1. Introduction

Asphalt pavement distress and failures mainly originate from cracks, like fatigue cracks [

1,

2]. Fatigue cracks mainly occur and proliferate in asphalt mixtures through the asphalt binder phase, resulting from cyclic traffic loading and seasonal weather changes [

3]. Hence, the bitumen fatigue cracking performance significantly affects the asphalt mixture and pavement fatigue cracking responses [

4,

5,

6].

One way to mitigate cracking occurrence is to study, understand, and promote the self-healing properties of asphalt pavements throughout their bitumen. This topic is attracting more and more attention from scholars [

7]. Linear amplitude sweep (LAS) test (AASHTO TP 101) and simplified viscoelastic continuum damage (S-VECD) theory are effective and efficient tools to evaluate bitumen fatigue cracking and self-healing performances [

8]. After conducting the LAS test and obtaining the corresponding results, the S-VECD method processes those data for evaluating and predicting the fatigue performance (including self-healing activity) of asphalt binder [

9,

10,

11].

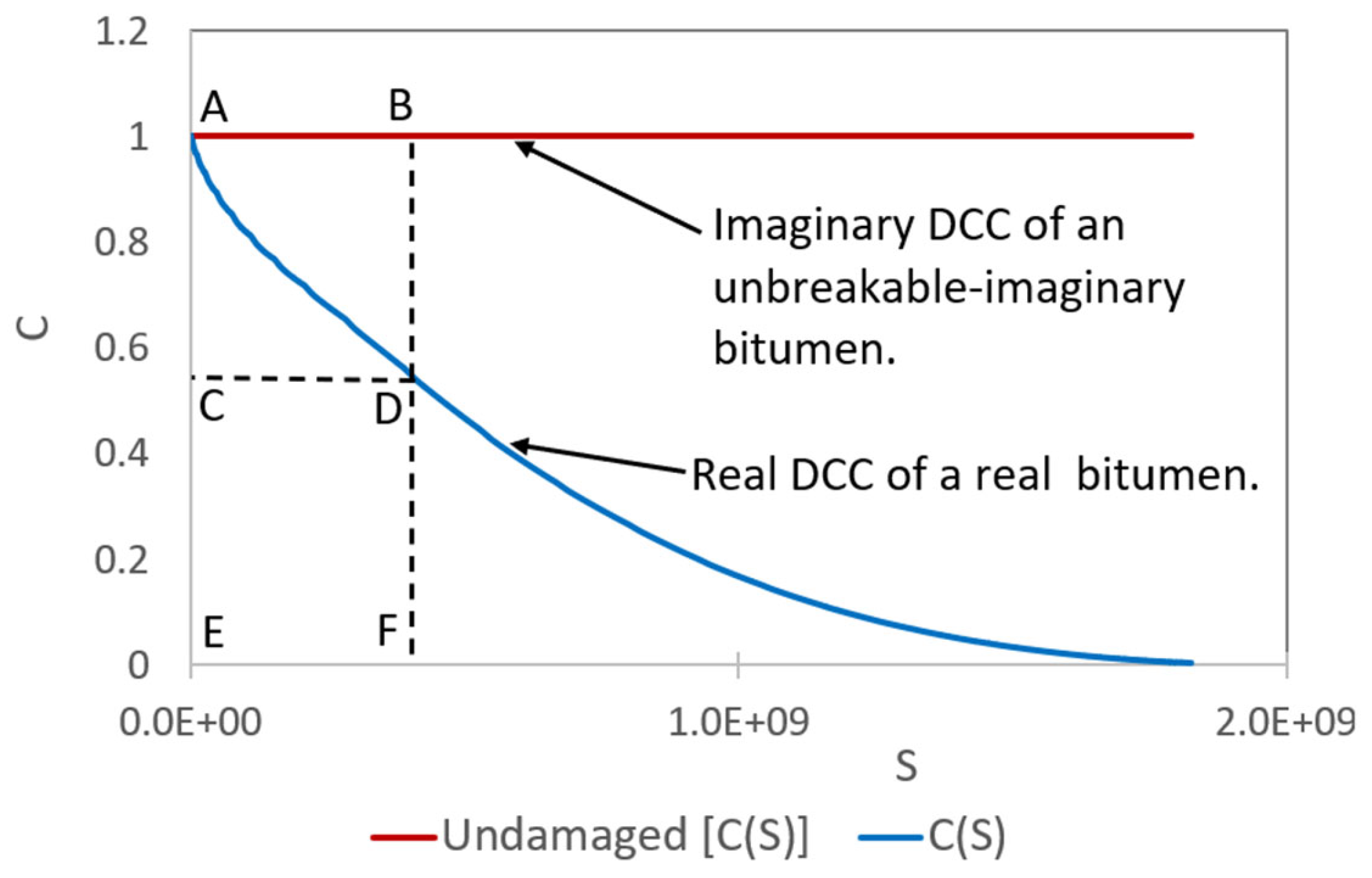

Subsequently, the material integrity (C) and S values can be determined. The former is also known as pseudo-stiffness and normalized dynamic shear modulus; the latter represents the material internal state variable resulting from applying the damage evolution of Schapery’s work potential theory (see equation 1). Then, the damage characteristic curve (DCC) can be plotted in a C vs. S graph [

12,

13].

Where , , and are damage evolution rate, reduced time, and pseudo-strain energy, respectively.

Numerous studies have assessed the self-healing capacities of neat asphalt binders (NA) and polymer-modified bitumens (PMBs). Xie et al. [

14] evaluated the self-healing capabilities of NA and SBSB by utilizing LAS, LASH, and S-VECD methods. This research team introduced the percent healing (%Hs) parameter and the rest-damage superposition principle to build the %Hs mastercurve. This study found a superior %Hs in NA than in SBSB. Wang et al. [

15] appraised the NA and SBSB self-healing performances after short- and long-term aging processes by using LASH, VECD, and %Hs mastercurve. Besides, this research work correlated the bitumen composition with self-healing behavior. This study identified two factors that diminished bitumen self-healing activity: the aging process and SBS. However, light fractions, small molecules, and longer molecules augmented the bitumen’s self-healing performance.

Wang et al. [

8] assessed the self-healing activity of NA and SBSB by conducting LASH, VECD, and microstructures tests. Researchers found that a superior number of saturates/aromatic fractions and small molecules promoted the bitumen self-healing behaviour. SBSB and NA exhibited similar self-healing activity, which is not in line with the findings of Xie et al. [

14] and Wang et al. [

15]. Aurilio [

16] and Aurilio and Baaj [

17] analyzed the performances of self-healing polymer(SP)-modified bitumen (SPB) and SBSB by utilizing LASH, a simplified LASH (SLASH), and S-VECD methods. Researchers found that the elastomeric properties of bitumen improved by adding the SP, but this material could not promote the self-healing capability in the asphalt binder. Besides, SBS stimulated the crack healing activity in the bitumen, which is in the opposite direction of findings in Xie et al. [

14] and Wang et al. [

15].

Aurilio et al. [

18] assessed the performances of chemical warm mix additive-modified bitumen (WMAB) and NA by utilizing SLASH and S-VECD methods. This study found that aged NA exhibited superior self-healing behavior than aged WMAB. Almutairi and Baaj [

19] appraised the behavior of NA, SBSB, glass powder (GP)-modified bitumen (GPB), GP- and phase-change material(GPCM)-modified bitumen (GPCMB) by conducting LASH and S-VECD methods. This study found that GPCM maintained similar and improved self-healing capacity of base asphalt when 5 and 30 minutes of RP were applied, respectively. Besides, GP increased and reduced the self-healing performance of NA and SBSB, respectively.

Lv et al. [

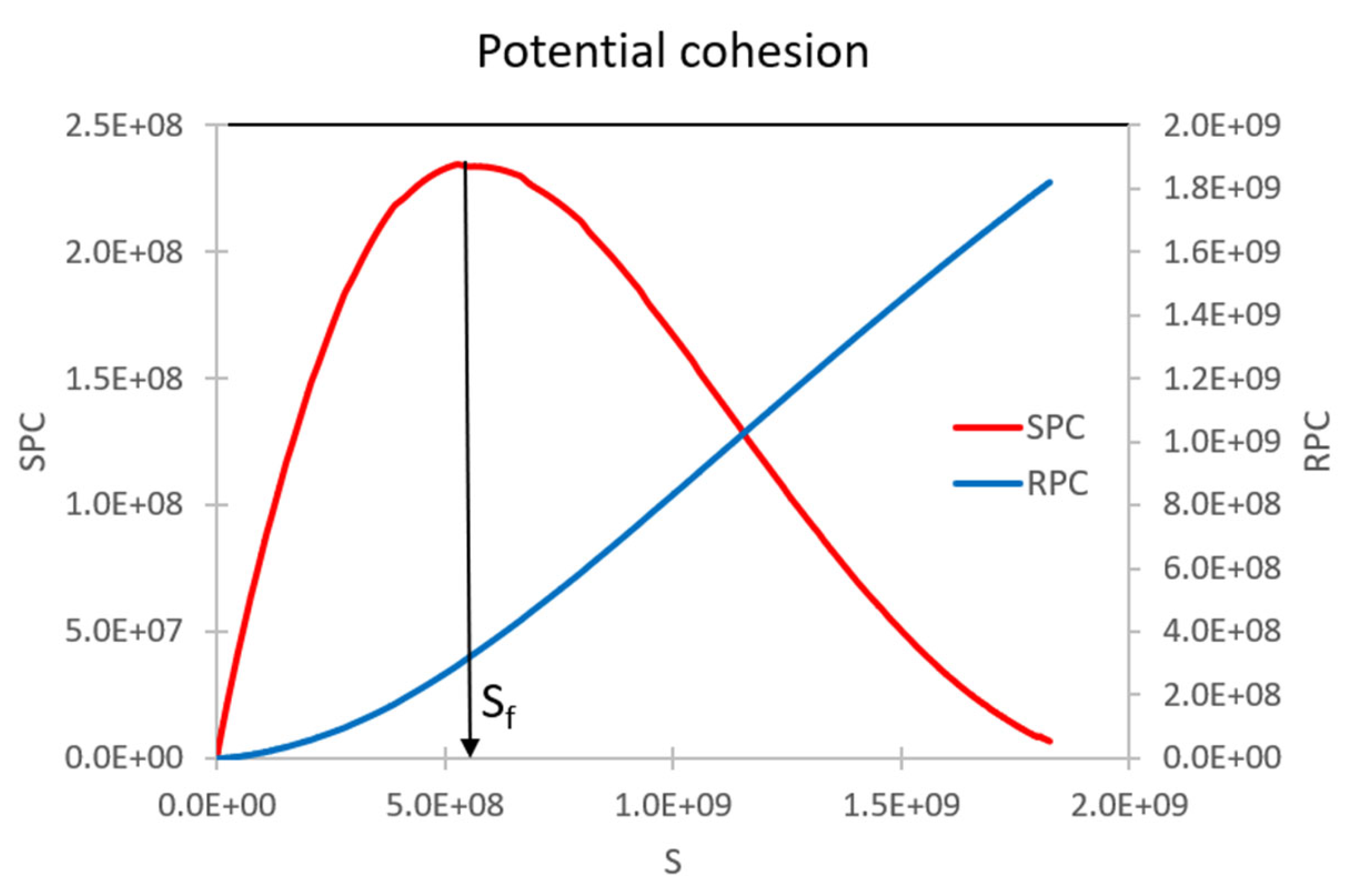

20] analyzed the self-healing performances of NA and STPB. This study utilized LASH and S-VECD in the testing process. Researchers found that STPU promoted the self-healing performance of base asphalt. Another finding was that the current framework could not fully accommodate the self-healing behavior of asphalt binders. As a result, a new procedure was proposed considering the area below the DCC.

All previous research works on bitumen self-healing analysis utilized the peak of stored pseudo-strain energy (PSE) to define the bitumen fatigue life (N

f). This concept identifies the needed number of loading cycles (N) to reach the bitumen failure point. However, Lv et al. [

20] and Wang et al. [

9] proved the existence of ranking inconsistency between bitumen fatigue life and DCC analysis in terms of asphalt binder fatigue performance. Hence, those studies reached conclusions based on a concept with inadequacy issues. As a result, Lv et al. [

21] introduced a new framework based on S instead of N to overcome the inconsistency mentioned above. Nonetheless, the effectiveness of this new framework in assessing the bitumen self-healing performance has yet to be verified.

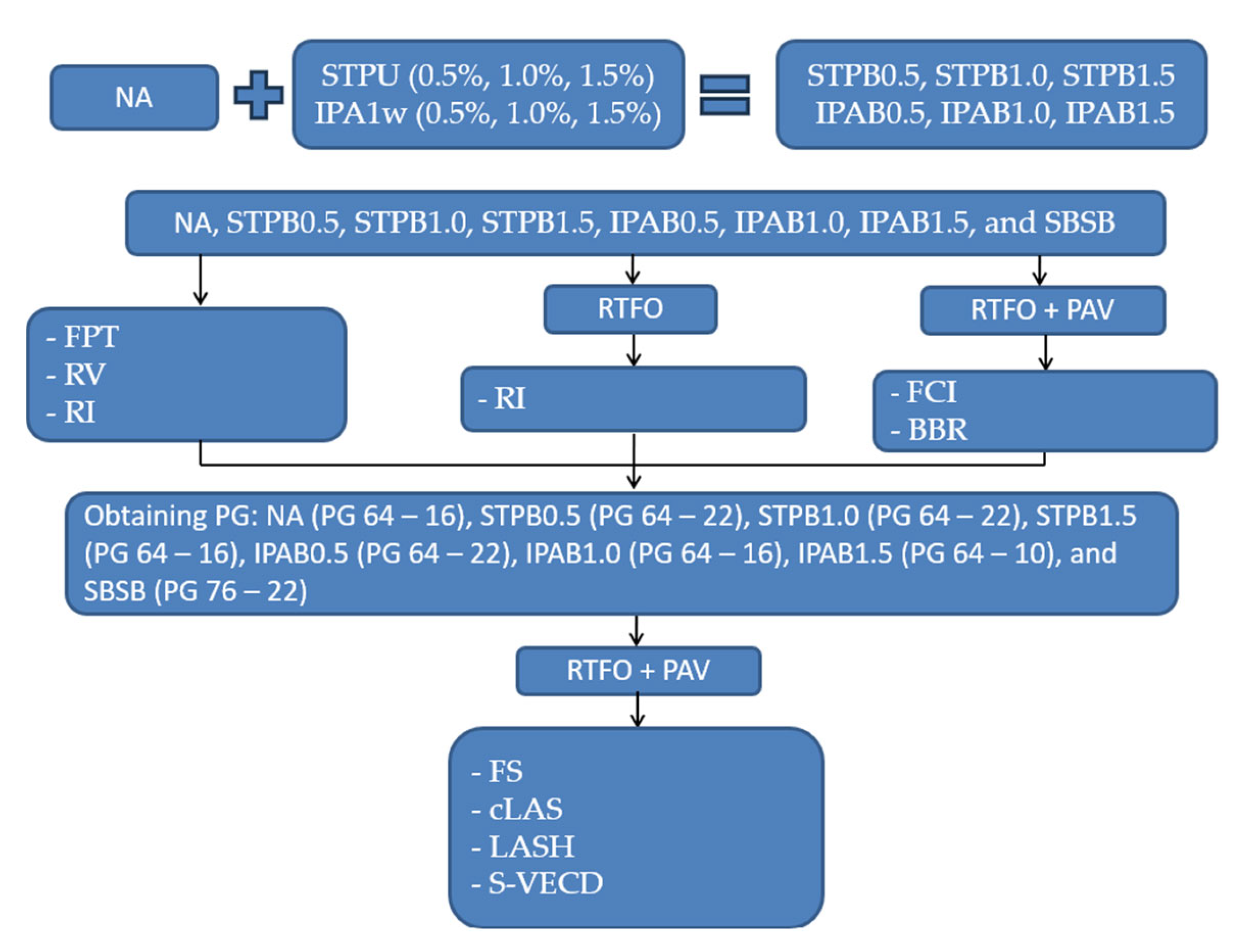

Hence, this study combines the new procedures from Lv et al. [

20] and Lv et al. [

21] to propose a composite process to comprehensively analyze the self-healing performance of NA, SPBs, and SBSB. Besides, the efficiency of the new method will be verified. This research work will introduce new parameters to assess and analyze the self-healing behavior of NA, SPBs, and SBSB. The new composite process will also verify the STPU and IPA1w capacities to promote the self-healing activity in the base asphalt.

4. Discussion

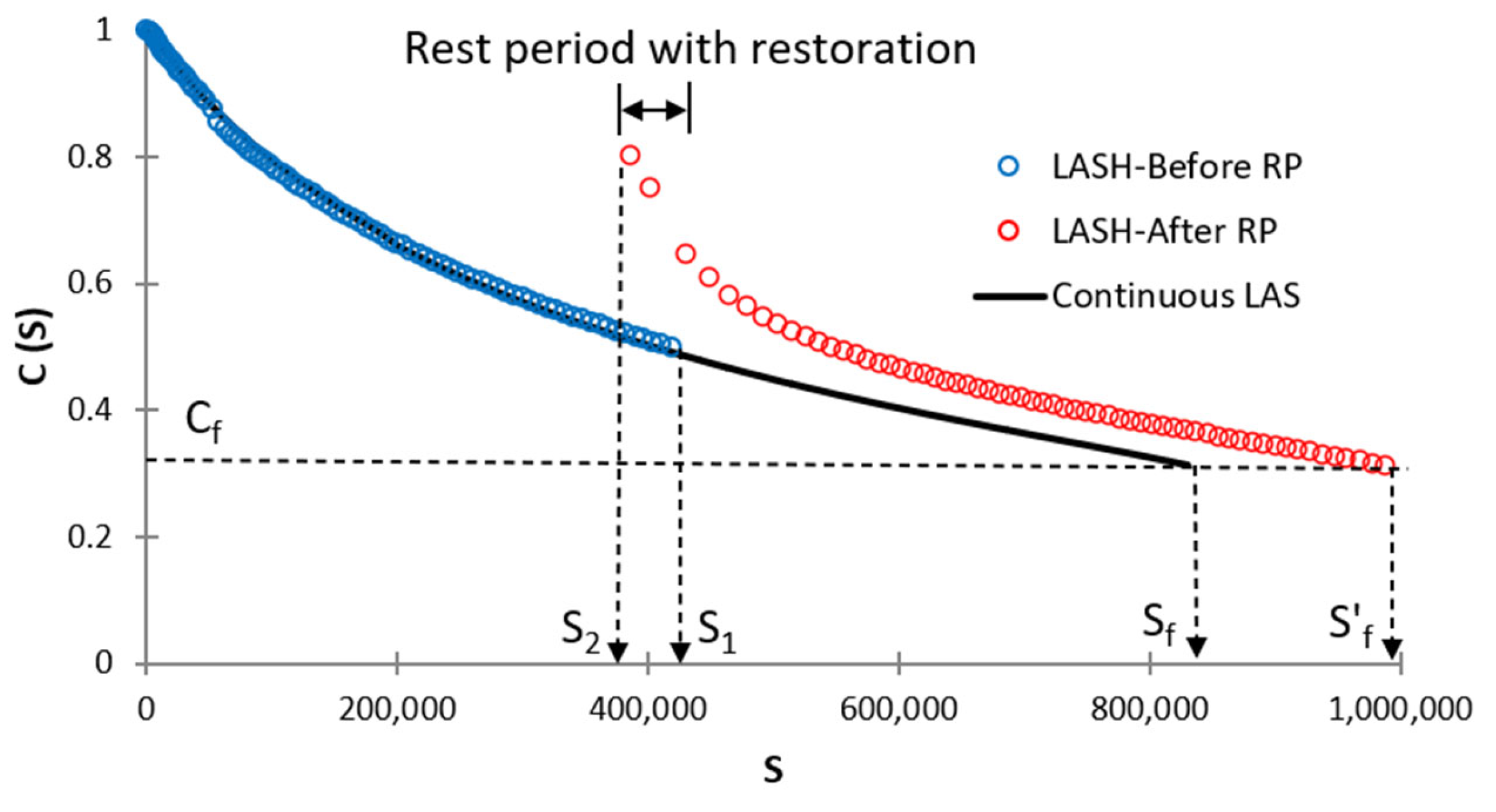

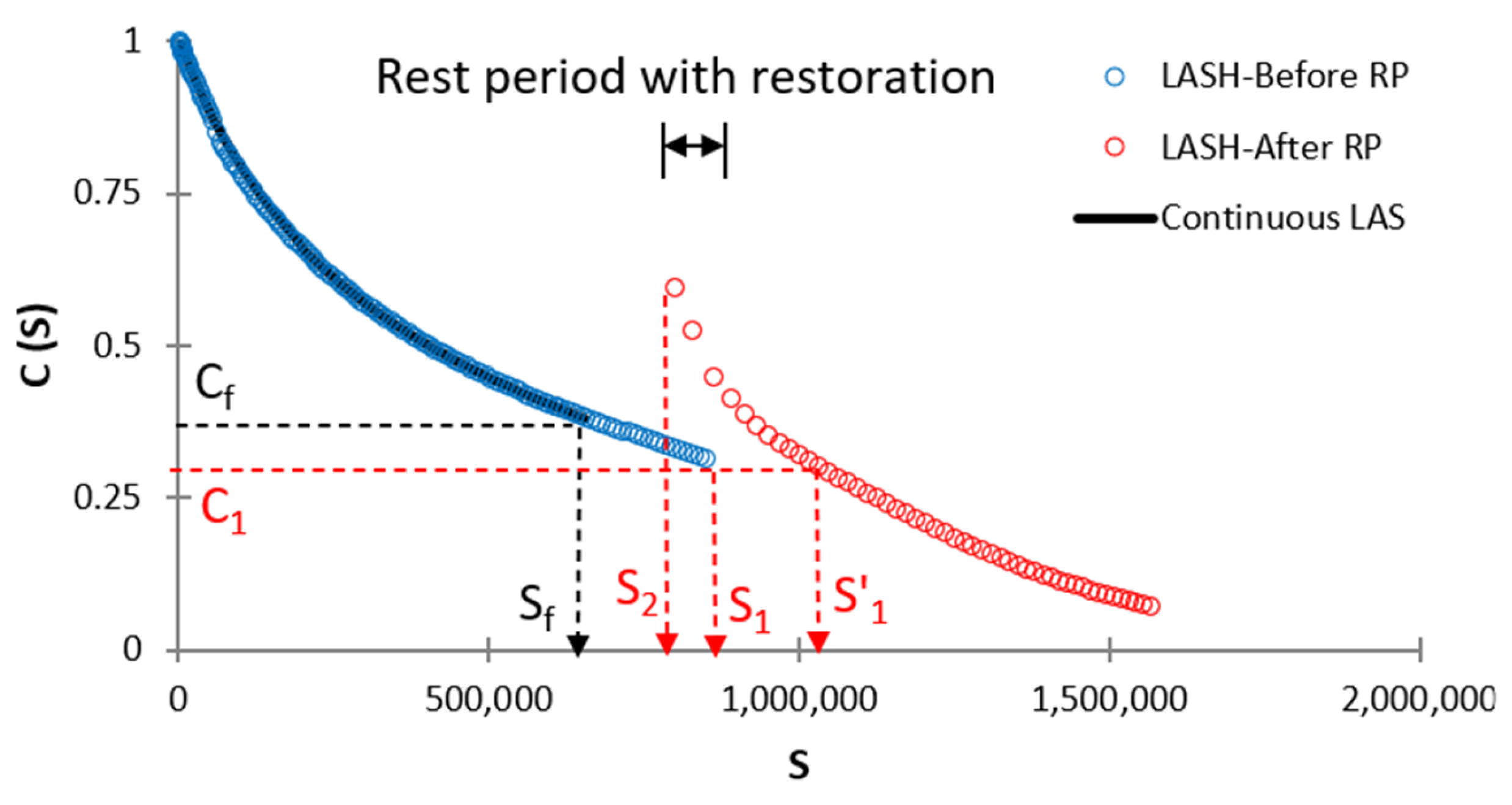

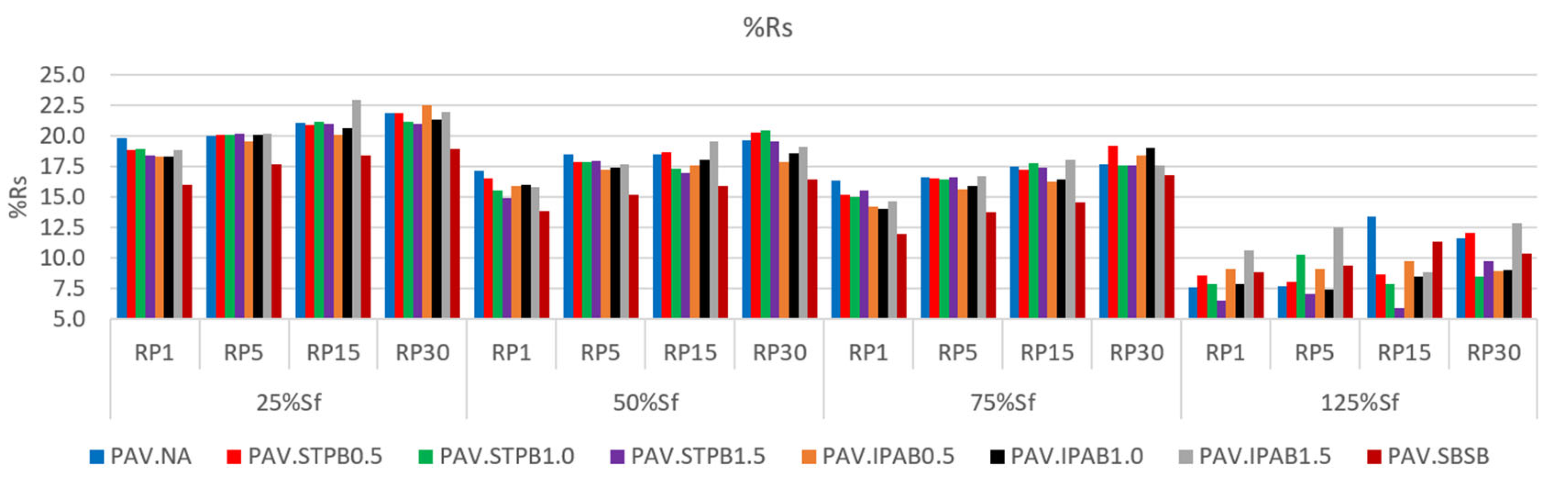

This research team considers that the %R

s proposed by Aurilio et al. [

18] has a limited view on asphalt binder fatigue performance because it only evaluates the bitumen behaviour at one specific point of DCC (during RP). As a result, this parameter cannot assess the performance of the bituminous materials before and after the RP. However, these two phases of the LASH test have a decisive influence on the bitumen’s final response. For instance, Xie et al. [

14] reported that in some cases, the DCCs linked with the LASH test, after the RP, collapsed with respect to the corresponding DCC related to the cLAS test. This fact means that the quality of the restoration process needed to be higher to ensure a superior fatigue performance of the asphalt binder after the RP and the %R

s parameter fails to assess the occurrence of this phenomenon.

“Supplementary materials” include Figures S6, S7, S8, S9, S10, S11, S12, and S13. These figures represent the DCCs of LASH at different RPs and DLs linked with PAV.NA, PAV.STPB0.5, PAV.STPB1.0, PAV.STPB1.5, PAV.IPAB0.5, PAV.IPAB1.0, PAV.IPAB1.5, and PAV.SBSB, respectively. These figures comprise the DCC associated with the cLAS test as a reference curve. This study also reports in the “Supplementary materials” some DCCs (linked with the LASH test) that slightly collapse concerning the corresponding DCC (associated with cLAS). The cases are as follows:

Figure S6 (a) PAV.NA (RP1 and 25%Sf), PAV.NA (RP1 and 125%Sf), (b) PAV.NA (RP5 and 25%Sf), PAV.NA (RP5 and 125%Sf);

Figure S7 (b) PAV.STPB0.5 (RP5 and 125%Sf), (c) PAV.STPB0.5 (RP15 and 125%Sf);

Figure S8 (a) PAV.STPB1.0 (RP1 and 25%Sf), PAV.STPB1.0 (RP1 and 125%Sf), (b) PAV.STPB1.0 (RP5 and 125%Sf), (c) PAV.STPB1.0 (RP15 and 125%Sf), (d) PAV.STPB1.0 (RP15 and 125%Sf);

Figure S9 (a) PAV.STPB1.5 (RP1 and 125%Sf), (b) PAV.STPB1.5 (RP5 and 125%Sf), (c) PAV.STPB1.5 (RP15 and 125%Sf);

Figure S10 (a) PAV.IPAB0.5 (RP1 and 25%Sf) and PAV.IPAB0.5 (RP1 and 50%Sf);

Figure S11 (a) PAV.IPAB1.0 (RP1 and 25%Sf), (b) PAV.IPAB1.0 (RP5 and 25%Sf) and PAV.IPAB1.0 (RP5 and 125%Sf), (d) PAV.IPAB1.0 (RP30 and 75%Sf);

Figure S12 (c) PAV.IPAB1.5 (RP15 and 125%Sf)

Hence, when conducting the LASH test at different RPs and DLs, the tendency of %R

s values fails to reflect the actual fatigue behaviour of asphalt binders during this test. This fact explains why bitumens with higher %R

s in

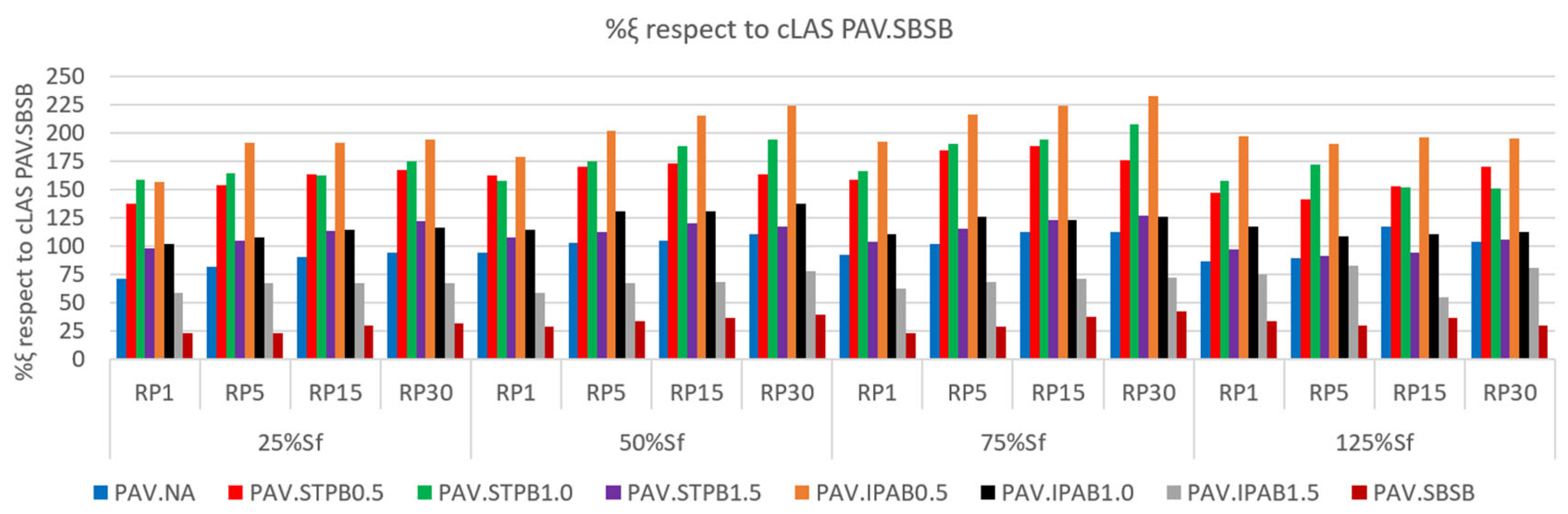

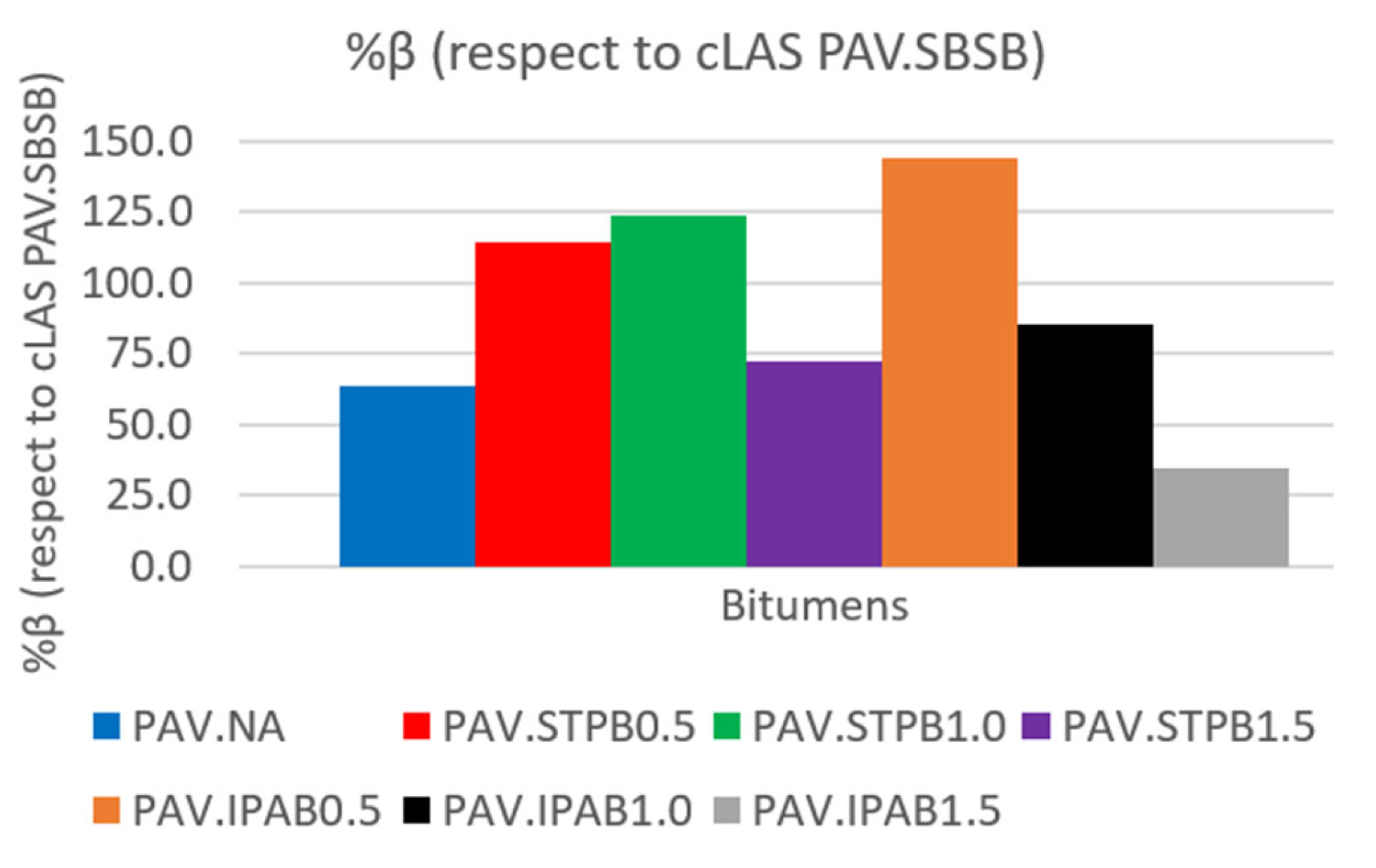

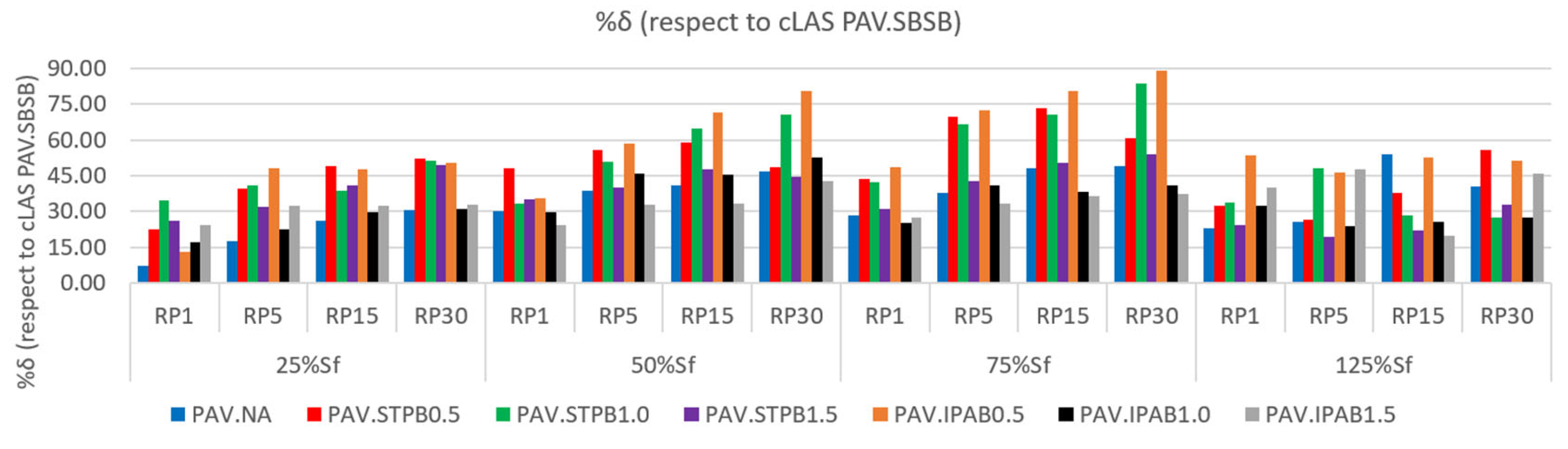

Figure 6 differ from asphalt binders with superior fatigue performance in Figures S1, S2, S3, and S4. As a result, the %Rs parameter is no longer convenient to evaluate the bitumen performance. In contrast, the %ξ can evaluate the bituminous material response before, during, and after the RP when carrying out the LASH test at diverse RPs and DLs because this parameter evaluates the area below the DCC up to the point of interest. As %ξ assesses the influence of adding polymer into NA, RPs, and DLs on bitumen fatigue response, at the same time, this research work introduced %β and %δ. The former parameter only evaluates the effect of mixing polymer and NA on the fatigue performance of the base asphalt binder. The latter appraises the influence of DLs and RPs on bitumen fatigue response, as explained before. This research team wants to clarify that %ξ, %β, and %δ parameters represent an integral view of the DCC that shows the total (from the starting point of the LASH test to the point of interest) and actual fatigue performance of the testing asphalt binders. Depending on which factors (adding polymer into NA, RPs, and DLs) the researchers want to evaluate.

In the section “3.1. Analysis of %R

s and %ξ (respect to cLAS of PAV.SBSB) values”,

Figure 7 shows that %ξ generally increases when RP and DL increase. This fact means bituminous materials in this study commonly improve their fatigue performance, considering all factors (addition of polymer into NA, RP, DL), while reaching closer to the failure point. This phenomenon represents a breakthrough finding because, until now, research works have found that applying the RP at higher DL (before the failure point) reduces bitumen fatigue response. For instance, Wang et al. [

40] and Wang et al. [

41]. Studying and fully understanding the self-restoration phenomenon in bituminous materials is crucial to fully understanding and modeling the fatigue response of asphalt pavement materials [

40]. As a result, the explanation of the possible reason for the phenomenon found in

Figure 7 is as follows:

The dissipative viscoelastic activity of bitumen can cause a temperature increment of this material while being subjected to loading cycles (cLAS or LASH test). This process causes the internal temperature in asphalt binder specimens to rise over the actual existing ambient temperature. Then, the asphalt binder cools back to its original temperature when the load is removed [

42]. The temperature change causes the variation of dynamic shear modulus [

43]. This phenomenon is named “self-cooling” [

44]. Thixotropy is an asphalt binder intrinsic property that diminishes its dynamic shear modulus during the loading phase because of microstructure breakdown and recovers its dynamic shear modulus when eliminating the load because of the building-up of microstructure [

43]. The evolution of asphalt material thixotropy highly depends on temperature augmentation. As a result, bitumen viscosity also influences on this phenomenon [

45]. Moreover, the temperature increment promotes the healing activity [

46], and this phenomenon represents the fracture crack reduction and effective area growth (which is an uncracked area) [

43].

As a result, this research team believes that by applying the RP at a higher DL (before the failure point), the asphalt binder will reach a higher internal temperature because of the phenomena mentioned above when applying loading cycles. If the asphalt binder reaches a superior internal temperature, its dynamic shear modulus and viscosity decrease. According to the explanation, this scenario creates the condition to promote thixotropy and self-healing processes during the RP. Hence, the material will have a superior opportunity to recover its original stage, dynamic shear modulus, and strength capacity, even though the bituminous material has a higher DL. This research team believes the asphalt binder follows the process described above while applying the RP before the failure point. Because the S values are not high enough to prevent the bitumen from recovering its original or at least a certain percentage of its original stage.

This explanation could explain why the %ξ increment occurs while the DL increases (before the failure point). However, more experiments are needed to understand this phenomenon fully. Furthermore, this research team recommends analyzing the whole DCC (up to the point of interest) instead of one specific point to precisely assess the bitumen fatigue performance. The finding from

Figure 7 agrees with the study by Lv et al. [

20].

The ranking analysis of the bitumen performance is also essential to decide which material should be used depending on the project characteristics.

Table 8 illustrates the final rankings after evaluating the results related to %ξ, %β, and %δ. When comparing the %β final rankings concerning those of %ξ (removing the influence of RPs and DLs on bitumen fatigue response), this research team confirms that the final rankings are the same. This finding does not mean that RP and DL do not influence asphalt binder performance because when these parameters change in

Table 5, the ranking positions of the asphalt binders change. Hence, RP and DL influence bitumen response, but this effect is not high enough to change the final rankings, according to %β and %ξ assessment. Besides, the final rankings differ when comparing %δ results regarding those of %ξ (deleting the effect of adding polymers). This finding proves that the influence of adding polymers into NA is high enough to change the final rankings, according to %δ and %ξ data evaluation, as mentioned before.

Consistent with the findings in the previous paragraph, this research team can confirm that adding polymer into NA has more influence on bitumen fatigue performance than the RP and DL (S value), according to %ξ, %β, and %δ evaluation. Even though previous research works have highlighted the importance of both parameters. For instance, Pérez-Jiménez et al. [

47] confirmed the strong influence of RP on the fatigue performance of asphalt binders; Motamedi et al. [

48] reported that S values have a considerable effect on bitumen fatigue life.

Future research works of this team will focus on a better understanding of the fatigue phenomenon related to %ξ, %β, and %δ parameters. Future studies will also include the design of asphalt mixtures with SPBs and assessing the relationship between fatigue performance and the microstructure of asphalt binders. Moreover, the findings related to %ξ, %β, and %δ parameters can change the factors to consider the convenient bitumen for one specific project and the criteria for evaluating the bitumen fatigue response.

Author Contributions

Conceptualization, S.L., D.G. and M.B.C.; methodology, M.B.C.; software, M.B.C., validation, M.B.C., formal analysis, M.B.C.; investigation, S.C., D.L. and W.Z.; resources, S.L., D.G., C.-H.L. and M.B.C.; data curation, M.B.C.; writing—original draft preparation, M.B.C. and C.-H.L; writing—review and editing, M.B.C. and C.-H.L.; visualization, S.L., D.G. and M.B.C.; supervision, S.L., D.G. and M.B.C.; project administration, S.L., D.G. and M.B.C.; funding acquisition, S.L., D.G., C.-H.L. and M.B.C. All authors have read and agreed to the published version of the manuscript.