Submitted:

08 June 2024

Posted:

10 June 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. BIM as a Response to a Sustainable Construction Industry

3. Theoretical Background

4. Methodology

4.1. Selection of Participants

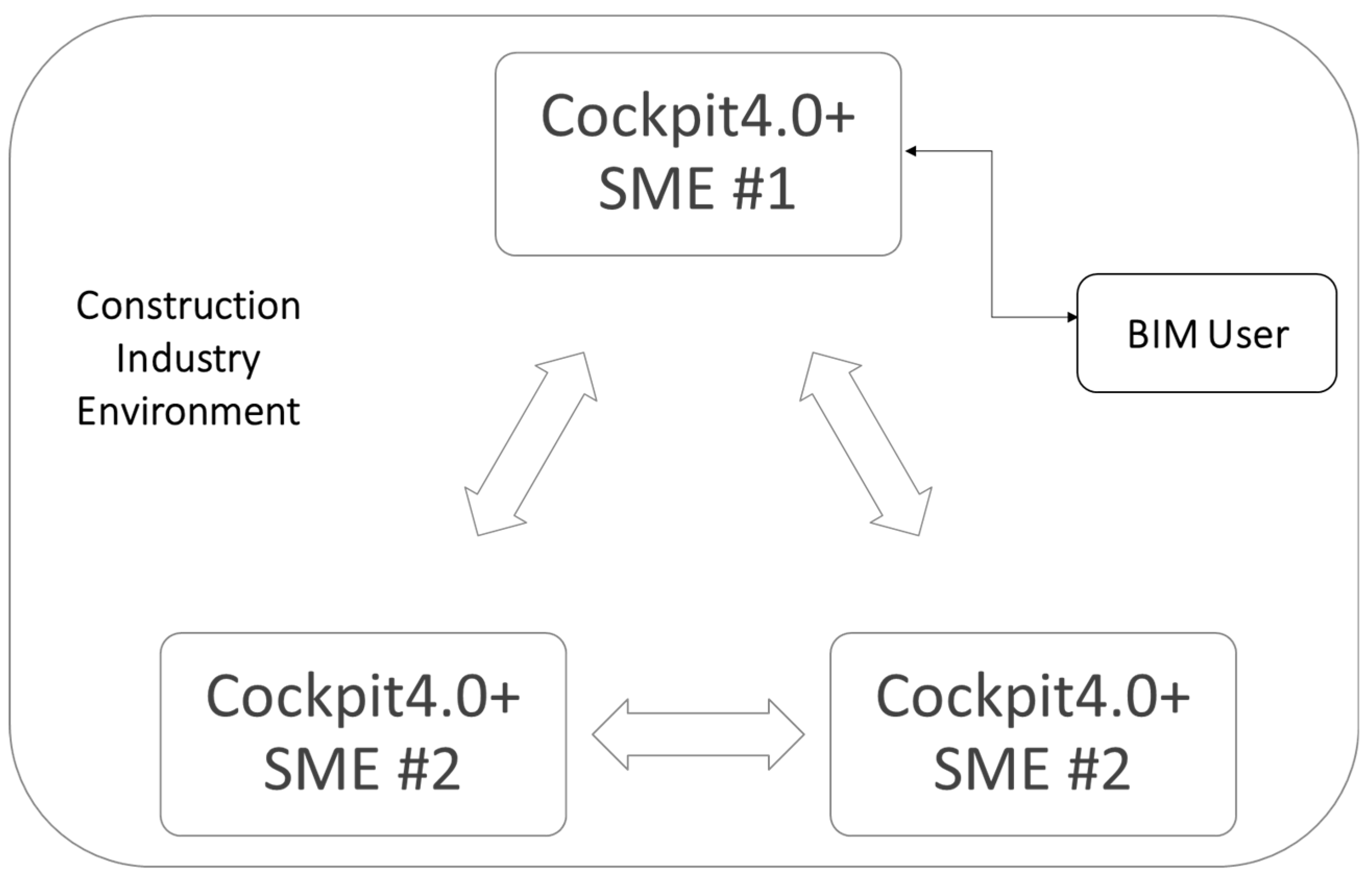

4.2. Coopetition Network Formation and Metrics

4.3. Data Collection

5. Results: Evaluating the Practices of Construction Industry Providers

6. Discussion on Enhancing BIM Dimensions through Coopetition Practices

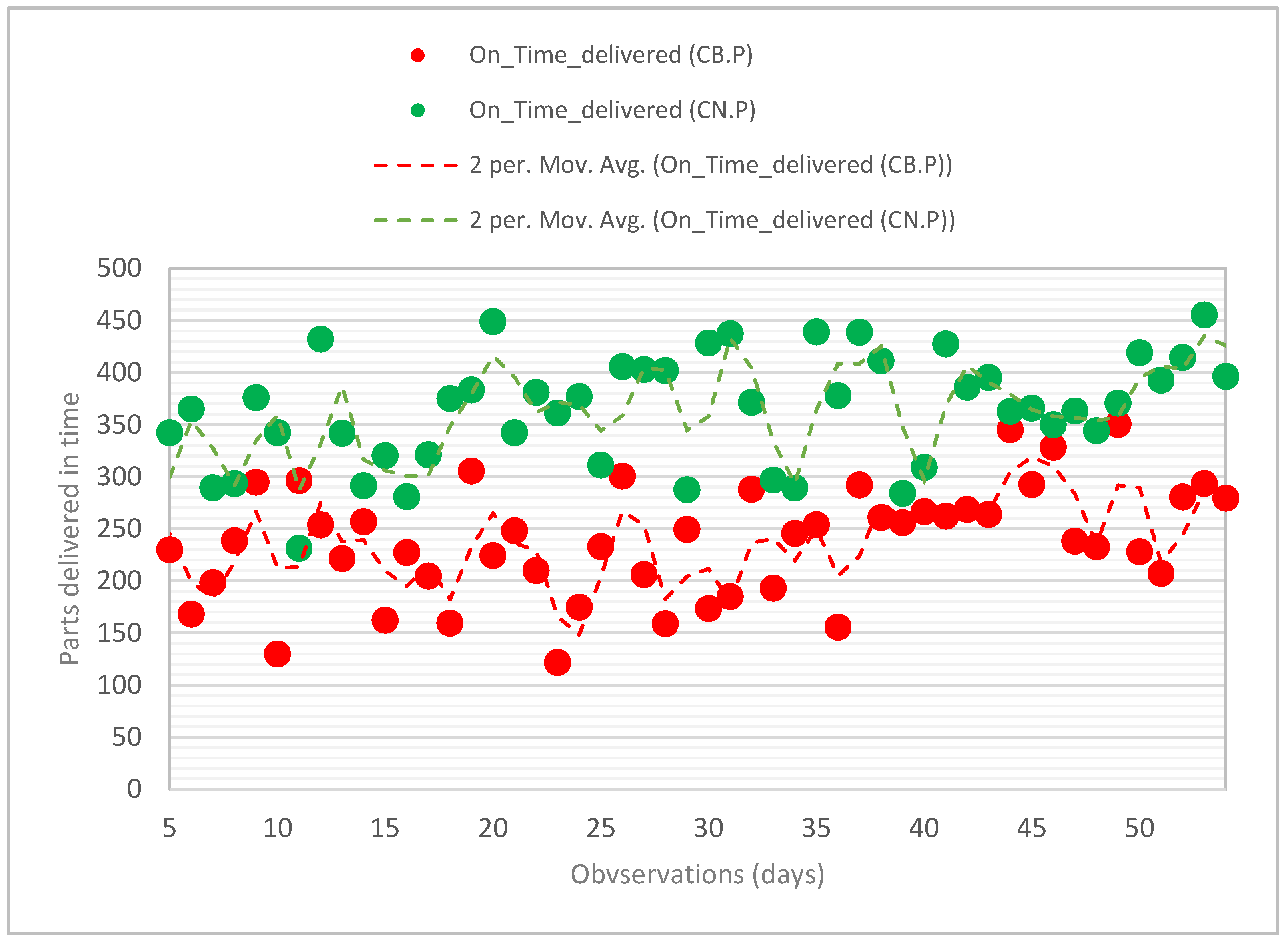

6.1. Responding to 4D BIM: Enhancing On-Time Delivery through Coopetition Practices

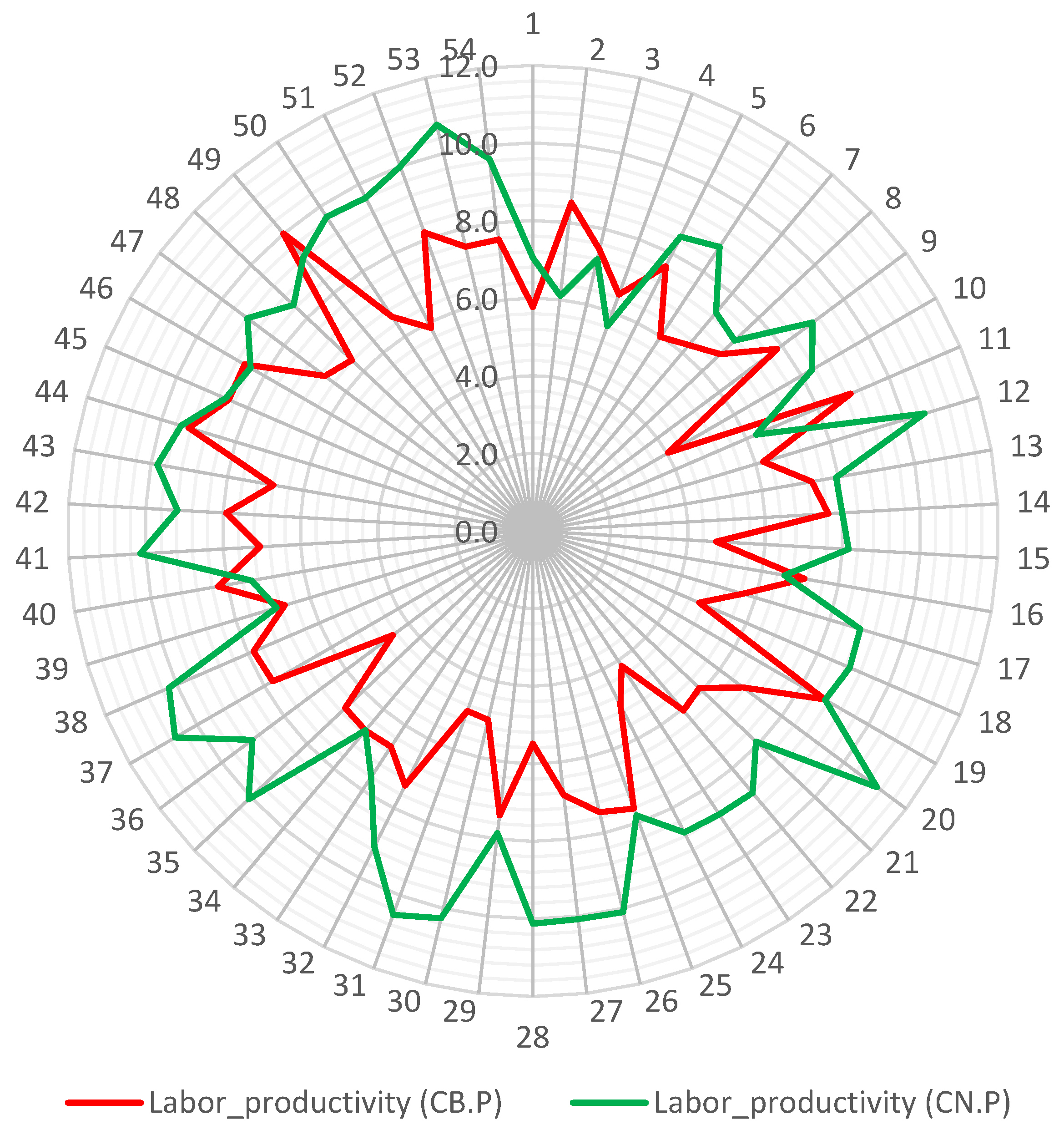

6.2. Responding to 5D BIM: Enhancing Labor Productivity through Coopetition Practices

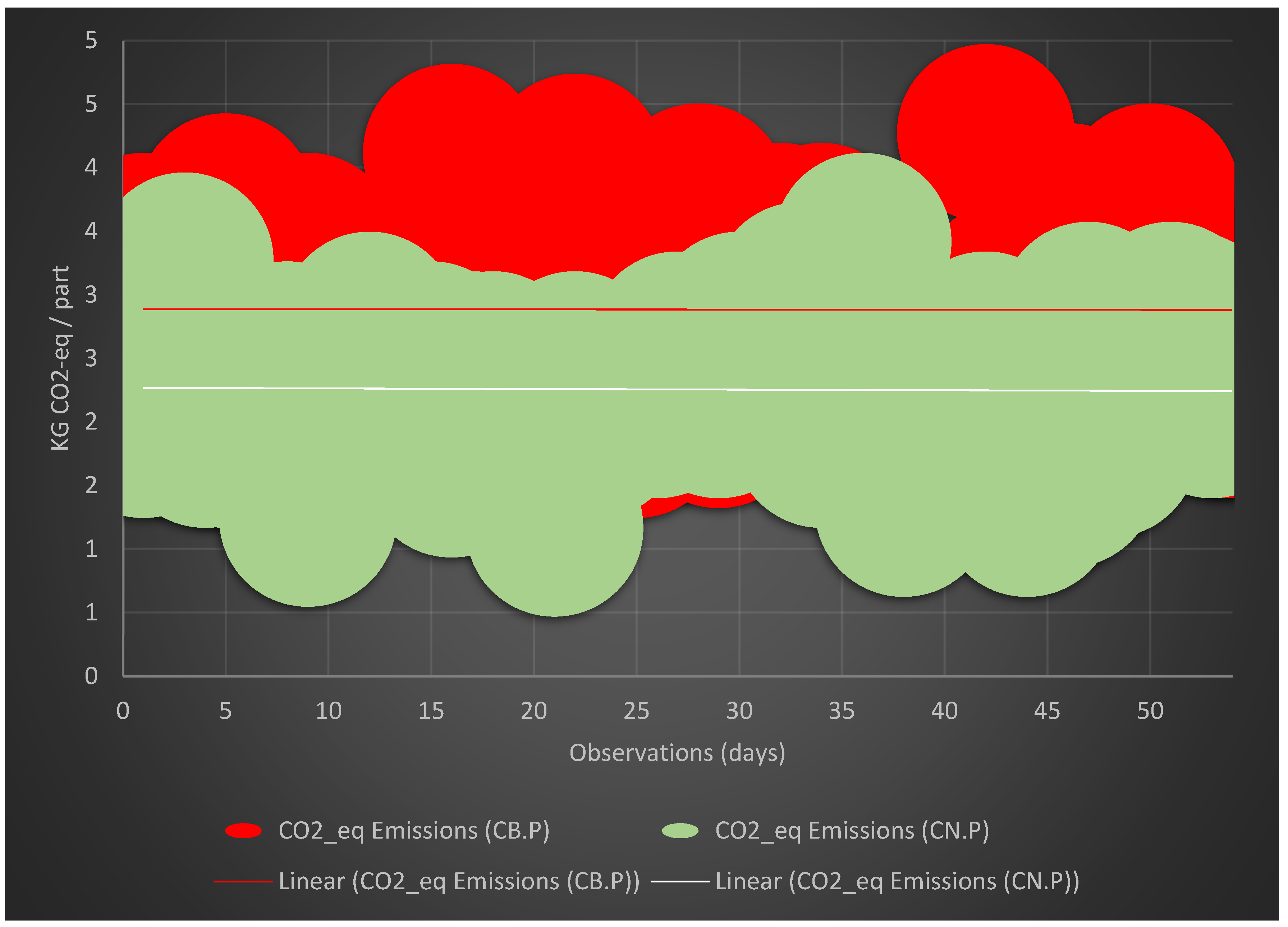

6.2. Responding to 6D BIM: Enhancing Sustainability through Coopetition Practices

7. Conclusions

References

- N. Fearnley, G. Robinson, and J. Leonard, “Global Construction Futures,” 2023. [Online]. Available online: https://www.oxfordeconomics.com/resource/global-construction-futures/.

- A. S. Kulinan, M. Park, P. P. W. Aung, G. Cha, and S. Park, “Advancing construction site workforce safety monitoring through BIM and computer vision integration,” Autom. Constr., vol. 158, p. 105227, Feb. 2024. [CrossRef]

- M. Altaf, W. S. Alalaoul, M. A. Musarat, A. A. Abdelaziz, and M. J. Thaheem, “Optimisation of energy and life cycle costs via building envelope: a BIM approaches,” Environ. Dev. Sustain., vol. 26, no. 3, pp. 7105–7128, Feb. 2023. [CrossRef]

- HM Government, “Digital Built Britain Level 3 Building Information Modelling - Strategic Plan,” 2015. [Online]. Available online: http://digital-built-britain.com/DigitalBuiltBritainLevel3BuildingInformationModellingStrategicPlan.pdf.

- M. Li, K. Lu, H. Wang, and S. Wang, “Integrating BIM with greenhouse-gas emissions in AEC: A scientometric review,” E3S Web Conf., vol. 143, pp. 0–4, 2020. [CrossRef]

- D. Mwesiumo, M. Harun, and H. Hogset, “Unravelling the black box between coopetition and firms’ sustainability performance,” Ind. Mark. Manag., vol. 114, pp. 110–124, Oct. 2023. [CrossRef]

- R. Bouncken, A. Kumar, J. Connell, A. Bhattacharyya, and K. He, “Coopetition for corporate responsibility and sustainability: does it influence firm performance?,” Int. J. Entrep. Behav. Res., vol. 30, no. 1, pp. 128–154, Jan. 2024. [CrossRef]

- Q. Xie, Y. Gao, N. Xia, S. Zhang, and G. Tao, “Coopetition and organizational performance outcomes: A meta-analysis of the main and moderator effects,” J. Bus. Res., vol. 154, no. October 2022, p. 113363, 2023. [CrossRef]

- UN, “The Sustainable Development Goals Report- United Nations,” 2019.

- F. G. B. Blanco and H. Chen, “The Implementation of Building Information Modelling in the United Kingdom by the Transport Industry,” Procedia - Soc. Behav. Sci., vol. 138, no. 0, pp. 510–520, 2014. [CrossRef]

- K. A. Abdumutalibovich and B. M. Lutfillaevna, “The Role of Bim Technologies in the Information System of Education,” Eur. J. Contemp. Bus. Law Technol. Cyber Law, Blockchain, Leg. Innov., vol. 1, no. 2, pp. 9–13, May 2023. [CrossRef]

- A. Silva, C. Rabadão, and C. Capela, “Towards Industry 4.0 | A case study of BIM deployment in ornamental stones sector,” Int. J. Innov. Technol. Explor. Eng., vol. 67, p. 24535, 2020. ISSN 2307-4531.

- F. Jalaei and A. Jrade, “Integrating building information modeling (BIM) and LEED system at the conceptual design stage of sustainable buildings,” Sustain. Cities Soc., vol. 18, pp. 95–107, 2015. [CrossRef]

- J. Vilas-Boas, V. Mirnoori, A. Razy, and A. Silva, “Outlining a New Collaborative Business Model as a Result of the Green Building Information Modelling Impact in the AEC Supply Chain,” PRO-VE 2019. IFIP Adv. Inf. Commun. Technol. vol 568. Publ. Springer, pp. 405–417, 2019. [CrossRef]

- A. Hadavi and S. Alizadehsalehi, “From BIM to metaverse for AEC industry,” Autom. Constr., vol. 160, p. 105248, Apr. 2024. [CrossRef]

- Z.-S. Chen, Z.-R. Wang, M. Deveci, W. Ding, W. Pedrycz, and M. J. Skibniewski, “Optimization-based probabilistic decision support for assessing building information modelling (BIM) maturity considering multiple objectives,” Inf. Fusion, vol. 102, p. 102026, Feb. 2024. [CrossRef]

- F. K. T. Cheung, J. Rihan, J. Tah, D. Duce, and E. Kurul, “Early stage multi-level cost estimation for schematic BIM models,” Autom. Constr., vol. 27, pp. 67–77, 2012. [CrossRef]

- R. D. Raut, S. Kumar, V. S. Narwane, B. B. Gardas, P. Priyadarshinee, and B. E. Narkhede, “Linking big data analytics and operational sustainability practices for sustainable business management,” J. Clean. Prod., vol. 224, pp. 10–24, 2019. [CrossRef]

- S. Shao and D. Cao, “Contagion of BIM Implementation Practices in Interproject Networks: An Empirical Study in China,” J. Manag. Eng., vol. 40, no. 1, Jan. 2024. [CrossRef]

- A. Waqar, A. H. Qureshi, and W. S. Alaloul, “Barriers to Building Information Modeling (BIM) Deployment in Small Construction Projects: Malaysian Construction Industry,” Sustainability, vol. 15, no. 3, p. 2477, Jan. 2023. [CrossRef]

- P. U. Wijeratne, C. Gunarathna, R. J. Yang, P. Wu, K. Hampson, and A. Shemery, “BIM enabler for facilities management: a review of 33 cases,” Int. J. Constr. Manag., vol. 24, no. 3, pp. 251–260, Feb. 2024. [CrossRef]

- M. Chowdhury, M. R. Hosseini, D. J. Edwards, I. Martek, and S. Shuchi, “Comprehensive analysis of BIM adoption: From narrow focus to holistic understanding,” Autom. Constr., vol. 160, p. 105301, Apr. 2024. [CrossRef]

- J. F. Moore, “The rise of a new corporate form,” Wash. Q., vol. 21, no. 1, pp. 167–181, 1998. [CrossRef]

- B. J. Nalebuff and A. M. Brandenburger, “Co-opetition: Competitive and cooperative business strategies for the digital economy,” Strateg. Leadersh., vol. 25, no. 6, pp. 28–33, Jun. 1997. [CrossRef]

- A. Meena, S. Dhir, and S. Sushil, “A review of coopetition and future research agenda,” J. Bus. Ind. Mark., vol. 38, no. 1, pp. 118–136, 2023. [CrossRef]

- C. Ramírez-López et al., “Coopetition: Cooperation among competitors to enhance applied research and drive innovation in elite sport,” Br. J. Sports Med., vol. 55, no. 10, pp. 522–523, 2021. [CrossRef]

- L. Corbo, S. Kraus, B. Vlačić, M. Dabić, A. Caputo, and M. M. Pellegrini, “Coopetition and innovation: A review and research agenda,” Technovation, vol. 122, no. September 2022, 2023. [CrossRef]

- A. Rouyre, A.-S. Fernandez, and O. Bruyaka, “Big problems require large collective actions: Managing multilateral coopetition in strategic innovation networks,” Technovation, vol. 132, p. 102968, 2024. [CrossRef]

- O. Gernsheimer, D. K. Kanbach, and J. Gast, “Coopetition research - A systematic literature review on recent accomplishments and trajectories,” Ind. Mark. Manag., vol. 96, no. May, pp. 113–134, 2021. [CrossRef]

- Estrada and J. Dong, “Learning from experience? Technological investments and the impact of coopetition experience on firm profitability,” Long Range Plann., vol. 53, no. 1, p. 101866, 2020. [CrossRef]

- Y. Hsu, “Integrating Service Science and Information System Technology : A Case Study,” Int. J. Organ. Innov., vol. 9, no. 1, pp. 158–173, 2016. [CrossRef]

- T. Hollweck, “Robert K. Yin.Case Study Research Design and Methods (5th ed.).,” Can. J. Progr. Eval., vol. 30, no. 1, pp. 108–110, Mar. 2015. [CrossRef]

- Carvalho, C. Lopes, A. Mateus, L. Martins, and M. Goulão, “Planning the future exploitation of ornamental stones in Portugal using a weighed multi-dimensional approach,” Resour. Policy, vol. 59, no. August, pp. 298–317, 2018. [CrossRef]

- A. Silva and A. Marques Cardoso, “BIM-based Supply Chain in AEC - Threats on the Portuguese Stone sector,” in Proceedings of the 7th Globalstone Congress, Batalha, 2023; ISBN 978-972-778-327-4, 2023, [Online]. Available online: https://repositorio.lneg.pt/bitstream/10400.9/4150/1/GSC2023_PT%20Natural%20Stones-Commercial%20Names%20harmonization.pdf.

- Silva and A. Pata, “Value Creation in Technology Service Ecosystems - Empirical Case Study,” in Innovations in Industrial Engeneering II, 2022, pp. 26–36. [CrossRef]

- Silva and M. M. Gil, “Industrial Processes Optimization in Digital Marketplace Context: A Case Study in Ornamental Stone Sector,” Results Eng., 2020. [CrossRef]

- Silva and A. Marques Cardoso, “Technology Paths towards Coopetition Ecosystems - The Portuguese Stone Sector,” in Proceedings of the 7th Globalstone Congress, Batalha, 2023, 2023, [Online]. ISBN 978-972-778-327-4.

- S. Destefanis, O. W. Maietta, F. Mazzotta, and L. Parisi, “Firm survival and innovation: direct and indirect effects of knowledge for SMEs,” Econ. Innov. New Technol., pp. 1–29, Oct. 2023. [CrossRef]

- Di Bella, A. Katsinis, J. Lagüera-González, L. Odenthal, M. Hell, and B. Lozar, “Annual Report on European SMEs 2022/2023,” 2023.

- C. L. Ng and S. Y. L. Wakenshaw, “The Internet-of-Things: Review and research directions,” Int. J. Res. Mark., vol. 34, no. 1, pp. 3–21, Mar. 2017. [CrossRef]

- S. Hoppe, “OPC Unified Architecture-Interoperability for Industrie 4.0 and the Internet of Things,” 2023. [Online]. Available online: https://opcfoundation.org/wp-content/uploads/2023/05/OPC-UA-Interoperability-For-Industrie4-and-IoT-EN.pdf.

- Barreto, A. Amaral, and T. Pereira, “Industry 4.0 implications in logistics: an overview,” Procedia Manuf., vol. 13, pp. 1245–1252, 2017. [CrossRef]

- G. Latif, G. Ben Brahim, S. E. Abdelhamid, R. Alghazo, G. Alhabib, and K. Alnujaidi, “Learning at Your Fingertips: An Innovative IoT-Based AI-Powered Braille Learning System,” Appl. Syst. Innov., vol. 6, no. 5, p. 91, Oct. 2023. [CrossRef]

- A. Silva, C. Rabadão, and C. Capela, “Towards Industry 4.0 | A case study of BIM deployment in ornamental stones sector,” Int. J. Innov. Technol. Explor. Eng., vol. 67, p. 24535, 2020.

- A. Silva, A. Dionisio, and I. Almeida, “Enabling Cyber-Physical Systems for Industry 4.0 operations: A Service Science Perspective,” Int. J. Innov. Technol. Explor. Eng., vol. 9, no. 8, pp. 838–846, Jun. 2020. [CrossRef]

- S. Vargo, H. Wieland, and M. Akaka, “Innovation through institutionalization: A service ecosystems perspective,” Ind. Mark. Manag., vol. 44, no. 2013, pp. 63–72, 2015. [CrossRef]

- G. Yilmaz, A. Akcamete, and O. Demirors, “BIM-CAREM: Assessing the BIM capabilities of design, construction and facilities management processes in the construction industry,” Comput. Ind., vol. 147, p. 103861, May 2023. [CrossRef]

- D. Jones, “European Electricity Review 2023,” 2023. [Online]. Available online: https://ember-climate.org/app/uploads/2023/01/Report-European-Electricity-Review-2023.pdf.

| Data ID | Description | Current Practices (CB.P) | Data (average daily) |

|---|---|---|---|

| Data 1 | Parts delivered | ∑ parts_delivered | 339 |

| Data 2 | Parts delivered on time | ∑ parts_delivered_on_time | 240 |

| Data 3 | Parts Shipped | ∑parts_shipped | 338.5 |

| Data 4 | Labours Involved (h) | ∑labour_involved | 49.3 |

| Data 5 | Energy Consumed (kWh) | ∑energy consumed producing parts | 4692 |

| Data 6 | Parts Produced | ∑parts_produced | 369.9 |

| Data ID | Description | Coopetition Practices (CN.P) | Data (average daily) |

|---|---|---|---|

| Data 7 | Parts delivered | ∑ parts_delivered | 454 |

| Data 8 | Parts delivered on time | ∑ parts_delivered_on_time | 358 |

| Data 9 | Parts Shipped | ∑parts_shipped | 415.8 |

| Data 10 | Labours Involved (h) | ∑labour_involved | 49.3 |

| Data 11 | Energy Consumed (kWh) | ∑energy consumed producing parts | 4071 |

| Data 14 | Parts Produced | ∑parts_produced | 416 |

| Key Performance Indicators (KPIs) | CB.P | CN.P | Quantitative Gain |

|---|---|---|---|

| KPI - On-Time Delivery (parts/parts) | 0.671 | 0.775 | 15.6% |

| KPI - Labor Productivity (parts/worker) | 6.84 | 8.72 | 27.38% |

| KPI - CO2-eq (KgCO2/part) | 3.41 | 2.68 | 21.8% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).