1. Introduction

In manufacturing, increasing productivity and product quality is very important for customers. In this’ condition monitoring plays a vital role to ensure product quality. So, preventive maintenance and condition monitoring are required to achieve greater machinery availability, improve the quality of the manufacturing process, enhance the machine reliability, maximize profit and productivity and reduce maintenance costs. Normally, an industrial investor will concern more about the profit and also to save cost of production due to heavy competition of the market. To increase productivity, condition monitoring is capable of providing warning based on fault detection in the early stage of production.

In drilling operations, If the condition of the drill tool is not monitored properly, drill tool will stick inside the work piece and possibility of breaks if operation is not stopped. Normally, the condition of the tools are analyzed based on mathematical models, physic-based models and data driven models which use the data using sensors and data acquisition systems. Since the mathematical model analysis is having more complexity and physics-based models require in-depth knowledge of physics involved in the process, there is an increasing trend of applying machine learning model-based analysis to predict the tool conditions more accurately. Drill tool condition monitoring is slightly complex in nature due to production tolerances and asymmetric profile of the drilling tool.

In this work, the predictive or condition-based maintenance is applied based on the wear condition of drill bit. This type is useful to monitor the condition of the drilling tool of a bench type CNC drilling machine which uses a specific technique which is drilling tool’s vibration signal. It can be used to detect the signal of the drill bit faults and analyses by using the time domain statistics and wavelet analysis as feature extraction. The extracted WT analyzed parameter to be fed as inputs features to an artificial neural network (ANN) for fault detection and classification.

The drilling fault detection techniques have been developed based on the wavelet analysis and ANN as automatic drill bit fault detection and classification. An experimental work has been employed to capture the vibration signals for analysis with different measuring intervals. The bench type CNC drill is used with high carbon steel tip drill bit and mild steel material as work piece. The drilling condition has been set to 12mm/min federate and the rpm of 800. The drill bit has drill dia 8 mm, Overall length 92 mm, the angle point is 135. Using accelerometers, vibration data has been collected and analyzed in the life cycle of the drill bit. In this experiment, The direction of sensor is vertical and the wear levels (0.0mm, 0.2mm, 0.4mm and 0.6mm) are changed.

Several methods of drill bit condition monitoring are investigated by researchers which includes both direct and indirect methods. The direct methods like visual inspection, machine vision and infra-red methodology are used to monitor the drill bit which will give less accuracy compared to indirect methods [

1]. Indirect methods include use of signals like force, vibrations, acoustic emission etc., in which the signal features have a relationship with wear condition / parameters Indirect methods include use of signals like force, vibrations, acoustic emission etc., in which the signal features have a relationship with wear condition / parameters [

2]. Acoustic Emission (AE) and vibration based drill bit monitoring are the most popular indirect methods which are used for assessing the condition with more accuracy for micro level measurements. Acoustic emission is a phenomenon which occurs when, for different reasons, a small surface displacement of a material surface is produced. This occurs due to stress waves generated when there is a rapid release of energy in a material, or on its surface which has frequency range from 10 to 70 kHz with non-linear frequency response. In some advanced testing, we can use 200 kHz sensor for tool wear and the 800 kHz sensor for tool breakage detection which will come under the broad band acoustic sensor. AE has been widely used for monitoring wear in the laboratory as well as at the industrial level for monitoring failures like scuffing, fretting, rolling contact fatigue etc.,[

1].

Furthermore, indirect methods are widely used in drill bit condition monitoring and as fault detection. They are used in different techniques such as cutting forces, acoustic emission, temperature, vibration, motor current and torque [

3]. However, vibration measurement for machinery condition monitoring is easy, less costly and yields a great deal of information that can be used to monitor the relative motion between the tool tip and the work piece for precision of the cutting operation [

4]. Waleed Abdulkarem et al., have reported that vibration analysis is widely accepted as a tool to monitor the operating conditions of a machine as it is nondestructive, reliable and permits continuous monitoring without intervening with the process. This study has demonstrated drill bit condition monitoring approach in drilling operation based on the vibration signal collected using sensor and data acquisition system. Advantages of this approach include availability, low cost, large information data, nondestructive, reliable and facilitating continuous on-line monitoring. This method allows substitution of another sensor (e.g., an acoustic sensor) or very cost-effective accelerometer [

5].

The novelty of this work is the proposal of WPT and ANN in drill condition monitoring. Many researchers have applied this kind of techniques to predict the faults in turning machine. But condition monitoring in drill bit is still under research since the drill bit having complex features. So, this attempt will open a path to do research to identify the drill bit faults which will useful in many fields. Particularly, Stone drilling process is very important process for oil and gas industries, so that, there is a huge demand for high level condition monitoring system for drill bit in oil and gas sector. We believe that the proposed methodology will play a significant role in stone drilling operations. The innovation in the research is to apply accelerometer/ acoustic emission sensor, Artificial neural network (deep learning based analysis), comparison of the results and to keep the error in below 3% which is not obtained in the previous researches.

2. Literature Review

AI algorithms such as ANN, fuzzy based techniques, Genetic Algorithms, Support Vector Machines etc are highly useful in fault diagnosis. So, AI is the future of condition monitoring to have preventive maintenance [

6]. Internet of Things and AI have many advantages in the prediction of the health of the machine which improve the productivity and profit of an industry [

7,

8].In the research paper by Miho Klaic et al., decision tree algorithm has been applied to predict tool wear. The research paper concluded that the methodology assured that 90% success rate and more reliable. The researcher has not compared the decision tree with deep learning algorithms which is a big research gap in this paper[

9]. Rui Zhao et al., surveyed related to deep learning and its application for machine health monitoring. He has concluded in this way in their research article as “It is believed that deep learning will have a more and more prospective future impacting machine health monitoring, especially in the age of big machinery data”. So, this paper reveals that deep learning can be used in a precise way to monitor tool wear and also the research concluded that deep learning is a promising technique to assess any kind of tool wear[

10]. P.Krishnakumar et al., used acoustic emission signal for tool condition monitoring during high-speed milling of Ti-6Al-4V. Discrete wavelet transform (DWT) was used to extract coefficients from vibration and acoustic emission signals. Machine learning algorithms like decision tree, Naïve Bayes, SVM, and ANN are used to predict the tool condition. The authors concluded that SVM based vibration analysis predicts tool condition effectively and assure that prediction accuracy is more than 99% [

11]. Yaochen Shi identified the wear in the drill bit based on the Local Mean Decomposition (LMD) and Back Propagation (BP) neural network. The research team used a multi-signal platform to acquire different parameters from the drilling machine. Then the feature parameter is predicted by the combination of noise-assisted LMD method and BP neural network. The accuracy of monitoring drill bit wear with multi-signal fusion is 95.8%[

12]. Lang Dai developed a new Deep Learning Model for Online Tool Condition Monitoring Using Output Power Signals. The output power from the sensor which is mounted on the cutting tool holder during its operation is used for further analysis. The date were analyzed using wider first-layer kernels (WCONV), and long short-term memory (LSTM) which is available in the deep learning algorithms. This paper concerns about the output power signals and its analysis on deep learning algorithms [

13]. Wang et al., have done a survey on tool Wear Monitoring Methods Based on Convolutional Neural Networks. The autho concluded that application convolution neural networks in tool wear and condition monitoring is more reliable. They added that the convolution neural network can improve accuracy, which is a great significance of the CNN [

14]. Chacon et al., used multi-threshold count-based feature extraction at multi-resolution level based on wavelet packet transform for extracting a redundant and non-optimal feature map from the AE signal. Recursive feature elimination is used to reduce and optimize the number of features and the random forest regression is used to estimate the tool wear; The performance is compared with other ML techniques like RF, SVM, ANN, KNN, and DT, to obtain the lowest RMSE for predicting tool flank wear [

15].

Kolar , P et al., dealt about indirect drill condition monitoring based on machine tool control system data. In this work, work piece vibration has been monitored and correlation of various features of signals are evaluated. As a result of this paper, researchers concluded that root mean square of the vibration and spindle torque signals strongly correlate with flank wear near bottom of the hole. In this paper, spindle current torque and Z slide drive current torque have been analyzed for flank wear [

16].

Reeber,T et al., demonstrated two anomaly detection approaches for drill condition monitoring. The XG Boost approach provide the timely detection near end of tool life. Machine learning models have been used to predict tool wear before any risk in drilling process. An another method called unsupervised autoencoder is also used by authors for anomaly detection from reconstruction errors [

17].

Anomaly detection using auto encoder or other neural networks are used to supervise equipment failure and predict the intervals for maintenance. These are unsupervised algorithms which is easy to apply in condition monitoring. Pores and blow holes in the work piece and potential dimensional inaccuracies (or) monitoring anomalies related to progressive tool wear for tool condition monitoring in CNC machines has been dealt by Netzer,M.,Palenga,Y and Fleischer [

18].

Anomaly detection algorithms for tool wear detection using sensors can be done using convolutional neural network (or) auto encoder which is supported by the papers of sun,s et al., Li,G et al., Ahmad et al., and Vonhahn,T and Mechefske,C.K [

19,

20,

21,

22].

Karri,V and Kiatcharoenpol,T used artificial neural network in drilling machine condition monitoring. In this paper, feed forward network is applied to predict tool life in terms of number of holes’ failure. By benchmarking root mean square (RMS) the results were obtained from thirty-two cutting condition inputs to predict failure in drilling [

23].

3. Wavelet Analysis and Kurtosis

A wavelet is a wave-like short oscillating function which begins at zero amplitude and will increase or decrease and then returns to zero one or more times. Wavelets are applied to transform the signal under examination into another representation which presents the signal information in a more amenable form for further analysis using AI techniques like machine learning/deep learning. This transformation is known as Wavelet Transform (WT) is a technique for converting a function or signal into another form, making certain features of the original signal more useful for analysis. There are five stages of wavelet transform in condition monitoring time–frequency analysis of machining signal,

The wavelet method overcomes the limitation of Fourier Transform such as inability to check continuity, fixed resolution , poor time frequency localization and limited time frequency resolution trade-off , by using a multi-resolution technique (time & frequency) [

26]. It has the ability to examine a signal simultaneously in time and frequency with a flexible mathematical foundation. Time information is obtained by shifting the wavelet over the signal. The frequencies are changed by contraction and dilatation of the wavelet function. Wavelet analysis is more sensitive and trustable than Fourier analysis for recognizing the tool wear states in turning [

22]. Wavelets were first mentioned by Alfred Haar in 1909. It can be moved at various locations on the signal and also it can be squeezed to different scales.

There are some requirements for the wavelet, which are: it must have finite energy, based on Fourier transform, the wavelet must have zero mean and for complex wavelets the Fourier transform must be both real and vanish for negative frequencies. To make the wavelet of chosen mother wavelet(original wavelet) more flexible, two basic manipulations are applied which are stretch or squeeze it (dilation) and move it (translation). The dilation of the wavelet is governed by the dilation parameter a. The movement of the wavelet along the time axis is governed by the translation parameter b. These shifted and dilated versions of the mother wavelet Ψ (t) are denoted by Ψ [(t – b)/a]. The wavelet represented by Maamar Al Tobi is [

27] :

Where, the factor is used to ensure energy preservation.

The sum over all time of the signal multiplied by scaled and shifted versions of the wavelet function Ψ is called the continuous wavelet transform (CWT). Continuous wavelet transforms are recognized as effective tools for both stationary and non-stationary signals. Based on the equation (3 – 9) the CWT given as:

Where, is the continuous wavelet transform (CWT), X (t) is the signal and the superscript asterisk ‘*’ stands for the complex conjugate.

It can be expressed in more compact form as an inner product:

The windowing techniques with variable-size regions in wavelet analysis can be overcome the limitations of the Short-Term Fourier Transform (STFT). Wavelet analysis allows the use of shorter time intervals where more precise high frequency information is desirable and long regions for low frequency information. Sometimes the wavelet is irregular and asymmetric waveform of effectively limited duration (average value zero), so the varieties of wavelets (Wavelet Families) are exist, and an analyst can choose from the wavelet families that suits his application best.

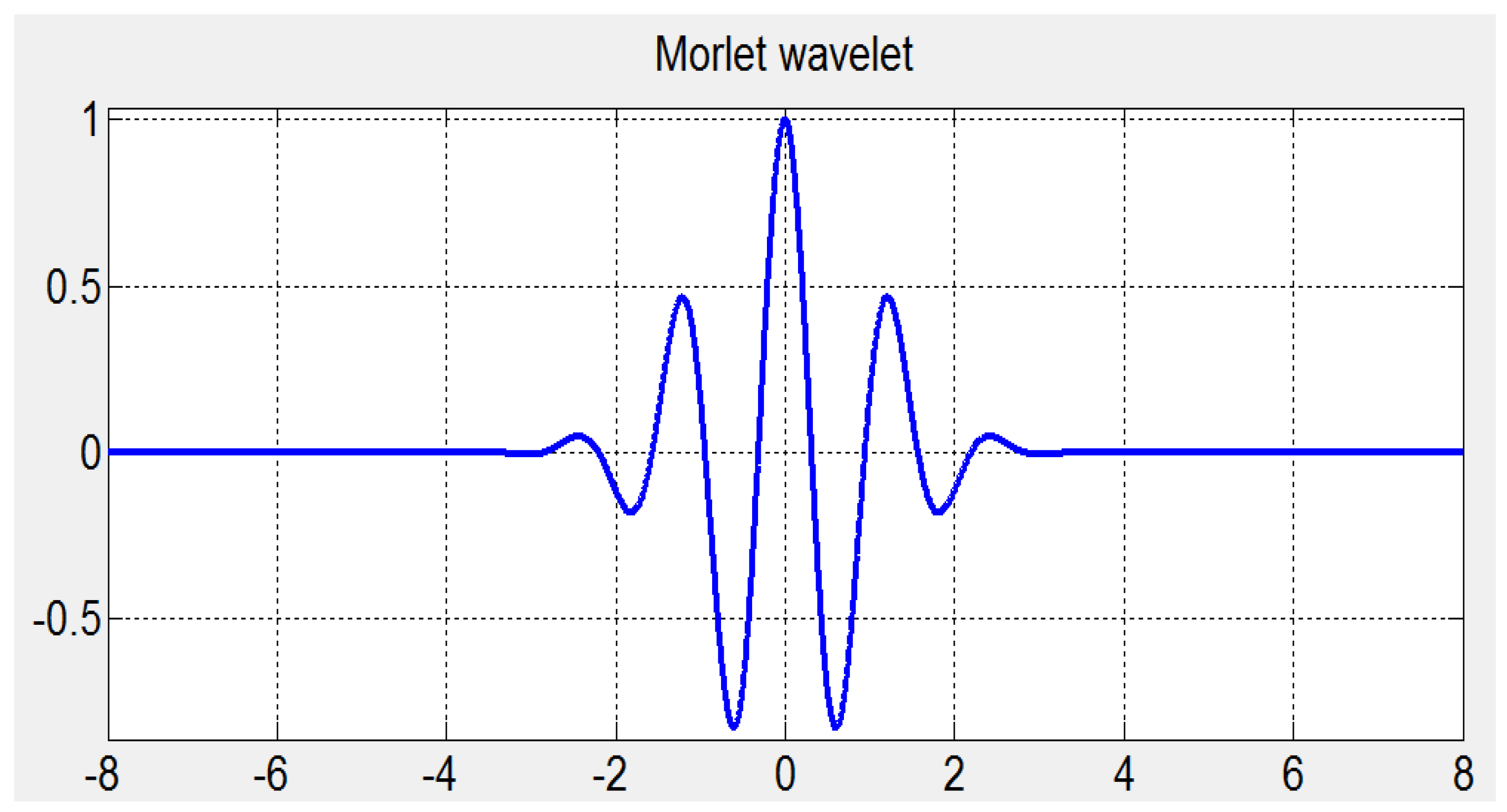

This project focuses on Daubechies wavelets (db10) and Morlet wavelet (morl) as basis function based on the role of features extraction, because they are more similar characteristics to the extracted signals. The morl wavelet is known by the following Equation(Eqn4) .

Figure 1 shows the morl wavelet.

The names of Daubechies family wavelets are signed db N (N is the order) as

Figure 2 shows the db 10 wavelet. The Daubechies wavelet is defined as given in equation (5) .

Where, Φ(t) is scaling function and = (-1) k α – k +1 , If N= 1, then α0= α = 1

In the wavelet transform, kurtosis prediction of vibration signal will help to find out the faulty as soon as possible. Normally, the wavelet transform is an important tool for nonlinear and non-stationary signal analysis which contains discreate wavelet transform (DWT) and wavelet packet transform (WPT). The next step in WPT is to decompose the detailed information of the signal in high frequency region. Thus WPT is used to decompose the kurtosis of the vibration signal into several sub signals with different frequency ranges [

27].

Kurtosis is a measure of peakedness and hence it is a fine indicator of signal impulsiveness in fault detection for rotating components expecially for drill bits.

Where µ = mean of time series x

σ = standard deviation of time series x

E{.} is the expectation operation

The minus 3 is to make kurtosis of the normal distribution of the normal distribution equal to zero.

Kurtosis have three measures which are called as mesokurtic, leptokurtic and platykurtic. when the kurtosis statistic of a distribution is similar to normal distribution or bell curve, then it is called as mesokurtic distribution. If the kurtosis value is greater than mesokurtic and then it is called as leptokurtic distribution. If the kurtosis value id smaller than mesokurtic , then it is called as platykurtic distribution. The

Figure 3 shows the various kurtosis distribution.

4. Modelling of Condition-Based Maintenance Using Artificial Intelligence

Traditional type monitoring involves a measurement system that contains sensors/wireless sensor and then the sensor data will undergo signal condition to process the signal. Then, the processed signal will be converted from analog to digital and then feature extraction is performed. Finally, the signal has been extracted for further analysis in AI techniques to predict the faults in a machine [

30,

31].

A block diagram of machine condition monitoring integrating with AI is given in

Figure 4.

Tool wear condition monitoring (TCM) is an important part of machining automation. In recent years, Machine learning (ML) and deep learning (DL) based TCM methods have been widely researched [

33].

As per Surucu , O et al., machine learning (ML) techniques are selected as an intelligent model for Predictive maintenance (PdM) or condition monitoring of a machine. They added that the efficacy of the predictive maintenance strategy relies on selecting the appropriate data processing method and ML model. Existing surveys do not comprehensively inform users or evaluate the quality of the monitoring systems proposed [

34]. The authors have given a machine condition monitoring model integrating with machine learning algorithms is given in

Figure 5.

The idea of Artificial Neural Network (ANN) is creating a computing system that simulates the biological neural systems of the human brain. The artificial neural network is particularly useful in the modeling of nonlinear mapping, and also in the recognition of distinctive features from chaotic input data even if it is not complete. The behavior of ANN modifies in response to its environment. The inputs will self-adjust while a set of them are given to the network to produce consistent responses through a process called learning. The learning process can change the weights systematically in order to achieve some desired results for a given set of inputs. The types of learning are, supervised and unsupervised; the supervised has been selected based on the environment knowing. The popular algorithm related to the supervised learning is known as the Back-Propagation. The construction of ANN involves the determination of the network properties depending on the network topology (connectivity), the type of connections, the order of connections, and the weight range. Moreover, it determines the node properties like the activation range and the activation function. Also, in dynamic system the ANN determines weight initialization scheme, the activation calculating formula and the learning rule.

A large number of researchers presented application of neural network models in Tool Condition Monitoring (TCM) and classification of tool wear. Artificial neural network (ANN) is useful as online prediction of tool wear based on back propagation network [

35]. The multi-layer feed-forward neural network with a back propagation (FFBP) training algorithm is successful in TCM as tool fault detection and classification [

36]. In this project the ANN is used as fault detection and wear condition classification based on Multi-layer feed-forward with back propagation.

Artificial neural network contains many connected neurons, which work as receiver for the impulses from input or other neurons. These neurons transform the input by giving the outcome to the output or other neurons. Also, ANN consists of different layers of connected neurons, which receive the input from the previous layer and transfer the output to the succeeding layer.

Figure 6 shows the model of a neuron, where the inputs are forwarded to the neuron and multiplied by their synaptic weights. Then, the outcome is forwarded to sum in summing junction and it is activated by the activation function. The inputs of the activation function are affected by the bias (bi), so it will increase if positive and decrease in the case of negative. Finally, the output will be given. The learning and storing of the knowledge will be possible by this model of the ANN.

Typically, in neural network architectures two types of layers are organized in the shape of a layered neural network. There are the signal-layer feed-forward perceptron (SLP) neural network and the feed-forward multilayer perceptron (MLP) ANN. The arrangement of neurons in each of the layers is entirely dependent on the user, hence they have the ability to represent a large range of output and input patterns. The

Figure 7 shows the limitations in the range of functions or processes that they can represent in signal-layer feed-forward (SLP) neural network. However, the feed-forward multilayer perceptron (MLP) neural network is selected in this study; because it has a wide range of processes and more powerful representation capacity which can be achieved by using more than one layer, as shown in

Figure 7 .

5. Experiment Setup

In this experimental work, four healthy drill bits were taken and wear was intentionally introduced in three of the drill bits using a grinding machine, leaving one as healthy drill bit. A grinding machine was operated in the speed of 450 rpm to create wear with the levels of 0.2mm, 0.4mm and 0.6mm at the tip of the carbide tool. The wear at carbide insert tips was measured using a microscope.

Figure 8 shows the process of creating wear levels. The work piece used in this experiment is mild steel in which the hole has been made using the healthy tool and wearied tools to collect the vibration data.

In the experimental work, the speed of the drilling condition has been set to 12mm/min feed rate and the rpm of 800. The drill bit has drill diameter of 8 mm, Overall length 92 mm, the angle point is 135. Using accelerometers, vibration data has been collected and analyzed in the life cycle of the drill bit. In this experiment, the direction of sensor is vertical and the wear levels (0.0mm, 0.2mm, 0.4mm and 0.6mm) are changed. vibration signals are captured by data acquisition card from National Instruments (DAQ Card) with Lab VIEW software. The output of the signal conditioning device is directly connected to a PC with a data acquisition card (DAQ card- NI C- DAQ- 9174) and LabVIEW software and this experimental works have been done with 16000 sampling rate. The signal conditioning device used for the signal processing is Type NI – 9234. In this experiment , the work piece and drill bit is fixed at the drilling machine and the distance between the work piece and the drill bit is adjusted with 50 mm. The drill bit with different wear is employed with the work piece and the direction of the accelerometer sensor (coated by aluminum coil for safety) is vertical which was placed on the tool head as shown in the

Figure 9.

In this experiment the vibration signals of the drill bit with different wear conditions (healthy, 0.2mm, 0.4mm and 0.6mm) are captured by the accelerometer sensor to shift and convert these signals from analogue to digital form using a PC with data acquisition card from National Instruments (DAQ Card) and Lab VIEW software.

Figure 10 shows the experiment setup. The signal has been collected with respect to time and frequency in the LabVIEW front panel for further analysis. In each of the drill bit, 20 experiments have been conducted and collected the signals and stored in the database.

Finally, LabVIEW shows the features of the vibration signals in the time domain and frequency domain as shown in

Figure 10(c). For further analysis of vibration signals, MATLAB is used based on Wavelet analysis and ANN for automatic drill bit fault detection and classification.

6. Experimental Results and Discussions

This section presents the results of applying the Continuous Wavelet Transform (CWT) for drill bit with different wear condition. The CWT is used also as features extraction method for generate the inputs feature to ANN. Morlet wavelet (morl) and Daubechies Wavelets (db 10) has been used as a mother wavelet function while obtains the CWT coefficients.

7. Automatic Fault Detection and Classification of Drill Bit Using ANN

Automatic fault detection and classification of drill bit condition using the features of wavelet and Artificial Neural Network (ANN) model is proposed in this project. By using The Artificial Neural Network (ANN) to classify the tool wear conditions the model of ANN is created based on feed-forward Multi-Layer Perceptron (MLP) and Back Propagation. The result features (peak, RMS, crest factor, kurtosis, shape factor and impulse factor) healthy condition and wear condition are feed to ANN to classify the wear condition. The signal consists of 38400 data for each condition (wear & healthy) and then 10 coefficients are taken for each of these wear conditions. To build the ANN model six features are extracted from 10 coefficients for each condition, then the values divided into 30 (5x6) values for training and 30 values (5x6) for testing. Also, the healthy condition is normalized as (0 1) and wear condition as (1 0) for training targets. The ANN model is created using input layer with six nodes (extracted features), two hidden layers consist five nodes for each and output layer as shown in

Figure 14. Back Propagation is applied to minimize the Mean Square Error (MSE) between the ANN outputs and the desired target values.

In this model two stages are applied which are training stage and testing stage. It is trained with 10E-10 training goal (MSE), 0.52044 training rate, with six attribute (features) and the maximum No. of iteration (epochs) of 1000 are selected.

Figure 15 shows the result of training process, in which it reached the desired goal stopping criteria after 27 epochs.

The regression curve for both training targets and the ANN output is shown in

Figure 16, a good correlation between the both can be concluded. The results for ANN classification for tool wear condition shown success rate based on the given six features.

The accuracy of the training process of the neural network is based on (1-L) where L is calculated by keeping the default setting of the loss function in the software [

38]. In the training of testing signal in ANN, the inputs are given based on the collection of signals from accelerometers.

In the classification with ANN with WPT outcome, the following factors was investigated.

- ➢

the maximum frequency of the WPT

- ➢

the number of neurons in the hidden layer

- ➢

the percentage of data used for training the nets

To analyze the effect of the number of neurons in the hidden layer, 5 to 30 neurons with intervals of 5 neurons are given in the ANN.

In the clarification with ANN based on statistics of acceleration data, the following factors was studied.

- ➢

The number of neurons in the hidden layer

- ➢

The number of statistics

- ➢

The percentage of data in training the nets

RMS, Peak, kurtosis of the wear signals are used as input for the ANN which allows better discrimination of the type of faults.

In the outcome of classification based on WPT acceleration signal, the networks built with WPT of 500 Hz or more and 10 or more neurons provide an accuracy of 98% and for less frequency it lies between 95 to 98%. So, it is required to analyze further in future for the less accuracy for lesser frequency.

As far as vertical accelerometer is concerned, classification by statistics are very accurate combination of RMS, peaks and kurtosis and the number of neurons achieved 100% accuracy.

However, detection error may lead to a reduction in efficiency of the machine and it would lead to unnecessary maintenance. The measurement of vibration signal using accelerometer in vertical placement is not so precise, no statistical data achieves an accuracy of 100%. So, finding statistical data and its combination will play an important in achieving 100% results.

Error value while using WPT output may come due to various reasons such as unrecognized faults, mistake in placing the sensors, power fluctuation during data acquisition and less frequency input to ANN. However, the networks with more neurons will perform well perform when trained with largest number of signals.

8. Conclusions

Condition monitoring via vibration signal analysis plays an important role in maintenance management to reduce unscheduled down time and avoid catastrophic accident in industrial sector. To do this an accurate fault detection is important to avoid downtime and loss in terms of cost and productivity [

39,

40]. WPT based signal analysis is one of the proved method in manufacturing industry [

41] which is extended to drill bit condition monitoring in this work. Based on the obtained results the overall conclusion can be summarized as follows:

For more accurate fault detection of the drill bit, An ANN based techniques has been developed, which are wavelet kurtosis factor and the histograms throughout using Morlet wavelet and Daubechies Wavelets as a mother wavelet function (similarity with the extracted fault pulses shape). This technique shows the ability to recognize between the healthy and wear conditions. The wavelet analysis is selected for drill bit vibration signal features extraction. The advantage of wavelet analysis is proven as a multi resolution, scaling and shifting of the wavelet through the vibrational signal. For high performance of the extracted wavelet features; the features are normalized between 0 and 1 in order to be the inputs in ANN. The ANN model based on supervised learning capability of Multi-Layer Perceptron (MLP) and Back Propagation has shown effectiveness to be as automatic drill bit fault detection and classification, as proven that the training process has been reached the desired goal stopping criteria after 27 epochs. And the ANN performance is shown as 98% success rate.

So, neural networks are effective tools and the results they provide depend heavily on dataset used to create them and the choices for their parameters. The data must be collected reliably and accurately to eliminate noise and errors and to extract the perfect features. The network must then be created and trained. The better result will be obtained when width of the spectrum increased [

42].

This research is having high significance to academic and scientific community and it will open a path for the implementation of Industrial 4.0 technologies in manufacturing and process industries to obtain high accuracy products, maintain reliability in machines and machining processes, reduce the down time and scrap, reduce the risk during the operations etc. So, this project has been proved the successful correlation between the wavelet transform (WT) and the drill bit wear condition using ANN based on the obtained results.

Author Contributions

Conceptualization, R.A. and K.V.; Literature collection, R.A. and K.V.; Formal analysis, R.A. and K.V.; Funding acquisition, R.A., K.V. and KPR ; Investigation, R.A and K.V ; Methodology, R.A., KPR and K.V.; Validation, R.A. and K.V.; Writing—original draft, R.A.; Review and editing, R.A., KPR and K.V. All authors have read and agreed to the published version of the manuscript

Funding

This work was performed as part of the research work titled” Deep learning based real time drill condition monitoring using acoustic emission sensor” funded by MOHERI, OMAN, grant number BFP/RGP/EI/22/433

Institutional Review Board Statement

This study was conducted according to the guidelines of the National University of science and Technology, Oman.

Data Availability Statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author/s.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Maamar Ali Saud AL Tobi, Ramachandran.KP., Saleh AL-Araimi., Rene Pacturan., Amuthakannan Rajakannu., Chetha Achuthan: Machinery Faults Diagnosis using Support Vector Machine (SVM) and Naïve Bayes classifiers; International Journal of Engineering Trends and Technology;70(12);PP26-34;(2022).

- Deshpande, Akhil & Kulkarni, Vinayak & Patil, Vinayak. (2017). Experimental Comparison of Bearing Vibration Amplitudes Obtained using MATLAB and LabVIEW Software for Developing a Condition Monitoring System. IAETSD Journal for Advanced Research in Applied Sciences. 4. 138-145.

- Kuntoğlu, M.; Aslan, A.; Pimenov, D.Y.; Usca, Ü.A.; Salur, E.; Gupta, M.K.; Mikolajczyk, T.; Giasin, K.; Kapłonek, W.; Sharma, S. A Review of Indirect Tool Condition Monitoring Systems and Decision-Making Methods in Turning: Critical Analysis and Trends. Sensors 2020, 21, 108. [Google Scholar] [CrossRef]

- Qiao Sun, Ying Tang, Wei Yang Lu and Yuan Ji (2005): Feature Extraction with Discrete Wavelet Transform for Drill Wear Monitoring, Journal of Vibration and Control, vol. 11, pp. 1375–1396.

- Waleed Abdulkarem, Rajakannu Amuthakkannan, Khalid F Al-Raheem: Centrifugal pump impeller crack detection using vibration analysis. In: 2nd International Conference on Research in Science, Engineering and Technology, pp206-211, (2014).

- Yasir Hassan Ali,: Artiicial Intelligence Application in Machine Condition Monitoring and Fault ; Artificial Intelligence - Emerging Trends and Applications,Chapter: 14; 275-291,(2018).

- Lior kitain, (2018): Condition Monitoring in the Oil and Gas Industry, Article: Available at: https://medium.com/@lior.kitain/condition-monitoring-in-the-oil-and-gas-industry-991805ea9335.

- Tiboni, M.; Remino, C. Condition Monitoring of Pneumatic Drive Systems Based on the AI Method Feed-Forward Backpropagation Neural Network. Sensors 2024, 24, 1783. [Google Scholar] [CrossRef] [PubMed]

-

Miho Klaic , Tomislav Staroveski, Toma Udiljak;, Tool Wear Classification using Decision Treesin Stone Drilling Applications: a Preliminary Study , 24th DAAAM International Symposium on Intelligent Manufacturing and Automation, 2013, Procedia Engineering, 69(2014), 1326-1336, Elsevier, Scence Direct; (2014).

- Rui Zhao, Ruqiang Yan, Zhenghua Chen, Kezhi Mao, Peng Wang, and Robert X. Gao, Deep Learning and Its Applications to Machine Health Monitoring: A Survey IEEE Transactions on Neural Networks and Learning Systems vol. 14, no. 8, august 2015; (2015).

- Krishnakumar, P.; Rameshkumar, K.; Ramachandran, K. Machine learning based tool condition classification using acoustic emission and vibration data in high speed milling process using wavelet features. Intell. Decis. Technol. 2018, 12, 265–282. [Google Scholar] [CrossRef]

- Shi, Y.; Liu, H.; Zhang, X.; Li, Q.; Guo, X. Wear Identification of Vibration Drilling Bit Based on Improved LMD and BP Neural Network. Math. Probl. Eng. 2020, 2020, 1–9. [Google Scholar] [CrossRef]

- Lang Dai,Tianyu Liu,Zhongyong Liu,Lisa Jackson,Paul Goodall,Changqing Shen,and Lei Mao ;An Improved Deep Learning Model for Online Tool Condition Monitoring Using Output Power Signals, Journal of Shock and Vibration, Hindawi , Volume 2020, Article ID 8843314, 12 pages, Available from : https://doi.org/10.1155/ 2020/8843314; ( 2020).

- Wang, Q.; Wang, H.; Hou, L.; Yi, S. Overview of Tool Wear Monitoring Methods Based on Convolutional Neural Network. Appl. Sci. 2021, 11, 12041. [Google Scholar] [CrossRef]

- Chacón, F.; Luis, J.; de Barrena, F.; Telmo, G.A. A Novel Machine Learning-Based Methodology for Tool Wear Prediction Using Acoustic Emission Signals. Sensors, Vol. 21, 5984; (2021).

- Kolar, P.; Burian, D.; Fojtu, P.; Masek, P.; Fiala, S.; Chladek, S.; Petracek, P.; Sveda, J.; Rytir, M. Indirect drill condition monitoring based on machine tool control system data. MM Sci. J. 2022, 2022, 5905–5912. [Google Scholar] [CrossRef]

- Reeber, T.; Henninger, J.; Weingarz, N.; Simon, P.M.; Berndt, M.; Glatt, M.; Kirsch, B.; Eisseler, R.; Aurich, J.C.; Möhring, H.-. .C. Tool condition monitoring in drilling processes using anomaly detection approaches based on control internal data. Procedia CIRP 2024, 121, 216–221. [Google Scholar] [CrossRef]

- Netzer, M.; Palenga, Y.; Fleischer, J. Machine tool process monitoring by segmented timeseries anomaly detection using subprocess-specific thresholds. Prod. Eng. 2022, 16, 597–606. [Google Scholar] [CrossRef]

- Sun, S.; Liu, Y.; Hu, X.; Zhang, W. A semisupervised autoencoder-based method for anomaly detection in cutting tools. J. Manuf. Process. 2023, 93, 315–327. [Google Scholar] [CrossRef]

- Ahmed, I.; Ahmad, M.; Chehri, A.; Jeon, G. A Smart-Anomaly-Detection System for Industrial Machines Based on Feature Autoencoder and Deep Learning. Micromachines 2023, 14, 154. [Google Scholar] [CrossRef]

- Li, G.; Fu, Y.; Chen, D.; Shi, L.; Zhou, J. Deep Anomaly Detection for CNC Machine Cutting Tool Using Spindle Current Signals. Sensors 2020, 20, 4896. [Google Scholar] [CrossRef]

- Von Hahn, T.; Mechefske, C.K. Self-supervised learning for tool wear monitoring with a disentangled-variational-autoencoder. Int. J. Hydromechatronics 2021, 1. [Google Scholar] [CrossRef]

- Karri, V. , Kiatcharoenpol, T. Tool Condition Monitoring in Drilling Using Artificial Neural Networks. In: Gedeon, T.(.D., Fung, L.C.C. (eds) AI 2003: Advances in Artificial Intelligence. AI 2003. Lecture Notes in Computer Science, 2003. Springer, Berlin, Heidelberg. [CrossRef]

- Ramakrishnan, S (2024) Introductory Chapter: Wavelet Theory and Modern Applications. Modern Applications of Wavelet Transform. IntechOpen. Available at:. [CrossRef]

- Bruno Torrésani, Priezzhev, V.B and Spiridonov, V.P. (1998) An Overview of Wavelet Analysis and Time-Frequency Analysis (a minicourse). International Workshop on Self-Similar Systems, Jul 1998, Dubna, Russia. pp.9-34. ffhal-01305494f.

- Siyam Sakhuja, 2024, Limitations of Fourier Transform and the role of Wavelet Transform, Available at: https://sakhujasaiyam.medium.com/disadvantages-of-fourier-transform-and-the-role-of-wavelet-transform-a4218d8cc6de#:~:text=In%20addition%20to%20the%20 inability,non%2Dstationary%20or%20transient%20behavior.

- Al Tobi, M.A.S.; P, R.K.; Al-Araimi, S.; Pacturan, R.; Rajakannu, A.; Achuthan, G. Maamar Ali Saud Al Tobi, Ramachandran K P, Saleh Al-Araimi, Rene Pacturan, Amuthakkannan Rajakannu, Geetha Achuthan: Machinery Fault Diagnosis using Continuous Wavelet Transform and Artificial Intelligence based classification; In: Proceedings of the 2022 3rd International Conference on Robotics Systems and Vehicle Technology July 2022; pp 51–59; https://doi.org/10.1145/3560453.3560463.

- Wang, Y.; Xiang, J.; Markert, R.; Liang, M. Spectral kurtosis for fault detection, diagnosis and prognostics of rotating machines: A review with applications. Mech. Syst. Signal Process. 2016, 66-67, 679–698. [Google Scholar] [CrossRef]

- Green, J. L. , Manski, S. E., Hansen, T. A., & Broatch, J. E. Descriptive statistics. In International Encyclopedia of Education, 4th ed,; Tierney, R.J., Rizvi, F., Ercikan, K.; Elsevier, 2023, pp.723-733. ISBN 9780128186299.

- Amuthakkannan,R Ramachandran, KP. And Vijayalakshmi, K 2024 Application of Artificial Intelligence in condition monitoring for oil and gas industries Approach, International Conference on Advanced Technology (ICAT-2024), National University of Science and Technology, Muscat, Oman, Apr 29-May 01 , p.144.

- Ali YH (2018) Artificial Intelligence Application in Machine Condition Monitoring and Fault Diagnosis. Artificial Intelligence - Emerging Trends and Applications. InTech. Available at:. [CrossRef]

- Marticorena, M. , Babaglio, D., Vaucheret, S., Mayer, R.I., Garrett,M., Vignolo,J., Peyrano, O.G. RA-6 research reactor Automatic Condition Monitoring System – Applications for predictive maintenance, International Conference on Research Reactors: Addressing Challenges and Opportunities to Ensure Effectiveness and Sustainability,Buenos Aires, Argentina, IAEA/CN-277/P.2.09.

- Zhou, Y.; Zhi, G.; Chen, W.; Qian, Q.; He, D.; Sun, B.; Sun, W. A new tool wear condition monitoring method based on deep learning under small samples. Measurement 2021, 189, 110622. [Google Scholar] [CrossRef]

- Surucu, O.; Gadsden, S.A.; Yawney, J. Condition Monitoring using Machine Learning: A Review of Theory, Applications, and Recent Advances. Expert Syst. Appl. 2023, 221. [Google Scholar] [CrossRef]

- R. R. Srikant, P. R. R. Srikant, P. Vamsi Krishna and N. D. Rao (2011): Online tool wear prediction in wet machining using modified back propagation neural network, Journal of Engineering Manufacture, Part B, vol.225, pp.1009- 1018.

- Issam Abu-Mahfouz (2003): Drilling wear detection and classification using vibration signals and artificial neural network, International Journal of Machine Tools & Manufacture, vol. 43, pp. 707–720.

- Camuñas-Mesa, L.A.; Linares-Barranco, B.; Serrano-Gotarredona, T. Neuromorphic Spiking Neural Networks and Their Memristor-CMOS Hardware Implementations. Materials 2019, 12, 2745. [Google Scholar] [CrossRef]

- Tiboni, M.; Remino, C.; Bussola, R.; Amici, C. A Review on Vibration-Based Condition Monitoring of Rotating Machinery. Appl. Sci. 2022, 12, 972. [Google Scholar] [CrossRef]

- Andrade, A.; Lopes, K.; Lima, B.; Maitelli, A. Development of a Methodology Using Artificial Neural Network in the Detection and Diagnosis of Faults for Pneumatic Control Valves. Sensors 2021, 21, 853. [Google Scholar] [CrossRef]

- Wang, H.; Sun, W.; Sun, W.; Ren, Y.; Zhou, Y.; Qian, Q.; Kumar, A. A novel tool condition monitoring based on Gramian angular field and comparative learning. Int. J. Hydromechatronics 2023, 6, 93–107. [Google Scholar] [CrossRef]

- Sharma, S.; Tiwari, S.K.; Singh, S. Diagnosis of gear tooth fault in a bevel gearbox using discrete wavelet transform and autoregressive modeling. Life Cycle Reliab. Saf. Eng. 2018, 8, 21–32. [Google Scholar] [CrossRef]

- Kumar, A.; Gandhi, C.; Tang, H.; Sun, W.; Xiang, J. Latest innovations in the field of condition-based maintenance of rotatory machinery: a review. Meas. Sci. Technol. 2023, 35, 022003. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).