Submitted:

26 June 2024

Posted:

27 June 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Synthesis of GO

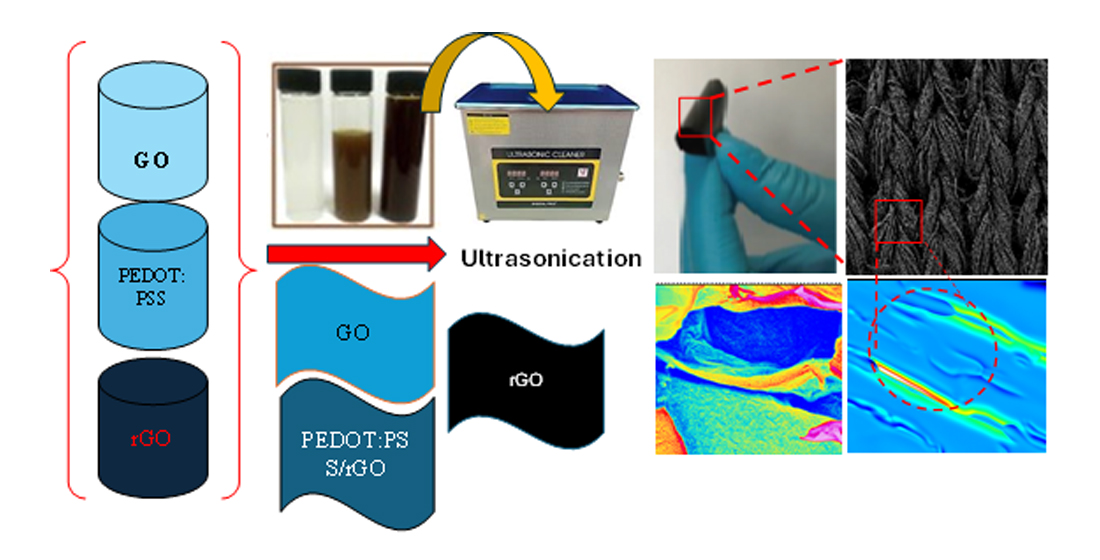

2.2. Fabrication of Graphene (Ultra sonication)

2.3. Reduction (rGO)

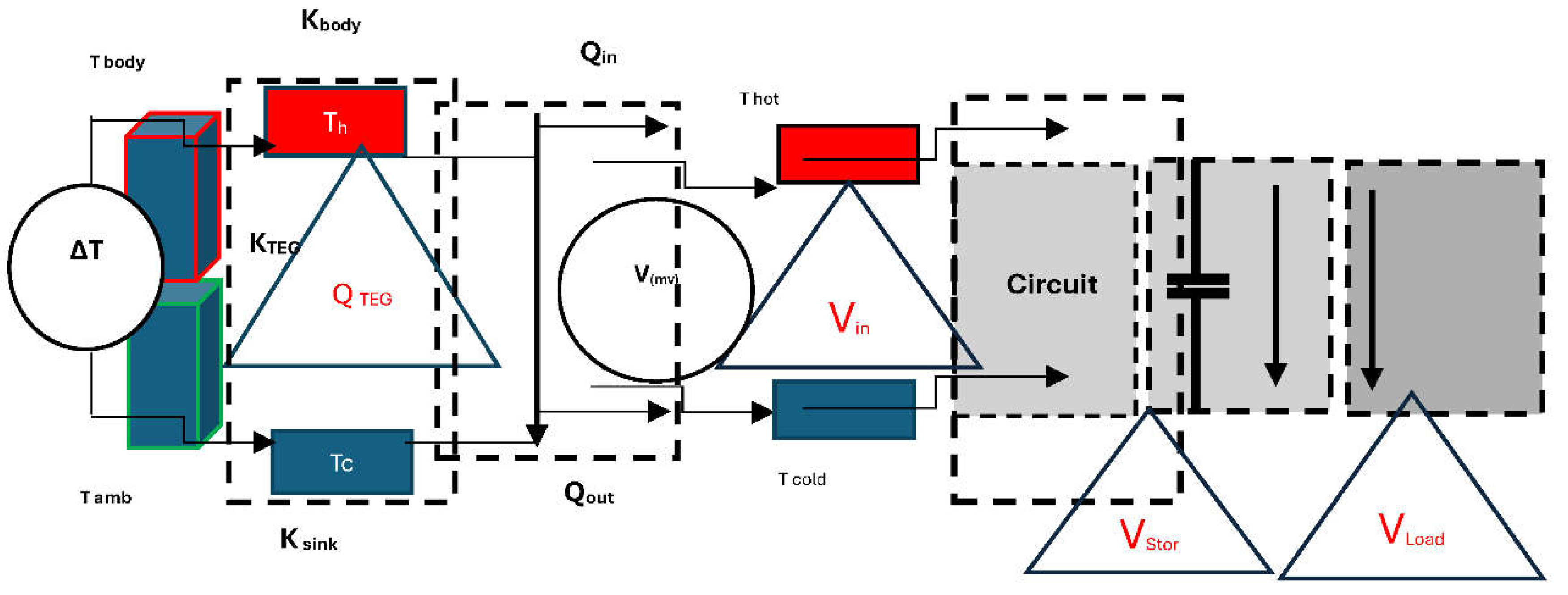

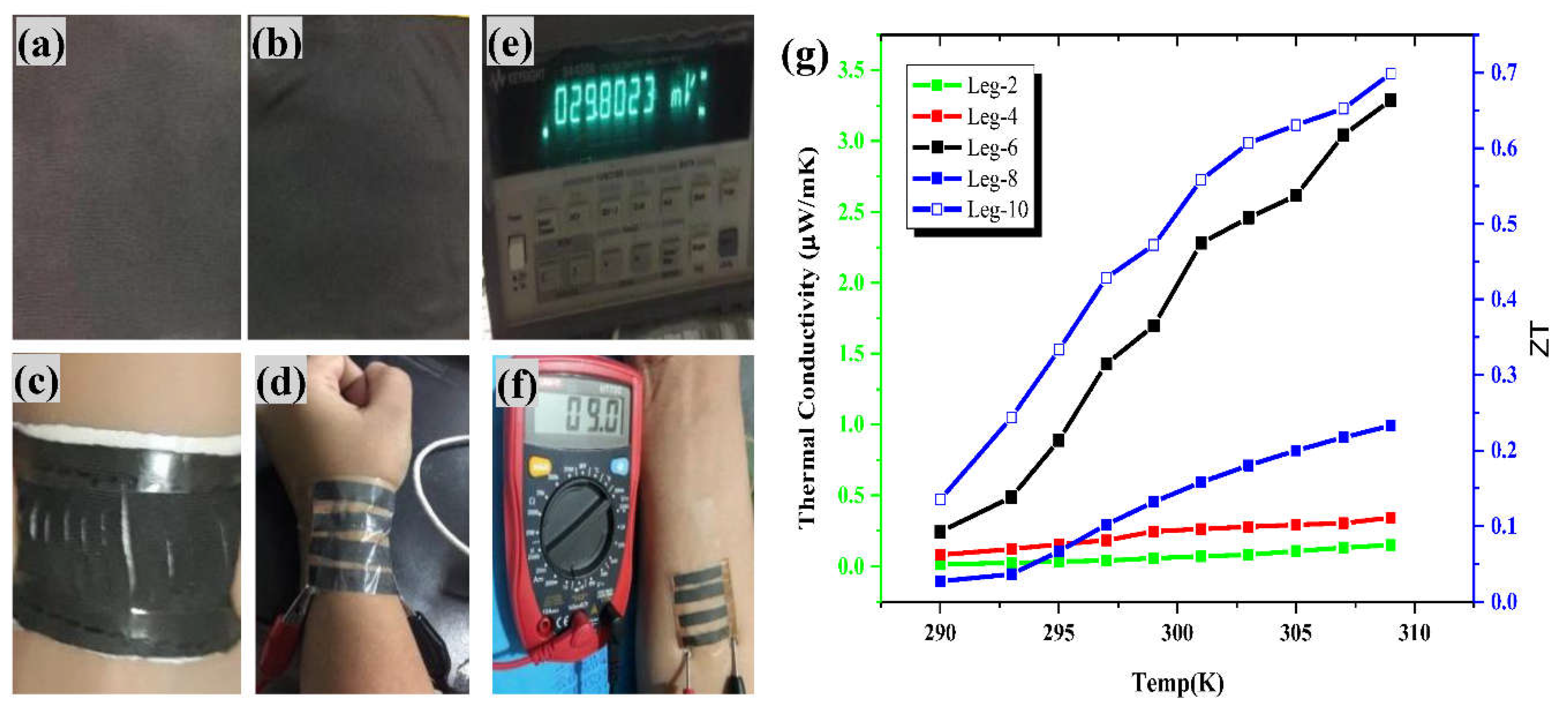

2.4. Designing Wearable TE Device

3. Characterizations

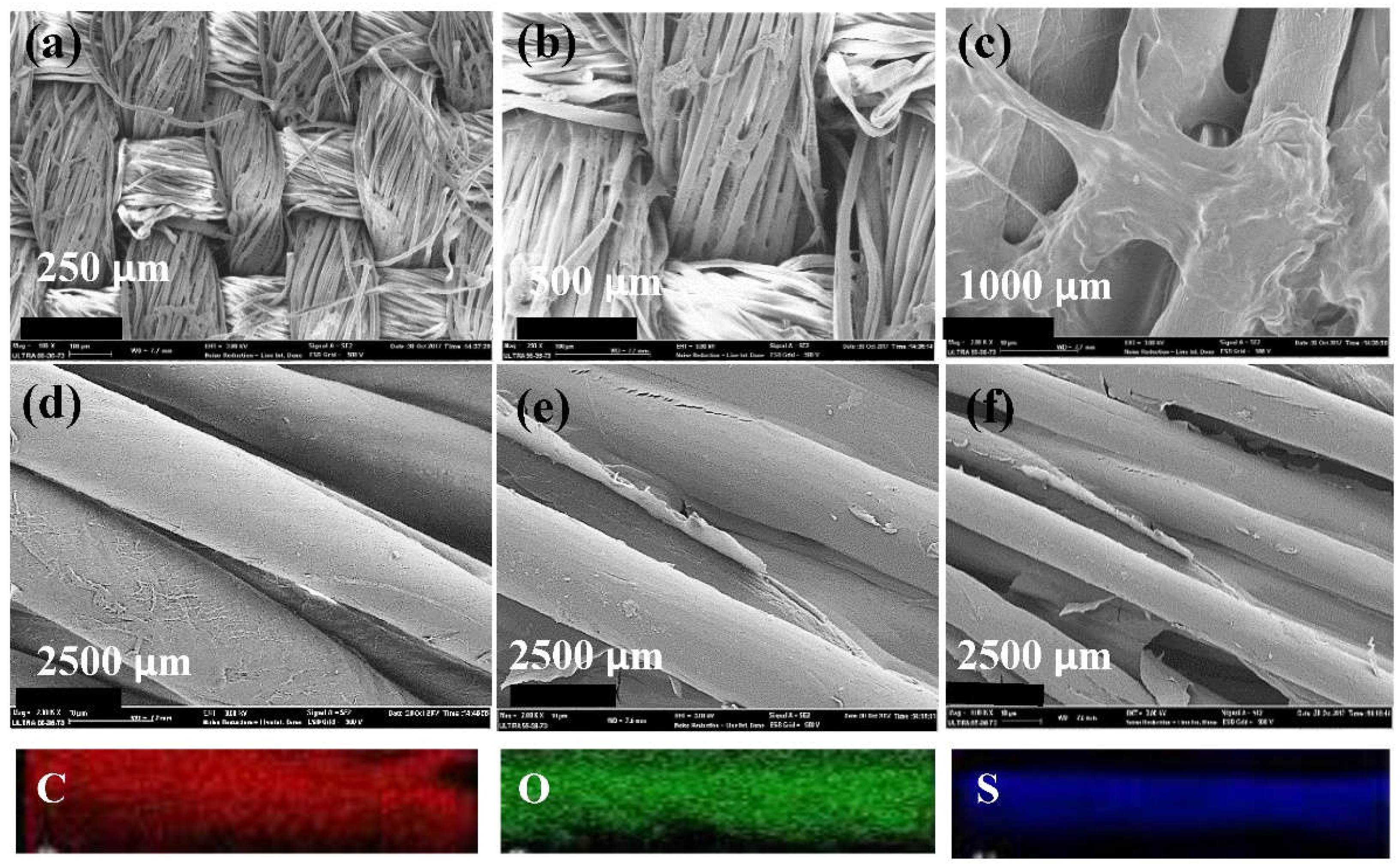

3.1. FESEM

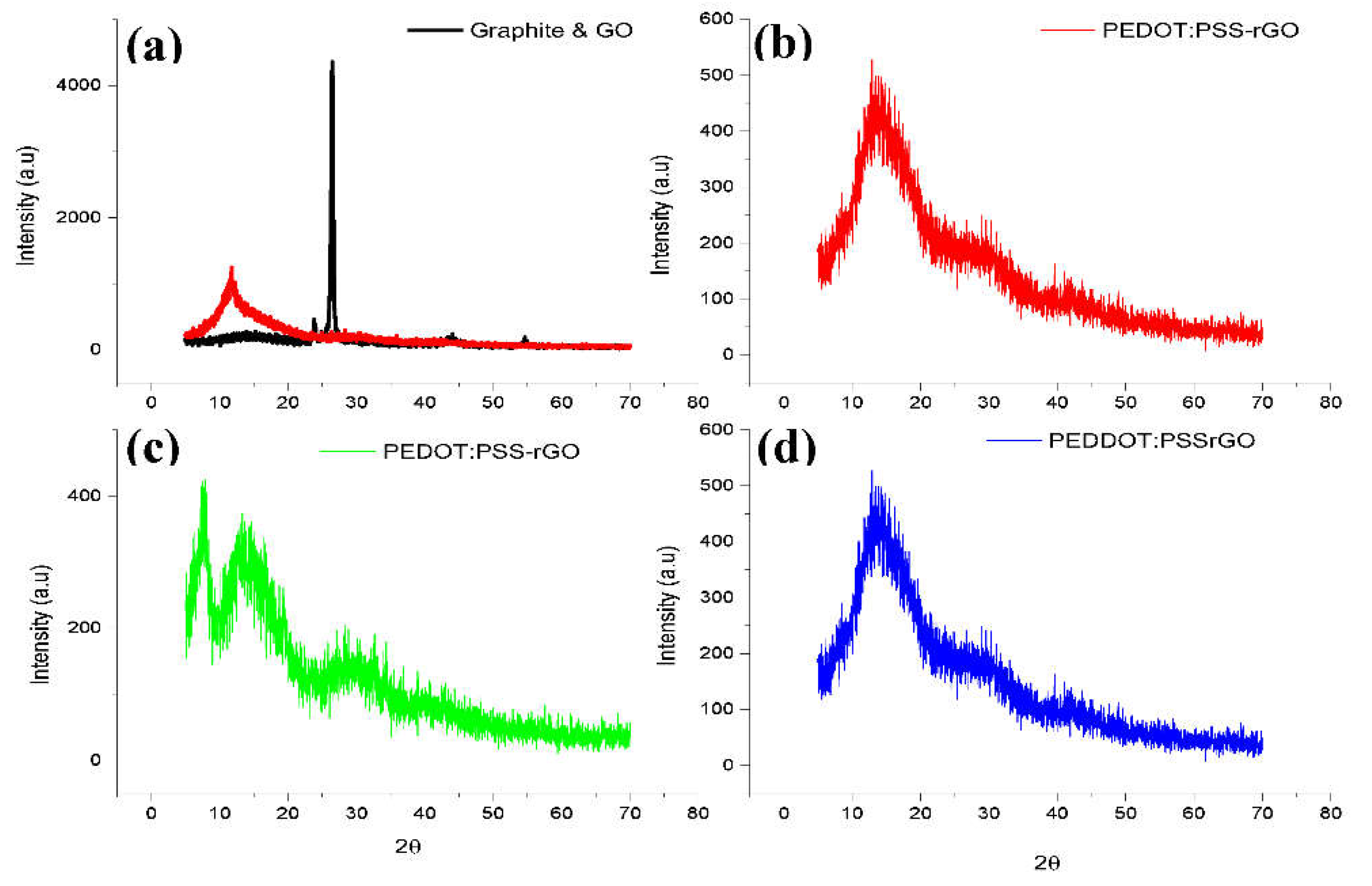

3.2. XRD Analysis

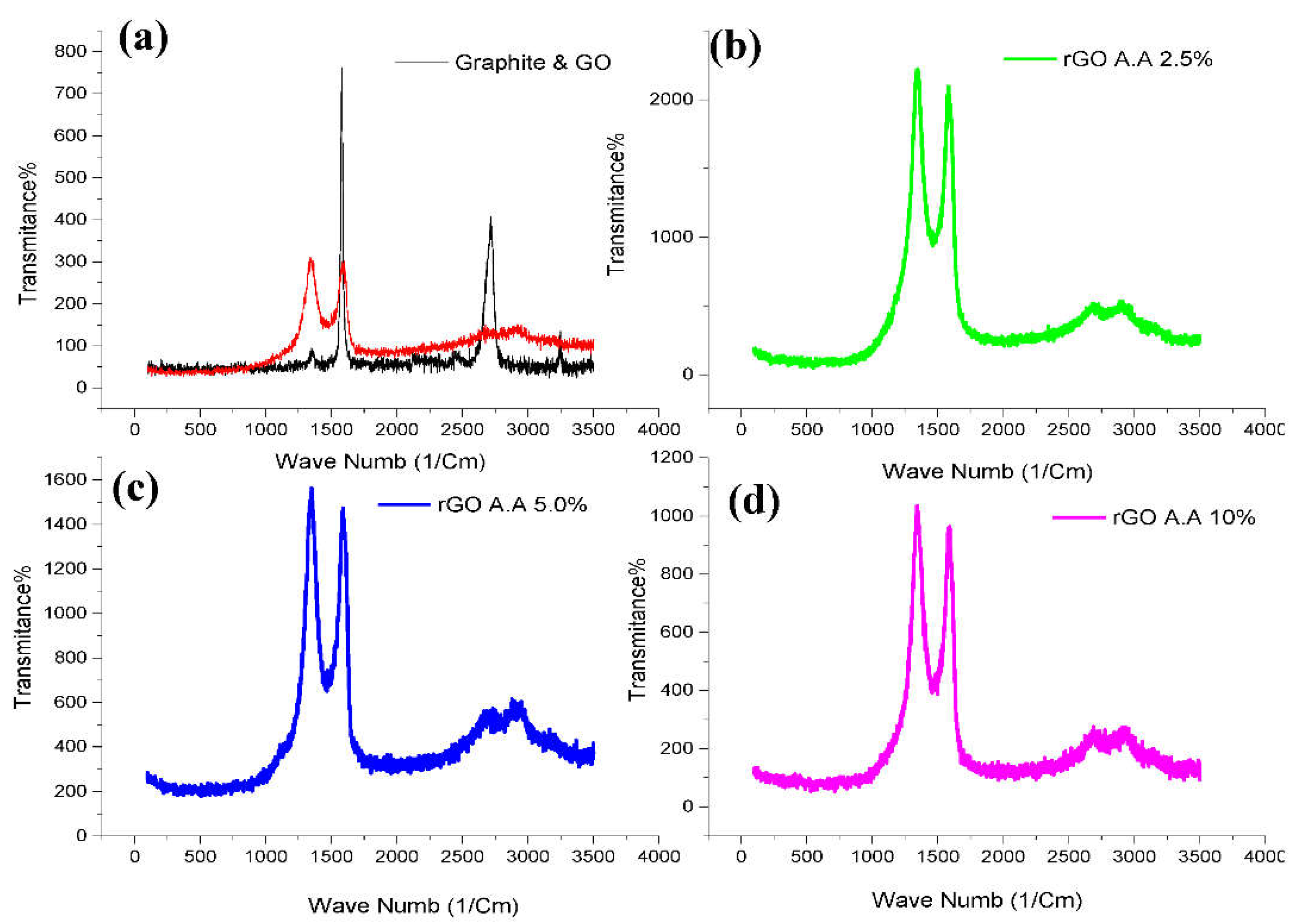

3.3. Raman Analysis

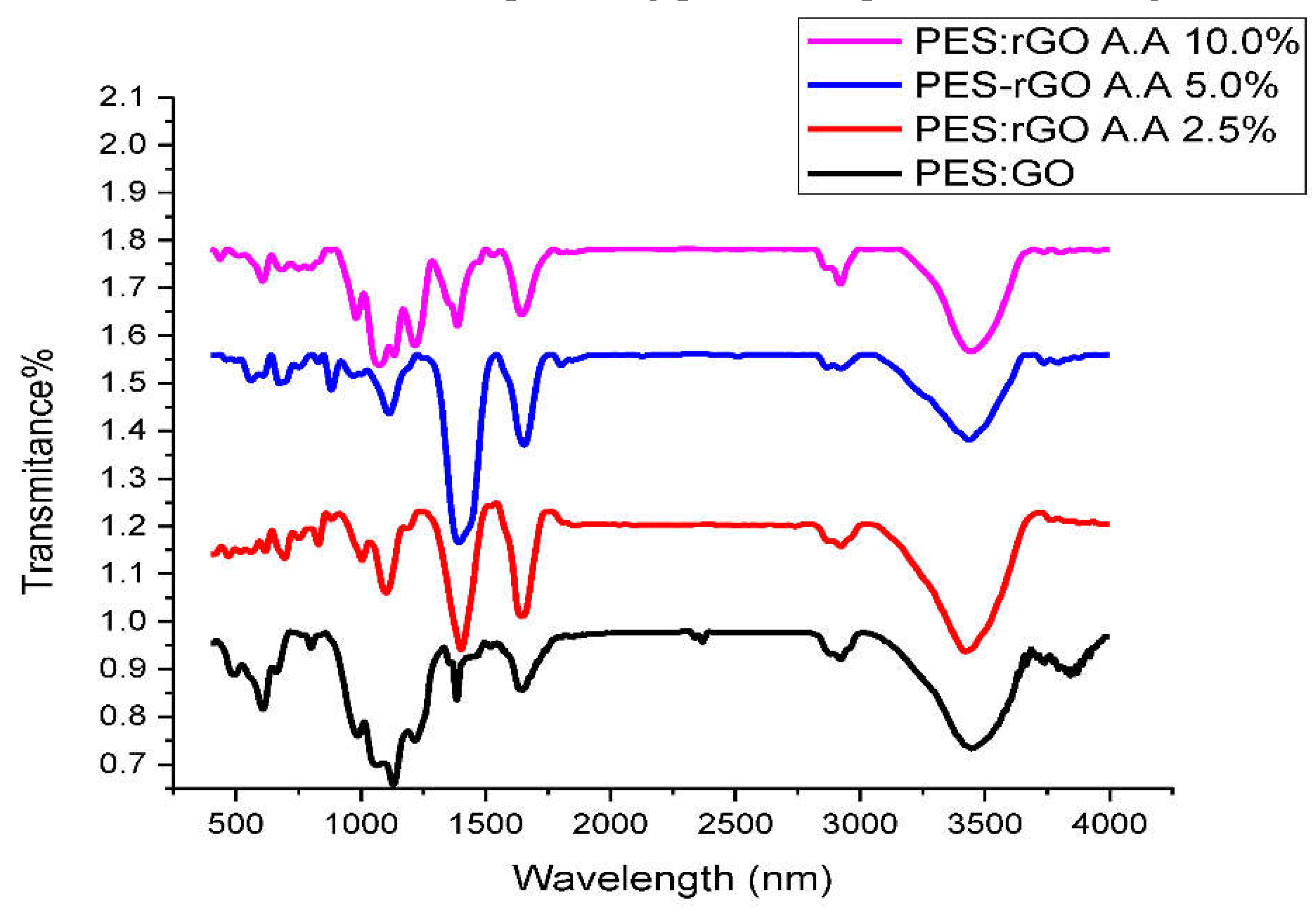

3.4. FTIR Analysis

4. Textile Properties

4.1. Air Permeability

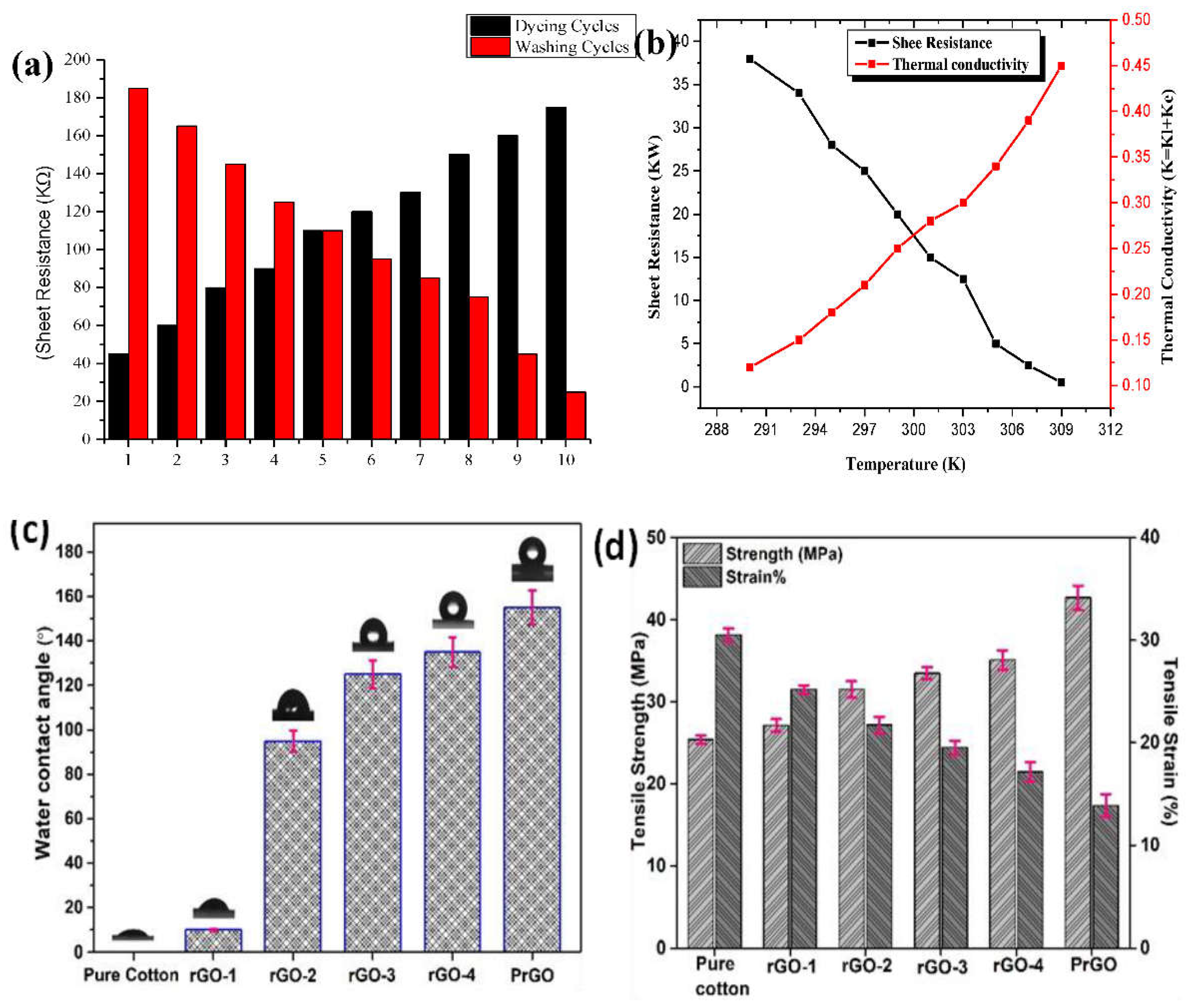

4.2. Water Contact Angle (WCA)

4.3. Tensile Strength

5. Performance Measurements

5.1. Electrical Performance (Sheet Resistance)

5.2. Thermoelectric Performance

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kim, H., & Ahn, J. H. (2017). Graphene for flexible and wearable device applications. Carbon, 120, 244-257. [CrossRef]

- Hu, L., Pasta, M., La Mantia, F., Cui, L., Jeong, S., Deshazer, H. D., & Cui, Y. (2010). Stretchable, porous, and conductive energy textiles. Nano letters, 10(2), 708-714.

- Aboutalebi, S. H., Jalili, R., Esrafilzadeh, D., Salari, M., Gholamvand, Z., Aminorroaya Yamini, S., & Innis, P. C. (2014). High-performance multifunctional graphene yarns: toward wearable all-carbon energy storage textiles. ACS nano, 8(3), 2456-2466.

- Acar, G., Ozturk, O., Golparvar, A. J., Elboshra, T. A., Böhringer, K., & Yapici, M. K. (2019). Wearable and flexible textile electrodes for biopotential signal monitoring: A review. Electronics, 8(5), 479.

- Kaushik, V., Lee, J., Hong, J., Lee, S., Lee, S., Seo, J., & Lee, T. (2015). Textile-based electronic components for energy applications: principles, problems, and perspective. Nanomaterials, 5(3), 1493-1531.

- Weng, W., Chen, P., He, S., Sun, X., & Peng, H. (2016). Smart electronic textiles. Angewandte Chemie International Edition, 55(21), 6140-6169.

- Wang, B., & Facchetti, A. (2019). Mechanically Flexible Conductors for Stretchable and Wearable E-Skin and E-Textile Devices. Advanced Materials, 31(28), 1901408.

- Novoselov, K. S., Fal, V. I., Colombo, L., Gellert, P. R., Schwab, M. G., & Kim, K. (2012). A roadmap for graphene. Nature, 490(7419), 192-200. [CrossRef]

- Lee, D., Lee, H., Ahn, Y., Jeong, Y., Lee, D. Y., & Lee, Y. (2013). Highly stable and flexible silver nanowire–graphene hybrid transparent conducting electrodes for emerging optoelectronic devices. Nanoscale, 5(17), 7750-7755. [CrossRef]

- Mirjalili, M. (2016). Preparation of electroconductive, magnetic, antibacterial, and ultraviolet-blocking cotton fabric using reduced graphene oxide nanosheets and magnetite nanoparticles. Fibers and Polymers, 17(10), 1579-1588.

- Zhang, Y., Xu, Q., Fu, F., & Liu, X. (2016). Durable antimicrobial cotton textiles modified with inorganic nanoparticles. Cellulose, 23(5), 2791-2808.

- Tissera, N. D., Wijesena, R. N., Perera, J. R., de Silva, K. N., & Amaratunge, G. A. (2015). Hydrophobic cotton textile surfaces using an amphiphilic graphene oxide (GO) coating. Applied Surface Science, 324, 455-463.

- Ji, Y., Li, Y., Chen, G., & Xing, T. (2017). Fire-resistant and highly electrically conductive silk fabrics fabricated with reduced graphene oxide via dry coating. Materials & design, 133, 528-535.

- Karimi, L., Zohoori, S., & Amini, A. (2014). Multi-wall carbon nanotubes and nano titanium dioxide coated on cotton fabric for superior self-cleaning and UV blocking. New Carbon Materials, 29(5), 380-385.

- Chakraborty, J. N., Mohapatra, M. R., & Kumar, J. (2018). Differential functional finishes for textiles using graphene oxide. Research Journal of Textile and Apparel. [CrossRef]

- Montazer, M., & Seifollahzadeh, S. (2011). Enhanced self-cleaning, antibacterial and UV protection properties of nano TiO2 treated textile through enzymatic pretreatment. Photochemistry and photobiology, 87(4), 877-883.

- Madan, D., Chen, A., Wright, P. K., & Evans, J. W. (2012). Printed Se-doped MA n-type Bi 2 Te 3 thick-film thermoelectric generators. Journal of electronic materials, 41(6), 1481-1486.

- Madan, D., Wang, Z., Wright, P. K., & Evans, J. W. (2015). Printed flexible thermoelectric generators for use on low levels of waste heat. Applied energy, 156, 587-592.

- Abu-Thabit, N. Y., & Makhlouf, A. S. H. (2016). Smart Textile Supercapacitors Coated with Conducting Polymers for Energy Storage Applications. In Industrial Applications for Intelligent Polymers and Coatings (pp. 437-477). Springer, Cham.

- Jia, L. C., Ding, K. Q., Ma, R. J., Wang, H. L., Sun, W. J., Yan, D. X., ... & Li, Z. M. (2019). Highly Conductive and Machine-Washable Textiles for Efficient Electromagnetic Interference Shielding. Advanced Materials Technologies, 4(2), 1800503. [CrossRef]

- Liu, L., Yu, Y., Yan, C., Li, K., & Zheng, Z. (2015). Wearable energy-dense and power-dense supercapacitor yarns enabled by scalable graphene–metallic textile composite electrodes. Nature communications, 6(1), 1-9. [CrossRef]

- Karimi, L., Zohoori, S., & Amini, A. (2014). Multi-wall carbon nanotubes and nano titanium dioxide coated on cotton fabric for superior self-cleaning and UV blocking. New Carbon Materials, 29(5), 380-385.

- Carey, T., Cacovich, S., Divitini, G., Ren, J., Mansouri, A., Kim, J. M., & Torrisi, F. (2017). Fully inkjet-printed two-dimensional material field-effect heterojunctions for wearable and textile electronics. Nature communications, 8(1), 1-11.

- Shao, Y., El-Kady, M. F., Wang, L. J., Zhang, Q., Li, Y., Wang, H., & Kaner, R. B. (2015). Graphene-based materials for flexible supercapacitors. Chemical Society Reviews, 44(11), 3639-3665.

- Montgomery, D. S., & Carroll, D. L. (2016). Improving upon flexible thin film thermoelectric generator design. Coupled thermoelectric and piezoelectric Meta structures for renewable energy generation, 96, 56.

- Navone, C., Soulier, M., Plissonnier, M., & Seiler, A. L. (2010). Development of (Bi, Sb) 2 (Te, Se) 3-based thermoelectric modules by a screen-printing process. Journal of electronic materials, 39(9), 1755-1759.

- Shathi, M. A., Minzhi, C., Khoso, N. A., Deb, H., Ahmed, A., & Sai, W. S. (2020). All organic graphene oxide and Poly (3, 4-ethylene dioxythiophene)-Poly (styrene sulfonate) coated knitted textile fabrics for wearable electrocardiography (ECG) monitoring. Synthetic Metals, 263, 116329.

- Sun, T., Wang, J. J., Khoso, N. A., Yu, L., & Zhang, Y. (2017). Facile synthesis of Poly (3, 4-ethylenedioxythiophene) nanostructure with controlled morphologies by using an aqueous surfactant soft-template-assisted technique. Materials Letters, 191, 61-64. [CrossRef]

- Sun, Y. C. (2015). Development and Characterization of Next Generation Flexible Dielectric and Thermoelectric Energy Harvesting Materials (Doctoral dissertation).

- Thielen, M., Sigrist, L., Magno, M., Hierold, C., & Benini, L. (2017). Human body heat for powering wearable devices: From thermal energy to application. Energy conversion and management, 131, 44-54.

- Tian, M., Hu, X., Qu, L., Du, M., Zhu, S., Sun, Y., & Han, G. (2016). Ultraviolet protection cotton fabric achieved via layer-by-layer self-assembly of graphene oxide and chitosan. Applied Surface Science, 377, 141-148.

- Tian, M., Hu, X., Qu, L., Zhu, S., Sun, Y., & Han, G. (2016). Versatile and ductile cotton fabric achieved via layer-by-layer self-assembly by consecutive adsorption of graphene doped PEDOT: PSS and chitosan. Carbon, 96, 1166-1174.

- Vondrak, J., Schmidt, M., Proto, A., Penhaker, M., Jargus, J., & Peter, L. (2019, June). Using Miniature Thermoelectric Generators for Wearable Energy Harvesting. In 2019 4th International Conference on Smart and Sustainable Technologies (SpliTech) (pp. 1-6). IEEE.

- Zeng, W., Shu, L., Li, Q., Chen, S., Wang, F., & Tao, X. M. (2014). Fiber-based wearable electronics: a review of materials, fabrication, devices, and applications. Advanced materials, 26(31), 5310-5336.

- Wong, H. P., & Dahari, Z. (2015, October). Human body parts heat energy harvesting using thermoelectric module. In 2015 IEEE Conference on Energy Conversion (CENCON) (pp. 211-214). IEEE.

- Hamada, J., Yamamoto, K., & Takashiri, M. (2018, July). Fabrication and characterization of roll-type thin-film thermoelectric generators. In Journal of Physics: Conference Series (Vol. 1052, No. 1, p. 012129). IOP Publishing. [CrossRef]

- Zhu, Z., Liu, C., Jiang, Q., Shi, H., Xu, J., Jiang, F., & Liu, E. (2015). Green DES mixture as a surface treatment recipe for improving the thermoelectric properties of PEDOT: PSS films. Synthetic Metals, 209, 313-318. [CrossRef]

- Dong, L., Xu, C., Li, Y., Wu, C., Jiang, B., Yang, Q., & Yang, Q. H. (2016). Simultaneous Production of High-Performance Flexible Textile Electrodes and Fiber Electrodes for Wearable Energy Storage. Advanced Materials, 28(8), 1675-1681.

- Du, Y., Xu, J., Wang, Y., & Lin, T. (2017). Thermoelectric properties of graphite-PEDOT: PSS coated flexible polyester fabrics. Journal of Materials Science: Materials in Electronics, 28(8), 5796-5801.

- Dunham, M. T., Barako, M. T., Cornett, J. E., Gao, Y., Haidar, S., Sun, N., & Goodson, K. E. (2018). Experimental characterization of microfabricated thermoelectric energy harvesters for smart sensor and wearable applications. Advanced Materials Technologies, 3(6), 1700383.

- Huang, Y., Hu, H., Huang, Y., Zhu, M., Meng, W., Liu, C., & Zhi, C. (2015). From industrially Weavable and knittable highly conductive yarns to large wearable energy storage textiles. ACS nano, 9(5), 4766-4775.

- Hyland, M., Hunter, H., Liu, J., Veety, E., & Vashaee, D. (2016). Wearable thermoelectric generators for human body heat harvesting. Applied Energy, 182, 518-524. [CrossRef]

- Islam, M. Z., Dong, Y., Khoso, N. A., Ahmed, A., Deb, H., Zhu, Y., ... & Fu, Y. (2019). Continuous dyeing of graphene on cotton fabric: Binder-free approach for electromagnetic shielding. Applied Surface Science, 496, 143636. [CrossRef]

- Jung, Y. S., Jeong, D. H., Kang, S. B., Kim, F., Jeong, M. H., Lee, K. S., ... & Choi, K. J. (2017). Wearable solar thermoelectric generator driven by unprecedentedly high temperature difference. Nano energy, 40, 663-672.

- Karim, N., Afroj, S., Tan, S., He, P., Fernando, A., Carr, C., & Novoselov, K. S. (2017). Scalable production of graphene-based wearable e-textiles. ACS nano, 11(12), 12266-12275.

- Pu, X., Liu, M., Li, L., Han, S., Li, X., Jiang, C., ... & Wang, Z. L. (2016). Wearable textile-based in-plane microsupercapacitors. Advanced Energy Materials, 6(24), 1601254.

- Sahito, I. A., & Khatri, A. (2017). Smart and Electronic Textiles. In Advanced Textile Testing Techniques (pp. 309-328). CRC Press.

- Sahito, I. A., Sun, K. C., Arbab, A. A., Qadir, M. B., & Jeong, S. H. (2015). Graphene coated cotton fabric as textile structured counter electrode for DSSC. Electrochimica Acta, 173, 164-171. [CrossRef]

- Shateri-Khalilabad, M., & Yazdanshenas, M. E. (2013). Preparation of superhydrophobic electroconductive graphene-coated cotton cellulose. Cellulose, 20(2), 963-972. [CrossRef]

- Kaushik, V., Lee, J., Hong, J., Lee, S., Lee, S., Seo, J., & Lee, T. (2015). Textile-based electronic components for energy applications: principles, problems, and perspective. Nanomaterials, 5(3), 1493-1531.

- Lin, Zhaoyang, Courtney Hollar, Joon Sang Kang, Anxiang Yin, Yiliu Wang, Hui-Ying Shiu, Yu Huang, Yongjie Hu, Yanliang Zhang, and Xiangfeng Duan. "A Solution Processable High-Performance Thermoelectric Copper Selenide Thin Film." Advanced Materials 29, no. 21 (2017): 1606662.

- https://www.astm.org/Standards/textile-standards.html.

- Khoso, N. A., Ahmed, A., Deb, H., Tian, S., Jiao, X., Gong, X. Y., & Wang, J. (2019). Controlled template-free in-situ polymerization of PEDOT for enhanced thermoelectric performance on textile substrate. Organic Electronics, 75, 105368.

- Kim, M. K., Kim, M. S., Lee, S., Kim, C., & Kim, Y. J. (2014). Wearable thermoelectric generator for harvesting human body heat energy. Smart Materials and Structures, 23(10), 105002. [CrossRef]

- Lee, S. H., Park, H., Son, W., Choi, H. H., & Kim, J. H. (2014). Novel solution-processable, dedoped semiconductors for application in thermoelectric devices. Journal of Materials Chemistry A, 2(33), 13380-13387. [CrossRef]

- Liu, H., Wang, Y., Mei, D., Shi, Y., & Chen, Z. (2017). Design of a wearable thermoelectric generator for harvesting human body energy. In Wearable sensors and robots (pp. 55-66). Springer, Singapore.

| Sample details | Dyeing Cycles (KΩ) | Washing Cycles (KΩ) |

Fabric Thickness (mm) |

Tensile Strength (mPa) |

Water Contact Angle (WCA) |

Air Permeability (g/Cm2/S) |

|---|---|---|---|---|---|---|

| Pure Cotton | 22 | 10 | 6-12 | 76 | ||

| GO | 25 | 12 | 20 | 74 | ||

| rGO | 185 | 195 | 26 | 20 | 45 | 72 |

| P-rGO-1 | 145 | 150 | 27 | 40 | 70 | 69 |

| P-rGO-2 | 125 | 135 | 28 | 60 | 84 | 66 |

| P-rGO-3 | 115 | 125 | 29 | 75 | 96 | 63 |

| P-rGO-4 | 85 | 95 | 30 | 80 | 110 | 60 |

| Pure Cotton | 185 | 195 | 26 | 20 | 45 | 72 |

| Sample No. | Composition (GO-PES%) | Average thickness (mm) | Electrical Conductivity (KΩ) | ||

|---|---|---|---|---|---|

| Before Washing | After Washing | Bending Cycles | |||

| Untreated | Nil | 22.0 | |||

| GO | 25.0 | 95.2 | 5.0 | 10.0 | |

| P-rGO-1 | 2.5 | 26.5 | 88.6 | 12.5 | 15.5 |

| P-rGO-2 | 5.0 | 27.7 | 74.8 | 18.5 | 22.5 |

| P-rGO-3 | 7.5 | 28.5 | 62.5 | 25.0 | 28.5 |

| P-rGO-4 | 10.0 | 30.4 | 31.9 | 35.6 | 38.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).