Submitted:

03 July 2024

Posted:

03 July 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Assumptions

2.2. Water Absorption Experiments

2.2.1. Description of the Experiments and Measurements

2.2.2. Moisture Content

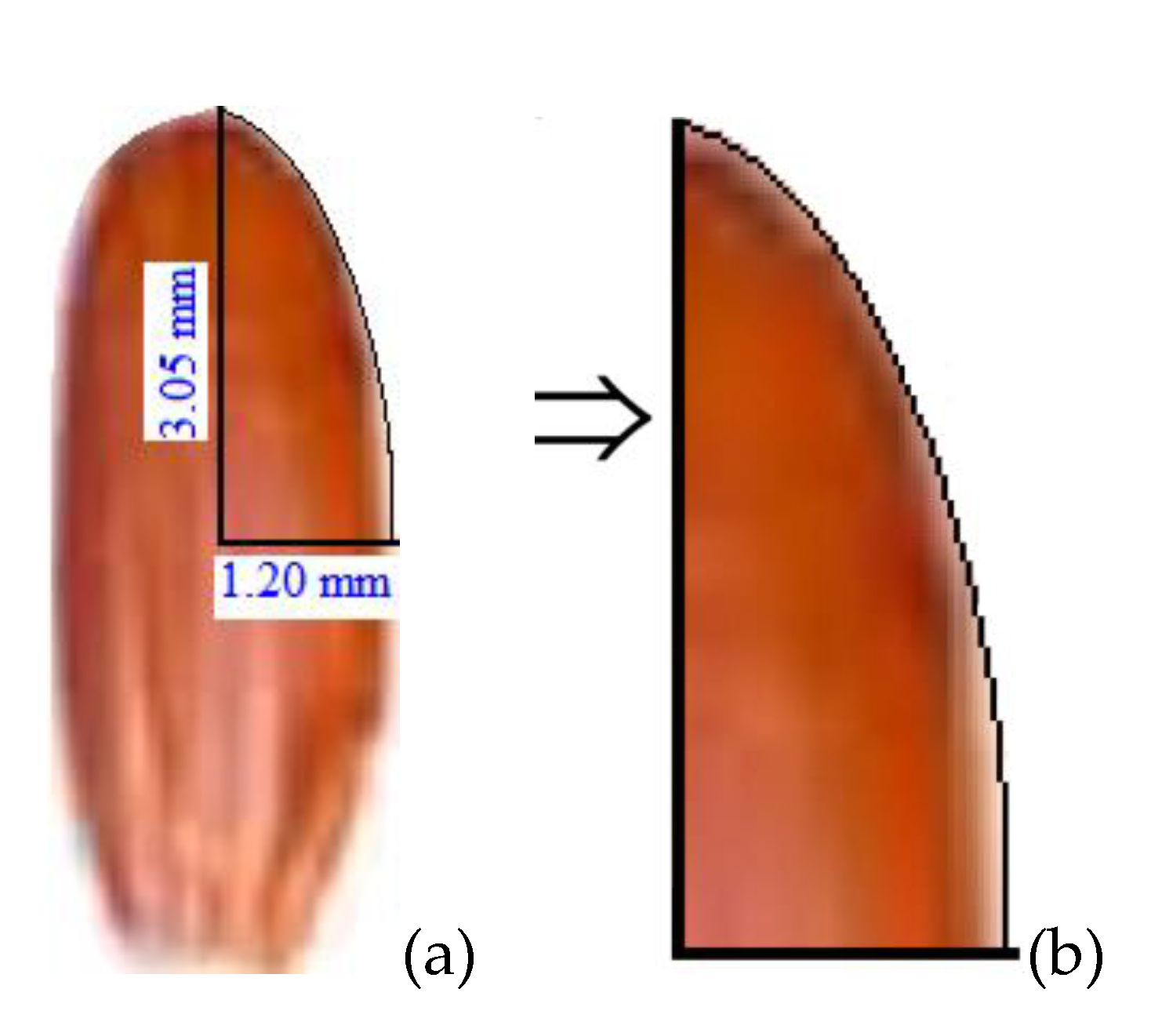

2.2.3. Growth in the Volume of Husked Red Rice Grains Over Time

2.3. Mathematical Model for Description of Water Absorption

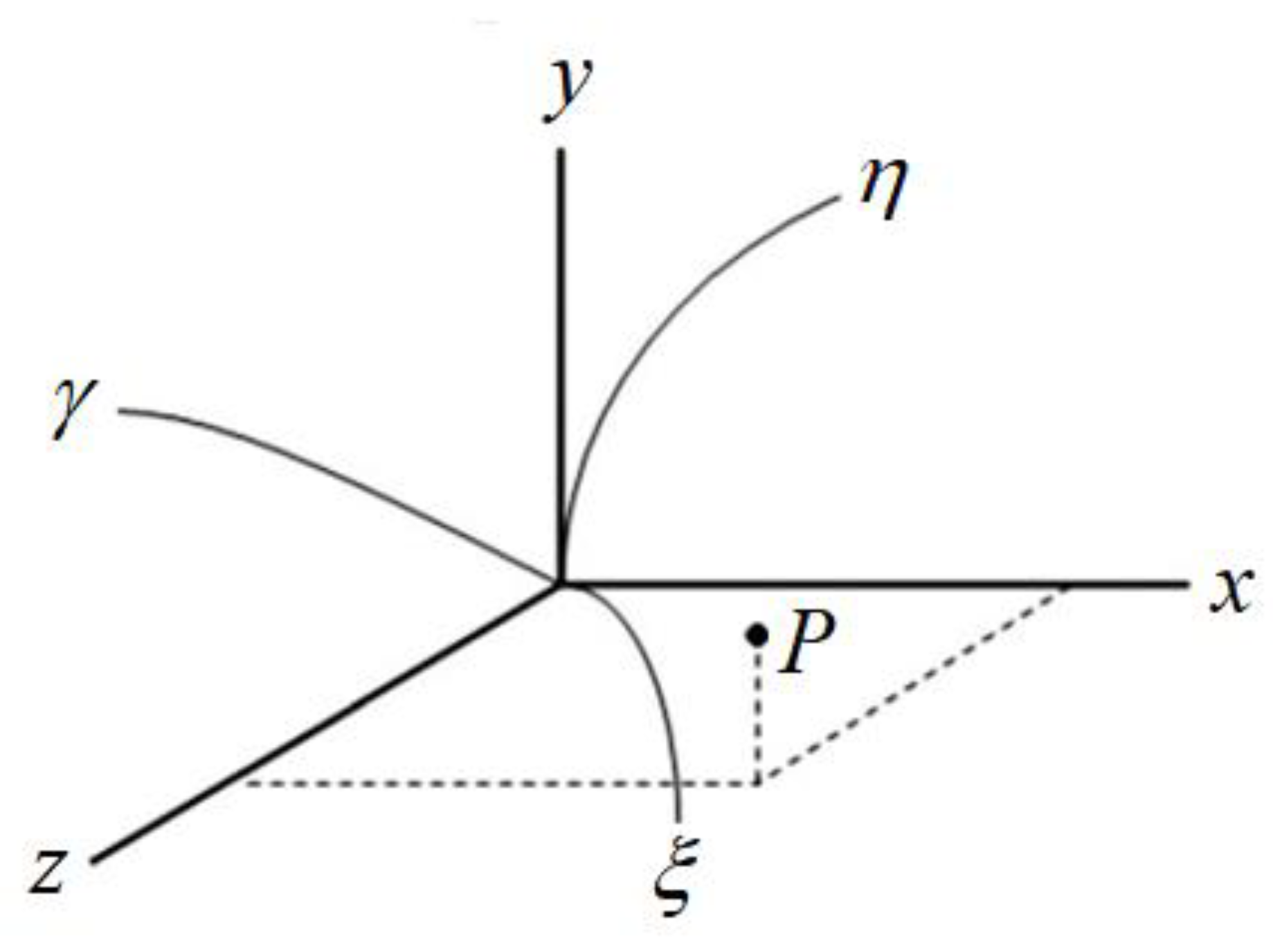

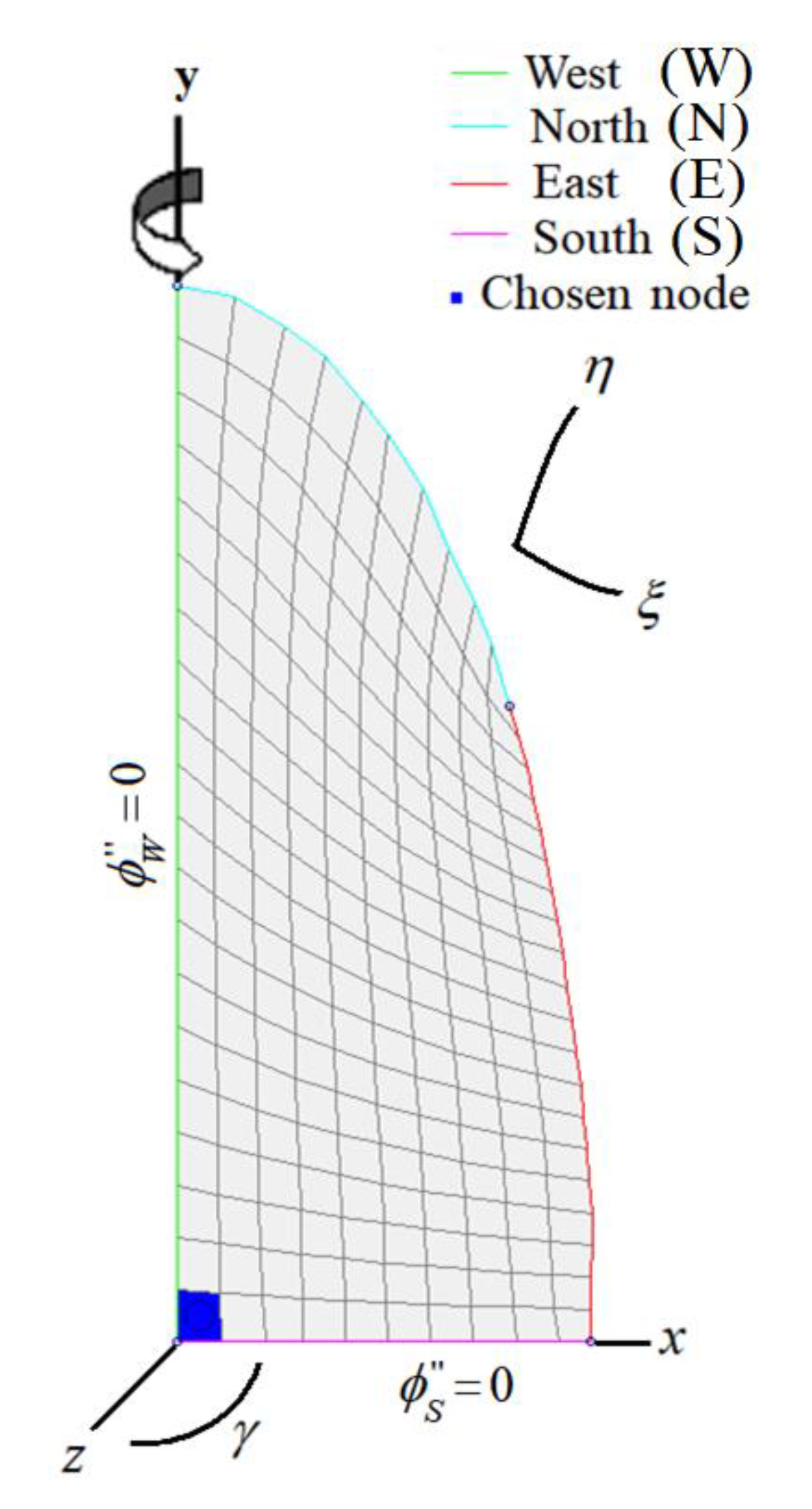

2.3.1. Diffusion Equation and System of Coordinates

2.3.2. Solution of the Two-Dimensional Diffusion Equation in Generalized Coordinates

2.3.3. Grid Generation, Grid and Time Refinement, Average Moisture Content, and Optimizations

3. Results and Discussion

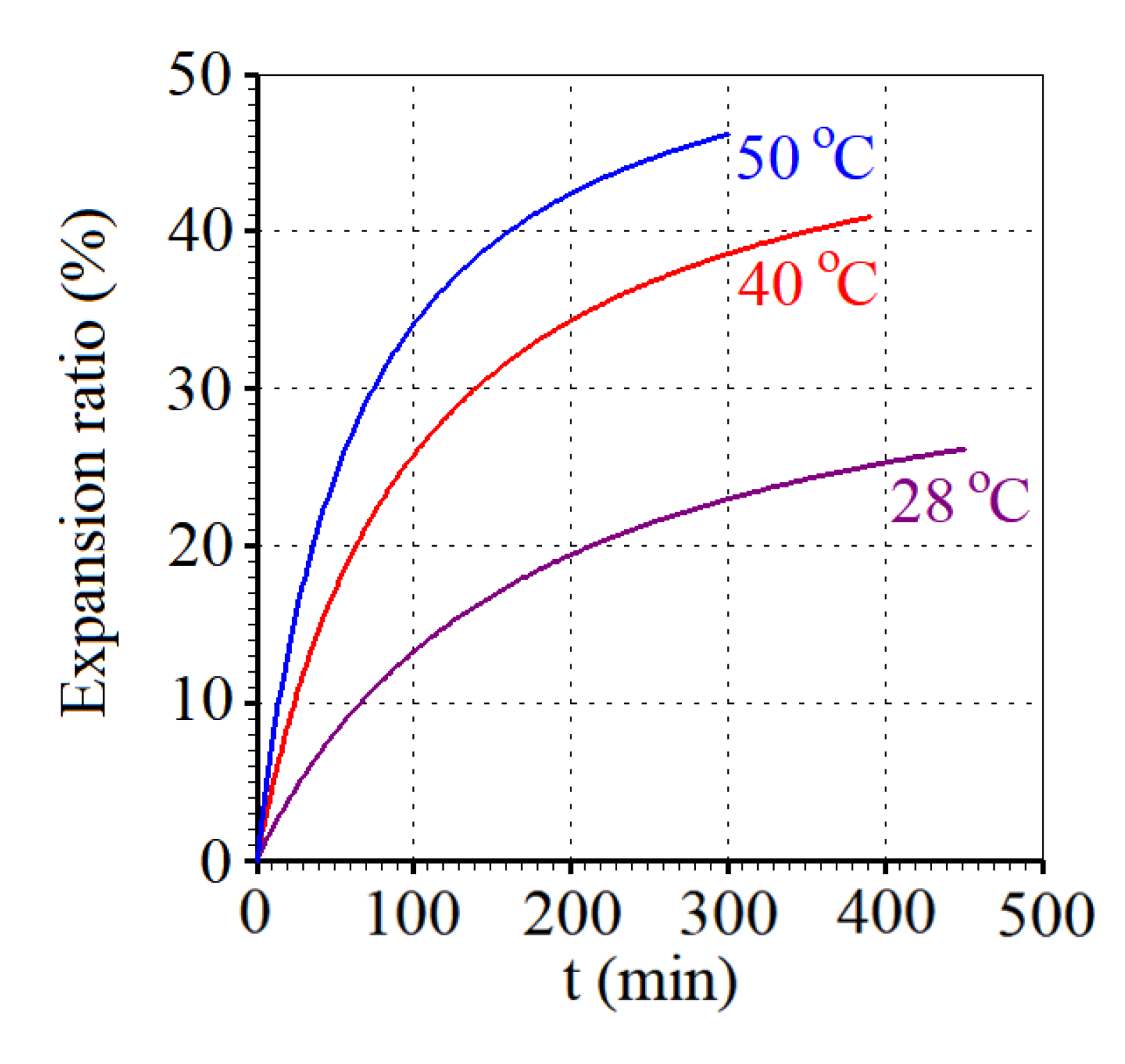

3.1. Results and Comments

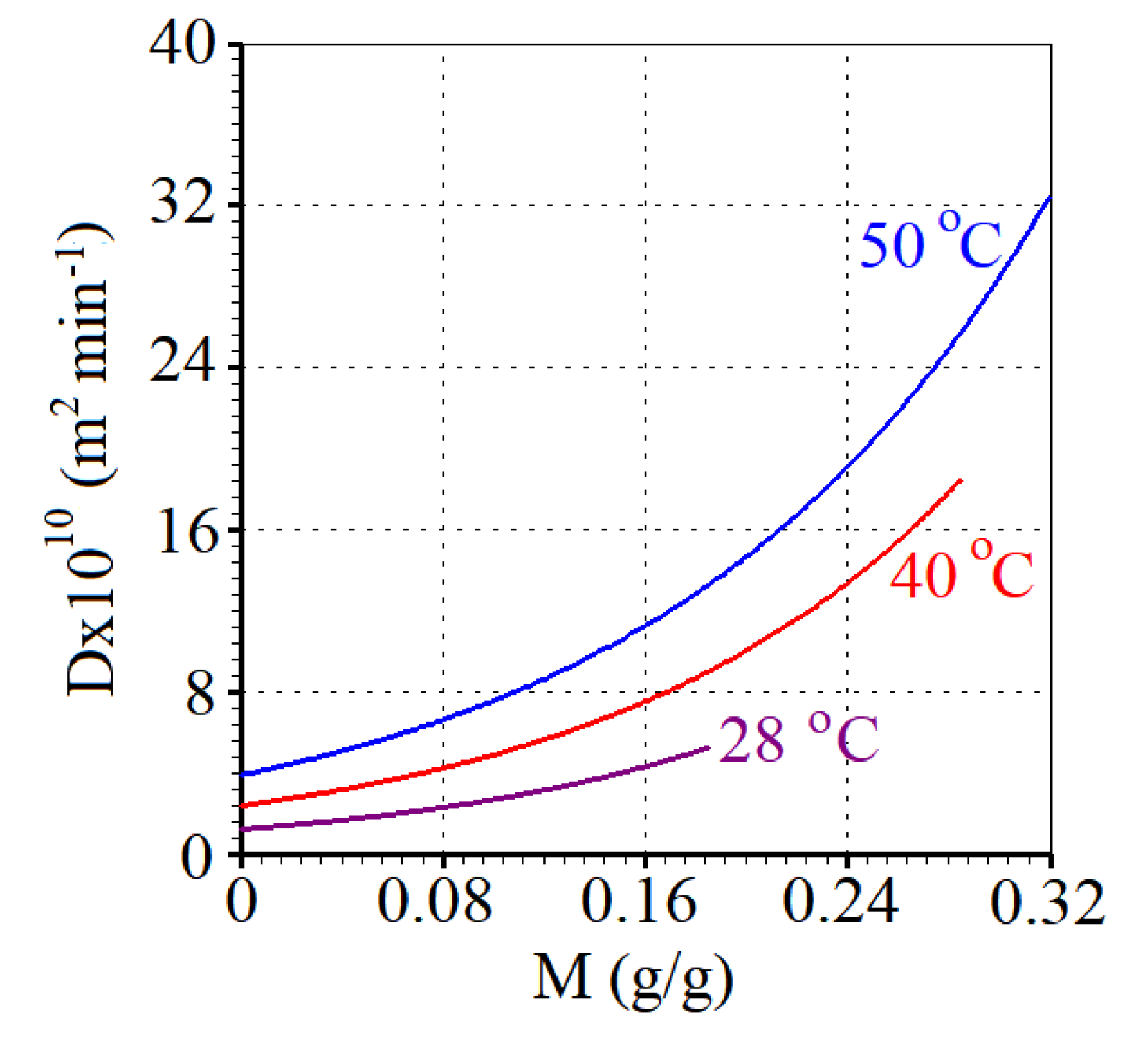

3.1.1. Optimizations

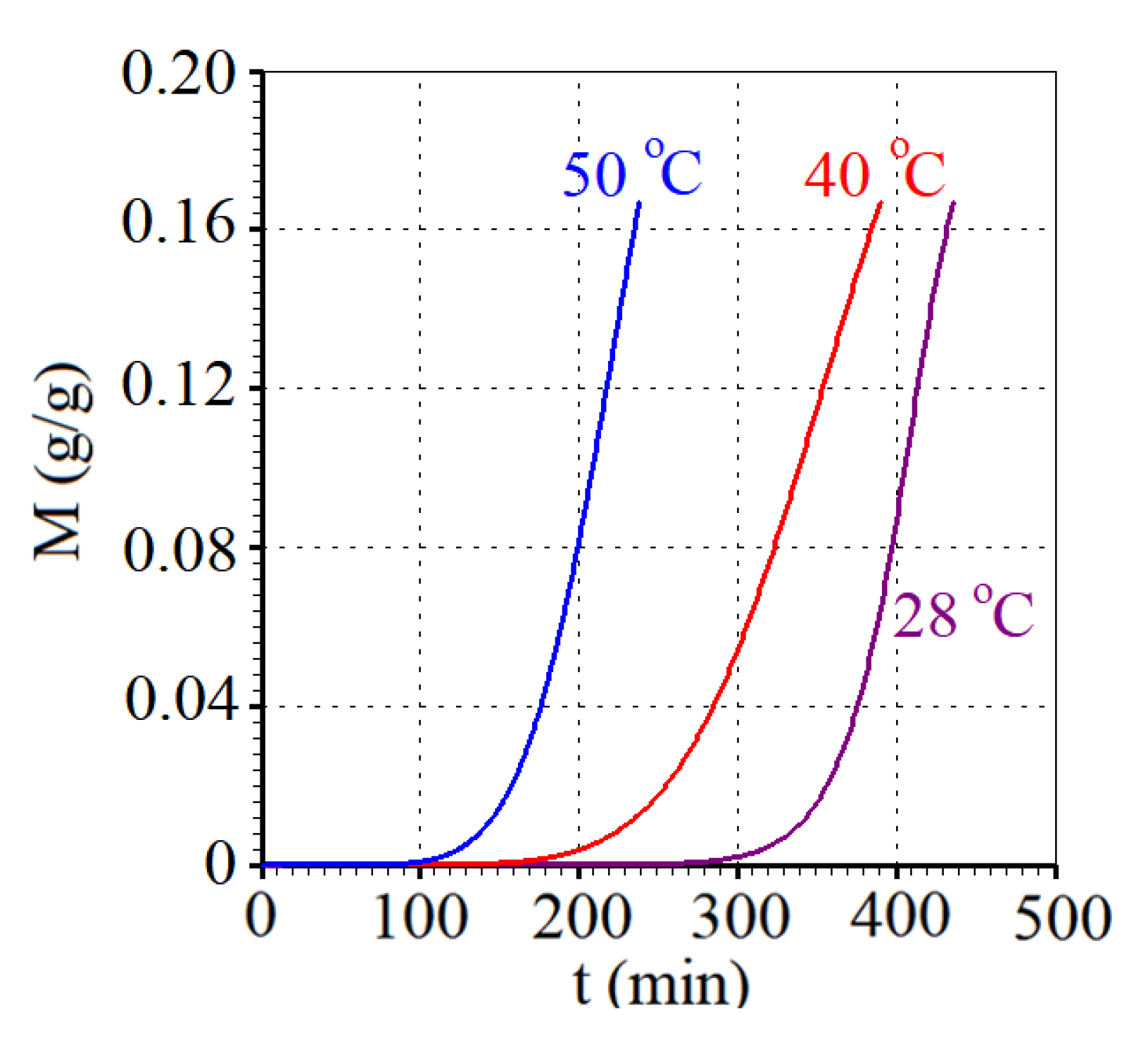

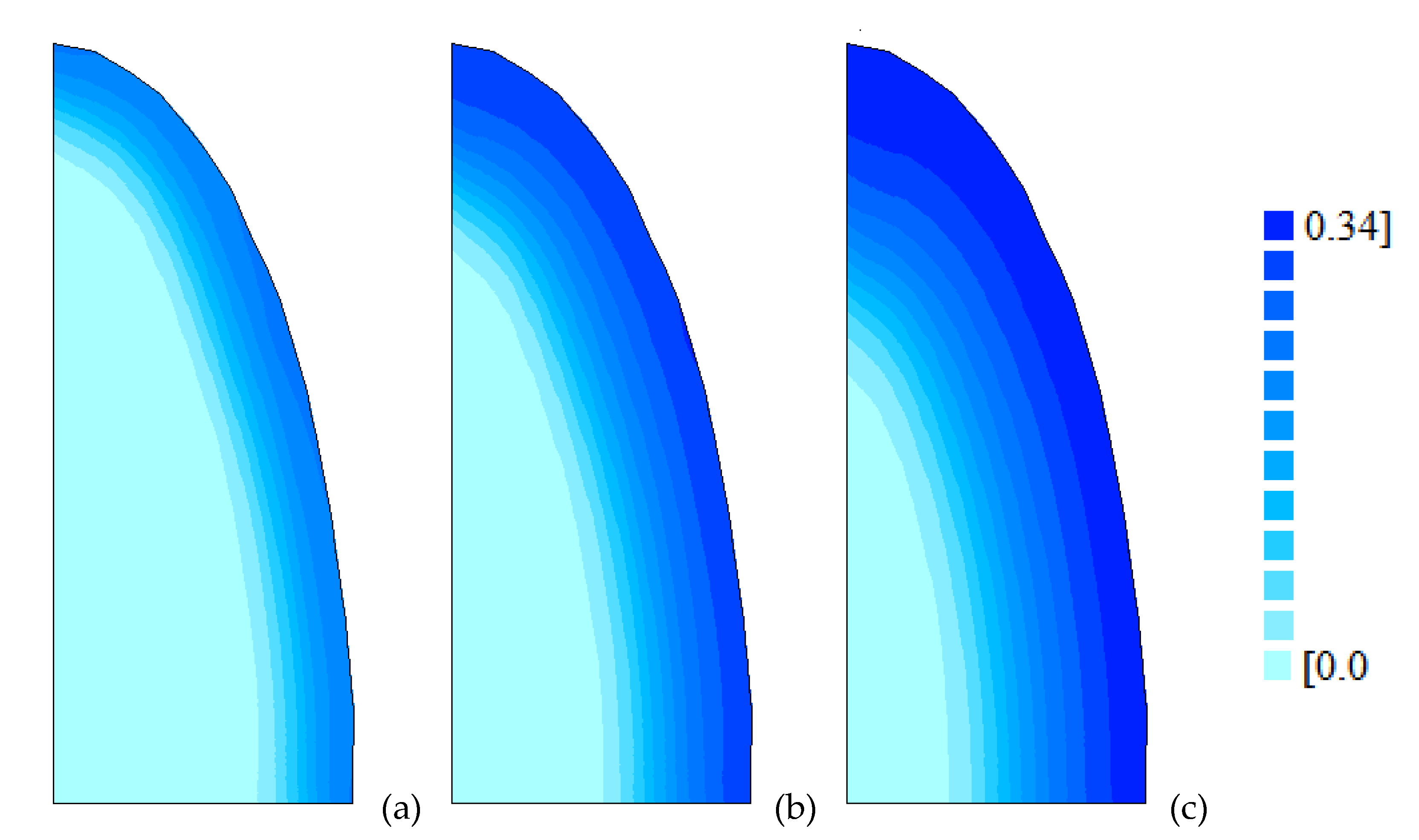

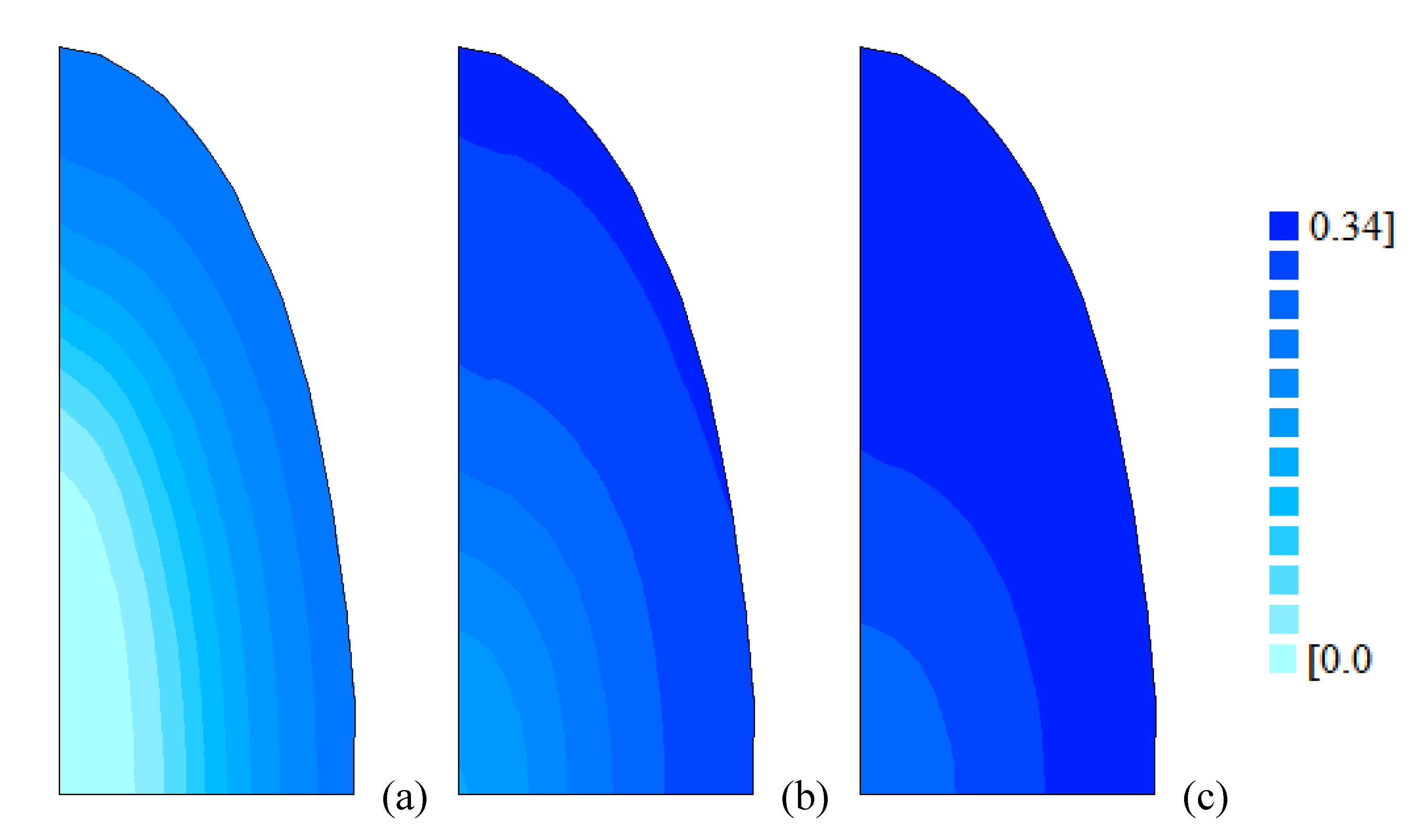

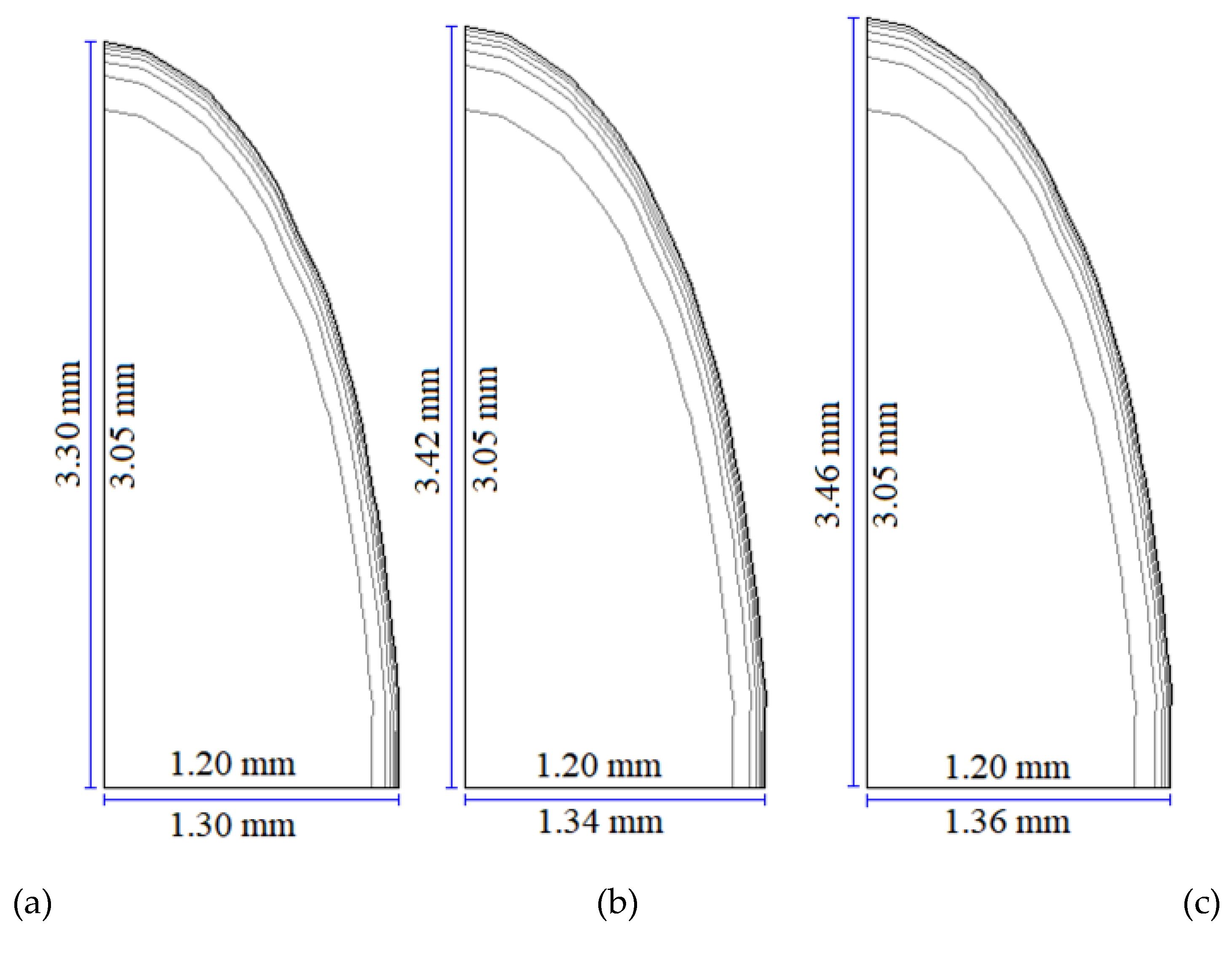

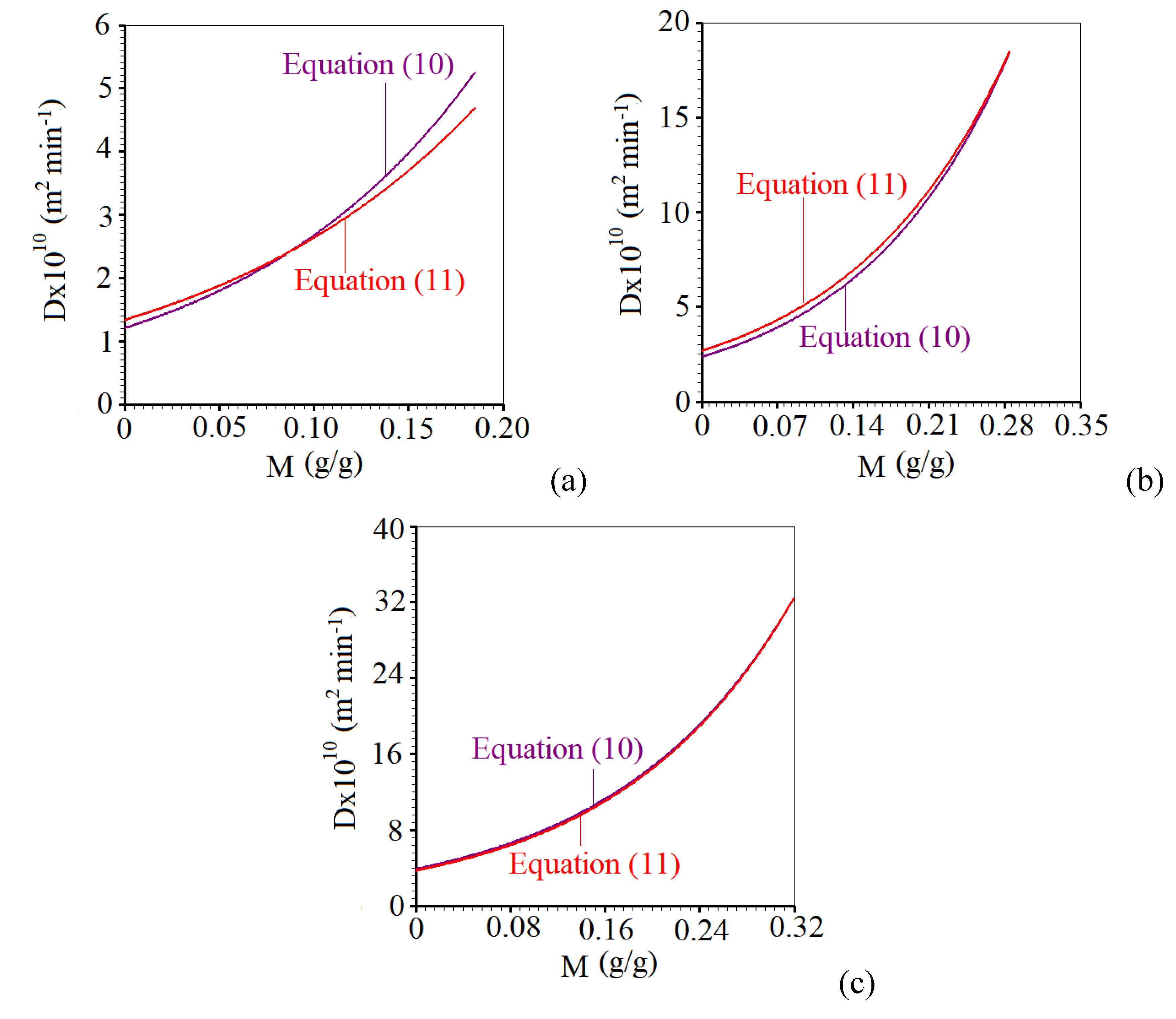

3.1.2. Simulations

3.2. Additional Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ribeiro-Filho, N.; Borges, S. R. S.; Menezes, P. H.; Oliveira, M. R. T.; Silva, A. P. G. Red rice (Oryza sativa L.) composition and its water interaction. Food and Humanity, v. 2, 2024. [CrossRef]

- Pereira, J. A.; Morais, O. P. As variedades de arroz vermelho brasileiras. Embrapa Meio-Norte, Teresina, 2014. 39 p.

- Walter, M., Marchezan, E., Avila, L.A. 2008. Rice: composition and nutritional characteristics. Ciência Rural, 38(4), 1184-1192. [CrossRef]

- Santos, N.C., Silva, W.P., Barros, S.L., Almeida, R.L.J., Araújo, A.J.B., Nascimento, A.P.S. 2020. Red rice (Oryza sativa L.) use in flour production: Convective drying and bioactive quality. Journal of Food Process Engineering, 4(10), 1-10. [CrossRef]

- Marques, B.C., Jorge, L.M.M., Jorge, R.M.M. 2016. Chemical properties and water absorption kinetics of transgenic corn grain (2B587 Hx) and its conventional isoline (2B587). Journal of Cereal Science, 71(1), 93-98. [CrossRef]

- Sharanagat, V.S., Kansal, V., Kumar, K. 2018. Modeling the effect of temperature on the hydration kinetic whole moong grain. Journal of the Saudi Society of Agricultural Sciences, 17(3), 268–274. [CrossRef]

- Alves Pereira, J.C., Silva, W.P., Silva, R.C., Silva, C.M.D.P.S., Gomes. J.P. 2021. Use of empirical and diffusion models in the description of the process of water absorption by rice. Engineering Computations, 39(4), 1556-1574. [CrossRef]

- Li, P., Li, Y., Wang, L., Zhang, H., Qi, X., Qian, H. 2020. Study on water absorption kinetics of black beans during soaking. Journal of Food Engineering, 283(1), 110030. [CrossRef]

- Costa, R., Fusco, F., Gândara, J.F.M. 2018. Mass transfer dynamics in soaking of chickpea. Journal of Food Engineering, 227(1), 42-50. [CrossRef]

- Costa, R.; Pedroso, V.; Madeira, T.; Gândara, J. 2022. Water uptake kinetics in soaking of grass pea. Food Science and Technology, 42(2022), 1-10. [CrossRef]

- Kuna-Broniowska, I., Blicharz-Kania, A., Andrejko, D.; Kubik-Komar, A., Kobus, Z., Pecyna, A., Stoma, M., Slaska-Grzywna, B., Rydzak, L. 2020. Modelling water absorption in micronized lentil seeds with the use of Peleg’s Equation. Sustainability, 12(1), 1-9. [CrossRef]

- Zhao, H., Yang, Z., Tao, Z. 2017. Drying kinetics of continuous and intermittent heat pump drying of green soybean seeds. International Journal of Food Engineering, 13(11), 1–15. [CrossRef]

- Almeida, R. L. J., Santos, N. C., Santos, P. T., Alcântara, S. V. M., Alcântara, R. V. H., Silva, L. R. I., & Silva, E. R. 2020. Melon seed drying kinetics described by a diffusion model. Research, Society and Development, 9, 32953146. [CrossRef]

- Costa da Silva, R., Silva, W.P., Gomes, J.P., Queiroz, A.J.M., Figueirêdo, R.M.F., Lima, A.G.B., Trindade Rocha, A.P., Silva, L.D., Ferreira Lima, J.P., Santos, D.C., Andrade, R.O. 2022. A new empirical model for predicting intermittent and continuous drying of “Neve” melon (Cucumis melo sp.) seeds. Agriculture, 12(1), 328. [CrossRef]

- Botelho, F.M., Corrêa, P.C., Goneli, A.L.D., Martins, M.A., Baptestini, F.M. 2010. Water absorption kinetics in parboiled husk rice. Ciência e Tecnologia de Alimentos, 30(3), 713-718. [CrossRef]

- Salimi, A., Ameri H., Hajighorbani, A. 2019. Investigating on effect of hot air and water temperature on kinetic of rehydration of celery by using Peleg’s model. Latin American Applied Research, 49(4), 249-254. [CrossRef]

- Martins, G.M.V., Pereira, V.S., B.L.R., Martins, Sousa, S., Duarte, M.E.M., Cavalcanti Mata, M.E.R.M. 2020. Study of the red rice parboilization process. Journal of Agricultural Studies, 8(2), 531-560. [CrossRef]

- Hu, Z., Yang, Y., Lu, L., Chen, Y., Zhu, Z., Huang, J., 2021. Kinetics of water absorption expansion of rice during soaking at different temperatures and correlation analysis upon the influential factors. Food Chemistry 346(2021), 128912. [CrossRef]

- Hanucharoenkul, P., Theerathanan, C., Pongsawatmanit, R. 2021. Influence of soaking temperature and time on the kinetics of water absorption and pasting properties of glutinous rice. Agriculture and Natural Resources, 55(1), 193–200. [CrossRef]

- Dincer, I. 1995. Transient heat transfer analysis in air cooling of individual spherical products. Journal of Food Engineering, 26(4), 453–467. [CrossRef]

- Wu, B., Yang, W., Jia, C. 2004. A three-dimensional numerical simulation of transient heat and mass transfer inside a single rice kernel during the drying process Biosystems Engineering, 87(2), 191–200. [CrossRef]

- Silva, W.P., E Silva, C.M.D.P.S., Farias, V.S., E Silva, D.D.P.S. 2010. Calculation of the convective heat transfer coefficient and cooling kinetics of an individual fig fruit. Heat and Mass Transfer, 46(3), 371-380. [CrossRef]

- Silva, W.P., Silva, C.M.D.P.S., Lins, M.A.A. 2011. Determination of expressions for the thermal diffusivity of canned foodstuffs by the inverse method and numerical simulations of heat penetration. International Journal of Food Science and Technology, 46(4), 811-818. [CrossRef]

- Cihan, A., Ece, M.C., 2001. Liquid diffusion model for intermittent drying of rough rice. Journal of Food Engineering, 49(4), 327–331. [CrossRef]

- Lima AGB, Queiroz MR, Nebra AS. 2002. Simultaneous moisture transport and shrinkage during drying of solids with ellipsoidal configuration. Chemical Engineering Journal, 86(1-2), 85–93. [CrossRef]

- Silva, W.P., Mata, M.E.R.M.C., Silva, C.D.P.S., Guedes, M.A., Lima, A.G.B. 2008. Determination of diffusivity and activation energy for cowpea grains (Vigna unguiculata (L.) Walp.), always-green variety, based on its drying behavior. Engenharia Agricola, 28(2), 325-333. [CrossRef]

- Silva, W.P., Silva e Silva, C.M.D.P., Farias, V.S.O., Lima A.G.B. 2011. Effect of the geometry on the description of the water absorption by composite materials using diffusion models. Material Science & Engineering Technology (Materialwissenschaft und Werkstofftechnik), 42(8). [CrossRef]

- Tomita, H., Fukuoka, M., Takemori, T., Sakai, N. 2019. Development of the visualization and quantification method of the rice soaking process by using the digital microscope. Journal of Food Engineering, 243(1), 33–38. [CrossRef]

- Dutta, A., Subramanian, A.S., Chakraborty, R., Erdogdu, F. 2020. Numerical modeling of water uptake in white rice (Oryza sativa L.) using variable diffusivity approach. Biosystems Engineering, 191(1), 116-128. [CrossRef]

- Hacihafizoglu, O., Cihan, A., Kahveci, K., de Lima, A.G.B. 2008. A liquid diffusion model for thin-layer drying of rough rice. European Food Research and Technology, 226(1), 787–793. [CrossRef]

- Genkawa, T., Tanaka, F., Hamanaka, D., Uchino, T. 2011. Incidence of open crack formation in short-grain polished rice during soaking in water at different temperatures. Journal of Food Engineering, 103(1), 457–463. [CrossRef]

- Pereira, J.C.A., Silva, W.P., Gomes, J.P., Queiroz, A.J.M., Figueirêdo, R.M.F., Melo, B.A., Santiago, Â.M., de Lima, A.G.B., Macedo, A.D.B. 2020. Continuous and intermittent drying of rough rice: Effects on process effective time and effective mass diffusivity. Agriculture 10(1), 282. [CrossRef]

- Kale, S.J., Jha, S.K., Jha, G.K., Sinha, J.P., Lal, S.B. 2015. Soaking induced changes in chemical composition, glycemic index and starch characteristics of basmati rice. Rice Science, 22(5), 227−236. [CrossRef]

- Silva, W.P., e Silva, C.M.D.P.S., da Silva Junior, A.F., Queiroz, A.J.M. 2015. A numerical approach to determine some properties of cylindrical pieces of bananas during drying. International Journal of Food Engineering, 11(3). [CrossRef]

- Lentzou, D., Boudouvis, A.G., Karathanos, V.T., Xanthopoulos, G. 2019. A moving boundary model for fruit isothermal drying and shrinkage: An optimization method for water diffusivity and peel resistance estimation. Journal of Food Engineering, 263(1), 299–310. [CrossRef]

- Balbinoti, T.C.V., Jorge, Matos., L.M., Jorge, R.M.M. 2018. Modeling the hydration step of the rice (Oryza sativa) parboiling process. Journal of Food Engineering, 216(1), 81-89. [CrossRef]

- Bello, M.O., Tolaba, M.P., Suarez, C. 2007. Water absorption and starch gelatinization in whole rice grain during soaking. LWT - Food Science and Technology, 40(2), 313–318. [CrossRef]

- Loisel, J., Cornuéjols, A., Laguerre, O., Tardet, M., Cagnon, D., Lamotte, O.D., Duret, S. 2022. Machine learning for temperature prediction in food pallet along a cold chain: Comparison between synthetic and experimental training dataset. Journal of Food Engineering, 335(1), 111156. [CrossRef]

- Wei, S., Xiao, B. Xie, W. Wang, F., Chen, P., Yang, D. 2020. Stress simulation and cracking prediction of corn kernels during hot-air drying. Food and Bioproducts Processing, 121(1), 202–212. [CrossRef]

- Mikac, U., Sepe, A., Serša, I. 2015. MR microscopy for noninvasive detection of water distribution during soaking and cooking in the common bean. Magnetic Resonance Imaging 33(3) 336–345. [CrossRef]

- Zhu, L., Cheng, L., Zhang, H., Wang, L., Qian, H., Qi, X., Wu, G. 2019. Research on migration path and structuring role of water in rice grain during soaking. Food Hydrocolloids, 92(2019), 41–50. [CrossRef]

- Cihan, A., Kahveci, K., Hacihafizoglu, O., de Lima, A.G.B. 2008. A diffusion based model for intermittent drying of rough rice. Heat Mass Transfer. 44(2008), 905–911. [CrossRef]

- Gomes da Silva, E., Gomez, R.S., Gomes, J.P., Figueirêdo, R.M.F., Queiroz, A.J.M., Silva, W.P., Santiago, Â.M., Macedo, A.D.B., Ferreira, J.P.L., Gomes, Í.A., Lima, A.G.B. 2020. Convective and microwave assisted drying of wet porous materials with prolate spheroidal shape: A Finite-Volume approach. Agriculture, 10(11), 507. [CrossRef]

- Hu, Z., Yang, H., Chaima, M., Fang, C., Lu, L., Hu, X., Du, B., Zhu, Z., Huang, J. 2020. A visualization and quantification method to evaluate the water-absorbing characteristics of rice. Food Chemistry, 331(1), 127050. [CrossRef]

- Xanthopoulos, G., Yanniotis, S., Boudouvis, A.G. 2012. Numerical Simulation of Variable Water Diffusivity during Drying of Peeled and Unpeeled Tomato. Journal of Food Science, 77(10), 287-296. [CrossRef]

- Bello, M., Tolaba, M.P., Suarez, C. 2004. Factors affecting water uptake of rice grain during soaking. LWT - Food Science and Technology, 37(8), 811-816. [CrossRef]

- Briffaz, A., Bohuon, P., Méot, J.-M., Dornier, M., Mestres, C. 2014. Modelling of water transport and swelling associated with starch gelatinization during rice cooking. Journal of Food Engineering, 121(), 143–151. [CrossRef]

- Bakalis, S., Kyritsi, A., Karathanos, V.T., Yanniotis, S. 2009. Modeling of rice hydration using finite elements. Journal of Food Engineering, 94(3-4), 321–325. [CrossRef]

- Irigoyen, R.M.T., Goñi, S.M., Giner, S.A. 2014. Drying–toasting kinetics of presoaked soybean. A mathematical model considering variable diffusivity, shrinkage and coupled heat transfer. Journal of Food Engineering, 142(1), 70–79. [CrossRef]

- Farias Aires, K.L.C.A., Silva, W.P., Farias Aires, J.E., Silva Júnior, A.F., da Silva e Silva, C.M.D.P. 2018. Apple osmotic dehydration described by three-dimensional numerical solution of the diffusion equation. Drying Technology, 36(16), 1970-1981. [CrossRef]

- Maliska, C.R. 2023. Fluid Mechanics and Its Applications (Volume 135): Fundamentals of Computational Fluid Dynamics. The Finite Volume Method. Springer, ISBN 978-3-031-18235-8 (eBook). [CrossRef]

- Silva, W.P., Ataíde, J.S.P., de Oliveira, M.E.G., Silva, C.M.D.P.S., Nunes, J.S. 2018. Heat transfer during pasteurization of fruit pulps stored in containers with arbitrary geometries obtained through revolution of flat areas. Journal of Food Engineering 217(1), 58-67. [CrossRef]

- Silva, W.P., Precker, J.W., Silva, D.D.P.S., Silva, C.D.P.S., de Lima, A.G.B. 2009. Numerical simulation of diffusive processes in solids of revolution via the finite volume method and generalized coordinates. International Journal of Heat and Mass Transfer, 52(21–22) 4976–4985. [CrossRef]

- Cloete, T.J. 2023. Extensions to the theorems of Pappus to determine the centroids of solids and surfaces of revolution. International Journal of Mechanical Engineering Education, 51(4), 319–332. [CrossRef]

- Press, W.H., Teukolsky, S.A., Vetterling, W.T. & Flannery, B.P. 2007. Numerical Recipes in Fortran 77. The Art of Scientific Computing, 3rd Edition. New York: Cambridge University Press. [CrossRef]

- Tolikas, P.K., Tzimopoulos, C.D., Tolikas, D.K. 1982. Horizontal absorption of water by soils with variable diffusivity. Journal of Hydrology, 58(1-2), 123-129. [CrossRef]

- Nicolin, D.J., Jorge, R.M.M., Jorge, L.M.M. 2016. Effects of variable diffusivity on soybean hydration modeling as a Stefan problem. The Canadian Journal of Chemical Engineering, 95(5), 1–10. [CrossRef]

- Levenberg, K. 1944. A method for the solution of certain problems in least squares. Quartely of Applied Mathemathics, 2(2), 164–168. [CrossRef]

- Marquardt, D. W. 1963. An algorithm for least-squares estimation of nonlinear parameters. Journal of the Society for Industrial and Applied Mathematics, 11(2), 431–441. [CrossRef]

- Wahengbam, E.D., Abdul, S., Hazarika, M.K. 2019. Water uptake in brown rice during soaking for production of no-cooking rice. Agricultural Engineering International: CIGR Journal, 21(3), 138-149. https://www.cigrjournal.

- Silva, W.P., Silva, C.M.D.P.S., Silva, L.D., Lins M.A.A. 2012. Comparison between models with constant and variable diffusivity to describe water absorption by composite materials. Material Science & Engineering Technology (Materialwissenschaft und Werkstofftechnik), 43(10), 825-831. [CrossRef]

- Silva, W.P., Hamawand, I., Silva, C.M.D.P.S. 2014. A liquid diffusion model to describe drying of whole bananas using boundary-fitted coordinates. Journal of Food Engineering, 137(1), 32–38. [CrossRef]

- Elbert, G., Tolaba, M.P., Suárez C. 2001. Model application: hydration and gelatinization during rice parboiling. Drying Technology, 19(3-4), 571-581. [CrossRef]

- Silva, W.P., Cavalcanti Mata, M.E.R.M., Silva, C.D.P.S., Guedes, M.A., Lima, A.G.B. 2008. Determination of diffusivity and activation energy for cowpea grains (Vigna unguiculata (L.) Walp.), always-green variety, based on its drying behavior. Engenharia Agricola, 28(2), 325-333. [CrossRef]

- Ruiz-López, I.I., Ruiz-Espinosa, H., Arellanes-Lozada, P., Bárcenas-Pozos, M.E., García-Alvarado, M.A. 2012. Analytical model for variable moisture diffusivity estimation and drying simulation of shrinkable food products. Journal of Food Engineering, 108(3), 427–435. [CrossRef]

- Batista, L.M., Rosa, C.A., Pinto. L.A.A. 2007. Diffusive model with variable effective diffusivity considering shrinkage in thin layer drying of chitosan. Journal of Food Engineering, 81(1), 127–132. [CrossRef]

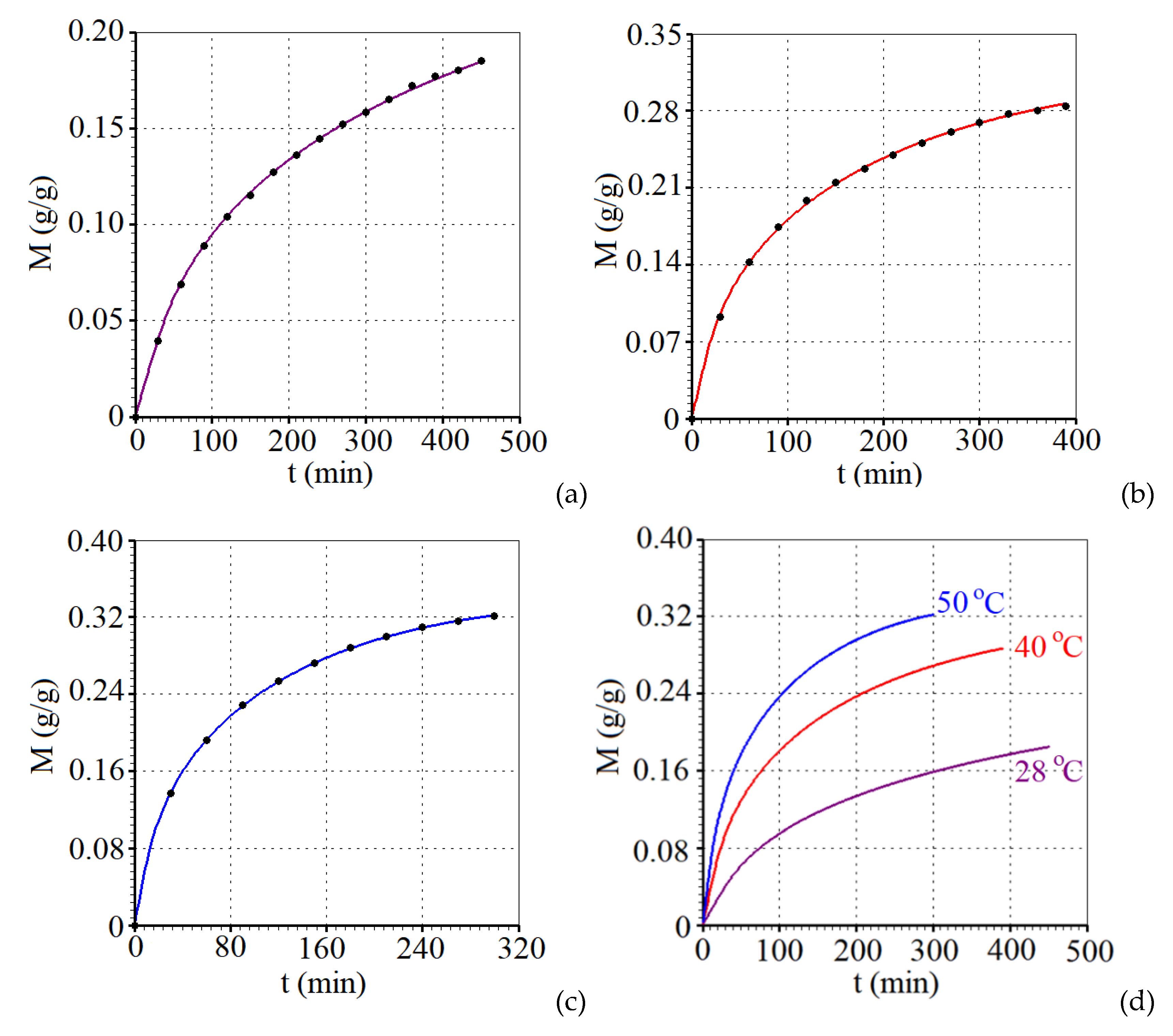

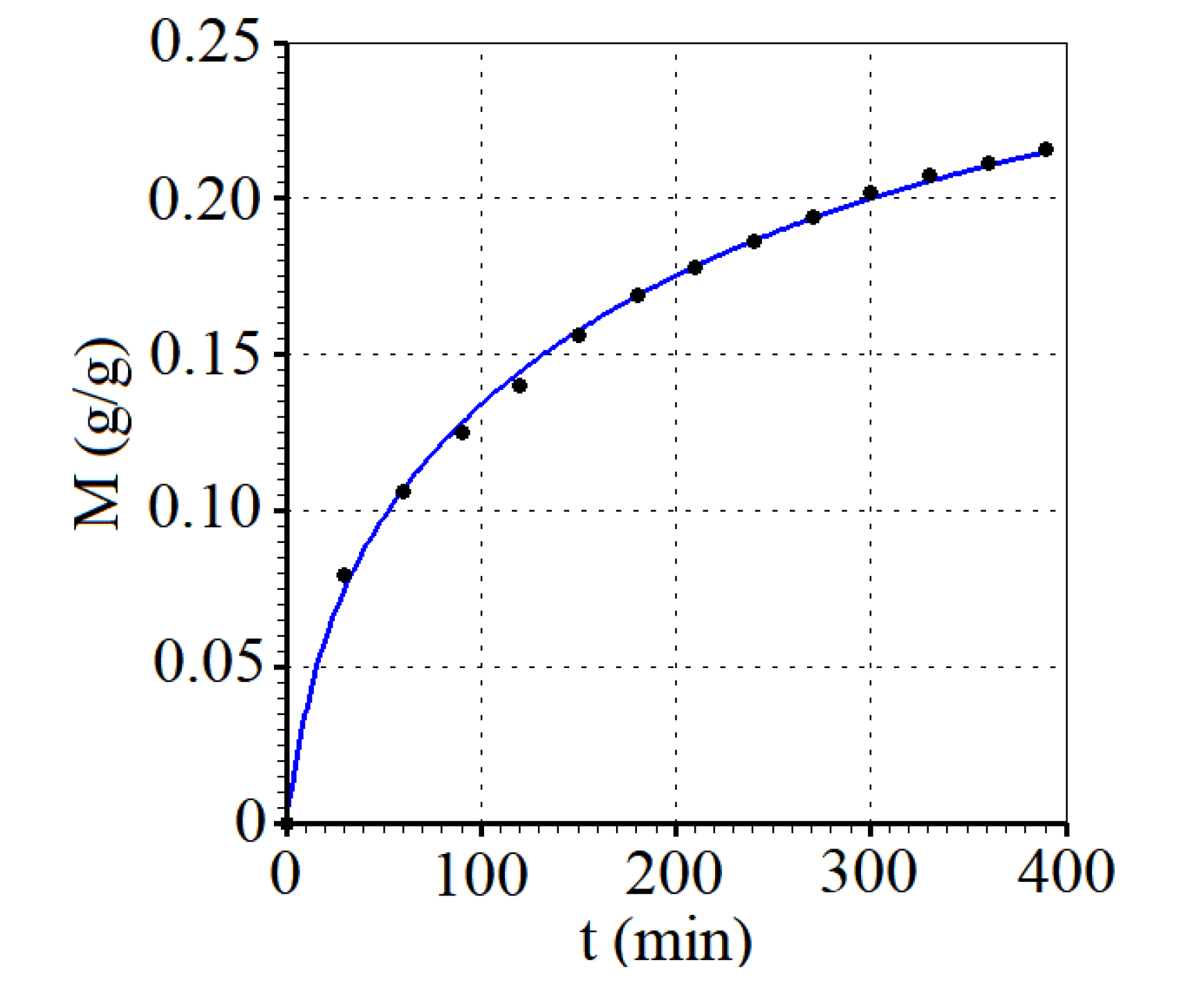

| T (°C) | a (-) | b×1010 (m2 min-1) | R2 | χ2×105 |

| 28.0 | 7.95 ± 0.22 | 1.206 ± 0.029 | 0.99979 | 1.2388 |

| 40.0 | 7.22 ± 0.17 | 2.363 ± 0.039 | 0.99957 | 3.8311 |

| 50.0 | 6.65 ± 0.12 | 3.874± 0.038 | 0.99991 | 0.8942 |

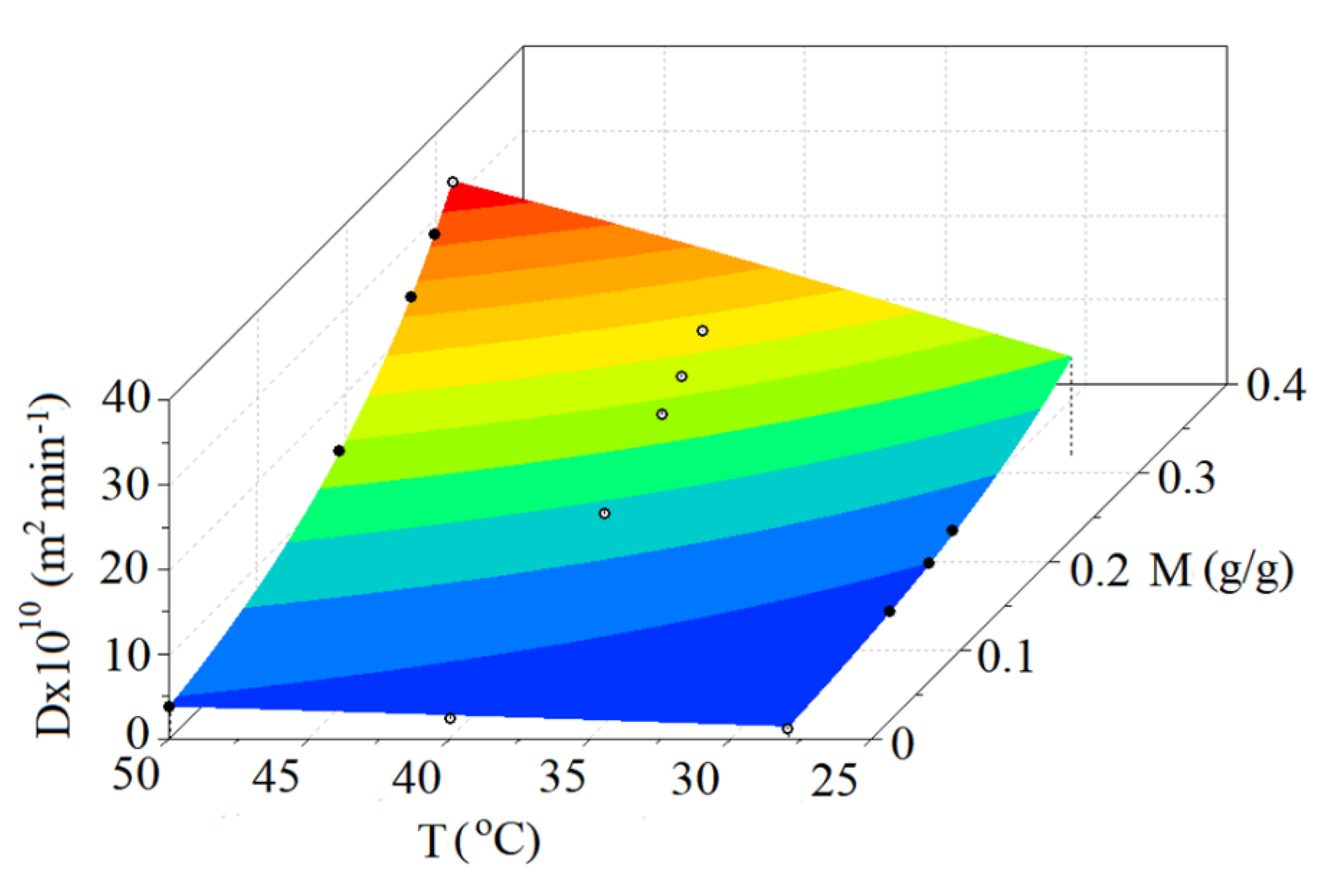

| T (°C) | M (g/g) | Dx1010 (m2min-1) |

| 28.0 | 0.0 | 1.206 |

| 28.0 | 0.1150 | 3.009 |

| 28.0 | 0.1585 | 4.252 |

| 28.0 | 0.1850 | 5.249 |

| 40.0 | 0.0 | 2.363 |

| 40.0 | 0.1745 | 8.330 |

| 40.0 | 0.2395 | 13.318 |

| 40.0 | 0.2609 | 15.543 |

| 40.0 | 0.2845 | 18.431 |

| 50.0 | 0.0 | 3.874 |

| 50.0 | 0.1921 | 13.898 |

| 50.0 | 0.2723 | 23.691 |

| 50.0 | 0.2994 | 28.369 |

| 50.0 | 0.3194 | 32.405 |

| 28.0 | °C | 40.0 | °C | 50.0 | °C |

| t (min) | V×109 (m3) | t (min) | V×109 (m3) | t (min) | V×109 (m3) |

| 0.0 | 9.247 | 0.0 | 9.247 | 0.0 | 9.247 |

| 75.0 | 10.30 | 65.0 | 11.17 | 50.0 | 11.54 |

| 150.0 | 10.79 | 130.0 | 11.91 | 100.0 | 12.36 |

| 225.0 | 11.11 | 195.0 | 12.36 | 150.0 | 12.85 |

| 300.0 | 11.35 | 260.0 | 12.67 | 200.0 | 13.17 |

| 375.0 | 11.54 | 325.0 | 12.89 | 250.0 | 13.38 |

| 450.0 | 11.70 | 390.0 | 13.06 | 300.0 | 13.53 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).