Submitted:

05 June 2024

Posted:

10 June 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Methods and Models

2.1. Formulation of the Conceptual Design Problem

2.2. Digital UAV Model

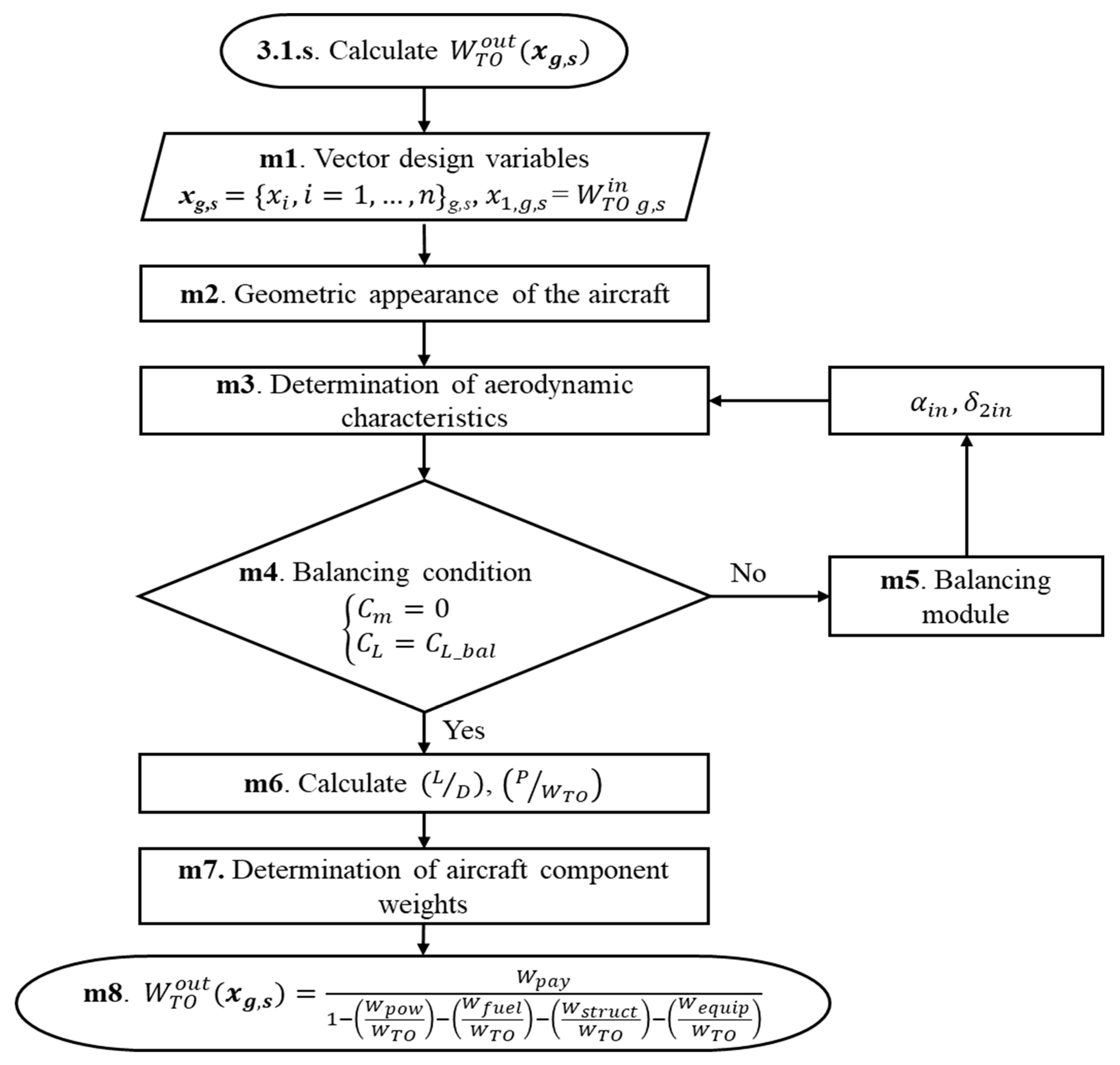

2.2.1. Objective Function

2.2.2. Constraints

2.2.3. Design Variables

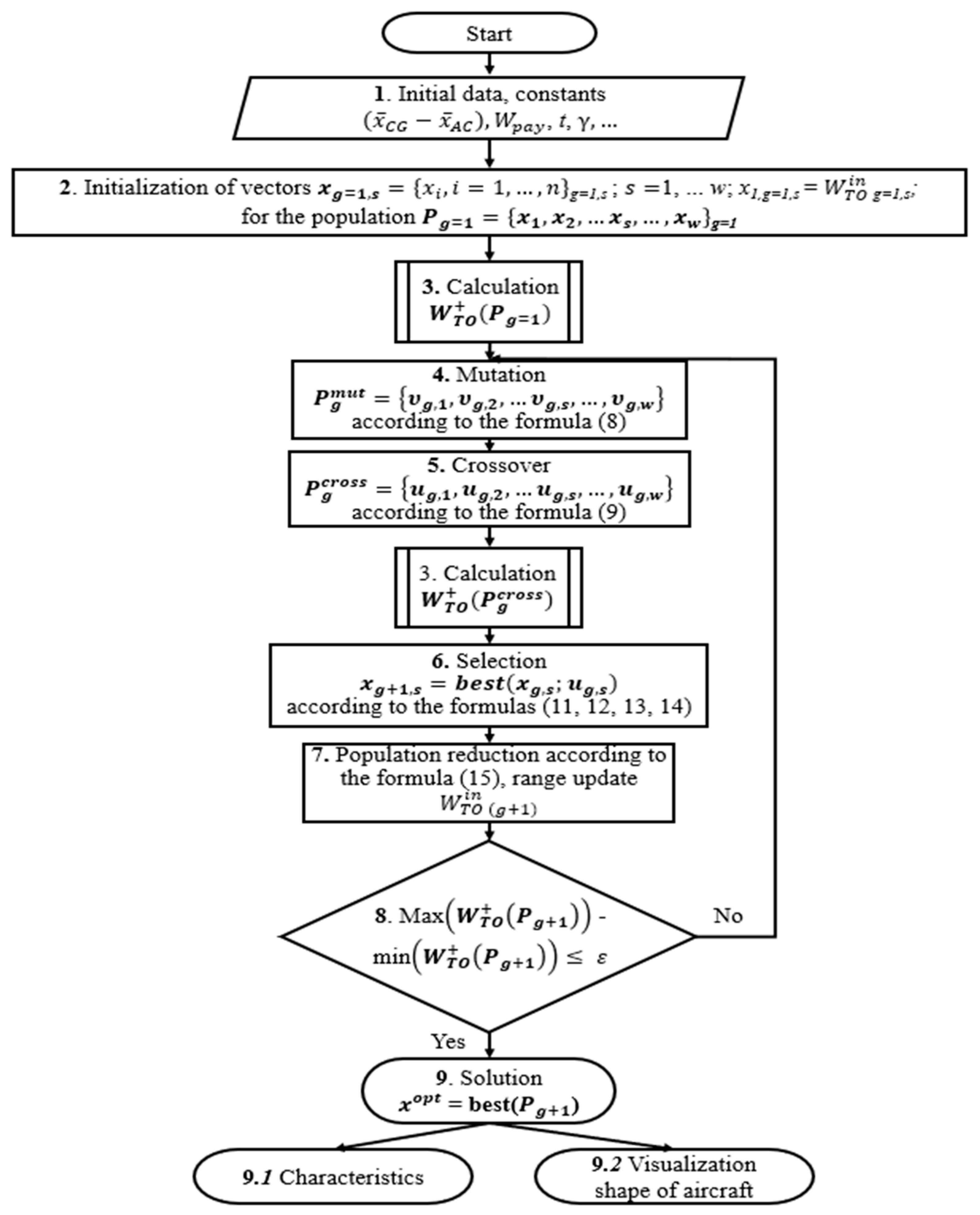

2.3. Methodology for Selecting the Optimal Parameters of an Aircraft-Type UAV

- Block 1

- Block 2

- Block 3

- Block 4 – Mutation

- Block 5 – Crossover

- Block 6 – Selection of individuals and the formation of new population

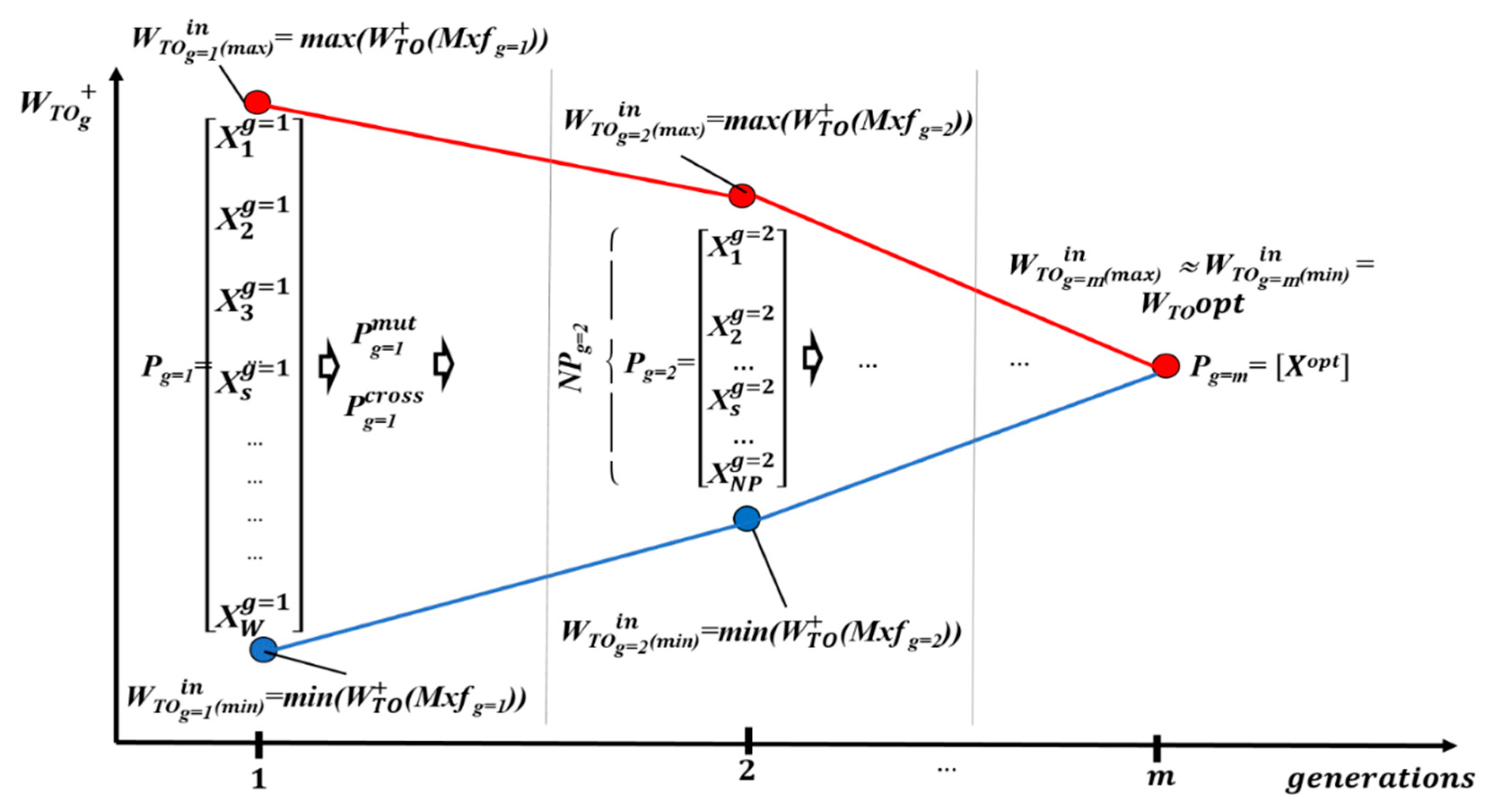

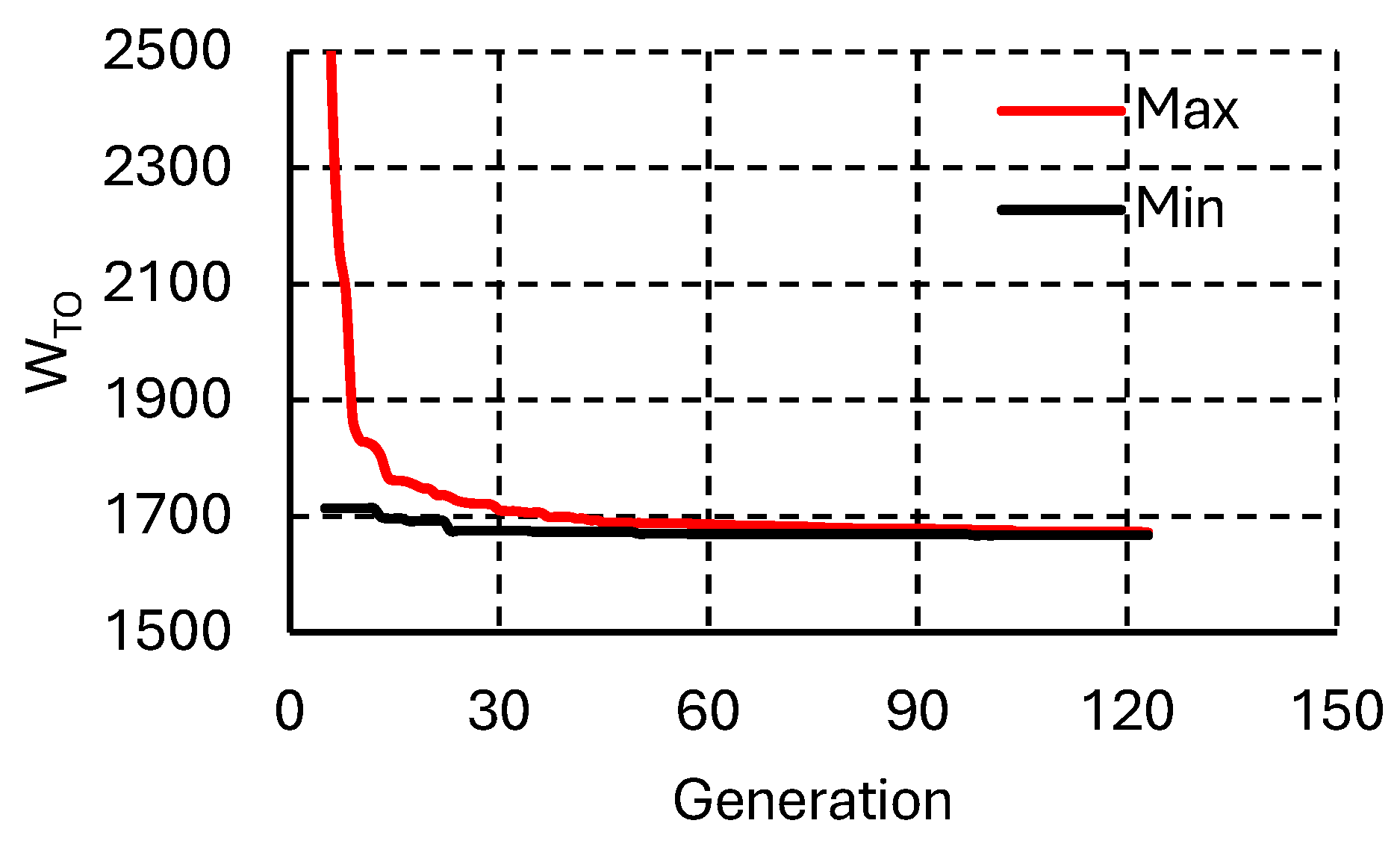

- Block 7 – Population reduction and convergence of the sizing equation

- Block 8

- Block 9

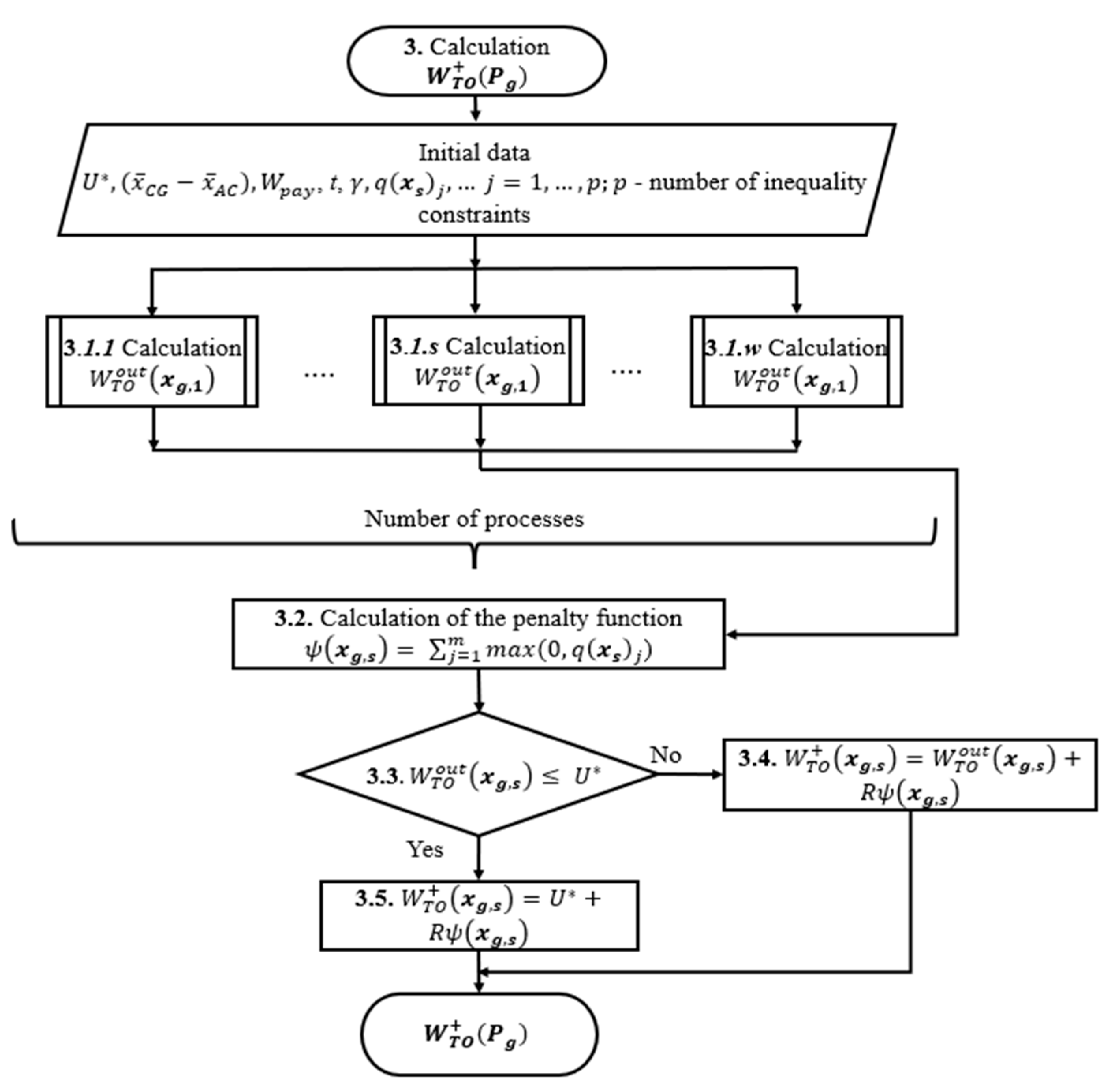

- Calculation of the weights of aircraft parts

- 1.

- Weight of energy carrier

- 2.

- The weight of the power plants

- 3.

- Weight of structure and on-board equipment

- Geometric characteristics (see Figure 5, Block m2)

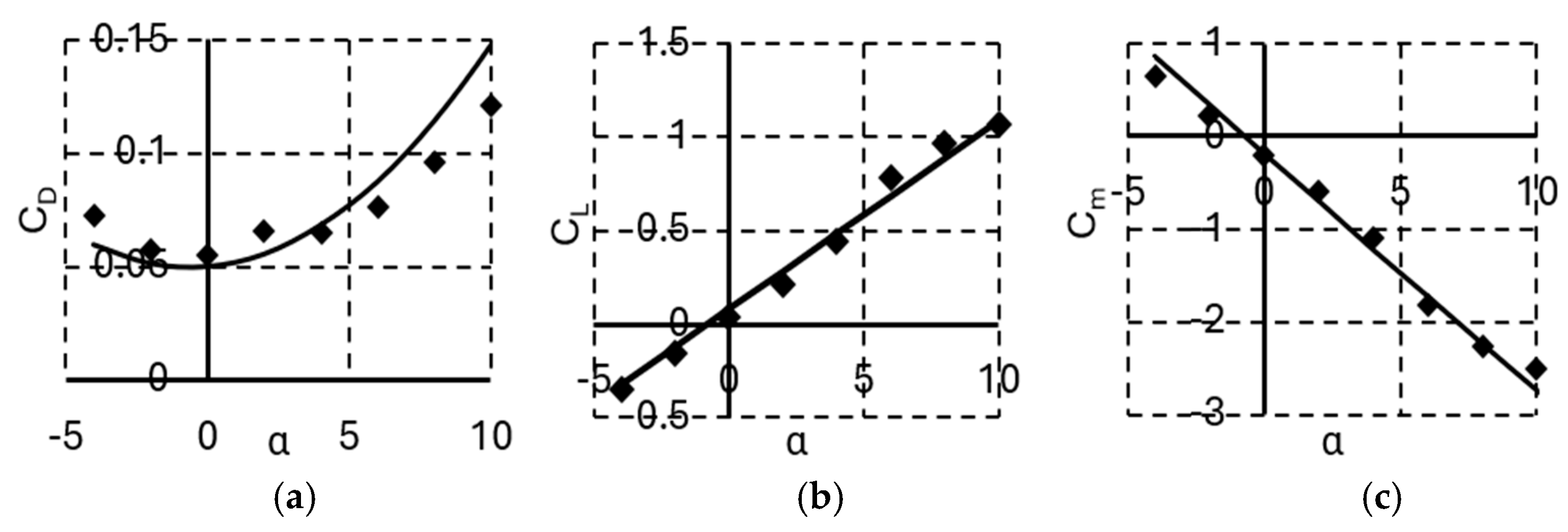

- Calculation of the aerodynamic characteristics of the UAV (see Figure 5, Block m3)

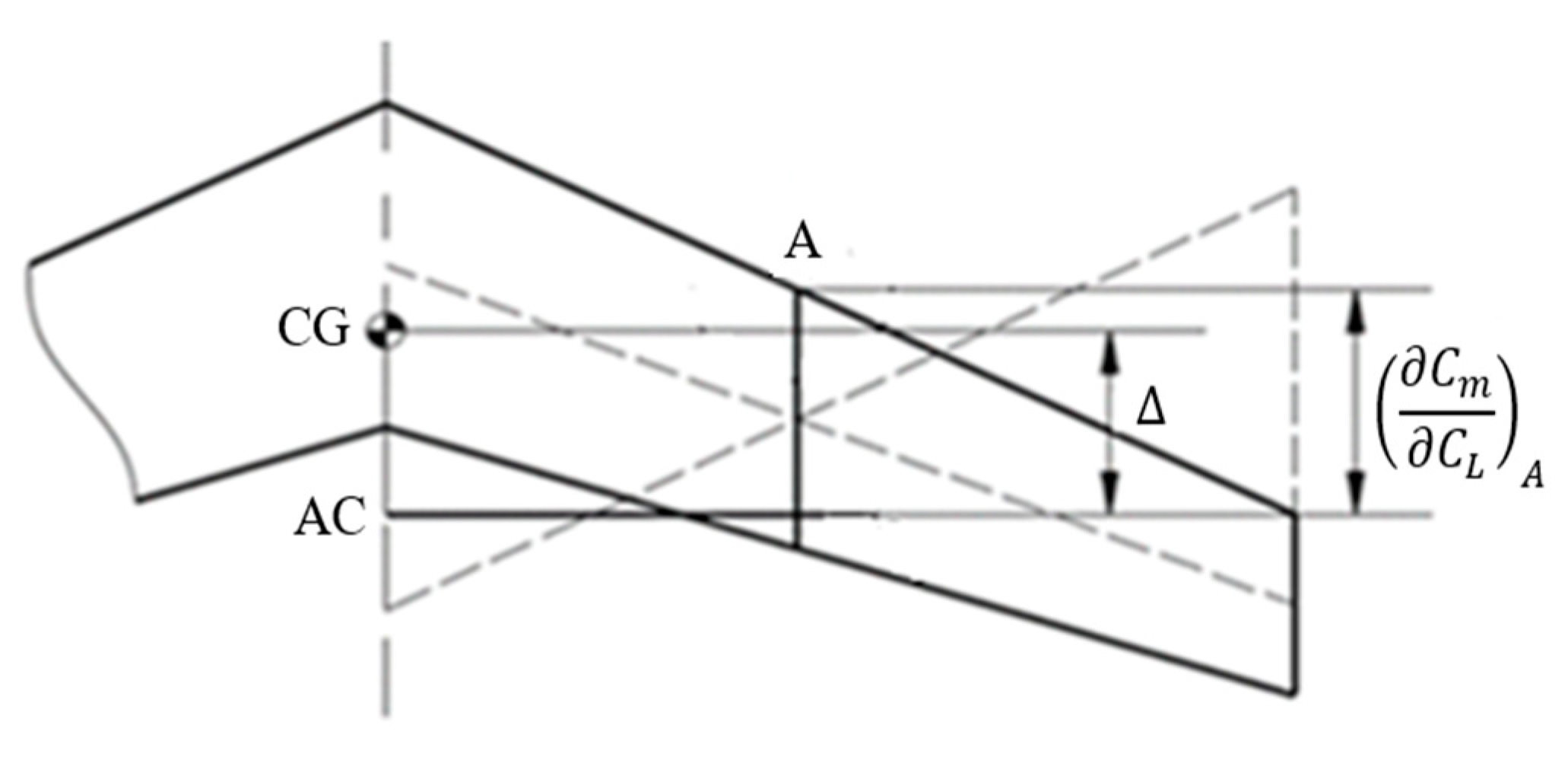

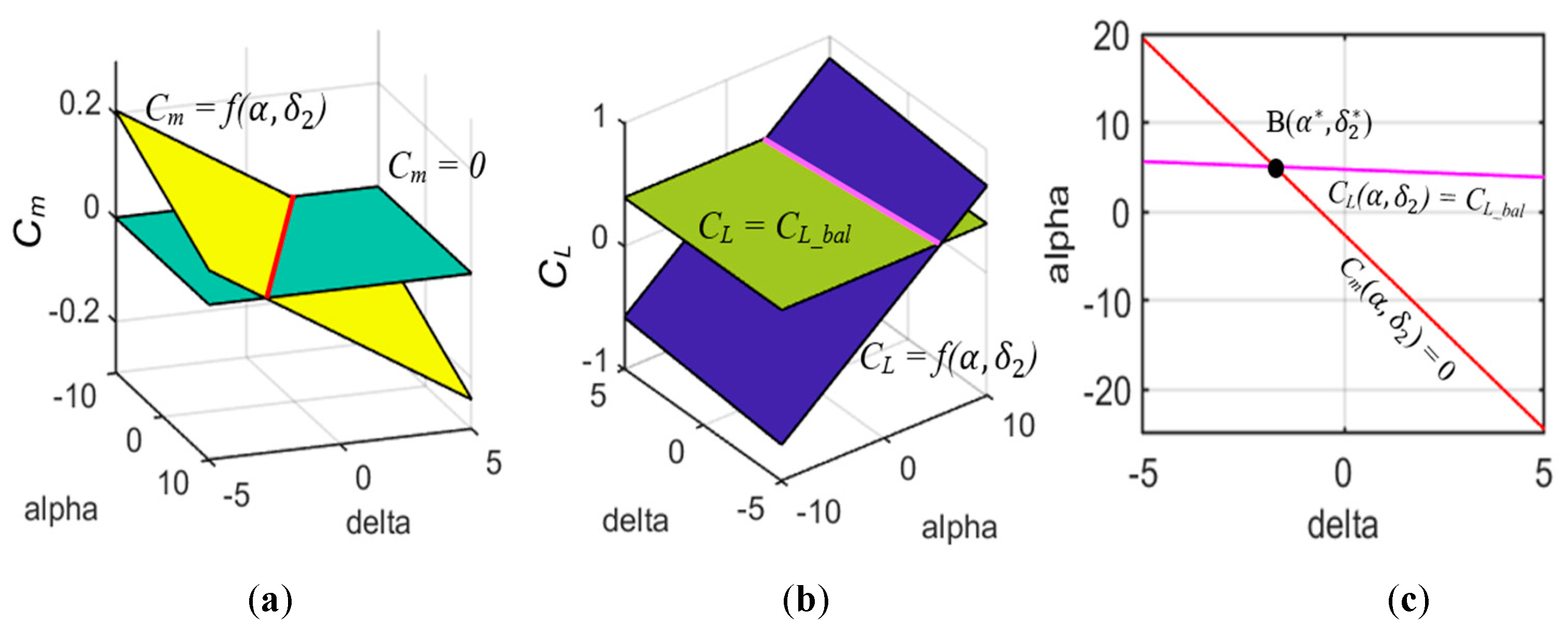

- UAV balancing (see Figure 5, Block m4)

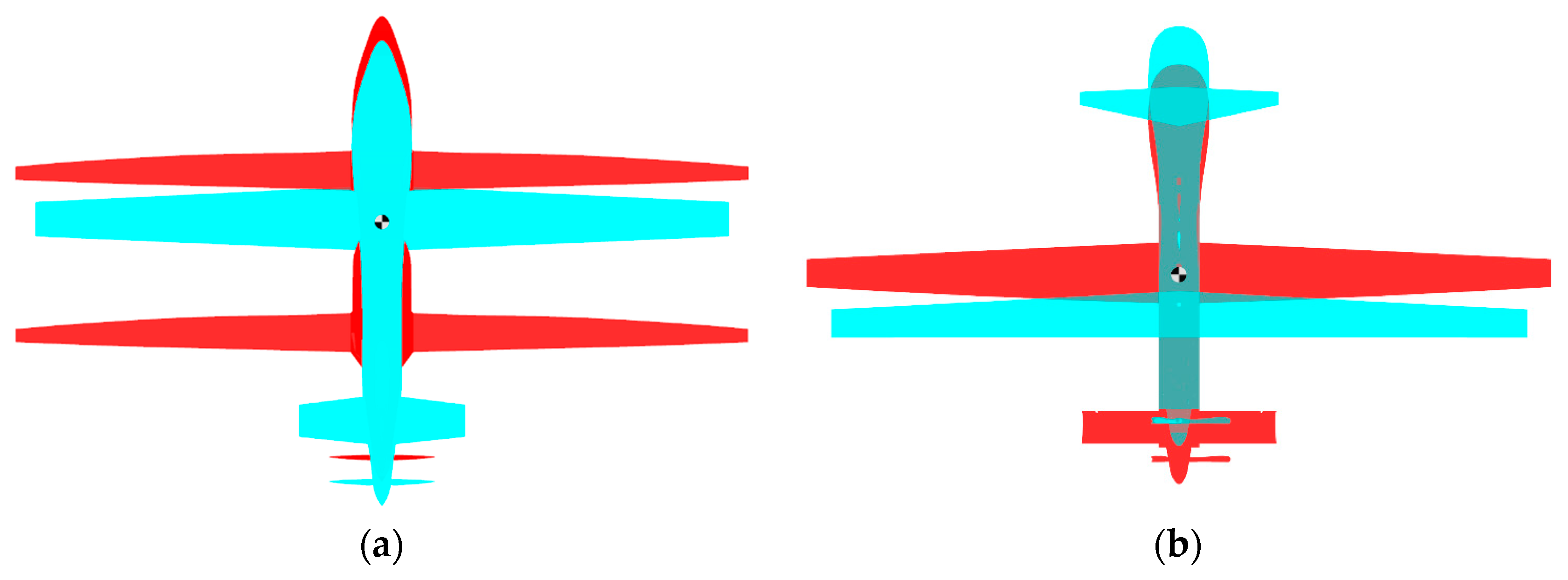

2.4. Visualization of Optimization Results in the Form of a Planned Projection of the Optimal Option and Its Three-Dimensional Model

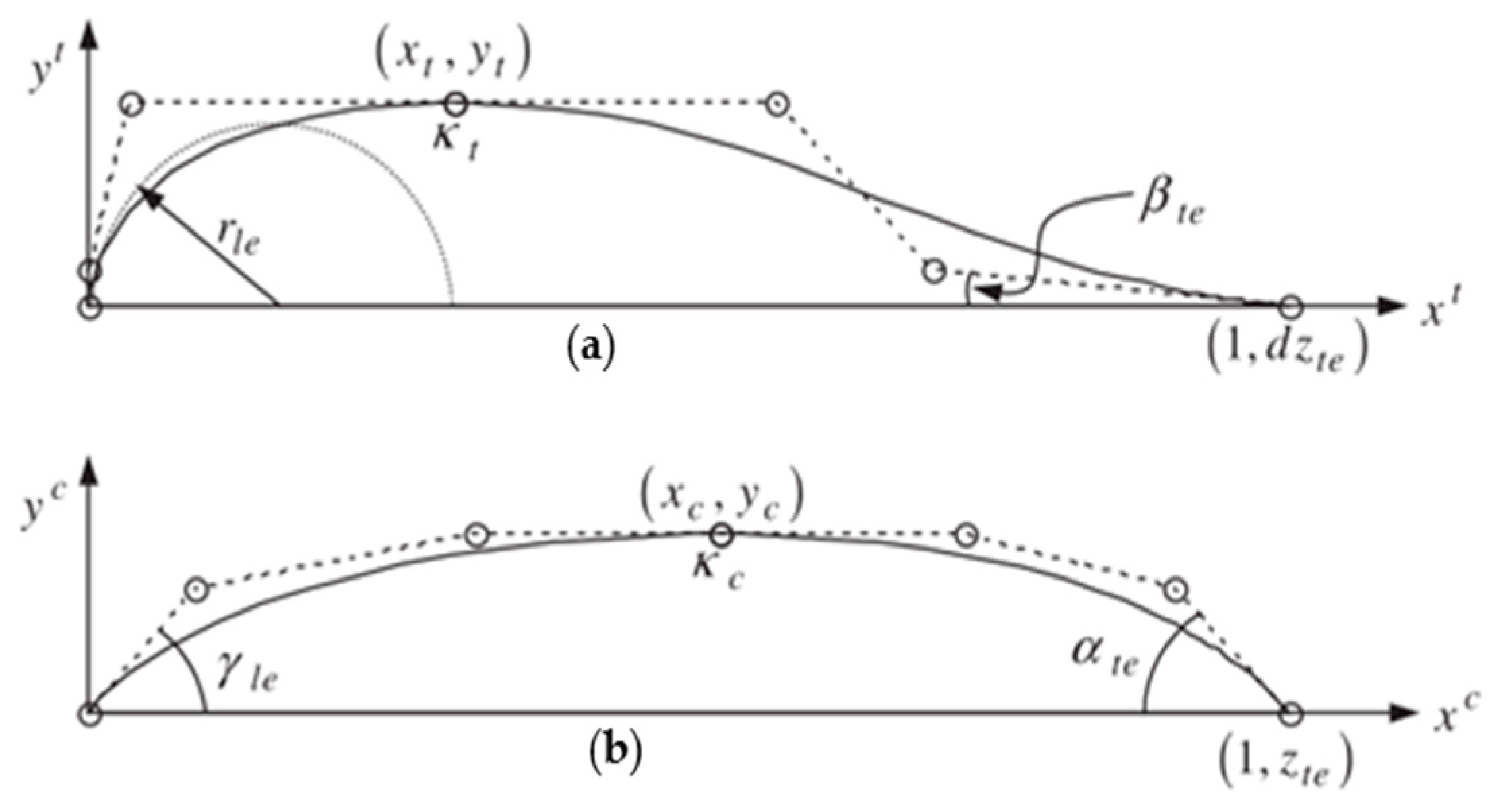

2.5. Selection of the Wing Airfoil with Multilayer Perceptron

3. Assessment of the Reliability of Models and Methods

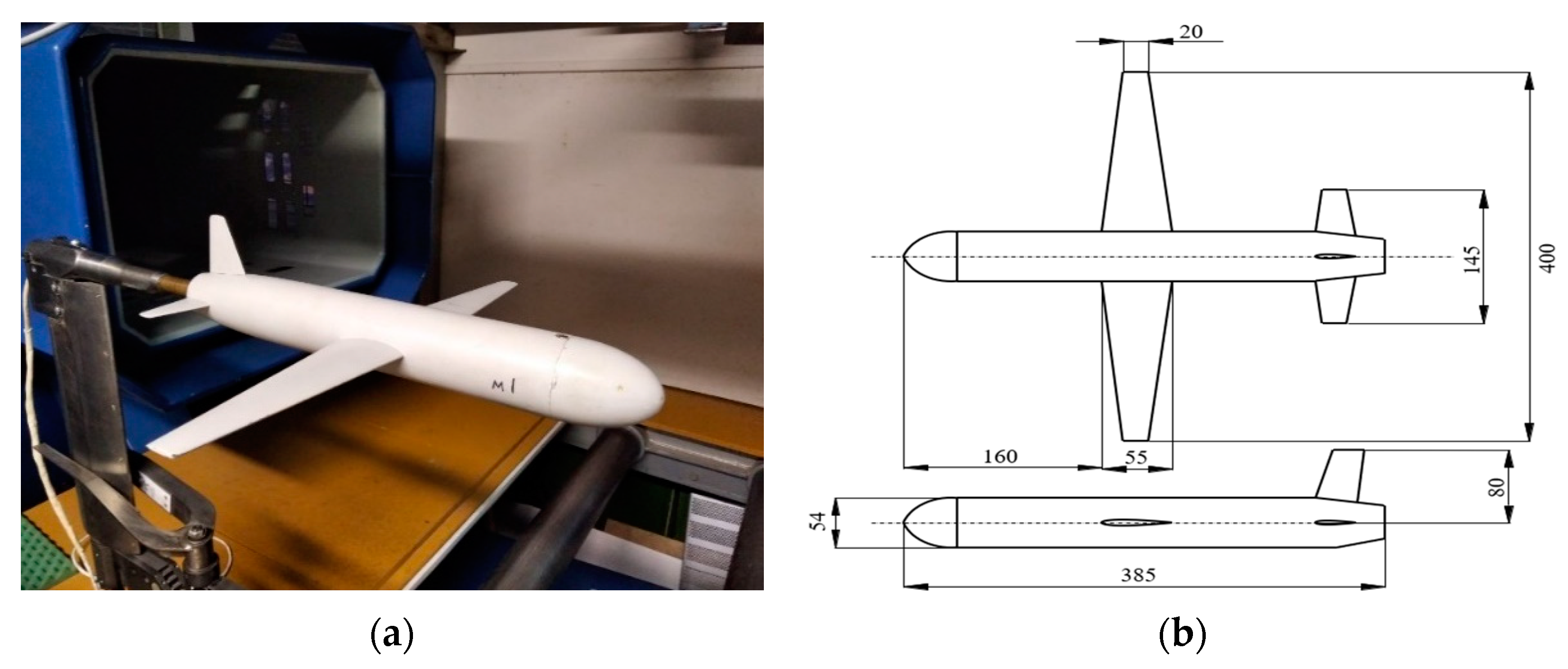

3.1. Validation of Mathematical Models of Aerodynamics

3.2. Validation of Models and Algorithm for Calculating the Objective Function

4. Solving Applied Optimization Problems

| Parameters | Value |

|---|---|

| Lift coefficient constraint (CL) | < 0.6 |

| Constraint of the horizontal tail volume coefficient (cHT) | [0.2…0.6] |

| Initial value of penalty (U*) [kg] | 60000 |

| Optimization stopping criterion: max - min | 1 |

| Number of design variables (D) | 12 |

| Number of initial population (NP0) | 10D |

| Minimum number of generations | 12 |

| Parameters | Optimization | ||||||

| Min value | Max value |

Optimal value |

Initial values | ||||

| U-40 | MQ-1 | U-40 | MQ-1 | ||||

| 1 | 4 | 20 | 14 | 7.6 | 20 | 19 | |

| 2 | [o] | 0 | 25 | 2.7 | 0 | 1 | 7.22 |

| 3 | 0.3 | 1 | 0.53 | 0.34 | 0.33 | 0.36 | |

| 4 | [o] | 0 | 5 | 2.5 | 0 | 2,5 | 2.5 |

| 5 | 4 | 20 | 4 | 18.7 | 20 | 6.75 | |

| 6 | [o] | 0 | 25 | 0 | 3 | 1 | 0 |

| 7 | 0.3 | 1 | 0.63 | 0.62 | 0.33 | 1 | |

| 8 | [o] | -10 | +10 | -2.2 | -2.0 | 2.2 | -2.62 |

| 9 | 3 | 8 | 5.1 | 4.6 | 5.55 | 4.37 | |

| 10 | 0.2 | 5 | 0.2 | 4.9 | 1 | 0.26 | |

| 11 | α [o] | -10 | +10 | 2.8 | 5.2 | - | - |

| 12 | V [m/s] | 40 | 90 | 50 | 45 | 55 | 47 |

| 13 | W/S [kg/m2] | 20 | 110 | 92 | 75 | 90 | 73.2 |

| 14 | WTO [kg] | 500 | 3000 | 1687 | 914 | 2000 | 1020 |

| Parameters | U-40 | MQ-1 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Initial values |

Optimal value |

, % | Initial values |

Optimal value |

, % | ||||||||

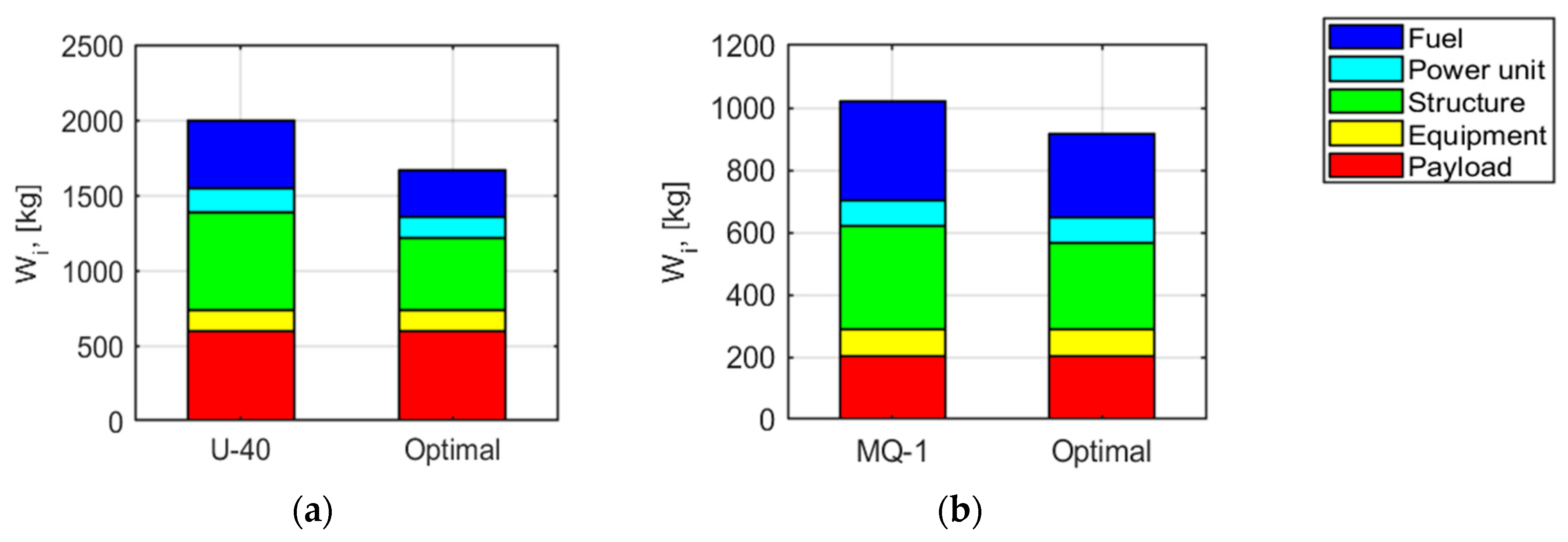

| Take-off weight [kg] | 2000 | 1667 | 16.7 | 1020 | 914 | 10.4 | |||||||

| Payload [kg] | 600 | 600 | 0 | 204 | 204 | 0 | |||||||

| Equipment weight [kg] | n/a | 137 | - | n/a | 84.1 | - | |||||||

| Weights [kg] | forward lift surface | n/a | 181.7 | - | n/a | 22.4 | - | ||||||

| aftward lift surface | n/a | 25.2 | - | n/a | 123.4 | - | |||||||

| vertical tail | n/a | 13.5 | - | n/a | 19.6 | - | |||||||

| fuselage | n/a | 171.6 | - | n/a | 77.6 | - | |||||||

| landing gear | n/a | 84.1 | - | n/a | 36.5 | - | |||||||

| Engine weight [kg] | 152 | 132 | 13.2 | 76 | 76 | 0 | |||||||

| Fuel weight [kg] | 450 | 313.5 | 30.3 | 302 | 266.6 | 11.7 | |||||||

| Propeller weight [kg] | n/a | 8.4 | - | n/a | 3.8 | - | |||||||

| Parameters | U-40 | MQ-1 | ||||

|---|---|---|---|---|---|---|

| Initial values |

Optimal value |

, % | Initial values |

Optimal value |

, % | |

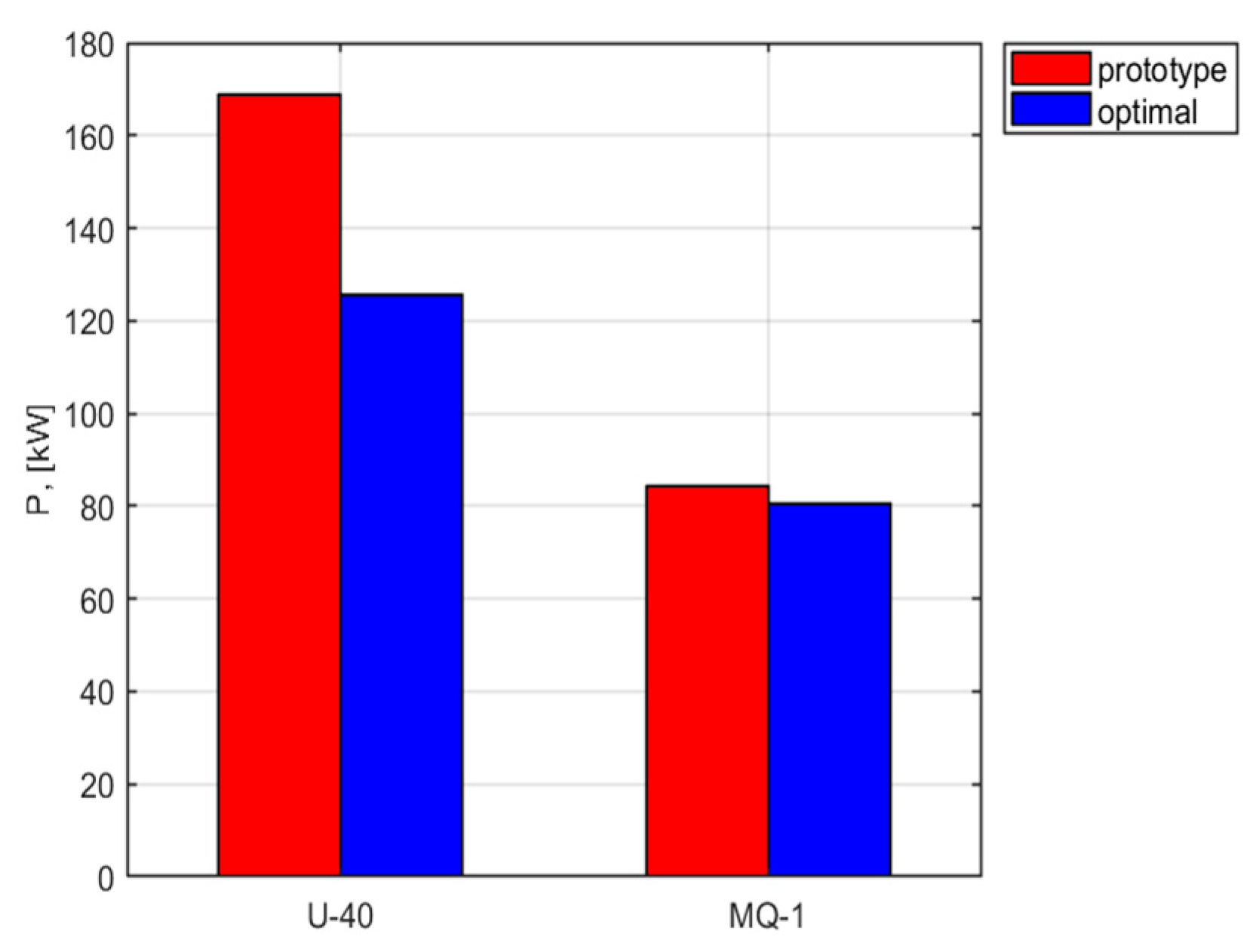

| Engine power [kW] | 2х84.5 | 2х62.9 | 25.6 | 1х84.5 | 1х80.6 | 4.6 |

| Relative position of the center mass | n/a | 0.54 | - | n/a | -0.651 | - |

| Cruise lift coefficient | n/a | 0.59 | - | n/a | 0.59 | - |

| Cruise lift-to-drag ratio | n/a | 26 | - | n/a | 24.7 | - |

5. Conclusion

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| 1 | // Initialization phase | ||||

| 2 | Input design constants; | ||||

| 3 | Input the interval of design variables [xmin, xmax]; | ||||

| 4 | Input optimization algorithm parameters G, NP, NPmin, NPmax, ε, U*, H, p, g=1; | ||||

| 5 | Initialize the initial population P using LHS; | ||||

| 6 | // Parallel loop using Joblib | ||||

| 7 | for s = 1 to w do | ||||

| 8 | Determine take-off weight with module 2; | ||||

| 9 | end for; | ||||

| 10 | Determine ψ(xg=1,s) according to (7) and (xg=1,s) according to (6); | ||||

| 11 | Update U*; | ||||

| 12 | Save(xg=1,s); | ||||

| 13 | Save data of generation g; | ||||

| 14 | Set all values in MCR, MF to 0.5; | ||||

| 15 | Archive A = ∅; | ||||

| 16 | Index counter g = 2; | ||||

| 17 | Index counter k = 1; | ||||

| 18 | // Main loop | ||||

| 19 | while Stop criteria not met do | ||||

| 20 | SCR = ∅, SF = ∅; | ||||

| 21 | for s = 1 to w do | ||||

| 22 | rs = select from [1, H] randomly; | ||||

| 23 | Determine Fg,s; Determine CRg,s; | ||||

| 24 | Determine the mutation vector vg,s; | ||||

| 25 | Define the crossover vector ug,s; | ||||

| 26 | end for; | ||||

| 27 | // Parallel loop using Joblib | ||||

| 28 | for s = 1 to w do | ||||

| 29 | Determine take-off weight with module 2; | ||||

| 30 | end for; | ||||

| 31 | Determine ψ(xg,s) according to (7) and (xg,s) according to (6); | ||||

| 32 | Update U*; | ||||

| 33 | for s = 1 to w do | ||||

| 34 | if(ug,s) ≤ (xg,s) then | ||||

| 35 | xg+1,s = ug,s; | ||||

| 36 | xg,s → A; | ||||

| 37 | CRg,s → SCR, Fg,s → SF; | ||||

| 38 | else | ||||

| 39 | xg+1,s = xg,s; | ||||

| 40 | end if; | ||||

| 41 | end for; | ||||

| 42 | // UpdateMCR,k, MF,k based on SCR, SF; | ||||

| 43 | if SCR = ∅ and SF= ∅ then | ||||

| 44 | MF,g+1,k = meanWL(SF); | ||||

| 45 | if MCR,g,k = -1 or max(SCR) = 0 then | ||||

| 46 | MCR,(g+1),k = -1; | ||||

| 47 | else | ||||

| 48 | MCR,(g+1),k = meanWL(SCR); | ||||

| 49 | end if; | ||||

| 50 | if k > H then | ||||

| 51 | k = 1; | ||||

| 52 | else | ||||

| 53 | k++; | ||||

| 54 | end if; | ||||

| 55 | else | ||||

| 56 | MCR,g+1,k = MCR,g,k; | ||||

| 57 | MF,g+1,k = MF,g,k; | ||||

| 58 | end if; | ||||

| 59 | Save(xg+1,s); | ||||

| 60 | // Update range | ||||

| 61 | Mxf = []; | ||||

| 62 | For s =1 to NP do | ||||

| 63 | if ψ(xg+1,s) = 0 then | ||||

| 64 | Mxf = append(Mxf, xg,s) | ||||

| 65 | end if; | ||||

| 66 | end for; | ||||

| 67 | if size(Mxf) = 0 then | ||||

| 68 | ; | ||||

| 69 | ; | ||||

| 70 | else | ||||

| 71 | = min(Mxf); | ||||

| 72 | = max(Mxf); | ||||

| 73 | end if; | ||||

| 74 | if g ≥ 3 then | ||||

| 75 | Determine NPg+1; | ||||

| 76 | (NPg – NPg+1)-th worst vector→ A; | ||||

| 77 | Delete (NPg – NPg+1)-th worst vector from Pg+1; | ||||

| 78 | end if; | ||||

| 79 | Save data of generation (g+1); | ||||

| 80 | if (max((Pg+1))– min((Pg+1)) then | ||||

| 83 | break; | ||||

| 81 | end if; | ||||

| 82 | g++; | ||||

| 83 | end while; | ||||

| 84 | Output xopt, (xopt); | ||||

Appendix B

| 1 | Input: , , , , , , , , W/S, V, ; | ||

| 2 | Create input files for AVL software to determine aerodynamic characteristics with module 3; | ||

| 3 | Determine αbal and δ2bal with module 4; | ||

| 4 | cxi, cya, mz = runAVL(, , , , , , , , W/S, V, αbal, δ2bal); | ||

| 5 | Determine сх0 according to empirical formulas; | ||

| 6 | Determine the lift-to-drag ratio ; | ||

| 7 | Determine ; | ||

| 8 | Determine CD; | ||

| 9 | Determine T; | ||

| 10 | // Determine weight components during climb, cruise, and descent phases | ||

| 11 | Determine according to (26); | ||

| 12 | according to (19); | ||

| 13 | if type_motor == ‘eltr’ then | ||

| 14 | according to (18); | ||

| 15 | ; | ||

| 16 | else | ||

| 17 | according to (17); | ||

| 18 | ; | ||

| 19 | end if; | ||

| 20 | |||

| 21 | = max (); | ||

| 22 | = max (); | ||

| 23 | Determine according to (16); | ||

Appendix C

| 1 | Input: , , , S1, , , , S2, L2, V, ; |

| 2 | Determine , , MACaccording to (29), (22), (25); |

| 3 | Write input file for AVL; |

| 4 | Determine CDi, CL, by AVL; |

Appendix D

| 1 | Input: , , , , , , , W/S, V, ; | |||

| 2 | Create input files for AVL software and determine aerodynamic characteristics with module 3; | |||

| 3 | Determine according to (28); | |||

| 4 | for i in range(2) do | |||

| 5 | for j in range(2) do | |||

| 6 | = [i]; | |||

| 7 | , runAVL(,,,,,,,, W/S, V,); | |||

| 8 | Cm0 = interpolation(0, , ); | |||

| 9 | Determine Cm() according to (30); | |||

| 10 | end for; | |||

| 11 | end for; | |||

| 12 | Determine αbal и δ2bal according to (29); | |||

References

- Komarov, V.A.; Borgest, N.M.; Vislov, I.P.; Vlasov, N.V.; Kozlov, D.M.; Korolkov, O.N.; Mainskov, V.N. Kontseptual'noe proektirovanie samoleta [Aircraft concept design]; Samara National Research University: Samara, Russia, 2013; ISBN 978-5-7883-0921-7. [Google Scholar]

- Raymer, D.P. Aircraft Design: A Conceptual Approach, 2nd ed.; American Institute of Aeronautics and Astronautics, Inc.: Washington, USA, 2018; ISBN 0-930403-51-7. [Google Scholar]

- Nicolai, L.M.; Carichner, G.E. Fundamentals of Aircraft and Airship Design; American Institute of Aeronautics and Astronautics: Columbia, LL, USA, 2010; ISBN 978-1-60086-751-4. [Google Scholar]

- Torenbeek, E. Advanced Aircraft Design: Conceptual Design, Technology and Optimization of Subsonic Civil Airplanes; Wiley: Hoboken, NJ, USA, 2013; ISBN 978-1-118-56811-8. [Google Scholar]

- Kroo, I.; Altus, S.; Braun, R.; Gage, P.; Sobieski, I. Multidisciplinary Optimization Methods for Aircraft Preliminary Design. In Proceedings of the 5th Symposium on Multidisciplinary Analysis and Optimization, Panama, FL, USA, 7–9 September 1994; pp. 697–707. [Google Scholar]

- Badyagin, A.A.; Mukhamedov, F.A. Proektirovanie legkikh samoletov [Design of light aircraft]; Mashinostroenie Publ: Moscow, Russia, 1978. [Google Scholar]

- Eger, S.M.; Mishin, V.F.; Liseytsev, N.K.; Badyagin, A.A.; Rotin, V.E.; Sklyansky, F.I.; Kondrashov, N.A.; Kiselev, V.A.; Fomin, N.A. Proektirovanie samoletov [Aircraft design]; Mashinostroenie Publ: Moscow, Russia, 1983. [Google Scholar]

- Sheinin, V.M.; Kozlovsky, V.I. Vesovoye proektirovanie i effektivnost' passazhirskikh samoletov [Weight design and efficiency of passenger aircraft]; Mashinostroenie Publ: Moscow, Russia, 1977. [Google Scholar]

- Komarov, V.A. Tochnoe proektirovanie [Concurrent design]. Ontology of Design 2012, 3, 8–23. [Google Scholar]

- Weishaar, T.A.; Komarov, V.A. Chelovecheskii faktor v proektirovanii aviatsionnykh konstruktsii [Human Factor in the Design of Aviation Structures]. All-Russian Scientific and Technical Journal "Flight" 1998, 1, 17–23. [Google Scholar]

- Komarov, V.A.; Weisshaar, T.A. New Approach to Improving the Aircraft Structural Design process. Journal of Aircraft 2002, 39(2), p. 227-233. [CrossRef]

- Manning, V.M. High Speed Civil Transport Design Using Collaborative Optimization and Approximate Models; Northern Trust Corporation: Chicago, LL, USA, 1997. [Google Scholar]

- Lukyanov, O. Razrabotka Metodiki Vybora Oblika Gruzovykh Samolotov s Ispol’zovaniyem Mnogodistsiplinarnoy Optimizatsii [Development of a Methodology for Selecting the Shape of Cargo Aircraft Using Multidisciplinary Optimization]. Candidate of engineering sciences thesis, Samara National Research University, Samara, Russia, 2019.

- Komarov, V.; Lukyanov, O. Multidisciplinary Optimization of the Cargo Airplane Wing Parameters. All-Russ. Sci.-Tech. J. Polet 2018, 3, 3–15. [Google Scholar]

- Martins, J.R.R.A.; Kenway, G.; Brooks, T. Multidisciplinary Design Optimization of Aircraft Configurations Part 2: High-Fidelity Aerostructural Optimization; University of Michigan: Ann Arbor, MI, USA, 2016. [Google Scholar]

- Wunderlich, T.; Dähne, S.; Heinrich, L.; Reimer, L. Multidisciplinary Optimization of an NLF Forward Swept Wing in Combination with Aeroelastic Tailoring Using CFRP. CEAS Aeronaut. J 2017, 8, 673–690. [Google Scholar] [CrossRef]

- Sgueglia, A.; Schmollgruber, P.; Bartoli, N.; Benard, E.; Morlier, J.; Jasa, J.; Martins, J.R.R.A.; Hwang, J.T.; Gray, J.S. Multidisciplinary Design Optimization Framework with Coupled Derivative Computation for Hybrid Aircraft Journal of Aircraft, 2020, 57(4), p. 715–729. [CrossRef]

- Leifsson, L. Multidisciplinary Design Optimization of Low-Noise Transport Aircraft [Electronic Resource]. Ph.D. thesis, Virginia Polytechnic Institute and State University, Virginia, Montgomery, 2005.

- Champasak, P.; Panagant, N.; Pholdee, N.; Bureerat, S.; Yildiz, A.R. Self-Adaptive Many-Objective Meta-Heuristic Based on Decomposition for Many-Objective Conceptual Design of a Fixed Wing Unmanned Aerial Vehicle. Aerosp. Sci. Technol 2020, 100, 105783. [Google Scholar] [CrossRef]

- Escobar-Ruiz, A.G.; Lopez-Botello, O.; Reyes-Osorio, L.; Zambrano-Robledo, P.; Amezquita-Brooks, L.; Garcia-Salazar, O. Conceptual Design of an Unmanned Fixed-Wing Aerial Vehicle Based on Alternative Energy. International Journal of Aerospace Engineering 2019, 2019, 8104927. [Google Scholar] [CrossRef]

- Chung, P.H.; Ma, D.M.; Shiau, J.K. Design, Manufacturing, and Flight Testing of an Experimental Flying Wing UAV. Appl. Sci. 2019, 9(15), 3043. [Google Scholar] [CrossRef]

- Boutemedjet, A.; Samardžic´, M.; Rebhi, L.; Rajic´, Z.; Mouada, T. UAV aerodynamic design involving genetic algorithm and artificial neural network for wing preliminary computation. Aerospace Science and Technology 2019, 84, 464–483. [Google Scholar] [CrossRef]

- Aksugur, M.; Inalhan, G. Design Methodology of a Hybrid Propulsion Driven Electric Powered Miniature Tailsitter Unmanned Aerial Vehicle. Journal of Intelligent & Robotic Systems, 2010; 57, 505–529. [Google Scholar] [CrossRef]

- Gu, H.; Lyu, X.; Li, Z.; Zhang, F. Coordinate Descent Optimization for Winged-UAV Design. Journal of Intelligent & Robotic Systems 2020, 97, 109–124. [Google Scholar] [CrossRef]

- Ming, L.; Junqiang, B.; Li, L.; Xiaoxuan, M.; Qian, L.; Bao, C. A gradient-based aero-stealth optimization design method for flying wing aircraft. Aerospace Science and Technology 2019, 92, 156–169. [Google Scholar] [CrossRef]

- Parada, L.M.A. Conceptual and Preliminary Design of a Long Endurance Electric UAV. Master’s Thesis, University of Lisbon, Lisbon, Portugal, 2016. [Google Scholar]

- Papageorgiou, A. Design Optimization of Unmanned Aerial Vehicles: A System of Systems Approach. Ph.D. dissertation, Linköping studies in science and technology, Linköping, Sweden, 2019.

- Bowers, P.M. Unconventional aircraft; Blue Ridge Summit, PA: TAB Books: New York, USA, 1984; 323p. [Google Scholar]

- Eger, S.M.; Liseytsev, N.K.; Samoilovich, O.S. Osnovyi avtomatizirovannovo proektirovaniya samoletov [Fundamentals of Automated Design of Aircraft]; Mashinostroenie Publ: Moscow, Russia, 1986; 232p. [Google Scholar]

- Malchevskiy, V.V. Matrichno-topologicheskii metod sinteza i komponovki samoleta (opyt avtomatizatsii tvorcheskoy deyatel'nosti konstruktora) [Matrix-topological method of synthesis and aircraft layout (experience of automation of the designer's creative activity)]; Monograph, Moscow Aviation Institute: Moscow, Russia, 2011; 356p. [Google Scholar]

- Safavi, E.; Tarkian, M.; Gavel, H.; Ölvander, J. Collaborative Multidisciplinary Design Optimization. A Framework Applied on Aircraft Conceptual System Design. Concurrent Engineering, 2015; 23, 236–249. [Google Scholar] [CrossRef]

- Cherniaev, A.; Komarov, V. Multistep Optimization of Composite Drive Shaft Subject to Strength, Buckling, Vibration and Manufacturing Constraints. Applied Composite Materials, 2015; 22, 475–487. [Google Scholar] [CrossRef]

- Komarov, V.A.; Pavlov, A.A.; Pavlova, S.A. Designing, manufacturing and testing of complex form structures from layered polymer composite materials. Deformation and destruction of composite materials and structures, 2018; 64–66. [Google Scholar]

- Kurkin, E.; Kishov, E.; Espinosa Barcenas, O.U.; Chertykovtseva, V. Gate Location Optimization of Injection Molded Aerospace Brackets Using Metaheuristic Algorithms. In Proceedings of the 2021 International Scientific and Technical Engine Conference (EC), Samara, Russian Federation; 2021; pp. 1–6. [Google Scholar] [CrossRef]

- Simanowitsch, D.; Theiss, A.; Sudhi, A.; Badrya, C. Comparison of Gradient-Based and Genetic Algorithms for Laminar Airfoil Shape Optimization. In: AIAA SciTech 2022 Forum, pp. 1-21. ARC. AIAA Scitech Forum 2022, 3.-7. Jan. 2022, San Diego, USA. ISBN 978-162410631-6. [CrossRef]

- Zingg, D.W.; Nemec, M.; Pulliam, T.H. A comparative evaluation of genetic and gradient-based algorithms applied to aerodynamic optimization. European Journal of Computational Mechanics 2008, 17, 2008. [Google Scholar] [CrossRef]

- Xin-She, Y. Engineering optimization: a introduction with metaheuristic applications; John Wiley & Sons, Inc: Hoboken, NJ, USA, 2010; 376p, ISBN 978-0-470-58246-6. [Google Scholar] [CrossRef]

- Blum, C.; Roli, A. Metaheuristics in combinatorial optimization: overview and conceptual comparison. ACM computing surveys, 2001; 35, 268–308. [Google Scholar] [CrossRef]

- Almufti, S.M.; Shaban, A.A.; Ali, Z.A.; Ali, R.I.; Fuente, J.A.D. Overview of metaheuristic algorithms. Polaris Global Journal of Scholarly Research and Trends, 2023; 2, 10–32. [Google Scholar] [CrossRef]

- Pioquinto, J.G.Q.; Moreno, R.A.F. Methods for increasing the efficiency of the differential evolution algorithm for aerodynamic shape optimization applications. In Proceedings of the XXVI All-Russian Seminar on motion Control and Navigation of Aircraft., Russia, 14-16 June 2023; pp. 166–171. [Google Scholar]

- Lazarev, I.B. Osnovy optimal'nogo proektirovaniya konstruktsii [Fundamentals of optimal design of structures]; Siberian State Academy of Railway Engineering: Novosibirsk, Russia, 1995; 295p. [Google Scholar]

- Malkov, V.P.; Ugodchikov, A.G. Optimization of elastic systems; Nauka Publ: Moscow, Russia, 1981. [Google Scholar]

- Srednevysonyi bespilotnyi letatel’nyi apparat bol’šoi prodolžiten’nosti polota United 40 [Medium-altitude long-endurance unmanned aerial vehicle United 40]. Available online: https://vpk.name/library/f/united-40.html (accessed on 2 December 2023).

- The General Atomics "Predator MQ-1" UAS. Available online: https://barnardmicrosystems.com/UAV/uav_list/predator.html (accessed on 2 December 2023).

- Bolkhovitinov, V.F. Puti razvitiya letatelnykh apparatov [Ways of development of flying apparatus]; Oborongiz Publ.: Moscow, Russia, 1962; 132p. [Google Scholar]

- Komarov, V.A. Vesovoy analiz aviatsionnykh konstruktsii: teoreticheskie osnovy [Weight analysis of aviation structures: theoretical foundations]. All-Russian Scientific and Technical Journal “Flight” 2000, 1, 31–39. [Google Scholar]

- Tanabe, R.; Fukunaga, A. Success-history based parameter adaptation for Differential Evolution. 2013 IEEE Congress on Evolutionary Computation, Cancun, Mexico, 2013, 71–78. [CrossRef]

- Jin, R.; Chen, W. An efficient algorithm for constructing optimal design of computer experiments. Proceedings of DETC’03 ASME 2003 Design Engineering Technical Conferences and Computers and Information in Engineering Conference Chicago, Illinois, USA, 2-6 September 2003. [Google Scholar]

- Viktorin, A.; Senkerik, R.; Pluhacek, M.; Kadavy, T.; Jasek, R. A Lightweight SHADE-Based Algorithm for Global Optimization - liteSHADE. Lecture Notes in Electrical Engineering 2020, 554, 197–206. [Google Scholar] [CrossRef] [PubMed]

- Storn, R.; Price, K. Differential Evolution - A Simple and Efficient Adaptive Scheme for Global Optimization Over Continuous Spaces. Journal of Global Optimization, 1995; 23. [Google Scholar]

- Storn, R.; Price, K. Differential evolution - A Simple and Efficient Heuristic for Global Optimization over Continuous Spaces. Journal of Global Optimization, 1997; 11, 341–359. [Google Scholar] [CrossRef]

- Ali, M.M.; Zhu, W.X. A penalty function-based differential evolution algorithm for constrained global optimization. Comput Optim Appl, 2013; 54, 707–739. [Google Scholar] [CrossRef]

- Pioquinto, J.G.Q.; Shakhov, V.G. Acceleration of Evolutionary Optimization for Airfoils Design with Population Size Reduction Methods. In Proceedings of 20 Int. Conf. on the Aviation and Cosmonautics. Samara, Russia, 2021; pp. 22–26. [Google Scholar]

- Wong, I.; Liu, W.; Ho, C.H.; Ding, X. Continuous adaptive population reduction (CAPR) for differential evolution optimization. SLAS Technology, 2017; 22, 289–305. [Google Scholar] [CrossRef]

- Tanabe, R.; Fukunaga, A.S. Improving the search performance of SHADE using linear population size reduction. Proceedings of 2014 IEEE Congress on Evolutionary Computation (CEC), Beijing, China; 2014; pp. 1658–1665. [Google Scholar] [CrossRef]

- Barcenas, O.U.E.; Pioquinto, J.G.Q.; Kurkina, E.; Lukyanov, O. Multidisciplinary Analysis and Optimization Method for Conceptually Designing of Electric Flying-Wing Unmanned Aerial Vehicles. Drones 2022, 6(10), 307. [Google Scholar] [CrossRef]

- AVL Overview. Available online: https://web.mit.edu/drela/Public/web/avl/ (accessed on 13 October 2023).

- Viana, F.A. A tutorial on Latin hypercube design of experiments. Quality and reliability engineering international, 2015; 32, 1975–1985. [Google Scholar] [CrossRef]

- Sharma, H. Lightweight Pipelining in Python. Using Joblib for Storing the Machine Learning Pipeline to a File. Available online: https://towardsdatascience.com/lightweight-pipelining-in-python-1c7a874794f4 (accessed on 2 November 2023).

- Belotserkovsky, S.M. Thin carrying surface in the subsonic flow of gas. Ed. by N.I. Rozalskaya, I.Sh. Axelrod, T.D. Doverman. Nauka Publ: Moscow, Russia, 1965; 244 p.

- Katz, J.; Allen, P. Low-Speed Aerodynamics, 2nd ed.; Cambridge University Press: Cambridge, UK, 2001; 126p. [Google Scholar] [CrossRef]

- Budziak, K. Aerodynamic Analysis with Athena Vortex Lattice (AVL); Hamburg university of applied sciences: Hamburg, Germany, 2015. [Google Scholar]

- FreeCAD. Available online: https://www.freecad.org/ (accessed on 21 January 2024).

- Nikolaev, N.V. Optimization of airfoils along high-aspect-ratio wing of long-endurance aircraft in trimmed flight. Journal of Aerospace Engineering 2019, 32(6). 32(6). [CrossRef]

- Derksen, R.W.; Rogalsky, T. Bezier-PARSEC: An optimized aerofoil parameterization for design. Advances in Engineering Software, 2010; 41, 923–930. [Google Scholar] [CrossRef]

- Espinosa Barcenas, O.U.; Quijada Pioquinto, J.G.; Kurkina, E.; Lukyanov, O. Surrogate aerodynamic wing modeling based on a multilayer perceptron. Aerospace, 2023; 10, 149. [Google Scholar] [CrossRef]

- Lukyanov, O.E.; Tarasova, E.V.; Martynova, V.A. Remote control of experimental installation and automation of experimental data processing. In Proceedings of the Samara Scientific Center of the Russian Academy of Sciences, Samara, Russia; 2017; pp. 128–132. [Google Scholar]

- Lukyanov, O.E.; Martynova, V.A. Eksperimental'nye issledovaniya aerodinamicheskikh kharakteristiki modeli korpusha nesushchey forma [Experimental studies of the aerodynamic characteristics of the model of the hull of the bearing form]. In Proceedings of the Samara Scientific Center of the Russian Academy of Sciences; 2016; pp. 83–89. [Google Scholar]

| Parameters | U-40 | Calculation | % | MQ-1 | Calculation | % |

|---|---|---|---|---|---|---|

| Take-off weight [kg] | 2000 | 2055 | 2.68 | 1020 | 1015 | 0.49 |

| Payload [kg] | 600 | 600 | 0 | 204 | 204 | 0 |

| Engine weight [kg] | 152 | 150 | 1.3 | 76 | 79 | 3.9 |

| Fuel weight [kg] | 450 | 458 | 1.8 | 302 | 316 | 4.4 |

| Empty weight [kg] | 950 | 997 | 4.7 | 514 | 495 | 3.7 |

| Max engine power [kW] | 2х84.5 | 2х84.1 | 0.01 | 84.5 | 88.3 | 4.3 |

| Cruise lift-to-drag ratio | n/a | 24.8 | - | n/a | 23.2 | - |

| Parameters | U-40 | MQ-1 | |

|---|---|---|---|

| Flight endurance [h] | 24 | 35 | |

| Static margin longitudinal stability | -0.1 | ||

| Specific fuel consumption [kg/(kW.h)] | Climb | 0.285 | |

| Cruise | 0.27 | ||

| Flight path angle [o] | Climb | +5 | |

| Cruise | 0 | ||

| Declimb | -5 | ||

| Propeller efficiency | 0.75 | ||

| Payload [kg] | 600 | 204 | |

| Specific weight engine [dаN/kW] | 0.87 | ||

| Parameter | Design interval | Parameter | Design interval |

|---|---|---|---|

| rle | [-0.030, -0.001] | γle | [-0.01, 0.32] |

| xt | [0.23, 0.50] | xc | [0.20, 0.85] |

| yt | [0.030, 0.095] | yc | [0.010, 0.065] |

| kt | [-0.9, -0.2] | kc | [-1.000, 0.025] |

| βte | [0.01, 0.40] | αte | [0.01, 0.70] |

| dzte | [0, 0] | zte | [0, 0] |

| α | [0, 4]° |

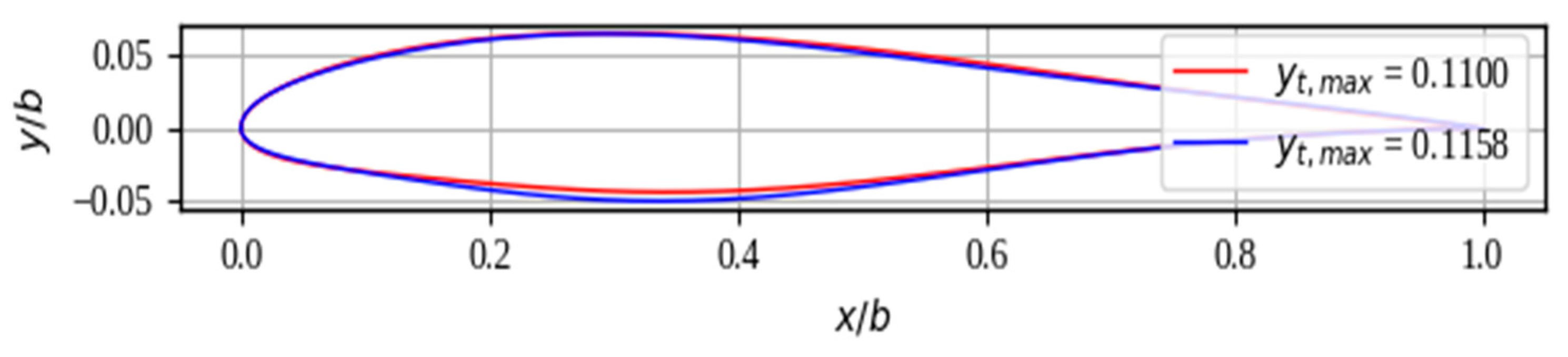

| Airfoil | α [°] | cl | cd | cl1.5/cd | yt,max |

|---|---|---|---|---|---|

| 1 | 3.9 | 0.59 | 0.0106 | 42.7059 | 0.1100 |

| 2 | 3.9 | 0.59 | 0.0106 | 42.7059 | 0.1158 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).