Submitted:

27 June 2024

Posted:

27 June 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

| RQ 1 | In what ways can the Prescriptive Digital Twin (PDT) Model be applied to improve occupant comfort and productivity in building spaces? |

| RQ 2 | What are the primary challenges encountered in the development and implementation of PDT within the context of buildings, and how can we overcome these barriers to create more efficient, sustainable, and smart buildings in the future? |

2. Digital Twin and Prescriptive Digital Twin

2.1. Building Information Modelling (BIM)

- BIM integrates 3D models to enable stakeholders to view the physical shape and structure of a building in geometry. This graphic depiction enhances communication and comprehension among architects, engineers, and other project partners.

- BIM records spatial connections among building elements, facilitating the examination of their interactions. This feature is essential for maximizing spatial arrangements and guaranteeing the optimum utilization of resources.

- BIM frequently contains geographic information, providing details on the location-related components of a construction project. This is especially beneficial for projects with intricate environmental factors or those located in unique geographical settings.

- BIM offers comprehensive data on quantities, encompassing materials and resources necessary for building. This facilitates precise cost estimate and resource allocation.

2.2. Definition of Digital Twin

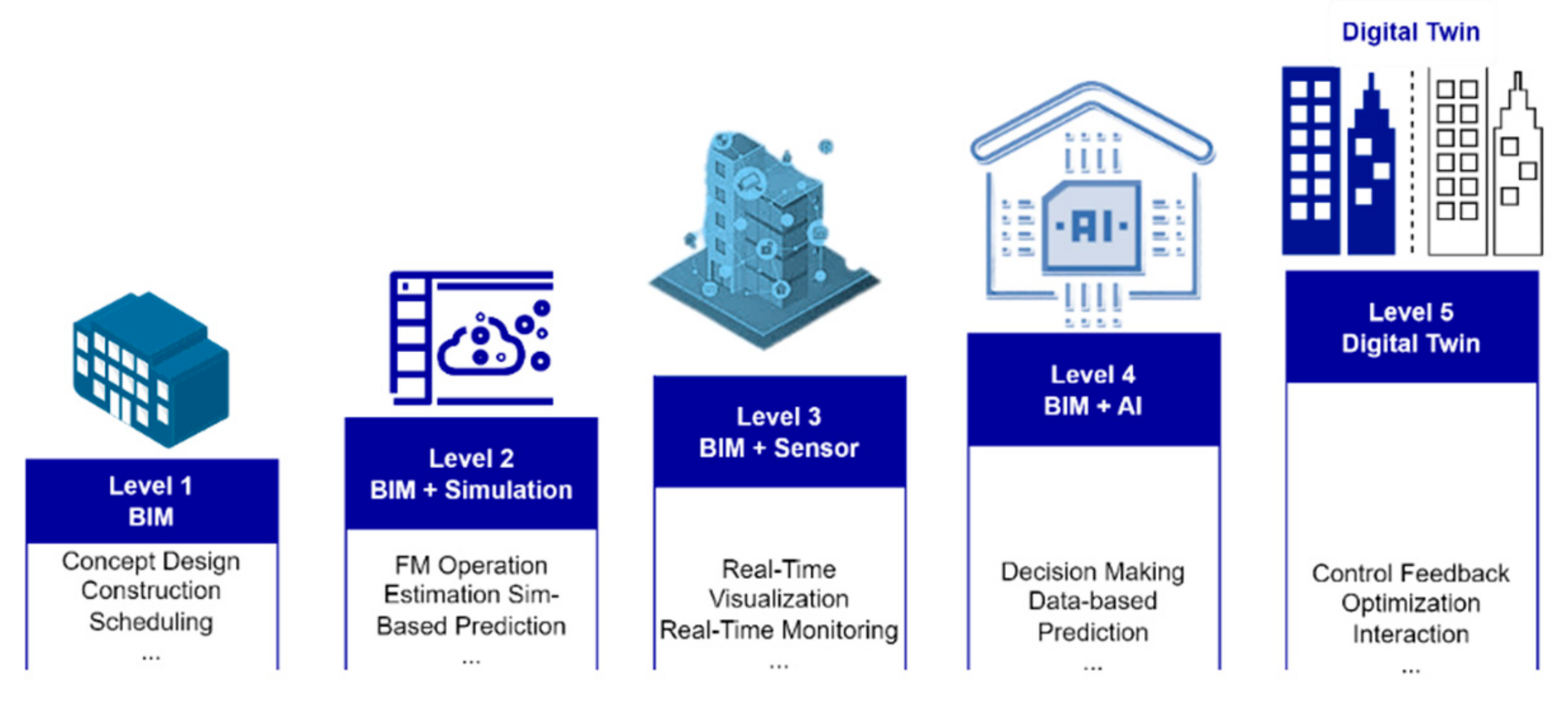

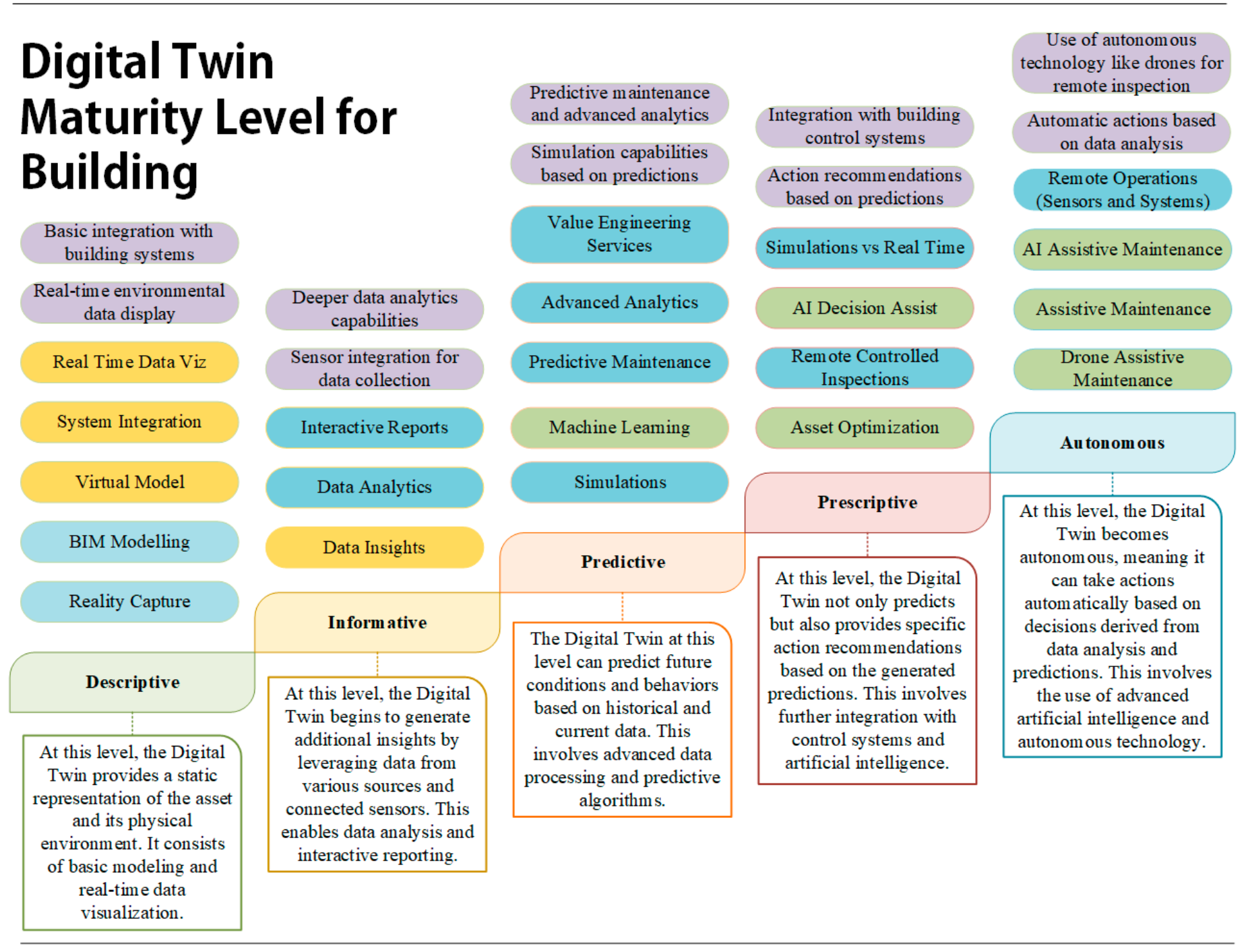

2.3. Differentiating Descriptive, Predictive, and Prescriptive Digital Twin

- Descriptive Level:

- Basic Feature: Real-time data collection and modeling of the physical system.

- Unique Feature: Thorough representation of the building’s structure, functions, and physical conditions.

- Additional Feature: Visualization of the building’s layout, systems integration, and real-time data display.

- 2.

- Informative Level:

- Basic Feature: Generation of structured information from collected data.

- Unique Feature: Presentation of data in an easily understandable format for informed decision-making.

- Additional Feature: Data analytics capabilities, interactive reports, and insights derived from data.

- 3.

- Predictive Level:

- Basic Feature: Utilization of historical data for forecasting future behaviors.

- Unique Feature: Identification of trends and patterns to make forecasts about future system behavior.

- Additional Feature: Simulation capabilities, predictive maintenance, and advanced analytics for value engineering.

- 4.

- Prescriptive Level:

- Basic Feature: Prediction of future behaviors.

- Unique Feature: Provision of recommendations or specific actions to achieve desired goals.

- Additional Feature: Action recommendations based on historical data and predictions, integration with building control systems for implementation.

- 5.

- Autonomous Level:

- Basic Feature: Independent operation with minimal human intervention.

- Unique Feature: Automatic monitoring, analysis, and decision-making based on collected data.

- Additional Feature: Use of autonomous technology (e.g., drones) for remote inspection, remote operations, and AI-assisted maintenance.

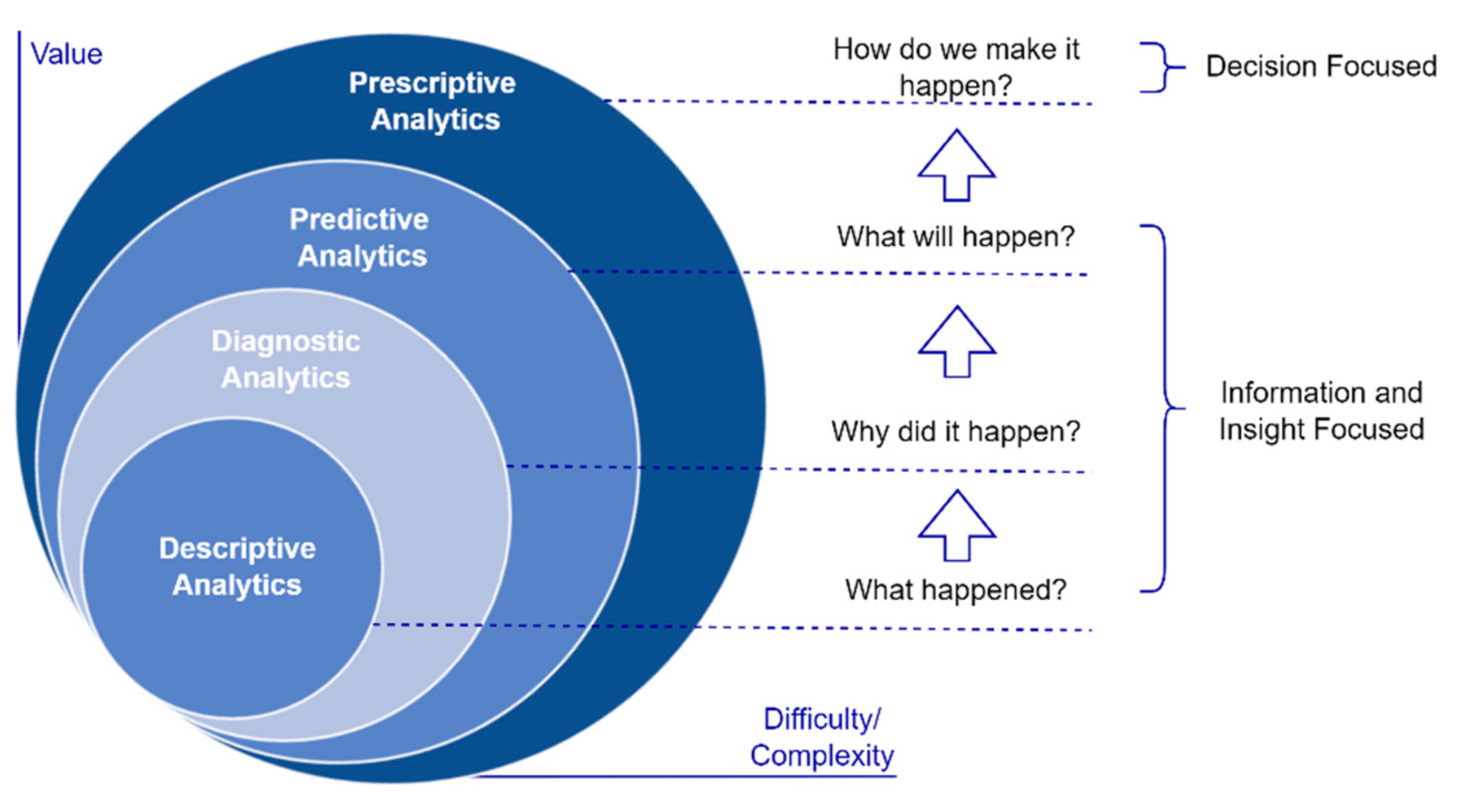

- Descriptive analytics: This stage compares the actual procedure to the planned one in an effort to determine “what happened” throughout the training process. For instance, a trainer desiring to enhance an athlete’s endurance performance can visualize the outcomes of a physical test to track advancement toward a training objective.

- Diagnostic analytics: By studying the relationships between the training process data, this stage attempts to address the “why did it happen” question. A practitioner can plan exercise intensity by, for instance, knowing the connection between the distribution of exercise intensity and an improvement in endurance performance.

- Predictive (predictive analytics): This stage uses previous data to forecast future outcomes in an effort to provide an answer to the query “what will happen” throughout the training process. For instance, predicting the possibility of injury to athletes using past data and taking the necessary safeguards.

- Prescriptive analytics: This step tries to answer the question “what should be done” in the training process by providing recommendations for actions that can be taken to achieve the training objectives. For example, providing recommendations on the types of exercises to do to achieve training goals.

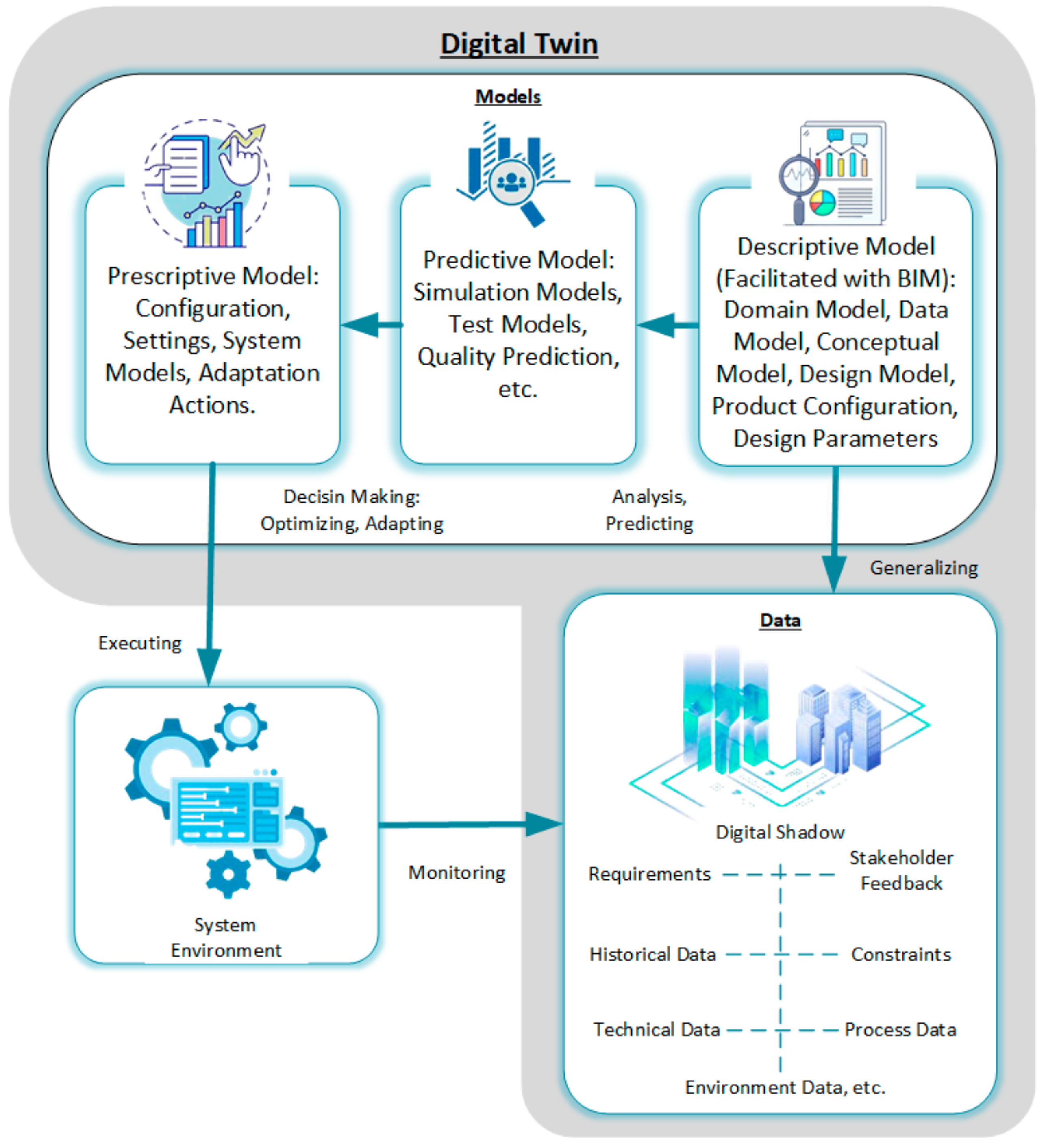

- Descriptive Model: Descriptive model facilitated by BIM are used to describe the existing system, encompassing the structure, behavior, and condition of the system. This model, with the incorporation of BIM, provides an overview of how the system works and how the system components interact with each other. Descriptive models can be used to understand existing systems and identify problems or areas that can be optimized.

- Predictive Models: Predictive models are used to predict the future behavior of the system. This model is based on historical data and can be used to predict how the system will behave in various situations. Predictive models can be used to assist decision making and analysis of trade-offs.

- Prescriptive Model: Prescriptive models are used to provide recommendations or actions to be taken to achieve certain goals. This model is based on historical data and predictions of the future and can be used to optimize system performance. Prescriptive models can be used to provide recommendations for actions to be taken to address critical situations or to optimize overall system performance.

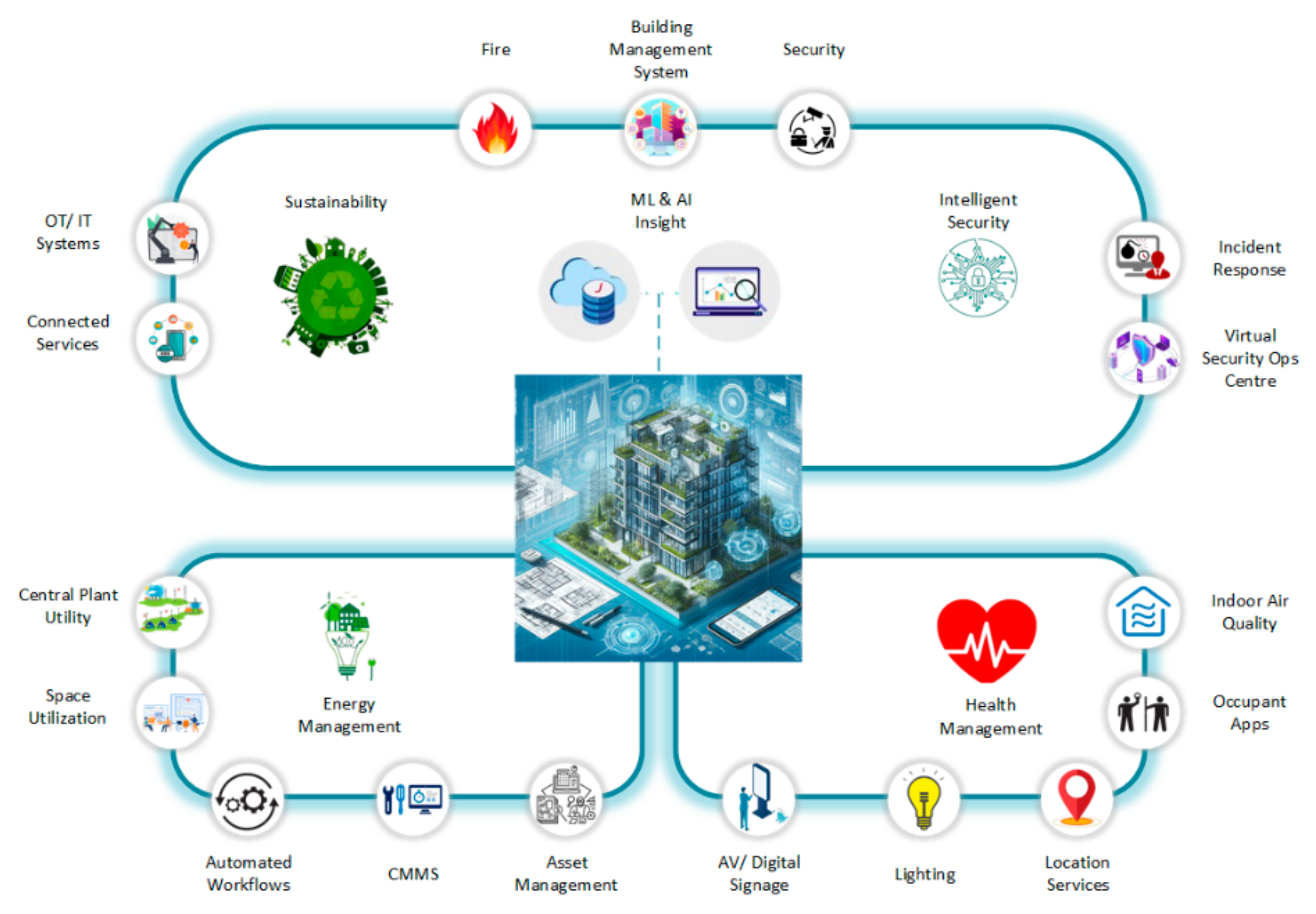

2.4. Benefits and Potential of Prescriptive Digital Twin in the Building Context

- Optimized Energy Consumption: Prescriptive Digital Twin enable real-time monitoring and analysis of energy usage within buildings. By providing actionable insights, they help optimize energy consumption, reduce costs, and enhance sustainability.

- Predictive Maintenance: These twins accurately predict maintenance needs by analyzing real-time data from sensors. This proactive approach prevents equipment failures, minimizes downtime, and prolongs the lifespan of building systems.

- Improved Indoor Air Quality: Prescriptive Digital Twin monitor environmental factors such as temperature, humidity, and air quality in real-time. They can adjust HVAC systems and ventilation to maintain optimal indoor air quality, ensuring the health and comfort of occupants.

- Enhanced Security and Risk Management: Prescriptive Digital Twin aid in identifying potential security threats and vulnerabilities within buildings. By analyzing data from surveillance cameras and access control systems, they enhance security measures and assist in risk mitigation.

- Cost Reduction: Through energy optimization, predictive maintenance, and efficient resource allocation, Prescriptive Digital Twin contribute to significant cost savings for building owners and operators.

- Data-Driven Decision Making: They provide decision-makers with actionable insights based on real-time data analysis. This data-driven decision-making approach ensures that choices are optimized for building performance and efficiency.

- Environmental Sustainability: By optimizing energy usage and reducing resource wastage, Prescriptive Digital Twin play a crucial role in promoting environmental sustainability, aligning with global green building initiatives.

- Enhanced Occupant Comfort: Maintaining optimal indoor conditions, such as temperature and lighting, leads to improved comfort for building occupants, positively impacting their productivity and well-being.

- Scalability: Prescriptive Digital Twin are adaptable to various building types and sizes, making them suitable for residential, commercial, and industrial structures.

- Future Potential: As technology advances, Prescriptive Digital Twin have the potential to become even more sophisticated. They may incorporate advanced AI algorithms, machine learning, and real-time feedback loops to continually optimize building performance.

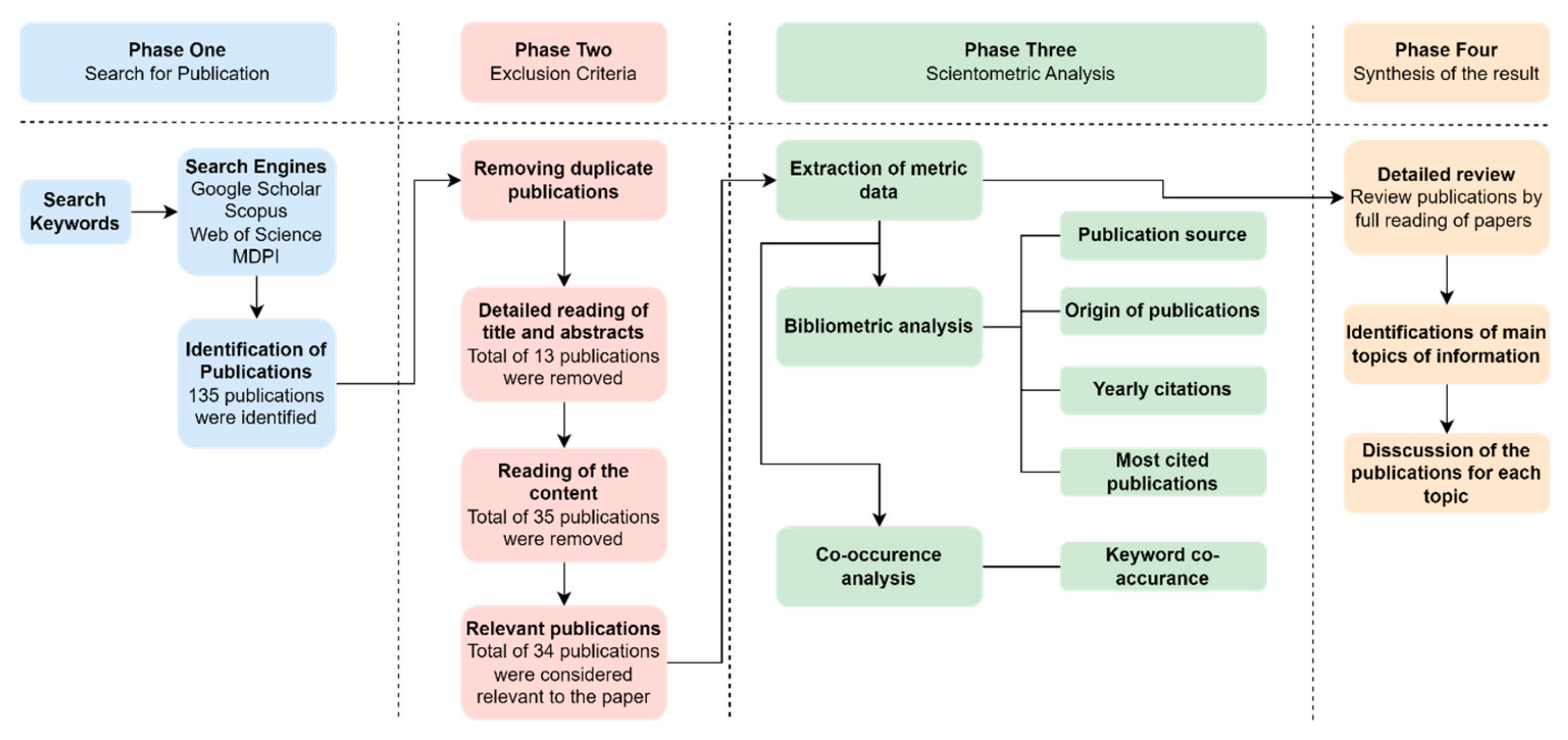

3. Methodology

- Narrative Review

- 2.

- Systematic Review

- 3.

- Meta-Analysis

4. Concepts and Components of Prescriptive Digital Twin for Buildings

5. Applications of Prescriptive Digital Twin for Building Performance Enhancement

6. Case Studies of Implementing Digital Twin in Real Buildings

- Monitoring and Control of Building Facades to Improve Energy Efficiency and Occupant Comfort: Digital Twin can monitor building facade conditions, such as temperature, humidity, and light intensity, optimizing HVAC and lighting systems usage to enhance energy efficiency and occupant comfort.

- Monitoring and Control of HVAC Systems to Increase Energy Efficiency and Occupant Comfort: Digital Twin can monitor environmental conditions inside buildings, such as temperature, humidity, and air quality, optimizing HVAC systems usage to improve energy efficiency and occupant comfort.

- Monitoring and Control of Lighting Systems to Improve Energy Efficiency and Occupant Comfort: Digital Twin can monitor lighting conditions inside buildings, optimizing lighting systems usage to increase energy efficiency and occupant comfort.

- Monitoring and Control of Building Security and Safety Systems to Enhance Occupant Safety: Digital Twin can monitor building security and safety systems, such as alarm systems and surveillance cameras, optimizing their usage to improve the security and safety of building occupants.

- Monitoring and Management of Space Utilization to Increase Productivity and Efficiency: Digital Twin can monitor space utilization in buildings, optimizing it to increase productivity and efficient space use.

- Monitoring and Maintenance of Buildings to Reduce Maintenance Costs and Increase Availability: Digital Twin can monitor building conditions and predict equipment or system failures, enabling preventive maintenance to reduce costs and increase building availability.

- Building Planning and Design to Enhance Future Building Performance: Architects and engineers can use Digital Twin to design more efficient and comfortable buildings. By utilizing data from existing building Digital Twin, they can improve future building designs to enhance building performance.

- a.

- Implementation Examples in Commercial Buildings (Offices, Malls, etc.)

- b.

-

Implementation Examples in Industrial or Factory Buildings

- Manufacturer: Digital Twin applications in manufacturing include real-time monitoring and repair of production machines, improving product quality, and reducing production costs.

- Aviation: Digital Twin applications in aviation encompass real-time aircraft performance monitoring, fuel efficiency improvement, and flight safety enhancement.

- Healthcare: Digital Twin applications in healthcare involve real-time monitoring of medical equipment performance, improving patient care efficiency, and enhancing disease diagnosis and treatment.

7. Challenges and Barriers in Developing Prescriptive Digital Twin for Buildings

| Challenges | Potential Solutions |

|---|---|

| Data Security and Privacy Issues [16,66] | Data Breaches: Implement robust encryption protocols to protect data during transmission and storage. Privacy Concerns: Utilize data anonymization techniques to balance data collection for optimization with individual privacy rights. |

| System Integration and Interoperability Challenges [67] | Diverse Systems: Utilize APIs and middleware solutions to facilitate communication between disparate building systems. Legacy Infrastructure: Promote and adopt industry standards for building system communication to ensure compatibility with modern technologies. |

| Complexity of Data Collection and Management [68,69] | Data Volume: Implement scalable infrastructure solutions like cloud and edge computing to efficiently handle large data volumes. Data Quality: Establish data validation processes to ensure the accuracy and reliability of collected data for effective decision-making. |

8. Discussion and Future Research

- a.

- Summary of Findings from Literature Review

| References | Description | Gap Analysis |

|---|---|---|

| [70] | Provides a comprehensive analysis of the state-of-the-art definitions of Digital Twin (DT), exploring its main characteristics, and investigating the domains in which DT applications are being developed. Design implications and discusses open issues and challenges related to DT. | The gap between the two papers lies in their specific focus areas, with the first paper providing a broader overview of DT definitions, characteristics, and applications, while the second paper delves deeper into the prescriptive digital twin model for building spaces. |

| [61] | Offers a comprehensive analysis of the current state of DT applications in the construction industry, including the concept, technologies, and six areas of application in the lifecycle phases of a project. | The gap between the two papers lies in their specific research focus. While the first paper provides a broader analysis of DT applications in the construction industry, the second paper narrows down the focus to the prescriptive digital twin model for the physical environment of a building space. |

| [66] | Provides an overview of the processes involved in establishing and using digital twin technologies in the construction industry, including data acquisition, transmission, modeling, integration, and servicing processes. | The gap analysis suggests that the latter paper provides a more detailed examination of the prescriptive digital twin model for the physical environment of a building space, while the former paper offers a broader overview of digital twin technologies in the construction industry. |

| [71] | Focuses on the construction of a systematic and clear architecture for DTs, with a specific emphasis on the operation and maintenance (O&M) phase. It presents a system architecture for DTs and shares lessons learned and challenges involved in developing DTs in real practices. | The gap between these two papers lies in their specific focuses and contributions. “Developing a Digital Twin at Building and City Levels” provides a roadmap and research efforts for asset management practitioners, policymakers, and researchers, while “Prescriptive Digital Twin Model for Physical Environment of a Building Space” lays the foundation for system architecture and demonstrator development. |

| [72] | Focuses on the application of digital twin information systems in construction, emphasizing the use of data-driven management and control of physical systems. | While both papers contribute to the understanding of Digital Twin in construction, they have different focuses. “Construction with digital twin information systems” emphasizes the use of digital twin information systems for closed-loop control in construction, while “Prescriptive Digital Twin Model for Physical Environment of a Building Space: A Comprehensive Literature Review” focuses on the prescriptive model for the physical environment of a building space. |

| [2] | Discusses the multifaceted applications of Building Information Modelling (BIM) during the construction stage and highlights the limits and requirements for a Construction Digital Twin (CDT). The paper emphasizes the need for a holistic, scalable semantic approach that factors in dynamic data at different levels. | The gap analysis between these two papers reveals that the first paper discusses the limitations and requirements for a Construction Digital Twin, while the second paper focuses on a prescriptive digital twin model for the physical environment of a building space. |

| [73] | Focuses on the application framework and methods of digital twin (DT) technology for product lifecycle management. It proposes an application framework for DT and provides a case study of a welding production line. | The gap between these two papers lies in their research focus. The first paper focuses on the application framework and methods of DT for product lifecycle management, while the second paper focuses on the prescriptive digital twin model for the physical environment of a building space. |

| [74] | Focuses on the review of Digital Twin (DT) applications for maintenance, which has not been previously explored. | The gap between these two papers lies in their different research focuses. The first paper explores the applications of DTs for maintenance in various industrial sectors, while the second paper focuses on the development of a specific prescriptive digital twin model for building spaces. |

- b.

- Challenges and Potential Directions for Further Research

- Data availability: Constructing an accurate prescriptive digital twin model requires a substantial and diverse amount of data regarding the space. However, often the required data is unavailable or difficult to access.

- Poor data quality: In addition to data availability issues, poor data quality can also pose challenges. Incomplete, inaccurate, or unstructured data can affect the quality of the constructed model.

- Model complexity: Complex and intricate prescriptive digital twin models demand significant resources for development and management. Model developers must ensure that the model is accessible and understandable to users.

- Environmental changes: Over time, a space can undergo changes such as the addition or removal of equipment, temperature fluctuations, or layout alterations, which can impact the performance of a prescriptive digital twin model.

- Technology and resource availability: Developing a prescriptive digital twin model requires extensive technology and resources, such as powerful computers and software, sensors, and monitoring systems. Limited availability of these resources can pose challenges.

- Model alignment with user needs: A prescriptive digital twin model must align with user requirements and expectations. Therefore, conducting a thorough study of user objectives and needs is essential before developing the model.

- Enhanced space efficiency and performance: By utilizing a prescriptive digital twin model, energy usage can be optimized, maintaining appropriate temperature and air quality, and improving HVAC system performance to save energy costs and ensure user comfort.

- Identifying issues before they occur: A prescriptive digital twin model enables users to simulate and predict problems or potential issues in the space before they happen, allowing for preventive or corrective actions to be taken.

- Improved decision-making: With a prescriptive digital twin model, decision-making is based on accurate and real-time data, enabling users to make better and more precise decisions.

- Enhanced user experience: A prescriptive digital twin model can help users choose a workspace that meets their preferences, such as desired temperature, lighting, and noise levels.

9. Conclusions

Acknowledgments

Conflicts of Interest

References

- Aquilani B, Piccarozzi M, Abbate T, Codini A. The role of open innovation and value co-creation in the challenging transition from industry 4.0 to society 5.0: Toward a theoretical framework. Sustain. 2020;12(21):1–21.

- Boje C, Guerriero A, Kubicki S, Rezgui Y. Towards a semantic Construction Digital Twin: Directions for future research. Autom Constr 2020;114(March):103179. [CrossRef]

- Botín-Sanabria DM, Mihaita S, Peimbert-García RE, Ramírez-Moreno MA, Ramírez-Mendoza RA, Lozoya-Santos J de J. Digital Twin Technology Challenges and Applications: A Comprehensive Review. Remote Sens. 2022;14(6):1–25.

- Wu HUI, Han H, Wang X, Sun S. Research on Artificial Intelligence Enhancing Internet of Things Security: A Survey. 2020;8.

- Rodr I, Shirvanizadeh N. Applications of Artificial Intelligence, Machine Learning, Big Data and the Internet of Things to the COVID-19 Pandemic: A Scientometric Review Using Text Mining. Environ Res Public Heal. 2021;18(16):8578.

- Johnson B, Zimmermann T, Bird C. The Effect of Work Environments on Productivity and Satisfaction of Software Engineers. IEEE Trans Softw Eng. 2021;47(4):736–57.

- Tagliabue LC, Cecconi FR, Maltese S, Rinaldi S, Ciribini ALC, Flammini A. Leveraging digital twin for sustainability assessment of an educational building. Sustain. 2021;13(2):1–16.

- Wang C, Zhang F, Wang J, Doyle JK, Hancock PA, Mak CM, et al. How indoor environmental quality affects occupants’ cognitive functions: A systematic review. Build Environ [Internet]. 2021;193(September 2020):107647. [CrossRef]

- Altomonte S, Schiavon S, Kent MG, Brager G. Indoor environmental quality and occupant satisfaction in green-certified buildings. Build Res Inf. 2019;47(3):255–74.

- Mujan I, Anđelković AS, Munćan V, Kljajić M, Ružić D. Influence of indoor environmental quality on human health and productivity - A review. J Clean Prod. 2019;217:646–57.

- Kaushik A, Arif M, Tumula P, Ebohon OJ. Effect of thermal comfort on occupant productivity in office buildings: Response surface analysis. Build Environ [Internet]. 2020;180(June):107021. [CrossRef]

- Candido C, Thomas L, Haddad S, Zhang F, Mackey M, Ye W. Designing activity-based workspaces: satisfaction, productivity and physical activity. Build Res Inf [Internet]. 2019;47(3):275–89. [CrossRef]

- Geng Y, Ji W, Wang Z, Lin B, Zhu Y. A review of operating performance in green buildings: Energy use, indoor environmental quality and occupant satisfaction. Energy Build [Internet]. 2019;183:500–14. [CrossRef]

- Godager B, Onstein E, Huang L. The Concept of Enterprise BIM: Current Research Practice and Future Trends. IEEE Access. 2021;9:42265–90.

- Olugboyega O, Edwards DJ, Windapo AO, Omopariola ED, Martek I. Development of a conceptual model for evaluating the success of BIM-based construction projects. Smart Sustain Built Environ. 2021;10(4):681–701.

- Pereira P, Ramos NMM, Zhao X, Shahzad M, Tariq Shafiq M, Douglas D, et al. Digital Twins in Built Environments: An Investigation of the Characteristics, Applications, and Challenges. Build 2022, Vol 12, Page 120 [Internet]. 2022 Jan 25 [cited 2023 Jul 14];12(2):120. Available online: https://www.mdpi.com/2075-5309/12/2/120/htm.

- Tuhaise VV, Tah JHM, Abanda FH. Technologies for digital twin applications in construction. Autom Constr. 2023 Aug 1;152:104931.

- Deng M, Menassa CC, Kamat VR. From BIM to digital twins: A systematic review of the evolution of intelligent building representations in the AEC-FM industry. J Inf Technol Constr. 2021;26(November 2020):58–83.

- Yang W, Zheng Y, Li S. Application Status and Prospect of Digital Twin for On-Orbit Spacecraft. IEEE Access. 2021;9:106489–500.

- Dassisti M, De Nicolò M. Enterprise integration and economical crisis for mass craftsmanship: A case study of an Italian furniture company. Lect Notes Comput Sci (including Subser Lect Notes Artif Intell Lect Notes Bioinformatics) [Internet]. 2012 [cited 2023 Sep 5];7567 LNCS:113–23. Available online: https://link.springer.com/chapter/10.1007/978-3-642-33618-8_19.

- Tao F, Cheng J, Qi Q, Zhang M, Zhang H, Sui F. Digital twin-driven product design, manufacturing and service with big data. Int J Adv Manuf Technol. 2018;94(9–12):3563–76.

- Grieves M, systems JV-T perspectives on complex, 2017 undefined. Digital twin: Mitigating unpredictable, undesirable emergent behavior in complex systems. Springer [Internet]. 2017 Jan 1 [cited 2022 ];85–113. Available online: https://link.springer.com/chapter/10.1007/978-3-319-38756-7_4.

- Leng J, Zhang H, Yan D, Liu Q, Chen X, Zhang D. Digital twin-driven manufacturing cyber-physical system for parallel controlling of smart workshop. J Ambient Intell Humaniz Comput [Internet]. 2019 Mar 13 [cited 2023 Sep 5];10(3):1155–66. Available online: https://link.springer.com/article/10.1007/s12652-018-0881-5.

- Bao J, Guo D, Li J, Systems JZ-EI, 2019 undefined. The modelling and operations for the digital twin in the context of manufacturing. Taylor Fr [Internet]. 2018 Apr 21 [cited 2023 Sep 5];13(4):534–56. Available online: https://www.tandfonline.com/doi/abs/10.1080/17517575.2018.1526324.

- Lee H, Appl TK-IELPB, 2018 undefined. Smart factory use case model based on digital twin. icicelb.orgHK Lee, T Kim Express Lett Part B Appl, 2018•icicelb.org [Internet]. 2018 [cited 2023 Sep 5];9(9):931–6. Available online: http://www.icicelb.org/ellb/contents/2018/9/elb-09-09-07.pdf.

- Haag S, Letters RA-M, 2018 U. Digital twin–Proof of concept. Elsevier [Internet]. 2018 [cited 2023 Sep 5];15:64–6. Available online: https://www.sciencedirect.com/science/article/pii/S2213846318300208.

- Melesse TY, Di Pasquale V, Riemma S. Digital Twin Models in Industrial Operations: A Systematic Literature Review. Procedia Manuf. 2020 Jan 1;42:267–72.

- Mazumder O, Roy D, Bhattacharya S, Sinha A, Pal A. Synthetic PPG generation from haemodynamic model with baroreflex autoregulation: A Digital twin of cardiovascular system. Proc Annu Int Conf IEEE Eng Med Biol Soc EMBS. 2019 Jul 1;5024–9.

- Borangiu T, Trentesaux D, Thomas A, Leitão P, Barata J. Digital transformation of manufacturing through cloud services and resource virtualization. Comput Ind. 2019 Jun 1;108:150–62.

- Grieves, M. Grieves M. Intelligent digital twins and the development and management of complex systems. Digit Twin. 2022 May 25;2:8.

- Grieves MW. Digital Twins: Past, Present, and Future. Digit Twin [Internet]. 2023 Jan 1 [cited 2024 Apr 4];1:97–121. Available online: https://link.springer.com/chapter/10.1007/978-3-031-21343-4_4.

- Jeong D-Y, Baek M-S, Lim T-B, Kim Y-W, Kim S-H, Lee Y-T, et al. Digital twin: technology evolution stages and implementation layers with technology elements. IEEE Access. 2022;10:52609–20.

- Houtmeyers KC, Jaspers A, Figueiredo P. Managing the training process in elite sports: From descriptive to prescriptive data analytics. Int J Sports Physiol Perform. 2021;16(11):1719–23.

- Eramo R, Bordeleau F, Combemale B, Brand M van den, Wimmer M, Wortmann A. Conceptualizing Digital Twins. IEEE Softw. 2022;39(2):39–46.

- Bosch-Sijtsema P, Claeson-Jonsson C, Johansson M, Roupe M. The hype factor of digital technologies in AEC. Constr Innov. 2021 Oct 21;21(4):899–916.

- Boje C, Guerriero A, Kubicki S, Rezgui Y. Towards a semantic Construction Digital Twin: Directions for future research. Autom Constr 2020;114(November 2019):103179. [CrossRef]

- Ozturk GB. Digital Twin Research in the AECO-FM Industry. J Build Eng 2021;40(May):102730. [CrossRef]

- Snyder, H. Literature review as a research methodology: An overview and guidelines. J Bus Res. 2019 Nov 1;104:333–9.

- Valverde-Berrocoso J, del Carmen Garrido-Arroyo M, Burgos-Videla C, Morales-Cevallos MB. Trends in Educational Research about e-Learning: A Systematic Literature Review (2009–2018). Sustain 2020, Vol 12, Page 5153 [Internet]. 2020 Jun 24 [cited 2024 Apr 4];12(12):5153. Available online: https://www.mdpi.com/2071-1050/12/12/5153/htm.

- Fang X, Wang H, Liu G, Tian X, Ding G, Zhang H. Industry application of digital twin: from concept to implementation. Int J Adv Manuf Technol [Internet]. 2022;121(7–8):4289–312. [CrossRef]

- Abdallah M, Abu Talib M, Feroz S, Nasir Q, Abdalla H, Mahfood B. Artificial intelligence applications in solid waste management: A systematic research review. Waste Manag 2020;109:231–46. [CrossRef]

- Opoku DGJ, Perera S, Osei-Kyei R, Rashidi M. Digital twin application in the construction industry: A literature review. J Build Eng [Internet]. 2021;40(May):102726. [CrossRef]

- Oztemel E, Gursev S. Literature review of Industry 4.0 and related technologies. J Intell Manuf [Internet]. 2020 Jan 1 [cited 2022 Dec 15];31(1):127–82. Available online: https://link.springer.com/article/10.1007/s10845-018-1433-8.

- Paul J, Criado AR. The art of writing literature review: What do we know and what do we need to know? Int Bus Rev. 2020 Aug 1;29(4):101717.

- Vivi QL, Parlikad AK, Woodall P, Ranasinghe GD, Heaton J. Developing a dynamic digital twin at a building level: Using Cambridge campus as case study. Int Conf Smart Infrastruct Constr 2019, ICSIC 2019 Driv Data-Informed Decis. 2019;2019:67–75.

- Khajavi SH, Motlagh NH, Jaribion A, Werner LC, Holmstrom J. Digital Twin: Vision, benefits, boundaries, and creation for buildings. IEEE Access. 2019;7:147406–19.

- Koulalis I, Dourvas N, Triantafyllidis T, Ioannidis K, Vrochidis S, Kompatsiaris I. A survey for image based methods in construction: from images to digital twins. ACM Int Conf Proceeding Ser [Internet]. 2022 Sep 14 [cited 2023 Jul 14];103–10. [CrossRef]

- Sharma A, Kosasih E, Zhang J, Brintrup A, Calinescu A. Digital Twins: State of the art theory and practice, challenges, and open research questions. J Ind Inf Integr 2022;30(August):100383. [CrossRef]

- Zhao J, Feng H, Chen Q, Garcia de Soto B. Developing a conceptual framework for the application of digital twin technologies to revamp building operation and maintenance processes. J Build Eng [Internet]. 2022;49(21):104028. [CrossRef]

- Lepenioti K, Bousdekis A, Apostolou D, Mentzas G. Prescriptive analytics: Literature review and research challenges. Int J Inf Manage. 2020 Feb 1;50:57–70.

- El Morr C, Ali-Hassan H. Descriptive, Predictive, and Prescriptive Analytics. 2019;31–55.

- Padovano A, Longo F, Nicoletti L, Gazzaneo L, Chiurco A, Talarico S. A prescriptive maintenance system for intelligent production planning and control in a smart cyber-physical production line. Procedia CIRP [Internet]. 2021;104(March):1819–24. [CrossRef]

- Poornima S, Pushpalatha M. A survey on various applications of prescriptive analytics. Int J Intell Networks [Internet]. 2020;1(July):76–84. [CrossRef]

- Andriopoulos N, Plakas K, Mountzouris C, Gialelis J, Birbas A, Karatzas S, et al. Local Energy Market-Consumer Digital Twin Coordination for Optimal Energy Price Discovery under Thermal Comfort Constraints. Vol. 13, Applied Sciences (Switzerland). 2023.

- Bortolini R, Rodrigues R, Alavi H, Vecchia LFD, Forcada N. Digital Twins’ Applications for Building Energy Efficiency: A Review. Energies. 2022;15(19).

- Moyne J, Qamsane Y, Balta EC, Kovalenko I, Faris J, Barton K, et al. A Requirements Driven Digital Twin Framework: Specification and Opportunities. IEEE Access. 2020;8:107781–801.

- Lu Q, Parlikad AK, Woodall P, Don Ranasinghe G, Xie X, Liang Z, et al. Developing a Digital Twin at Building and City Levels: Case Study of West Cambridge Campus. J Manag Eng. 2020;36(3):1–19.

- Zou H, Zhou Y, Yang J, Spanos CJ. Towards occupant activity driven smart buildings via WiFi-enabled IoT devices and deep learning. Energy Build. 2018 Oct 15;177:12–22.

- Zhang M, Tao F, Huang B, Liu A, Wang L, Anwer N, et al. Digital twin data: methods and key technologies. Digit Twin. 2022;1:2.

- Zhang L, Zhou L, Horn BKP. Building a right digital twin with model engineering. J Manuf Syst. 2021;59(November 2020):151–64.

- Opoku DGJ, Perera S, Osei-Kyei R, Rashidi M. Digital twin application in the construction industry: A literature review. J Build Eng [Internet]. 2021;40(February):102726. [CrossRef]

- Camposano JC, Smolander K, Ruippo T. Seven Metaphors to Understand Digital Twins of Built Assets. IEEE Access. 2021;9:27167–81.

- van Dyck M, Lüttgens D, Piller FT, Brenk S. Interconnected digital twins and the future of digital manufacturing: Insights from a Delphi study. J Prod Innov Manag [Internet]. 2023 Jul 1 [cited 2024 Apr 4];40(4):475–505. Available online: https://onlinelibrary.wiley.com/doi/full/10.1111/jpim.12685.

- Tao F, Zhang H, Liu A, Nee AYC. Digital Twin in Industry: State-of-the-Art. IEEE Trans Ind Informatics. 2019;15(4):2405–15.

- Redelinghuys AJH, Basson AH, Kruger K. A six-layer architecture for the digital twin: a manufacturing case study implementation. Vol. 31, Journal of Intelligent Manufacturing. 2020. p. 1383–402.

- Feng H, Chen Q, de Soto BG. Application of digital twin technologies in construction: an overview of opportunities and challenges. Proc Int Symp Autom Robot Constr. 2021;2021-Novem(November):979–86.

- Kirchhof JC, Michael J, Rumpe B, Varga S, Wortmann A. Model-driven digital twin construction: Synthesizing the integration of cyber-physical systems with their information systems. Proceedings - 23rd ACM/IEEE International Conference on Model Driven Engineering Languages and Systems, MODELS 2020. 2020. p. 90–101.

- Slot M, Huisman P, Lutters E. A structured approach for the instantiation of digital twins. Procedia CIRP 2020;91:540–5. [CrossRef]

- Qi Q, Tao F, Hu T, Anwer N, Liu A, Wei Y, et al. Enabling technologies and tools for digital twin. J Manuf Syst [Internet]. 2021;58(August):3–21. [CrossRef]

- Barricelli BR, Casiraghi E, Fogli D. A survey on digital twin: Definitions, characteristics, applications, and design implications. IEEE Access. 2019;7(Ml):167653–71.

- Lu Q, Parlikad AK, Woodall P, Don Ranasinghe G, Xie X, Liang Z, et al. Developing a Digital Twin at Building and City Levels: Case Study of West Cambridge Campus. J Manag Eng. 2020;36(3):05020004.

- Sacks R, Brilakis I, Pikas E, Xie HS, Girolami M. Construction with digital twin information systems. Data-Centric Eng. 2020;1(6).

- Zheng Y, Yang S, Cheng H. An application framework of digital twin and its case study. J Ambient Intell Humaniz Comput [Internet]. 2019;10(3):1141–53. [CrossRef]

- Errandonea I, Beltrán S, Arrizabalaga S. Digital Twin for maintenance: A literature review. Comput Ind. 2020;123.

| References | Definition of Digital Twin |

|---|---|

| [19] | The behavior of a “digital twin”—an integrated multi-physics, multi-scale, probabilistic simulation of a vehicle or system—is imitated by using the best physical models currently available, sensor updates, fleet history, etc. |

| [20] | A computerized representation of a real-world system that may be used to mimic, forecast, and improve the behavior of the real-world system. |

| [21] | A digital depiction of a real-world product or system that spans its whole life cycle, employing real-time data to facilitate comprehension, learning, reasoning, and dynamic performance calibration. |

| [22] | A digital twin is a representation of a physical system or thing that uses real-time data to enable comprehension, learning, and reasoning throughout the object’s life cycle. |

| [21] | A digital twin is a dynamic digital replica of a real-world thing or system that mimics its characteristics throughout its existence. |

| [23] | A digital twin is a virtual representation of a procedure, a good, or a service that may simulate how it might act in various situations. |

| [24] | To imitate the relevant behavior and properties of actual objects in real time, virtual models are employed in virtual space. |

| [25] | Digital representation of actual items or processes that is updated in close to real time to help businesses perform better. A smart factory built on a digital twin combines the ideas of IoT (Internet of Things) and IoS (Internet of Service). |

| [26] | A thorough digital depiction of each thing. Through models and data, it incorporates the characteristics, circumstances, and behaviors of actual objects. |

| [27] | A digital twin is an accurate, live-streamed replica of a physical manufacturing system that accurately captures all of its features. |

| [28] | A digital twin is a synchronized and interconnected digital representation of a physical asset that captures both the elements and the dynamics of how systems and devices function in their surroundings and evolve over time. |

| [29] | A digital model of a physical system that may be used to simulate, forecast, and optimize the behavior of the physical system and its operations. This representation is updated continually with data from the physical system and its surroundings. |

| Concept | Components | Description |

|---|---|---|

|

Building Representation Model: The building representation model is the foundational digital framework that mirrors the physical building in a virtual environment. It serves as a comprehensive and detailed digital twin of the actual building [16,45]. |

Geospatial Data | This component involves mapping the physical layout of the building, including its location, dimensions, and geographical context. |

| BIM (Building Information Modeling) | BIM is a comprehensive virtual model of a building in a form of object oriented-database, encompassing detailed geometry and non-geometry information. | |

| Sensor Integration | Real-time data from various sensors embedded throughout the building is integrated into the model. This includes data from environmental sensors, occupancy sensors, and more [2,46]. | |

|

Sensors and Data Monitoring: Sensors are essential components that continuously collect real-time data regarding various aspects of the building’s environment and operations [47]. |

Environmental Sensors | These sensors monitor conditions like temperature, humidity, air quality, and lighting levels, ensuring that the indoor environment remains comfortable and efficient. |

| Occupancy Sensors | Occupancy sensors detect the presence of individuals in different areas of the building, which can be used to optimize lighting, HVAC systems, and security. | |

| Energy Meters | These meters measure electricity, water, and gas consumption, providing data for energy management and sustainability efforts. | |

| Security Sensors | Security sensors include surveillance cameras, access control systems, and intruder alarms, enhancing building safety and security. | |

|

Integration with IoT (Internet of Things) Technologies: Prescriptive Digital Twin rely on IoT technologies to enable seamless connectivity and data transmission between sensors, devices, and the digital twin framework [48] |

Wireless Communication Protocols | Communication Protocols: IoT sensors and devices communicate using various protocols like MQTT, Zigbee, LoRa, and more, ensuring efficient data transfer. |

| Gateways | Gateways serve as intermediaries between IoT devices and the digital twin, facilitating data aggregation and transmission. | |

| IoT Platforms | IoT platforms provide the software infrastructure for managing and analyzing IoT data, ensuring data integrity and accessibility. | |

|

Big Data Analysis and Real-Time Data Processing: Prescriptive Digital Twin employ big data analytics and real-time data processing engines to derive meaningful insights from the vast amount of data generated by sensors and other sources [49]. |

Data Warehouses | Data warehouses serve as repositories for historical data, enabling the comparison of current data with past trends. |

| Machine Learning Algorithms | Machine learning algorithms are used for predictive and prescriptive analysis, identifying patterns and making recommendations. | |

| Complex Event Processing (CEP) | CEP engines analyze data in real time, detecting events and anomalies as they occur, which is crucial for immediate decision-making. | |

|

Cloud Computing and Edge Computing in Prescriptive Digital Twin: Prescriptive Digital Twin leverage both cloud and edge computing to optimize data storage, processing, and decision-making [50,51,52,53] |

Cloud Infrastructure | Cloud computing provides scalable and remote data processing capabilities, making it suitable for handling vast datasets and resource-intensive tasks. |

| Edge Devices | Edge computing involves on-site data processing at the source of data generation, reducing latency and enabling immediate actions in real time. | |

| Fog Computing | Fog computing is a hybrid approach that combines cloud and edge capabilities, providing flexibility and efficiency in data processing and decision distribution. |

| Improved Performance | Descriptions |

|---|---|

| Building Energy Efficiency & Conservation [54,55] | |

| Demand Response | Real-time data analysis allows adjustments in energy consumption patterns to match supply, optimizing energy costs. |

| Energy Monitoring | Continuous monitoring and analysis of energy usage identify areas for efficiency improvements, reducing waste. |

| HVAC Optimization | The digital twin fine-tunes heating, ventilation, and air conditioning systems for optimal comfort and energy savings. |

| Renewable Energy Integration | Integration with renewable energy sources, like solar panels, ensures efficient utilization. |

| Prediction and Maintenance Needs Management [46,56] | |

| Predictive Maintenance | Real-time sensor data and predictive algorithms forecast equipment failures, allowing timely repairs and reducing downtime. |

| Maintenance Scheduling | The digital twin optimizes maintenance schedules, minimizing disruption to building occupants. |

| Inventory Management | Tracking equipment and spare parts ensures maintenance teams have what they need when they need it. |

| Work Order Management | Streamlining work orders and tracking their progress enhances maintenance efficiency. |

| Indoor Air Quality and Environment Regulation [11,57,58] | |

| Air Quality Control | Monitoring pollutants and adjusting HVAC systems ensures occupants breathe clean air. |

| Occupancy-Based Controls | Adjusting ventilation, heating, and cooling based on occupancy levels improves comfort and energy efficiency. |

| Lighting Control | Adaptive lighting systems create optimal lighting conditions for productivity and well-being. |

| Noise Reduction | Sensors detect excessive noise levels and adjust sound insulation and HVAC systems accordingly. |

| Risk Management and Building Security [16] | |

| Security Monitoring | Real-time surveillance camera feeds and access control data are analyzed to identify security threats. |

| Anomaly Detection | The digital twin detects unusual activities or unauthorized access and triggers immediate alerts. |

| Emergency Response | Integration with emergency systems facilitates rapid response to fires, intrusions, or other emergencies. |

| Visitor Management | Enhancing visitor tracking and access control improves overall security. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).