Ca3Co4O9 by edge-free spark plasma texturing. Scripta Materialia 2012, 66, 258–260. [Google Scholar] [CrossRef]

- Noudem, J.G. A new process for lamellar texturing of thermoelectric Ca3Co4O9 oxides by spark plasma sintering. Journal of the European Ceramic Society 2009, 29, 2659–2663. [Google Scholar] [CrossRef]

- Ikram, A.; Awais, M.; Sheridan, R.; Walton, A.; Kobe, S.; Pušavec, F.; Žužek Rožman, K. Spark Plasma Sintering as an Effective Texturing Tool for Reprocessing Recycled HDDR Nd-Fe-B Magnets with Lossless Coercivity. Metals 2020, 10. [Google Scholar] [CrossRef]

- 15. Xia, -.H.-m.; Zhang, -.L.; Zhu, -.Y.-c.; Li, -.N.; Sun, -.Y.-q.; Zhang, -.J.-d.; Ma, -.H.-z. - Mechanical properties of graphene nanoplatelets reinforced 7075 aluminum alloy composite fabricated by spark plasma sintering. - Int. J. Miner. Metall. Mater. 1295. [CrossRef]

- Bhagavatam, A.; Ramakrishnan Sudha, A.; Adapa, K.; Adapa, V.; Dinda, G. Laser Metal Deposition of Aluminum 7075 Alloy. International Journal of Material Science and Research 2018, 2. [Google Scholar] [CrossRef]

- Garbiec, D.; Leshchynsky, V.; García-Junceda, A.; Swadźba, R.; Siwak, P.; Adamek, G.; Radwański, K. Microstructure and Mechanical Properties of Spark Plasma Sintered and Severely Deformed AA7075 Alloy. Metals 2021, 11. [Google Scholar] [CrossRef]

- Yang, B.; Vehoff, H. Grain size effects on the mechanical properties of nanonickel examined by nanoindentation. Materials Science and Engineering A-structural Materials Properties Microstructure and Processing - MATER SCI ENG A-STRUCT MATER 2005, 400, 467–470. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).