Submitted:

08 July 2024

Posted:

08 July 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

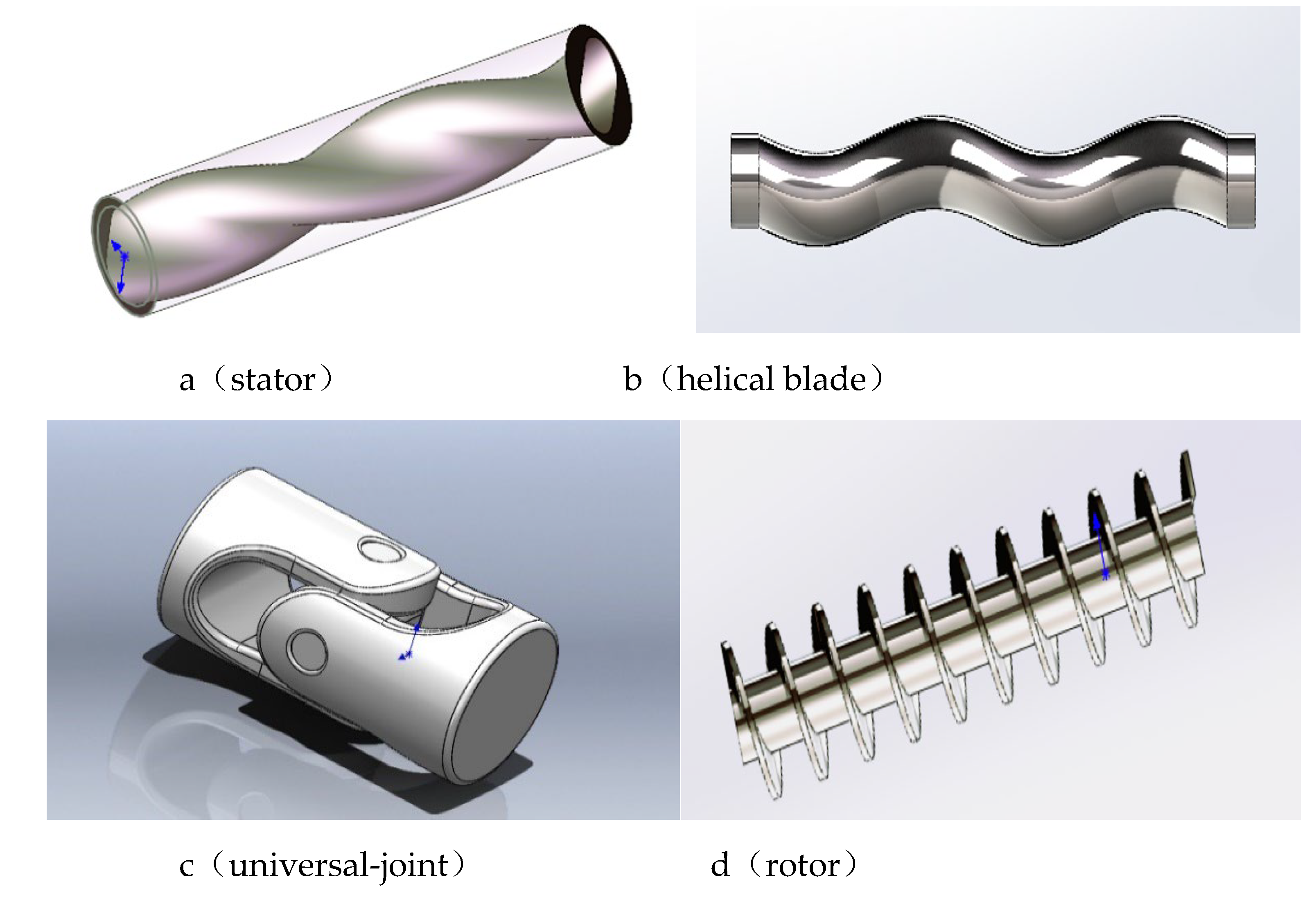

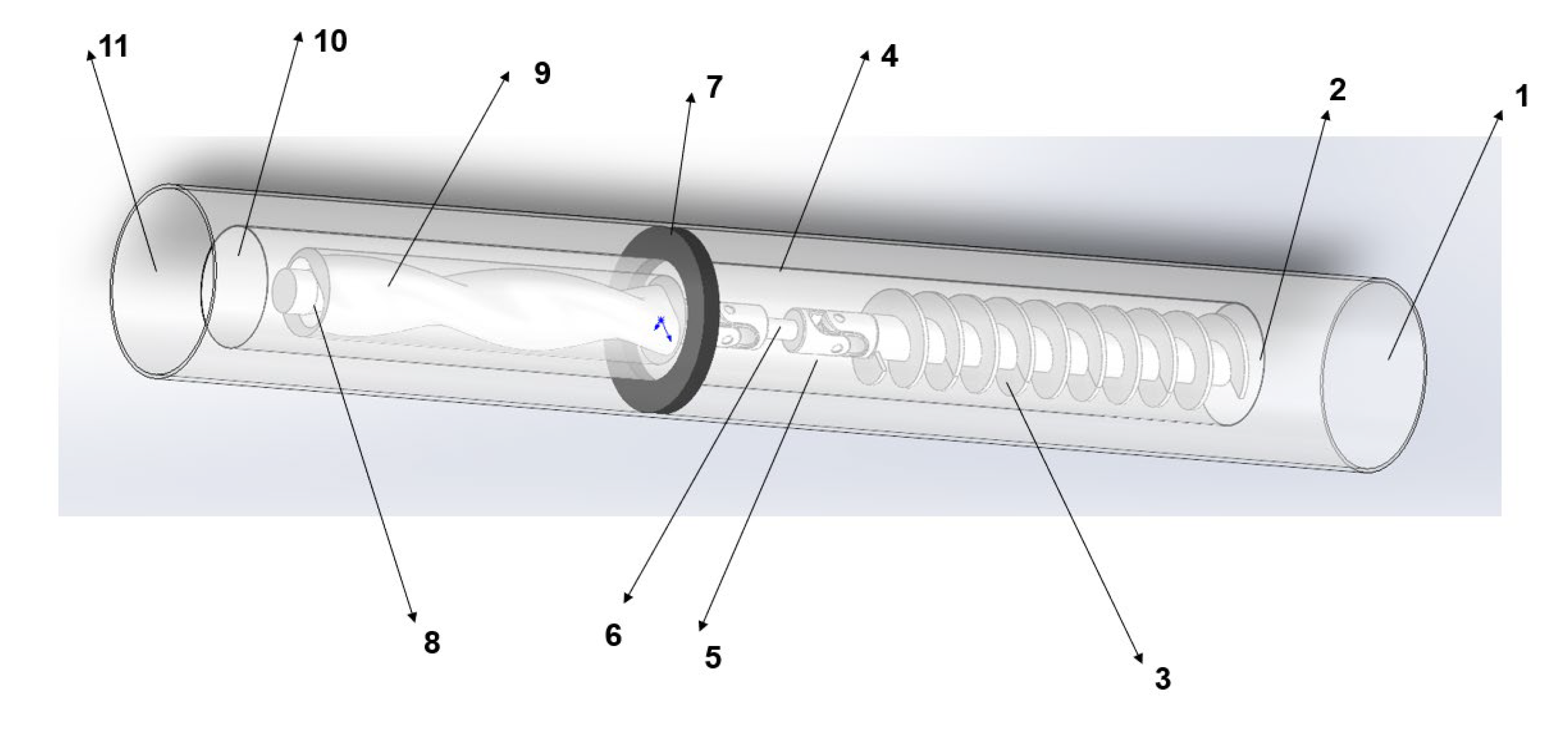

2. The Structure of the Suction-Type Falling ECD Tool

2.1. Tool Structure and depressurization Principle

2.2. Parameters of Tools

3. Numerical Simulation

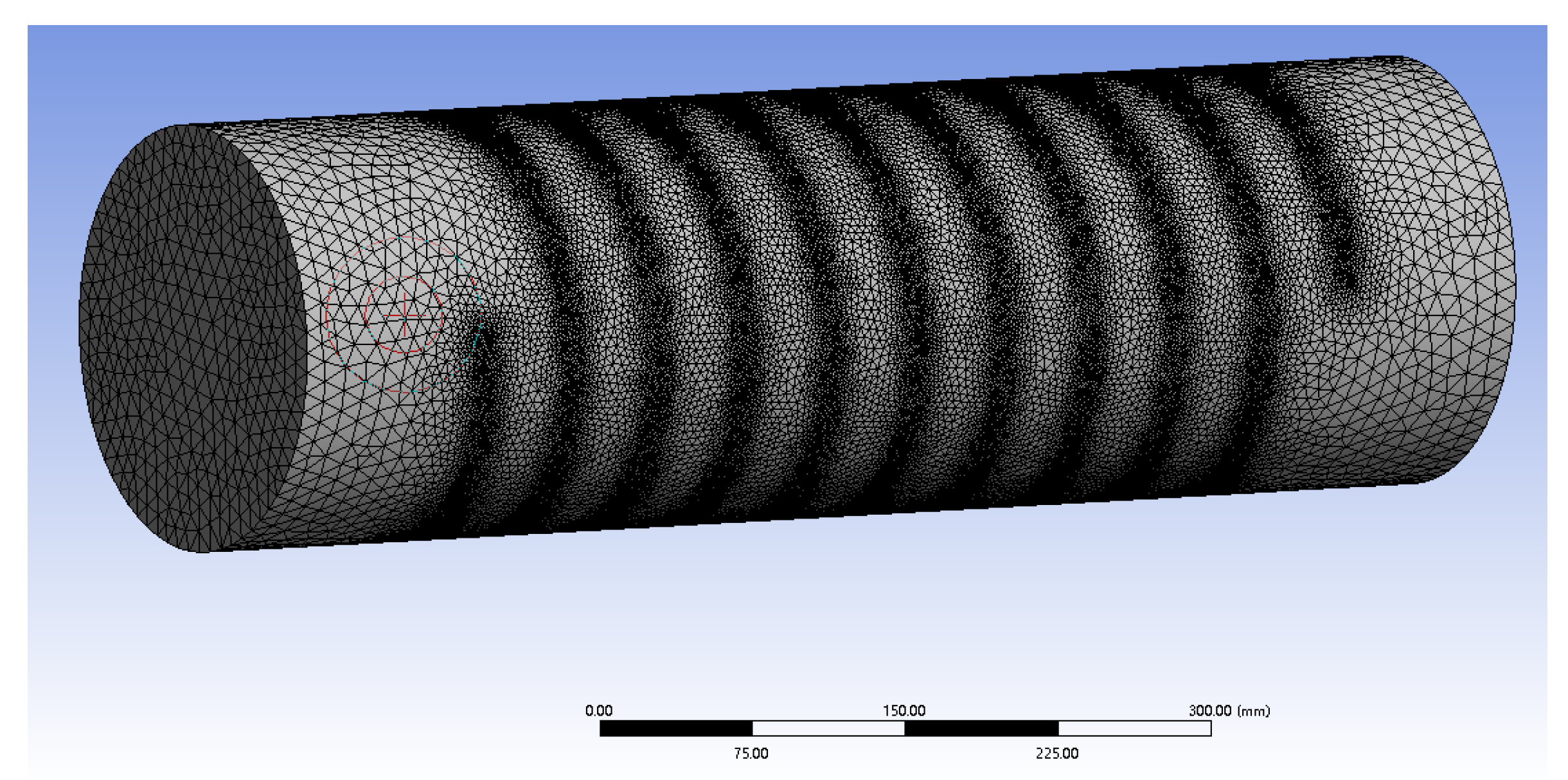

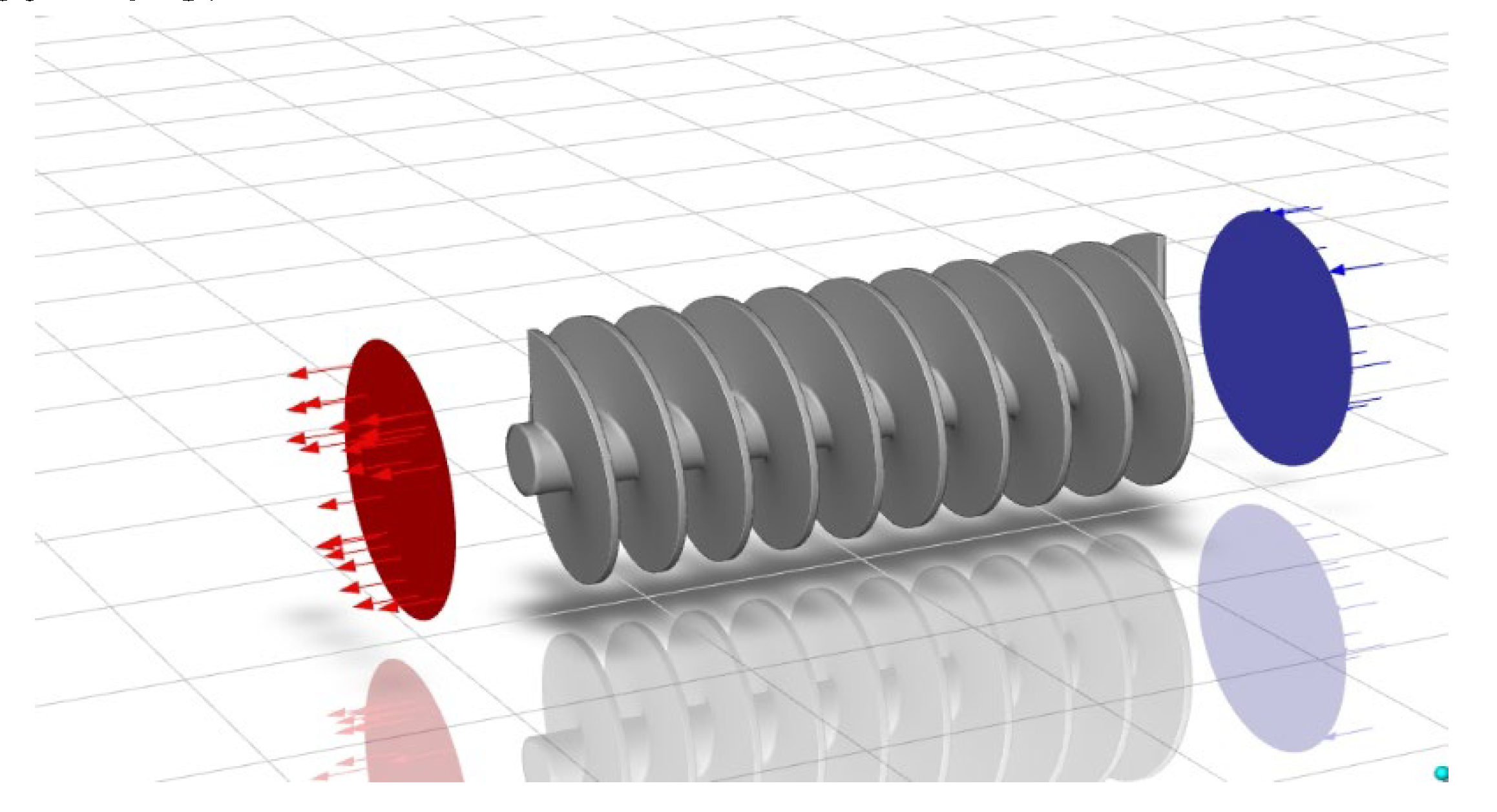

3.1. The Simulation Pretreatment of the Liquid-Suction ECD reduction Tool Model

3.1.1. Computation Module

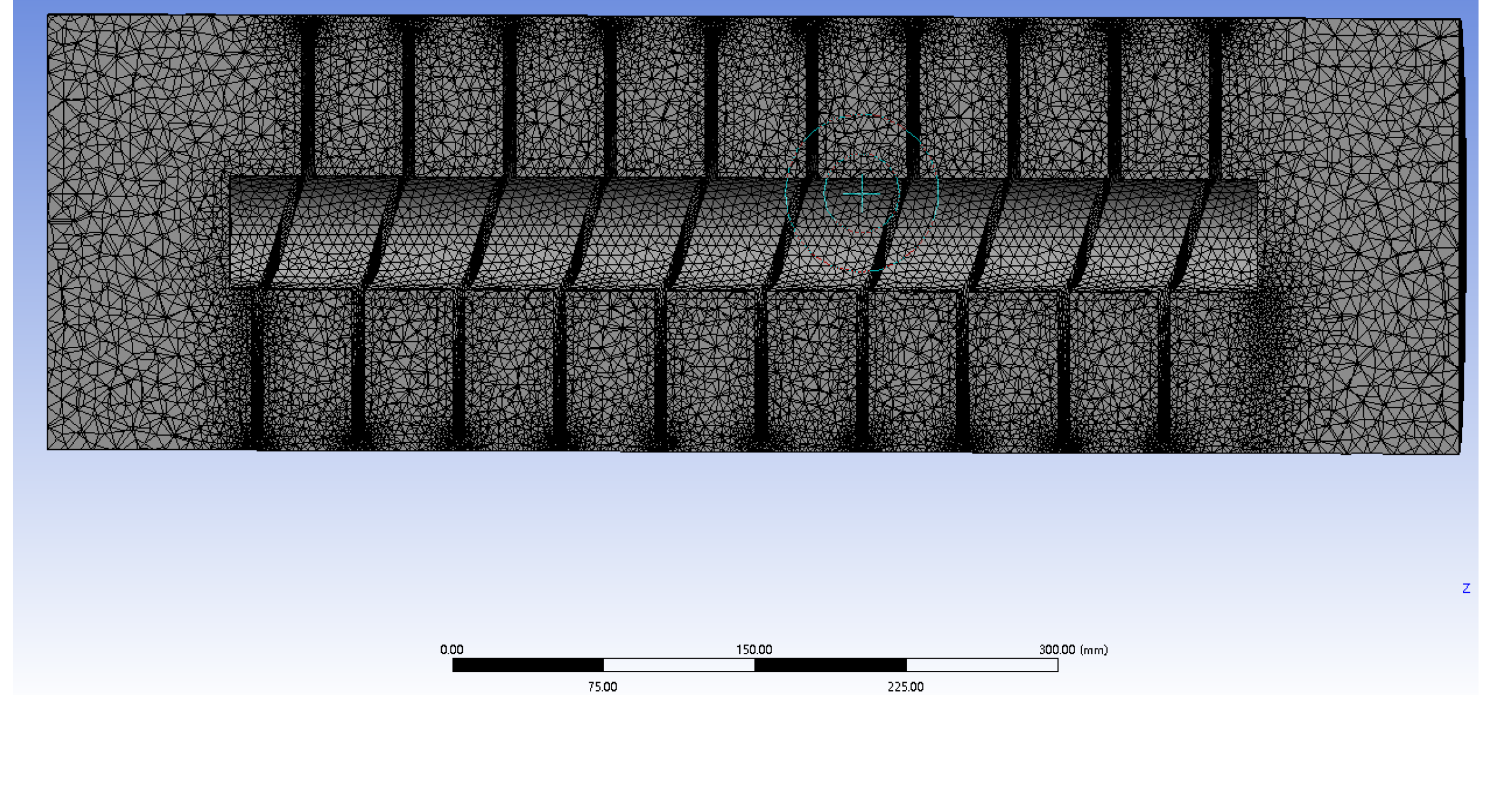

3.1.2. Meshing and Boundary Condition Setting

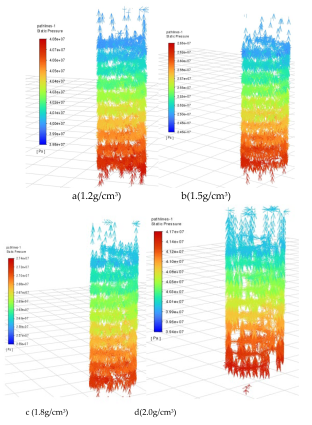

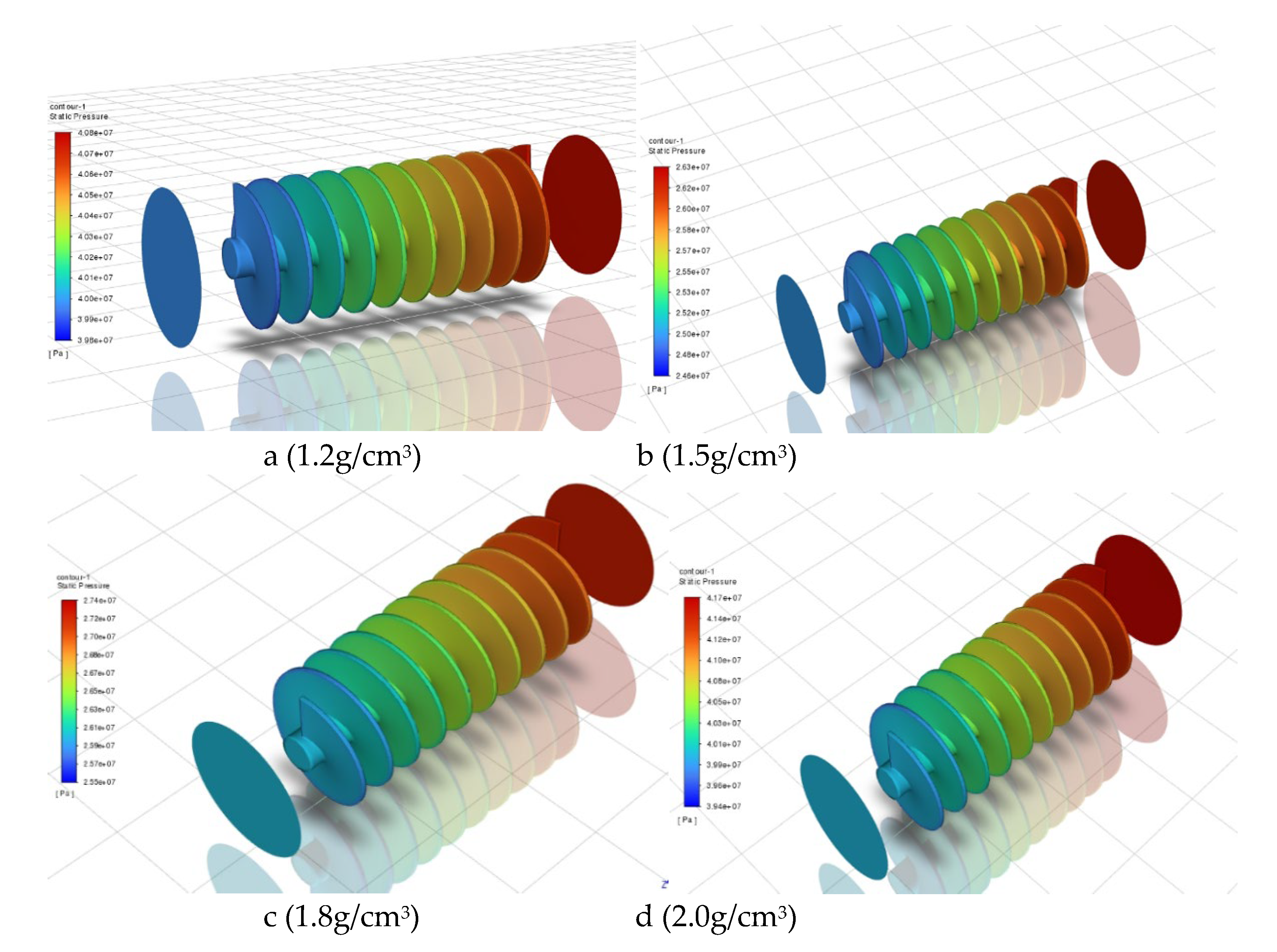

3.2. The Pressure Drop Distribution of the Liquid-Absorbing ECD-Reducing Tool when Drilling Fluid Flows with Different Densities

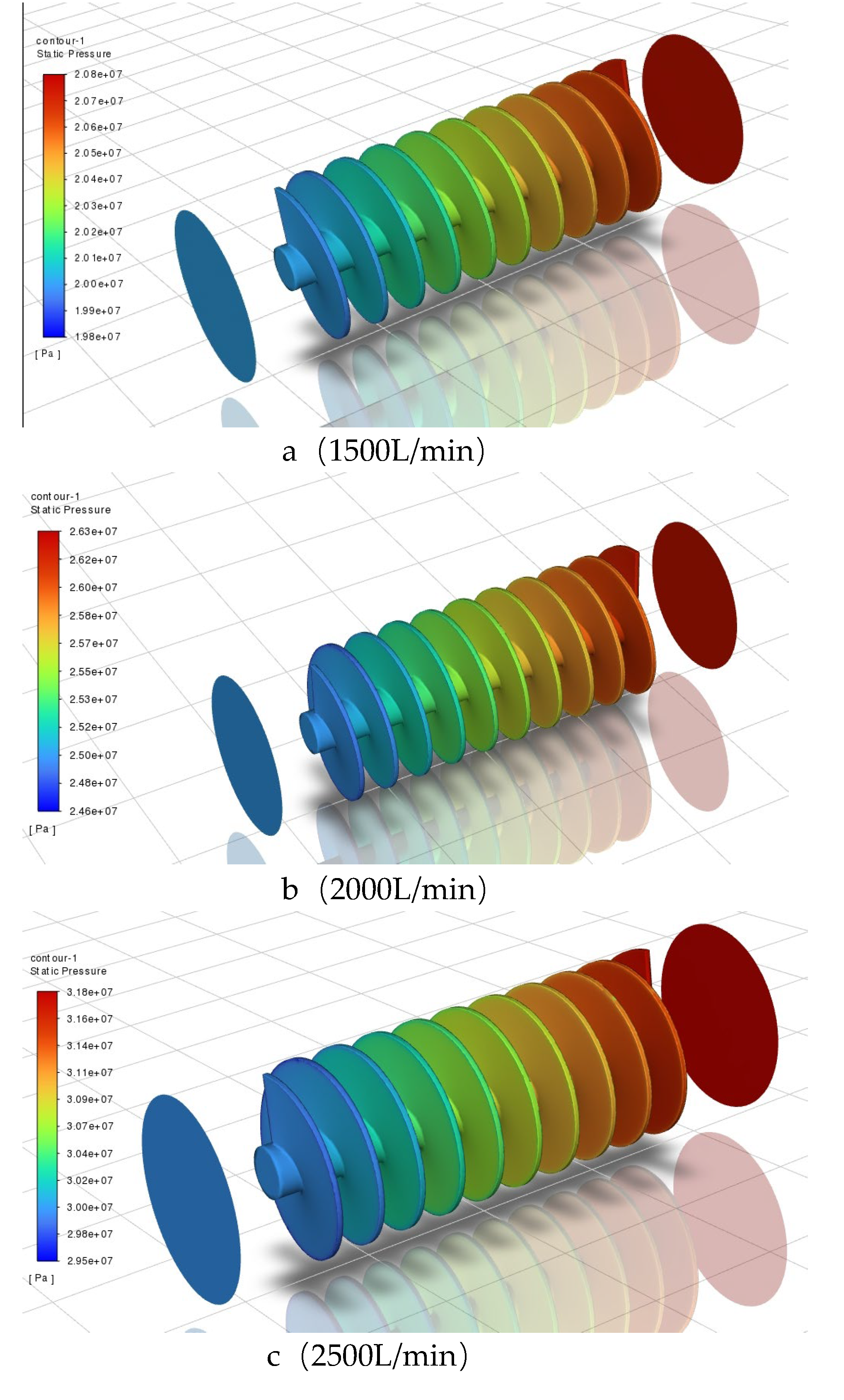

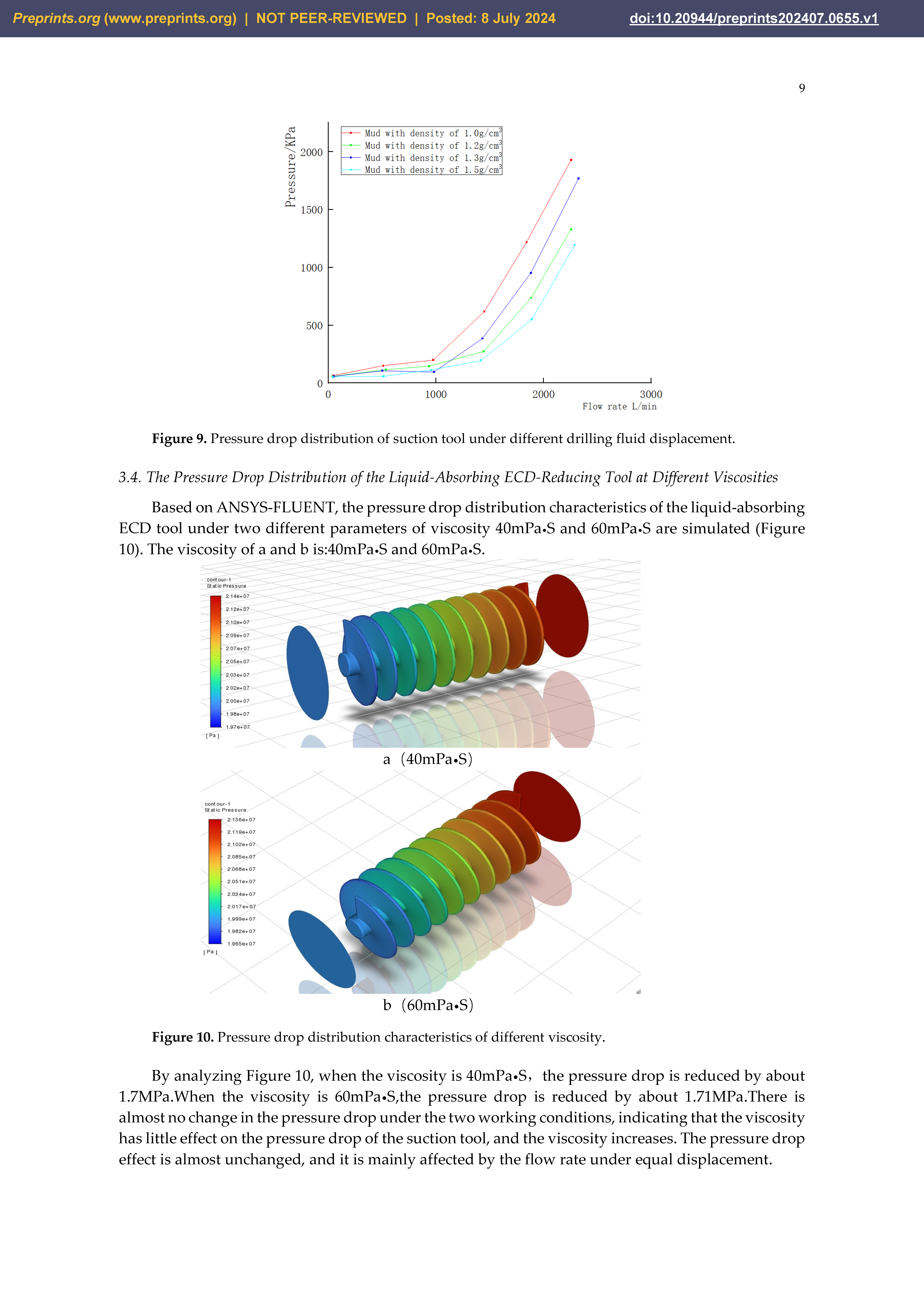

3.3. The Pressure Drop Distribution of the Liquid Absorption ECD Tool at Different Displacement

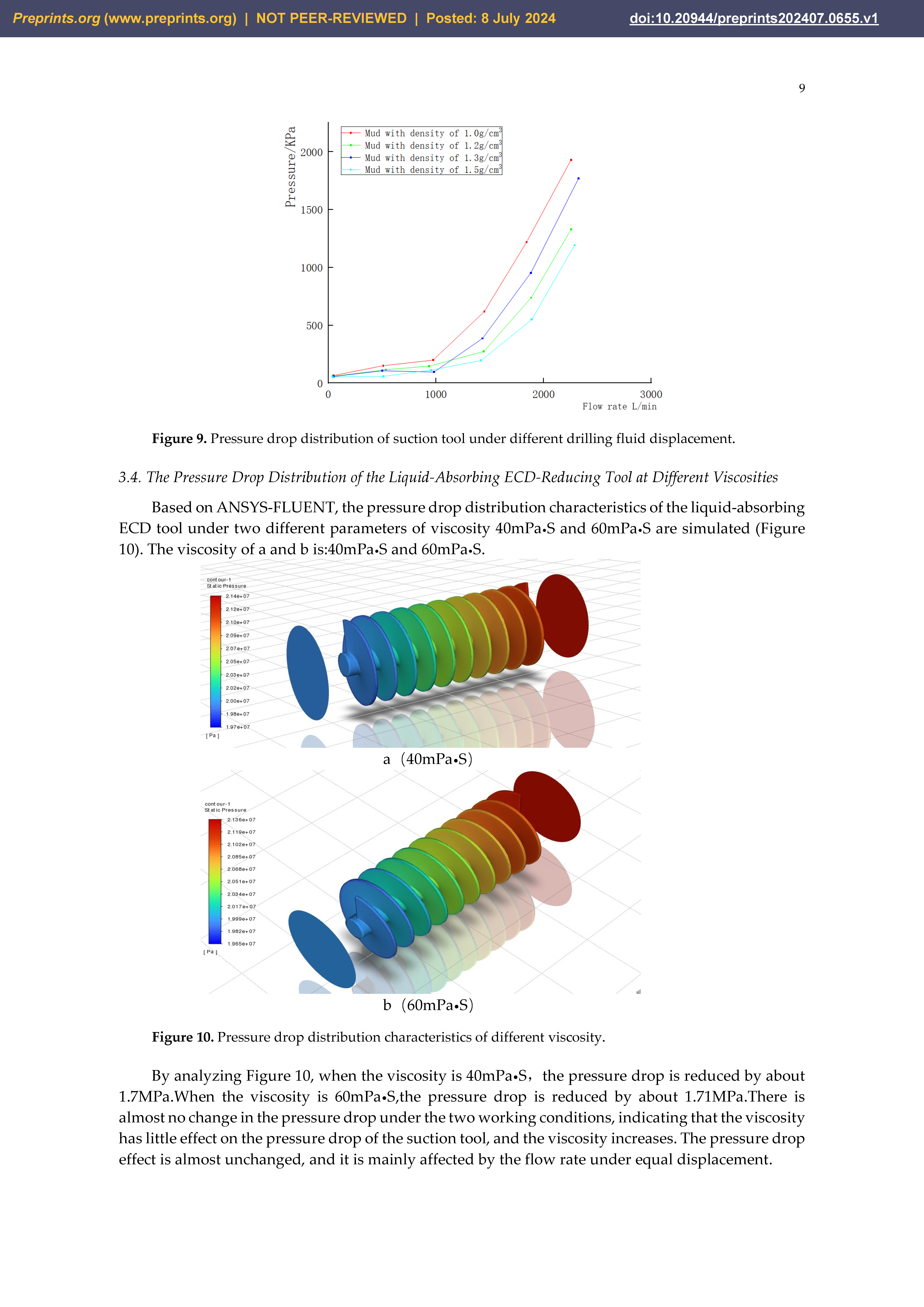

3.4. The Pressure Drop Distribution of the Liquid-Absorbing ECD-Reducing Tool at Different Viscosities

4. Field test

5. Conclusion

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zheng Fenghui,Yu Shuijie,Li Gensheng,etc.Jet hydraulic depressurization experimental study [J].Petroleum Machinery,2008(07):4-6+22+88.

- Yuan Guangyu.Research Status and Performance Analysis of Jet Pump Tool for Reducing Bottom Hole Pressure Difference [J].Oil Drilling Technology,2012,40(04):76-80.

- Zhu Haiyan,Deng Jingen,He Yufa,etc.Hydraulic jet technology to reduce bottom hole pressure difference [ J ].Journal of China University of Petroleum ( Natural Science Edition ),2013,37 ( 02 ) : 50-56.

- Dokhani V,MaY,Yu M.Determination of equivalent circulating density of drilling fluids in deepwater drilling [J].Journal of Natural Gas Science and Engineering,2016,341096-1105.

- Erge O,Ozbayoglu M E,Miska Z S,et al.Equivalent circulating density modeling of Yield Power Law fluids validated with CFD approach [J].Journal of Petroleum Science and Engineering,2016,140 16-27.

- Abdelgawad Z K,Elzenary M,Elkatatny S,et al.New approach to evaluate the equivalent circulating density (ECD) using artificial intelligence techniques [J].Journal of Petroleum Exploration and Production Technology,2019,9 (2):1569-1578.

- Huang, Yi; et al. Quantitative risk assessment method for high temperature and high pressure drilling engineering in Yingqiong Basin [J].Offshore Oil and Gas of China,2019,31(4):119-124.

- Chen Yuwei and so, on. Extended reach well hole cleaning and ECD control [J].China Science and Technology Paper,2021,16(09):1017-1022.

- Huang Wei.Study on ECD calculation method of Changning shale gas horizontal well [D].China University of Petroleum (Beijing),2021.

- Duan Hongzhi.Study on the calculation method of high temperature and high pressure ECD of oil-based drilling fluid in Xinjiang Oilfield [D].China University of Petroleum (Beijing),2022.

- Foued B,Vamegh R,Nidhal B.Impact of hole cleaning and drilling performanceon the equivalent circulating density [J].Journal of Petroleum Science and Engineering,2022,211.

- Gao, Yongde; et al. Prediction model and application of drilling fluid equivalent circulation density in deepwater HTHP wells [J].Special oil and gas reservoirs,2022,29 (03):38-143.

- Wei Xiaoqi.Key points of ECD check and control technology for high temperature and high pressure wells [J].Chemical management,2022(18):157-160.

- Li, Wentuo; et al. Annular ECD comprehensive calculation model of high temperature and high pressure slim hole horizontal well [J] Petroleum drilling and production technology,2023,45(03):259-268.

- Okonkwo F I S,Joel F O.Modelling the Effects of Temperature and Pressure on Equivalent Circulating Density (ECD) During Drilling Operations Using Artificial Neural Networks [J].Journal of Engineering Research and Reports,2023,25 (9): 70-82.

- Mohammed A ,Mohammed A ,Bayan A ,et al.A Developed Robust Model and Artificial Intelligence Techniques to Predict Drilling Fluid Density and Equivalent Circulation Density in Real Time.[J].Sensors (Basel,Switzerland),2023,23 (14):. [CrossRef]

- Liang, Xu; et al. Density calculation model and influence analysis of high temperature and high pressure oil-based drilling fluid [J].Petrochemical application,2023,42(03):64-69.

| Well Depth/m | Normal Drilling Pressure/MPa | Contains Pressure Relief Tool Pressure/MPa | Depressurization Value /MPa |

|---|---|---|---|

| 800 | 11.76 | 10.08 | 1.68 |

| 1000 | 14.70 | 12.96 | 1.74 |

| 1200 | 17.64 | 15.98 | 1.66 |

| 1400 | 20.58 | 18.81 | 1.77 |

| 1600 | 23.52 | 21.70 | 1.82 |

| 1800 | 26.46 | 24.87 | 1.59 |

| 2000 | 29.40 | 27.48 | 1.92 |

| 2200 | 32.34 | 30.32 | 2.02 |

| 2400 | 35.28 | 33.39 | 1.89 |

| 2600 | 38.22 | 36.23 | 1.99 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).