1. Introduction

Bone drilling is a medical procedure that involves the creation of small holes or drilling into bones for various purposes, including diagnosis, treatment, and research. Although bone drilling may be invasive, this technique has become an integral part of modern medical science and offers various important benefits. Bone drilling plays a crucial role in accurately diagnosing various diseases and conditions. In addition to diagnosis, bone drilling also makes a significant contribution to medical research. The development of safer and more precise drilling equipment and techniques has become possible because of the efforts of scientists and doctors. These innovations have a positive impact on patient safety and the effectiveness of medical procedures and can help reduce the risk of complications and speed up the healing process. In bone drilling, bone structures that are examined and treated with nails and screws are generally composed of three layers of the inner base bone, namely the first cortical bone, spongy bone, and second cortical bone layer [

1].

Currently, in orthopedic surgery, bone drilling is carried out using a manual hand drill, and the speed at which the drill bit moves into the bone is controlled by the surgeon. The bone drilling task depends on a high level of dexterity and experience of the orthopedist and surgeon. The drilling procedures are performed without visual guidance, making it difficult for surgeons to determine the depth of the holes they are creating [

2]. Thus, the effectiveness of the drilling largely relies on the surgeon’s skill and their ability to gauge the drilling process based on their perception [

3]. The force experienced by the surgeon during drilling is subjective, as it depends on factors such as the speed of the drill bit, the condition of the bone, and the type of drill bit employed [

4,

5].

A recent study that compares ultrasonic-assisted drilling to conventional drilling in bone surgeries is presented in [

6]. The study examines optimal drilling parameters such as drilling force, temperature elevation, osteonecrosis, and micro-crack formation. The study found that the ultrasonic drilling resulted in less force and did not produce micro-cracks in cortical bone compared to the conventional drilling. However, it has the side effect that the temperature elevation is higher than the conventional drilling. In addition, histopathological and Scanning Electron Microscopic (SEM) analysis is conducted to evaluate the osteonecrosis and structural damage. The result shows that ultrasonic-assisted drilling is more advantageous for bone surgeries than the conventional method because it can reduce tissue damage. Another comparison study of conventional and ultrasonic-assisted drilling techniques is presented in [

7]. In detail, the study presents the comparative analysis of diametric delamination in the drilling of cortical bone using conventional drilling and ultrasonic-assisted drilling techniques. A coordinate measuring machine (CMM) is used in the study to characterize delamination during bone drilling. A quantitative comparison was also presented in this study with the finding that ultrasonic-assisted drilling causes less delamination than conventional drilling, with maximum delamination for ultrasonic-assisted drilling and for conventional drilling of 8.54% and 9.15%, respectively. Ultrasonic actuation application in bone drilling is also presented in [

8]. The objective is to reduce the cutting force and temperature during the bone drilling. The comparison between conventional drilling and ultrasonic-assisted drilling. The study found that ultrasonic-assisted drilling has a higher viability and greater pullout strength which can be potential for low-trauma surgeries.

In recent years, bone drilling research mostly presented monitoring techniques and drilling parameters. An automated system is the future direction of this research area. An idea is to create a bone-drilling medical training system [

9]. The bone drilling medical training system is a sophisticated tool designed to train medical professionals in the application of force during bone drilling procedures. This system operates in virtual environments (VEs) and aims to teach users how to apply force within a specific range, thereby maintaining a constant drilling thrust velocity. The virtual reality simulator consists of visual, acoustic, and haptic warning signals [

9]. Another study that presents the training system with 3 degrees of freedom (DOF) force feedback is presented in [

10]. A proposed medical training system (MTS) concept is presented in [

11]. The concept generally consists of (1) the system architecture based on haptic display (HD) and graphical user interface (GUI); and (2) a control system using proportional derivative (PD) position control.

A comprehensive review of surgical simulators for orthopedic and neurosurgeries which focuses on haptic and virtual reality technologies is presented in [

12]. The review paper informs that the main part of the orthopedic simulator is the haptic system. The haptic system in the simulator is expected to provide tactile sensations that mimic the real-life feel of orthopedic surgery. The haptic system is supported by the force feedback which is calculated based on the interaction between virtual tools and the simulated anatomy [

12]. More detail of the review study on medical training systems and potential automated systems in bone drilling is presented in Chapter 3.

A current review paper provides a different side of bone drilling which discussed the vibration analysis of different bone layers. The structure of the paper is as follows: Chapter 2 presents a summary of the previously published review paper on bone drilling. Chapter 3 presents the review of published papers on bone drilling vibration analysis and the application of machine learning for bone layer classifications. Chapter 4 presents the lab experimental setup. Chapter 5 presents the machine learning used in the paper and its classification results. Chapter 6 presents the conclusions and the future direction of the study.

2. Previous Review Studies on Bone Drilling

Extensive review studies related to bone drilling have been presented. Information about what is the difference between the present review paper and other published review papers is presented in

Table 1. The following is a more detailed description of

Table 1:

A detailed review paper of various studies on bone drilling is presented in [

4]. The paper compares various studies on bone drilling, highlighting the influence of bone drilling parameters and drill specifications to find the optimized bone drill specifications for a better outcome. The study described that a significant risk during drilling is the increase in bone temperature, which can lead to osteonecrosis and can affect the stability and strength of the bone fixation. In the future direction, the authors, emphasize the need for more advanced drilling methods, precise experimental setups, and automated systems to minimize human error and reduce associated risks. At the end of the paper, the authors provided eight points for future works. One of which is to improve the control penetration of the manual skill in typical bone drilling by developing automated drilling systems using a fuzzy logic controller that analyzes the current consumption by the DC motor.

A study that presents practicality, limitations, and complications related to surgical drill bits in bone drilling is discussed in [

13]. The study starts with the types and anatomy of surgical drill bits followed by the cutting operation which caused heat generation. Mechanical properties of the drill bit such as moment of inertia, wear, and dulling of the cutting face are also explained. Intraoperative and post-operative complications of the drill bit during surgical bone drilling are also presented comprehensively. A study also summarizes the previous research related to the thermonecrosis biological models. In the future direction, the study mentioned that ultrasonic or vibration-assisted drilling is one technology to reduce both axial thrust force and drilling torque.

The study that reviews the importance of maintaining temperature during drilling is presented in [

14]. Drill design, drill parameters, and coolant were reported as the important factors for controlling heat in the bone drilling. Other factors such as spindle speed and feed rate are also important to avoid bone damage.

A comprehensive review study of the mechanical and thermal responses in bone drilling, which is a critical aspect of various procedures is presented in [

15]. The discussion of the paper includes the bone structure, drill-bit geometry, operating conditions of bone drilling, and techniques and optimization. In bone structure, it discusses the inhomogeneity and anisotropy of bone tissues and their impact on drilling outcomes. The influence of drill-bit design on the efficiency and safety of bone drilling is a part of the drill-bit geometry section. The effect of drilling parameters such as spindle speed and feed rate on the mechanical and thermal responses during drilling is presented in the operating condition of the bone drilling section. Current techniques used in bone drilling and parameters optimization are presented in the last part of the review paper. However, future works or future direction was not provided.

Another review that discusses the factors affecting heat generation in bone drilling is presented in [

16]. The paper focused on the thermal osteonecrosis that occurred during the bone drilling. The study suggests the need for more in vivo studies on human bone and how drilling parameters interact to influence heat generation. However, there is a challenge in the measurement method of bone temperature due to the complex properties of bone tissue and the lack of a standard method.

Another comprehensive review study on the bone drilling process investigation and possible research is presented in [

17]. A typical schematic diagram of the bone drilling process is discussed. Factors influencing bone drilling efficiency and temperature rise are also discussed. The study mainly focused on the investigations on conventional bone drilling to obtain a few of information such as bone type, experimental type, experimental details, and research outcome. To complement the conventional bone drilling review, the authors also provided the investigations on non-conventional bone drilling studies such as ultrasonic-assisted drilling (UAD) [

18], vibrational drilling technique [

19], water-jet drilling [

20], automatic drilling process [

21], and acoustic emission (AE) based monitoring process [

22]. In the summary section, the Authors highlight that most of the previously published research articles presented the temperature measurement and analysis during orthopedic drilling. Another summary can be read in detail in the paper.

Heat is one of the major issues in the bone drilling procedure and the study in [

23] presents the factors affecting drilling behavior to prevent excessive heat generation. The study also presents a model of bone drilling to find the relationships between the drilling parameters. The study also highlights the necessity of the improved drill bit to minimize thermal and mechanical damage to the bone in the future direction. The development and application of a robotic bone drilling system as an advanced bone drilling procedure is also necessary and emphasized in the paper.

A state-of-the-art review and comprehensive analysis of orthopedic drilling are presented in [

24]. The review study summarized numerous articles on conventional and non-conventional drilling parameters and technologies. Bone drilling characteristics and control variables were presented in very detail and inclusively. Apart from the detailed review, non-conventional techniques in orthopedic drilling are also described. It includes water-jet-assisted drilling, laser-assisted drilling, and ultrasonic-assisted drilling. Design of experiments and modeling in orthopedic drilling based on the Taguchi method, ANOVA, and fuzzy logic is also presented. The review paper also provided several future directions, two of which are (1) the vibrational bone drilling with an internal closed-loop irrigation system is potentially used to minimize heat and thrust force; and (2) robotic bone drilling with multiobjective optimization can reduce thermal and mechanical damage.

A review paper that particularly highlights the use of robotics and autonomous systems designed in bone drilling as part of Computer-Aided Orthopedic Surgery (CAOS) is presented in [

25]. The robotic autonomous systems were designed to optimize drilling speed and safety, as well as the effectiveness of various drilling parameters. The study also reviews several potential signal processing-based approaches for detecting when a drill bit breaks through bone. Therefore, the authors mentioned that the signal processing method of the existing signals in conventional drills for breakthrough detection are potential new research area.

A review study that focuses on the advancements in surgical drill bit design and its impact on reducing thermomechanical damage during bone drilling is presented in [

26]. The paper discusses how different geometries of drill bits influence bone damage especially the importance of precise cutting tools to prevent damage to surrounding tissues. The review study explores various drill bit geometries highlighting how each design influences bone damage. The general objective of the review study is to provide guidelines for designing drill bits to minimize damage and improve the safety and effectiveness of bone drilling surgeries. The paper suggests future research directions for improving surgical drill bit design, including flexible drill bits and chip-breaker designs, to enhance safety.

Jung et al. [

27] present internal and external factors on heat generation. Drill properties, drill diameter, drill coating, and wear are categorized as internal factors. The external factors include drilling speed or feed rate, drilling energy, cooling, drilling depth, methodology used, and patient individual factors. An almost similar review study that also discussed drill bit heat generation on surgical bone drilling is presented in [

28]. The paper highlights that drill bit design is one of the important factors in reducing thermal damage during surgical bone drilling. In addition, other key parameters such as feed rate and applied force also contribute to heat generation. Another review paper on the impact of temperature on the bone drilling process is presented in [

29]. The review paper encapsulates several related studies that emphasize the critical role of temperature control in the bone drilling process.

3. A Brief Review of Medical Training System and Robotic Drilling

A medical training system development for bone drilling is presented in [

9]. The main objective of the development is to train and enhance the medical professionals’ skills via virtual environments (VEs). In particular, the training system aims to teach the user during the bone drilling to apply force in a certain range and maintain the drill thrust velocity constant at a certain given time. Three training strategies are discussed in the paper i.e. enhanced, multi-user, and training via a training model which are unique features for each strategy. One of the important parts of the training system is the haptic feedback for simulating realistic bone drilling sensations. The training system was validated through user tests and assessed using Euclidean distance.

A virtual training simulation approach called machine learning-based guidance (LbG) was introduced in [

30]. The LbG approach aims for kinesthetic human-robot interaction in virtual training simulations, particularly for bone surgical drilling. A femur bone drilling simulation is developed based on haptic feedback and X-ray views to help orthopedic residents practice, train, and improve their skills. The skill levels of users and to model of surgical expertise were assessed using machine learning tools. In addition, the virtual training system uses adaptive LbG forces which are informed by expert surgeon knowledge to enhance the resident’s performance during simulation.

Another study that applied haptic feedback for virtual reality (VR) simulation of surgical drilling is presented in [ 31]. The general objective of the study is to shift surgical training with VR simulation for otolaryngology and temporal bone dissection due to the anatomy complexity. The haptic feedback in the VR simulation is used to provide a realistic sense of touch, especially the rendering of vibrations during surgical drill use. In detail, the ability of four different haptic hand controllers was evaluated to render realistic drill vibrations in VR surgical training. A future application of the study i.e. to enhance VR surgical simulators by incorporating vibrotactile feedback to improve the training experience for procedures that involve drilling is also mentioned.

A study that discussed the use of both physical and virtual prototypes for temporal bone drilling simulation is presented in [

32]. The authors mentioned that a combination of physical and virtual prototypes offers advantages such as ease of access, the possibility of repeated practice, and the absence of ethical issues. The future work of the study is to develop and use virtual reality in bone surgical simulation.

4. An Application of Vibration and Machine Learning Methods for Bone Drilling

This section presents a review study of the use of vibration signals and techniques in bone drilling including ultrasonic and acoustic emission signals. This section also presents an application of various machine learning methods to optimize, regression, and classification in the area of bone drilling.

4.1. Bone Drilling Vibration

When a drill bit has mechanical contact with bone during bone drilling, the drill bit applies force to the bone surface causing it to penetrate and trigger a vibration signal. The vibration signal exhibited from this process can be captured using an accelerometer. A study of vibration signal characteristics for bone drilling especially for bone layer classification is presented in [

33]. The vibration signal was acquired when the drill bit passed through three different layers i.e. periosteum (layer 1), first cortical (layer 2), and spongy (layer 3). Time and frequency domain features were extracted for the acquired vibration signal. The features analysis results of the frequency domain show outperformed time domain features indicating that frequency domain features have more information related to the bone layer. This is because the frequency characteristics of bone layer classification refer to the distinctive patterns or properties exhibited by different layers of bone when analyzed in terms of frequency. These characteristics can be observed further through various imaging techniques or signal processing methods.

In another study, it is mentioned that by analyzing the frequency response of bone layers, it is possible to differentiate between cortical bone and cancellous bone based on their unique frequency patterns [

34]. Cortical bone typically exhibits higher frequency responses, indicating higher density and hardness, while cancellous bone displays lower frequency responses due to its porous nature. Understanding the frequency characteristics of bone layers can aid in various applications, including bone quality assessment, orthopedic surgeries, and the development of diagnostic tools for bone-related conditions.

A novel ultrasonic vibration-assisted drilling technique for precise bone surgery is presented by Kong and Lee [

35]. An analytical force model is developed for ultrasonic vibration-assisted bone drilling. In [

18] performed an experimental study on bovine bone utilizing ultrasonically assisted drilling and discovered that force and torque were significantly reduced as compared to the conventional drilling approach. In addition, Gupta et al. [

3,

36] discovered that compared to conventional drills, sensors-aided drilling could create lower temperatures when the vibration frequency was held at 20 kHz and the vibration amplitude was kept at 4-20 μm.

4.2. Applied Machine Learning Methods

An application of the machine learning method for optimum bone drilling parameters prediction is presented in [

37]. A genetic algorithm (GA) is used to find a minimum thrust force value from the combination of the bone drilling parameters during bone drilling. A mathematical model of the thrust force as a function of feed rate and spindle speed is calculated using response surface methodology (RSM). In the study, the optimal value of the spindle speed and the feed rate to achieve the minimum thrust force during bone drilling is developed using the GA method. A developed RSM of thrust force is used as an objective function in the GA method. The GA optimization result shows that a feed rate of 30 mm/min and a spindle speed of 1000 rpm are the optimal parameters for the minimum thrust force value. The GA predicted result is also compared to the experiment result for a similar feed rate and spindle speed value of 710.

Pandey et al. [

38] presented a combined method to obtain an optimized grey fuzzy reasoning grade (GFRG) from all quality characteristics of bone drilling. The combined method consists of grey relation analysis (GRA) and fuzzy logic. The GFRG is used to determine the optimal combination of bone drilling parameters that minimize temperature, force, and surface roughness. The highest GFRG is obtained for the feed rate of 40 mm/min and the speed of 500 rpm.

A study that reported the use of radial basis function neural network (RBFNN) for drill wear classification in bone drilling is available [

39]. The RBFNN is utilized to develop a drill wear classification model based on a multi-sensor approach. The features for the RBFNN classification model were extracted from signals such as cutting forces, servomotor drive currents, and acoustic emission.

Various machine learning models such as support vector regression (SVR), k-nearest neighbors (KNN), decision tree (DT), and random forest (RF) were used for predicting temperature elevation rotary ultrasonic bone drilling (RUBD) [

40]. The machine learning models were compared with the standard response surface methodology (RSM) analysis. The result shows that SVR is the most outperformed model for this application compared to other machine learning methods.

The monitoring and prediction of temperature elevation during real-time in vivo medical surgery is a challenging task. A study that presents the Ridge regression for prediction of the temperature rise during orthopedic bone drilling is presented by Agarwal et al. [

41]. The Ridge regression model is compared with other machine learning models such as multilayer perceptron, lasso regression, and multi-linear regression. According to the performance metrics such as mean absolute error (MAE), root mean square error (RMSE), and mean square error (MSE), the error metrics of the Ridge regression than other ML models indicated that the proposed method outperformed other models. In another the study presented by Agarwal et al. [

42], the Ridge regression was compared with other ML models such as lassor regression, support vector regression (SVR), multi-linear regression, and artificial neural network (ANN). Ridge regression and other ML methods are to predict the surface roughness and cutting force during rotary ultrasonic bone drilling. According to the statistical analysis of the predictive results, it was observed that Ridge regression has the least error metrics compared to other ML methods in terms of surface roughness prediction. In the case of the cutting force prediction, SVR was the most accurate model compared to other ML models.

K-nearest neighbors (KNN) and ensemble classifiers were utilized in [

43] for breakthrough detection in robotic orthopedic surgery. A feature set containing closed-loop control signals and force sensor data were the training datasets to develop the prediction models. It is found that the ML models accurately detect the breakthrough during bone drilling operations. The best accuracy of breakthrough detection is 98.1±0.2% for sheep femur bone.

A successful approach to categorizing bone drilling levels (bone layers) using a customized convolutional neural network (CNN) is presented in [

44]. The CNN classification used vibration signals from a three-axial accelerometer attached to the cow femur bone. The CNN accurately classified raw vibration signals from the three-axial accelerometer into three distinct bone layers i.e. periosteum (the outermost layer), first cortical (the next layer beneath the periosteum), and spongy (the innermost layer).

Table 2.

Summary of the application of machine learning methods on bone drilling.

Table 2.

Summary of the application of machine learning methods on bone drilling.

| Author (year) |

Data used in the machine learning method |

Machine learning method |

Machine learning is used for? |

The purpose of using machine learning method |

| Pandey et al. (2014) [37] |

Temperature, force, and surface roughness |

grey relation analysis and fuzzy logic |

Optimization |

To determine the optimal combination of bone drilling parameters that minimize temperature, force, and surface roughness. |

| Pandey et al. (2014) [38] |

Temperature, force, and surface roughness |

Grey fuzzy reasoning grade |

Classification |

To find an optimal value of feed rate (mm/min) and speed (rpm). |

| Staroveski et al. (2015) [39] |

Cutting forces, servomotor drive currents, and acoustic emission |

Radial basis function neural network |

Classification |

To develop a drill wear classification model based on a multi-sensor approach. |

| Torun et al. (2020) [43] |

Closed-loop signal and force sensor data |

K-nearest neighbors and ensemble classifier |

Classification |

To detect breakthroughs and to estimate the condition of the drill bit in robotic bone drilling. |

| |

| Agarwal et al. (2022) [40] |

Temperature |

K-nearest neighborsSupport vector regressionDecision treesRandom forest |

Regression |

To introduce different machine learning methods for predicting temperature elevations in rotary ultrasonic bone drilling. |

| Agarwal et al. (2022) [41] |

Temperature |

Multilayer perceptronLasso regressionRidge regression |

Regression |

To predict temperature rise during bone drilling. |

| Agarwal et al. (2022) [42] |

Surface roughness and cutting force |

Ridge regression, lasso regression, support vector regression, multi-linear regression, artificial neural network |

Regression |

To predict the surface roughness and cutting force during rotary ultrasonic bone drilling. |

| Caesarendra et al. (2024) |

Vibration signal |

Convolutional neural network |

classify |

To classifiy three bone layers based on vibration signal. |

5. Experimental Procedure of Bone Drilling

5.1. Previous Studies

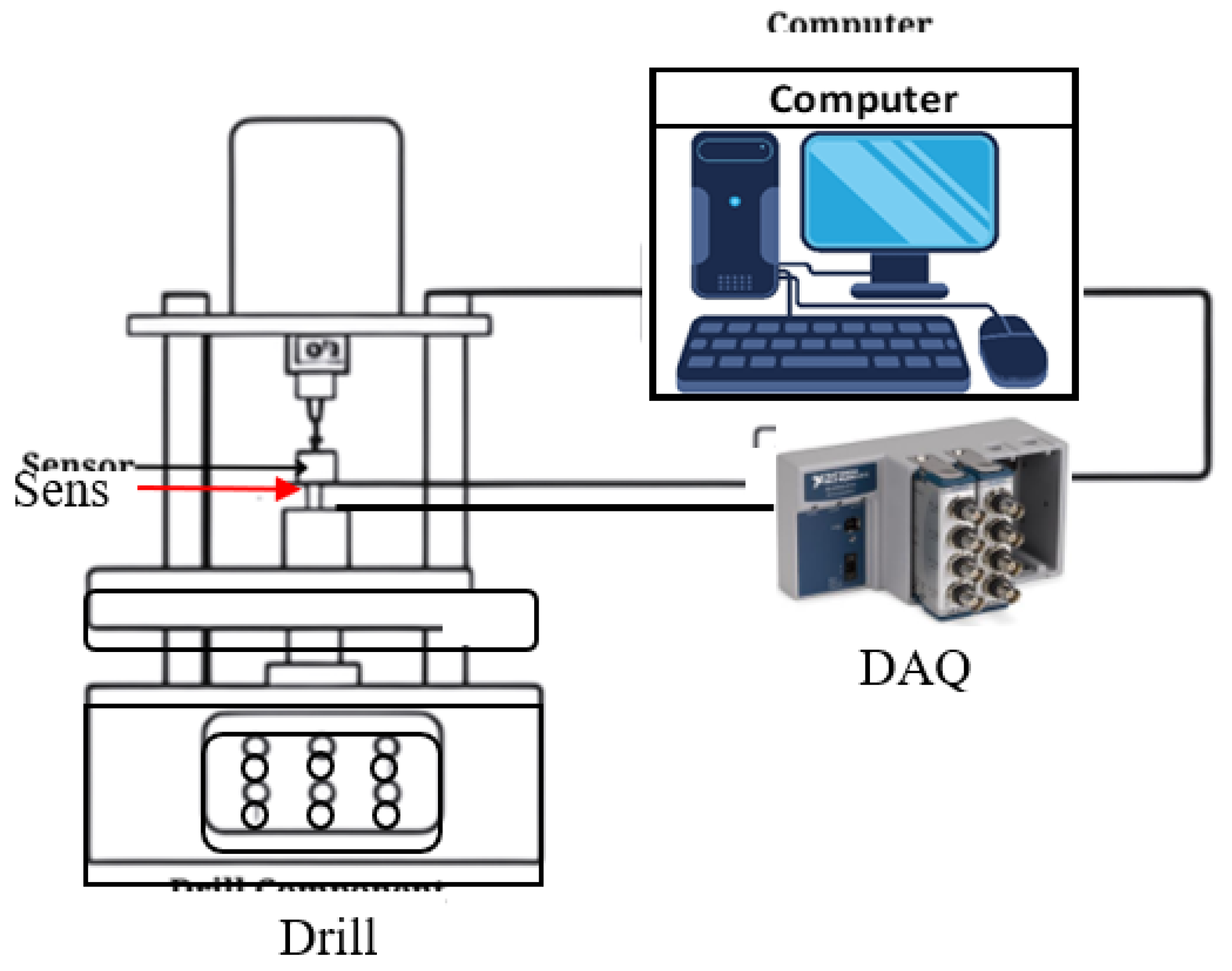

Several tools are required in the drilling process, namely the hand drill and drill bit. In drilling, a tool called a hand drill is required. Currently, the drilling speed of hand drills varies between 500 and 1,500 rpm. The reason for this difference is that some manufacturers have also introduced high speeds as an advantage in their marketing activities. Drill bits are also employed in preparing bone tunnels, for instance, in anterior ligament reconstructions. Typically, drilling is utilized to create holes in the bone before inserting screws. Nevertheless, since rigid bone is invariably surrounded by soft tissues like muscles, fat, ligaments, and tendons, which allow for bone movement, the bone can deviate from its normal position due to the shearing forces exerted by the drilling tool. The process of drilling a bone is depicted in a typical block diagram in

Figure 1.

Several other critical performance characteristics that determine the success of bone drilling include the straightness of the created hole, an efficient coefficient of friction, and healing time. Therefore, during surgical procedures, the force exerted by the surgeon and the position of the drill bit must be accurate. The accuracy of drilled holes during orthopedic fracture treatment relies greatly on the manual skills of the surgeon. However, currently, bone drilling tools used in surgeries do not include any mechanisms for penetration control. Thus, an automatic drilling system must be developed to minimize human errors during bone drilling. Much research has been conducted to explore new drill-bit designs [13-16] and new drilling techniques [17-19]. This was performed to avoid the accumulation of heat at the point where the drill was located.

In [

45] there are two approaches to minimize thermal damage during bone drilling. The first strategy involves employing a higher feed rate to decrease the duration of the drilling process. The second method involves utilizing a lower feed rate to achieve a lower maximum temperature.

Bone drilling has been studied in past decades and is still a promising and developing research area.

Table 3 shows the selected research from 1976 to 2023 that particularly described briefly the bone sample used, the experimental description and procedure, and the outcome of the study.

3.2. Bone Drilling Lab Experiment of the Present Study

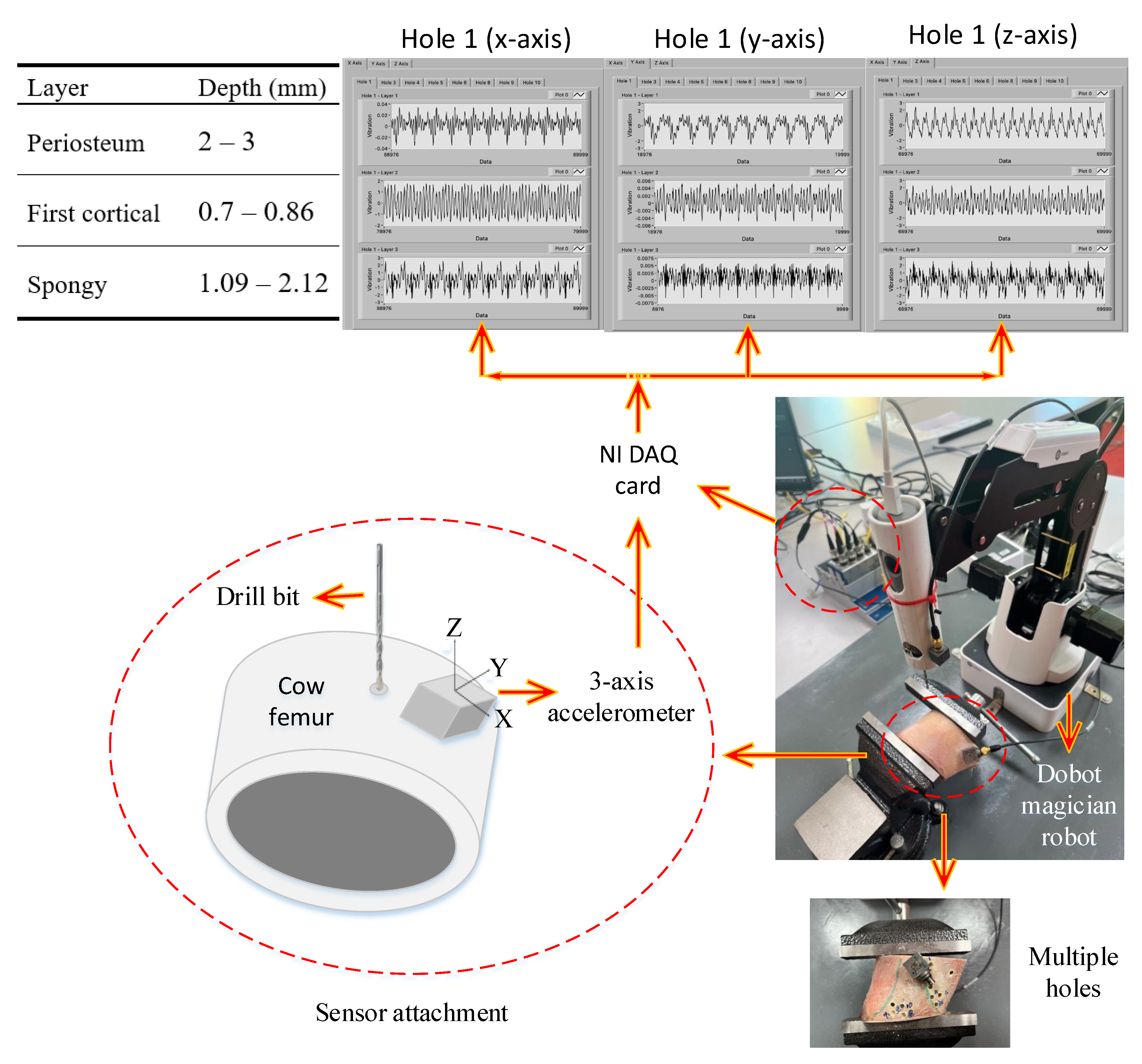

A bone drilling lab experiment utilized a Dobot Magician robot, National Instrument (NI) data acquisition (DAQ) module NI-9345, Brüel & Kjær three-axis accelerometer type 4535-B, and standalone academic LabVIEW software. A Dobot Magician robot was connected to a PC with available software for robot programming. A schematic of the bone drilling lab experiment is presented in

Figure 2.

The original end effector of the Dobot Magician robot was replaced with the customized drilling mechanism as presented in

Figure 2. The objective of using the Dobot Magician robot is to control the drilling process and to provide an accurate depth penetration of each layer in the bone drilling experiment. Bone drilling vibration was performed intermittently from the periosteum layer (the outermost layer), first cortical layer (the layer beneath the periosteum layer), and spongy layer (the innermost layer). An illustration of the bone layer is also presented in

Figure 2. The vibration signal was acquired with a sampling frequency of 5 kHz. During the experiment, the drill was operated with 0.002 to 0.006 in/min feed rate and 500 rpm. The drill geometry was chosen as a twisted drill bit with a 3.5 mm diameter.

One three-axial accelerometer was attached near the hand drilling and another one was attached to the bone that will undergo drilling to obtain vibration signals during the drilling process as presented in

Figure 2. The drill bit was then placed at the anterior surface of the proximal femur and drilled in clockwise rotation continuously. A fresh frozen cow femur was used in this research because this type of bone has almost similar characteristics to human bone [

16]. The sample was fixed with a laboratory clamp while the drilling process was performed. The bone drilling was repeated up to about 8 holes, however, only three holes were used in the machine learning method.

To be able to separate the recordings and assign them to respective labels, the breakthrough sequence form drilling was recorded through the second cortical layer of the femur until breaking through into the adjacent soft tissue. Overall, ten individual drill holes were captured, however, only 8 holes were successfully drilled (holes 2 and 7 were unsuccessful). All recordings processed within the vibration signal were recorded using LabVIEW software as presented in the LabVIEW tabs plot in

Figure 2.

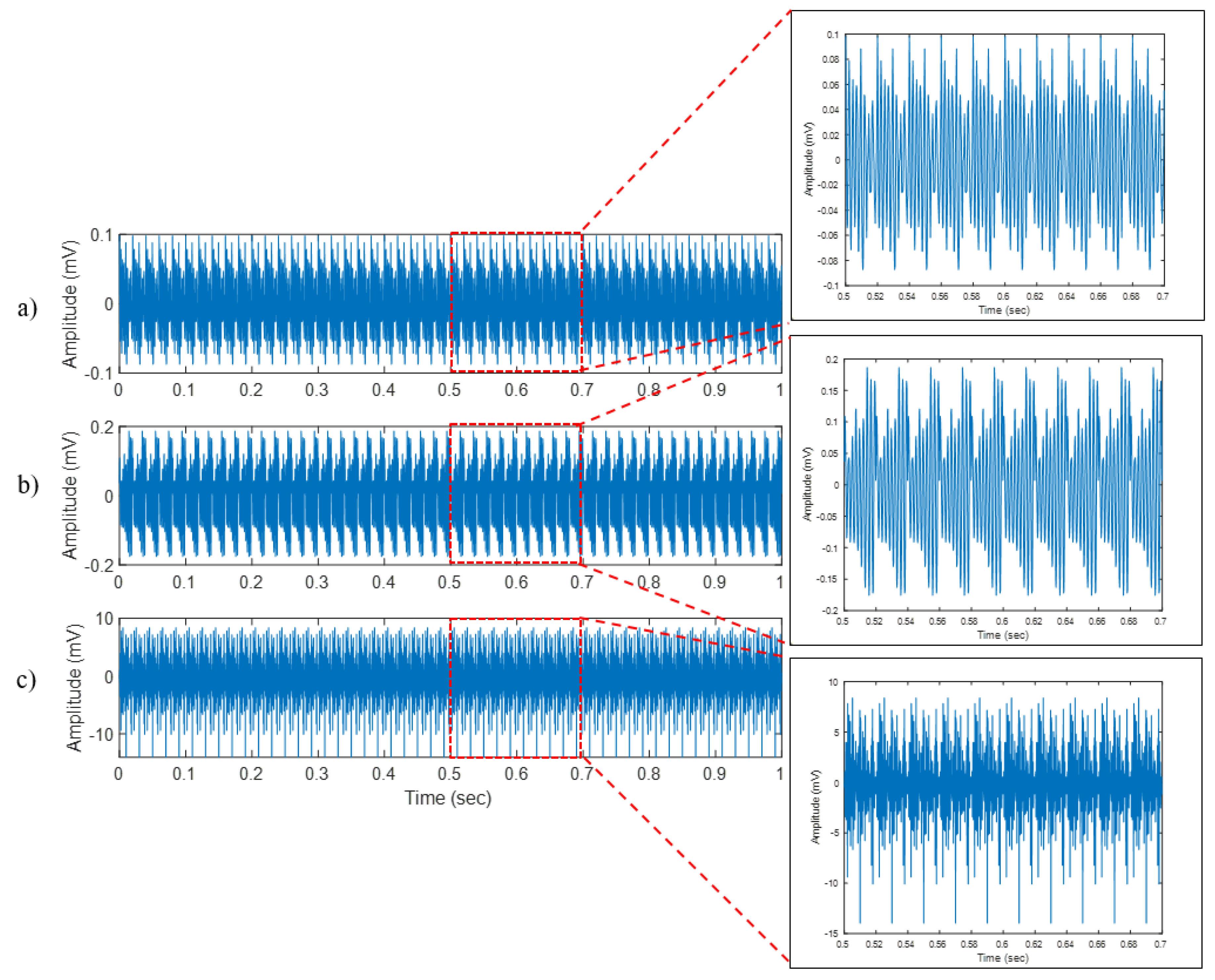

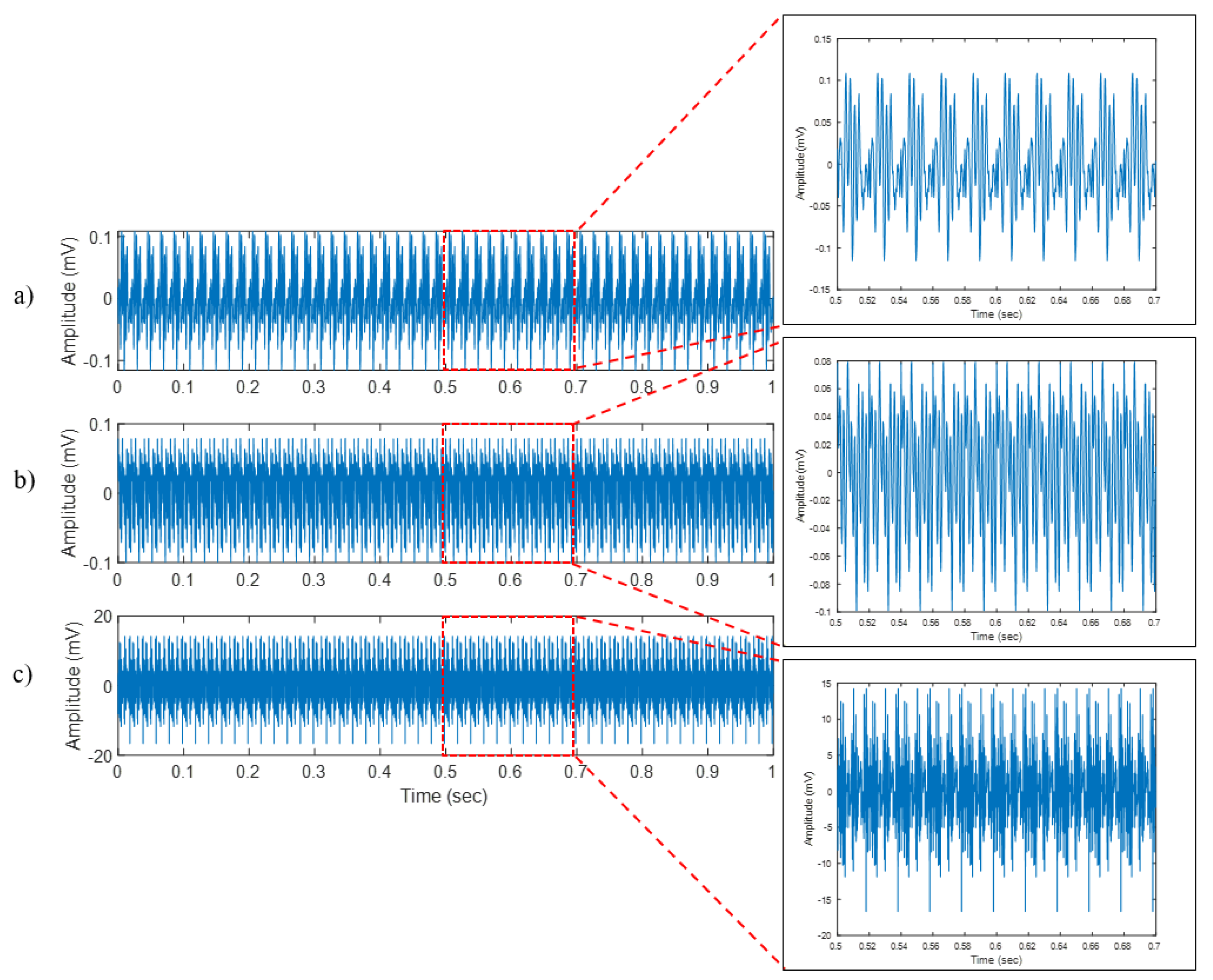

The vibration data of the bone drilling experiment for three different layers is presented in

Figure 3,

Figure 4 and

Figure 5.

Figure 3 presents the bone drilling vibration data (x-axis) for the duration of one second.

Figure 3(a),

Figure 3(b), and

Figure 3(c) are the vibration signals from the periosteum layer, first cortical layer, and spongy layer, respectively. The raw vibration signals of different layers are difficult to distinguish. However, if the vibration signal was plotted only for 0.2 seconds (0.5 ~ 0.7 sec) for zooming purposes, it shows a different vibration signal shape as presented in Zoom in parts of Figures 3(a)-(c). Another information that can be revealed in

Figure 3 is the vibration signal amplitude of each layer. The deeper the drill bit comes in, the higher the amplitude (in mV) of the vibration signal.

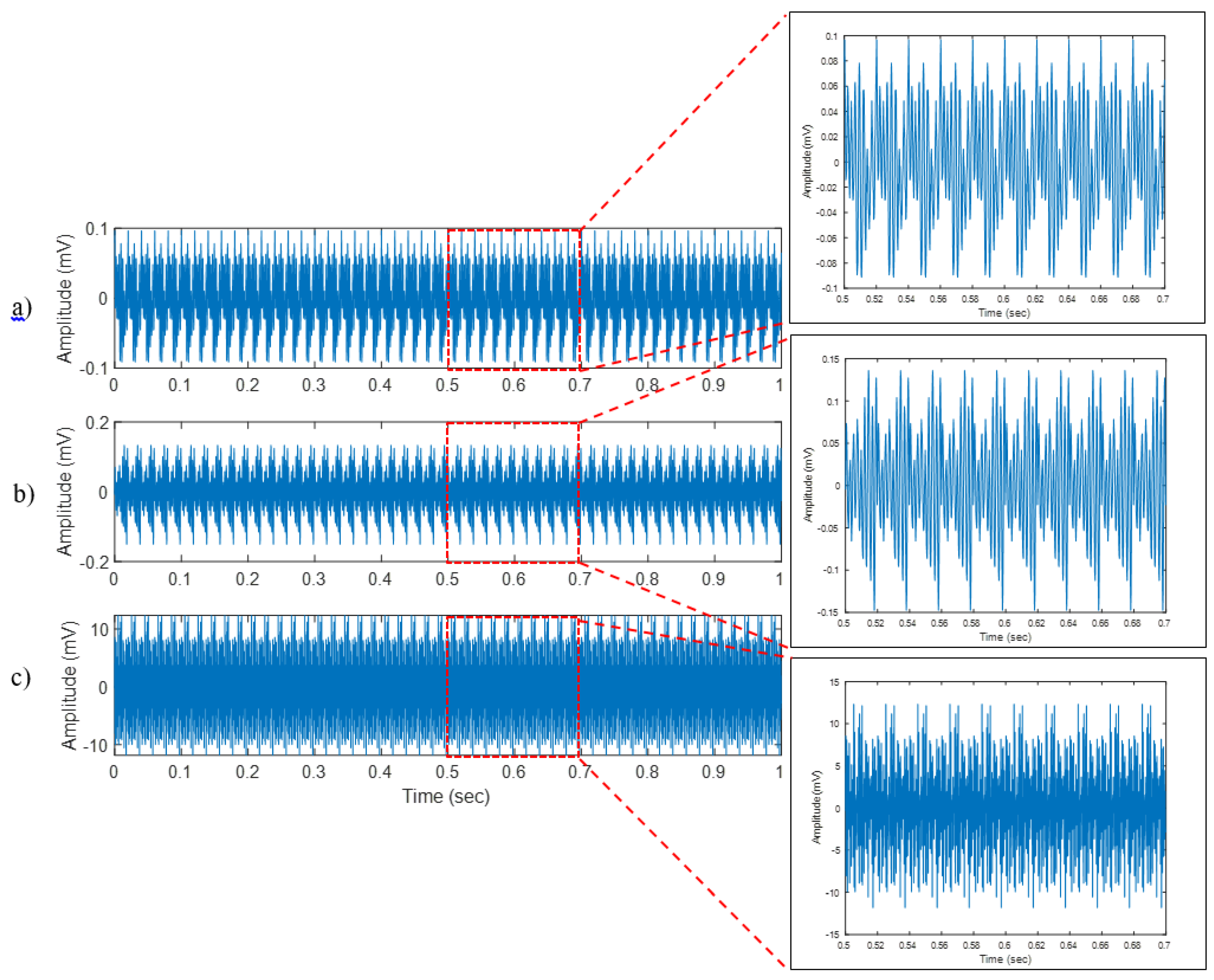

Figure 4 presents the bone drilling vibration data (y-axis) for the duration of one second.

Figure 4(a),

Figure 4(b), and

Figure 4(c) are the vibration signals from the periosteum layer, first cortical layer, and spongy layer, respectively. Similar to

Figure 3, the raw vibration signals of three different layers in

Figure 4 are also difficult to distinguish visually. However, if the vibration signal was plotted only for 0.2 seconds (0.5 ~ 0.7 sec) for zoom-in purposes, it shows a different vibration signal shape and amplitude as presented in zoom-in parts of

Figures 4(a)-(c).

Figure 5 presents the bone drilling vibration data (z-axis) for the duration of one second.

Figure 5(a),

Figure 5(b), and

Figure 5(c) are the vibration signals from the periosteum layer, first cortical layer, and spongy layer, respectively. Similar to

Figure 3 and

Figure 4, the raw vibration signals of three different layers in

Figure 5 are not distinguishable visually. If the vibration signal was zoomed in for 0.2 seconds (0.5 ~ 0.7 sec), it shows a different vibration signal shape and amplitude.

A root mean square (RMS) of the bone drilling vibration amplitude is presented in

Table 4. It is shown that the RMS amplitude increases as the drill bit goes through deeper. It indicates that the bone structure of each layer is different and when the bone structure has contact with the drill bit and triggers the vibration signal. In detail, an increase in RPM values from the periosteum to the first cortical layer is not as high as an increase in RPM values from the first cortical to the spongy layer. It indicates that the spongy layer has less stiffness than the other two layers (periosteum and first cortical).

Table 2.

Vibration amplitude of different axes and different layers represented by RMS.

Table 2.

Vibration amplitude of different axes and different layers represented by RMS.

| Layer |

RMS of x-axis vibration (mV) |

RMS of y-axis vibration (mV) |

RMS of z-axis vibration (mV) |

| Periosteum |

0.044 |

0.044 |

0.044 |

| First cortical |

0.092 |

0.063 |

0.051 |

| Spongy |

4.044 |

5.505 |

5.853 |

4. Long Term-Short Memory (LSTM) Method

Long short-term memory (LSTM) is a type of recurrent neural network (RNN) architecture that is designed to handle sequential data. The LSTM is an improved method of RNN which was designed by Hochreiter and Schmidhuber for sequence prediction tasks [

53]. In addition, the LSTM method excels in capturing long-term dependencies in sequence data and handling the vanishing gradient problem [

53]. The LSTM method has been applied previously in an ECG-rhythm classification study [

54] and is applied to optimize reactive power usage in high-rise buildings [

55]. According to the summary of the machine learning application presented in

Table 2, LSTM has not been used for orthopedic bone drilling and this is the motivation for selecting the LSTM method in the present bone layer classification study.

An example application of the LSTM method for reproducing variable forces in haptic technology focusing on tactile feedback enhancement in real-time robotic surgery simulation is presented in [

56]. in [

56] the LSTM method is used specifically for (1) to reproduce variable forces feedback during the skin layers surgical procedure; and (2) to improve force prediction accuracy in robotic surgery simulation.

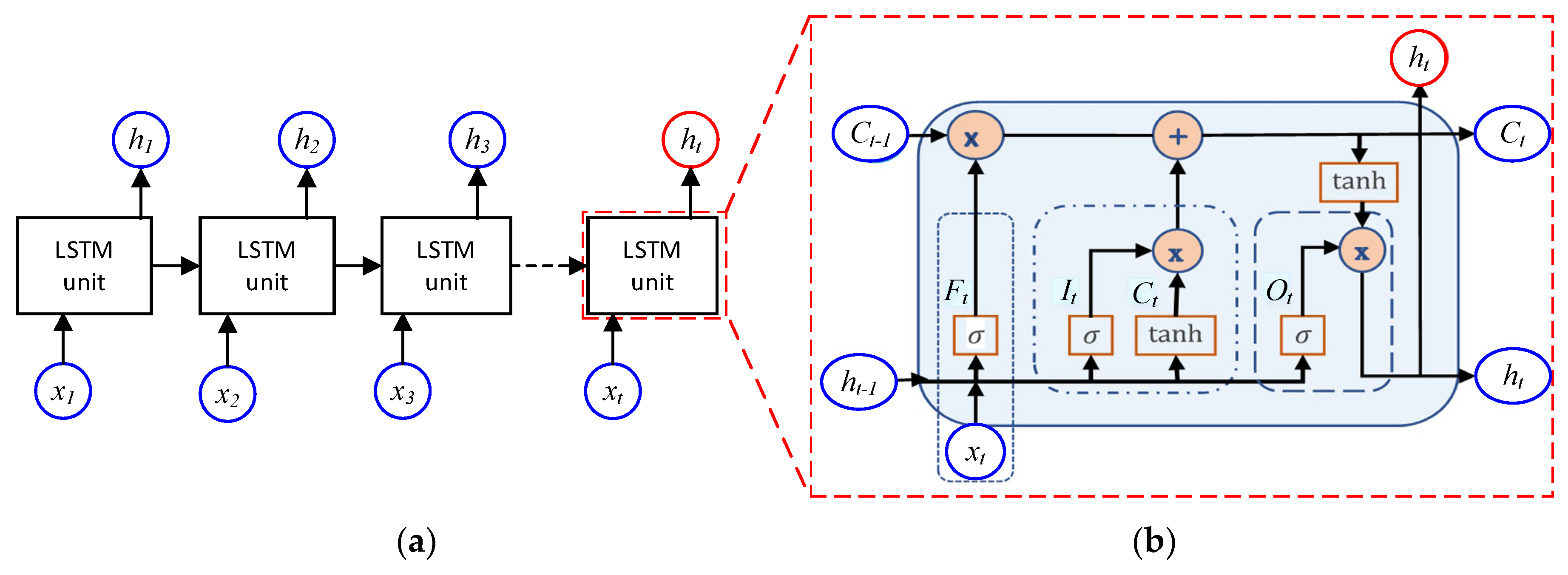

4.1. LSTM Architecture

The characteristic of LSTM is a chain of repeating modules as presented in

Figure 6(a). Each module looks at some input

xt and outputs a hidden state value

ht. A loop allows information to be passed from one step of the network to the next time step. The difference between RNN and LSTM is in the construction of the chained units. The unit of standard RNN has a simple structure, like a single tanh layer, while LSTM has a more complicated unit as presented in

Figure 6(b). The keys of LSTM are cell state and gates. The cell state is kind of like a conveyor belt. The cell state (memory) learns new information from the input. The LSTM does have the ability to remove or add information to the cell state

Ct using a structure called gates. Gates can remove or add information to the cell state. Gates decides whether information should be added to the units or not. In general, the gate equation is presented in (1) [

57]:

where

U,

W, and

b are the parameters of the door, and the parameters of each door are different. The variable

xt in the current input, and

ht-1 is the previous hidden state.

There are three gates in an LSTM unit: forget gate, input gate, and output gate. Forget gate (Ft) is responsible for controlling what information should be removed from the cell state. Input gate (It) determines which information from the previous timestamps should be remembered or forgotten. The input gate also determines how much new information should be added to the cell state. Output gate (Ot) selects useful information from the current cell state and produces it as the output. The output gate is also responsible for passing updated information to the next timestamp.

The forget gate (

Ft), input gate (

It), and output gate (

Ot) equations in presented in (2)-(4), respectively [

57].

5. LSTM Results

During the Lab experiment, eight holes were successfully drilled through the femur bone in the bone drilling experiment, however, the LSTM method in this study only used two holes i.e. holes 5 and 6. This is because the other holes will be used in further work.

5.1. LSTM Model

In this study, the LSTM algorithm that is available in TensorFlow Keras was used. To develop the LSTM model, 70 % vibration data was used for training, and 30% data was used for testing. The validation data was obtained from 20% of the training data. The LSTM architecture used in this project is presented in Table X and the summary is as follows: Input Layer -> LSTM Layer (return_sequences=True) -> LSTM Layer -> Flatten Layer -> Dense Layer (Output Layer). With this architecture, the model can accept the sequential vibration data from the x-, y-, and z-axis for each layer. The sequential vibration data was processed in two LSTM layers to obtain the prediction model for multiclass classification. The ‘softmax’ activation function was selected as the dense layer.

Table 2.

LSTM architecture for multi-class classification.

Table 2.

LSTM architecture for multi-class classification.

| Layer (type) |

Output shape |

Param # |

| input_1 (InputLayer) |

[(None, 3, 1)] |

0 |

| Astm (LSTM) |

[(None, 3, 32)] |

4352 |

| lstm_1 (LSTM) |

(None, 32) |

8320 |

| flatten (Flatten) |

(None, 32) |

0 |

| dense (Dense) |

(None, 3) |

99 |

| Total params: 12771 (49.89 KB) |

| Trainable params: 12771 (49.89 KB) |

| Non-trainable params: 0 (0.00 Byte) |

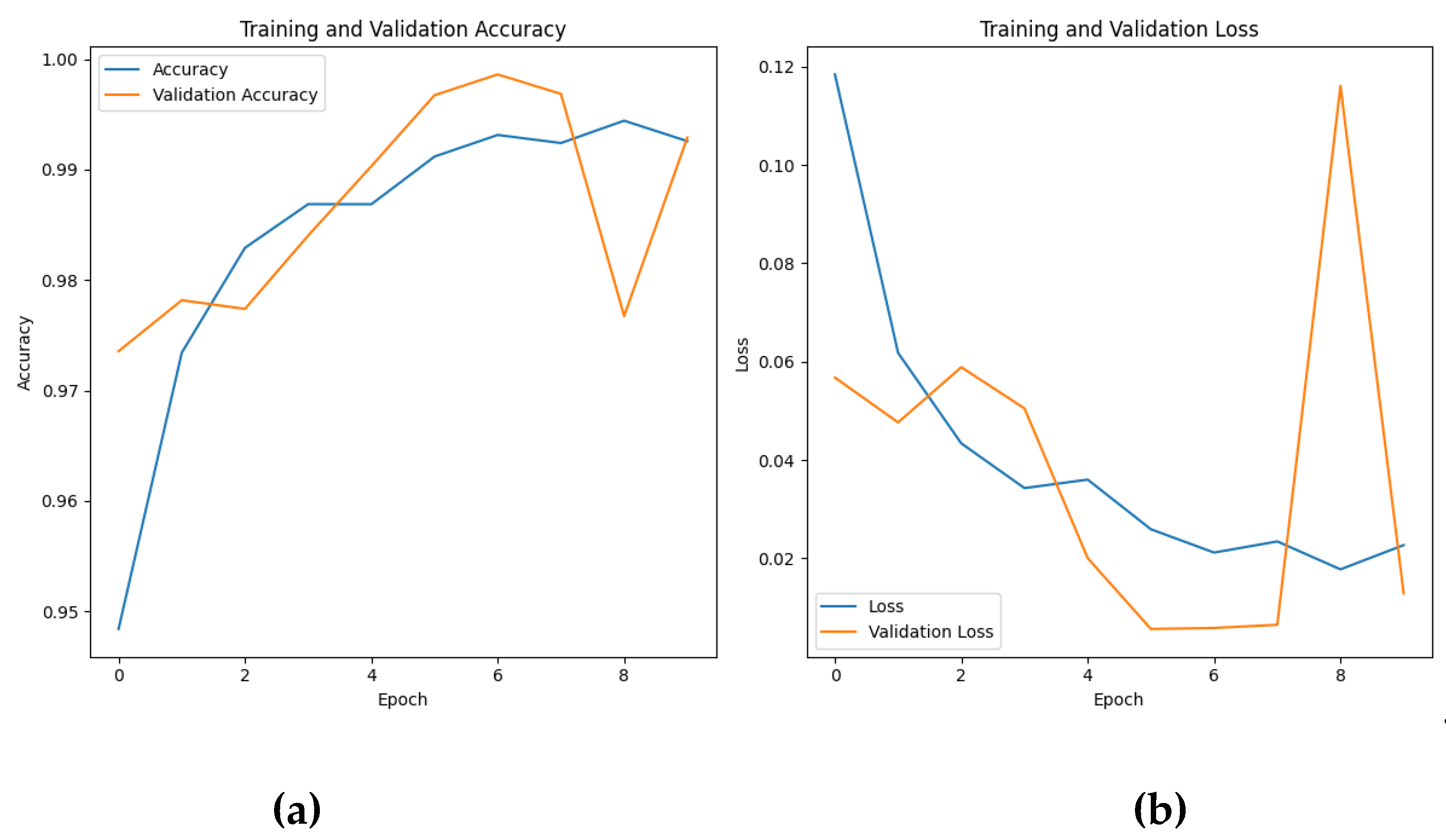

5.3. LSTM Classification Results and Discussion

Once the model is developed, the next step is to compile and train the LSTM model. At the compilation stage, the LSTM model is configured with an ‘adam’ optimizer, a ‘categorical_crossentropy’ loss function because this is a multiclass classification problem. Some ‘callback’ functions such as EarlyStopping, ModelCheckpoint, and LearningRateScheduler are also used to control the training process. An ‘accuracy’ metric to evaluate the model’s performance is used during the training process. The model evaluation is presented in

Figure 7 with has test loss of 0.013 and test accuracy of 0.993

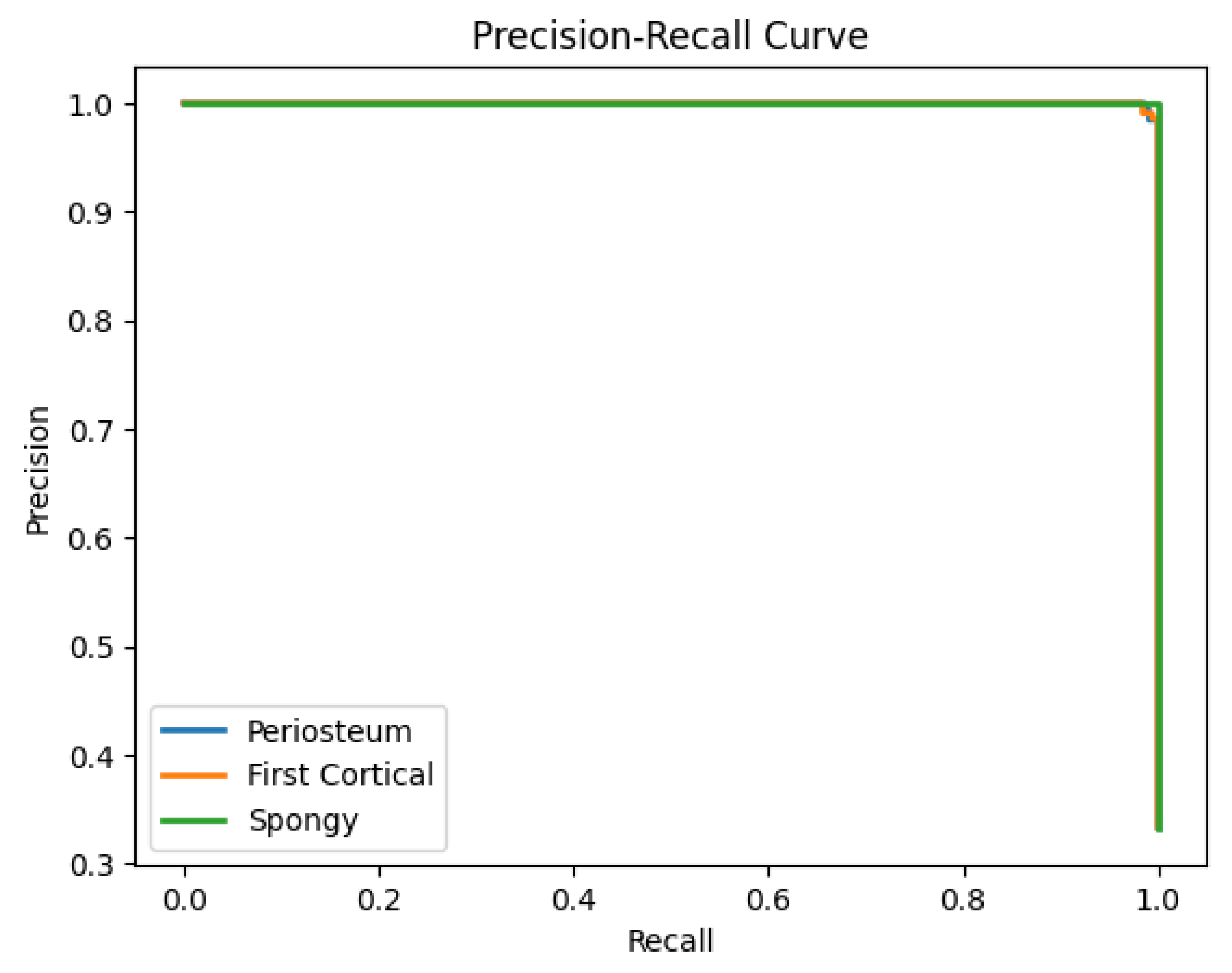

Table 2 shows a classification report which provides detailed information regarding model performance for each target class. The evaluation results of layer 1 (periosteum) and layer 2 (first cortical) show that the model has 0.99 for precision, recall, and

f1-score. In the case of layer 3 (spongy) layer, it produces perfect classification as shown in precision, recall, and

f1-score of 1.00.

Figure 8 shows the precision-recall curve that shows layer 3 has perfect results compared to the other two layers (periosteum and first cortical) which have small different.

Table 2.

LSTM classification report.

Table 2.

LSTM classification report.

| |

Precision |

Recall |

F1-score |

Support |

| Periosteum (layer 1) |

0.99 |

0.99 |

0.99 |

29993 |

| First cortical (layer 2) |

0.99 |

0.99 |

0.99 |

30087 |

| Spongy (layer 3) |

1 |

1 |

1 |

29920 |

| |

|

|

|

|

| Accuracy |

|

|

0.99 |

90000 |

| Macro avg |

0.99 |

0.99 |

0.99 |

90000 |

| Weighted avg |

0.99 |

0.99 |

0.99 |

90000 |

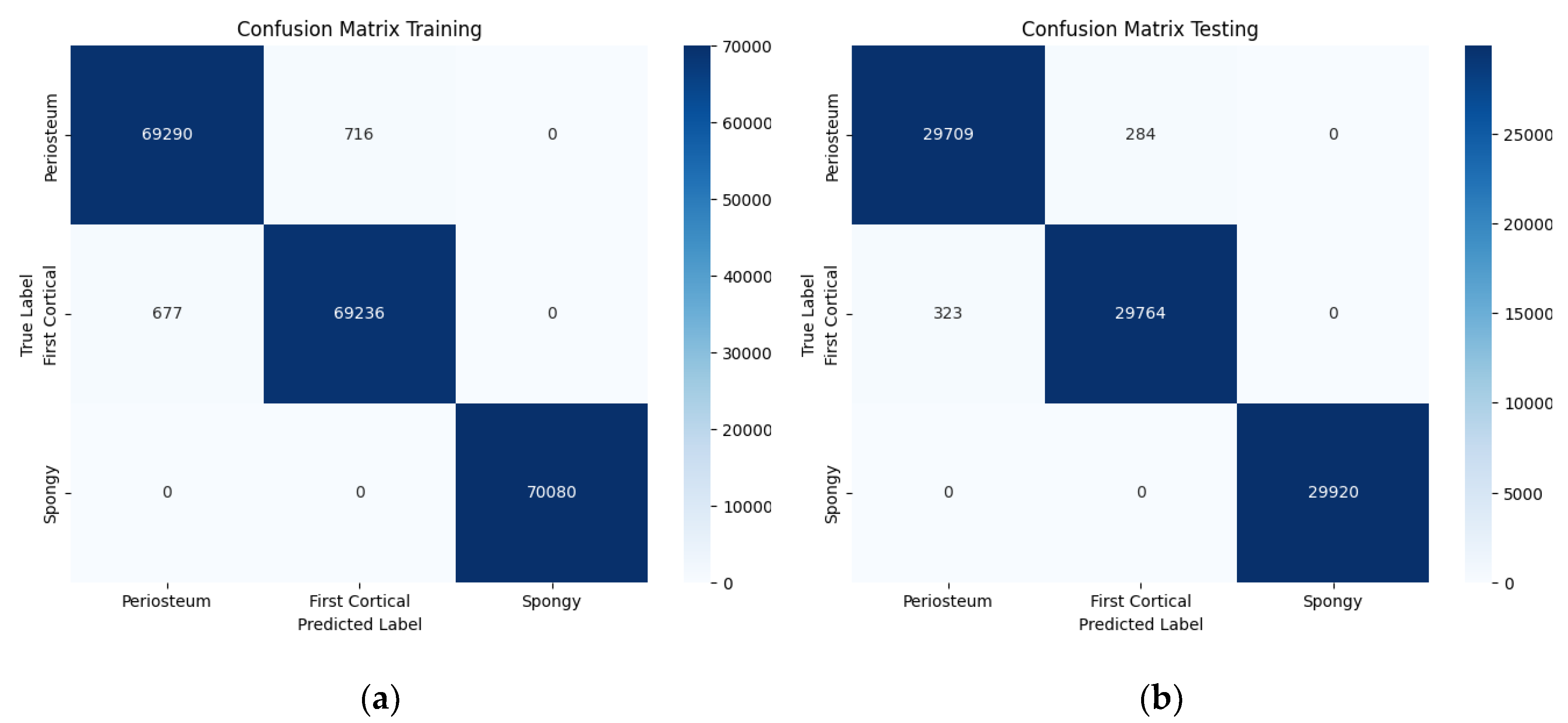

A confusion matrix for the training and testing process of LSTM model development with 10 epochs is presented in

Figure 9. It is shown the classification of the three bone layers is generally successful. However, there were a few misclassification results as presented in the confusion matrix of training and testing. In the training confusion matrix, the periosteum layer of about 716 out of 70006 data is classified in a first cortical layer which is about 1.02 % incorrect prediction. Another misclassification is also found in the first cortical layer with 677 out of 69913 data predicted in the periosteum layer which is about 0.97 % classification error. The perfect classification result was shown in the spongy layer where 100% data was classified correctly.

In the testing confusion matrix, the periosteum layer of about 284 out of 29993 data is classified in a first cortical layer which is about 0.95 % incorrect prediction. Another misclassification is also found in the first cortical layer with 323 out of 30084 data predicted in the periosteum layer which is about 1.07 % classification error. The perfect classification result was shown in the spongy layer where 100% data was classified correctly.

6. Conclusions

A review of an orthopedic bone drilling study with an example of bone layer classification using vibration signal and LSTM method is presented. This review study aimed to provide a state-of-the-art bone drilling study that will be useful for the researchers in developing a new method or a new research direction. One summary that can be highlighted according to the review study is the potential research direction in the development of the medical training system simulation and robotic driving. The medical training system simulation needs several sensor inputs for user feedback. This paper presented potential information that can be provided from the accelerometer. An example of the machine learning method i.e. LSTM is selected to show the benefit of utilizing the vibration signal for bone drilling study, especially for bone layer classification. Since only 2 datasets from 2 bone drilling holes used in this review paper, the future studt will analyse all the available data with several machine learning and deep learning methods.

Author Contributions

Conceptualization, W.C.; methodology, W.C.; software, W.C.; validation, W.C.; formal analysis, W.C.; investigation, W.C.; resources, W.C.; writing—original draft preparation, W.C.; writing—review and editing, W.C.; visualization, W.C.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is unavailable due to privacy or ethical restrictions.

Acknowledgments

The Author would like to thank Putri Wulandari Yoyo and Mochammad Denny Surindra for the experimental data acquisition in the laboratory.

Conflicts of Interest

The author declares no conflicts of interest.

References

- Torun, Y.; Malatyali, S. Power Analysis of Robotic Medical Drill with Different Control Approaches. Cumhur. Sci. J. 2020, 41, 527–533. [Google Scholar] [CrossRef]

- Tsai, M.-D.; Hsieh, M.-S.; Tsai, C.-H. Bone Drilling Haptic Interaction for Orthopedic Surgical Simulator. Comput. Biol. Med. 2007, 37, 1709–1718. [Google Scholar] [CrossRef]

- Gupta, V.; Pandey, P.M.; Silberschmidt, V.V. Rotary Ultrasonic Bone Drilling: Improved Pullout Strength and Reduced Damage. Med. Eng. Phys. 2017, 41, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Pandey, R.K.; Panda, S.S. Drilling of Bone: A Comprehensive Review. J. Clin. Orthop. Trauma 2013, 4, 15–30. [Google Scholar] [CrossRef] [PubMed]

- Han, Y.; Lv, Q.; Song, Y.; Zhang, Q. Influence of Parameters on Temperature Rise and Chips Morphology in Low-Frequency Vibration-Assisted Bone Drilling. Med. Eng. Phys. 2022, 103, 103791. [Google Scholar] [CrossRef] [PubMed]

- Pourgiv, S.; Mosavar, A.; Jamshidi, N.; Mohammadi, A. Ultrasonic-Assisted Drilling of Cortical and Cancellous Bone in a Comparative Point of View. Heliyon 2024, 10, e26248. [Google Scholar] [CrossRef] [PubMed]

- Singh, G.; Babbar, A.; Jain, V.; Gupta, D. Comparative Statement for Diametric Delamination in Drilling of Cortical Bone with Conventional and Ultrasonic Assisted Drilling Techniques. J. Orthop. 2021, 25, 53–58. [Google Scholar] [CrossRef] [PubMed]

- Agarwal, R.; Gupta, V.; Singh, J. Leveraging Ultrasonic Actuation during Inclined Orthopaedic Bone Drilling: An Experimental and Histological Study. Appl. Acoust. 2023, 211, 109520. [Google Scholar] [CrossRef]

- Esen, H.; Yano, K.; Buss, M. Bone Drilling Medical Training System. In The Sense of Touch and its Rendering; Bicchi, A., Buss, M., Ernst, M.O., Peer, A., Eds.; Springer Tracts in Advanced Robotics; Springer Berlin Heidelberg: Berlin, Heidelberg, 2008; ISBN 978-3-540-79034-1. [Google Scholar]

- Esen, H.; Yano, K.; Buss, M. A Virtual Environment Medical Training System for Bone Drilling with 3 DOF Force Feedback. In Proceedings of the 2004 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS) (IEEE Cat. No.04CH37566); Vol. 4; IEEE: Sendai, Japan, 2004; pp. 3631–3636. [Google Scholar]

- Esen, H. ; Ken’ichi Yano; Buss, M. A Control Algorithm and Preliminary User Studies for a Bone Drilling Medical Training System. In Proceedings of the The 12th IEEE International Workshop on Robot and Human Interactive Communication, 2003. Proceedings. ROMAN 2003.; IEEE: Millbrae, CA, USA, 2003; pp. 153–158. [Google Scholar]

- Syamlan, A.; Fathurachman; Denis, K. ; Vander Poorten, E.; Pramujati, B.; Tjahjowidodo, T. Haptic/Virtual Reality Orthopedic Surgical Simulators: A Literature Review. Virtual Real. 2022, 26, 1795–1825. [Google Scholar] [CrossRef]

- Bertollo, N.; Robert, W. Drilling of Bone: Practicality, Limitations and Complications Associated with Surgical Drill-Bits. In Biomechanics in Applications; Klika, V., Ed.; InTech, 2011 ISBN 978-953-307-969-1.

- Ginta, T.L.; Ari-Wahjoedi, B. Cutting Force and Temperature Variation in Bone Drilling - A Review. Adv. Mater. Res. 2013, 845, 934–938. [Google Scholar] [CrossRef]

- Lee, J.; Chavez, C.L.; Park, J. Parameters Affecting Mechanical and Thermal Responses in Bone Drilling: A Review. J. Biomech. 2018, 71, 4–21. [Google Scholar] [CrossRef] [PubMed]

- Timon, C.; Keady, C. Thermal Osteonecrosis Caused by Bone Drilling in Orthopedic Surgery: A Literature Review. Cureus 2019. [Google Scholar] [CrossRef] [PubMed]

- Bohra, A.; Chandrasekaran, M.; Teyi, N. Bone Drilling Investigation and Possible Research: A State of the Art Review.; Tamilnadu, India, 2019; p. 050022.

- Alam, K.; Mitrofanov, A.V.; Silberschmidt, V.V. Experimental Investigations of Forces and Torque in Conventional and Ultrasonically-Assisted Drilling of Cortical Bone. Med. Eng. Phys. 2011, 33, 234–239. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Cao, M.; Zhao, Y.; Zhou, G.; Liu, W.; Li, D. Experimental Investigations on Microcracks in Vibrational and Conventional Drilling of Cortical Bone. J. Nanomater. 2013, 2013, 1–5. [Google Scholar] [CrossRef]

- Den Dunnen, S.; Mulder, L.; Kerkhoffs, G.M.M.J.; Dankelman, J.; Tuijthof, G.J.M. Waterjet Drilling in Porcine Bone: The Effect of the Nozzle Diameter and Bone Architecture on the Hole Dimensions. J. Mech. Behav. Biomed. Mater. 2013, 27, 84–93. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Shi, Y.; Yang, N.; Yuan, X. Experimental Analysis of Drilling Process in Cortical Bone. Med. Eng. Phys. 2014, 36, 261–266. [Google Scholar] [CrossRef] [PubMed]

- Liao, Z.; Axinte, D.A. On Monitoring Chip Formation, Penetration Depth and Cutting Malfunctions in Bone Micro-Drilling via Acoustic Emission. J. Mater. Process. Technol. 2016, 229, 82–93. [Google Scholar] [CrossRef]

- Samarasinghe, C.; Uddin, M.; Bari, S.; Xian, C. Surgical Bone Drilling: A Review. In Proceedings of the Volume 3: Biomedical and Biotechnology Engineering; American Society of Mechanical Engineers: Salt Lake City, Utah, USA, November 11, 2019; p. 003. [Google Scholar]

- Jamil, M.; Rafique, S.; Khan, A.M.; Hegab, H.; Mia, M.; Gupta, M.K.; Song, Q. Comprehensive Analysis on Orthopedic Drilling: A State-of-the-Art Review. Proc. Inst. Mech. Eng. [H] 2020, 234, 537–561. [Google Scholar] [CrossRef] [PubMed]

- Torun, Y.; Pazarci, O.; Department of Orthopedics and Traumatology, Sivas Cumhuriyet University School of Medicine, Sivas, Turkey; Ozturk, A. ; Department of Electrical and Electronics Engineering, Sivas Cumhuriyet University School of Medicine, Sivas, Turkey Current Approaches to Bone-Drilling Procedures with Orthopedic Drills. Cyprus J. Med. Sci. 2020, 5, 93–98. [Google Scholar] [CrossRef]

- Akhbar, M.F.A.; Sulong, A.W. Surgical Drill Bit Design and Thermomechanical Damage in Bone Drilling: A Review. Ann. Biomed. Eng. 2021, 49, 29–56. [Google Scholar] [CrossRef]

- Jung, O.; Lindner, C.; Pantermehl, S.; Barbeck, M. Heat Development During Medical Drilling: Influencing Factors and Examination Methods – Overview and First Results. In Vivo 2021, 35, 3011–3017. [Google Scholar] [CrossRef] [PubMed]

- Islam, M.A.; Kamarrudin, N.S.; Daud, R.; Mohd Noor, S.N.F.; Azmi, A.I.; Razlan, Z.M. A Review of Surgical Bone Drilling and Drill Bit Heat Generation for Implantation. Metals 2022, 12, 1900. [Google Scholar] [CrossRef]

- Chouhan, P.S.; Dwivedi, V. Temperature Distribution in Bone Drilling: A Review. Int. J. Res. Publ. Rev. 2023, 4, 2616–2618. [Google Scholar]

- Zahedi, E.; Khosravian, F.; Wang, W.; Armand, M.; Dargahi, J.; Zadeh, M. Towards Skill Transfer via Learning-Based Guidance in Human-Robot Interaction: An Application to Orthopaedic Surgical Drilling Skill. J. Intell. Robot. Syst. 2020, 98, 667–678. [Google Scholar] [CrossRef]

- Ghasemloonia, A.; Baxandall, S.; Zareinia, K.; Lui, J.T.; Dort, J.C.; Sutherland, G.R.; Chan, S. Evaluation of Haptic Interfaces for Simulation of Drill Vibration in Virtual Temporal Bone Surgery. Comput. Biol. Med. 2016, 78, 9–17. [Google Scholar] [CrossRef] [PubMed]

- Aussedat, C.; Venail, F.; Marx, M.; Boullaud, L.; Bakhos, D. Training in Temporal Bone Drilling. Eur. Ann. Otorhinolaryngol. Head Neck Dis. 2022, 139, 140–145. [Google Scholar] [CrossRef] [PubMed]

- Wulandari, P.; Caesarendra, W.; Lai, D.T.C.; Surindra, M.D.; Królczyk, G.; Tjahjowidodo, T. A Study of Vibration Signal Feature Extraction for Bone Drilling Layer Classification. In Proceedings of the 2023 8th International Conference on Mechanical Engineering and Robotics Research (ICMERR); IEEE: Krakow, Poland, December 8, 2023; pp. 50–54. [Google Scholar]

- Li, S.; Shu, L.; Kizaki, T.; Bai, W.; Terashima, M.; Sugita, N. Cortical Bone Drilling: A Time Series Experimental Analysis of Thermal Characteristics. J. Manuf. Process. 2021, 64, 606–619. [Google Scholar] [CrossRef]

- Kong, F.; Lee, Y.-S. Analytical Modeling of Ultrasonic Vibration Assisted Drilling of Bones for Medical Surgical Applications. In Proceedings of the Volume 2: Materials; Biomanufacturing; Properties, Applications and Systems; Sustainable Manufacturing; American Society of Mechanical Engineers: Charlotte, North Carolina, USA, June 8, 2015; p. 002. [Google Scholar]

- Gupta, V.; Pandey, P.M. Experimental Investigation and Statistical Modeling of Temperature Rise in Rotary Ultrasonic Bone Drilling. Med. Eng. Phys. 2016, 38, 1330–1338. [Google Scholar] [CrossRef]

- Pandey, R.K.; Panda, S.S. Genetic Algorithm Based Prediction of an Optimum Parametric Combination for Minimum Thrust Force in Bone Drilling. In Recent Advances in Information and Communication Technology; Boonkrong, S., Unger, H., Meesad, P., Eds.; Advances in Intelligent Systems and Computing; Springer International Publishing: Cham, 2014; ISBN 978-3-319-06537-3. [Google Scholar]

- Pandey, R.K.; Panda, S.S. Optimization of Bone Drilling Parameters Using Grey-Based Fuzzy Algorithm. Measurement 2014, 47, 386–392. [Google Scholar] [CrossRef]

- Staroveski, T.; Brezak, D.; Udiljak, T. Drill Wear Monitoring in Cortical Bone Drilling. Med. Eng. Phys. 2015, 37, 560–566. [Google Scholar] [CrossRef]

- Agarwal, R.; Singh, J.; Gupta, V. Prediction of Temperature Elevation in Rotary Ultrasonic Bone Drilling Using Machine Learning Models: An in-Vitro Experimental Study. Med. Eng. Phys. 2022, 110, 103869. [Google Scholar] [CrossRef]

- Agarwal, R.; Singh, J.; Gupta, V. An Intelligent Approach to Predict Thermal Injuries during Orthopaedic Bone Drilling Using Machine Learning. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 320. [Google Scholar] [CrossRef]

- Agarwal, R.; Gupta, V.; Singh, J.; Jain, V. Prediction of Surface Roughness and Cutting Force Induced during Rotary Ultrasonic Bone Drilling via Statistical and Machine Learning Algorithms. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 11123–11135. [Google Scholar] [CrossRef]

- Torun, Y.; Öztürk, A. A New Breakthrough Detection Method for Bone Drilling in Robotic Orthopedic Surgery with Closed-Loop Control Approach. Ann. Biomed. Eng. 2020, 48, 1218–1229. [Google Scholar] [CrossRef]

- Caesarendra, W.; Wulandari, P. ; Gatnar, Kamil Bone Drilling Vibration Signal Classification Using Convolutional Neural Network to Determine Bone Layers. In Proceedings of the In: Triwiyanto, T., Rizal, A., Caesarendra, Biomedical Engineering, and Health Informatics. Lecture Notes in Electrical Engineering; 1182, W. (eds) Proceedings of the 4th International Conference on Electronics; Springer, Singapore: Surabaya, Indonesia, April 28 ; Vol, 2024; pp. 577–592. [Google Scholar]

- Song, S.; Cheng, X.; Li, T.; Shi, M.; Zheng, G.; Liu, H. Experimental Study of Bone Drilling by Kirschner Wire. Med. Eng. Phys. 2022, 106, 103835. [Google Scholar] [CrossRef]

- Chen, H.L.; Gundjian, A.A. Specific Heat of Bone. Med. Biol. Eng. 1976, 14, 548–550. [Google Scholar] [CrossRef]

- Cordioli, G.; Majzoub, Z. Heat Generation during Implant Site Preparation: An in Vitro Study. Int. J. Oral Maxillofac. Implants 1997, 12, 186–193. [Google Scholar]

- Hillery, M.T.; Shuaib, I. Temperature Effects in the Drilling of Human and Bovine Bone. J. Mater. Process. Technol. 1999, 92–93, 302–308. [Google Scholar] [CrossRef]

- Lee, J.; Gozen, B.A.; Ozdoganlar, O.B. Modeling and Experimentation of Bone Drilling Forces. J. Biomech. 2012, 45, 1076–1083. [Google Scholar] [CrossRef]

- Pandey, R.K.; Panda, S.S. Optimization of Multiple Quality Characteristics in Bone Drilling Using Grey Relational Analysis. J. Orthop. 2015, 12, 39–45. [Google Scholar] [CrossRef] [PubMed]

- Sarparast, M.; Ghoreishi, M.; Jahangirpoor, T.; Tahmasbi, V. Experimental and Finite Element Investigation of High-Speed Bone Drilling: Evaluation of Force and Temperature. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 349. [Google Scholar] [CrossRef]

- Alam, K.; Qamar, S.Z.; Iqbal, M.; Piya, S.; Al-Kindi, M.; Qureshi, A.; Al-Ghaithi, A.; Al-Sumri, B.; Silberschmidt, V.V. Effect of Drill Quality on Biological Damage in Bone Drilling. Sci. Rep. 2023, 13, 6234. [Google Scholar] [CrossRef]

- Hochreiter, S.; Schmidhuber, J. Long Short-Term Memory. Neural Comput. 1997, 9, 1735–1780. [Google Scholar] [CrossRef]

- Darmawahyuni, A.; Nurmaini, S.; Sukemi; Caesarendra, W. ; Bhayyu, V.; Rachmatullah, M.N.; Firdaus Deep Learning with a Recurrent Network Structure in the Sequence Modeling of Imbalanced Data for ECG-Rhythm Classifier. Algorithms 2019, 12, 118. [Google Scholar] [CrossRef]

- Rofii, A.; Soerowirdjo, Busono; Irawan, Rudi; Caesarendra, W. Utilize the Prediction Results from the Neural Network Gate Recurrent Unit (GRU) Model to Optimize Reactive Power Usage in High-Rise Buildings. Int. J. Robot. Control Syst. 2024, 4, 628–654. [Google Scholar]

- Sabique, P.V.; Pasupathy, G.; Ramachandran, S. A Data Driven Recurrent Neural Network Approach for Reproduction of Variable Visuo-Haptic Force Feedback in Surgical Tool Insertion. Expert Syst. Appl. 2024, 238, 122221. [Google Scholar] [CrossRef]

- Lu, S.; Yang, J.; Yang, B.; Li, X.; Yin, Z.; Yin, L.; Zheng, W. Surgical Instrument Posture Estimation and Tracking Based on LSTM. ICT Express 2024, S240595952400002X. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).