Introduction and Background

Modularization, prefabrication, industrialized buildings, and pre-assembly are some of the terms used for describing the construction of the building when the structural components are manufactured at factories and the only task that takes place on site is earthwork and assembly (Generalova et al., 2016). Modular construction is the process where different modules also known as, sections of the buildings like walls, ceilings, floors, etc. are produced at a plant/factory under controlled conditions; The modules are then shipped and assembled at the site location for a faster more efficient construction. These modules are prepared by following the same codes and standards that would apply to conventional construction and upon assembly these modular structures look identical to a well-designed, specifications-oriented site-built building without any compromises (Smith, 2016).

Prefabrication construction involves fabricating building components in a factory and then transporting them to a construction site for installation (Deluxe Modular, 2019). This method offers benefits such as faster and safer manufacturing, better quality control, and lower environmental impacts (Lawson et al., 2018; Yu and Chen, 2018). It leads to sustainability benefits through material efficiency, reduced onsite waste (up to 90%), and improved working conditions. The use of modular construction technologies can reduce construction time by 50% and save costs by 20% based on recent case studies (Stern, 2017). The concept of prefabrication construction is gaining interest due to technological advancements, economic demands, and changing mindsets. It is seen as a potential solution to the affordable housing crisis by providing housing supply quickly with reduced costs (Jin et al., 2020; WRAP, 2018; Jiang et al., 2019). There are three classes of prefabricated construction based on the degree of prefabrication: 1-D single element, 2-D panelized system, and 3-D volumetric system (Kamali and Hewage, 2016; McKinsey, 2019; Thomson, 2019; Boafo et al., 2016; Mortice, 2019; Harrison; 2018). Panelized and volumetric construction, also known as modular construction, is the most efficient class of prefabricated construction, allowing for 70% to 95% of a building to be prefabricated in a factory before onsite assembly. This method is believed to shape the future of the construction industry (Davies, 2013; Pan and Hon, 2019; Shan et al., 2019).

This review paper discusses what modular construction is and how it is different from traditional on-site construction. Environmental impacts of using modular construction and what leads to it being more efficient and faster than on-site construction.

Modular Construction Building Types

Modular Construction Buildings are of two types re-locatable modular construction and permanent modular construction (Smith, 2016).

Re-Locatable Modular

Re-locatable Modular also referred to as Temporary Modular, is the construction of buildings that are made to meet the temporary needs of the place and people. These buildings are made to be purchased but they might also be leased for a short term. Once the buildings have served their purpose and are not required anymore, they can either be broken down into pieces and recycled or they can be moved from one place to another where there is a requirement for such buildings. Examples of such buildings include Job site trailers, Communication pods, temporary classrooms, and showrooms (Smith, 2016) (see

Figure 1).

Permanent Modular

Permanent Modular Construction or PMC has been used in European countries for decades, but it isn’t as popular in the American construction Industry. However, over the past couple of decades, more companies have adapted to this style of construction. PMC had only 25% of the market share within the modular industry in 2012-13 but in 2016 the percentage jumped to over 50%. PMC as the name suggests is the construction of permanent buildings following the modular construction process. These buildings, unlike temporary modular, are big and permanent, and the only way to move them is to tear the building down into small pieces. PMC building are similar to site-built structures as they are structurally sound and constructed by following the International Building Code (IBC). The only difference is that PMC buildings are manufactured at plants and assembled on-site. Examples of PMC include Multifamily structures, healthcare facilities, hotels, schools, and other building types that can be found in on-site construction (Smith, 2016) (see

Figure 2).

Process and Key Players in Modular Construction

Re-locatable modular or permanent modular, both methods of modular construction are excellent, but the factors that make one better than the other are just the conditions and requirements of the project (Bertram et al., 2019). What are these conditions and requirements? Who decides whether to use temporary modular or permanent modular for construction? To answer these questions let’s look at the important stakeholders and the process of modular construction (Kamali and Hewage, 2016; McKinsey, 2019; Thomson, 2019; Boafo et al., 2016; Mortice, 2019; Harrison; 2018).

Figure 2.

Permanent Modular Construction (Adapted from Smith, 2016).

Figure 2.

Permanent Modular Construction (Adapted from Smith, 2016).

Looking at some of the stakeholders from the traditional on-site construction method, we have owners, architects, engineers, contractors, construction managers, subcontractors, and suppliers. Stakeholders within the modular process have two major additions, Dealers and manufacturers/manufacturer direct. The role of a dealer is to get in touch with the owner and understand their needs/requirements and contact the manufacturers to get the modules made for the owner. Consider dealers as the middleman between owners and manufacturers. The role of a manufacturer is to manufacture the modules in the factory. Manufacturers could be companies that own such facilities and produce modules for different dealers handling various projects. Manufacturers are manufacturers that provide contractors and dealers with the module, but they can also contract directly with the owner providing manufactured modules acting as contractors themselves (Smith, 2016; Kamali and Hewage, 2016; McKinsey, 2019; Thomson, 2019; Boafo et al., 2016; Mortice, 2019; Harrison; 2018).

Moving on to the process that is followed with a modular construction project. Similar to the on-site construction process, the owner of the project contacts the architect, engineer, and construction manager in the initial stages of the project. During the feasibility phase of the project, it is decided whether the construction will be modular or on-site. Various factors must be considered when making this decision, like site location, availability of resources, distance from the factory, experience of stakeholders with modular construction, and many more (Smith, 2016). These factors are discussed in brief in a later part of the report.

After the decision has been made to move forward with the modular construction process, the owner contacts the dealer or contractor with experience in the modular construction project. There may or may not be a bidding phase, this decision solely depends on the owner. Once the contract has been established with the dealer or a contractor, the next step is performed by the dealer or contractor to contact the manufacturer regarding the requirements of the construction. Alongside the manufacturing process, site work and foundation are also completed. When the modules are manufactured and completed at the factory, they are then shipped to the site location for assembly and connecting utilities. Once the building is assembled, final inspections take place, and the project is handed back to the owner (Kamali and Hewage, 2016; McKinsey, 2019; Thomson, 2019; Boafo et al., 2016; Mortice, 2019; Harrison; 2018).

Figure 3 shows the different types of modules that are manufactured at the factory. Mainly there are two types of modules, 2D panels and 3D Volumetric Units. 2D panels as the names suggest are made as panels that are shipped and assembled at the site locations. Whereas 3D volumetric units are fully fitted units that are shipped as a whole to the site and utilities are connected. There can also be projects with a hybrid of 2D panels and 3D volumetric units.

Modular Construction – Benefits Compared to On-Site Construction

So far, we have looked at the types and processes of modular construction, now let’s look at the benefits of using modular construction and why this method has the potential of being a problem-solving method. Modular construction has benefits and drawbacks depending on the situation and goals of the project. This section only discusses the benefits that you can find in most projects with modular construction methods (Kamali and Hewage, 2016; McKinsey, 2019; Thomson, 2019; Boafo et al., 2016; Mortice, 2019; Harrison; 2018).

Responsibilities and Risks

On-site construction has always been a method that forces responsibilities upon the stakeholders without any flexibility. Such responsibilities make the parties involved in the construction develop a risk-avoiding behavior, which could lead to parties not getting involved in a more collaborative process, resulting in the failure of the project. Modular construction on the other hand is more straightforward with the process. The parties involved do not have to worry about the smallest of things going wrong because the construction on site is limited and things happening in the factory occur under a very controlled environment (Smith, 2016).

Time Reduction

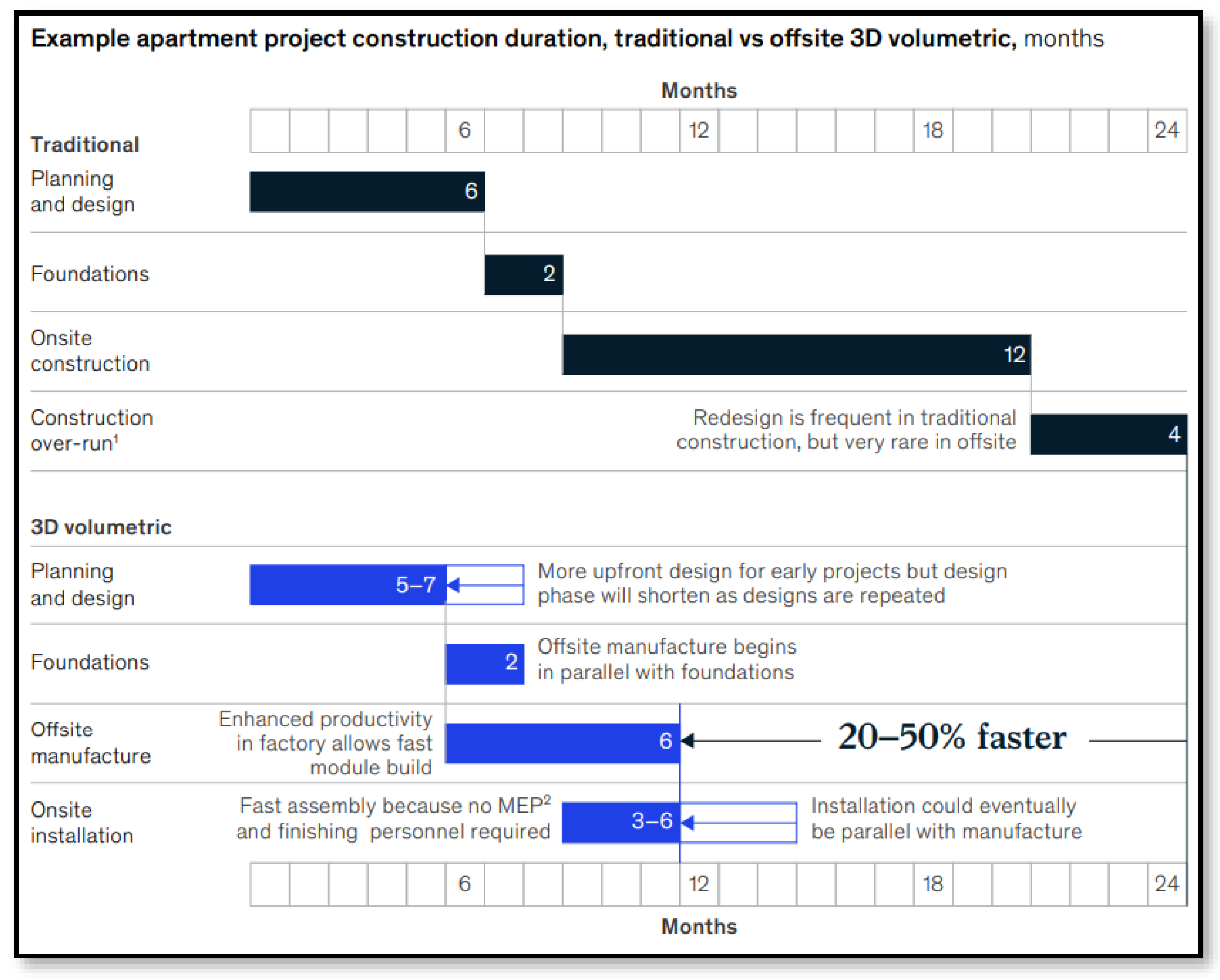

One of the biggest benefits of using modular construction over traditional on-site construction is the time reduction in the construction process. First, let’s look at the design process; Modular construction takes a longer time to design than traditional on-site construction, because the designs made must be perfect, and decisions must be made early in the project because changes late in the project can be costly and difficult to make. Moving on to the construction phase, this phase is very fast with the modular construction process since manufacturing of the modules can be completed parallel to the foundation work. The time taken to manufacture the modules is way less than the time it takes to construct a building on-site, this is due to the increasing automation and controlled environment of the manufacturing facilities. The on-site phase of modular construction is also very simple and fast. Mostly it comes down to assembling the 3D modules on-site and connecting utilities, this makes it faster and cheaper labor compared to on-site construction. Quality control is also much easier in a factory than onsite, this reduces the chances of rework, which significantly improves the schedule. In the on-site construction, there is also a risk of mistakes not being identified until months or years after the completion of the project, such mistakes can be harder and expensive to fix. With modular construction such mistakes are easily avoided as the modules are being created by machines in vast numbers, which makes it easier to spot the mistake (Bertram et al., 2019).

Looking at

Figure 4, we see that by using the modular construction method over the traditional method can reduce the construction time by 20-50 percent. All the steps we discussed earlier are the ones that you can see in the figure that reduce the construction time.

Safety of Workers

Worker safety is crucial in any project, whether it is an on-site or a modular construction project. The smallest of mistakes can lead to a big accident and cause worker injuries and deaths. More than 20% of the total number of fatal accidents happen in the construction industry. On-site construction is more prone to such incidents due to numerous factors that could go wrong on-site like falling structures, dangerous weather, collapsing scaffolding, getting struck by machines or debris, electrocution, etc. Modular construction on the other hand is a lot safer for the workers as the manufacturing that takes place in the factory happens under controlled conditions. Most processes are now being taken over by automated machines, which reduces the risk of injury even more. Working in a fixed factory with a comfortable environment and not having a transient lifestyle can make the workers happier and more productive during work (Hoínková, 2021).

Environmental Impact Assessment

Increasing concerns with global warming have led people to take steps that could lower the emissions and global warming effects on the environment, and the construction industry being the leading industry has a lot to contribute towards reducing global warming on earth. After numerous studies and research on the effects of modular construction, it has been found that, on average, modular construction has lower environmental impacts compared to on-site construction. There are a lot of varied factors that must be addressed when comparing the life cycle of the on-site and modular construction methods such as the production of materials and their transportation, energy usage on-site and modular, worker transportation, and waste management. One other key factor of the life cycle analysis, which is not easy to compare is the ‘use’ phase of the building because it varies a lot depending on the design (Kamali and Hewage, 2016; McKinsey, 2019; Thomson, 2019; Boafo et al., 2016; Mortice, 2019; Harrison; 2018; Smith and Quale, 2017).

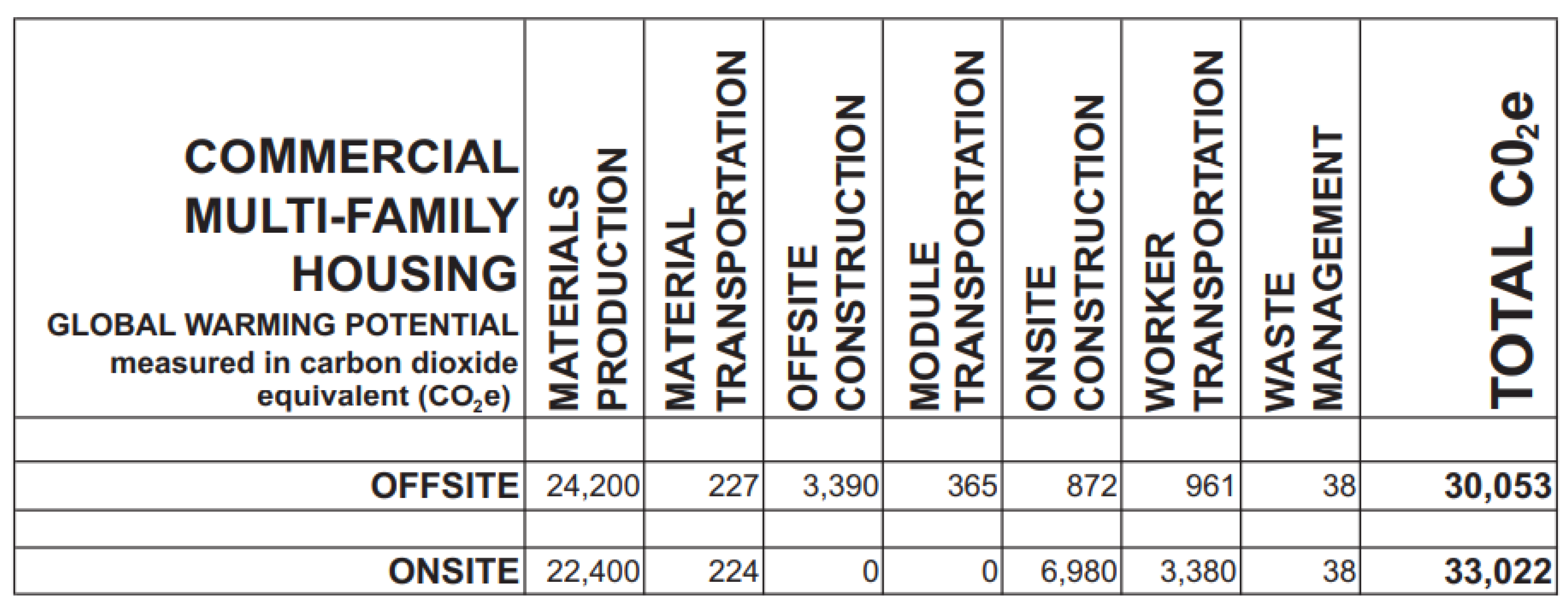

The research (see

Figure 4) by John D. Quale and his team on Green House Gas (GHG) emissions from commercial modular construction compares the modular and onsite construction on various life cycle factors that have a potential impact on the environment. As we can see the total global warming potential measured in carbon dioxide equivalent for modular construction is 30,053 and onsite construction is 33,022. The categories that modular construction leads to and has a higher global warming potential are material production, modular construction, and module transportation. Categories where onsite construction leads and has a higher global warming potential are onsite construction and worker transportation. This indicates that on average modular construction has less environmental impact compared to on-site construction (Smith and Quale, 2017).

When and Where to Use Modular Construction

Despite looking at the results from the research in the previous section, it is still possible to have some situations where onsite construction is the better option to use. For example, if a factory is located in a rural area and runs on natural oil it produces more emissions, and the transportation to and from the factory also leads to more carbon emissions. In such scenarios choosing on-site construction can be better. There are several factors that need to be looked at when choosing the construction method as mentioned earlier in the report. Now let’s look at some situations where it is actually beneficial to choose modular construction methods over on-site construction (Smith and Quale, 2017).

Projects with Tight Schedules

Projects with tight schedules tend to have time constraints as a big priority in the project. For example, building a new section of the school/college before the semester starts in the fall. Using modular construction in such situations can help reduce the schedule time and if possible, can also leave more time at the end to fix errors or mistakes that could happen along the way.

Projects Having Repeating Modules

Projects with repeating modules like offices, laboratories, and schools can benefit the most from modular construction. It takes more time to replicate things in on-site construction than it takes to manufacture the exact same module multiple times. Additionally, with manufacturing, you also get more accurate-looking modules compared to onsite construction.

Design-Build and Integrated Project Delivery Methods

Whether or not modular construction is beneficial largely depends on the delivery method. Even though it is possible to use modular construction with any method of delivery, Design-Build and Integrated project delivery methods have shown the best results. Because the designing of the building is done early, and the manufacturing/fabrication can begin early in the project.

Experience of the Stakeholders

One of the most important factors to consider when choosing whether to use modular construction is the ability and experience of the stakeholders. Modular construction is a relatively new concept compared to on-site construction. It can also be challenging to manage the project if the stakeholders don’t have experience in modular construction, as the procedures for modular construction tend to be different than on-site construction.

Conclusions and Future Recommendations

In conclusion, the positive and negative impacts of modular and traditional on-site construction were reviewed. Modular construction has been proven to offer a wide range of advantages compared to traditional on-site construction methods. It not only saves construction time and reduces costs but also has a significant positive impact on the environment. The streamlined and efficient nature of modular construction makes it particularly well-suited for high-rise buildings. Embracing modular methods has the potential to significantly transform and advance the construction industry in the future. Modular construction is supposed to have a very powerful technological advancement and using it correctly is important to achieve its true potential and get the most benefits.

References

- Bertram, N., Fuchs, S., Mischke, J., Palter, R., Strube, G., Woetzel, J. (2019). “Modular Construction: From Projects to Products” McKinsey & Company, 2019.

- Boafo FE, Kim J-H, Kim J-T. Performance of modular prefabricated architecture: Case study-based review and future pathways. Sustainability 2016;8:558.

- Building and Construction Authority. Code of practice on building design/ buildability, Singapore; 2017.

- Davies G. The future of DfMA is the future of construction. Eng Excellence J 2013: 1–77.

- Deluxe Modular. The differences between prefab and modular construction, from https://www.deluxemodular.com/learning-center/modular-vs-prefab; 2019.

- Generalova, E., Generalov, V., Kuznetsova, A. (2016). “Modular Buildings in Modern Construction” Elsevier Ltd., 2016.

- Harrison G. The future is prefabricated, from https://pursuit.unimelb.edu.au/ articles/the-future-is-prefabricated; 2018.

- Hoínková, D. (2021). “Advantages and Disadvantages of Modular Construction, including Environmental Impacts” IOP Publishing Ltd., 2021.

- Jellen A, Memari A. The state-of-the-art application of modular construction to multi-story residential building. Proceedings of the 1st Residential Building Design & Construction Conference 2013:284–293. [22].

- Jiang Y, Zhao D, Wang D, Xing Y. Sustainable performance of buildings through modular prefabrication in the construction phase: A comparative study. Sustainability 2019;11:5658. [CrossRef]

- Jin R, Hong J, Zuo J. Environmental performance of off-site constructed facilities: A critical review. Energy Build 2020;207:109567. [CrossRef]

- Kamali M, Hewage K. Life cycle performance of modular buildings: A critical review. Renew Sustain Energy Rev 2016;62:1171–83. [CrossRef]

- Lawson RM, Grubb PJ, Prewer J, Trebilcock PJ. Modular construction using light steel framing: An architect’s guide. The Steel Construction Institute 1999:1–105.

- McKinsey. Modular construction: From projects to products, from https://www. mckinsey.com/industries/capital-projects-and-infrastructure/our-insights/mo dular-construction-from-projects-to-products; 2019.

- Mortice Z. Can this Chicago apartment factory make new homes affordable? from https://www.citylab.com/design/2019/07/chicago-new-construction-apartment -affordable-rent-skender/592444/; 2019.

- Pan W, Hon CK. Modular integrated construction for high-rise buildings. Proc Inst Civ Eng Munic Eng 2019. [CrossRef]

- Pan W, Su R, Cai Y, Young B. Engineering modular systems for high-rise buildings: an update. Proc Inst Civ Eng Civ Eng 2018;171:148-148. [CrossRef]

- Ruoheng Z, J ZAS, Saeed T, Jennifer W. Long-standing themes and new developments in offsite construction: The case of UK housing. Proc Inst Civ Eng Civ Eng 2019;172:29–35.

- Shan S, Looi D, Cai Y, Ma P, Chen M-T, Su R, et al. Engineering modular integrated construction for high-rise building: a case study in Hong Kong. Proc Inst Civ Eng Civ Eng 2019;172:51-57. [CrossRef]

- Smith RE. Prefab Architecture: A Guide to Modular Design and Construction. John Wiley & Sons; 2011.

- Smith, R. (2016). “Off-Site and Modular Construction Explained” National Institute of Building Sciences and Off-Site Construction Council, 2016.

- Smith, R., Quale, J. (2017). “Offsite Architecture Constructing the Future” New York: Routledge, 2017.

- Stern D. Steel-framed modular construction for high-rise hotels, from https ://www.hotel-online.com/press_releases/release/steel-framed-modular-const ruction-for-high-rise-hotels-what-you-need-to-kno; 2017: 1–12.

- Thomson J. Modular construction: A solution to affordable housing challenges. Cornell Real Estate Rev 2019;17:90–7.

- World Economic Forum. Shaping the future of construction: A breakthrough in mindset and technology; 2016.

- WRAP. Waste reduction potential of offsite volumetric construction. WAS 003- 003: Offsite Construction Case Study; 2018: 1–11.

- Yu Y, Chen Z. Rigidity of corrugated plate sidewalls and its effect on the modular structural design. Eng Struct 2018;175:191–200. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).