Submitted:

10 July 2024

Posted:

11 July 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Applications of Value Analysis for Analyzing the Mechanical Behavior of PETG and ASA 3D Printed Samples

3.1.1. Tensile Testing

3.1.1. Compressive Testing

3.2. Optimization of FDM parameters based of Value Analysis for improve the 3D printing efficiency for samples made by PETG and ASA

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Amaya-Rivas, J.L.; Perero, B.S.; Helguero, C.G.; Hurel, J.L.; Peralta, J.M.; Flores, F.A.; Alvarado, J.D. Future Trends of Additive Manufacturing in Medical Applications: An Overview. Heliyon 2024, 10, e26641. [Google Scholar] [CrossRef] [PubMed]

- Srivastava, M.; Rathee, S. Additive Manufacturing: Recent Trends, Applications and Future Outlooks. Progress in Additive Manufacturing 2021, 7. [Google Scholar] [CrossRef]

- D’Addona, D.; Raykar, S.; Singh, D.; Kramar, D. Multi Objective Optimization of Fused Deposition Modeling Process Parameters with Desirability Function. Procedia CIRP 2021, 99, 707–710. [Google Scholar] [CrossRef]

- Zisopol, D.; Tanase, M.; Portoaca, A. Innovative Strategies for Technical-Economical Optimization of FDM Production. Polymers 2023, 15, 3787. [Google Scholar] [CrossRef]

- Ramadan, S.; Altwarah, Q.; Abu-Shams, M.; Alkurdi, D. Optimizing Tensile Strength and Energy Consumption for FDM through Mixed-Integer Nonlinear Multi-Objective Optimization and Design of Experiments. Heliyon 2024, 10, e30164. [Google Scholar] [CrossRef] [PubMed]

- Le, L.; Rabsatt, M.A.; Eisazadeh, H.; Torabizadeh, M. Reducing Print Time While Minimizing Loss in Mechanical Properties in Consumer FDM Parts. International Journal of Lightweight Materials and Manufacture 2022, 5, 197–212. [Google Scholar] [CrossRef]

- Rahman, M.M.; Sultana, J.; Rayhan, S.; Ahmed, A. Optimization of FDM Manufacturing Parameters for the Compressive Behavior of Cubic Lattice Cores: An Experimental Approach by Taguchi Method. The International Journal of Advanced Manufacturing Technology 2023, 129, 1–15. [Google Scholar] [CrossRef]

- Kothandaraman, L.; Balasubramanian, N.K. Optimization of FDM Printing Parameters for Square Lattice Structures: Improving Mechanical Characteristics. Materials Today: Proceedings 2024. [CrossRef]

- Jaisingh Sheoran, A.; Kumar, H. Fused Deposition Modeling Process Parameters Optimization and Effect on Mechanical Properties and Part Quality: Review and Reflection on Present Research. Materials Today: Proceedings 2020, 21, 1659–1672. [Google Scholar] [CrossRef]

- Ghosh, M.; D’Souza, N.A. Improved Mechanical Performance in FDM Cellular Frame Structures through Partial Incorporation of Faces. Polymers 2024, 16, 1340. [Google Scholar] [CrossRef] [PubMed]

- Ben hadj Hassine, S.; Chatti, S.; Louhichi, B.; Seibi, A. Experimental Study of the Tensile Behavior of Structures Obtained by FDM 3D Printing Process. Polymers 2024, 16, 1562. [Google Scholar] [CrossRef] [PubMed]

- Zisopol, D.G.; Minescu, M.; Iacob, D.V. A Study on the Evaluation of the Compression Behavior of PLA Lattice Structures Manufactured by FDM. Engineering, Technology & Applied Science Research 2023, 13, 11801–11806. [Google Scholar] [CrossRef]

- Tagliaferri, V.; Trovalusci, F.; Guarino, S.; Venettacci, S. Environmental and Economic Analysis of FDM, SLS and MJF Additive Manufacturing Technologies. Materials (Basel, Switzerland) 2019, 12. [CrossRef]

- Ponticelli, G.S.; Venettacci, S.; Tagliaferri, F.; Guarino, S. Fused Deposition Modelling for Aeronautics: Techno-Economic and Environmental Assessment for Overhead Locker Supports Replacement. The International Journal of Advanced Manufacturing Technology 2023, 128. [Google Scholar] [CrossRef]

- Amithesh, S.; Shanmugasundaram, B.; Kamath, S.; Adhithyan, S.; Murugan, R. Analysis of Dimensional Quality in FDM Printed Nylon 6 Parts. Progress in Additive Manufacturing 2023, 9. [Google Scholar] [CrossRef]

- Ciornei, M.; Iacobici, R.; Savu, I.; Dalia, S. FDM 3D Printing Process - Risks and Environmental Aspects. Key Engineering Materials 2021, 890, 152–156. [Google Scholar] [CrossRef]

- Zhai, C.; Wang, J.; (Paul) Tu, Y.; Chang, G.; Ren, X.; Ding, C. Robust Optimization of 3D Printing Process Parameters Considering Process Stability and Production Efficiency. Additive Manufacturing 2023, 71, 103588. [Google Scholar] [CrossRef]

- Wei, H.; Tang, L.; Qin, H.; Wang, H.; Chen, C.; Li, Y.; Wang, C. Optimizing FDM 3D Printing Parameters for Improved Tensile Strength Using the Takagi–Sugeno Fuzzy Neural Network. Materials Today Communications 2024, 38, 108268. [Google Scholar] [CrossRef]

- Fountas, N.A.; Zaoutsos, S.; Chaidas, D.; Kechagias, J.D.; Vaxevanidis, N.M. Statistical Modelling and Optimization of Mechanical Properties for PLA and PLA/Wood FDM Materials. Materials Today: Proceedings 2023, 93, 824–830. [Google Scholar] [CrossRef]

- Ermergen, T.; Taylan, F. Investigation of DOE Model Analyses for Open Atmosphere Laser Polishing of Additively Manufactured Ti-6Al-4V Samples by Using ANOVA. Optics & Laser Technology 2024, 168, 109832. [Google Scholar] [CrossRef]

- Pratap Singh, D.; Kumar Dwivedi, V.; Agarwal, M. “Application of the DoE Approach to the Fabrication of Cast Al2O3-LM6 Composite Material and Evaluation of Its Mechanical and Microstructural Properties.” Materials Today: Proceedings 2023. [CrossRef]

- Singh, B.J.; Kalra, G. Mixture DoE: A Strategic Approach for Multi-Response Optimization of AA1100 Metal-Matrix Hybrid Composites. Materials Today: Proceedings 2022, 50, 1480–1495. [Google Scholar] [CrossRef]

- Nyabadza, A.; Mc Donough, L.M.; Manikandan, A.; Ray, A.B.; Plouze, A.; Muilwijk, C.; Freeland, B.; Vazquez, M.; Brabazon, D. Mechanical and Antibacterial Properties of FDM Additively Manufactured PLA Parts. Results in Engineering 2024, 21, 101744. [Google Scholar] [CrossRef]

- Fountas, N.A.; Papantoniou, I.; Kechagias, J.D.; Manolakos, D.E.; Vaxevanidis, N.M. Modeling and Optimization of Flexural Properties of FDM-Processed PET-G Specimens Using RSM and GWO Algorithm. Engineering Failure Analysis 2022, 138, 106340. [Google Scholar] [CrossRef]

- Sandhu, G.S.; Sandhu, K.S.; Boparai, K.S. Effect of Extrudate Geometry on Surface Finish of FDM Printed ABS Parts. Materials Today: Proceedings 2024. [CrossRef]

- Pratheesh Kumar, M.R.; Saravanakumar, K.; Arun Kumar, C.; Saravanakumar, R.; Abimanyu, B. Experimental Investigation of the Process Parameters and Print Orientation on the Dimensional Accuracy of Fused Deposition Modelling (FDM) Processed Carbon Fiber Reinforced ABS Polymer Parts. Materials Today: Proceedings 2024, 98, 166–173. [Google Scholar] [CrossRef]

- Camposeco-Negrete, C. Optimization of FDM Parameters for Improving Part Quality, Productivity and Sustainability of the Process Using Taguchi Methodology and Desirability Approach. Progress in Additive Manufacturing 2020, 5. [Google Scholar] [CrossRef]

- Jatti, V.; Sapre, M.; Jatti, A.; Khedkar, N.; Jatti, V. Mechanical Properties of 3D-Printed Components Using Fused Deposition Modeling: Optimization Using the Desirability Approach and Machine Learning Regressor. Applied System Innovation 2022, 5, 112. [Google Scholar] [CrossRef]

- Rivera-López, F.; Pavón, M.M.L.; Correa, E.C.; Molina, M.H. Effects of Nozzle Temperature on Mechanical Properties of Polylactic Acid Specimens Fabricated by Fused Deposition Modeling. Polymers 2024, 16, 1867. [Google Scholar] [CrossRef] [PubMed]

- Almuflih, A.S.; Abas, M.; Khan, I.; Noor, S. Parametric Optimization of FDM Process for PA12-CF Parts Using Integrated Response Surface Methodology, Grey Relational Analysis, and Grey Wolf Optimization. Polymers 2024, 16, 1508. [Google Scholar] [CrossRef] [PubMed]

- Van, C.N.; Hoang, A.L.; Long, C.D.; Hoang, D.N. Surface Roughness in Metal Material Extrusion 3D Printing: The Influence of Printing Orientation and the Development of a Predictive Model. Engineering, Technology & Applied Science Research 2023, 13, 11672–11676. [Google Scholar] [CrossRef]

- Belarbi, B.; Ghernaout, M.E.A.; Benabdallah, T. Implementation of a New Geometrical Qualification (DQ) Method for an Open Access Fused Filament Fabrication 3D Printer. Engineering, Technology & Applied Science Research 2019, 9, 4182–4187. [Google Scholar] [CrossRef]

- Park, H.S.; Tran, N.H.; Hoang, V.T.; Bui, V.H. Development of a Prediction System for 3D Printed Part Deformation. Engineering, Technology & Applied Science Research 2022, 12, 9450–9457. [Google Scholar] [CrossRef]

- Subramonian, S.; Kadirgama, K.; Al-Obaidi, A.S.M.; Salleh, M.S.M.; Vatesh, U.K.; Pujari, S.; Rao, D.; Ramasamy, D. Artificial Neural Network Performance Modeling and Evaluation of Additive Manufacturing 3D Printed Parts. Engineering, Technology & Applied Science Research 2023, 13, 11677–11684. [Google Scholar] [CrossRef]

- Anh, N.T.; Quynh, N.X.; Tung, T.T. Study on Topology Optimization Design for Additive Manufacturing. Engineering, Technology & Applied Science Research 2024, 14, 14437–14441. [Google Scholar] [CrossRef]

- Ziółkowski, M.; Dyl, T. Possible Applications of Additive Manufacturing Technologies in Shipbuilding: A Review. Machines 2020, 8, 84. [Google Scholar] [CrossRef]

- Srivastava, M.; Rathee, S. Additive Manufacturing: Recent Trends, Applications and Future Outlooks. Progress in Additive Manufacturing 2021, 7. [Google Scholar] [CrossRef]

- Kanishka, K.; Acherjee, B. Revolutionizing Manufacturing: A Comprehensive Overview of Additive Manufacturing Processes, Materials, Developments, and Challenges. Journal of Manufacturing Processes 2023, 107, 574–619. [Google Scholar] [CrossRef]

- Attaran, M. The Rise of 3-D Printing: The Advantages of Additive Manufacturing over Traditional Manufacturing. Business Horizons 2017, 60, 677–688. [Google Scholar] [CrossRef]

- Dusanapudi, S.; Krupakaran, R.L.; Srinivas, A.; Nikhil, K.S.; Vamshi, T. Optimization and Experimental Analysis of Mechanical Properties and Porosity on FDM Based 3D Printed ABS Sample. Materials Today: Proceedings 2023. [CrossRef]

- Zisopol, D.G.; Minescu, M.; Iacob, D.V. A Study on the Influence of FDM Parameters on the Compressive Behavior of PET-G Parts. Engineering, Technology & Applied Science Research 2024, 14, 13592–13597. [Google Scholar] [CrossRef]

- Zisopol, D.G.; Minescu, M.; Iacob, D.V. A Study on the influence of FDM parameters on the compressive behavior of ASA parts. Engineering, Technology & Applied Science Research 2024, (submitted).

- Zisopol, D.G.; Minescu, M.; Iacob, D.V. A Study on the Influence of FDM Parameters on the Tensile Behavior of Samples Made of PET-G. Engineering, Technology & Applied Science Research 2024, 14, 13487–13492. [Google Scholar] [CrossRef]

- Zisopol, D.G.; Minescu, M.; Iacob, D.V. A Study on the Influence of FDM Parameters on the Tensile Behavior of Samples made of ASA, Technology & Applied Science Research 2024, (preprint).

- Zisopol, D.G.; Minescu, M.; Iacob, D.V. A Theoretical-Experimental Study on the Influence of FDM Parameters on the Dimensions of Cylindrical Spur Gears Made of PLA. Engineering, Technology & Applied Science Research 2023, 13, 10471–10477. [Google Scholar] [CrossRef]

- Dev, S.; Srivastava, R. Experimental Investigation and Optimization of FDM Process Parameters for Material and Mechanical Strength. Materials Today: Proceedings 2020, 26, 1995–1999. [Google Scholar] [CrossRef]

- Iacob, D. V.; “Stadiul actual al cercetărilor în domeniul fabricației aditive”, Phd report, Mechanical Engineering Department, Petroleum- Gas University, Ploiești, România, May 2024.

- Zisopol, D.G. Ingineria valorii; Editura Universităt, ii Petrol-Gaze din Ploies, ti: Ploies¸ti, Romania, 2004; ISBN 973-7965-96-5.

- Zisopol, D.G.; Nae, I.; Portoaca, A.I.; Ramadan, I. A Theoretical and Experimental Research on the Influence of FDM Parameters on Tensile Strength and Hardness of Parts Made of Polylactic Acid. Eng. Technol. Appl. Sci. Res. 2021, 11, 7458–7463. [Google Scholar] [CrossRef]

- Zisopol, D.; Nae, I.; Portoaca, A. Compression Behavior of FFF Printed Parts Obtained by Varying Layer Height and Infill Percentage. Engineering, Technology and Applied Science Research 2022, 12, 9747–9751. [Google Scholar] [CrossRef]

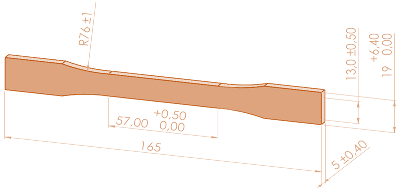

- ASTM D638-14 Standard Test Method for Tensile Properties of Plastics.

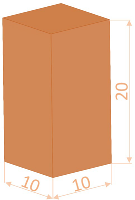

- ISO 604:2002 Plastics: Determination of compressive properties. ISO, 2002.

- https://www.minitab.com/en-us/, (accessed June. 15, 2024).

- Eurostat Statistics Explained. Electricity Price Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Electricity_price_statistics, (accessed June. 15, 2024).

- https://3dkordo.eu/en/product-category/everfil (accessed June. 15, 2024).

- https://store.anycubic.com/products/anycubic-4max-pro-3d-printer (accessed June. 15, 2024).

- D. G. Zisopol, "The Place and Role of Value Analysis in the Restructuring of Production (Case Study)," Economic Insights - Trends and Challenges, vol. I, no. 4/2012, pp. 27–35, 2012.

- M. Minescu and D. G. Zisopol, Sudarea țevilor şi fitingurilor din polietilenă de înaltă densitate (HDPE Pipe & Fittings Welding). Ploiesti, Romania: UPG Ploieşti Publishing House, 2021.

- D. G. Zisopol and A. Dumitrescu, Ecotehnologie. Studii de caz. Romania: Editura Universității Petrol-Gaze din Ploiești, 2021.

- D. Zisopol, Tehnologii industriale și de construcții. Aplicații practice și studii de caz. Ploiesti, Romania: Publisher: Editura Universității din Ploiești, 2003.

| Technology name | Draw | Components | Details | |

|---|---|---|---|---|

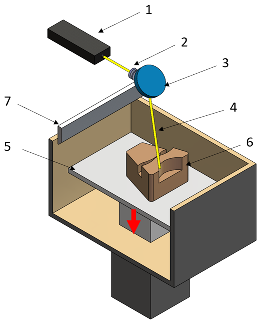

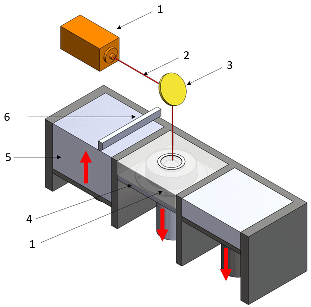

| Stereolitograpgy, (SL). |

|

1 - laser generator; 2 - optic system; 3 - galvanometric mirror; 4 - laser beam; 5 - construction platform; 6 - piece; 7 - blade. |

Used materials: photopolymers, ceramic materials. Advantages: + high accuracy of parts; + high print speed. Disadvantages: - laborious post-processing of printed parts; - the fragility of the parts. |

|

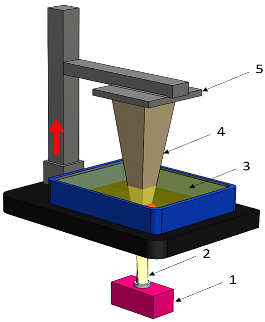

| Digital exposure of light, (DEL). |

|

1 - digital projector; 2 - UV light; 3 - resin; 4 - piece; 5 - construction platform. |

Materials used: resins, photopolymers, wax-based polymers. Advantages + the high quality of the surfaces; + high print speed. Disadvantages: - high cost of materials; - the print volume is limited. |

|

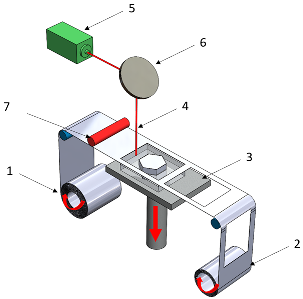

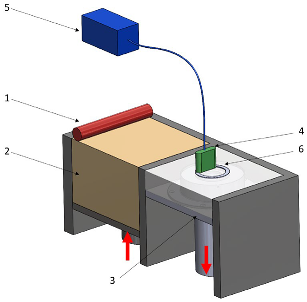

| Layered manufacturing by laminating layers, (LMLL). |

|

1 - driven roller; 2 - driving roller; 3 - construction platform; 4 - laser beam; 5 - laser generator; 6 - galvanometric mirror; 7 - heated roller. |

Materials used: paper, metals. Advantages: + high accuracy of parts; + high stability of the structures. Disadvantages: - significant losses of material. - laborious post-processing of printed objects. |

|

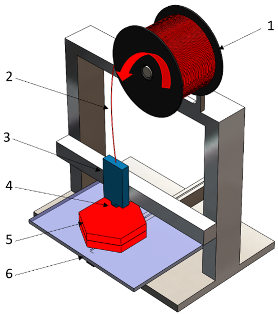

| Thermoplastic extrusion, (TE). |

|

1 - winding with material; 2 - filament; 3 - extruder; 4 - extrusion nozzle; 5 - piece; 6 - construction platform. |

Materials used: thermoplastic materials. Advantages: + simple technology; + low cost of materials and equipment. Disadvantages: - the poor quality of the surfaces of the parts; - the printing speed is low. |

|

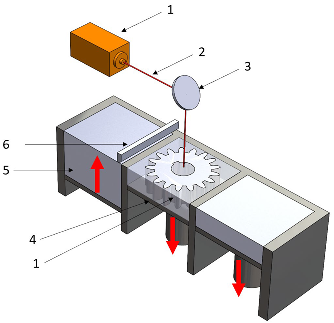

| Selective laser sinterising, (SLS). |

|

1 - laser generator; 2 - laser beam; 3 - galvanometer 4 - construction platform; 5 - raw material container; 6 - blade. |

Materials used: thermoplastic, metallic, ceramic powders,. Advantages: + the resistance of the parts is high; + good precision of parts. Disadvantages: - the quality of the surfaces is poor; - the high cost of equipment and materials. |

|

| 3D inkjet printing (3DP). |

|

1 - scraper blade; 2 - enclosure with raw material; 3 - work platform; 4 - print head; 5 - binder tank; 6 - track. |

Materials used: powders (starch, plaster, plastic powders). Advantages: + high printing speed; + reduced costs for materials and equipment. Disadvantages: - fragile parts; - the quality of the surfaces is poor. |

|

| Selective laser melting, (SLM). |

|

1 - laser generator; 2 - laser beam; 3 - galvanometer 4 - construction platform; 5 - raw material container; 6 - blade. |

Materials used: metal powders. Advantages: + the use of high-performance materials; + the resistance of the parts is high. Disadvantages: - the high cost of equipment and materials; - high time for cooling the parts. |

|

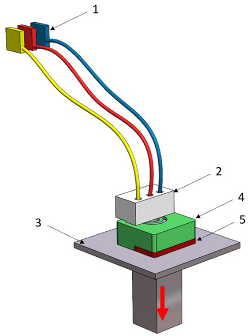

| Polyjet printing with photopolymers, (PJP). |

|

1 - liquid polymer tanks; 2 - print head; 3 - construction platform; 4 - piece; 5 - piece support. |

Materials used: photopolymers. Advantages: + good precision; + simple post-processing operations. Disadvantages: - weak resistance of the parts; - the high cost of materials. |

| Printing parameters | PETG | ASA |

|---|---|---|

| Part orientation, Po | X-Y | X-Y |

| Extruder temperature, Et Platform temperature, Pt Printing speed, Ps Infill pattern, Ip Layer height, Lh Infill density, Id Plate adhesion, Pa |

250 °C 70 °C 30 mm/s Grid 0.10/0.15/0.20 mm 50/75/100 % Brim |

240 °C 90 °C 30 mm/s Grid 0.10/0.15/0.20 mm 50/75/100 % Brim |

| Materials | Extruder temperature, (°C) |

Platform temperature, (°C) |

Density, (g/cm3) |

Tensile strength, (MPa) |

Charpy impact strength, (kJ/m2) |

|---|---|---|---|---|---|

| PETG ASA |

220-250 230-245 |

70-90 85-100 |

1.27 1.08 |

50 50 |

179 33.5 |

| Mechanical test | Testing condition | Sample dimensions |

|---|---|---|

| Tensile |

- Barrus White 20 kN universal testing machine; - speed 5 mm/min; - ambient temperature 20 °C; - humidity 40%. |

|

| Compression |

- Barrus White 20 kN universal testing machine; - speed 10 mm/min; - ambient temperature 20 °C - humidity 40% |

|

| Sample set | Lh, (mm) | Id, (%) | , (Euro) | , (Euro) | , (Euro) |

|---|---|---|---|---|---|

| 1 | 0.10 | 100% | 0.99 | 1.01 | 2.00 |

| 2 | 75% | 0.86 | 0.69 | 1.55 | |

| 3 | 50% | 0.73 | 0.60 | 1.33 | |

| 4 | 0.15 | 100% | 0.99 | 0.63 | 1.63 |

| 5 | 75% | 0.86 | 0.48 | 1.34 | |

| 6 | 50% | 0.73 | 0.43 | 1.16 | |

| 7 | 0.20 | 100% | 0.99 | 0.51 | 1.51 |

| 8 | 75% | 0.86 | 0.35 | 1.22 | |

| 9 | 50% | 0.73 | 0.31 | 1.04 |

| Sample set | Lh, (mm) | Id, (%) | , (Euro) | , (Euro) | , (Euro) |

|---|---|---|---|---|---|

| 1 | 0.10 | 100% | 1.04 | 1.01 | 2.05 |

| 2 | 75% | 0.90 | 0.69 | 1.59 | |

| 3 | 50% | 0.76 | 0.60 | 1.36 | |

| 4 | 0.15 | 100% | 1.04 | 0.63 | 1.67 |

| 5 | 75% | 0.90 | 0.48 | 1.38 | |

| 6 | 50% | 0.76 | 0.43 | 1.19 | |

| 7 | 0.20 | 100% | 1.04 | 0.51 | 1.55 |

| 8 | 75% | 0.90 | 0.35 | 1.26 | |

| 9 | 50% | 0.76 | 0.31 | 1.07 |

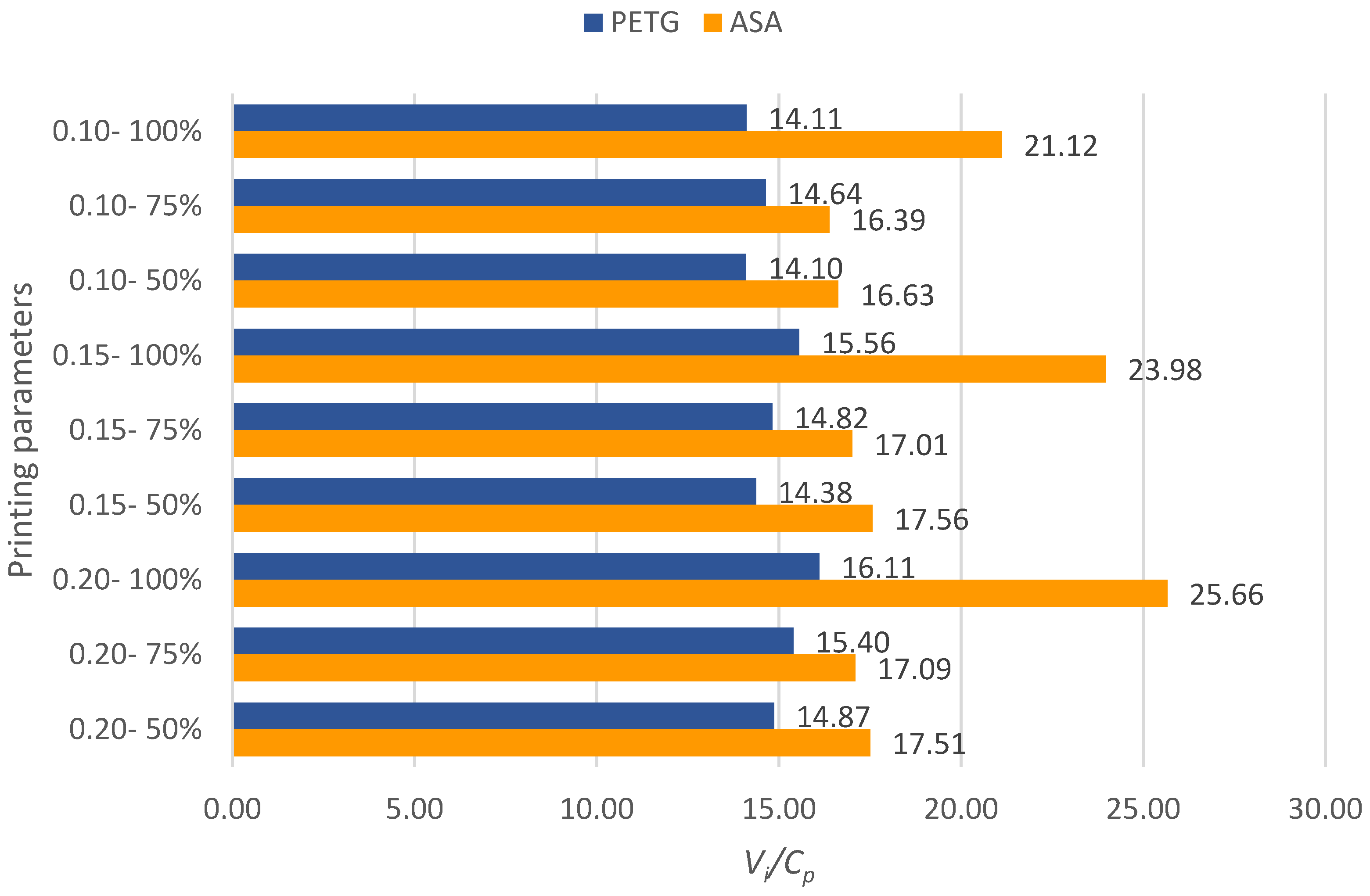

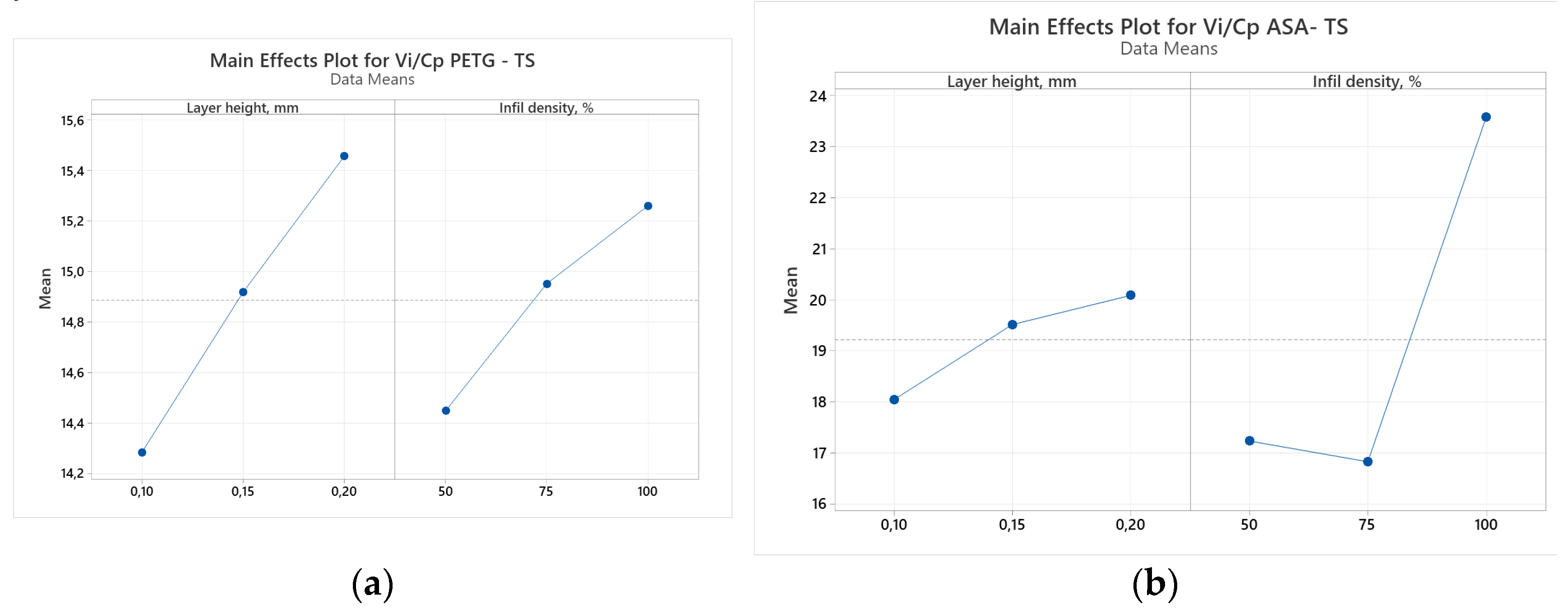

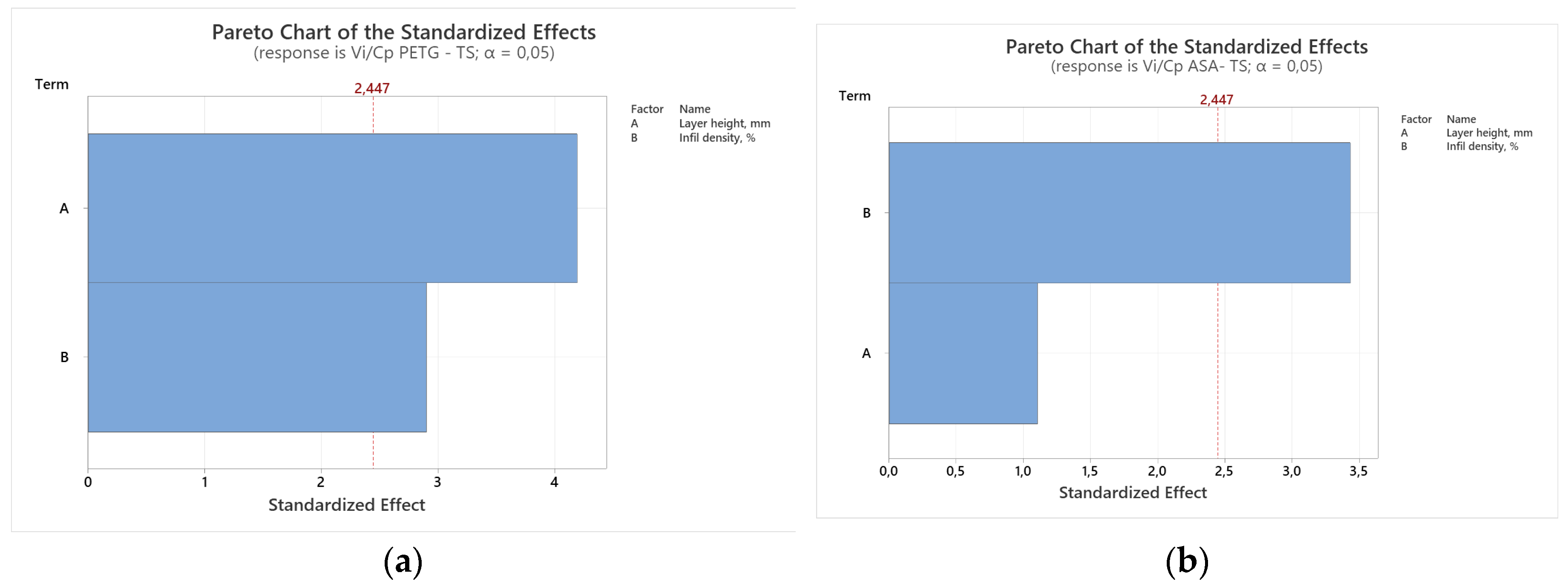

| Sample set | Ultimate tensile strength, (MPa) | , (Euro) | Vi/Cp |

|---|---|---|---|

| 1 | 28.25 | 2.00 | 14.11 |

| 2 | 22.66 | 1.55 | 14.64 |

| 3 | 18.76 | 1.33 | 14.10 |

| 4 | 25.34 | 1.63 | 15.56 |

| 5 | 19.85 | 1.34 | 14.82 |

| 6 | 16.61 | 1.16 | 14.38 |

| 7 | 24.29 | 1.51 | 16.11 |

| 8 | 18.72 | 1.22 | 15.40 |

| 9 | 15.48 | 1.04 | 14.87 |

| Sample set | Ultimate tensile strength, (MPa) | , (Euro) | Vi/Cp |

|---|---|---|---|

| 1 | 43.24 | 2.05 | 21.12 |

| 2 | 26.01 | 1.59 | 16.39 |

| 3 | 22.69 | 1.36 | 16.63 |

| 4 | 40.13 | 1.67 | 23.98 |

| 5 | 23.46 | 1.38 | 17.01 |

| 6 | 20.87 | 1.19 | 17.56 |

| 7 | 39.87 | 1.55 | 25.66 |

| 8 | 21.46 | 1.26 | 17.09 |

| 9 | 18.82 | 1.07 | 17.51 |

| Sample set | Lh, (mm) | Id, (%) | , (Euro) | , (Euro) | , (Euro) |

|---|---|---|---|---|---|

| 1 | 0.10 | 100% | 0.22 | 0.29 | 0.51 |

| 2 | 75% | 0.22 | 0.19 | 0.41 | |

| 3 | 50% | 0.22 | 0.16 | 0.38 | |

| 4 | 0.15 | 100% | 0.22 | 0.20 | 0.42 |

| 5 | 75% | 0.22 | 0.13 | 0.35 | |

| 6 | 50% | 0.22 | 0.11 | 0.33 | |

| 7 | 0.20 | 100% | 0.22 | 0.15 | 0.37 |

| 8 | 75% | 0.22 | 0.10 | 0.32 | |

| 9 | 50% | 0.22 | 0.08 | 0.30 |

| Sample set | Lh, (mm) | Id, (%) | , (Euro) | , (Euro) | , (Euro) |

|---|---|---|---|---|---|

| 1 | 0.10 | 100% | 0.23 | 0.29 | 0.52 |

| 2 | 75% | 0.23 | 0.19 | 0.42 | |

| 3 | 50% | 0.23 | 0.16 | 0.39 | |

| 4 | 0.15 | 100% | 0.23 | 0.20 | 0.43 |

| 5 | 75% | 0.23 | 0.13 | 0.36 | |

| 6 | 50% | 0.23 | 0.11 | 0.34 | |

| 7 | 0.20 | 100% | 0.23 | 0.15 | 0.38 |

| 8 | 75% | 0.23 | 0.10 | 0.33 | |

| 9 | 50% | 0.23 | 0.08 | 0.31 |

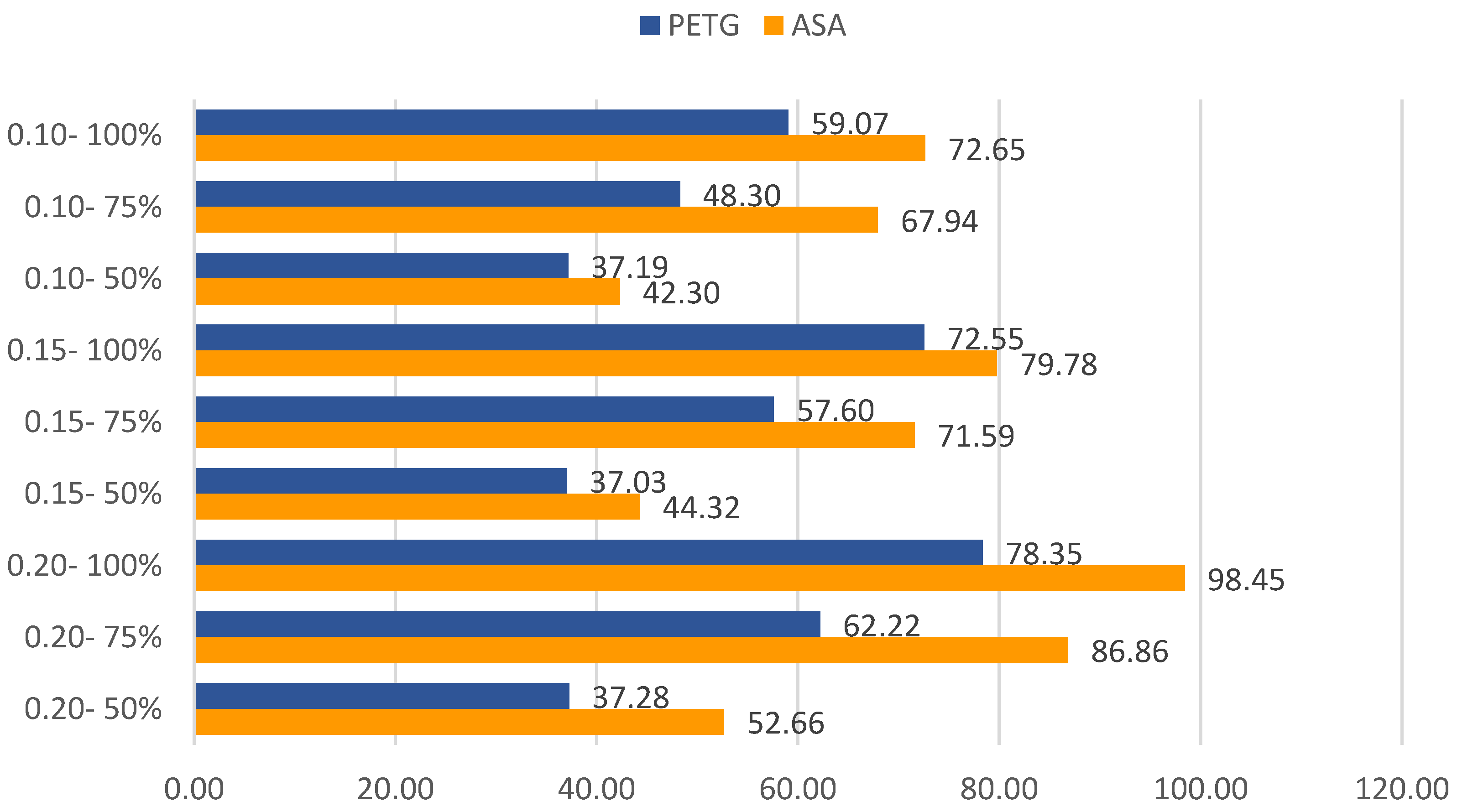

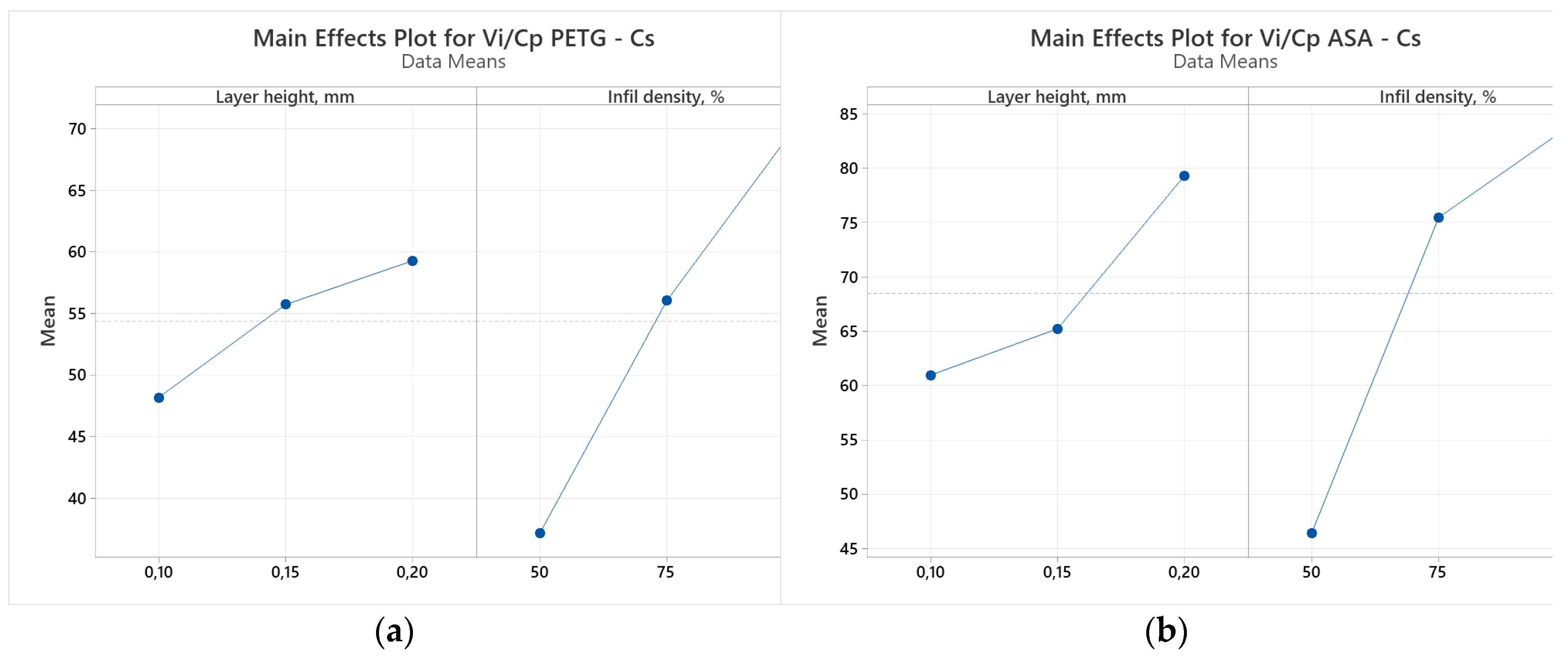

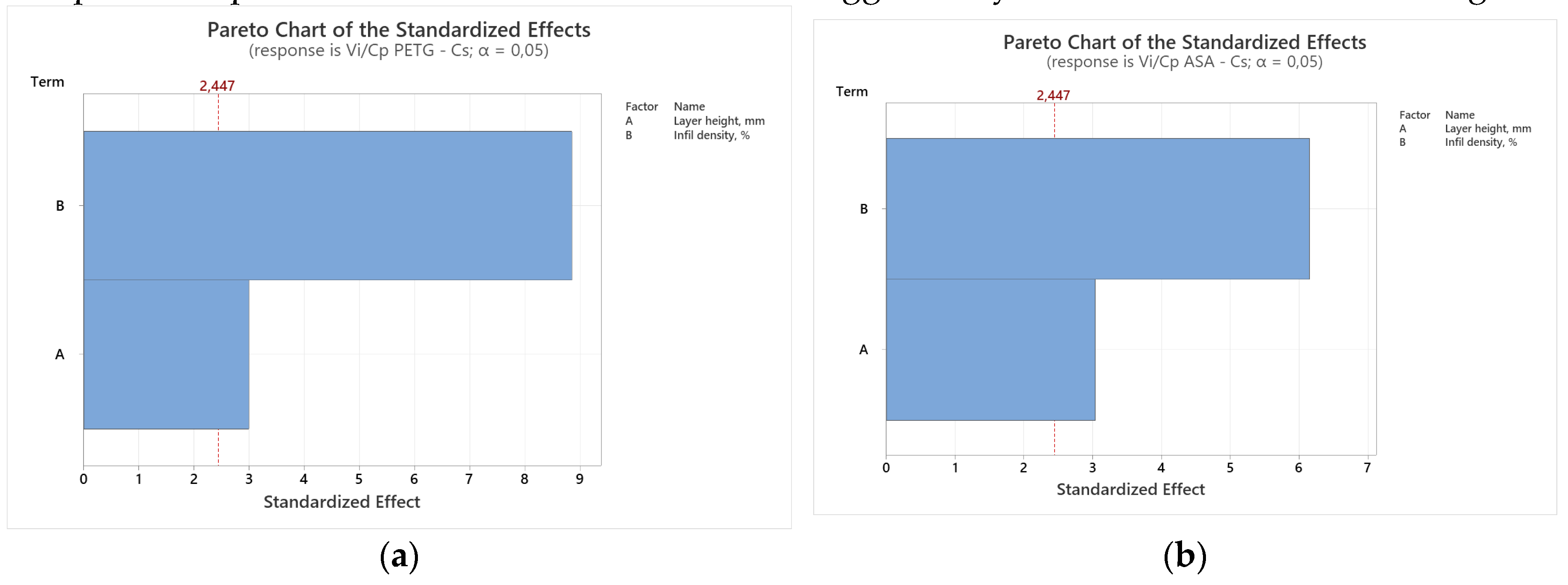

| Sample set | Compressive strength, (MPa) | , (Euro) | Vi/Cp |

|---|---|---|---|

| 1 | 30.33 | 0.51 | 59.07 |

| 2 | 19.83 | 0.41 | 48.30 |

| 3 | 14.06 | 0.38 | 37.19 |

| 4 | 30.57 | 0.42 | 72.55 |

| 5 | 20.22 | 0.35 | 57.60 |

| 6 | 12.20 | 0.33 | 37.03 |

| 7 | 29.20 | 0.37 | 78.35 |

| 8 | 19.82 | 0.32 | 62.22 |

| 9 | 11.27 | 0.30 | 37.28 |

| Sample set | Compressive strength, (MPa) | , (Euro) | Vi/Cp |

|---|---|---|---|

| 1 | 38.04 | 0.52 | 72.65 |

| 2 | 28.58 | 0.42 | 67.94 |

| 3 | 16.42 | 0.39 | 42.30 |

| 4 | 34.43 | 0.43 | 79.78 |

| 5 | 25.85 | 0.36 | 71.59 |

| 6 | 15.04 | 0.34 | 44.32 |

| 7 | 37.68 | 0.38 | 98.45 |

| 8 | 28.54 | 0.33 | 86.86 |

| 9 | 16.45 | 0.31 | 52.66 |

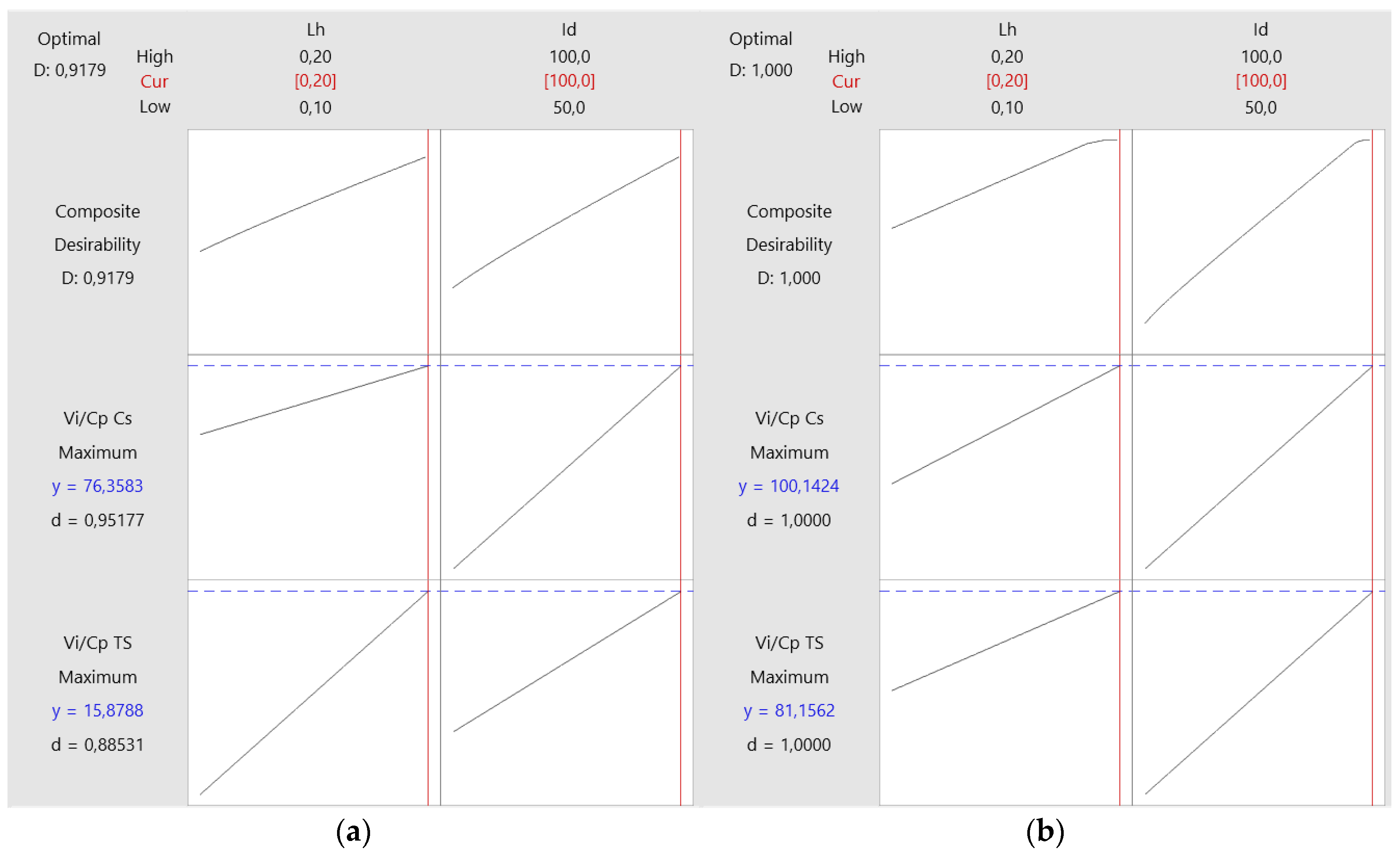

| Response, | Goal | Lower | Target | Weight | Importance | ||

|---|---|---|---|---|---|---|---|

| Vi/Cp | PETG | ASA | PETG | ASA | |||

| Tensile, [MPa/Euro] | Maximum | 14.10 | 16.39 | 16.11 | 25.66 | 1 | 1 |

| Compression, [MPa/Euro] | 37.03 | 42.30 | 78.35 | 98.45 | |||

| Printing parameters | Material | ||

|---|---|---|---|

| Layer height, (mm) |

Infill density, (%) |

PETG | ASA |

| Composite desirability | Composite desirability | ||

| 0.10 | 100 | 0.453350 | 0.56643 |

| 75 | 0.168040 | 0.29452 | |

| 50 | 0.000000 | 0.01430 | |

| 0.15 | 100 | 0.696297 | 0.80768 |

| 75 | 0.405383 | 0.44291 | |

| 50 | 0.066163 | 0.05602 | |

| 100 | 0.917938 | 1.00000 | |

| 0.20 | 75 | 0.615557 | 0.59118 |

| 50 | 0.275221 | 0.09752 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).