1. Introduction

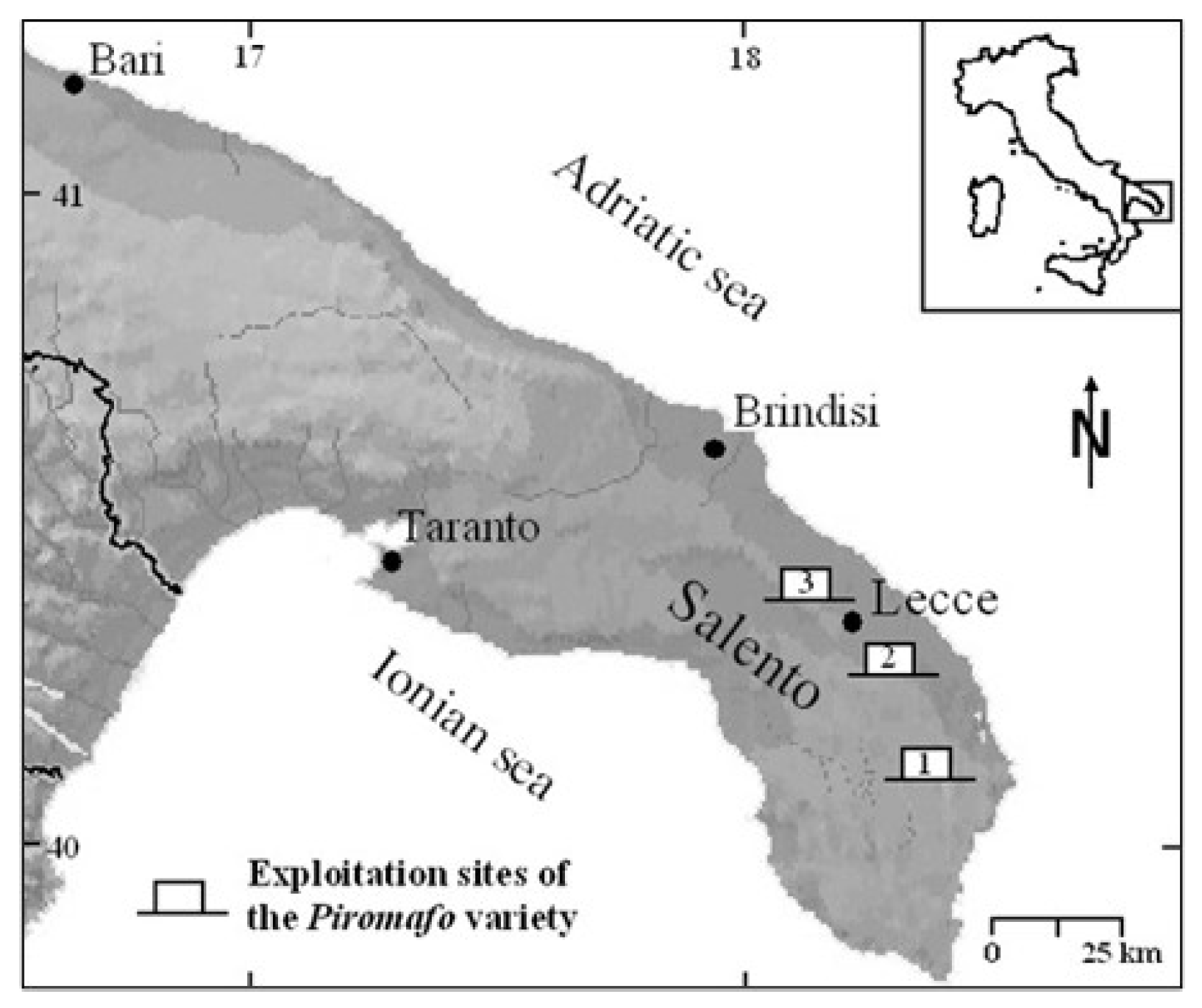

The Salento area, in particular the city of Lecce (Apulia, southern Italy), is very famous for the splendor of its 17th–18th c. Baroque architecture characterized by the use of stones derived from the Pietra Leccese Fm. (Late Burdigalian-early Messinian) which crops out locally throughout the area [

1,

2,

3,

4]. The Pietra Leccese Fm. is comprised mainly of a white-yellowish, fine-grained, calcarenite. It is a hemipelagic chalk-like carbonate, homogeneous and porous with a wackestone/packstone depositional texture, composed of calcareous microfossils, such as Foraminifera, and bioclasts of Bivalves, Ostracods, Echinoderms and pellets. Additional allochems also include intraclasts. Within this unit, different lithofacies alternate both vertically and laterally, constituting many varieties which are identified with traditional local building stone, names such as:

Mazzara,

Leccisu,

Pietra bastarda,

Dura,

Bianca,

Dolce,

Gagginara,

Piromafo,

Cucuzzara,

Saponara and

Niura. These stone varieties differ considerably in color and stone pattern, as well as physical and mechanical performance which are strongly dependent on depositional fabric and, degree and type of diagenesis. At the same time, the material durability, defined as the property of natural building stone to resist the weathering agents in the course of time and preserve its appearance and characteristics of strength, is not the same in the different varieties.

Piromafo (

Pirómafo or

Pirómaco) is a phosphatic-glauconitic biomicrite rich in plancktonic Foraminifera. It is characterised by its greenish-brown or greenish-grey colours and stone pattern due to the presence of macrofossils, at places, concentrated in some levels [

5]. Its name comes from the ancient Greek πῦρ (fire) combined with the verb μάχομαι (fight), which reflects its good refractory and thermal insulation properties [

6]. Today, in fact, due to its high thermal resistance, it is suitable for the furnishing of fireplaces, hearths, ovens, kilns and chimneys, while the historical use of this material is much more interesting, especially from the Roman times (

Figure 1) and Baroque period. The well-known Baroque Convent of Agostiniani (1573-1662), at Melpignano (South of Salento), and the monumental pier of San Cataldo (Lecce), the main coastal harbour of the Roman town of Lupiae, are just two examples [

7]. The outcrops of

Piromafo are numerous even if limited in thickness (few meters) and include the areas of Novoli and Surbo to the North of Lecce, Vernole, Vanze, Strudà, Acaya, and Pisignano to the South-East of Lecce, and Cursi, Melpignano, Martano, Zollino, and Poggiardo to the South of Salento (

Figure 2).

The purpose of this work is to present a comprehensive review of the main petrophysical and mechanical properties of the

Piromafo stone given the absence in the literature of a complete characterization of this material. From the comprehensive literature review presented and discussed in this study, in fact, it is possible to state that the existing research done since the past century on

Piromafo has been focused on the geo-stratigraphic and mineralogical features, leaving aside information concerning technical properties and durability, in spite of its predisposition to weathering and carsogenesis [

8].

Thus, studies addressing different technical aspects, especially in terms of hydraulic and thermal properties, constitute fundamental tools and knowledge for qualitative and quantitative performance assessment of the stone’s resistance to weathering processes. This should be both significant and appealing, especially when the study method is innovative because it includes a multidisciplinary approach involving both standard and unconventional techniques.

Therefore, rock fabric inspection was performed by means of transmitted light on standard thin-sections using an optical polarizing microscope. Specific gravity, density, porosity, water absorption and degree of saturation were obtained following the test procedure described in the ISRM, ASTM and EN standards. Pore-size distribution was carried out by mercury intrusion Porosimetry (MIP) and image analysis (IA) performed on photomicrographs applying the methods of quantitative stereology. Computer analysis of digital images was applied to determine also the grain-size distribution. Water permeability tests were conducted on cylindrical rock samples using the falling head method. The thermal parameters were determined with the experimental “cut-core” method [

9,

10,

11], first in the dry state and then in the saturated state.

Unconfined compressive strength, flexural strength, indirect tensile strength, Point Load index and Schmidt hammer rebound were calculated and compared. Particularly, compressive strength and tangent modulus were correlated with the Schmidt hammer rebound values.

2. Materials and Methods

Samples of the

Piromafo stone were taken from the quarry districts of Strudà-Acaja (South-East of Lecce) and Cursi-Melpignano, along the road which connects Cursi to Melpignano (

Zezza quarry, South Salento) where quarry walls carved in the Pietra Leccese Fm. expose

Piromafo in outcrops about two meters thick. In both the sampling sites, the

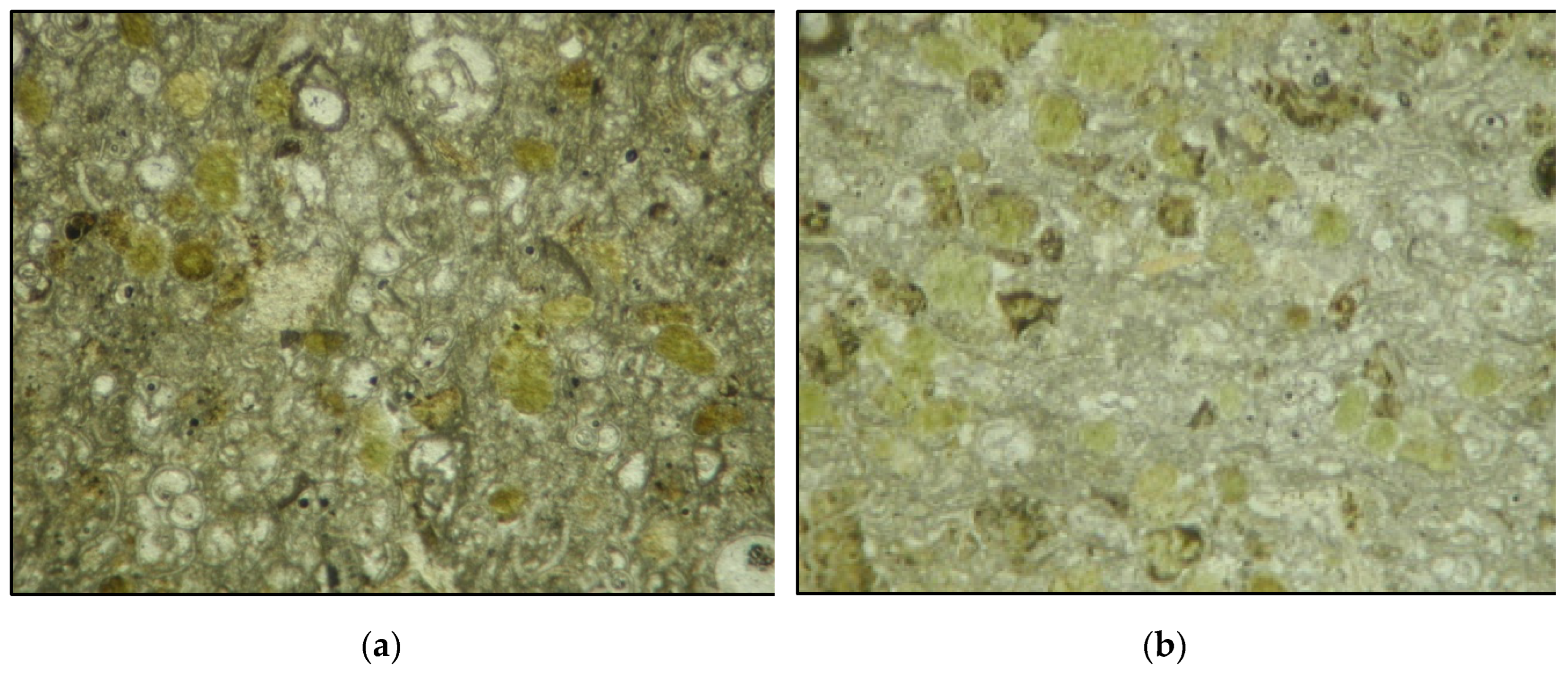

Piromafo facies is represented by a strongly glauconitic biomicrite, greenish or greenish-brown in the upper part and greenish-grey, massive beds very rich in bivalves (mainly pectinids) in the lower part (

Figure 3). The green and brown grains are respectively glauconitic and phosphatic, apatitic nodules (a few millimetres to 2-3 cm in size), which at places, are concentrated in decimeter thick dark green lenses. Therefore, the different greenish shades of the outcrops are attributable to the presence of glauconite and apatite and depend on the degree of crystallization or alteration of glauconite and the percentage of phosphates present [

12,

13]. At the Cursi-Melpignano sites, two lenses of about 0.3 meters thick are characterized by a wavy pattern with such a high concentration of apatite nodules and macrofossils (Bivalves) which the local quarrymen call

mussel levels [

14]. The glauconite biomicrites show a gradually change up-section due to the decrease of the glauconitic content and the increase in the carbonate component resulting in a graded contact with the overlying Calcareniti di Andrano Fm. (Messinian). Patterns of bioturbation can be observed, especially where the concentrations in fossil bivalve shells is higher (mainly at Strudà-Acaja site). These are, mainly, horizontal burrowing trace fossils.

The origin of glauconite is controversial and lacks a consensus of views and interpretations regarding all the chemical reactions and the parameters that control the development of the mineral. Some authors, in fact, believe that glauconite is not an environmental indicator. They provide evidence that it has been found in both tidal-sea and deep-sea sediments of low sedimentation rate [

15,

16,

17,

18,

19,

20]. The apatite grains are detrital in origin and derive from the erosion of pre-existing sediments that included phosphate levels of variable percentages depending on the biogenic or terrigenous nature of the original clasts [

21,

22].

Figure 3.

This Mesoscopic appearances of the Piromafo specimens respectively from Strudà-Acaja (a) and Cursi-Melpignano (b).

Figure 3.

This Mesoscopic appearances of the Piromafo specimens respectively from Strudà-Acaja (a) and Cursi-Melpignano (b).

Evaluating physical and mechanical properties of stones used as building and ornamental material is an interesting and complex challenge due to the often encountered need to adapt, modify or implement the methods and techniques described in international standards to the characteristics l.s. of materials, especially in terms of rock composition and fabric, with respect to the purposes of investigation. For this study, a multidisciplinary approach using traditional methods of investigation associated with new experimental unconventional techniques was used. Therefore, polarized optical microscopy and image analysis (IA) on microphotos coupled with mercury intrusion porosimetry technique (MIP) and basic geotechnical testing were used to classify the materials and their pore structures. According to ASTM [

40], a chemical analysis of samples crushed and powdered by mechanical method with porcelain mortars and pestles was performed.

Furthermore, block samples were collected during the field investigation and then transferred to the Geotechnical Laboratory at the Department of Earth and Environmental Science, ALDO MORO University of Bari (Italy). Testing specimens were prepared in five shapes: irregular, cylinder, square bar or slab, disc and cubic. Standard tolerance limits for linear measures were adopted with an accuracy of 0.1 mm, as required by EN [

23]. Physical and mechanical properties were determined on 95 samples (44 samples from the Strudà-Acaja and 51 samples from the Cursi-Melpignano areas), which enabled mutual correlation of values. Irregular specimens were used for thin sections, mercury intrusion porosimetry (MIP) and the Point Load test (PLT). Cylindrical specimens (diameter of 71 mm and height of 140 mm) were used for the water permeability test and thermal conductivity measurements. Square bars (length of 350 mm, height of 15 mm, width of 15 mm) were used for the thermal linear expansion test. Square tile specimens (length of 300 mm, height of 50 mm, width of 50 mm) were used to conduct the flexural strength test and disc specimens (diameter of 54 mm, height to diameter ratio was 0.5:1) were prepared from cylinder specimens and used for the indirect tensile strength test (Brazilian test). Cubic specimens (80 mm in length) were used for Schmidt hammer and unconfined compressive strength (UCS) tests. Hygrometric and capillary properties were evaluated on the cubic specimens, successively saturated under vacuum and used also for UCS tests. Density measures were performed on all the samples of regular geometric shape.

Following the standard test procedures outlined in ISRM [

24,

25,

26,

27] and EN [

28,

29,

30], specific gravity (G

s), dry density (ρ

d), saturated density (ρ

sat), total porosity (n), unconfined compressive strength in the dry (σ

n) and saturated state (σ

sat), flexural strength (σ

f) and tensile strength in the dry state (σ

t) were determined. For the UCS test, a group of 30 samples (14 from the Strudà-Acaja and 16 from the Cursi-Melpignano areas) were used half in the dry state and half in the saturated state. Stress-strain curves were obtained by estimating the stress with a pressure transducer and the axial displacement with an LVTD sensor; lateral displacement was not recorded. The modulus of elasticity was derived from the UCS test on dry samples from the slope of the stress-strain curves by tangent modulus (Et). A group of 12 samples (6 both from the Strudà-Acaja and the Cursi-Melpignano areas) was used respectively for flexural strength and tensile strength in the dry state. It was not possible to perform all the mechanical tests both in the dry and saturated state due to lack of material.

According to Andriani and Walsh [

31,

32] water absorption (w

a) and degree of saturation (Sr) were evaluated on 12 specimens (6 both from the Strudà-Acaja and the Cursi-Melpignano areas) immersed and suspended in distilled water at 20 °C for 48 h and then saturated completely under vacuum (80 kPa) without removing them from the water basket. Specific Gravity was determined (5 samples from both the Strudà-Acaja and the Cursi-Melpignano areas) by measuring the grain volume with the pulverization method by displacement of an equivalent volume of distilled water in a pycnometer. The MIP tests were carried out as outlined by ASTM [

33] on 6 oven-dried samples of about 2.5 g (3 from both the Strudà-Acaja and the Cursi-Melpignano areas). A Micromeritics AutoPore IV 9500 porosimeter was used at low (3.44–345 kPa) and high pressure (0.1–228 MPa), both in intrusion and in extrusion, covering pore diameters between 420 and 0.005 μm, approximately. In particular, total pore area, average pore diameter, pore-size distribution, complementary measures of porosity (“effective” porosity), tortuosity and permeability were evaluated. The results of the MIP test were integrated with the pore-size distribution obtained by image analysis on microphotographs of thin sections, according to the procedure proposed by Andriani and Walsh [

31], and Andriani et al. [

34]. Water permeability tests were conducted with a purpose-built cell using the falling head method according to the procedure proposed by Andriani and Walsh [

32]. A group of 10 cylindrical specimens (4 from the Strudà-Acaja and 6 from the Cursi-Melpignano areas) were used for this test. The hydraulic conductivity standardized at 20 °C (k

20) was evaluated for a range of hydraulic gradients between 0.5 and 15. The thermal properties of

Piromafo were obtained from the measurement of the thermal linear expansion coefficient (α

l), based on mechanical length-change measurements at 20, 40, 60 and 80 °C according to EN [

35]. For these measurements, 4 and 7 square bar samples were prepared respectively for the Strudà-Acaja and the Cursi-Melpignano areas. The thermal conductivity (λ) in variable regime was obtained on 4 specimens for each study site by means of the experimental “cut-core” method [

9,

10,

11,

36]; measurements were taken on the same samples first in the dry state and then in the saturated state. The hygroscopic sorption properties of the material were carried out through the equilibrium moisture content measured using the desiccator method as specified in EN ISO [

37] on 14 cubic specimens (7 from both the Strudà-Acaja and the Cursi-Melpignano areas) in equilibrium with air at the specific temperature of 21 ± 1 °C and relative humidity (RH) of 61 ± 2%. The test ended when the weight of the specimens became stable, specifically after 4 days. The capillary water absorption coefficient (Aw) was estimated according to EN [

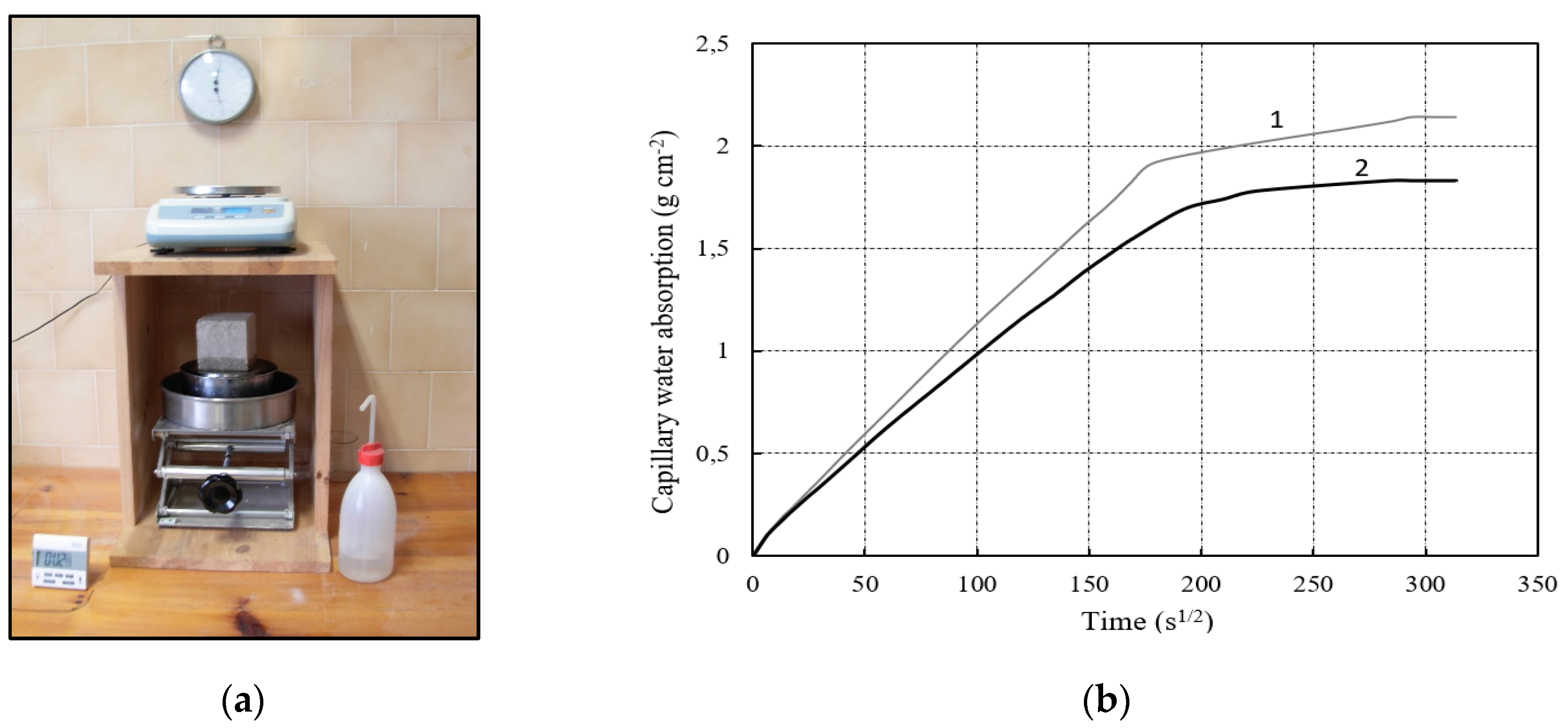

29] at the specific temperature of 21 ± 1 °C and relative humidity (RH) of 52 ± 2%, with the tangent method by plotting the cumulative mass of water absorbed per unit area against the square root of time.

Schmidt hammer tests were performed on the same cubic samples employed for the UCS test using an L-type instrument according to Aydin [

38]. The rebound values (thirty for each block, five measures on every face) obtained in vertical downwards impact directions were normalized using the correction curves provided by the manufacturer. According to the ISRM [

39], the Point Load test was performed on 5 irregular lumps for each study site and the uncorrected Point Load Strength Index (Is) was recalculated to the Size-corrected Point Load Strength Index Is (50) which corresponds to the standard core diameter of 50 mm. By comparing and combining analysis of the experimental results with literature data and information, a critical assessment of petrophysical and mechanical properties of the material was carried out, suitable for deriving relationships between the different parameters considered in this study and evaluating its susceptibility to weathering.

4. Discussion

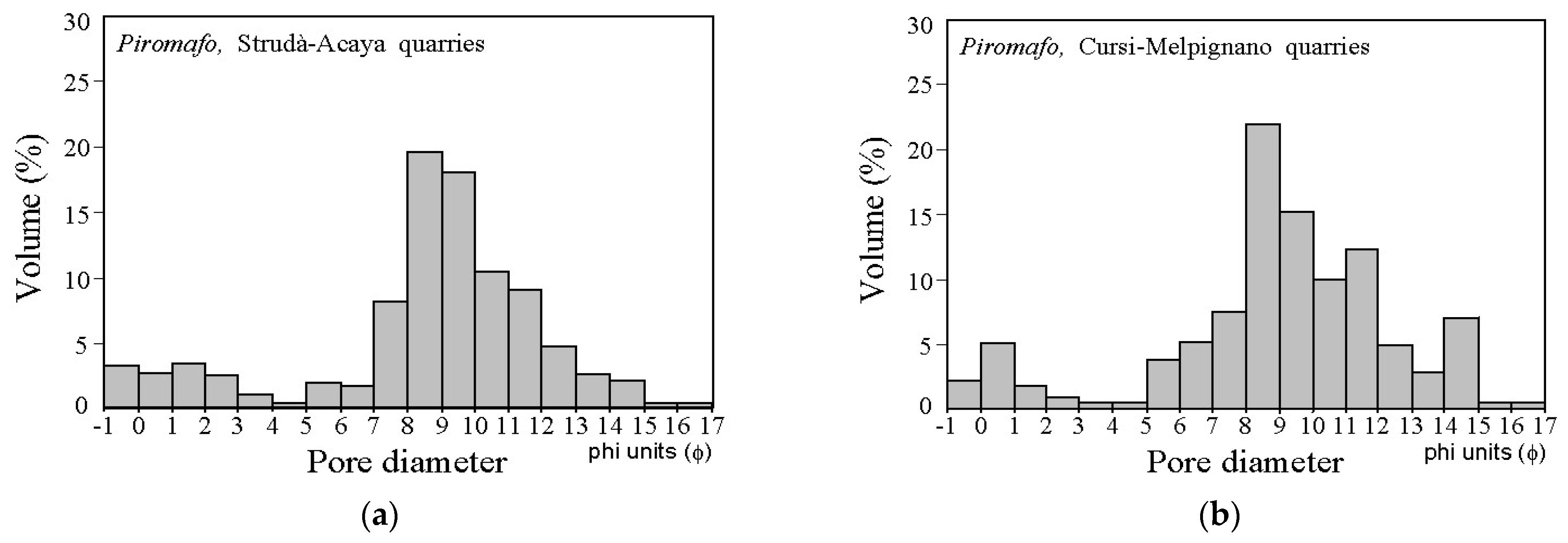

According to rock type classification of The Geological Society of London [

44],

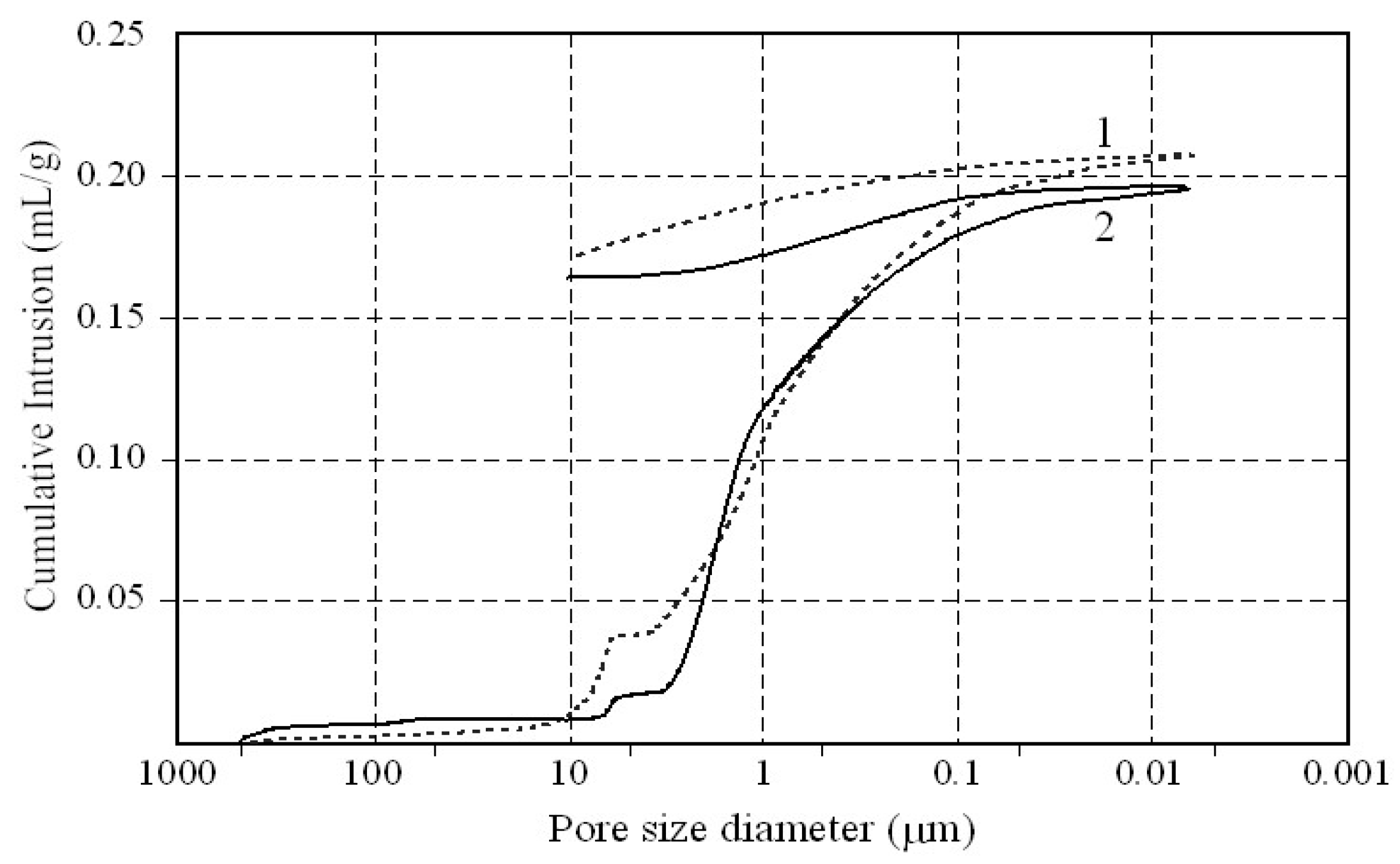

Piromafo is a medium/fine-grained calcarenite with a pore network constituted, almost in its entirety, of capillary pores smaller than 4 μm (

Figure 5). The MIP measures give interesting information not only about the volume of open voids, but also about pore shape and size, thus providing an important tool to understand the contribution of porosity and the 3D pore system with respect to the material’s durability [

45].

Comparing the results obtained for the two sites, it can be noted that the Cursi-Melpignano samples show a more marked presence of large and medium capillary pores, sensu Mindess [

46] and a minor presence of entrained air pores (> 75 μm), probably linked to microcraks (through pores). In fact, from the extrusion curves, it is possible to state that for Cursi-Melpignano samples the presence of bottle-neck pores is more remarkable. Indeed, the tortuosity factor is, on average, 1.34 for Strudà-Acaja and 1.85 Cursi-Melpignano.

In this study, the pore-size distributions obtained by MIP are very similar to those found by other authors for different facies belonging to the Pietra Leccese Fm. [

47,

48,

49], but with a higher and slightly wider pore-size distribution around the modal class of 2-4 microns. Furthermore, the pore-size distributions obtained from a combination of porosimetry results and image and textural analysis results, according to the method proposed by Andriani and Walsh [

31] and Andriani et al. [

34], demonstrate that the Strudà-Acaja samples have a greater presence of pores greater than 63 μm, intragranular and microfracture in type, above all controlled by fossils and microcracks (

Figure 6). Thus, as has been shown by Andriani et al. [

34] for other calcarenite lithofacies cropping out in Apulia (eg. Calcarenite di Gravina Fm.), also as regards the pore structure of the

Piromafo stone it is possible to affirm the existence of a dual porosity which influences its hydraulic behaviour in terms of such properties as capillarity, water absorption and water flow in unsaturated and saturated conditions.

The specific gravity average value is 2.73 and 2.72 for the samples from Strudà-Acaja and Cursi-Melpignano, respectively; these values are on average higher than the classic one for Apulian carbonates (2.70) due especially to the presence of apatite nodules and glauconite granules with high iron content. The dry density average value is 1.67 Mg/m3 and 1.69 Mg/m3 for the samples from Strudà-Acaja and Cursi-Melpignano, respectively; it is therefore midway between soft and medium hard rocks.

Figure 6.

Pore-size distribution obtained from combination of the MIP results and, image and textural analysis, according to the method proposed by Andriani and Walsh [

31] and Andriani et al. [

34].

a) Strudà-Acaja.

b) Cursi-Melpignano.

Figure 6.

Pore-size distribution obtained from combination of the MIP results and, image and textural analysis, according to the method proposed by Andriani and Walsh [

31] and Andriani et al. [

34].

a) Strudà-Acaja.

b) Cursi-Melpignano.

According to the total porosity average values (39% and 37% respectively for Strudà-Acaja and Cursi-Melpignano), those of total water absorption (24% and 22% respectively for Strudà-Acaja and Cursi-Melpignano) and those of degree of saturation (98% in both cases), the material has high total porosity which can be considered, mainly, an effective porosity. It follows that when the material is completely submerged, it absorbs a great proportion of water because the greatest part of pores in the rock particle systems are interconnected and continuous. The

Piromafo samples adsorbed around 80% of the total absorbed water in the first 20 minutes of the testing, afterwards, the absorption of water slowly increases, up to the maximum. Hygroscopic moisture content is on average equal for the samples of the two sites. It is 0.7 % with a degree of saturation between 3.2 % and 3.7 %. The higher values characterize the samples coming from Cursi-Melpignano, probably due to a greater presence of hygroscopic minerals, such as glauconite, sulphates and clay minerals, the latter as very fine grains attached to micrite matrix. It is important to emphasize that the hygroscopic water varies with the relative humidity and temperature of the environment. The absorption of water due to capillary forces is on average higher for the samples from Cursi-Melpignano. This is a consequence of a greater presence of capillary pores (< 5 µm, sensu Mehta and Monteiro [

50]) and pores open only at one end, and a lesser presence of macropores with respect to the samples from Strudà-Acaja. The capillary water absorption coefficient is found to be on average 9.0 and 10.8 mg/cm

2 s

½ respectively for the samples from Strudà-Acaja and Cursi-Melpignano. All samples exhibit first stage curves defined by a straight line. As a result, calculation of the capillary water absorption coefficient by the tangent method according to EN [

29] is more easily achieved (

Figure 7).

In the falling head test, the hydraulic conductivity measurements are found to be approximately between 10

-5 and 10

-6 m/s for the two varieties studied; the ranges of data measured reveal overall a moderate water permeability for the

Piromafo. The range of the hydraulic conductivity values is strongly conditioned by the presence of macrofossils and other discontinuities such as microfractures or other structural features. The evidence of a wider range of values with respect to other varieties of the Pietra Leccese Fm. is thus attributed to the effects of secondary permeability which provide rapid fluid transfer across the material, although at the sample scale secondary permeability does not always occur. Furthermore, the presence of glauconite, as well as clayey minerals finely distributed in the micrite matrix, decreases the material’s capacity to transmit water, thereby increasing the time of residence of water within the material. Not surprisingly, an insoluble residue content of about 12% was calculated for the

Piromafo stone. This is consistent with the observation that, other factors being equal, the samples that appeared more cemented, continuous and homogeneous showed the lowest values of the hydraulic conductivity. Additionally,

Piromafo, compared to the other varieties of the Pietra Leccese Fm. [

47,

48] shows a wider distribution of pores and more pronounced dual porosity. Thus, the weathering susceptibility of

Piromafo could be linked to its wider pore-size distribution, which, as shown in

Figure 6, includes a large number of pores smaller than 30 μm connected by pore channels and throats to larger pores. These larger pores enhance water infiltration into the material, while the smaller pores retain water by capillary forces against drainage forces. The longer the water remains inside the material, the greater the effects of stone decay are.

With respect to the thermal properties, no substantial differences were observed between the samples from the two sites. The thermal linear expansion is found to be on average 3.38 and 3.75 10-6 K-1. The thermal conductivity in the dry state is on average 0.67 and 0.68 W m-1 K-1, while the thermal conductivity in the saturated state is on average 0.92 and 0.98 W m-1K-1, respectively for the samples from Strudà-Acaja and Cursi-Melpignano. It is possible to observe how the substitution in the pore system of air with water caused an increase in thermal conductivity.

A further consideration is that

Piromafo shows a lower capability to conduct and propagate heat with respect to other varieties of the Pietra Leccese Fm. [

4,

36]. This feature can be attributable to the chemical and mineralogical composition of the material in its insoluble residue content rather than to the differences of porosity and pore network topology, taking into account that the total porosity is quite similar for all the varieties of the Pietra Leccese Fm., although the distribution of the pores can be different.

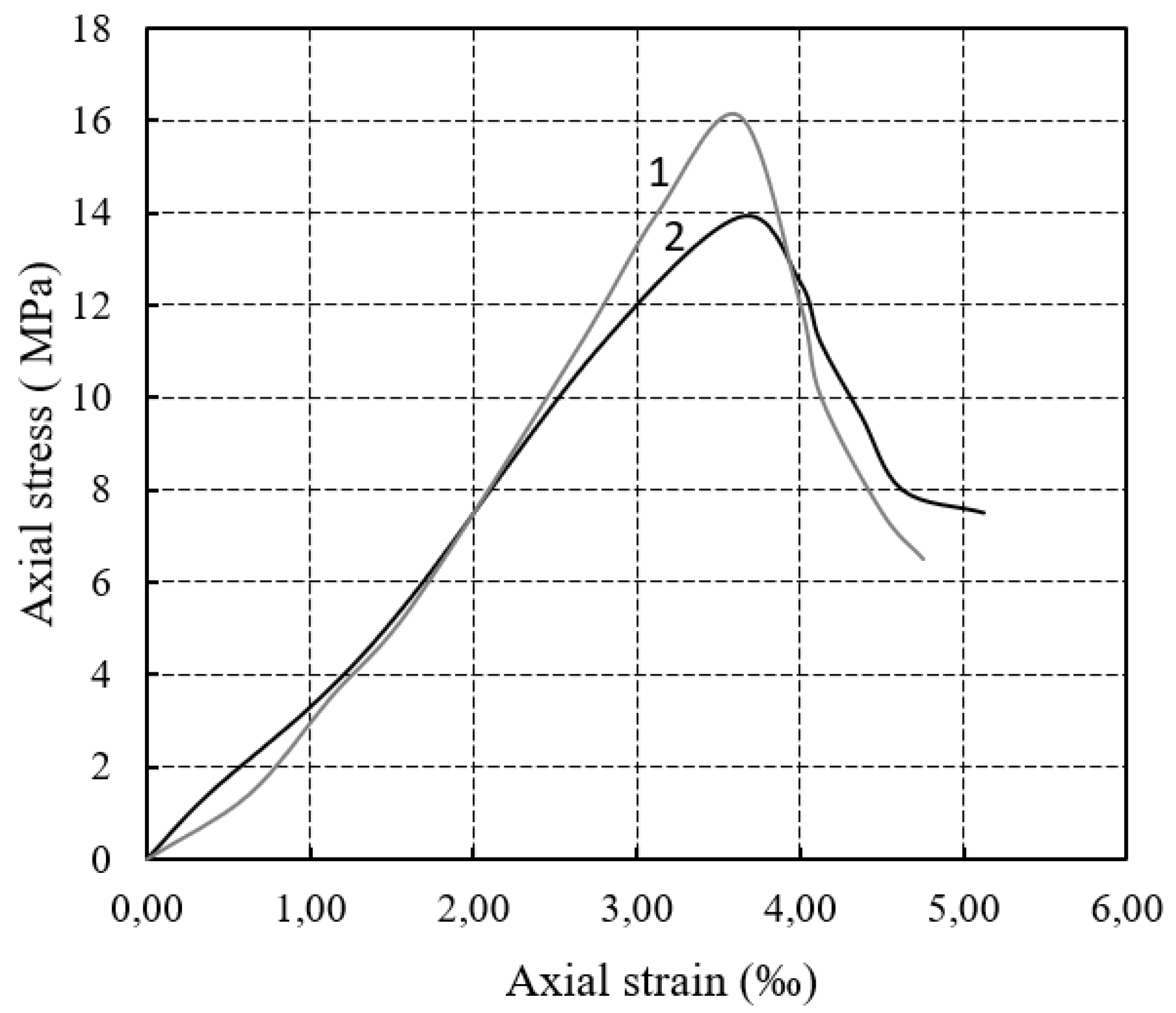

The uniaxial compressive strength and elastic modulus of the material at the dry state are found to be on average 14.1 and 15.0 MPa, and 4.7 and 5.5 GPa, respectively for the samples from Strudà-Acaja and Cursi-Melpignano. According to ISRM [

26],

Piromafo is a weak rock (R2). The overall mechanical behavior shows elastic–brittle features. Elastoplastic–brittle behavior was observed only for some samples in saturated conditions, especially for the lithofacies from Strudà-Acaja.

Considering the engineering classification for intact rock by strength and deformation properties after Deere and Miller [

51],

Piromafo is characterised by a very low strength (E) and average modulus ratio (M). According to the classification of the Apulian calcarenites (AC) by strength and rock fabric features after Andriani and Walsh [

4],

Piromafo is a moderately soft rock (AC1). Complete stress-strain curves illustrate that

Piromafo is a material with medium stiffness and medium brittleness (

Figure 8).

The uniaxial compressive strength of the material in the saturated state, the flexural strength, the indirect tensile strength, the Point Load Test index and the Schmidt Rebound Number at the dry state are found to be on average 7.8 and 7.7 MPa, 2.5 and 2.8 MPa, 1.6 and 1.9 MPa, 1.5 and 1.6 MPa, and 16 and 18, respectively for the samples from Strudà-Acaja and Cursi-Melpignano. Therefore, the presence of water in the pores of the rock leads to a reduction of the compressive strength values on average of 47%, indicating that saturation decreases the surface energy of crack faces and enables dissolution processes, especially in neomorphic calcite microcrystals and clay minerals dispersed in the micrite matrix. Consequently, both the overall cementation and the friction between the granules decrease, as well as the rock strength and elastic modulus. In particular, for the samples from Strudà-Acaja and Cursi-Melpignano the loss of strength at the saturated state is respectively of 45 and 49%. This is probably due to the better ability of the Cursi-Melpignano samples to hold water and to a greater possibility of water loss from the macropores during the test for the samples from Strudà-Acaja. Similar information about significant loss of strength and increase in deformability modulus of other calcarenite types due to water saturation are available in literature [

52,

53,

54 and references therein].

Figure 8.

Typical stress–strain curves obtained for servo-controlled uniaxial compression tests on dry samples of the Piromafo variety: 1) Cursi-Melpignano; 2) Strudà-Acaja.

Figure 8.

Typical stress–strain curves obtained for servo-controlled uniaxial compression tests on dry samples of the Piromafo variety: 1) Cursi-Melpignano; 2) Strudà-Acaja.

The ratio between uniaxial compressive strength, flexural strength and indirect tensile strength at the dry state is on average 5.5 and 8.4. The greater values of this ratio characterize the samples from Strudà-Acaja with values of 5.6 and 8.8, while values of 5.4 and 7.9 were found for the samples from Cursi-Melpignano. Generally, it can be said that the samples from Cursi-Melpignano are more resistant to flexural and tensile forces compared to those of Strudà-Acaja, but the differences are slight. The ratio between uniaxial compressive strength and the Point Load Test index at the dry state is on average 9.4 and 10, respectively for the samples from Strudà-Acaja and Cursi-Melpignano. The ratio between uniaxial compressive strength (MPa) and the Schmidt Rebound Number at the dry state are found to be on average 0.9 and 0.8, respectively for the samples from Strudà-Acaja and Cursi-Melpignano. Correlating the Schmidt hammer rebound values with compressive strength and tangent modulus for the Piromafo, the following power equations were obtained:

These equations do not agree well with those obtained and presented by other researchers in the literature for both similar and different materials [

38,

39,

55,

56,

57,

58,

59,

60]. This evidence highlights the difficulty in finding relationships applicable to all carbonate rocks caused by the extreme variability and complexity of the fabric features which make the material anisotropic and affect its engineering behaviour.

Other correlations between mechanical properties were not considered statistically significant due to the limited data for some measurements.

5. Conclusions

In this work, Piromafo, a stone variety material derived from the Pietra Leccese Fm. was investigated, in terms of petrophysical and mechanical properties. Unfortunately, despite the historical use of this material, especially from the Roman times and the Baroque period, there exists very few references in the literature with a complete characterization of this material.

Destructive and non-destructive testing was used on samples taken from two extraction areas in the Lecce province (Apulia, southern Italy): 1) Strudà-Acaja; 2) Cursi-Melpignano. In particular, the study method was based on a multidisciplinary approach involving both standard and unconventional techniques.

The attention was focused, especially, on fabric and mineral content influencing the thermal and hydraulic properties, weathering propensity and mechanical behaviour which are strongly controlled by the presence of water in pore spaces.

Some conclusions can be obtained as follows:

i) at the study sites, the Piromafo facies is represented, principally, by packed glauconitic biomicrites (Strudà-Acaja) and poorly washed glauconitic biosparites (Cursi-Melpignano), in which the total porosity (n) ranges from 37 to 42 % and from 35 to 40 % respectively. Determination of water absorption and degree of saturation on specimens completely immersed and suspended in distilled water under vacuum has shown that porosity for both the materials coming from the two study sites is almost all open with intercommunicating voids;

ii) the presence of both large and medium capillary pores and entrained air pores has demonstrated a wide pore-size distribution and dual porosity which can be responsible for the weathering susceptibility of the Piromafo stone;

iii) the experimental data demonstrated that the Piromafo stone is better as a refractory and heat insulation material with respect to other varieties of the Pietra Leccese Fm. and this is due to the chemical and mineralogical composition of the insoluble residue content (12%), which is comprised of glauconite, apatite, rare quartz grains and clayey minerals finely distributed in the matrix, rather than to the differences of total porosity, pore network topology and pore-size distribution;

iv) the results obtained from mechanical testing allowed the acquisition of important relationships between the strength of the material evaluated for different loading conditions. Thus, Piromafo can be classified as a moderately soft rock with medium stiffness and medium brittleness. Furthermore, the strength and elastic properties of the material decrease in the presence of water in the pores due to the decrease of the surface energy of crack faces and dissolution processes which involve both the neomorphic calcite microcrystals and clay minerals dispersed in the micrite matrix;

v) new equations were obtained for estimating compressive strength and tangent modulus by Schmidt hammer rebound values and are quite different from those available in the literature for similar materials.

The data and findings presented in this paper have many practical applications and theoretical implications. They can be useful for better understanding the susceptibility to damage of soft limestones and for planning conservation actions and preventive interventions.