Submitted:

12 June 2024

Posted:

12 June 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

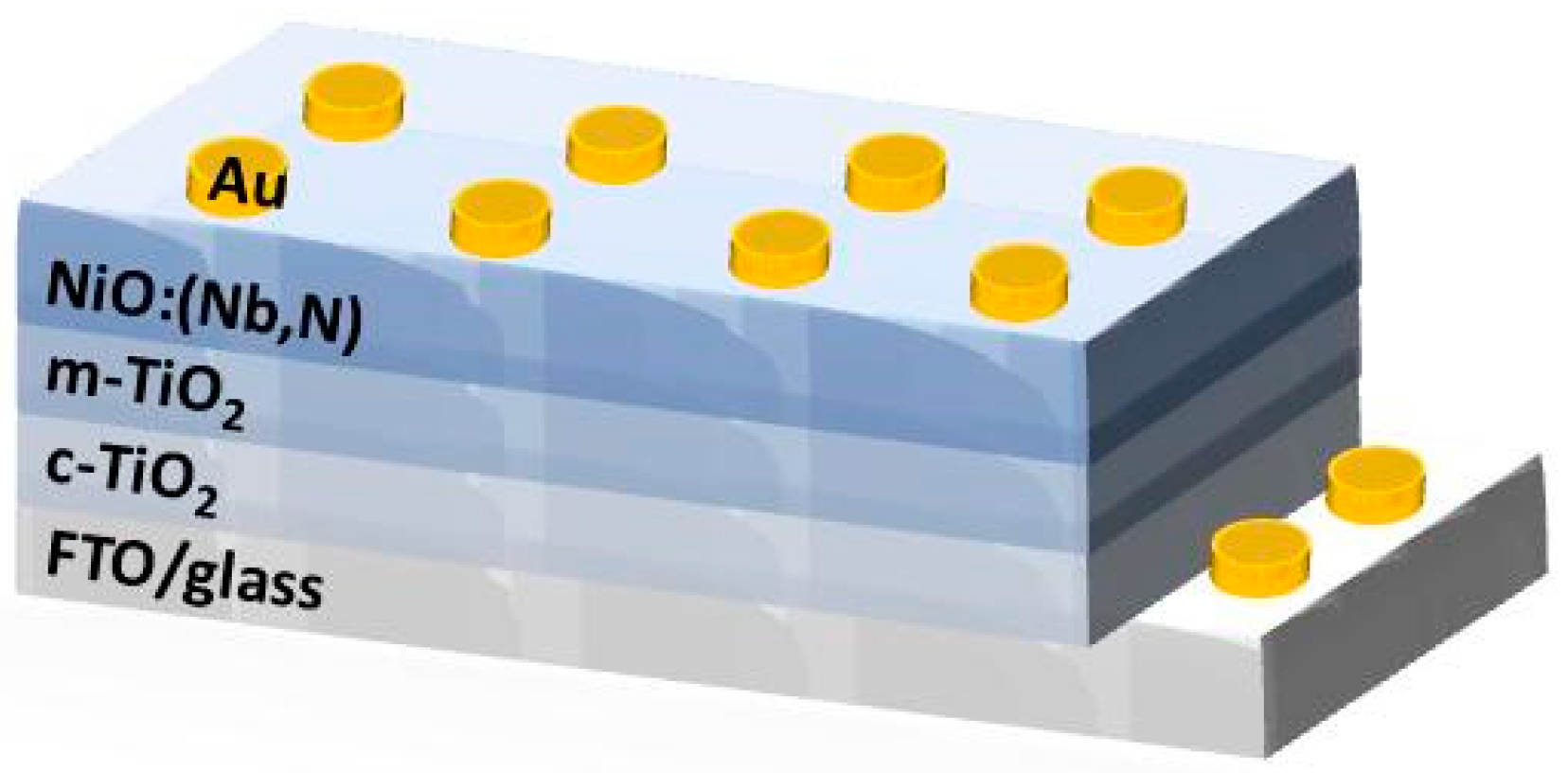

2.1. Thin Films Deposition and Device Fabrication

2.2. Characterization Methods of Thin Films and Devices

3. Results and Discussion

3.1. Thin Films Properties

3.1.1. Properties of TiO2 Layer

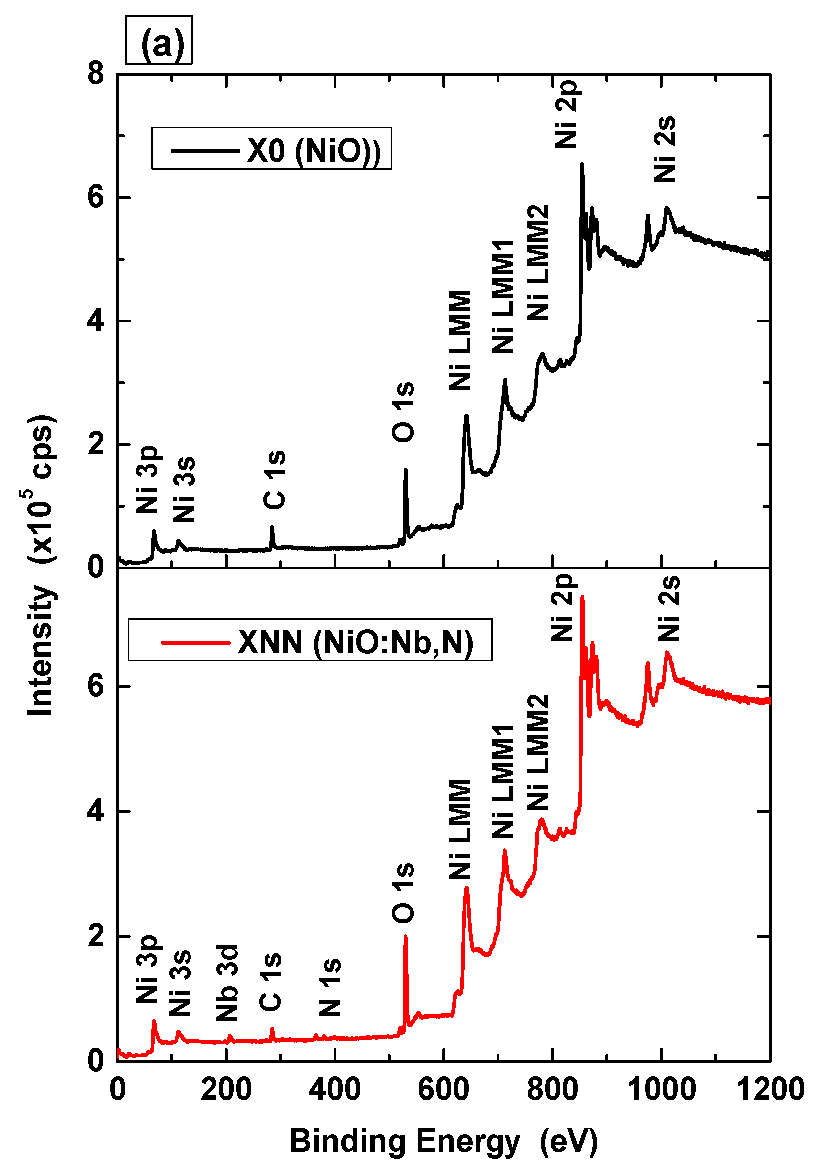

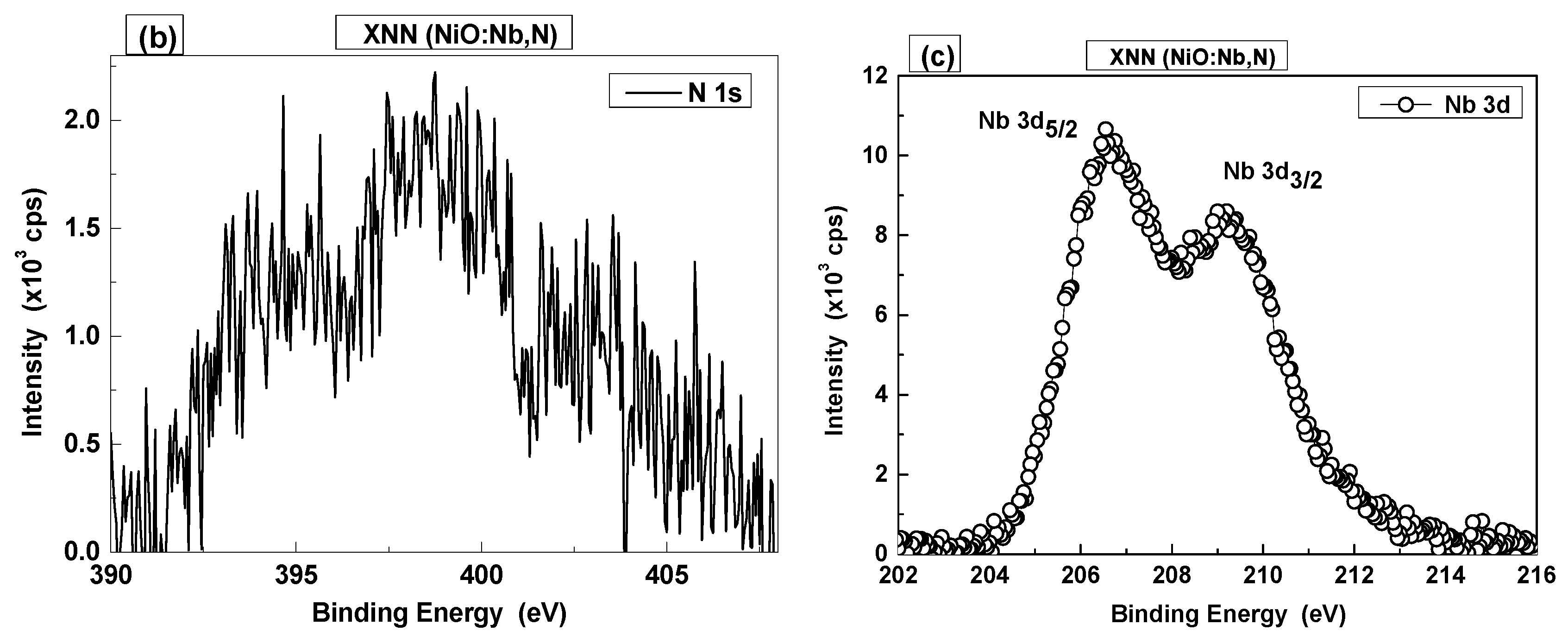

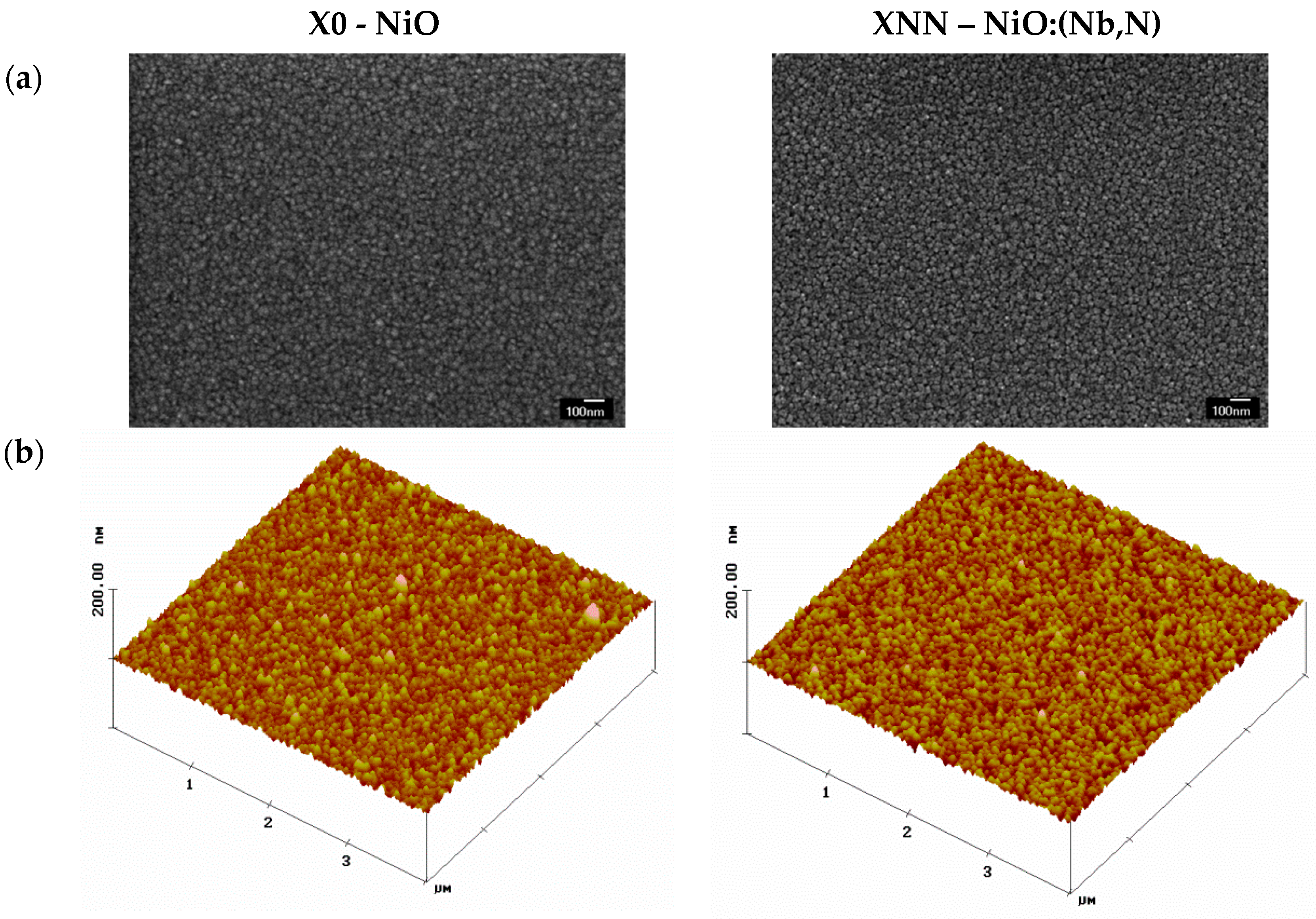

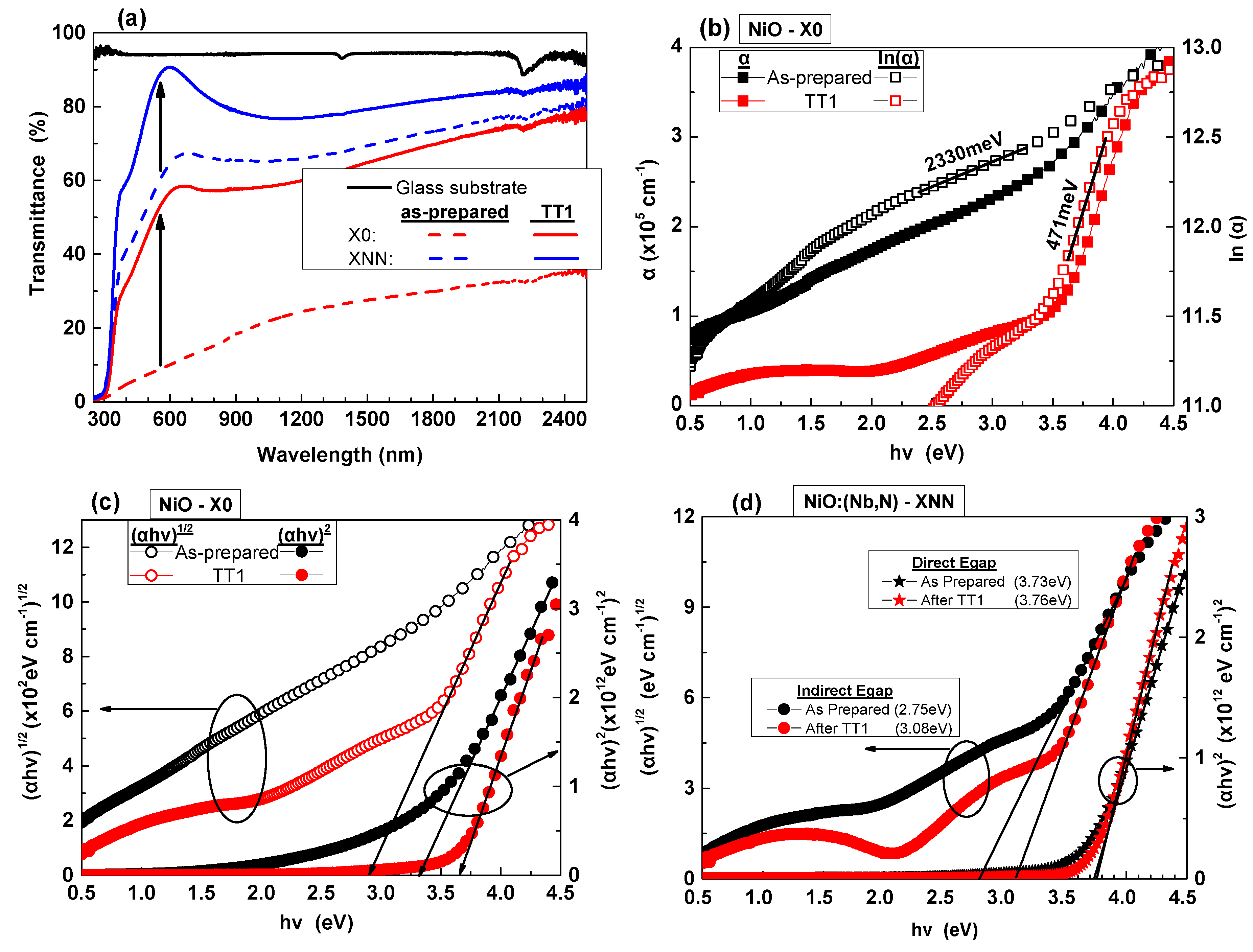

3.1.2. Properties of NiO and NiO:(Nb,N) Thin Films

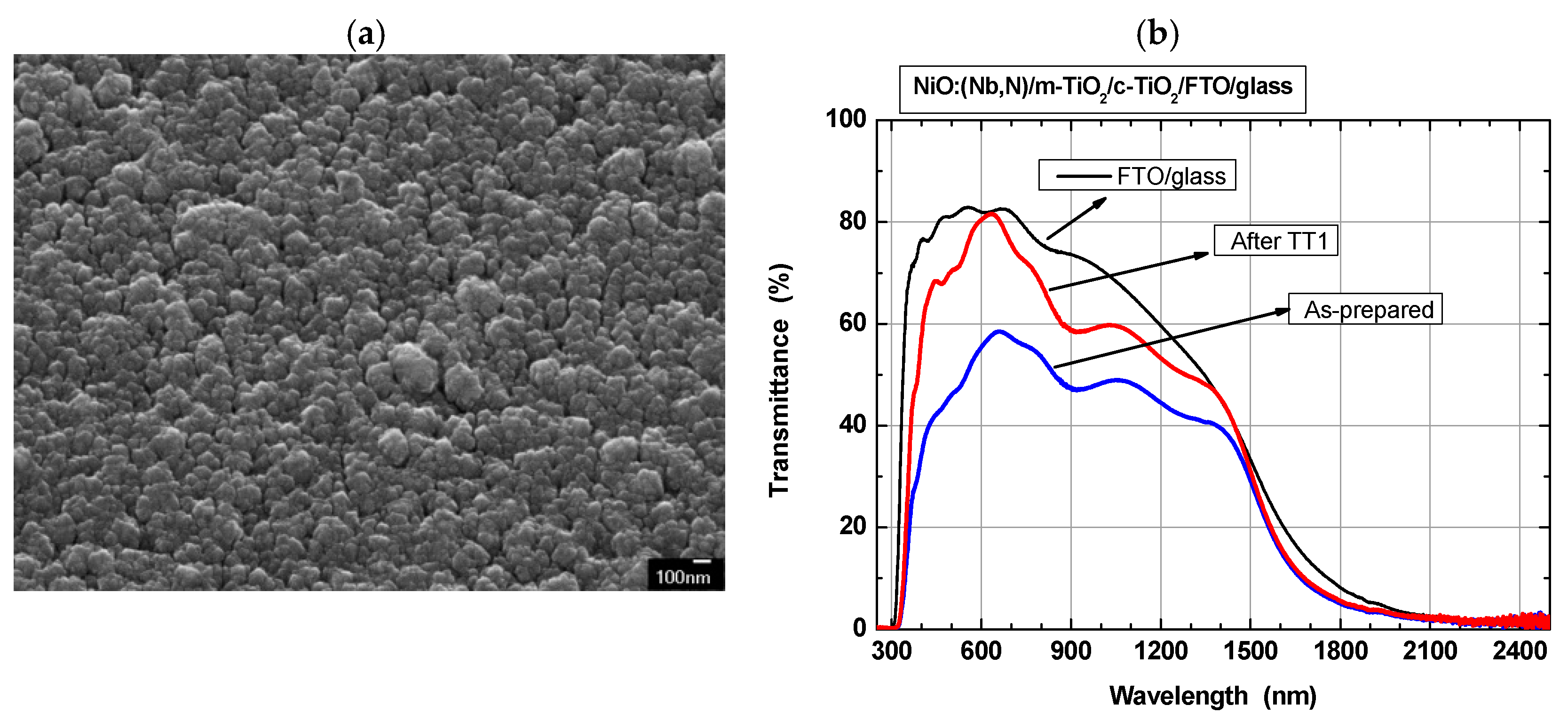

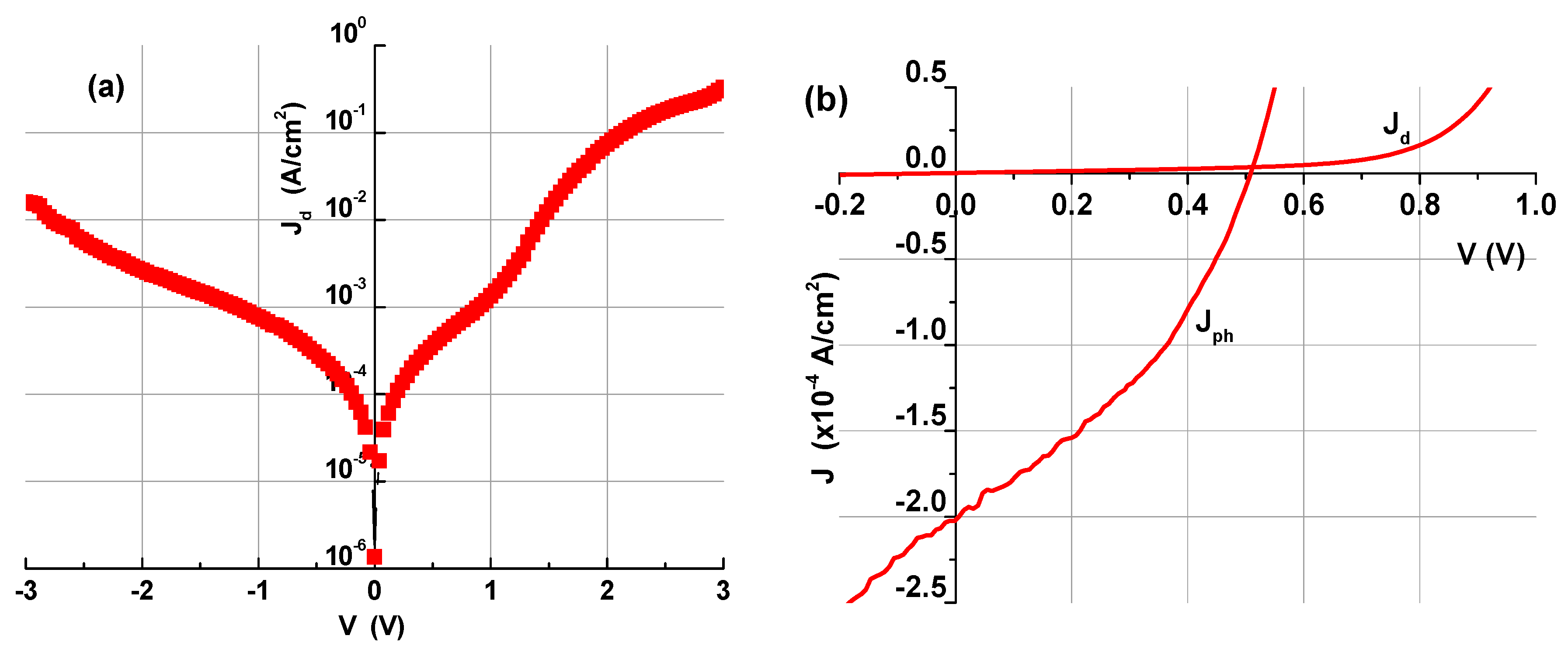

3.3. Properties of NiO:(Nb,N)/TiO2 Heterostructure

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lemmet S., ‘Buildings and climate change: summary for decision-makers Sustainable Buildings & Climate Initiative’, Paris: United Nations Environmental Programme; 2009, p. 1–62.

- Yang, L.; Yan, H.; Lam, J.C. ‘Thermal comfort and building energy consumption implications - a review’, Appl. Energy 115 (2014) 164–173. [CrossRef]

- Wang, Z.; Wang, X.; Cong, S.; Geng, F.; Zhao, Z. “Fusing electrochromic technology with other advanced technologies: A new roadmap for future development”, Materials Science & Engineering R 140 (2020) 100524. [CrossRef]

- Lunt, R. R. “Theoretical limits for visibly transparent photovoltaics”, Appl. Phys. Lett. 101 (2012) 043902. [CrossRef]

- Ukoba, K.O.; Inambao, F.L.; Eloka-Eboka, A.C. “Fabrication of affordable and sustainable solar cells using NiO/TiO2 P-N heterojunction”, Int. J. Photoenergy 7 (2018) 6062390. [CrossRef]

- Abbas, S.; Kim, J. “All-metal oxide transparent photodetector for broad responses”, Sens. Actuators A 303 (2020). [CrossRef]

- Aivalioti, Ch.; Manidakis, E.G.; Pelekanos, N.T.; Androulidaki, M.; Tsagaraki, K.; Viskadourakis, Z.; Spanakis, E.; Aperathi- tis, E. “Niobium-doped NiO as p-type nanostructured layer for transparent photovoltaics”, Thin Solid Films 778 (2023) 139910. [CrossRef]

- Xu, J.; Cao, R.; Shi, S.; Li, L.; Zhu, K.; Su, Y. “Self-powered ultraviolet photodetectors based on match like quasi one- dimen- sional n-TiO2/p-NiO core-shell heterojunction arrays with NiO layer sputtered at different power”, J. Alloys and Compounds 928 (2022) 167126. [CrossRef]

- Kumar, N.; Patel, M.; Nguyen, T.T.; Kim, S.; Kim, J. “Effect of TiO2 layer thickness of TiO2/NiO transparent photovoltaics”, Prog Photovolt Res Appl. 2021;1–10. [CrossRef]

- Klochko, N.P.; Kopach, V.R.; Tyukhov, I.I.; Zhadan, D.O.; Klepikova, K.S.; Khrypunova, G.S.; Petrushenko, S.I.; Lyubov, V.M.; Kirichenko, M.V.; Dukarov, S.V.; Khrypunova, A.L. “Metal oxide heterojunction (NiO/ZnO) prepared by low temper ature solution growth for UV-photodetector and semi-transparent solar cell”, Solar Energy 164 (2018) 149–159. [CrossRef]

- Nguyen, T.T.; Patel, M.; Kim, J.W.; Lee, W.; Kim, J. “Functional TiO2 interlayer for all transparent metal-oxide photovoltaics”, J Alloys Compd. 816 (2020) 8. Article 152602. [CrossRef]

- Grundmann, M.; Klüpfel, F.; Karsthof, R.; Schlupp, P.; Schein, F.-.L.; Splith, D.; Yang, C.; Bitter, S.; von Wenckstern, H. “Oxide bipolar electronics: materials, devices and circuits”, J. Phys. D Appl. Phys 49 (25pp) (2016). [CrossRef]

- Karsthof, R.; Racke, P.; von Wenckstern, H.; Grundmann, M. “Semi-transparent NiO/ZnO UV photovoltaic cells”, Phys. Sta- tus Solidi A 213 (2016) 30–37. [CrossRef]

- Ghosh, S.; Patel, M.; Lee, J.; Kim, J. “All-Oxide Transparent Photodetector Array for Ultrafast Response through Self-Powered Excitonic Photovoltage Operation”, Small 2023, 2301702. [CrossRef]

- Hovel, H.J.; Willardson, R.K.; Beer, A.C. in “Solar Cells”, Chapter 2, Semiconductors and Semimetals Series, 11, Academic Press, New York, 1976. Solar Cells, Chapter 2ISBN 10: 0127521119ISBN 13: 9780127521114].

- Patel, M.; Nguyen, T.T.; Kumar, M.; Ban, D.K.; Won, D.; Zhao, M.; Kim, J.; Kim, Y.K.; Yang, H.; Wong, C.P. “2D layer-embedded transparent photovoltaics”, Nano Energy 68 (2020). [CrossRef]

- Fu, W.; Pan, J.; Niu, J.; Fu, Y.; Xiao, G.; Wang, J.; Zheng, Y.; Li, C. “A transparent photovoltaic device of NiO/MgO quantum dots/TiO2 arrays pn junction with carrier injection of MgO QDs”, J Mater Sci: Mater Electron (2022) 33:652–662. [CrossRef]

- Aivalioti, Ch.; Papadakis, A.; Manidakis, E.; Kayambaki, M.; Androulidaki, M.; Tsagaraki, K.; Pelekanos, N.T.; Stoumpos, C.; Modreanu, M.; Crăciun, G.; Romanitan, C.; Aperathitis, E. “Transparent All-Oxide Hybrid NiO:N/TiO2 Heterostructure for Optoelectronic Applications”, Electronics 10 (2021) 988 (18pp). [CrossRef]

- Aivalioti, Ch.; Papadakis, A.; Manidakis, E.; Kayambaki, M.; Androulidaki, M.; Tsagaraki, K.; Pelekanos, N.T.; Stoumpos, C.; Modreanu, M.; Craciun, G.; Romanitan, C.; Aperathitis, E. “An Assessment of Sputtered Nitrogen-Doped Nickel Oxide for all-Oxide Transparent Optoelectronic Applications: The Case of Hybrid NiO:N/TiO2 Heterostructure”, Recent Trends in Chemical and Material Sciences, Vol. 6, Chap. 8, 12 February 2022, Page 86-111. [CrossRef]

- Yang, D.; Zhou, X.; Yang, R.; Yang, Z.; Yu, W.; Wang, X.; Li, C.; Liu, S.; R.P. H. Chang, “Surface optimization to eliminate hysteresis for record efficiency planar perovskite solar cells”, Energy Environ. Sci., 2016, 9, 3071. [CrossRef]

- Gagaoudakis, E.; Michail, G.; Kampylafka, V.; Tsagaraki, K.; Aperathitis, E.; Moschovis, K.; Binas, V.; Kiriakidis, G. “Room Temperature p-Type NiO Nanostructure Thin Film Sensor for Hydrogen and Methane Detection”, Sensor Letters 2017, 15, 663-667. [CrossRef]

- Nath, D.; Singh, F.; Das, R. “X-ray diffraction analysis by Williamson-Hall, Halder-Wagner and size-strain plot methods of CdSe nanoparticles- a comparative study”, Mat. Chem. and Phys., 239 (2020), Article 122021. [CrossRef]

- Pankove, J. “Optical Processes in Semiconductors”, Dover Publications, NY, 1971, p. 87 (Ch. 4).

- Davis, E.A.; Mott, N.F. “Conduction in non-crystalline systems V. “Conductivity, optical absorption and photoconductivity in amorphous semiconductors”, Philosophical Magazine 22 (1970) 0903-0922. [CrossRef]

- Sze, S.M. “Physics of Semiconductor Devices”, 2nd ed., John Wiley and Sons Ltd1981, 2nd edition (November 18, 1981), ISBN-13: 978-0471098379 Wiley, New York.

- Bi, Z.; Liu, X.; Zhang, Y.; Zhang, Y.; Ma, Y.; Chen, Y.; Zhou, J.; Ruan, S. “An MSM photodetector based on an InGaO/TiO2 heterojunction for high-performance UV detection”, Appl. Phys. Lett. 124, 022101 (2024);. [CrossRef]

- Naas, L.-A; Bouaouina, B.; Bensouici, F.; Mokeddem, K.; Abaidia, S.E. "Effect of TiN thin films deposited by oblique angle sputter deposition on sol-gel coated TiO2 layers for photocatalytic applications", Thin Solid Films 793 (2024) 140275. [CrossRef]

- Shalaan, E.; Ibrahim, E.; Al-Marzouki, F.; Al-Dossari, M. "Observation of mixed types of energy gaps in some II–VI semi- conductors nanostructured films: towards enhanced solar cell performance", Appl. Phys. A 126 (2020) 852 (16p). [CrossRef]

- Choudhury, B.; Choudhury, A. “Oxygen defect dependent variation of band gap, Urbach energy and luminescence property of anatase, anatase–rutile mixed phase and of rutile phases of TiO2 nanoparticles”, Physica E 56 (2014) 364–371. [CrossRef]

- Kavan, L. “Electrochemistry and band structure of semiconductors (TiO2, SnO2, ZnO): Avoiding pitfalls and textbook er- rors”, Journal of Solid State Electrochemistry, 2024. [CrossRef]

- Mor, G.K.; Varghese, O.K.; Paulose, M.; Shankar, K.; Grimes, C.A. “A review on highly ordered, vertically oriented TiO2 na- notube arrays: Fabrication, material properties, and solar energy applications” Solar Energy Materials & Solar Cells 90 (2006) 2011–2075. [CrossRef]

- Keraudy, J.; Ferrec, A.; Richard-Plouet, M.; Hamon, J.; Goullet, A.; Jouan, P.-Y. “Nitrogen doping on NiO by reactive magne- tron sputtering: A new pathway to dynamically tune the optical and electrical properties”, Appl. Surf. Sci. 2017, 409, 77-84. [CrossRef]

- Himmerlich, M.; Koufaki, M.; Ecke, G.; Mauder, Ch.; Cimalla, V.; Schaefer, J.A.; Kondilis, A.; Pelekanos, N.T.; Modreanu, M.; Krischok, S.; Aperathitis, E. “Effect of Annealing on the Properties of Indium−Tin−Oxynitride Films as Ohmic Contacts for GaN-Based Optoelectronic Devices”, ACS Appl. Mater. Interfaces 2009, 1, 1451-1456. [CrossRef]

- Jin, S.; Guan, W.; Tsang, C.-W.; Yan, D.Y.S.; Chan, C.-Y.; Liang, C. “Enhanced Hydroconversion of Lignin-Derived Oxy- gen-Containing Compounds Over Bulk Nickel Catalysts Though Nb2O5 Modification”, Catal. Lett., 147 (2017), pp. 2215–2224. [CrossRef]

- Qiu, L.; Zhang, S.; Huang, J.; Wang, C.; Zhao, R.; Qu, F.; Wang, P.; Yang, M. “Highly selective and sensitive xylene sensors based on Nb-doped NiO nanosheets”, Sensors & Actuators: B. Chemical, 308 (2020), Article 127520. [CrossRef]

- Hwang, J.D.; Ho, T.H. “Effects of oxygen content on the structural, optical, and electrical properties of NiO films fabricated by radio-frequency magnetron sputtering”, Mat. Sci. Semicond. Processing 2017, 71, 396-400. [CrossRef]

- Tian, Y.; Gong, L.; Qi, X.; Yang, Y.; Zhao, X. “Effect of Substrate Temperature on the Optical and Electrical Properties of Nitrogen-Doped NiO Thin Films”, Coatings 9 (2019) 634(10pp). [CrossRef]

- Peng, W.B.; Zhou, Y.J.; Xiang, G.J.; Liu, Y.; Zhang, J.H.; Zhang, J.M.; Huang, H.X.; Mei, M.Y.; Wang, H.; Zhao, Y. “Prepara- tion of AlN thin film and the impacts of AlN buffer layer on the carrier transport properties of p-NiO/n-InN heterojunction by magnetron sputtering”, Materials Science in Semiconductor Processing 2022, 141, 106417. [CrossRef]

- Lin, C.-W.; Chung, W.-C.; Zhang, Z.-D.; Hsu, M.-C. “P-channel transparent thin-film transistor using physical -vapor-deposited NiO layer”, Jpn. J. Appl. Phys. 2018, 57, 01AE01(5pp). [CrossRef]

- Park, S.G.; Lee, K.H.; Lee, J.-H.; Bang, G.; Kim, J.; Park, H.J.; Oh, M.S.; Lee, S.; Kim, Y.-H.; Kim, Y.-M.; Hosono, H.; Bang, J.; Lee, K. “Improved polaronic transport under a strong Mott–Hubbard interaction in Cu substituted NiO”, Inorg. Chem. Front. 7 (2020) 853-858. [CrossRef]

- Siddique, M.N.; Ahmed, A.; Tripathi, P. “Enhanced optical properties of pure and Sr doped NiO nanostructures: A compre- hensive study”, Optik 2019, 185, 599-608. [CrossRef]

- Zanatta, A.R. “Revisiting the optical bandgap of semiconductors and the proposal of a unified methodology to its determi- nation”, Scientific Reports 9 (2019) 11225. [CrossRef]

- Gong, H.; Chen, X.; Xu, Y.; Chen, Y.; Ren, F.; Liu, B.; Gu, S.; Zhang, R.; Ye, J. “Band Alignment and Interface Recombination in NiO/β-Ga2O3 Type-II p-n Heterojunctions”, IEEE Trans. Electron Devices 2020, 67, 3341-3347. [CrossRef]

- Popescu, I.; Skoufa, Z.; Heracleous, E.; Lemonidou, A.; Marcu, I.-C. “A study by electrical conductivity measurements of the semiconductive and redox properties of Nb-doped NiO catalysts in correlation with the oxidative dehydrogenation of ethane”, Phys. Chem. Chem. Phys. 2015, 17, 8138-8147. [CrossRef]

- Polyakov, A.Y.; Smirnov, N.B.; Shchemerov, I.V.; Vasilev, A.A.; Kochkova, A.I.; Chernykh, A.V.; Lagov, P.B.; Pavlov, Y.S.; Stolbunov, V.S; Kulevoy, T.V.; Borzykh, I.V.; Lee, I.-H.; Ren, F.; Pearton, S.J. “Crystal orientation dependence of deep level spectra in proton irradiated bulk β-Ga2O3”, J. Appl. Phys. 130, 035701 (2021);. [CrossRef]

- Karsthof, R.; von Wenckstern, H.; Zúniga-Pérez, J.; Deparis, C.; Grundmann, M. “Nickel Oxide–Based Heterostructures with Large Band Offsets”, Phys. Status Solidi B 2020, 257, 1900639. [CrossRef]

- Vygranenko, Y.; Wang K.; Nathan, A. “Low leakage heterostructure ultraviolet sensor”, Appl. Phys. Lett. 89, 172105 (2006). [CrossRef]

- Nguyen, T.T.; Patel, M.; Kim, J. “All-inorganic metal oxide transparent solar cells”, Solar Energy Materials & Solar Cells 217 (2020) 110708. [CrossRef]

- Wang, J.; Ren Y.; Wang, P. “(Fe, F) co-doped nickel oxyhydroxide for highly efficient oxygen evolution reaction”, J. Mater. Chem. A, 2023, 11, 4619, DOI: DOI: 10.1039/d2ta09224g.

- Wen, C.-K.; Xin, Y.-Q.; Chen, S.-C.; Chuang, T.-H.; Chen, P.-J.; Sun, H. “Comparison of microstructural and optoelectronic properties of NiO:Cu thin films deposited by ion-beam assisted rf sputtering in different gas atmospheres”, Thin Solid Films, 677 (2019), pp. 103-108. [CrossRef]

- Raj, I.L.P.; Valanarasu, S.; Ade, R.; Bitla, Y.; Mohanraj, P.; Ganesh, V.; Yahia, I.S. “Enhancing the ultraviolet photosensing properties of nickel oxide thin films by Zn–La co-doping”, Ceramics International 48 (2022) 5026–5034. [CrossRef]

- Dong, D.; Wang, W.; Barnabe, A.; Presmanes, L.; Rougier, A.; Dong, G.; Zhang, F.; Yu, H.; He, Y.; Dia, X. “Enhanced elec- trochromism in short wavelengths for NiO:(Li,Mg) films in full inorganic device ITO/NiO:(Li, Mg)/Ta2O5/WO3/ITO”, Elec- trochimica Acta, 263 (2018), pp. 277-285. [CrossRef]

- Abbas, H.; Nadeem, K.; Munir, S.; Ahmed, U.; Usman, M.; Kostylev, M. “Fe–Co co-doping effects on antiferromagnetic core of NiO nanoparticles”, Ceramics International 48 (2022) 3435–3447. [CrossRef]

- Ahmed, A.A.A.; Alahsab, E.A.A.; Abdulwahab, A.M. “The influence of Zn and Mg doping on the structural and optical properties of NiO nano-structures for optoelectronic applications”, Results in Physics 22 (2021) 103938. [CrossRef]

- El Sayed, A.M.; “Exploring the morphology, optical and electrical properties of nickel oxide thin films under lead and iri- dium doping”, Physica B 600 (2021) 412601. [CrossRef]

| (A) m-TiO2/c-TiO2 films | ||

| Details |

Compact TiO2 – c-TiO2 |

Mesoporous TiO2 – m-TiO2 |

| Spin-coating | HCl:C₂H₆O:C12H28O4Ti=50µL:2.3mL:150µL | TiO2 paste + C₂H₆O |

| Rounds per minute / duration (sec) | 2000 / 30 | 6000 / 30 |

| Thermal treatment | 500◦C / air / 15 min | 500◦C / air / 15 min |

| Thickness (nm) | 40 | 200 |

| Substrates | FTO/glass (2 mm thick glass) | c-TiO2/FTO/glass |

| (B) NiO-based films | ||

| Details |

NiO – Film X0 |

NiO:(Nb,N) – Film XNN |

| Target | Ni | Ni-Nb |

| Gases flow rates | Ar:O2 = 50:50 | Ar:O2:N2 = 50:25:25 |

| Pressure (Pa) | 0.67 | 0.67 |

| Power (W) | 300 | 300 |

| Deposition rate (nm/min) | 1.52 | 1.28 |

| Thickness (nm) | 145 | 130 |

| Target pre-cleaning | 300 W/0.67 Pa Ar/45 minutes | |

| Substrates | Si (100) pieces, fused silica (1 mm thick), TiO2/FTO/glass | |

| (200) Peak Position, 2θ (degree) | Crystallite Size, D (nm) | Lattice Strain, ε (x10-3) | Lattice Constant (Å) | ||

|---|---|---|---|---|---|

| X0 - NiO | As-prepared | 42.56 | 5.33 | 17.7 | 4.245 |

| TT1 | 43.40 | 7.44 | 12.4 | 4.166 | |

| XNN – NiO:(Nb,N) | As-prepared | 42.66 | 10.07 | 9.4 | 4.235 |

| TT1 | 43.04 | 9.13 | 10.2 | 4.200 |

| Direct Egap (eV) | Indirect Egap (eV) | Urbach width, EU (meV) | ||||

|---|---|---|---|---|---|---|

| As-prepared | TT1 | As-prepared | TT1 | As-prepared | TT1 | |

| NiO | 3.28 | 3.67 | - | 2.97 | 2330 | 471 |

| NiO:(Nb,N) | 3.73 | 3.76 | 2.75 | 3.08 | 586 | 313 |

| TiO2 | 3.72 | 3.28 | 211 | |||

| p/n layers | Deposition Techn./Thickness | TVIS (%) | λ (nm)/PIN (mW/cm2) | JSC or ISC | Voc (mV) | Year/[Ref.] | |

|---|---|---|---|---|---|---|---|

| p-NiO layer | n-TiO2 layer | ||||||

| NiO/TiO2 | SP | SP | - | Solar Simul./100 | 16.8 mA | 350 | 2018/[5] |

| NiO/SnS/TiO2 | DC S/30nm | DC S/80nm | 40-60 | 365nm/70 | 27.4 μA/cm2 | 765 | 2020/[16] |

| NiO/TiO2 | DC S | DC S+RTP /100nm | 60-70 | 365-520nm/ -- | 0.7-20 μA/cm2 | 25-250 | 2020/[48] |

| NiO/TiO2:N | 30 | DC S+RTP /120nm | 25-45 | 365-520nm/6.5 | 558-66 μA | 130 | 2020/[6] |

| NiO/TiO2 | DC S | DC S+RTP /350nm | 40-55 | 365 nm/30 | 7-8 mA/cm2 | 300-500 | 2021/[47] |

| NiO:Nb/m-TiO2/c-TiO2 | RF MS/150 | Spin coating /240 nm | 55-65 | 325nm/710 | 1.4 μA/cm2 | 200 | 2023/[7] |

| NiO:(Nb,N)/m-TiO2/c-TiO2 | RF MS/130 | Spin coating /240 nm | 70-80 | 325nm/710 | 200 μA/cm2 | 500 | [2024] This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).