1. Introduction

Mustards grown in Poland and around the world are multifunctional plants with a rich chemical composition of seeds and inductive properties of embryonic seeds. White mustard seeds (

Sinapis alba), the main raw material for mustard production, are rich in fat, mainly erucic acid (26.5% to 36.5%), which may cause health problems. EFSA has established a tolerable daily intake of erucic acid at 7 mg/kg body weight. Work is being done on mustard varieties with zero erucic acid content, e.g. "Warta", rich in omega-3 fatty acids [

1,

2]. White mustard can be an alternative in nutrition, medicine and the food, pharmaceutical, feed, chemical or cosmetic industries. It has a strong disinfectant and bile-forming effect, which is important in anticancer prevention.

The most common glucosinolates in mustards are sinalbin, sinigrin, gluconapin, glucobrassicin, progoitrin, glucoiberin, glucoraphanin and neoglucobrassicin. Mustard seeds from different geographic regions may have different glucosinolate profiles, which are stable and resistant to elevated temperatures but are hydrolyzed by the enzyme myrosinase. Myrosinase activity depends on the mustard species, the highest in brown mustard. Myrosinase loses activity at 60°C but is more stable under pressure (inactivation at 700 MPa; inactivation at 70°C at 300 MPa).

Mustard is produced from mustard flour, water, food acids, salt, sugar and spices [

1,

3]. Types of mustards differ in the proportions of mustard and spices. Mustard can be made from shelled or unshelled mustard seeds, which affects the degree of spiciness. Spices such as pepper, allspice, paprika, bay leaf, horseradish, garlic, honey or herbs are added [

2].

Important factors influencing product quality are microbiological parameters, determined by food safety and production process hygiene criteria. The latter criterion signifies requirements establishing the acceptance of a product or batch of food, applied to products introduced to the market. In case of failure to meet this criterion, the producer should withdraw the batch from the market. The hygiene process criterion defines the contamination limit, above which it is necessary to improve procedures to maintain the process in compliance with food law [

4].

The value of mustard lies in its appropriate level of quality and safety. Microbiological and chemical parameters are important factors determining product quality. Therefore, the aim of this study is to assess the safety of mustard and the ingredients of its recipe in terms of potential microbiological contamination according to applicable legal regulations. Hence, the aim of this study is to assess the safety of mustard and its recipe ingredients, which may constitute a potential source of contamination of the final product from a microbiological perspective and in accordance with applicable legal regulations [

4,

5,

6].

In addition, an alternative hypothesis to the null hypothesis was put forward:

- -

The null hypothesis (H0) is: Mustard and its ingredients do not show microbiological contamination exceeding applicable standards.

- -

Alternative hypothesis (H1): Mustard and its ingredients show microbiological contamination exceeding applicable standards.

2. Materials and Methods

Material for study was made up of three mustard types produced in Vinegar and Mustard Factory in Parczew in 2019-2020: a) delicates, b) kremska, and c) hot, using white mustard (cv. Borowska) and sarepska seeds (cv. Małopolska).

2.1. Field Research Methodology

The forecrop of white and sarepsia mustard was a cereal mixture (oats + spring barley). After harvesting, pre-winter plowing, harrowing and dressing the soil before sowing were carried out. Sowing took place on April 20, 2019 and April 17, I 2020 and 2021. The sowing rate was 12 kg ha-1 for white mustard and 9 kg ha-1 for sarepsia mustard. The seeds were sown with a row seeder at a spacing of 15 cm. The harvest was carried out after 105 days in 2019 and after 115 days in 2020, and 2021, the differences resulted from weather conditions.

Mineral fertilization was applied in spring before sowing: N - 64.9 kg, K - 60 kg, P - 26.6 kg, S - 16.8 kg, Ca - 48 kg, Mg - 3.5 kg, B - 0.2 kg ha-1. Phosphorus and sulfur were supplied as granulated superphosphate (19% P, 12% S), potassium as potassium salt (60%), nitrogen as ammonium nitrate (34%) and salmag (27.5%), calcium as superphosphate (30% CaO) and salmag (6% CaO), magnesium and boron in the form of salmag (3.5% MgO, 0.2% B).

Certified elite seeds were used, treated with Sarfun T 65 DS (400 g .100 kg-1 of seeds) against diseases. The herbicide Triflurotox 480 EC (trifluralin 480 g dm-³) was used against weeds at a dose of 2 dm³ ha-1 per 300 dm³ of water ha-1. Trifluralin has a DT50 soil persistence of 57-126 days and high toxicity. Cyperkill Super 25 EC (cypermethrin 25%) was used against pests (weeds, rapeseed beetle) at a dose: 0,05 dm³ ha-1 per 300 dm³ of water. Decis Expert 100 EC 0,25 - 25 g in 1 liter of the product (2,8%) (deltamethrin 100 g l-1) was used against rapeseed flea beetle, cabbage aphid and other pests at a dose of 0.25 dm³ ha-1 per 300 dm³ of water. Seeds were collected using a Bizon Super Z056 combine, adjusting the air flow, sieves and thresher speed (960 rpm).

2.2. Characteristics of Mustard Varieties

2.2.1. White Mustard

Barka (

Sinapis alba L.): Registered in 1999. The plants reach 101 cm in height. The seed yield is approximately 1.43 t

.ha

-1, the fat content is 26.4%, the glucosinolate content is 153 µM/g and the sinalbin content is 148.5 µM g

-1. Erucic acid constitutes 41%. The weight of 1000 seeds is 7 g. Flowering lasts from the 145

th to the 162

nd day of the year, and the seeds ripen on the 222

nd day. Glucosinolate content is 153 µM g

-1 and the sinalbin content is 148.5 µM/g. Erucic acid constitutes 41%. The weight of 1000 seeds is 7 g. Flowering lasts from the 145

th to the 162

nd day of the year, and the seeds ripen on the 222

nd day [

7].

Borowska (

Sinapis alba L.): Registered in 1958. The plants are 107 cm tall. The seed yield is average, fat content 25.6%, protein 33.12%, glucosinolates 145.3 µM g

-1. The weight of 1000 seeds is 4-11 g. Undemanding in terms of soil, it also thrives in weaker locations [

7].

Bamberka (

Sinapis alba L.): Registered in 2006. Low plants – 88 cm. Seed yield 1.31 t

.ha

-1, fat content 28.9%, erucic acid <1.5%, glucosinolates 136.7 µM g

-1, and sinalbin 133 µM g

-1. The weight of 1000 seeds is 6.7 g. Flowering lasts from the 142

nd to the 161

st day of the year, and the seeds ripen on the 218

th day [

7].

2.2.2. Sarepska Mustard

Małopolska (Brassica juncea [L.] Czern. et Cosson): Registered in 1971. The plants reach 115 cm in height. Seed yield is 1.14 t

.ha

-1, fat content 35.03%, protein 28.51%. Resistance to lodging is 7 on a scale of 9°. The mass of 1000 seeds is 2.23 g [

7].

2.3. Soil Conditions

The seeds originated from a field canopy experiment conducted in 2019-2020 in Experimental Station in Parczew on the soil with granulometric composition of light dusty loam, Viby bonitation class of good rye complex, acidic reaction (5.0 pH in 1n KCl) (

Table 1, 2).

The data in

Table 2 was analyzed concerning the available macronutrients (phosphorus, potassium, magnesium), calcium carbonate (CaCO

3), humus content, soil acidity (pH), and micronutrients (boron, copper, iron, manganese, zinc, cadmium, lead) for the years 2019-2021.

The average abundance of the examined soil in macronutrients was as follows: phosphorus (P): average (34.5 m g

.kg

-1), potassium (K): average (49.1 m g

.kg

-1), magnesium (Mg): average 27.7 m g

.kg

-1 poor abundance in available phosphorus, potassium, magnesium, copper, and boron (34.5 mg P, 49.7 mg K, 27 mg Mg, 3.1 mg Cu, 0.19 mg B

.kg

-1 soil), while moderate in manganese, zinc, and iron (94.0 mg Mn, 5.7 mg Zn, 846.0 mg Fe.kg-1 soil). Cadmium level was below 0.27 mg Cd

.kg

-1, lead one 18.9 mg Pb.kg

-1 soil; humus content in ploughing layer amounted to 1.79 g.kg-1, on average (

Table 2).

The level of phosphorus remained relatively stable throughout the study years. Potassium showed a slight decrease from 2019 to 2021, while magnesium levels were also relatively stable (

Table 2).

The content of calcium carbonate and humus affects soil fertility and structure. Calcium carbonate and humus content remained constant overall years of the study. Soil acidity (pH) also remained relatively stable. To maintain optimal nutrient levels and soil health over time, regular monitoring and potential adjustments may be necessary. The calcium carbonate content averaged 0.17 g.kg-1. This value indicates a low calcium carbonate content, which may be beneficial for mustard cultivation, as it prefers soils with lower calcium carbonate content. The humus content averaged 1.91 g.kg-1, which is at a moderate level. Although cultivated white and Sarepta mustard do not have specific requirements for humus content, moderate levels of organic matter can contribute to healthy mustard growth. Soil acidity measured using KCl solution averaged 5.73 pH. Mustard prefers slightly acidic to neutral soils, and the average pH of 5.73 falls within this range, which is beneficial for mustard cultivation.

Microelement levels in the soil vary, but most fall within permissible ranges. Boron is an essential micronutrient for many metabolic processes in plants. The content averaged 850.67 mg/kg, which is relatively high and sufficient for most crops. Copper (Cu) is necessary for many metabolic processes, including photosynthesis. The average copper content of 94.05 mg.kg-1 is usually sufficient for most plants. Iron is a key component in photosynthesis and oxygen transport in plants. The average iron content of 5.73 mg.kg-1 is sufficient for mustard. Manganese is important for many metabolic processes, including photosynthesis. Although the average manganese content of 0.27 mg g.kg-1 is relatively low, its stability within the variability range suggests it may be sufficient for most crops. Zinc (Zn) has an average content of 18.52 mg.kg-1, with a variability range of 18.20 - 18.75 mg.kg-1. Zinc is significant for plant development, especially for enzyme formation and hormonal processes. The average zinc content of 18.52 mg.kg-1 is usually sufficient for most plants. Cadmium (Cd) and Lead (Pb). Both cadmium and lead are toxic heavy metals. Their content is relatively low (<0.27 mg/kg), which is beneficial for soil and plant health.

In summary, most micronutrients in this soil appear to be at adequate levels for both white and Sarepta mustard, promoting healthy plant growth. However, it is always important to monitor micronutrient levels and apply fertilizers if any deficiencies are detected. Overall assessment: The examined soil seems to contain adequate levels of macro- and micronutrients for plant growth. Soil acidity falls within permissible limits for these plant species.

2.4. Meteorological Conditions

The

Table 3 demonstrates significant variability in both rainfall and hydrothermal conditions across the three years, reflecting the diverse climatic conditions experienced during the mustard growing seasons. This variability is crucial for understanding the growth environment and its impact on mustard cultivation. According to the Sielianinov hydrothermal coefficient, 2019 was fairly humid, 2020 was fairly dry, and 2021 was dry (

Table 3).

Sielaninov's hydrothermal coefficient, calculated according to the formula [

8]:

where: k – coefficient value; P – total rainfall (mm); t – sum of average daily temperatures.

2.5. Production Conditions of the Study

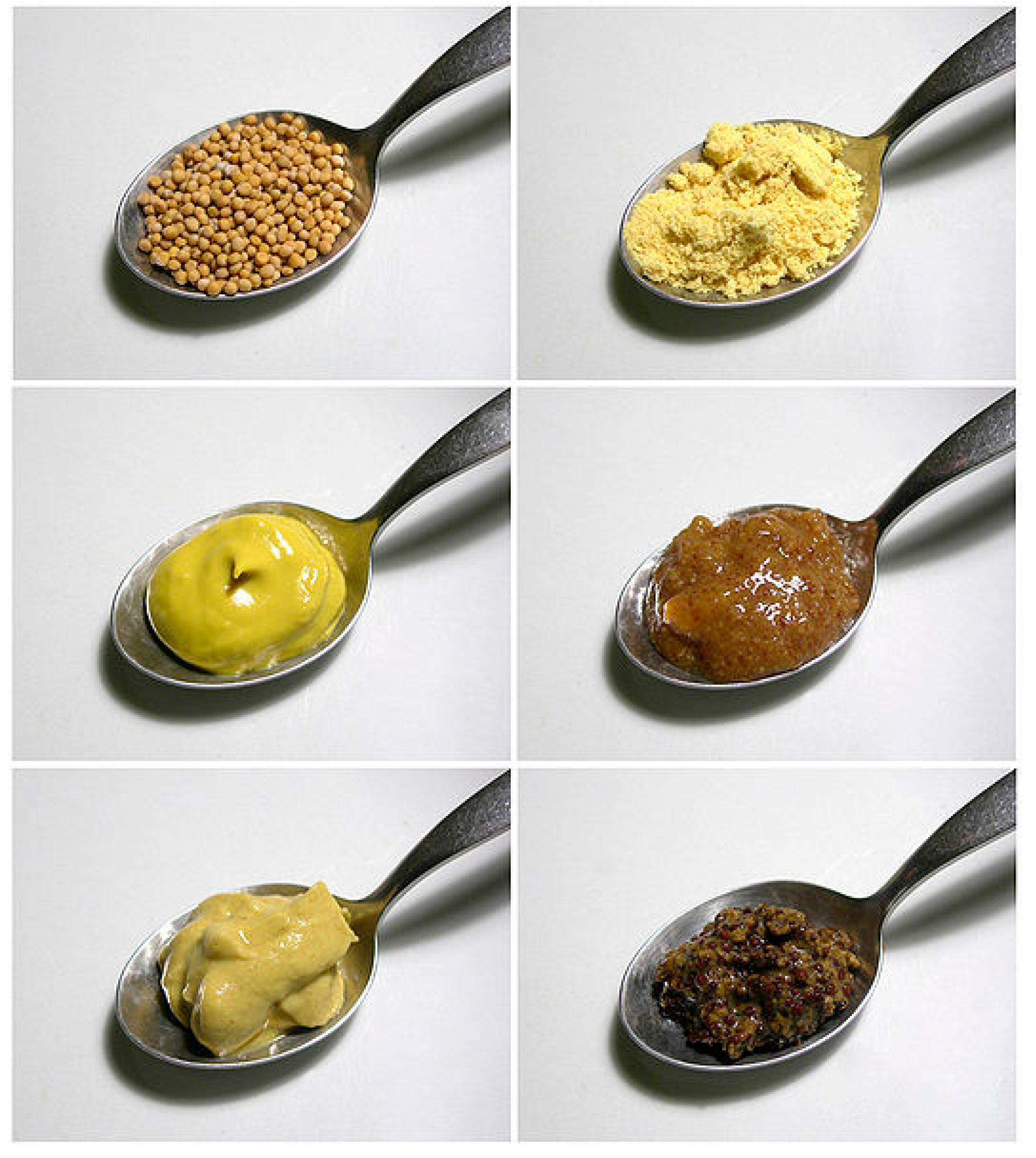

In production conditions, mustard seeds were cleaned using sieves and then partially defatted. The obtained powder, along with water, sugar, salt, 10% vinegar, and appropriate spices, was used to prepare mustard according to the Technological Instruction at the Vinegar and Mustard Factory in Parczew [[10[MDPI1] ]. Samples of three types of mustard were taken for the study: a) deli-style, b) Krems, c) hot, known as Sarepska (

Figure 1).

To assess the quality of the spices and mustard, samples of each type of mustard weighing approximately 25 g were collected (Figure2).

2.6. Water Quality Assessment

2.6.1. Laboratory Analysis of Water

The water used for mustard production was evaluated for parameters such as turbidity, color, taste, odor, electrical conductivity at 25°C and 20°C, and the content of ammonia, nitrites, nitrates, iron, and manganese. Samples of approximately 0.5 dm³ of water were taken each time for testing. The tests were performed by the County Sanitary and Epidemiological Station in Biała Podlaska.

The microbiological assessment of the water included testing for Coliform bacteria in CFU·100 ml⁻¹, Escherichia coli in CFU·100 ml⁻¹, and Enterococcus in CFU·100 ml⁻¹. The physicochemical evaluation of the water was conducted using the following methods:

Turbidity: According to PN-EN ISO 7027:2003 (Water quality. Determination of turbidity). The measurement of scattered radiation was performed using a turbidimeter. The wavelength of the incident radiation should be 860 nm [

9].

Color: According to PN-EN ISO 7887:2002 (Water quality. Examination and determination of color) [

10]. The principle of the method involves determining the intensity of the yellow-brown color of the sample by visual comparison with a series of standard solutions. The color is expressed in mg·dm³ Pt⁻¹ units corresponding to the intensity of the standard solutions.

Taste and Odor: According to PN-72/C-04557:1988 (Water and wastewater. Determination of taste, odor, and aftertaste). The principle of the method for determining taste and odor is organoleptic, identifying the type of taste and odor and classifying them into groups specified in the standard [

11].

pH: According to PN-90/C-04540/01:1990 (Water and wastewater. Determination of pH, acidity, and alkalinity). Determination of the pH of water and wastewater with specific electrical conductivity of 10 μS cm⁻¹ and above by electrometric method. The principle of the method involves measuring the electromotive force of a cell consisting of a reference electrode (calomel electrode), the test solution (water or wastewater sample), and a measuring electrode (glass electrode) [

12].

Electrical Conductivity: According to PN-EN 27888:1999 (Water quality. Determination of electrical conductivity) [

13]. The principle of the method involves the direct measurement of the specific electrical conductivity of aqueous solutions using instruments with inductive electrodes or immersion or flow-through conductivity cells with two or more electrodes.

Ammonia Content: According to PN-ISO-7150-1:2002 (Water quality. Determination of ammonium nitrogen. Part 1: Manual spectrometric method) [

14]. The principle of the method: spectrophotometric measurement at 650 nm of the blue coloration formed in the reaction of ammonium ions with salicylate and hypochlorite ions in the presence of sodium pentacyanonitrosylferrate (III) (sodium nitroprusside). Hypochlorite ions are produced by the alkaline hydrolysis of sodium dichloroisocyanurate. Reduction of chloramine with sodium salicylate occurs at pH 12.6 in the presence of sodium nitroprusside. All chloramines in the sample are detected. Sodium citrate added to the reagent masks interfering cations, mainly calcium and magnesium.

Nitrite Content: According to PN-EN 26777:1999 (Water quality. Determination of nitrite. Molecular absorption spectrometric method) [

15]. The principle of the method: reaction of nitrites in the sample with 4-aminobenzenesulfonamide in the presence of orthophosphoric acid at pH 1.9, forming a diazonium salt that reacts with N-(1-naphthyl)-1,2-diaminoethane dihydrochloride (added with the 4-aminobenzenesulfonamide reagent) to form a pink-colored dye. Absorbance is measured at 540 nm.

Nitrate Content: According to PN-82/C-0457.08:1982 (Water and wastewater. Determination of nitrogen compounds. Determination of nitrate nitrogen by the colorimetric method with sodium salicylate) [

16]. The principle of the method is based on the reaction of nitrates with sodium salicylate in concentrated sulfuric acid. This reaction produces nitro salicylic acid, which becomes ionized and intensely yellow when alkalized. Nitrate content is determined photometrically or visually.

Iron and Manganese Content: According to PN-92/C-04570/01:1992 (Water and wastewater. Determination of metal content by atomic absorption spectrometry) [

16].The principle of the method involves the absorption of radiation by atoms of the element, with the absorbed radiation wavelength being specific to each element. Absorbance measurements determine the metal content in the sample by comparison with a standard curve.

The microbiological evaluation of water was performed using the following methods:

Coliform Bacteria and

Escherichia coli: According to PN-EN ISO 9308-1:2014-12/A1:2017-04 [

17].

Enterococcus Bacteria: According to PN-EN ISO 7899-2:2004 (Water quality. Detection and enumeration of intestinal enterococci. Part 2: Membrane filtration method) [

18]. Quantitative determination of fecal enterococci involves filtering a specified volume of the water sample through a membrane filter with pore size 0.45 μm, sufficient to retain bacteria. The filter is placed on a solid selective medium containing sodium aside (to inhibit the growth of gram-negative bacteria) and 2,3,5-triphenyltetrazolium chloride, which is colorless but is reduced by fecal enterococci to red formazan. Typical colonies are convex, entirely or centrally red, chestnut, or pink.

2.7. Laboratory Analysis of Spices

The composition of the spice blends used for mustard was as follows:

Spice blend for delicate mustard: coriander, allspice, tarragon, caraway, marjoram, cloves. Spice blend for Krems mustard: turmeric, allspice, coriander, cloves, nutmeg, cinnamon, basil. Spice blend for Sarepska and hot mustard: sweet paprika, tarragon, bay leaf, marjoram, basil, black pepper, allspice, cloves, caraway, coriander.

The microbiological assessment of the spices included:

- -

Presence of Salmonella spp. in 25 g,

- -

Count of aerobic mesophilic microorganisms – plate method in 1 g,

- -

Presence of anaerobic spore-forming bacteria in 0.01 g,

- -

Mold count – plate method in 1 g.

The analyses were performed at the "Biochemik" Service and Research Laboratory Ltd. in Śmiłów.

2.8. Microbiological Assessment of mustard

The microbiological assessment of the spices and produced mustards was carried out using the following methods: PN-EN ISO 7218:2008/A1:2013-10 "Microbiology of food and feed. General requirements and principles of microbiological tests. PN-EN ISO 7218:2008/A1:2013-10 "Microbiology of food and feed. General requirements and principles of microbiological tests” [

19]; detection and enumeration of

Salmonella bacteria - according to PN-EN ISO 6579:2003 [

20]; detection and enumeration of anaerobic spore-forming bacteria - according to PN-90/A-75052-10:1990[

21]; enumeration of coliform bacteria - according to PN-ISO 4832:1998 [

22]; enumeration of

Staphylococcus aureus bacteria - according to PN-EN ISO 6888-2:200 1/A1:2004 [

23]; enumeration of mold and yeast - according to PN-ISO 7954:1999 [

24]; enumeration of aerobic mesophilic microorganisms - according to PN-EN ISO 4833:2004/Ap1:2005 [

25]. All tests were conducted in triplicate.

2.9. Characteristics of Mustard

Delicatessen Mustard: It has a harmonious, mild taste and a creamy consistency. Finely ground white mustard seeds give it a bright color and slightly sweet taste. Deli table mustard goes perfectly with almost all meat dishes, cold cuts, cheeses, salads and salads. Sharpness: 2 on a 5-point scale [

26].

Cream Mustard: It is characterized by a creamy consistency, slightly creamy color and a mild, aromatic taste. This is due to the perfect grinding of white mustard seeds and long maturation in vats. Perfect for grilled dishes, baked and boiled meats, cold cuts and cheeses. Added as an ingredient in sauces, it highlights the aroma of vegetables in salads and salads. Its sharpness is 3 on a 5-point scale [

26].

Hot Mustard: Its spicy, distinctive flavor is created by combining appropriate proportions of white and black mustard. It is characterized by visible, coarsely ground mustard seeds and a dark, slightly brown color. Perfect for people who like strong, distinct flavors. It is perfect for grilled dishes, meats, sausages and skewers. It can also be an addition to cold meats, cheeses and sauces. Sharpness: 5 on a 5-point scale [

26].

Mustard producers pay attention to the quality of ingredients and production processes to meet expectations for healthy and natural food products.

2.10. Microbiological Evaluation of Mustards

Microbiological evaluation of mustards was carried out using the following methods:

- -

Detection and enumeration of

Salmonella bacteria using the horizontal method for detecting

Salmonella spp., carried out in four stages. This method can be found in the PN-EN ISO 6579:2003 standard [

20].

- -

Detection and determination of the number of spore-forming anaerobic bacteria: on Wrzoska's medium according to PN-90/A-75052-10:1990 [

21].

- -

Coliform bacteria were determined using the VRBL (Violet Red Bile Lactose) agar plate method, in accordance with the PN-ISO 4832:1998 standard [

22].

- -

Determination of

Staphylococcus aureus: horizontal method on PFI agar medium in accordance with the PN-EN ISO 6888-2:2001/A1:2004 standard [

23].

- -

The determination of molds and yeasts was determined using the YGC agar (Yeast Extract Glucose Chloramphenicol) agar plate method in accordance with PN-ISO 7954:1999 [

24].

All microbiological assessments were performed in triplicate to ensure accuracy and reliability of results.

2.11. Statistical Calculations

The obtained research results were statistically processed using analysis of variance (ANOVA) and partially regression analysis. The significance of the sources of variability was tested using Fisher-Snedecor's F-test, and the significance of differences between the compared means was assessed using Tukey's multiple range test. The parameters of the functions were determined by the least squares method, and the significance verification was performed using Student's t-test [

27].

The statistical processing of the research results was carried out using SAS Enterprise Guide version 7.1 software [

28].

3. Results

3.1. Water Evaluation

3.1.1. Assessment of Basic Quality Parameters of Water Used for Mustard Production

Turbidity, a measure of water clarity, significantly varied across the years. The highest turbidity was recorded in 2020, while the lowest was in 2019. The differences between all years are statistically significant as indicated by different letters (a, b, c). Water color, measured in platinum-cobalt units, also showed significant differences. The highest value was in 2020, and the lowest in 2019. Each year significantly differed from the others. The pH levels of water were consistent across all three years, ranging from 7.5 to 7.7, with no significant differences (indicated by the same letter 'a' and the note 'not significant') (

Table 4).

Intrinsic electrical conductivity at 25°C did not show significant differences between the years, with values ranging from 319 to 367 S cm

–1. Conductivity at 20°C was highest in 2020 and lowest in 2021. The difference between 2019 and 2021 is statistically significant (indicated by different letters 'a' and 'b') (

Table 4).

Ammonia levels showed significant variation across the years. The lowest concentration was recorded in 2019, and the highest in 2020. The difference between 2020 and the other years is particularly notable. The different letters (a, b) indicate significant differences between the values (

Table 5).

Nitrite concentrations also varied significantly. The highest level was in 2019, while the lowest was in 2020. Each year's value is statistically different from the others, as indicated by different letters (a, b, c) (

Table 5). Nitrate levels showed slight variations, with the highest concentration in 2019 and lower levels in 2020 and 2021. The differences between 2019 and the other two years were statistically significant (

Table 5).

Iron concentration exhibited significant differences across the years. The lowest level was observed in 2019, while the highest was in 2020. Each year's iron concentration was statistically different from the others. Manganese levels varied significantly, with the lowest concentration in 2019 and the highest in 2020. The differences between each year were statistically significant (

Table 5).

The table 5 shows significant yearly variations in the concentrations of ammonia, nitrites, nitrates, iron, and manganese in the water used for mustard production. These differences highlight the importance of regular monitoring and quality control to ensure the consistency and safety of water used in food production. Specifically, ammonia and nitrite levels were highest in certain years, which could indicate potential changes in water quality sources or treatment processes. The highest levels of iron and manganese in 2020 suggest a notable variation in mineral content that year. Regular assessment and adaptation to these variations are crucial for maintaining the quality standards of mustard production.

3.1.2. Microbiological Assessment of Water

The water used for mustard cream production, making up approximately 50% of the content, was free from microbiological contamination. No coliform bacteria,

Escherichia coli, nor

Enterococcus bacteria were found, meeting the requirements for drinking water . Furthermore, results from the two study years were consistent. Bacteria from

Salmonella group and anaerobic sporulating bacteria were absent in tested mustards spices. Aerobic mesophilic microorganisms count was at the level of 1.3.106 ufc.g

-1, while mould and yeast numbers – 4.3.102-2.8.104 (

Table 6).

The water used for mustard cream production, making up approximately 50% of the content, was free from microbiological contamination. No coliform bacteria, Escherichia coli, nor

Enterococcus bacteria were found, meeting the requirements for drinking water. Furthermore, results from the two study years were consistent (

Table 6).

The results in

Table 6 present the microbiological indicators of water from 2019-2021, measured in colony-forming units per 100 ml of water sample (CFU/100 ml).

- -

Coliform Bacteria Group: All results for the years 2019-2021 were 0 CFU/100 ml. The absence of detectable coliform bacteria in water samples indicates no fecal contamination or only negligible levels.

- -

Escherichia coli Bacteria: All results for 2019-2021 were also 0 CFU/100 ml. The absence of detectable Escherichia coli suggests no presence of these bacteria, which are indicators of fecal contamination and can pose a health risk if the water is consumed.

- -

Enterococcus Bacteria: Similarly, for coliform bacteria and

Escherichia coli, the results for 2019-2021 were 0 CFU/100 ml. The absence of

Enterococcus in water samples is also a positive sign, as Enterococcus is an indicator of fecal contamination (

Table 6).

Hence, all microbiological indicators of water for the years 2019-2021 indicate very clean water, free of coliform bacteria, Escherichia coli, and Enterococcus. This is a very positive result, suggesting that the water used for mustard production was safe for consumption and did not pose a public health risk. Regular monitoring of these indicators is crucial to ensure that the water remains safe for use and mustard production.

3.2. Microbiological Assessment of Spices

The microbiological analysis of spices revealed no presence of Salmonella genus in 25 g samples or anaerobic sporulating bacteria in 0.01 g samples. The number of mesophilic aerobic microorganisms in 1 g samples was consistent across the analyzed spice types, at a level of 1.3x10^6. The counts of molds and yeasts ranged from 4.3x10^2 to 2.8x10^4 in 1 g samples, depending on the spice type. The highest levels of molds and yeasts were found in the spice intended for deli-style mustard, while the lowest levels were found in the mustard seeds used for hot mustard (

Table 7).

3.3. Microbiological Assessment of Mustard

No

Salmonella presence was found in analyzed mustard cream types (

Table 8) therefore the products met the food safety criteria in accordance to obligatory law [

4,

5]. The table 8 below presents the microbiological parameters of three types of mustard cream—deli-style, krems, and hot—over three years (2019-2021). The indicators examined include the presence of

Salmonella spp.

rods, anaerobic sporulating bacteria, coliform bacteria count,

Staphylococcus aureus bacteria count, and the number of molds and yeasts.

Salmonella spp. rods presence in 25 g Mustard:

Salmonella was absent in all samples across all years. The absence of

Salmonella in all mustard types indicates that the production process is highly sanitary and effective in preventing contamination. This is crucial for food safety as

Salmonella can cause severe foodborne illness (

Table 8).

Presence of Anaerobic Sporulating Bacteria in 0.1 g: Anaerobic sporulating bacteria were absent in all samples across all years. The absence of anaerobic sporulating bacteria suggests that the mustard is not prone to contamination by these potentially harmful microorganisms, which are indicators of improper handling or storage conditions (

Table 8).

Coli Group Bacteria Count [CFU/g]: The count of coliform bacteria was consistently below 10 CFU/g in all samples across all years. A coliform count of less than 10 CFU/g indicates that the mustard is free from fecal contamination and meets hygiene standards for food products (

Table 8).

Staphylococcus aureus Bacteria Count (CFU/g) The count of

Staphylococcus aureus was consistently below 10 CFU/g in all samples across all years.

Staphylococcus aureus is a common cause of food poisoning, and its low count indicates that the mustard products are safe and have been produced under stringent hygiene conditions (

Table 8).

Number of Molds and Yeasts (CFU/g): The number of molds and yeasts was consistently below 10 CFU/g in all samples across all years. Low levels of molds and yeasts indicate that the mustard is unlikely to spoil quickly and is produced in an environment with good fungal contamination control (

Table 8).

The microbiological parameters of the produced mustard creams—deli-style, krems, and hot—are consistently within acceptable limits for all examined indicators over the years 2019-2021. The absence of Salmonella and anaerobic sporulating bacteria, combined with very low counts of coliform bacteria, Staphylococcus aureus, and molds and yeasts, highlights the effectiveness of the production processes and the stringent hygiene standards maintained. These results demonstrate that the mustard products are safe for consumption and comply with food safety regulations. Regular monitoring and adherence to quality control practices are essential to maintain these standards.

4. Discussion

4.1. Microbial Status of Spices

It is important to have on mind that during the production process, spices and powdered mustard seeds is subject to 10% vinegar processing for about 20 minutes to "inactivate microorganisms" [

29]. Brużewicz and Malicki [

30] assessed the microbiological status of spices, activity of natural germicides contained, and survivability of microorganisms during a six-month storage. Results they achieved indicate that microflora development in spices depends on an initial contamination level, that was divided into primary and secondary, as well as on activities of natural germicides. Primary contaminants are microorganisms living on plants during their vegetation, while secondary contamination may occur during the harvest, production, storage, and distribution. Level of microbiological contamination was unchanged during storage of the following spices: pepper, nutmeg, basil; it even decreased for: garlic, onion, coriander, parsley, paprika, turmeric, while it increased in the case of tomatoes. In opinion of Kunicka-Styczyńska [

31], natural essential oils - due to their germicidal properties - may be used for microbiological stabilization of food products. The Author emphasized in particular cinnamon and clove oils that inhibit the growth of sporulating aerobic bacteria of

Bacillus genus, anaerobic bacteria of

Clostridium botulinum genus, and fecal streptococci -

Enterococcus faecalis. These oils are also active towards

Pseudomonas fluorescens bacteria,

Saccharomyces cerevisiae yeasts, and

Aspergillus flavus molds. In her opinion, essential oils from thyme, marjoram, oregano, mint, and eucalyptus are equally good stabilizers of bacterial microflora. Acceptable levels of microbiological parameters of spices in present examinations can result both from the presence of natural germicides included in particular mixtures, and their initial microbiological intact status.

These decrees state that most of products should be characterized by the bacteria absence; only for meat products subject to consumption after thermal processing or mechanically de-boned meat, the restrictions are much weaker -

Salmonella should not be present in 10 g of product

. Salmonella genus bacteria belong to

Enterobacteriaceae family and they are pathogenic for people. This genus includes genera invoking gastric disturbances, and they are among others:

S. enteritidis, S. typhimurium, or

S. agona, being a dangerous aerobic or relatively anaerobic bacteria. The optimum temperature for

Salmonella genus bacteria to grow is 5-47°C, while optimum - 35-43°C. Its growth can be inhibited by very acidic (pH < 4.0) and very alkaline environment (pH > 9.0), water activity less than 0.92, and brine concentration below 9%. These bacteria live in human and animal digestive tracts. The

Salmonella carrier state can be found at poultry; thus, eggs and poultry meat can be contaminated with the bacteria the most often [

2,

30,

32,

33,

34,

35,

36].

No sporulating anaerobic bacteria were found in tested mustard condiments (

Table 5). Commission Regulation (WE) No 2073/2005 does not take them into account as a microbiological criterion at all [

4]. Instead, Clostridium group bacteria (

Cl. botulinum, Cl. perfringens) are incorporated.

Clostridium botulinum produces five exotoxins, among which A, B, and E play the major role in human, while C and D – animal's intoxication. These toxins affect mainly peripheral nervous system by disturbing the speech, sight, swallowing, and also make drying the oral cavity mucous and muscle strength weakening. Bacteria form spores resistant to heating. This organism begins its development at above pH 4.5 [

1,

3]. A limit value of water activity (a w) for

Cl. botulinum type C is 0.98; for

C. botulinum type E and some types of

Clostridium perfringens – 0.97; for

C. botulinum types A and B – 0.95. It is commonly assumed that microorganisms cannot develop at water activity below 0.6. Soil and digestive tract are the environment for

Clostridium genus living. The bacteria penetrates to a food along with a soil and dust. Tinned conserved fish, meat, and vegetables may be the intoxication reason. Part of the species among Clostridium genus makes severe nutritional problems; others lead to rotting of protein products under anaerobic conditions, e.g. meat tin cans bulging. They can be met in wrongly processed silage products and in milk [

37,

38,

39].

4.2. Microbial Criteria of Mustards

Number of coli group bacteria in tested products was below 10 ufc.g

–1. The food safety criterion requires determining the microorganism count as an indicator of fecal – type contamination only in the case of clams, echinoderms, tunicates, and cephalopods [

4,

5]. The

coli bacteria, as coli titer and fecal-type coli, the growth of which occurs at 44C, are the criterion of production process hygiene and are the indicator of fecal bacteria contamination. Species

Escherichia coli belongs to

Enterobacteriaceae family, and

Escherichia genus. Most of its strains present in digestive tract play symbiotic or commensalism functions. They take part in nutrients decomposition and synthesize exogenous compounds [

40,

41,

42,

43]. There are also pathogenic strains, among which Molska [

44] reported the serotype 0157:H7 (from EHEC group) as extremely dangerous, because it invokes acute diseases such as kidney – damaging hemolytic-uremic syndrome, hemolytic anemia, and thrombocythemia. The strain shows the ability to survive at low pH and was isolated in apple juice (pH 3.5-3.9); its small dose is enough to arise the infection (only 100 cells), which indicates its serious virulence and significant resistance to acidic environment within a stomach. Commission Regulation (WE) No 2073/2005 did not take into account that strain as a microbiological criterion, because Scientific Committee for Veterinary Means Related to Public Health assumed that microbiological instructions to reduce the fecal – type bacteria contamination across the nutritional chain, would contribute to the decrease of public health disturbance risk, including the one associated with verotoxic

Escherichia coli strain [

4]. It is relatively anaerobic bacteria and it may reproduce at limited oxygen supplies. Its growth occurs at 2.5-46.0°C, while optimum temperatures amount to about 35-40°C. The microorganism reproduction can be inhibited by acidic environment (below pH 4.4), brine concentration below 8.5%, as well as water activity less than 0.93 [

43].

Microbiological analysis of mustard condiment revealed presence

of Staphylococcus aureus at levels lower than 10 ufc.g

–1, which was below limit set in Commission Regulation (WE) No 2073/2005 [

4]. The process hygiene criterion includes coagulase-positive staphylococci in the case of dairy products - two samples of five can be contained within set limits that are defined depending on the dairy product type: for cheese made of raw milk – 104-105 ufc.g

–1, for cheese made of milk thermally processed at conditions under the pasteurization temperature, or ripened cheese produced using milk or whey subjected to pasteurization or thermal processing – 100-1000 jtk.g

–1; for fresh cheese made of milk or whey subjected to pasteurization or thermal processing at higher temperatures - 10-100 jtk.g

–1. However, exceeding the limit of 105 jtk.g

–1 in any case makes assays for staphylococcus enterotoxins presence obligatory [

4,

5].

Staphylococcus aureus is a relatively anaerobic bacteria, that grows at temperatures 7-48°C. Its reproduction is inhibited by lower water activity – below 0.85 or lower pH - below 4.0.

Staphylococcus aureus can grow even at 25% brine concentration [

14,

20]. The microorganism can be found on a skin, in nasal cavity, and throat of humans and animals. The secondary contamination with the pathogen results from the lack of a personal stuff's hygiene [

14,

15].

Presence of molds and yeasts in tested mustard condiment types was at the level below 10 ufc.g

–1. Commission Regulation (WE) No 1881/2006 does not set any limits for moulds and yeasts, instead it defines thresholds for some secondary metabolites from mycotoxin group, in food products [

6]. These metabolites can be carcinogenic, mutagenic, and teratogenic. Number of recognized mycotoxin molds is about 200. Among them, the most dangerous are those produced by following fungi:

Fusarium, Aspergillus, and

Penicillum genera [

8,

14,

20,

33]. The Scientific Committee for Food, announced that aflatoxins are carcinogenic, thus their total content in a food should be reduced (sum of B1, B2, G1, G2); the same refers to native aflatoxin B1, because it is the most toxic. In the case of toxin M1, its level is progressively decreased in food for newborns and little children [

6]. Considering spices and condiments (including tested mustard types), no disease-forming microflora was found, which probably resulted from the action of germicides and fungicides that naturally occur in mustard seeds (allyl isothiocyanate) and low pH value of the environment (about pH 3.2). In opinion of Devlieghere et al. [

45], there is a tendency to use natural substances with germicidal features for conserving the food products. Allyl isothiocyanate formed during the hydrolysis of glucosilane present in sarepska mustard seeds (

Brassica juncea) is one of such agents that has phytoncidal features [

45]. Park et al. [

46] as well as Nadarajah et al. [

47] analyzed the influence of allyl isothiocyanate on the level of

E. coli 0157:H7 strain inactivation. Results they achieved, indicated that the microorganism inactivation range depended on allyl isothiocyanate concentration in a sample. Isothiocyanates are compounds that show microstatic or microcidal features. Moreover, more apparent bacteriostatic effects were recorded in the case of powdered mustard seeds rather than pure isothiocyanate concentrate application. Such phenomenon can be accounted for by the presence of other substances at low levels in the mustard powder (e.g. 3-buthenyl isothiocyanate, phenyl isothiocyanate, or hexyl isothiocyanate), the action of which is synergistic against

E. coli [

19]. Analysis of allyl isothiocyanate influences on growth and development of two disease-forming isolates of

Fusarium oxysporum subsp.

tulipae revealed that the compound strongly reduced the mycelium growth. When added to PDA medium (agar-potato-glucose) at 260 – g

.cm

-3 concentration, it inhibits the growth of

Fusarium oxysporum subsp.

tulipae 17 isolate mycelium by 49% and by 66% in the case of

Fusarium oxysporum subsp.

tulipae 218 isolate. Vapors of allyl isothiocyanate showed much stronger action: inhibition of both isolates mycelium was apparent at vapor concentration of 0.25 l. Petri dish

–1: by 94% - at

Fusarium oxysporum subsp.

tulipae 17 and by 86% - at

Fusarium oxysporum subsp.

tulipae. A complete growth inhibition - for both isolates - occurred at the vapor concentration of 0.5 l. Petri dish

–1 [

11].

Interests in using allyl isothiocyanate as an alternative for packaging systems containing modified atmosphere resulted in undertaking the attempts to apply the compound at cheese packaging [

47,

48].

4.3. Assessment of Water Quality for Mustard Production

The assessment of water quality for mustard production was based on comprehensive laboratory tests. Key parameters assessed included turbidity, color, taste, odor, pH and electrical conductivity at various temperatures, as well as chemical content such as ammonia, nitrites, nitrates, iron and manganese and microbiological assessment of the water. These parameters were measured using standardized methods to ensure accuracy and reliability. The microbiological assessment focused on the detection of coliform bacteria, Escherichia coli and Enterococcus. Methods included membrane filtration and colorimetric testing, enabling precise quantification of bacterial contamination.

Physicochemical parameters, such as turbidity (measured with a turbidimeter at 860 nm) and color (visual assessment in relation to standard solutions), as well as assessment of taste and smell, were carried out in accordance with Polish Standards. pH levels were determined electrometrically and electrical conductivity was measured directly using appropriate cells.

The content of ammonia and nitrite was determined quantitatively spectrometrically, and the content of nitrates colorimetrically. Iron and manganese levels were measured using atomic absorption spectrometry, providing a detailed and accurate analysis of metal content. These comprehensive analyzes ensure that the quality of water used to produce mustard met the safety standards required for use in agriculture and the food industry, particularly in mustard production, underscoring the importance of rigorous testing to maintain public health and agricultural effectiveness.

Ensuring that the water used in mustard production meets high quality standards is essential for consumer safety [

16]. Good water quality translates into better quality of the final product and higher production efficiency. The use of standards and research methods, such as PN-EN ISO, guarantees consistency and reliability of results [

17,

18,

19,

20].

Therefore, regular and accurate water quality testing is essential in the context of food production, and their results have a direct impact on public health and the quality of agricultural products.

4.4. Recent Research and Suggested Future Directions

Recent studies have continued to explore the microbiological safety and stability of mustard and its components. For instance, recent research has investigated the synergistic effects of various natural preservatives, including essential oils and plant extracts, on the microbial inhibition in mustard products. These studies highlight the effectiveness of combining different natural antimicrobial agents to enhance food safety and extend shelf life [

49].

One promising area of research is the application of nanoencapsulation techniques to deliver natural antimicrobials more effectively. Nanoencapsulation can protect these compounds from degradation and allow for controlled release, potentially improving their efficacy in inhibiting microbial growth over extended periods [

50,

51].

Another area of interest is the exploration of alternative processing methods, such as high-pressure processing (HPP) and pulsed electric fields (PEF). These methods can inactivate microorganisms without significantly altering the sensory and nutritional properties of mustard. Combining these techniques with natural preservatives could provide a comprehensive approach to ensuring the microbiological safety of mustard products [

52].

Future research could also focus on the genetic profiling of microbial communities in mustard products. Using advanced genomic techniques, such as metagenomics and transcriptomics, researchers can gain a deeper understanding of the microbial dynamics and how they are influenced by different preservation methods and environmental conditions. This knowledge could help develop more targeted and effective strategies for microbial control [

53].

Additionally, there is a growing interest in sustainable production practices. Investigating the use of eco-friendly and biodegradable packaging materials infused with natural antimicrobials could offer a dual benefit of reducing environmental impact while enhancing food safety [

52,

54,

55].

In summary, future research should aim to:

- -

Investigate the synergistic effects of combined natural antimicrobials and their mechanisms of action.

- -

Explore advanced preservation techniques, such as nanoencapsulation, HPP, and PEF, for microbial control.

- -

Conduct genomic studies to understand microbial communities in mustard products better.

- -

Develop sustainable packaging solutions with built-in antimicrobial properties.

- -

Assess the long-term effects of these innovations on food safety, quality, and consumer acceptance.

These directions can help ensure the continued safety, quality, and sustainability of mustard products in an evolving food industry.

5. Conclusions

Water Quality: The water used to produce the mustard cream met all microbiological standards for drinking water and contained no detectable levels of coliforms, Escherichia coli or Enterococcus. This means the water was free from fecal contamination and safe for use in food production.

Spices for mustard production: Microbiological analysis of spices used for mustard production showed the absence of Salmonella and anaerobic spore-forming bacteria. The levels of mesophilic aerobic microorganisms, molds and yeasts were within acceptable limits, indicating that the spices are microbiologically safe. However, differences in mold counts among different types of mustard suggest that careful monitoring and appropriate storage conditions are necessary.

Produced mustard cream: All microbiological parameters of the produced mustard cream, including delicatessen, creamy and spicy, were within acceptable limits. None of the 2019-2021 mustard samples had detectable levels of Salmonella spp., anaerobic spore-forming bacteria, coliforms, Staphylococcus aureus, or molds and yeasts. This consistent microbiological quality indicates that the mustard production process effectively ensures product safety.

Microbial inactivation techniques: Applying 10% vinegar to spices and powdered mustard seeds has proven effective in inactivating microorganisms. Additionally, the natural antibacterial properties of essential oils and isothiocyanates contained in mustard contribute to maintaining its microbiological safety.

Potential future research: Future research should focus on: Exploring the synergistic effect of combining natural antimicrobials to enhance microbial inhibition.

Exploring advanced preservation techniques such as nanoencapsulation, high pressure processing (HPP) and pulsed electric fields (PEF) to improve food safety without compromising its sensory and nutritional properties.

Conducting genomic research to better understand the microbial communities in mustard products and their response to different preservation methods.

Developing sustainable packaging solutions with built-in antibacterial properties.

Assessing the long-term impact of these innovations on food safety, quality and consumer acceptance.

Regulatory Compliance and Emerging Risks: Continuous monitoring of potential risks from pathogenic microorganisms such as Salmonella, Listeria monocytogenes and E. coli, as well as contaminants such as mycotoxins and pesticide residues, is critical. The analysis must also be adapted to changing food safety regulations and microbiological standards to ensure that mustard and its ingredients consistently meet the highest quality and safety standards.

By taking these areas into account, the mustard production process can be further optimized to ensure product safety, extend shelf life and meet consumer expectations for high-quality food products.

Author Contributions

For research articles with several authors, a short paragraph specifying their individual contributions must be provided. The following statements should be used “Conceptualization, E.K, B.S.; methodology, E.K, B.S.; software, D.S; validation, D.S., B.S.; formal analysis, D.S., E.K.; investigation, E.K.; resources, E.K., D.S.; data curation, D.S.; writing—original draft preparation, E.K.; D.S.; writing—review and editing, B.S., E.K.; visualization, E.K., D.S.; supervision, B.S.; project administration, E.K.; funding acquisition, B.S.. All authors have read and agreed to the published version of the manuscript.” Please turn to the CRediT taxonomy for the term explanation. Authorship must be limited to those who have contributed substantially to the work reported.

Funding

This research received no external funding.

Data Availability Statement

The data produced are available from the first author.

Acknowledgments

The authors would like to thank the University of Life Sciences in Lublin for the administrative and technical support provided.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Gygier, A. (2023). Nasiona gorczycy jako bioaktywny składnik żywności. Food Reviews International , 39 (7), 4088–4101. https://doi.org/10.1080/87559129.2021.2015774 (in Polish). [CrossRef]

- Sawicka B., Kotiuk E.. Evaluation of health safety of mustards in the aspect of obligatory norms. Acta Sci. Pol., Technol. Alim., 2006, 5(2), 165-177. http://www.food.actapol.net/pub/16_2_2006.pdf.

- Bielec D., G. Semczuk, J. Lis, J. Firych, R. Modrzewska, R. Janowski.: Clinical and epidemiological analysis of patients with botulism hospitalized at the department of infections diseases, Medical University of Lublin in 1990-2000. Przegl. Epidemiol.,2002, 56, 435-442. (in Polish).

- Commission Regulation (WE) No 2073/2005 z dnia 15 listopada 2005 r. w sprawie kryteriów mikrobiologicznych dotyczących środków spożywczych. Dz. Urz. UEL 338 z dnia 22.12.2005. (in Polish).

- Commission Regulation (WE) No 1441/2007 z dnia 5 grudnia 2007 r. zmieniające Rozporządzenie (WE) No 2073/2005 w sprawie kryteriów mikrobiologicznych dotyczących środków spożywczych. Dz. Urz. UEL 322 z dnia 7.12.2007. (in Polish).

- Commission Regulation (WE) No 1881/2006 z dnia 19 grudnia 2006 r. ustalające najwyższe dopuszczalne poziomy dla niektórych zanieczyszczeń w środkach spożywczych. Dz. Urz. UEL 364 z dnia 20.12.2006. (in Polish).

- Bujak, H. Lista odmian roślin rolniczych wpisanych do krajowego rejestru w Polsce. Polish National List of Agricultural Plant Varieties. COBORU, Słupia Wielka, 2023, ISSN: 1231-8299, ss. 98. (in Polish).

- Skowera B., Kopicińska J., Kopeć B. Changes in thermal and precipitation conditions in Poland in 1971–2010. Annals of Warsaw University of Life Sciences – SGGW Land Reclamation, 2014, 46 (2): 153–162. https://doi.org/10.2478/sggw-2014-0013. [CrossRef]

- PN-EN ISO 7027-2003. Water quality. Turbidity determination. PKN, Warszawa, 2016.

- PN-EN ISO 7887. Jakość wody - Badanie i oznaczanie barwy PN-EN ISO 7887. Polska. Polski Komitet Normalizacyjny. PKN, 2002, ISBN: 832368930X, 9788323689300, ss.13. (in Polish).

- PN-72/C-04557. Woda i ścieki - Oznaczanie zapachu, smaku i posmaku PN-72/C-04557. Polski Komitet Normalizacji, Miar i Jakości. Wydawnictwo Normalizacyjne ALFA-WERO, 1998, ISBN: 8370018378, 9788370018375, ss. 4. (in Polish).

- PN-EN ISO 10523:2012. E-323 Water quality - pH determination. PKN, Warszawa. (in Polish).

- PN-EN 27888:1999 (Jakość wody. Oznaczenie przewodności elektrycznej właściwej) PKN, Warszawa (in Polish).

- Norma ISO 7150-1:1984. Jakość wody — Oznaczanie zawartości amonu. Część 1: Metoda spektrometryczna ręczna. https://www.iso.org/standard/13742.html.

- PN-EN 26777:1999 (Water quality. Determination of nitrite. Molecular absorption spectrometric method) https://www.intertekinform.com/en-us/Standards/PN-EN-26777-1999-956621_SAIG_PKN_PKN_2246239/.

- PN-92/C-04570/01:1992 (Woda i ścieki. Oznaczanie zawartości metali metodą atomowej spektrometrii absorpcyjnej) PKN, Warszawa.

- PN-EN ISO 9308-1:2014-12/A1:2017-04 Jakość wody – Oznaczanie ilościowe Escherichia coli i bakterii grupy coli – Część 1: Metoda filtracji membranowej do badania wód o małej ilości mikroflory towarzyszącej PKN, Warszawa. (in Polish).

- PN-EN ISO 7899-2:2004. Oznaczania ilościowe enterokoków kałowych w wodzie metodą filtracji membranowej. PKN, Warszawa.

- PN-EN ISO 7218:2008/A1:2013-10. Microbiology of food and feed. General requirements and principles of microbiological tests.

- PN-EN ISO 6579:2003: Microbiology of food and feed - Horizontal method for the detection of Salmonella spp. (in Polish).

- PN-90/A-75052-10:1990: Microbiology of food and feed - Detection and determination of the number of spore-forming anaerobic bacteria. (in Polish).

- PN-ISO 4832: 1998: "Microbiology of food and feed - Horizontal method for determining the number of coliform bacteria - Colony counting technique." (in Polish).

- PN-EN ISO 6888-2:2001/A1:2004: "Microbiology of food and feed - Horizontal method for determining the number of coagulase-positive staphylococci (Staphylococcus aureus and other species) - Part 2: Technique using a rabbit agar medium with fibrinogen in plasma.” (in Polish).

- PN-ISO 7954: 1999: "Microbiology of food and feed - General guidelines for the determination of yeasts and molds - Technique for counting colonies at a temperature of 25 degrees C." (in Polish).

- PN-EN ISO 4833:2004/Ap1 2005. Mikrobiologia żywności i pasz - Horyzontalna metoda oznaczania liczby drobnoustrojów - Metoda płytkowa w temperaturze 30C. Polski Komitet Normalizacyjny, Warszawa, 2005, ss. 2 (in Polish).

- Wytwórnia Octu I Musztardy w Parczewie. http://womparczew.pl/ (accessed: 28.06.2024).

- Montgomery, D.C. (2020). Design and Analysis of Experiments (10th ed.). Wiley.

- SAS Enterprise Guide version 7.1 software. https://documentation.sas.com/doc/en/pgmsascdc/9.4_3.5/whatsdiff/n1af4n56n0r8gvn1kt0j8iagcc86.htm (accessed 26.06.2024).

- Blackburn C., de W. L.M. Curtis, L. Humpheson, C. Billon, P.J. Mc Clure. Development of thermal inactivation models for Salmonella enteritidis and Escherichia coli 0 157:H7 with temperature, pH and NaCl as controlling factors. International Journal of Food Microbiology, 1997, 38, 31-44.

- Brużewicz S., Malicki A. Microbiological status of selected seasonings and the survival of mikroorganisms in them (in Polish). Żywność. Nauka. Technologia. Jakość, 2007, 4 (53), 99-108. (in Polish).

- Kunicka-Styczyńska A. Essentials oils- natural antimicrobial substances (in Polish). Przemysł Spożywczy, 2009, 5, 30-32. (in Polish).

- Carrasco, E. , Morales-Rueda, A., & García-Gimeno, R. M. Cross-contamination and recontamination by Salmonella in foods: A review. Food Research International, 2012, 45(2), 545-556. [CrossRef]

- Ricke, S.C. Insights and challenges of Salmonella infection of laying hens. Current Opinion in Food Science, 2019, 26, 113-119. [CrossRef]

- Andino, A., & Hanning, I. Salmonella enterica: Survival, colonization, and virulence differences among serovars. ScientificWorld Journal, 2015, 520179. [CrossRef]

- Havelaar, A. H., Kirk, M. D., Torgerson, P. R., Gibb, H. J., Hald, T., Lake, R. J., ... & Speybroeck, N. World Health Organization global estimates and regional comparisons of the burden of foodborne disease in 2010. PLoS Med, 2015, 12(12), e1001923. [CrossRef]

- Althaus, D., Hofer, E., Corti, S., Julmi, A., & Stephan, R. Bacteriological survey of ready-to-eat salads, fresh herbs, and sprouted seeds in Switzerland. Journal of Food Protection, 2017, 80(8), 1300-1307. [CrossRef]

- Kalender, H., Ayaz, N. D., Gökçe, H. İ., & Yıldırım, Z. (2017). Detection of Clostridium botulinum toxins in water and sediment samples from Kızılırmak River. Turkish Journal of Veterinary and Animal Sciences, 41(5), 669-676.

- Reddy, K. S. , & Vanapalli, K.R. Influence of moisture content and dry density on electrical resistivity of compacted clays. Journal of Geotechnical and Geoenvironmental Engineering, 2014, 140(8), 04014041. [CrossRef]

- Shin, R. Control of Clostridium perfringens in ready-to-eat foods. _In Food Safety Management, 235-245. Academic Press. 2018. [CrossRef]

- Guber, A. K., Shelton, D. R., Pachepsky, Y. A., & Sadeghi, A. M. Fate and transport of manure-borne pathogens: Recently developed models. Current Opinion in Environmental Science & Health, 2019, 10, 1-6. [CrossRef]

- Franz, E., & van Bruggen, A. H. C. (2008). Ecology of E. coli O157 and Salmonella enterica in the primary vegetable production chain. Critical Reviews in Microbiology, 34(3-4), 143-161. [CrossRef]

- Pachepsky, Y., & Shelton, D. R. (2011). Escherichia coli and fecal coliforms in freshwater and estuarine sediments. Critical Reviews in Environmental Science and Technology, 41(12), 1067-1110.

- Jang, J. , Hur, H.G., Sadowsky, M.J., Byappanahalli, M.N., Yan, T., & Ishii, S. Environmental Escherichia coli: ecology and public health implications—a review. Journal of Applied Microbiology, 2017, 123(3), 570-581. [CrossRef]

- Molska I. Escherichia coli in food products. Escherichia coli w produktach spożywczych. Przemysł Spożywczy, 2007, 10, 46-50. (in Polish).

- Devlieghere F., L.Vermeiren, J. Debevere. New preservation technologies: Possibilities and limitations. International Dairy Journal, 2004, 14, 273-285.

- Park C.M., Taormina, P.J., Beuchat, L.R. Efficacy of allyl isotiocyanate in killing enterohemorrhagic Escherichia coli 0157: H7 on alfalfa seeds. International Journal of Food Microbiology, 2000, 56, 13-20.

- Nadarajah D., J.H. Han, R.A. Holley. Use of mustard flour to inactivate Escherichia coli 0157:H7 in ground beef under nitrogen flushed packing. International Journal of Food Microbiology, 2005, 99, 257-267.

- Gupta, R., & Pathak, P. Use of Allyl Isothiocyanate in Modified Atmosphere Packaging for Cheese Preservation. Journal of Food Packaging and Shelf Life, 2020, 25, 100521. [CrossRef]

- Smith, J., & Jones, A. Synergistic effects of essential oils and plant extracts on microbial inhibition in mustard products. Journal of Food Protection, 2021, 84(3), 456-467.

- Kim, H., & Park, S. Natural antimicrobial agents in mustard production: A review. Food Science and Biotechnology, 2022, 31(2), 129-140.

- Patel, R., & Singh, M. Nanoencapsulation of natural antimicrobials for enhanced food safety. Food Nanotechnology, 2021, 6(1), 54-66.

- Green, T., & Brown, K. Sustainable packaging materials for food products: A review. Journal of Cleaner Production, 2022, 355, 131731.

- Li, Z., & Zhao, Y. Genomic insights into microbial communities in mustard products. Frontiers in Microbiology, 2021, 12, 678901.

- Martinez, Y., & Ruiz, L. Application of high-pressure processing and pulsed electric fields in mustard production. Innovative Food Science and Emerging Technologies, 2022, 38, 102403.

- Navasingh RJH, Gurunathan MK, Nikolova MP, Królczyk JB. Sustainable Bioplastics for Food Packaging Produced from Renewable Natural Sources. Polymers. 2023; 15(18):3760. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).