Submitted:

09 June 2024

Posted:

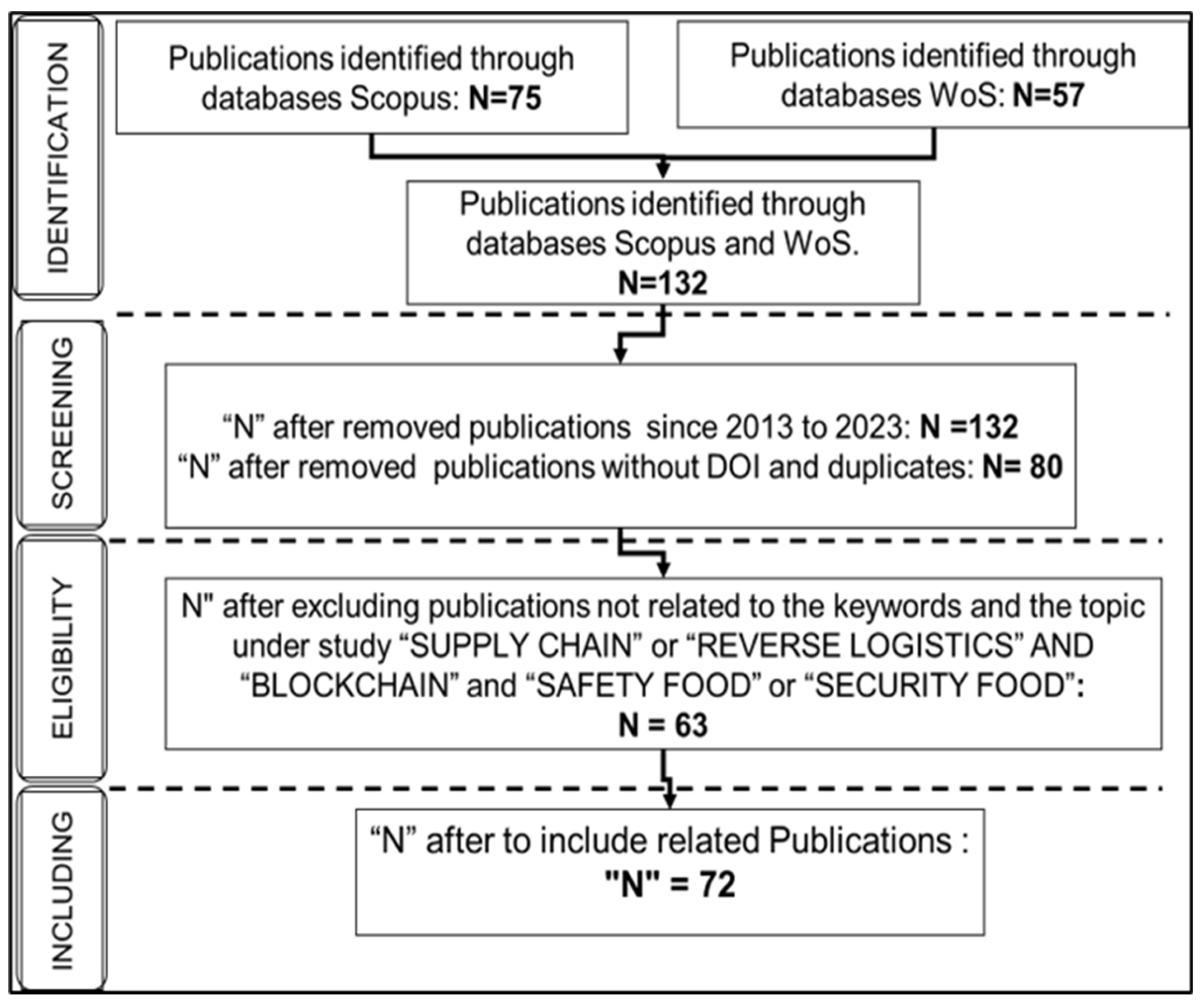

11 June 2024

You are already at the latest version

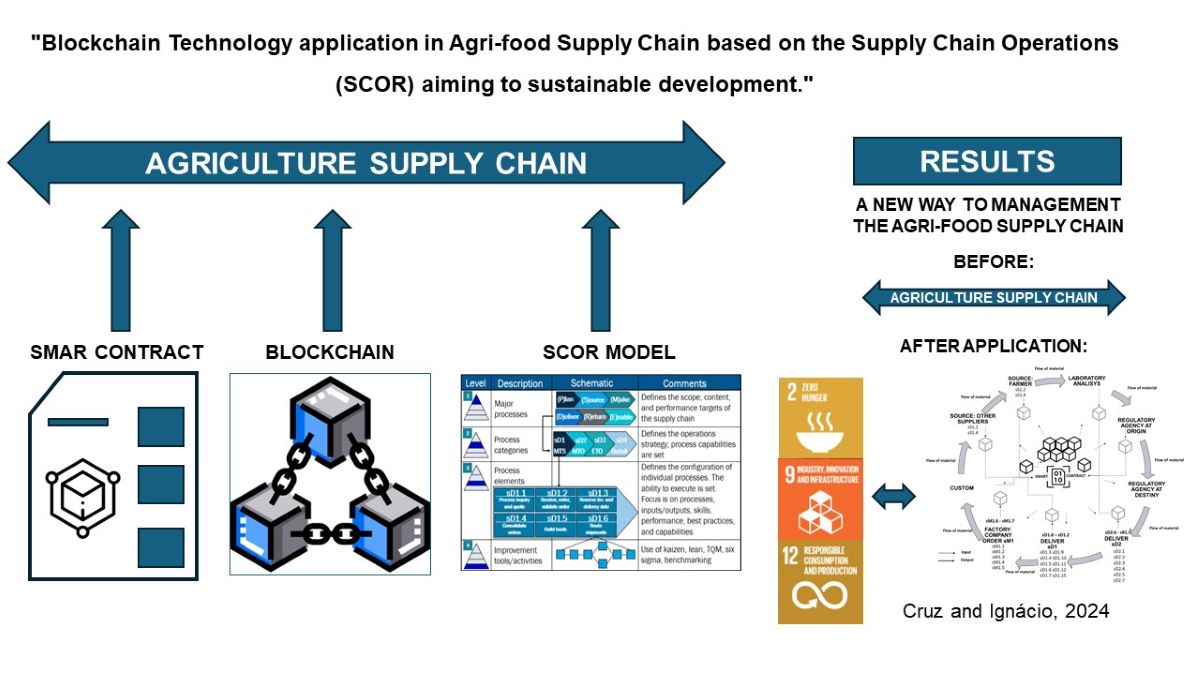

Abstract

Keywords:

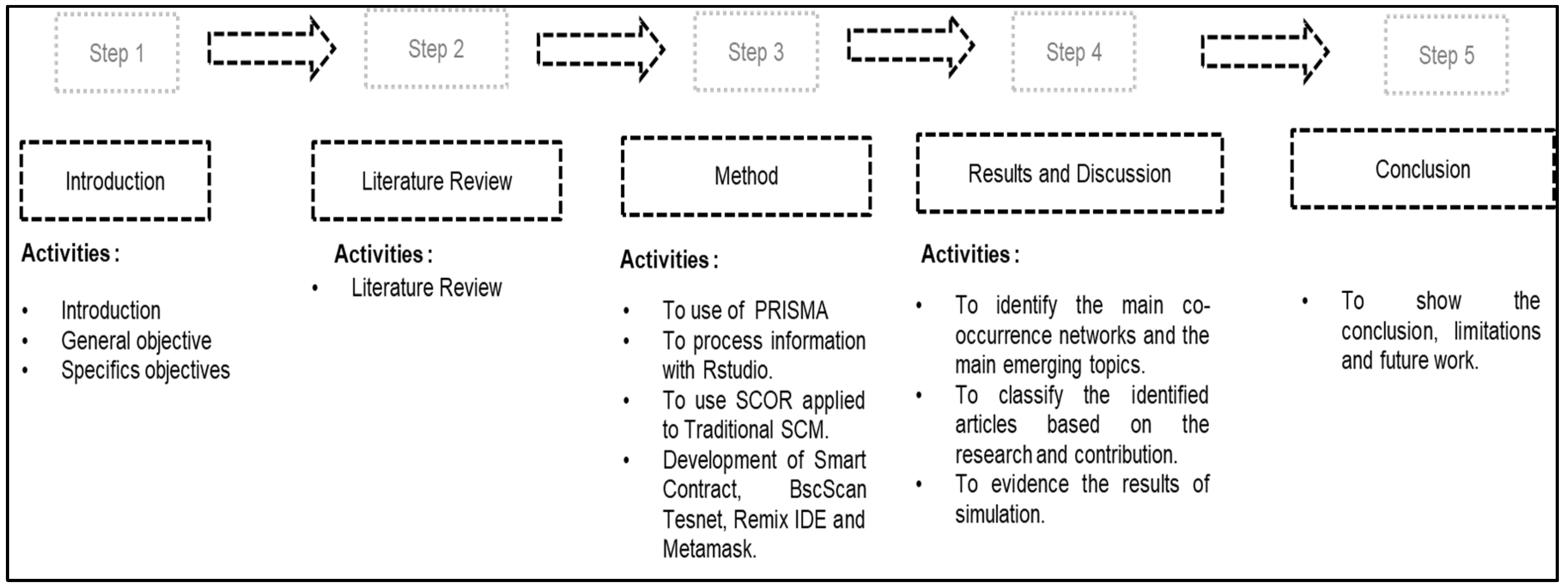

1. Introduction

2. Literature Review

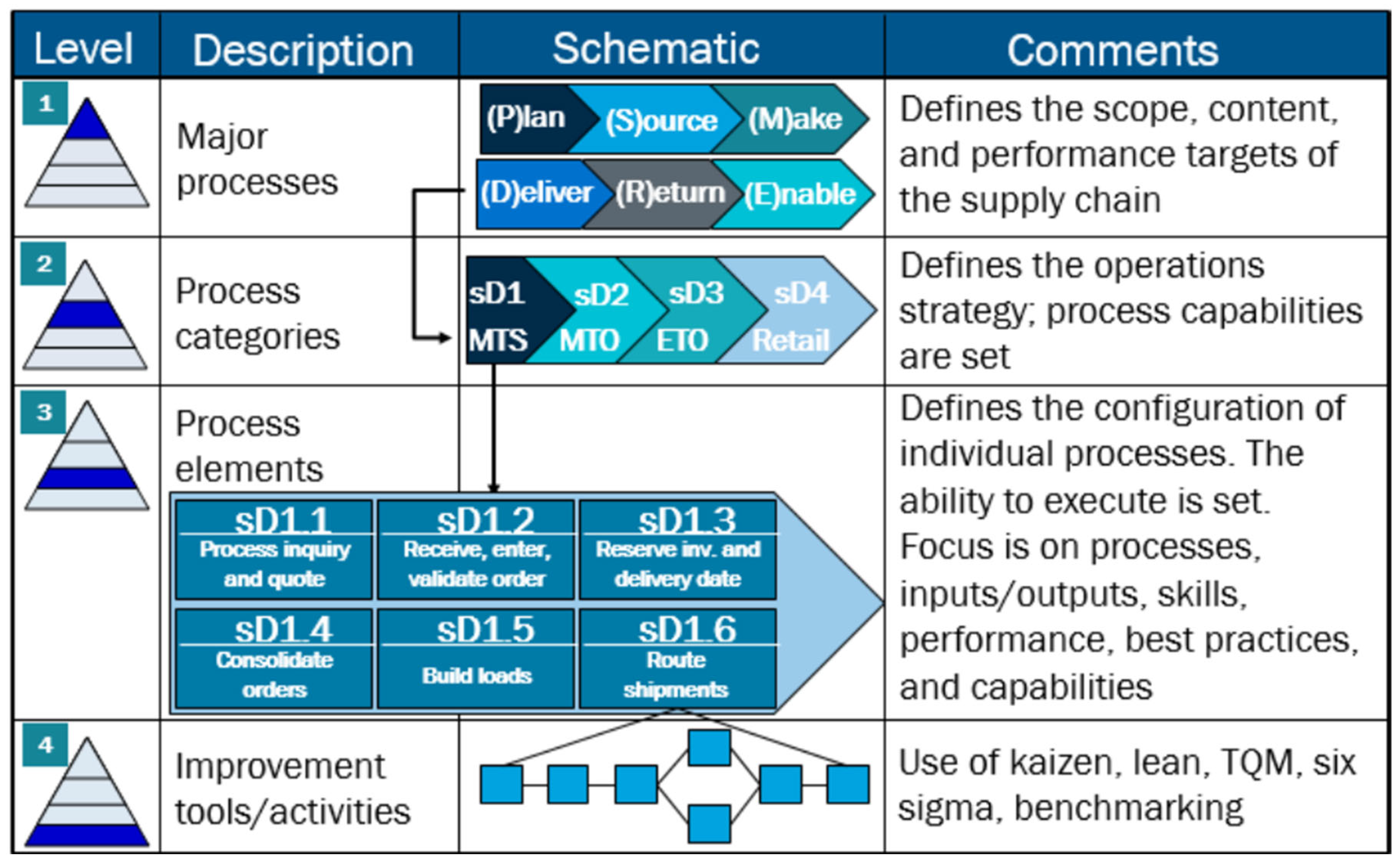

2.1. SCOR Model

2.2. Agrifood Supply Chains, Reverse Logistic and Sustainability

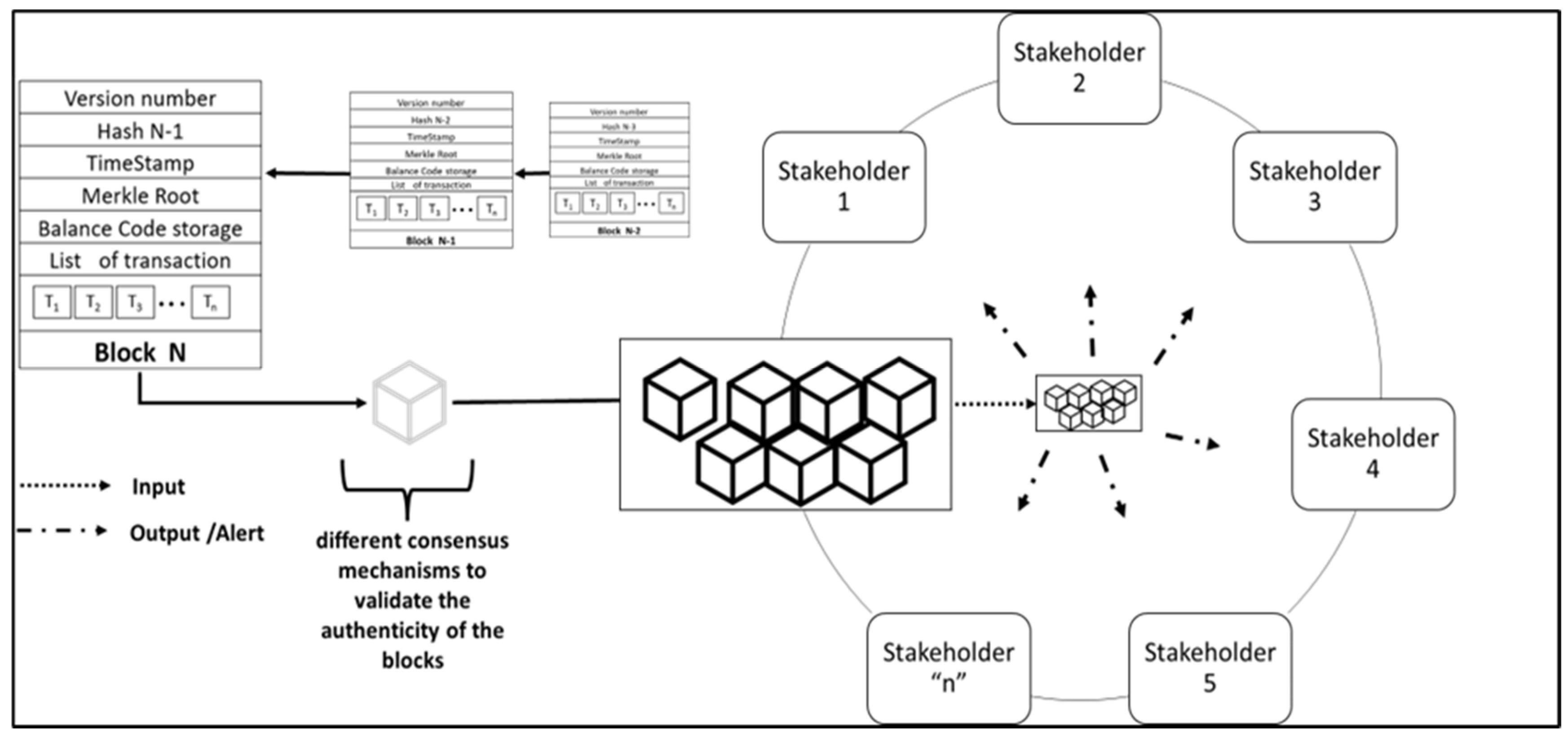

2.3. Disruptive Technology Blockchain

3. Materials and Methods

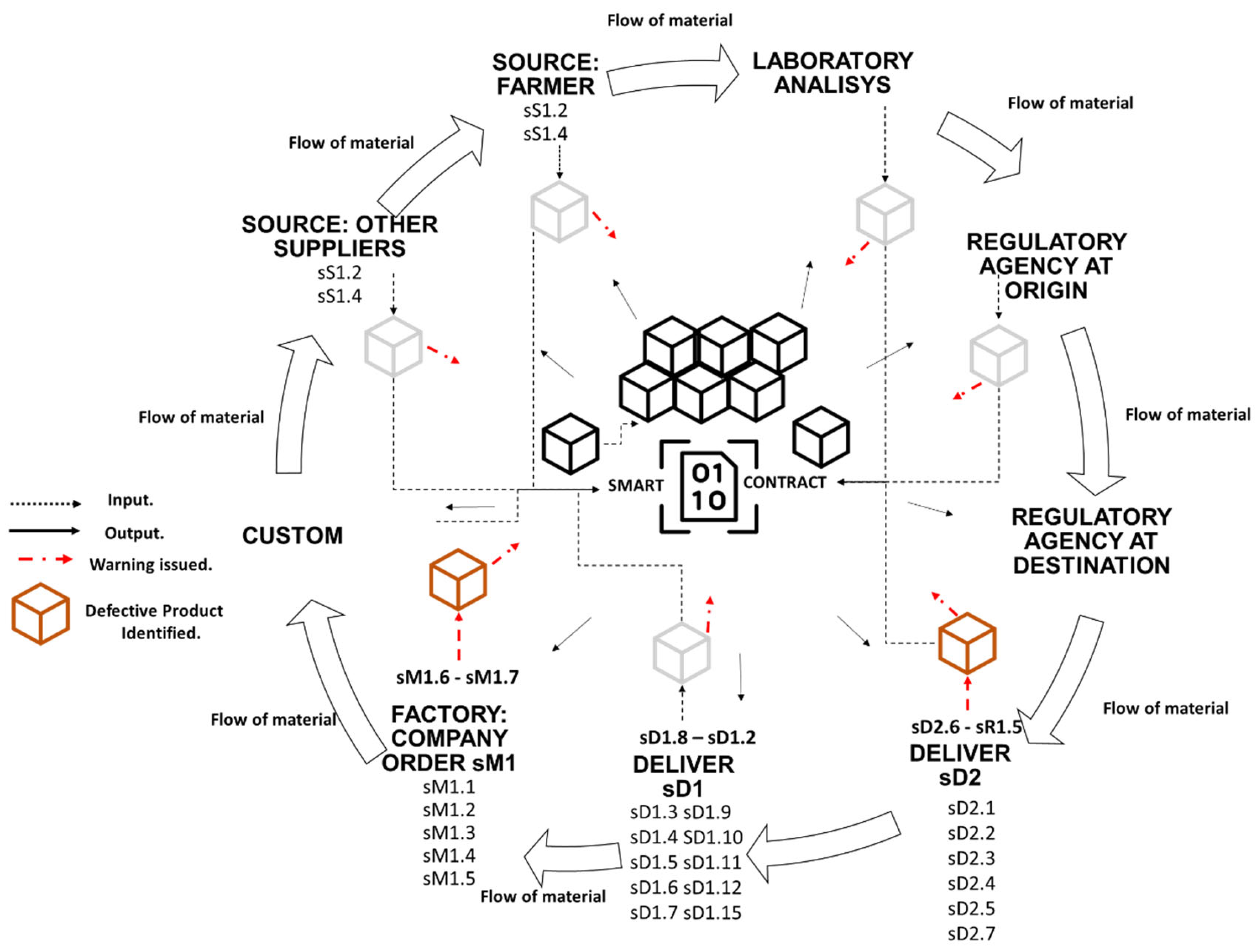

4. Development and Results

5. Conclusions

5.1. Social Implications

5.2. Practical Implications

- Different agri-food chains may not be identical to those addressed in this case. However, they could consider many of the inputs presented in the study.

- The Smart Contract may be limited or not depending on the technical capabilities of different tools.

- Future Work:

- Agri-food chains and the current scenario offer constant changes; future studies could be oriented towards:

- Efficiency of the blockchain network in real-world scenarios.

- Conceptual and technical evaluation of the level of participation and willingness of each actor in the agri-food chain.

- The relationship between the application of blockchain technology in different processes and its connection to sustainable development goals.

References

- Abdulhussein, A.B.; Hadi, A.K.; Ilyas, M. (2020). Design a tracing system for a seed supply chain based on blockchain. 2020 3rd International Conference on Engineering Technology and Its Applications, IICETA 2020, 209–214. [CrossRef]

- Agnusdei, G.P.; Coluccia, B. Sustainable agrifood supply chains: Bibliometric, network and content analyses. Science of the Total Environment 2022, 824. [CrossRef] [PubMed]

- AlJemy, K. ; AlAnazi, M.; AlSofiry, M.; Baig, A.; IEEE. (2019). Improving IoT Security Using Blockchain. In 2019 IEEE 10TH GCC CONFERENCE & EXHIBITION (GCC) (Issue 10th IEEE GCC Conference and Exhibition (GCC)). [CrossRef]

- Andrade, A. F.; Costa, A.F.; da Poli, L.E.; Borelli, E.; Robles Junior, A. (2022). Custos de exportação e correlação com indicadores de desempenho. In Revista Eniac Pesquisa (Vol. 11, Issue 1). [CrossRef]

- Antonucci, F.; Figorilli, S.; Costa, C.; Pallottino, F.; Raso, L.; Menesatti, P. A review on blockchain applications in the agri-food sector. Journal of the Science of Food and Agriculture 2019, 99, 6129–6138. [CrossRef] [PubMed]

- APICS. Quick reference guide. Nursing Standard 2017, 13, 29–29. [CrossRef]

- Bansal, L.; Chaurasia, S.; Sabharwal, M.; Vij, M. (2022). Blockchain Integration with end-to-end traceability in the Food Supply Chain. 2022 2nd International Conference on Advance Computing and Innovative Technologies in Engineering, ICACITE 2022, 1152–1156. [CrossRef]

- Barbosa, M.W. Uncovering research streams on agri-food supply chain management: A bibliometric study. GLOBAL FOOD SECURITY-AGRICULTURE POLICY ECONOMICS AND ENVIRONMENT 2021, 28. [CrossRef]

- Bhatia, S.; Albarrak, A.S. A Blockchain-Driven Food Supply Chain Management Using QR Code and XAI-Faster RCNN Architecture. SUSTAINABILITY 2023, 15. [CrossRef]

- Chandan, A.; John, M.; Potdar, V. Achieving UN SDGs in Food Supply Chain Using Blockchain Technology. SUSTAINABILITY 2023, 15. [CrossRef]

- Chaudhary, S.; Kumar, S.; Kumar, V.; Singh, B.; Dhiman, A. Irradiation: A tool for the sustainability of fruit and vegetable supply chain-Advancements and future trends. Radiation Physics and Chemistry 2024, 217. [CrossRef]

- Collart, A.J.; Canales, E. (2022). How might broad adoption of blockchain-based traceability impact the <scp>U.S.</scp> fresh produce supply chain? Applied Economic Perspectives and Policy, 44, 219–236. [CrossRef]

- Cossu, D.; Zanchi, L.; Maranghi, S.; Zamagni, A.; Gaias, G.; Duce, P.; Vagnoni, E. Ecolabelling for improving sustainability of agri-food supply chain: An experimental implementation of the Made Green in Italy scheme on the hard sheep milk cheese. Cleaner Environmental Systems 2024, 12, 100153. [CrossRef]

- Cruz, L.; De Arruda Ignacio, P.S. Application of blockchain disruptive technology in agri-food chains for sustainable development, a systematic review. International Journal of Supply and Operations Management 2023, 10, 523–544. [CrossRef]

- CSCMP; //cscmp: (2023). Council for Supply Chain Management Professionals (CSCMP). https.

- Dabees, A.; Barakat, M.; Elbarky, S.S.; Lisec, A. A Framework for Adopting a Sustainable Reverse Logistics Service Quality for Reverse Logistics Service Providers: A Systematic Literature Review. Sustainability (Switzerland) 2023, 15. [CrossRef]

- Dey, K.; Shekhawat, U. Blockchain for sustainable e-agriculture: Literature review, architecture for data management, and implications. Journal of Cleaner Production 2021, 316. [CrossRef]

- Dey, S.; Saha, S.; Singh, A.K.; McDonald-Maier, K. SmartNoshWaste: Using Blockchain, Machine Learning, Cloud Computing and QR Code to Reduce Food Waste in Decentralized Web 3.0 Enabled Smart Cities. Smart Cities 2022, 5, 162–176. [CrossRef]

- Galanakis, C.M.; Rizou, M.; Aldawoud, T.M.S.; Ucak, I.; Rowan, N.J. Innovations and technology disruptions in the food sector within the COVID-19 pandemic and post-lockdown era. TRENDS IN FOOD SCIENCE & TECHNOLOGY 2021, 110, 193–200. [CrossRef] [PubMed]

- González-Puetate, I.; Marín-Tello, C.; Pineda, H.R. Agri-food safety optimized by blockchain technology: review. Revista Facultad Nacional de Agronomia Medellin 2022, 75, 9839–9851. [CrossRef]

- Gopi, K.; Mazumder, D.; Sammut, J.; Saintilan, N. Determining the provenance and authenticity of seafood: A review of current methodologies. TRENDS IN FOOD SCIENCE & TECHNOLOGY 2019, 91, 294–304. [CrossRef]

- Gupta, R.; Shankar, R. (2023). Managing food security using blockchain-enabled traceability system. Benchmarking-an international journal. [CrossRef]

- Gupta, S.; Berenji, H.R.; Shukla, M.; Murthy, N.N. (2023). Opportunities in farming research from an operations management perspective. Production And Operations Management. [CrossRef]

- Guruswamy, S.; Pojic, M.; Subramanian, J.; Mastilovic, J.; Sarang, S.; Subbanagounder, A.; Stojanovic, G.; Jeoti, V. Toward Better Food Security Using Concepts from Industry 5.0. SENSORS 2022, 22. [CrossRef] [PubMed]

- Hang, L.; Ullah, I.; Kim, D.-H. A secure fish farm platform based on blockchain for agriculture data integrity. Computers and Electronics in Agriculture 2020, 170. [CrossRef]

- Hassoun, A.; Boukid, F.; Pasqualone, A.; Bryant, C.J.; Garcia, G.G.; Parra-Lopez, C.; Jagtap, S.; Trollman, H.; Cropotova, J.; Barba, F.J. Emerging trends in the agri-food sector: Digitalisation and shift to plant-based diets. CURRENT RESEARCH IN FOOD SCIENCE 2022, 5, 2261–2269. [CrossRef] [PubMed]

- Hew, J.J.; Wong, L.W.; Tan, G.W.H.; Ooi, K.B.; Lin, B.S. (2020). The blockchain-based Halal traceability systems: a hype or reality? SUPPLY CHAIN MANAGEMENT-AN INTERNATIONAL JOURNAL, 25, 863–879. [CrossRef]

- Hilt, M. ; Shao, D.; Yang, B.J.; Machinery, A.C. (2018). RFID Security, Verification, and Blockchain: Vulnerabilities within the Supply Chain for Food Security. In SIGITE’ 18. [CrossRef]

- Hofman, W. J. (2019). A Methodological Approach for Development and Deployment of Data Sharing in Complex Organizational Supply and Logistics Networks with Blockchain Technology. In IFAC PAPERSONLINE (Vol. 52, Issues 15th International-Federation-of-Automatic-Control (IFAC) Symposium on Large Scale Complex Systems (IFAC LSS), pp. 55–60). [CrossRef]

- Joshi, P.; Tewari, V.; Kumar, S.; Singh, A. (2023). Blockchain technology for sustainable development: a systematic literature review. JOURNAL OF GLOBAL OPERATIONS AND STRATEGIC SOURCING. [CrossRef]

- Joshi, S.; Sharma, M.; Ekren, B.Y.; Kazancoglu, Y.; Luthra, S.; Prasad, M. Assessing Supply Chain Innovations for Building Resilient Food Supply Chains: An Emerging Economy Perspective. SUSTAINABILITY 2023, 15. [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Sharma, R. Modeling the blockchain enabled traceability in agriculture supply chain. International Journal of Information Management 2020, 52. [CrossRef]

- Kayikci, Y.; Subramanian, N.; Dora, M.; Bhatia, M.S. Food supply chain in the era of Industry 4.0: blockchain technology implementation opportunities and impediments from the perspective of people, process, performance, and technology. Production Planning & Control 2022, 33, 301–321. [CrossRef]

- Kazancoglu, I.; Ozbiltekin-Pala, M.; Mangla, S.K.; Kumar, A.; Kazancoglu, Y. (2022). Using emerging technologies to improve the sustainability and resilience of supply chains in a fuzzy environment in the context of COVID-19. Annals of Operations Research. [CrossRef] [PubMed]

- Khan, A.A.; Shaikh, Z.A.; Belinskaja, L.; Baitenova, L.; Vlasova, Y.; Gerzelieva, Z.; Laghari, A.A.; Abro, A.A.; Barykin, S. A Blockchain and Metaheuristic-Enabled Distributed Architecture for Smart Agricultural Analysis and Ledger Preservation Solution: A Collaborative Approach. Applied Sciences 2022, 12. [CrossRef]

- Kumar, D.; Rahman, Z.; Chan, F.T.S. A fuzzy AHP and fuzzy multi-objective linear programming model for order allocation in a sustainable supply chain: A case study. International Journal of Computer Integrated Manufacturing 2017, 30, 535–551. [CrossRef]

- Kumar, M.; Choubey, V.K.; Raut, R.D.; Jagtap, S. Enablers to achieve zero hunger through IoT and blockchain technology and transform the green food supply chain systems. Journal Of Cleaner Production 2023, 405. [CrossRef]

- Kumar, P.; Singh, R.K.; Shahgholian, A. (2022). Learnings from COVID-19 for managing humanitarian supply chains: systematic literature review and future research directions. Annals of Operations Research. [CrossRef] [PubMed]

- Lee, M. J.; Luo, J.T.; Shao, J.J.; Huang, N.F.; IEEE. (2021). A Trustworthy Food Resume Traceability System Based on Blockchain Technology. In 35TH INTERNATIONAL CONFERENCE ON INFORMATION NETWORKING (ICOIN 2021) (Issue 35th International Conference on Information Networking (ICOIN), pp. 546–552). [CrossRef]

- Li, Y.; Zhang, X.; Zhao, Z.; Xu, J.; Jiang, Z.; Yu, J.; Cui, X. Research on Grain Food Blockchain Traceability Information Management Model Based on Master-Slave Multichain. Genetics Research 2022, 2022. [CrossRef]

- Lin, W.J.; Huang, X.H.; Fang, H.; Wang, V.; Hua, Y.N.; Wang, J.J.; Yin, H.N.; Yi, D.W.; Yau, L.H. Blockchain Technology in Current Agricultural Systems: From Techniques to Applications. IEEE Access 2020, 8, 143920–143937. [CrossRef]

- Luo, Z.Y.; Zhu, J.Y.; Sun, T.T.; Liu, Y.R.; Ren, S.H.; Tong, H.H.; Yu, L.; Fei, X.C.; Yin, K. (2022). Application of the IoT in the Food Supply Chain-From the Perspective of Carbon Mitigation. Environmental Science & Technology. [CrossRef]

- Maity, M.; Tolooie, A.; Sinha, A.K.; Tiwari, M.K. Stochastic batch dispersion model to optimize traceability and enhance transparency using Blockchain. Computers & Industrial Engineering 2021, 154. [CrossRef]

- Majdalawieh, M.; Nizamuddin, N.; Alaraj, M.; Khan, S.; Bani-Hani, A. Blockchain-based solution for Secure and Transparent Food Supply Chain Network. Peer-To-Peer Networking And Applications 2021, 14, 3831–3850. [CrossRef]

- Makarov, E. I.; Polyansky, K.K.; Makarov, M.E.; Nikolaeva, Y.R.; Shubina, E.A. (2019). Conceptual approaches to the quality system of dairy products based on the blockchain technology. In Studies in Computational Intelligence (Vol. 826, pp. 1059–1069). Springer Verlag. [CrossRef]

- Mistry, I.; Tanwar, S.; Tyagi, S.; Kumar, N. Blockchain for 5G-enabled IoT for industrial automation: A systematic review, solutions, and challenges. Mechanical Systems and Signal Processing 2020, 135. [CrossRef]

- Mohammed, A.; Potdar, V.; Quaddus, M.; Hui, W.Y. Blockchain Adoption in Food Supply Chains: A Systematic Literature Review on Enablers, Benefits, and Barriers. IEEE ACCESS 2023, 11, 14236–14255. [CrossRef]

- Niknejad, N.; Ismail, W.; Bahari, M.; Hendradi, R.; Salleh, A.Z. Mapping the research trends on blockchain technology in food and agriculture industry: A bibliometric analysis. Environmental Technology and Innovation 2021, 21. [CrossRef]

- Patidar, A. ; Sharma, M.; Agrawal, R.; Sangwan, K.S. (2021). A Smart Contracts and Tokenization Enabled Permissioned Blockchain Framework for the Food Supply Chain. In A. Dolgui, A. Bernard, D. Lemoine, G. VonCieminski, & D. Romero (Eds.), ADVANCES IN PRODUCTION MANAGEMENT SYSTEMS: ARTIFICIAL INTELLIGENCE FOR SUSTAINABLE AND RESILIENT PRODUCTION SYSTEMS, APMS 2021, PT I (Vol. 630, Issue International-Federation-of-Information-Processing-Working-Group-5.7 (IFIP WG 5.7) International Conference on Advances in Production Management Systems (APMS), pp. 228–235). [CrossRef]

- Patidar, S.; Sukhwani, V.K.; Shukla, A.C. Modeling of Critical Food Supply Chain Drivers Using DEMATEL Method and Blockchain Technology. Journal of The Institution of Engineers (India): Series C 2023, 104, 541–552. [CrossRef]

- Patra, S. S.; Misra, C.; Singh, K.N.; Gourisaria, M.K.; Choudhury, S.; Sahu, S. (2021). qIoTAgriChain: IoT Blockchain Traceability Using Queueing Model in Smart Agriculture. In EAI/Springer Innovations in Communication and Computing (pp. 203–223). Springer Science and Business Media Deutschland GmbH. [CrossRef]

- Pearson, S.; May, D.; Leontidis, G.; Swainson, M.; Brewer, S.; Bidaut, L.; Frey, J.G.; Parr, G.; Maull, R.; Zisman, A. Are Distributed Ledger Technologies the panacea for food traceability? Global Food Security-Agriculture Policy Economics And Environment 2019, 20, 145–149. [CrossRef]

- Phua, C.; Andradi-Brown, D.A.; Mangubhai, S.; Ahmadia, G.N.; Mahajan, S.L.; Larsen, K.; Friel, S.; Reichelt, R.; Hockings, M.; Gill, D.; Veverka, L.; Anderson, R.; Augustave, L.C.; Awaludinnoer, Bervoets, T.; Brayne, K.; Djohani, R.; Kawaka, J.; Kyne, F., … Wells, S. Marine protected and conserved areas in the time of covid. Parks 2021, 27, 85–102. [CrossRef]

- Prashar, D.; Jha, N.; Jha, S.; Lee, Y.; Joshi, G.P. Blockchain-Based Traceability and Visibility for Agricultural Products: A Decentralized Way of Ensuring Food Safety in India. SUSTAINABILITY 2020, 12. [CrossRef]

- Prataviera, L.B.; Creazza, A.; Perotti, S.; Rodrigues, V.S. How to align logistics environmental sustainability with corporate strategy? An Italian perspective. International Journal of Logistics Research and Applications 2023, 1–23. [CrossRef]

- Rajput, S.; Jadhav, A.; Gadge, J.; Tilani, D.; Dalgade, V. (2023). Agricultural Food supply chain Traceability using Blockchain. 2023 International Conference on Innovative Trends in Information Technology, ICITIIT 2023. [CrossRef]

- Raki, H.; Aalaila, Y.; Taktour, A.; Peluffo-Ordóñez, D.H. Combining AI Tools with Non-Destructive Technologies for Crop-Based Food Safety: A Comprehensive Review. Foods 2024, 13. [CrossRef] [PubMed]

- Rashid, A.; Baber Ali, S.; Rasheed, R.; Amirah, N.A.; Ngah, A.H. (2022). A paradigm of blockchain and supply chain performance: a mediated model using structural equation modeling. Kybernetes. [CrossRef]

- Rejeb, A.; Rejeb, K.; Appolloni, A.; Iranmanesh, M.; Treiblmaier, H.; Jagtap, S. Exploring Food Supply Chain Trends in the COVID-19 Era: A Bibliometric Review. Sustainability 2022, 14. [CrossRef]

- Rezaei, L.; Babazadeh, R. An Overview of The Impact of Blockchain Technology on the Meat, Fruit and Vegetable Supply Chains. International Journal of Industrial Engineering and Production Research 2022, 33. [CrossRef]

- Ribašauskienė, E.; Volkov, A.; Morkūnas, M., Žičkienė, A.; Dabkiene, V.; Štreimikienė, D.; Baležentis, T. Strategies for increasing agricultural viability, resilience and sustainability amid disruptive events: An expert-based analysis of relevance. Journal of Business Research 2024, 170, 114328. doi:. [CrossRef]

- Rogerson, M.; Parry, G.C. Blockchain: case studies in food supply chain visibility. Supply Chain Management-An International Journal 2020, 25, 601–614. [CrossRef]

- Runzel, M.A.S.; Hassler, E.E.; Rogers, R.E.L.; Formato, G.; Cazier, J.A. Designing a Smart Honey Supply Chain for Sustainable Development. IEEE Consumer Electronics Magazine 2021, 10, 69–78. [CrossRef]

- Saha, A.S.; Raut, R.D.; Yadav, V.S.; Majumdar, A. Blockchain Changing the Outlook of the Sustainable Food Supply Chain to Achieve Net Zero? Sustainability 2022, 14. [CrossRef]

- Scuderi, A. ; Selvaggi, R.; Sturiale, L.; La Via, G.; Timpanaro, G. (2022). A Multicriteria Evaluation of Blockchain-Based Agrifood Chain in the New Scenario Post-Covid 19. In C. F.; D. S. L.; P. M. M.J. (Eds.), Lecture Notes in Networks and Systems: Vol. 482 LNNS (pp. 1384–1399). Springer Science and Business Media Deutschland GmbH. [CrossRef] [PubMed]

- Sharma, R.; Kamble, S.S.; Gunasekaran, A.; Kumar, V.; Kumar, A. A systematic literature review on machine learning applications for sustainable agriculture supply chain performance. Computers and Operations Research 2020, 119. [CrossRef]

- Siddh, M.M.; Soni, G.; Jain, R.; Sharma, M.K.; Yadav, V.; Shukla, O.J.; Tyagi, P. Agri-fresh food supply chain quality and organisational sustainability: an empirical investigation. International Journal of Logistics Systems and Management 2024, 47, 125–141. [CrossRef]

- Srhir, S.; Jaegler, A.; Montoya-Torres, J.R. (2023). Uncovering Industry 4.0 technology attributes in sustainable supply chain 4.0: A systematic literature review. Business Strategy and the Environment. [CrossRef]

- Sunar, N.; Swaminathan, J.M. Socially relevant and inclusive operations management. Production And Operations Management 2022, 31, 4379–4392. [CrossRef]

- Tanwar, S.; Parmar, A.; Kumari, A.; Jadav, N.K.; Hong, W.-C.; Sharma, R. Blockchain Adoption to Secure the Food Industry: Opportunities and Challenges. Sustainability 2022, 14. [CrossRef]

- Tsolakis, N.; Niedenzu, D.; Simonetto, M.; Dora, M.; Kumar, M. Supply network design to address United Nations Sustainable Development Goals: A case study of blockchain implementation in Thai fish industry. Journal Of Business Research 2021, 131, 495–519. [CrossRef]

- Untari, D.T.; Satria, B. The relationship between supply chain management and environmental sustainability: The mediating role of eco culinary product. Uncertain Supply Chain Management 2024, 12, 595–600. [CrossRef]

- Vangala, A.; Das, A.K.; Kumar, N.; Alazab, M. Smart Secure Sensing for IoT-Based Agriculture: Blockchain Perspective. IEEE Sensors Journal 2021, 21, 17591–17607. [CrossRef]

- Vivek, S.; Dalela, R. (2022). Blockchain Solutions for Covid - policy Enforcement versus Food Security: A Demonstration of Customizable Benefits of Blockchain for e-Governance and e-Business. 5th International Conference on Inventive Computation Technologies, ICICT 2022 - Proceedings, 12–15. [CrossRef]

- Vostriakova, V. ; Swarupa, M.L.; Rubanenko, O.; Gundebommu, S.L. (2022). Blockchain and Climate Smart Agriculture Technologies in Agri-Food Security System. In K. A.; F. J. I.; G. P.K.; D. J.; Z. Z.J.; U. M. (Eds.), Communications in Computer and Information Science: Vol. 1673 CCIS (pp. 490–504). Springer Science and Business Media Deutschland GmbH. [CrossRef] [PubMed]

- Wunsche, J.F.; Fernqvist, F.; Wünsche, J.F.; Fernqvist, F. The Potential of Blockchain Technology in the Transition Towards Sustainable Food Systems. Sustainability 2022, 14. [CrossRef]

- Yadav, S.; Singh, S.P. An integrated fuzzy-ANP and fuzzy-ISM approach using blockchain for sustainable supply chain. Journal of Enterprise Information Management 2020, 34, 54–78. [CrossRef]

- Yakubu, B.M.; Latif, R.; Yakubu, A.; Khan, M.I.; Magashi, A.I. RiceChain: secure and traceable rice supply chain framework using blockchain technology. Peerj Computer Science 2022, 8. [CrossRef] [PubMed]

- Yang, L. Q.; Liu, X.Y.; Kim, J.S.; IEEE. (2020). Cloud-based Livestock Monitoring System Using RFID and Blockchain Technology. In 2020 7th Ieee International Conference On Cyber Security And Cloud Computing (Cscloud 2020)/2020 6th Ieee International Conference On Edge Computing And Scalable Cloud (Edgecom 2020) (Issue 7th IEEE International Conference on Cyber Security and Cloud Computing (CSCloud) / 6th IEEE International Conference on Edge Computing and Scalable Cloud (EdgeCom), pp. 240–245). [CrossRef]

- Yontar, E. Critical success factor analysis of blockchain technology in agri-food supply chain management: A circular economy perspective. Journal Of Environmental Management 2023, 330. [CrossRef]

- Zkik, K.; Belhadi, A.; Rehman Khan, S.A.; Kamble, S.S.; Oudani, M.; Touriki, F.E. (2022). Exploration of barriers and enablers of blockchain adoption for sustainable performance: implications for e-enabled agriculture supply chains. International Journal of Logistics Research and Applications. [CrossRef]

| Compliance | Description | Cost of Operation | Time Operation |

|---|---|---|---|

| Border compliance | The Border compliance includes:

|

US$862 | 49 Hours |

| Documentary Compliance | The Documentary Compliance includes:

|

US$226 | 12 Hours |

| Conceptual | (Yontar, 2023); (S. Gupta et al., 2023); (S. Joshi et al., 2023); (R. Gupta & Shankar, 2023); (P. Joshi et al., 2023); (Chandan et al., 2023); (Mohammed et al., 2023); (S. Patidar et al., 2023); (Rajput et al., 2023); (Kayikci et al., 2022); (Rejeb et al., 2022); (Agnusdei & Coluccia, 2022); (Collart & Canales, 2022); (Khan et al., 2022); (Saha et al., 2022); (S. Dey et al., 2022); (Rejeb et al., 2022); (Yakubu et al., 2022); (Wunsche et al., 2022); (Hassoun et al., 2022); (P. Kumar et al., 2022); (Guruswamy et al., 2022); (Scuderi et al., 2022); (Bansal et al., 2022); (Vostriakova et al., 2022); (Rezaei & Babazadeh, 2022); (Sharma et al., 2020); (Galanakis et al., 2021); (Antonucci et al., 2019); (Pearson et al., 2019); (Tsolakis et al., 2021); (Gopi et al., 2019); (Barbosa, 2021); (Patra et al., 2021); (A. Patidar et al., 2021);(Cruz & De Arruda Ignacio, 2023); (Srhir et al., 2023);(Tanwar et al., 2022); |

| Empirical | (M. Kumar et al., 2023); (R. Gupta & Shankar, 2023); (S. Patidar et al., 2023); (Kayikci et al., 2022); (Wunsche et al., 2022); (Rogerson & Parry, 2020); (Hew et al., 2020); (Kazancoglu et al., 2022); (Maity et al., 2021); (Phua et al., 2021); |

| Modelling | (Yontar, 2023); (Bhatia & Albarrak, 2023); (M. Kumar et al., 2023); (S. Joshi et al., 2023); (S. Patidar et al., 2023); (Rajput et al., 2023); (Khan et al., 2022); (Lee et al., 2021); (Scuderi et al., 2022); (Bansal et al., 2022); (Luo et al., 2022); (Li et al., 2022); (Kamble et al., 2020); (Prashar et al., 2020); (Yadav & Singh, 2020); (Phua et al., 2021); (Runzel et al., 2021); (Yang et al., 2020); (Abdulhussein et al., 2020); (Patra et al., 2021); (AlJemy et al., 2019); (A. Patidar et al., 2021) |

| Technical | (Bhatia & Albarrak, 2023); (Khan et al., 2022); (D. Kumar et al., 2017); (Lee et al., 2021); (Bansal et al., 2022); (Prashar et al., 2020); (Majdalawieh et al., 2021); (Hilt et al., 2018); (Makarov et al., 2019); (Hofman, 2019); |

| Food Safety and Food Security | (Bhatia & Albarrak, 2023); (M. Kumar et al., 2023); (S. Patidar et al., 2023); (Rajput et al., 2023); (Rajput et al., 2023); (Kayikci et al., 2022); (Collart & Canales, 2022); (Khan et al., 2022); (Saha et al., 2022); (Saha et al., 2022); (S. Dey et al., 2022); (Yakubu et al., 2022); (Wunsche et al., 2022); (Lee et al., 2021); (Scuderi et al., 2022); (Bansal et al., 2022); (Rogerson & Parry, 2020); (Tsolakis et al., 2021); (Prashar et al., 2020); (Abdulhussein et al., 2020); (Majdalawieh et al., 2021); (Patra et al., 2021); |

| Quality | (M. Kumar et al., 2023); (Khan et al., 2022); (Saha et al., 2022); (Yakubu et al., 2022); (Wunsche et al., 2022); (Scuderi et al., 2022); (Majdalawieh et al., 2021); (Patra et al., 2021); |

| Sustainable management and efficient use of natural resources | (Bhatia & Albarrak, 2023); (P. Joshi et al., 2023); (Chandan et al., 2023); (Kayikci et al., 2022); (Collart & Canales, 2022); (Khan et al., 2022); (Yakubu et al., 2022); (Wunsche et al., 2022); (Scuderi et al., 2022); (Bansal et al., 2022); (Vostriakova et al., 2022); (Prashar et al., 2020); (Cruz & De Arruda Ignacio, 2023) |

| Prevention, reduction, recycling | (S. Gupta et al., 2023); (Khan et al., 2022); (Wunsche et al., 2022); |

| Monitoring and Supervising | (Bhatia & Albarrak, 2023); (R. Gupta & Shankar, 2023); (Rajput et al., 2023); (Khan et al., 2022); (Yakubu et al., 2022); (Lee et al., 2021); (Scuderi et al., 2022); (Bansal et al., 2022); (Luo et al., 2022); (Kazancoglu et al., 2022); (Abdulhussein et al., 2020); (Patra et al., 2021); (AlJemy et al., 2019); |

| Food Provenance | (Bhatia & Albarrak, 2023); (Rajput et al., 2023); (Kayikci et al., 2022); (Collart & Canales, 2022); (Khan et al., 2022); (Yakubu et al., 2022); (Wunsche et al., 2022); (Lee et al., 2021); (Gopi et al., 2019); (Hew et al., 2020); (Kazancoglu et al., 2022); (Runzel et al., 2021); (Yang et al., 2020); (Majdalawieh et al., 2021); (Patra et al., 2021); |

| resilient infrastructure | (Yontar, 2023); (Bhatia & Albarrak, 2023); (S. Joshi et al., 2023); (Mohammed et al., 2023); (S. Patidar et al., 2023); (Rejeb et al., 2022); (Khan et al., 2022); (S. Dey et al., 2022); (Rejeb et al., 2022); (Yakubu et al., 2022); (Wunsche et al., 2022); (Kamble et al., 2020); (Sharma et al., 2020); (Antonucci et al., 2019); (Pearson et al., 2019); (Tsolakis et al., 2021); (Yadav & Singh, 2020); (Maity et al., 2021); (Hilt et al., 2018); (AlJemy et al., 2019); (Hofman, 2019); (A. Patidar et al., 2021); |

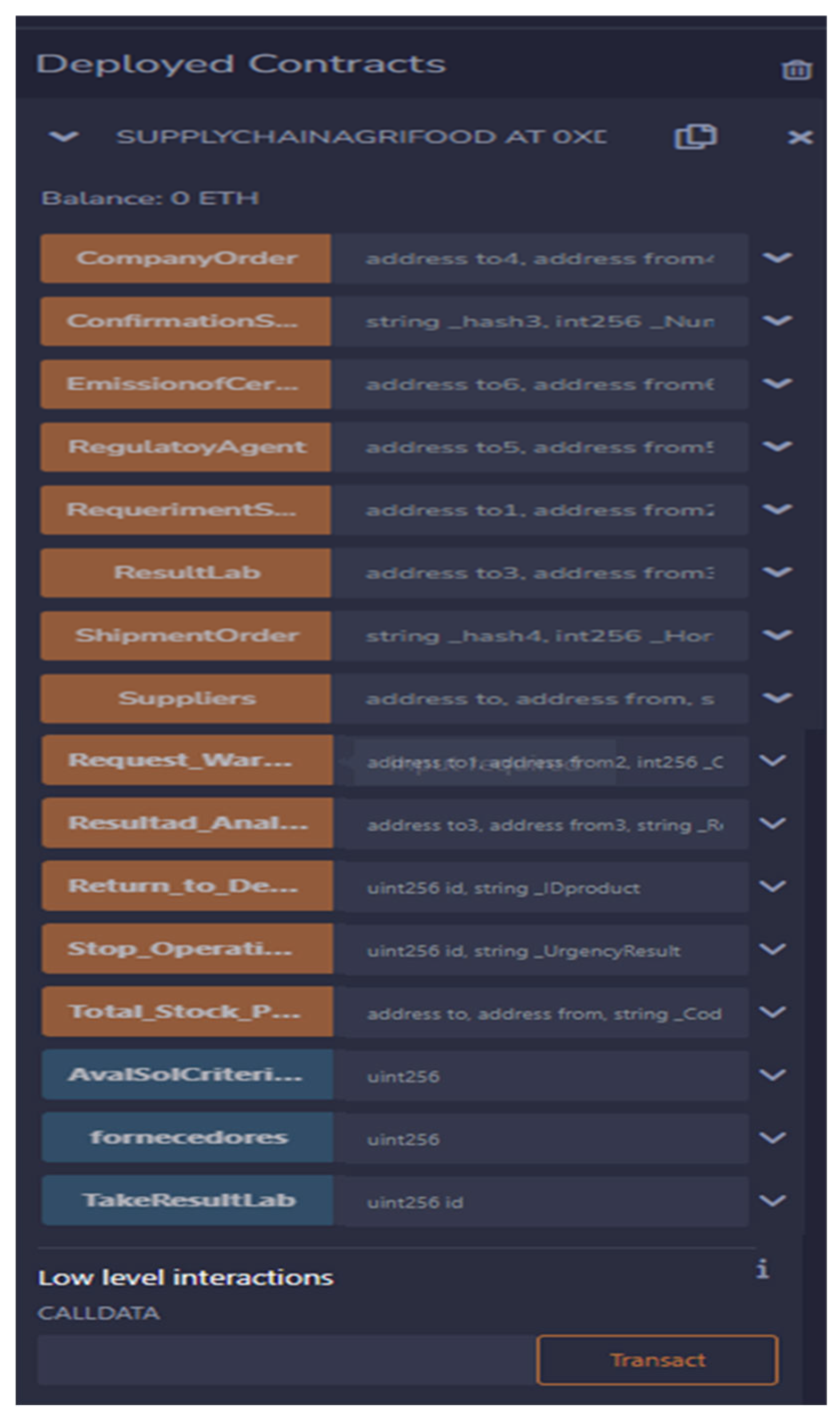

| Item | Overview |

|---|---|

| Transaction Hash | 0xcef8f159f95d154833c0a3aae834cd4a92587647af310b03a618c0e796da19fd |

| Status | Success |

| Block | 30922185 (7 Block confirmation) |

| Timestamp | 24 seconds ago. (May-22-2024 07:53:31 PM +UTC) |

| From | 0c089f0bbdf0f2405bb26438bb0af3e8f735e42f4f |

| To | Contract 0x5c54711eae649da59a07690888294fe7217be884 |

| Value | 0 BNB |

| Transaction Fee | 0.00305299 BNB ($0,75) |

| Gas price | 0.0000000001 BNB (10 Gwwi) |

| SDGs | Indicator | The convergence between Blockchain and SCOR Model ensures: | This application offers: | |||

|---|---|---|---|---|---|---|

|

2.1.2 | Prevalence of moderate or severe food insecurity in the population, based on the Food Insecurity Experience Scale (FIES) | Security and safety of foods based on the verification and monitoring of each step in the Agri-food Chain. | Ensuring a high level of traceability for all operations and knowledge of product delocalizations. It is important when there is a possible agri-food contamination, so that in such an event, the flow of the Agri-food supply chain can be halted, and reverse logistics applied. | ||

| 2.3.1 | Volume of production per labour unit by classes of farming/pastoral/forestry enterprise size | Accurate localization of products at their origin and of each participant in the Agri-food Chain (Stakeholders). | Traceability of participants in the agri-food supply chain and their contributions to each process | |||

| 2.3.2 | Average income of small-scale food producers, by sex and indigenous status | Transparency in each sales operation within the Agri-food Chain, aiming for the correct distribution of profits or gains. | ||||

| 2.C.1 | Indicator of food price anomalies | Identification of market fluctuations and evaluation of those changes. | To understand the variability of costs for each step in the supply chain | |||

|

9.3.1 | Proportion of small-scale industries in total industry value added | Adding new value to the Agri-food Chain and offering new consumption opportunities. | Added value by decentralizing and transforming the Agri-food Supply Chain, considering all stakeholders in each process. | ||

| 9.4.1 | CO2 emission per unit of value added | Identifying each process with a high footprint in the Agri-food Chain and sharing that risk. | With each step identified, it is possible to measure the CO2 emissions for each activity within the Agri-food Supply Chain, considering logistics activities through to the value and costs of each stage of the product. | |||

| 9.B.1 | Proportion of medium and high-tech industry value added in total value added | Taking advantage of the benefits of integrating Blockchain and the SCOR Model (traceability, decentralization of information, auditability, trust). | Easy access to traceability for each stakeholder. In this case, every actor can measure the impact of their activities and replicate that logic for their stakeholders. | |||

|

12.2.1 | Material footprint, material footprint per capita, and material footprint per GDP | Measuring the foodprint at each step of the Agri-food Supply Chain | Traceability for each process and step, enabling the measurement of footprints and other impacts. | ||

| 12.2.2 | Domestic material consumption, domestic material consumption per capita, and domestic material consumption per GDP | Improving resource consumption based on decentralized information | Flexibility in decision-making based on historical information for each process and product. These data can be used to improve material consumption | |||

| 12.3.1 | (a) Food loss index and (b) food waste index | "Identifying and measuring these indices based on historical information. | A database with a higher level of precision because this information cannot be modified. | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).