3. Results

The controlled arrangement of nano-sized structural units based on nanoarchitectonic approaches is receiving a major boost in the design of advanced functional architectures.[

12] In this sense, 2D solids with intercalation and delamination properties that could involve surface interactions of their single layers, present extraordinary potential as building blocks for these purposes.[

13] In this way, layered silicates (clay minerals) and more recently MXenes are excellent candidates for generating different functional nanoarchitectures.[

10,

14] The exfoliation/delamination of 2D solids allows further conformations as films (restacking) or foams (freeze-drying), which in addition to their ability to assemble diverse nanoparticles, polymers or biological fragments, can generate functional nanoarchitectures suitable for a wide range of applications, from reinforcement of polymeric matrices and membrane technologies to several transport properties, like optical, electronic, magnetic, etc.[

15,

16,

17]

The possibility of designing complex systems with individual layers of different 2D solids highly dispersed in silica matrices allowing to combine their textural properties (high specific surface area and porosity) with the inherent properties of the 2D solid, represents a very attractive opportunity. For example, delaminated clay minerals and related solids, like layered double hydroxides, associated with silica generated by sol-gel processes have been a breakthrough in the production of clay-silica nanocomposites with synergistic properties of both components, i.e., surface properties of the silica and ion exchange properties of the involved clay mineral.[

18,

19,

20,

21] Intermediate phases of 2D solids modified by the intercalation of cationic alkylammonium species (e.g., hexadecyltrimethylammonium bromide, CTAB) have been found to generate an organic-inorganic interface that facilitates the association and stabilization of alkoxysilanes, and other alkoxides, providing a suitable environment for the subsequent hydrolysis and controlled polycondensation of the alkoxides to form 3D silica networks.[

21,

22] In addition to alkoxysilanes, Al- and Ti-based alkoxides, as well as other types of metalorganic precursors, have also been successfully used to introduce selected functionalities (acidity, photoactivity, etc.).[

23,

24,

25,

26,

27,

28] Previous systems dealing with the assembly of MXenes and silica have been successfully produced by co-intercalation of tetraethyl orthosilicate (TEOS) with long chain alkylamines. The resulting materials have been consolidated by calcination giving rise to Ti

3C

2T

x MXenes with SiO

2 pillars being characterized by a permanent increase of the basal interlayer spacing up to 3 nm, as indicated by the corresponding XRD patterns. These materials also show a significant increase in their specific surface area, reaching values greater than 200 m2 g−1. [

29,

30]

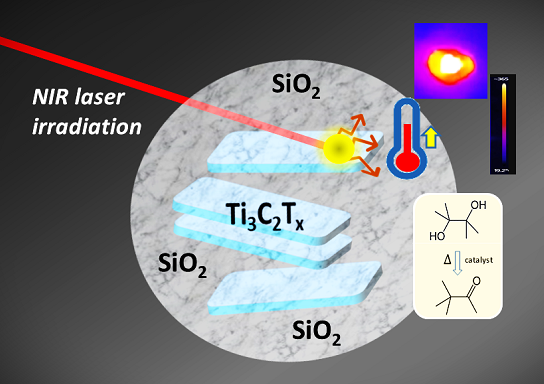

Herein, we report the synthesis of new nanoarchitectures derived from Ti

3AlC

2 carbide (MAX phase) leading to a high dispersion of Ti

3C

2T

x MXene single layers within a silica framework generated from tetramethyl orthosilicate (TMOS). This procedure involves the preparation of an intermediate phase by intercalation of the MXene by the cationic surfactant CTAB (MXene-CTAB) that facilitates the exfoliation and subsequent assembly with the SiO

2 generated by the hydrolysis and condensation of TMOS (

Figure 1). The resulting MXene-silica nanoarchitectures are materials that simultaneously exhibit high porosity and photothermal properties inherent to the MXene layers.

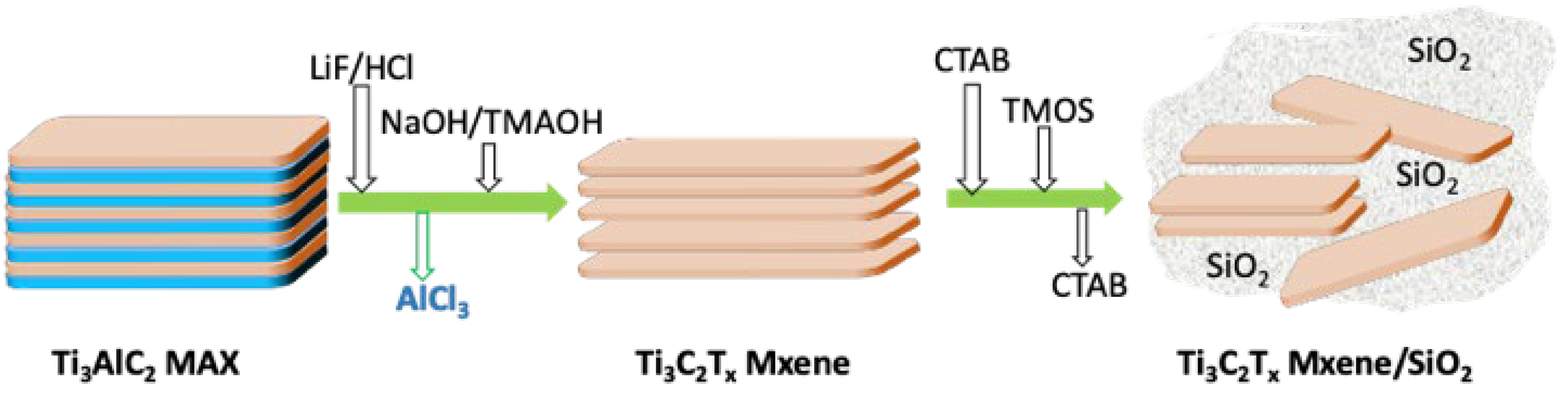

The general procedure followed to prepare the MXene-silica nanoarchitectured materials (

Figure 1) is inspired on our previously developed protocol on the preparation of clay-silica nanocomposites.[

18,

30] The initial first step of the overall process consists in the transformation of the MAX phase (Ti

3AlC

2) into the Ti

3C

2T

x MXene by treatment with LiF dissolved in concentrated HCl to produce the etching of the Al layer of MAX, according the procedure first reported by Ghidiu and co-workers[

11], followed by the neutralization of the resulting products with dilute NaOH. At this stage, it is also used here tetramethylammonium hydroxide (TMAOH) as both, neutralizing and etchant agent, taking into account the amphoteric nature of Al

3+, which can be extracted from the MAX structure leading to MXenes with Al(OH)

4− species as terminal groups.[

31] In a second step, the cationic surfactant (CTAB), is intercalated in the fresh resulting MXene with the aim to expand its interlayer spacing and facilitate the further access of the TMOS alkoxide used as a silica source. Once MXene-CTAB-SiO

2 nanocomposite are generated, the extraction of the surfactant by treatment with a mixture of ethanol/HCl solutions give rise to MXene-SiO

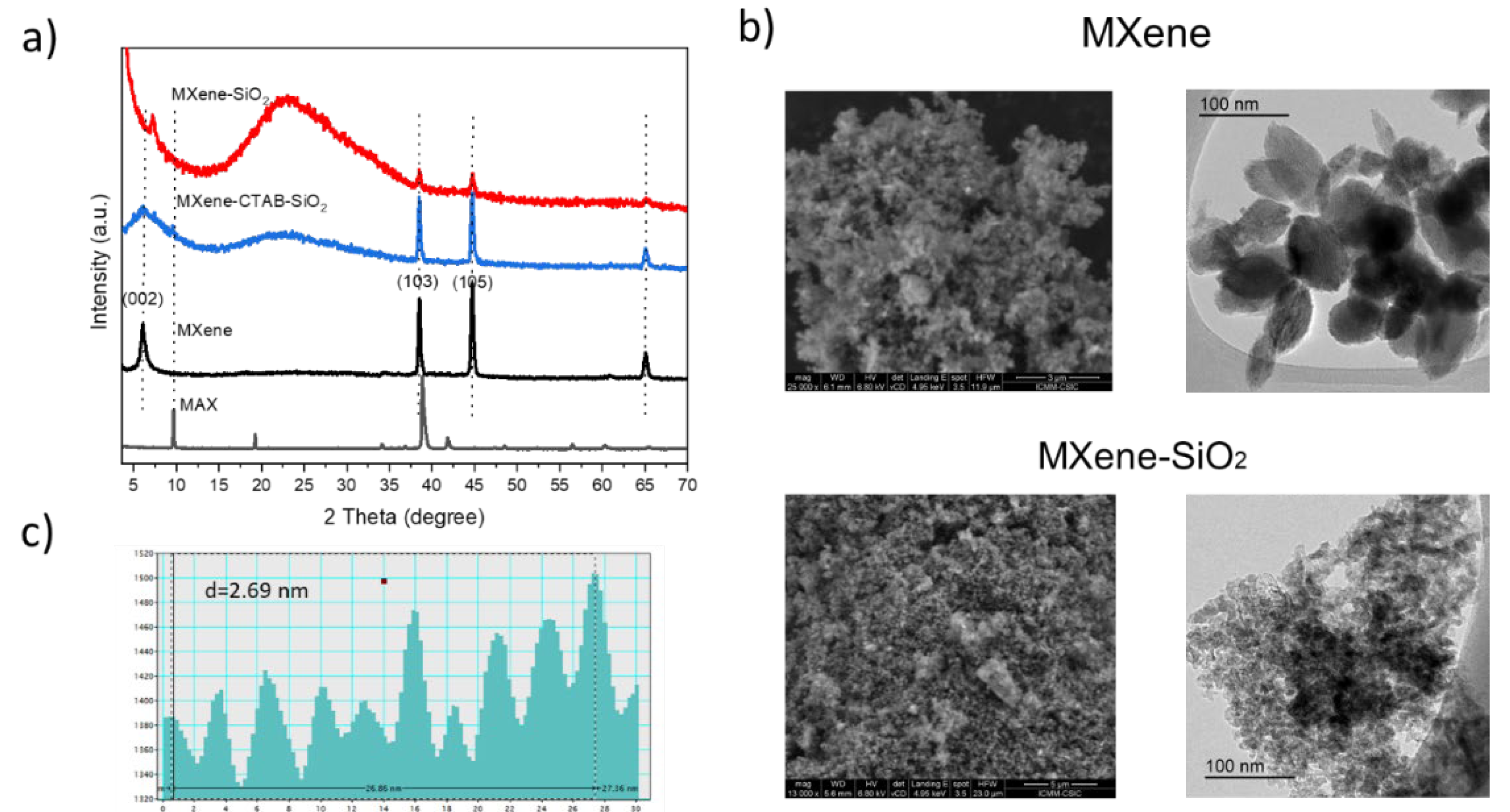

2 nanoarchitectures. Details of these reactions carried out in the laboratory under mild conditions. The powder X-Ray diffraction (PXRD) patterns (

Figure 2a) confirm the formation of the Ti

3C

2T

x MXene from the MAX phase by reaction with LiF/HCl solution[

9]. The characteristic diffraction peak assigned to (002) plane is broader and shifted to lower angles in comparison to the one present at the MAX phase indicating an increase in the interlayer distance (d

L) from 0.91 to 1.45 nm. This fact points to the removal of the Al layer from Ti

3AlC

2, subsequently confirmed by EDX analyses (

vide infra). In addition to plane (002), planes (103) and (105) belonging to the layered carbide structure are clearly identified in the resulting material and are shown here at 0.23 and 0.20 nm, respectively. A similar profile has been recently reported by Wang and co-workers[

32] interpreting such diffractogram as indicative of an incomplete etching of the MAX phase based on the presence of remaining peaks assigned to (103) and (105) planes. However, the energy-dispersive X-ray spectroscopy (EDX) results (

Figure S1 and

Figure S2, ESI) show a low Al content (≤ 2 wt. %) in the etched MAX sample (

Figure S3, ESI), proving the extraction of the majority Al layer. The elemental composition of the prepared MXenes also shows the presence of trace amounts of Cl (2.3 wt. %) and the existence of a large amount of F (9.8 wt. %) and O (25.1 wt. %), suggesting that the terminal surface groups (Tx) are mainly −O and −F terminations. EDX results from TEM. The observed increase on the basal spacing after Al extraction from the MAX phase can be attributed to intercalation between the MXene sheets of water molecules and cations, i.e. Li

+ from LiF, Na

+ and TMA

+ from the corresponding hydroxides used for controlling the pH dispersion,[

9,

33] in addition to methanol molecules further used in the process that could co-intercalate with H

2O molecules playing an active role in the subsequent delamination/exfoliation and facilitating the access of reagents to the interlayer region.

After treatment with CTAB and TMOS driving to the MXene-CTAB-SiO

2 intermediate nanocomposite, the diffraction peak assigned to the (002) plane widens further, while a broad hump appears centred at approximately 22º (2θ degrees), which is characteristic of the amorphous silica produced by the hydrolysis of the alkoxides (TMOS), in accordance with the Standards Joint Committee on Powder Diffraction (JCPDS) corresponding to the standard pattern of amorphous SiO

2.[

34] The presence of CTAB is evidenced from the ATR spectra, showing the characteristic peaks at 2922, 2850, and 1460 cm

–1 that are respectively assigned to the asymmetric and symmetric stretching vibrations of C–H (ν

asym(-CH

2) and νs(-CH

2)) and δ (-CH

2) bending vibrations of methylene groups in the CTA

+ species assembled to the MXene. The intense IR bands at around 1060 cm

-1 are attributed to the ν

Si-O stretching vibrations of silica siloxane bonds. (

Figure S4, ESI)

The MXene-SiO

2 nanoarchitecture is finally produced after the removal of CTAB, included as CTA

+ cations in the MXene-CTAB-SiO

2 sample, which is achieved by treatments with ethanol/HCl mixture. The XRD pattern (

Figure 2a) shows a broad band centred at 22° (2θ) attributed to amorphous silica along with a broad peak at 6.08° (2θ) corresponding to the (002) plane of the layered carbide. The latter signal appears here with a relatively small intensity compared to the intensity of the other observed reflexions of the carbide (i.e., the (103) and (105) planes). The broadness of the peak corresponding to the (002) plane can be attributed to the distinct interlayer distances produced by the silica access to the MXene interlamellar spacings. The resulting spacings vary over a wide range, the MXene layers being poorly ordered that result in structural disorganization in the stacking of the carbide single layers.

Figure 2b shows a representative TEM image of MXene-SiO

2 samples including the corresponding Line Profile (

Figure 2c) that could be related with the d-spacings of 2D solids[

35], which indicates here an estimated average distance between consecutive planes of d=2.7 nm, the observed increase of this interlayer distance being attributed to the incorporation of silica in the interlayer region. This value measured from the Line Profile deduced from TEM images, should be taken with caution since it is not the result of measurements by conventional diffraction techniques, but it represents an approximation that is consistent with results obtained from related MXene-silica systems.[

29] It should also be considered that a partial MXene exfoliation or delamination is also produced, whose identification by TEM in the silica matrix would be very difficult to observe due to the very thin single layer thickness of the carbide together its folding ability leading to corrugated/rolled solids. The effectiveness of the CTAB extraction is confirmed by ATR spectroscopy as it shows the absence of C-H vibrations typical of the cationic surfactant (

Figure S4, ESI, which was detected in the intermediate MXene-CTAB sample).

FE-SEM/EDX results of the MXene-derived nanoarchitectures show the dispersion of the layered carbide among the silica particles. At higher magnifications, it is observed that the latter nanoparticles are closely associated with the MXene and, in good agreement with the XRD results, the 2D carbide should be present as a MXene few-layers or as a disordered/delaminated solid dispersed on the generated silica matrix.

Figure 2b shows FE-SEM and TEM images of the synthetized MXene and the MXene-SiO

2 nanoarchitecture. In the latter sample, TEM images show a certain organisation in the stacking of the MXene layers, which appears as a nanostructured solid with an almost regular 00l arrangement that periodically repeats at layer spacings of about 2.7 nm (Line Profile,

vide infra) (

Figure 2c). This expansion is attributed to the interlamellar insertion of silica

in situ generated by the hydrolysis of TMOS in an environment of the MXene layers with CTA

+ cations as intercalated species. Semi-quantitative EDX analytical results point out to a relatively high content of the Ti and Si elements (belonging to carbide and silica, respectively) as well as a low content of Al compared to the starting MAX phase. An appreciable amount of O and F content is also detected, the former being associated to the assembled silica and the latter consisting mainly of -F terminations. Elements such as Al, Ca, etc., which could contribute to insolubilize fluorides, are not detected, supporting the assignation of –F as T

x terminations in the MXene layers (

Figure S2, ESI).

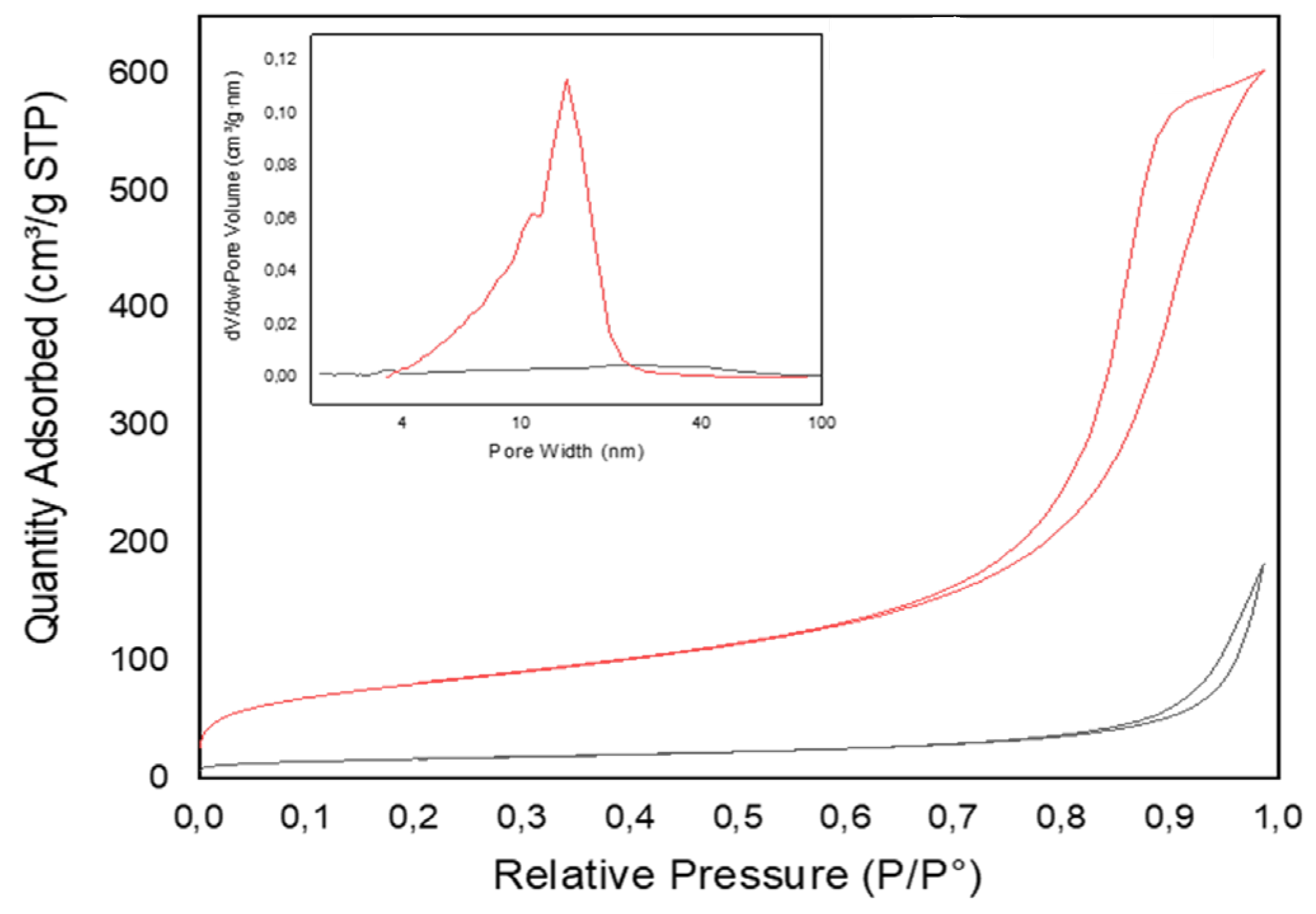

The resulting MXene-SiO

2 nanoarchitectures show a significant increase in porosity and specific surface area with respect to the pristine MXene showing development of new pores in the range of mesopores (

Figure 3). The adsorption of N

2 at liquid nitrogen temperature on MXene-SiO

2 nanoarchitectures shows an type-IV, H1-type isotherms associated with porous materials consisting of well-defined cylindrical-like pore channels or agglomerates of compacts quasi-uniform spheres,[

36] meanwhile the pristine MXene can be ascribed as type-III, H3-type ascribed to plate-like aggregates of layers with slit-shape holes in good agreement with the nitrogen adsorption isotherm.

Brunauer-Emmett-Teller (BET) specific surface area measurements show a large increase in surface area from about 60 m

2.g

-1 in the untreated MXene to above 290 m

2.g

-1 in the nanoarchitecture (

Table S1, ESI) and an average pore width of 12 nm. In relation to this overall increase in the apparent surface area of the material, the pore volume also underwent a considerable increase, i.e. more than 3 times with respect to the initial MXene.

In addition to the development of adsorption capacity, the nanoarchitectures built here should show an effective light-to-heat conversion capacity, more usually known as photothermal conversion, assured by the presence of MXene. This property is a topic that is attracting increased interest focusing important applications such as steam generation, water desalination and cancer therapy.[

7,

37] Photothermal conversion is also remarkable in nanocomposite materials such as those containing biopolymers (e.g., nanocellulose) assembled to MXenes, which incorporate thermoelectric properties useful in biomedicine and even in amazing behaviors such as controllable light-driven photothermal properties inherent to their 2D carbide component.

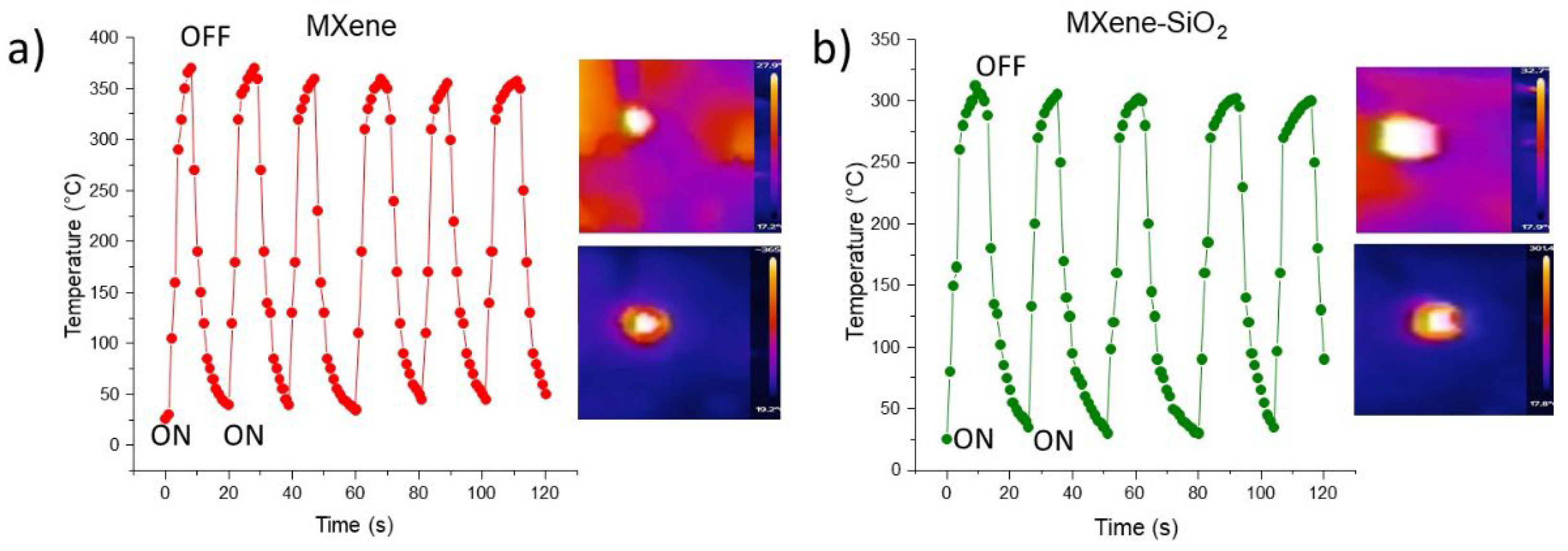

Cyclic on-off laser irradiation at regular time intervals shows the concomitant increase in temperature (

Figure 4) demonstrating excellent repetitive photothermal response activity over long periods of time. We have found that this activity is maintained by storing the samples at atmosphere without special storage precautions at least one year after preparation.

The multifunctionality of the MXene-SiO

2 materials, i.e. their high porosity, together with the properties conferred by the inclusion of the MXene, are of interest in terms of their potential photoactivity and electrical conductivity. These properties are theoretically promising for potential applications such as e.g. active phase of sensors, porous electrodes, heterogeneous catalysis, etc.[

38]

Interestingly, the MXene-SiO

2 nanoarchitectures prepared here retain the characteristic photothermal properties of the MXene component together the surface properties of the associated porous silica. In this regard, we have shown that the adsorption of organic molecules on MXene-SiO

2 can be further transformed following a photothermal activation based on NIR laser irradiation. Thus, in a preliminary approach consisting in the adsorption of 2,3-dimethylbutane-2,3-diol, (pinacol) on MXene-SiO

2, after acid doping and NIR laser irradiation a fast and efficient rearrangement reaction to 3,3-dimethylbutan-2-one (pinacolone) was observed in a similar way as it takes place in liquid phase or adsorbed on porous solids.[

39], [

40,

41] As it is well known, the rearrangement reactions of 1,2-diols catalyzed by mineral acids or Lewis solids represent a classical model in organic chemistry,[

39] where thermal activation has been traditionally achieved by heating in a conventional oven or under microwave irradiation.[

42] In the present case, a very short time (10 minute) irradiation with a NIR laser attenuated to heat at 80-100 ºC on H

2SO

4-doped MXene-SiO

2 containing adsorbed pinacol, produces its rapid transformation in pinacolone, as detected by the 2,4-dinitrophenylhydrazine test with formation of orange colored 2,4-dinitrophenylhydrazone.[

39]