1. Introduction

The generation and management of municipal solid waste (MSW) is a current development problem. Conservatively projecting the value calculated by the World Bank in 2016, i.e., considering the average generation per inhabitant constant over the years, it is estimated that in 2024, 2.20 billion tons of MSW will be generated in the world and that this amount will probably rise to 3.40 billion tons per year by 2050 [

1]. Due to the high volume of MSW generated, its management becomes a challenge to the countries. Among these challenges there are the collection, the selective collection, reverse logistics, and the final destination of the MSW. In countries with per capita income below US

$ 1,025, only 39% of the MSW generated is collected, while in countries with income over US

$ 12,476, this percentage is 96% [

1]. Brazil, a country with medium-high per capita income (between US

$ 4,036 and US

$ 12,475) [

1], collected 93% of the MSW generated in 2022 [

2].

The final disposal options most used worldwide are landfills, recycling, incineration, dumps, and compost [

1]. MSW is a problem mainly due to the environmental impacts that its inappropriate final disposition leads to, such as water pollution by the leachate and emission of greenhouse effect gases. However, the fact that incineration is among the main final destinations shows that with proper management, it is possible to transform the problem into an opportunity in bioenergy.

The dispositions vary according to countries' income [

1]. High-income countries are the ones that most apply this energetic potential, and low-income ones have the worst percentage of application. The medium-low-income countries (between US

$ 1,026 and US

$ 4,035 per capita) do not present a significant percentage of MSW managed by incineration. Besides the energetic utilization, it is also possible to create value from MSW through recycling and composting, mainly in high-income countries.

There is a hierarchy of waste management aiming to prioritize final destinations with minimal impacts on society, public health, and the environment. According to this hierarchy, preference must be given first to reduce waste production, second to reuse the waste generated, and finally to material recovery. In this last one, recycling is preferred over composting and biodigestion. Solid waste that could not be recovered must be sent to incineration with energy recovery. Finally, only a minimum amount of reminiscent waste must be settled in landfills [

3]. Brazilian National Solid Waste Policy, implemented in 2010, foresees such a hierarchy [

3]. Nevertheless, the rate of MSW used in Brazil's energy utilization was lower than 0.2% in 2022, when 97,6% was sent to final disposition (dumps and landfills) [

4]. On the other hand, the European Union (EU) reveals much more appropriate numbers compared to what the hierarchy stablishes. In 2018, the EU sent 46% of MSW to material recovery – recycling and compost – and 28% to energy recovery [

1]. The United States (USA) is a positive reference too: 12.8% of its waste was sent to energy recovery [

5]. Japan presents even better numbers, sending only 10% for final disposal, while 21% is recycled and 69% is sent to incineration with power generation [

6].

In parallel, there is an increase in energy demand in Brazil. It is estimated that electrical demand in the country will increase by an average of 2.5% per year until 2026; in 2023, there was an increase of 4%. This growth is due to growing economic activity and increased residential demand due to the electrification program Luz Para Todos (Light for All), which is expected to bring electricity to more than 2 million people by 2026 [

7].

Different processes, such as anaerobic digestion, pyrolysis, gasification, and incineration, are used worldwide to utilize MSW energy potential. The product of each one of these technologies can be used as bioenergy [

1,

8]. There are some MSW treatment process assessments in the literature. In [

9], the decision-making in MSW management was supported by a multi-objective optimization, considering the financial risk involved as an objective function. In [

10], a mathematical formulation was proposed to find the optimal process design for the co-digestion of MSW and sludge, using NPV as the objective function. In [

11], a model for optimal planning for the reuse of MSW was proposed, considering economic, environmental, and safety aspects, such as annual net profit, the amount of reused waste, and fatalities generated, respectively. The work in [

12] presented a methodology for building indicators for MSW management, encompassing the social aspect with indicators such as environmental sanitation diseases and collectors in dumps and on the streets. However, although there are the assessments mentioned above, they are for specific scenarios and consider only a few aspects. Therefore, there is a gap in the literature regarding decision-making tools that simultaneously consider technical-economic, environmental, and social aspects, which can be applied to different scenarios.

This study presents the processes used worldwide to generate energy from MSW and proposes indicators to support decision-making on how to treat MSW, encompassing the sustainability tripod. Then, a case study is carried out for Rio de Janeiro, – a Brazilian state – presenting its preliminary technical-economic, environmental, and social indicators evaluation.

2. Materials and Methods

The present work first identified the leading technologies available for generating bioenergy from MSW in the literature and provided a brief global overview of them, including the most used technical-economic, environmental, and social indicators. We then hierarchized these technologies based on energy production.

To contribute to the decision-making on how to treat MSW focusing on energy production, this work proposes technical-economic, environmental, and social indicators and, through a case study of the Brazilian state Rio de Janeiro, tested them.

2.1. Hierarchization of Technologies

Since there is an increase in energy demand in Brazil, energy production is a decisive factor in the hierarchization of technologies. Besides helping the issue of rising electrical demand, energy production is associated with achieving the United Nations' Sustainable Development Goals (SDGs) [

13]. The average values of energy production per ton of MSW found in the literature for each technology was used to rank technologies according to their energy production.

The calculation of this average for incineration technology was based on the values of energy production per ton of MSW listed for plants in Germany – which contained complete data in the ISWA report [

14], and with the energy yield values presented by Michaels and Krishnan [

15] for plants in the USA, the two countries with the largest installed capacity worldwide, except for China [

16]. This country is responsible for 60% of the world's installed capacity, 21.4 GW, and its plants can treat over 1 million tons of MSW per year [

16,

17]. We, therefore, consider it an outlier, not a reference.

The case of anaerobic digestion was analyzed by the document produced by the US Environmental Protection Agency (EPA), Anaerobic Digestion Facilities Processing Food Waste in the United States (2019): Survey Results [

18]. Their results were presented for three groups of digesters: food waste, food waste co-digested with agricultural waste, and water treatment waste. For this study, only the first type of digesters was considered because they are the ones that most resemble the organic fraction of MSW. In addition to the data presented in the EPA document, the plant presented in the Best Available Techniques Reference Document for Waste Treatments [

19] and the one presented in the report Economic Analysis of Options for Managing Biodegradable Municipal Waste [

20] were used for the average energy generated per ton of MSW.

This last report was also used as a source for the gasification and pyrolysis technologies. Companies' data presented in [

10] was also used for gasification. The article presents the energy production of five companies and their MSW treatment capabilities, so the energy production per ton of MSW was calculated. For pyrolysis technology, the average energy production per ton of MSW was also calculated based on the case study in [

21].

2.2. Indicators

For the technical-economic aspect, this work considered the technology readiness level (TRL) and net present value (NPV). NPV indicates the viability of the project and is widely used in technical-economic evaluations, such as in the economic assessment of MSW incineration and gasification for energy generation [

22], in the economic assessment of a MSW gasification combined with the ammonia production process [

23], and in the analysis of the economic feasibility of implementing MSW incineration plants in Brazil [

24]. It is also essential to consider the data availability and the risk associated with technology related to the TRL [

25].

The main environmental impacts of MSW management are leaching, air pollution, and greenhouse gas emissions [

1]. The indicators presented in

Table 1 were proposed for evaluating these impacts, also considering the SDGs, such as clean water and sanitation, affordable and clean energy, and climate action [

13].

Table 1 also presents their calculation form.

The social aspect is not yet consolidated, as it is sometimes neglected due to its subjectivity [

26]. The indicators presented in

Table 2 are related to the generation of employment and income, waste pickers, and reduction in the amount of MSW sent to landfill, which reduces the population's potential exposure to disease vectors [

27]. The authors emphasize the existence of waste pickers in South America who informally collect, separate, classify, and market recyclable wastes. Critical points for identifying the indicators presented in

Table 2 were the generation of employment and income and the reduction in the amount of MSW sent to landfill.

2.3. Case Study

The present work will apply the proposed methodology to Rio de Janeiro. To this end, data is initially collected to identify the state's waste scenario. To calculate the potential for energy generation by technology, the percentage of MSW served by collection in the state will be considered – since only collected MSW can be sent for treatment – and the rate of recyclables sent for recycling will be deducted from the fraction treated for technologies that accept recyclables – pyrolysis, gasification, and incineration – since recycling is preferred to energy recovery in the waste management hierarchy.

Then, the proposed sustainability indicators will be calculated. To determine the NPV, some steps are necessary, including location study; study and projection of demand; projection of prices; investments and production costs estimation.

The amount of MSW generated by the administrative region of Rio de Janeiro was identified. The demand projection – the amount of MSW that requires treatment – combined with the plant's capacity will be used as criteria for location, verifying which ones of the administrative regions' demand for MSW treatment are in the typical range of installed capacities. A projection was made of the amount of MSW generated per year for the next 20 years. The projection considered the population increase in the regions and the increase in per capita generation of MSW through the analysis of the historical series of per capita generation of MSW in the city of Rio de Janeiro from 1990 to 2014 [

28].

The latest New Energy Auction A-5 from the Brazilian National Electric Energy Agency (ANEEL) was used to forecast the price of electricity [

29]; for MSW incineration, the average price of the electricity was US

$ 109.98/MWh. The price projection for glass and metal waste for recycling was carried out based on data provided by the Recycling Yearbook [

30]. The public institutions responsible for managing MSW pay a gate fee to dispose of this waste in landfills; this amount, in Brazil, varies between US

$ 7.48/t to US

$ 13.10/t [

31]. This study will consider US

$ 10.74/t of MSW, which is the amount paid for the Waste Treatment Center – CTR Rio, in the state of Rio de Janeiro [

31].

To estimate the investments and fixed and variable costs (FC and VC) of the plants studied, reference values found in the literature were used, as presented in

Table 3. To extrapolate the installed capacity, the typical exponential scale factor of 0.60 for thermal plants was used [

32]. The indexes from the Chemical Engineering magazine, Chemical Engineering Plant Cost Index (CEPCI), or CE index, were used to update over time. For nationalization in value, the factor of 1.14 was applied [

33].

In [

34,

35,

36] there are no cost data; therefore, for these subsystems, the production cost (PC) was estimated based on correlations presented in Equation (1) [

37,

38]. The estimated labor cost (LC) for the complex mechanical screening at Rio de Janeiro is US

$ 3.45 million, considering four workers per shift, while for the gasification technology, it is US

$ 13.8 million, for 80 workers.

For the environmental and social indicators calculation, this work drew up a database with literature information, i.e., a compilation developed by the authors based on data from different plants. The indicators were calculated with the average values of the necessary information considering plants similar to those in the case study.

3. Results and Discussion

3.1. Technologies

The knowledge of technology alternatives available worldwide is very important for using MSW in energy production.

Table 4 shows the technologies required for the management of MSW. It also shows the positive and negative aspects of each alternative.

Anaerobic Digestion is an alternative technology for value aggregation on MSW, which Germany, Denmark, and Netherlands have used for almost 30 years [

39]. There are 31 plants in operation in the European Union [

19] and 275 plants managing food waste and water treatment in the USA [

18].

The Indian Company Agile Process Chemicals LLP (APC), also known as Pyrocrat, is an expert in developing pyrolysis plants of plastic, tires, and biomass waste. The company has designed and put into operation over 35 plants in India, Indonesia, Kenya, and the United Kingdom [

40]. However, according to the European Commission, the number of pyrolysis plants is decreasing, and their development has not yet been proven [

41].

Enerkem, Air Liquide, Nouryon (the old AkzoNobel Specialty Chemicals), Shell, and Port of Rotterdam established a partnership to build the first European plant to transform waste into chemicals [

42]. The plant will gasify the MSW non-recycling, including plastic, generating syngas for biomethanol production. The partnership plans to convert 360,000 tons of solid waste into 200,000 tons of biomethanol (equivalent to 270 million liters). Compared to the production of methanol from fossil sources, there is an economy of 300,000 tons in CO

2 emission [

42].

In Europe, which had an installed capacity in 2023 of 5.0 GW [

16], there were 498 incineration plants in operation in 2021, 98 of which were installed in Germany [

43]. The USA had 75 plants of WtE (waste to energy) in 2018, processing 94,243 tons per day of MSW, equivalent to 29.3 million per year, and a potency of 2.5 GW. The average installed capacity of the USA plants is 392,199 tons per year [

15].

A fundamental factor for the hierarchy of the technologies, beyond the aspects presented in

Table 4, is the energy production per ton of MSW managed.

Table 5 presents the calculated values for each technology. This result shows that anaerobic digestion and pyrolysis are the technologies that present the lowest yields. Anaerobic digestion only treats the organic fraction, which has a lower calorific value.

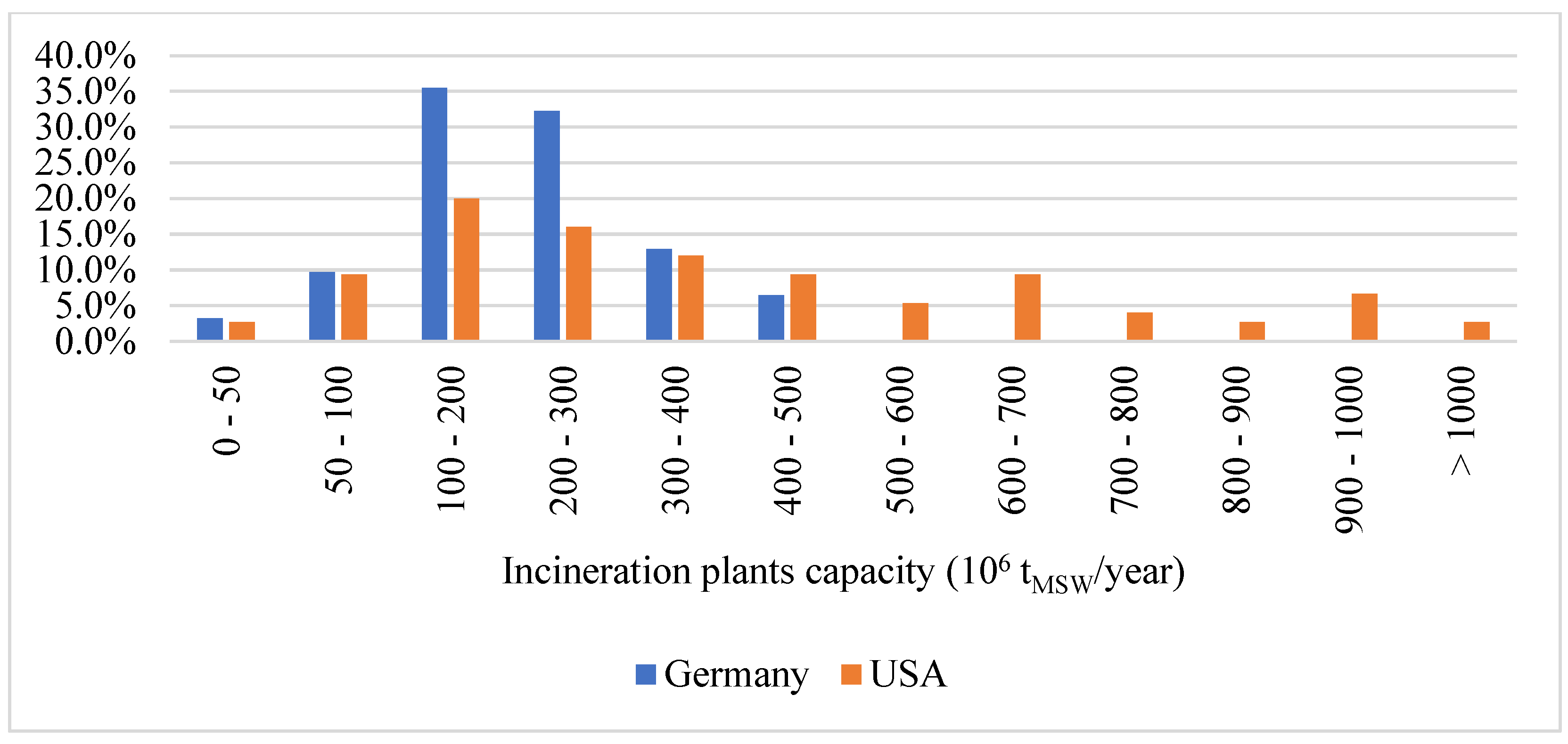

A significant difference can be verified in the sizes of both the USA and German plants, which can justify the high standard deviation.

Figure 1 shows the distribution of incineration plants per capacity in Germany and the USA, where it is possible to observe a higher concentration of plants with capacity going from 100 to 400 thousand tons of MSW managed per year, so we considered this the typical range of installed capacities.

3.2. Rio de Janeiro – Case Study

3.2.1. MSW Scenario

The Brazilian National Sanitation Information System (SNIS) annually conducts the Diagnosis of Urban Solid Waste Management [

4], with MSW management data reported by the municipal sanitation agencies. It is the most significant information system in the sector in Brazil. Still, when we check its data, it is important to consider the sample space since not all municipalities inform the requested data. Of the 92 municipalities of the state of Rio de Janeiro, 88 submitted information to SNIS, representing 99,7% of the state's urban population. This population generated 6.4 million tons of MSW in 2018 [

4], allowing the state's total MSW generation to be estimated at 7.2 million tons per year.

According to SNIS [

4], 97,8% of the population of Rio de Janeiro sampled by the diagnostic is served by collection. Of these, 0.84% goes to open-air dumps, an improvement from the last state report that presented 4.4% for dumps. This report showed that the state recycling rate is 2% [

44].

The organic fraction is the most representative fraction from Rio de Janeiro state MSW, corresponding to 53%, followed by recyclable fractions of plastic (19%) and paper and cardboard (16%) [

44]. These three major components represent 88% of the state's MSWs, and there is a possibility of generating value from MSWs. The large fraction of organic matter shows a potential for energy generation with biogas. Metals correspond to 2% of the MSW, while glass is 3%, and 7% by "other", i.e., the portion of dry waste with recycling potential composed of less noble materials.

3.2.2. Technologies Hierarchy

In

Table 6, we present the result of the power generation potential by technology in the Rio de Janeiro state, and it is possible to identify that incineration is the best technology in terms of energy potential. This technology also has one of the greatest potentials for treating MSW. Although anaerobic digestion and pyrolysis have approximately the same power generation potential per ton of MSW, as shown in

Table 5, pyrolysis treats a larger fraction of MSW than anaerobic digestion, as this last one only deals with fraction of organic matter. The potential of energy generation by pyrolysis technology was higher than via anaerobic digestion, even discounting the share of recyclables. However, considering the need to generate energy due to increased electrical demand, this work will not consider these two technologies.

According to the Brazilian Statistical Yearbook of Electricity [

45], the energy consumption of Rio de Janeiro state in 2021 was 2,184 kWh per inhabitant. Considering that the energy consumption per capita in the city of Rio de Janeiro is equal to that of the state, it is projected that the energy potential of the state of Rio de Janeiro, through incineration technology, can supply 66% of the city of Rio de Janeiro demand for energy, or 26% of state demand, applying gasification technology can supply 55% of the city of Rio de Janeiro demand or 21% of state demand.

Table 7 presents the potential of energy generation by the administrative region of the state of Rio de Janeiro.

It is possible to observe that the greatest potential for energy generation comes from the metropolitan region. However, the generation of MSW from this region is far above the typical range presented in Figure 2, indicating the need for multiple plants to cover this region. The second largest potential for energy generation is 430 GWh, provided by the waste generated in the Norte Fluminense region, followed by the Baixadas Litorâneas, Médio Paraíba Region, and Serrana regions.

The last four highlighted regions generate between 200 and 400 thousand tons of MSW annually. Considering that most of the analyzed plants have a capacity of 100 to 400 thousand tons per year of MSW, these regions of the state of Rio de Janeiro annually generate a quantity of MSW within this range, so the installation of one plant allows to treat the whole waste generated in these regions. However, over the operating time of a waste-to-energy plant, the generation of MSW in these regions would exceed the typical capacity range. Therefore, this work will consider the maximum capacity of the range (400 thousand tons of MSW per year) for the case study and two scenarios: S1, with the plant installed in the Médio Paraíba region, i.e., considering the projection of its amount of MSW generated per year for the next 20 years; and S2, with the plant installed in the Metropolitan region, i.e. considering 100% of the plant since the beginning of the operation.

3.2.3. Indicators Evaluation

The TRL 9 was identified for incineration technology since there are several MSW incineration plants in the world [

21], while gasification presents TRL 8 since it is also validated in full scale, but not as long as incineration.

Table 8 presents the NVP for both technologies. For S1, the plant occupancy rate reached 100% in the tenth year of operation.

The negative NPVs confirm that none of the plants studied are economically feasible. However, several units are operating worldwide, which leads to the following question: what are the differences that make an investment project of this nature feasible in Europe and the USA and unfeasible in Rio de Janeiro?

The first difference highlighted was the need for a complex mechanical screening to carry out the project in Rio de Janeiro. The high investment and operational cost may be essential factors that make the investment project in the state of Rio de Janeiro unfeasible. A second aspect is the price paid by the government for the treatment of MSW. In Rio de Janeiro, the amount currently paid by the government for the disposal of MSW in landfills is 10.74 USD/ton of MSW [

31]. However, in Germany, for example, the government pays a fee that varies from 107.27 to 375.44 USD/ton of MSW to be treated for energy recovery [

8].

To verify the low gate fee impact, the NVP was recalculated considering the extremes of the German gate fee and the medium value (

Table 9). For incineration, the minimum value applied in Germany was enough to make the project economically feasible. However, for gasification, the maximum value is necessary to make the project feasible in S1, and the medium value is in S2.

The necessary gate fee value to make both projects viable was also calculated. A gate fee of 94.69 USD/ton of MSW makes incineration technology viable on S1, and of 75.27 USD/ton of MSW on S2. While for gasification the value is 255.39 USD/ton of MSW for S1, 6% above the medium value in Germany, for S2 the value is 225,07 USD/ton of MSW. The result indicates that for the economic aspect incineration is the most appropriate process for these specific cases. Working at 100% capacity from the start of operations also presents better results. This is especially true for facilities located in regions with high population density (like S2), where the benefits are even greater when considering logistics since smaller areas can accommodate the waste necessary to operate the facility, leading to reduced waste truck traffic. But for the sustainability assessment, it is essential to bring into discussion the environmental and social indicators.

Table 10 presents these indicators results.

The indicator “Salary increase with the absorption of waste pickers”, although enlightens important data about those informally works, does not differentiate between technologies. So, it is an indicator that does not help in comparing incineration and gasification technologies. Population served and reduction in MSW sent to landfill indicators are also similar between the technologies since both can treat the same fraction of MSW. However, these two indicators will differentiate technologies that treat different fractions, such as anaerobic digestion, so they are relevant for sustainability assessments. Furthermore, the job creation indicator values were also similar for incineration and gasification. So, from the social aspect, it was not possible to identify the most promising technology.

Gasification obtained better results in 60% of the environmental indicators, GWP, land use, and acidification. GWP is an important indicator related to both the main environmental impacts of MSW management and the SDGs. However, gasification, while demonstrating slightly superior results, exhibited only a marginal reduction of 18% in value compared to incineration.

Conversely, incineration presented better results in energy and water intensity indicators, highlighting the water intensity as almost 80% smaller than in gasification. This indicator can be associated with the location; as Rio de Janeiro does not have a critical water scarcity, it could be neglected in the decision-making on the best technology to treat MSW. However, the Brazilian National Water Agency warns about the efficient use and management of water resources due to the potential 40% decrease in water availability in some regions of the state by 2040 [

46], emphasizing the importance of considering this indicator in decision-making. On the other hand, energy intensity is an important indicator as it is linked to managing the rise in electrical demand and achieving the SDGs; however, although incineration offers better results, gasification only shows a modest 17% reduction.

The results show how challenging it is to consider all aspects of sustainability simultaneously. Different elements of sustainability can point in different directions, and even indicators within the same aspect can suggest different technologies. Therefore, decision makers must prioritize their most pertinent points, also considering their specific location.

5. Conclusions

Despite the Brazilian National and State Solid Waste Policies, many MSW management limitations remain, such as lack of collection for 100% of the population, low number of municipalities with selective collection, low recycling rate, and practically null energy recovery. In this context, sustainability indicators were proposed to help in technology decision-making. Focusing on the MSW problem and the increase in electrical demand in Brazil, incineration and gasification were selected as the most promising technologies.

The case study evaluated the sustainability of both technologies by applying the selected indicators. It highlighted the technical-economic unfeasibility – despite TRL 9 and 8 – and the differences between implementation in Brazil and other countries. This emphasizes the need for public policies in Brazil to make the projects viable, as well as increase the gate fee value, since it was identified that the gate fee applied in Rio de Janeiro is far below the range applied in other countries, such as Germany. It also emphasizes the need to envision environmental and social gains that are not considered in the technical-economic assessment.

However, social indicators do not make it possible to differentiate between incineration and gasification technologies in this specific case. Although the environmental indicators differentiate both technologies, the final decision between them has to be made by the decision maker (as a public manager), considering the most relevant indicators for their scenario, since gasification got better results on 60% of the indicators, but incineration got in two very important ones, water and energy intensities, besides the better results on the technical-economic aspect.

Due to the increase in electrical demand, the best result in energy intensity is essential. However, power generation has already been considered in the selection of both technologies and the technical-economic evaluation since energy sales are a revenue. Water intensity is also relevant, since it was the environmental indicator with the most significant difference in value between technologies. It is also important to highlight the GWP indicator, as it is associated with climate change. The difference in the value was not as important as it was on the water intensity indicator. So, for the specific case study, the result indicates that incineration seems to be the most promising technology, considering the increase in the gate fee to at least 94.69 USD/ton of MSW to S1 or 75.27 USD/ton of MSW to S2 – much more viable increases than to 255.39 or 225.07 USD/ton of MSW, which is necessary for gasification.

Author Contributions

Conceptualization, J.O., F.P., A.M, F.A. and A.S.; methodology, J.O., F.P., A.M, F.A. and A.S.; formal analysis, J.O.; investigation, J.O.; resources, J.O., F.P., A.M, , F.A. and A.S.; data curation, J.O.; writing—original draft preparation, J.O.; writing—review and editing, F.P., A.M, F.A. and A.S.; visualization, F.P., A.M, F.A. and A.S.; supervision, F.P., A.M, F.A. and A.S.; funding acquisition, J.O. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Conselho Nacional de Desenvolvimento Científico e Tecnológico, grant number 140734/2020-1.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Kaza, S.; Yao, L.C.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; Washington, DC: World Bank: Washington, DC, 2018; ISBN 978-1-4648-1329-0. [Google Scholar]

- ABREMA, (Associação Brasileira de Resíduos e Meio Ambiente) Panorama Dos Resíduos Sólidos No Brasil 2023; 2023.

- Brasil Lei No 12.305, de 2 de Agosto de 2010: Institui a Política Nacional de Resíduos Sólidos; Altera a Lei No 9.605, de 12 de Fevereiro de 1998; e Dá Outras Providências.; Institui a Política Nacional de Resíduos Sólidos; altera a Lei no 9.605, de 12 de fevereiro de 1998; e dá outras providências.: Brasília, 2010.

- Brasil Diagnóstico Temático Manejo de Resíduos Sólidos Urbanos - Visão Geral - Ano de Referência: 2022; Brasília/DF, 2023.

- Bhoi, P.R.; Huhnke, R.L.; Kumar, A.; Indrawan, N.; Thapa, S. Co-Gasification of Municipal Solid Waste and Biomass in a Commercial Scale Downdraft Gasifier. Energy 2018, 163, 513–518. [Google Scholar] [CrossRef]

- Amemiya, T. Current State and Trend of Waste and Recycling in Japan. International Journal of Earth & Environmental Sciences 2018, 2018, 155. [Google Scholar] [CrossRef]

- IEA, (International Energy Agency) Electricity 2024 - Analysis and Forecast to 2026; 2024.

- Neuwahl, F.; Cusano, G.; Benavides, J.G.; Holbrook, S.; Roudier, S. Best Available Techniques (BAT) Reference Document for Waste Incineration: Industrial Emissions Directive 2010/75/EU (Integrated Pollution Prevention and Control); Luxembourg, 2019.

- Diaz-Barriga-Fernandez, A.D.; Santibañez-Aguilar, J.E.; Betzabe González-Campos, J.; Nápoles-Rivera, F.; Ponce-Ortega, J.M.; El-Halwagi, M.M. Strategic Planning for Managing Municipal Solid Wastes with Consideration of Multiple Stakeholders. Computer Aided Chemical Engineering 2018, 44, 1597–1602. [Google Scholar] [CrossRef]

- Morero, B.; Montagna, A.F.; Campanella, E.A.; Cafaro, D.C. Integrated Process Design Optimization Accounting for Co-Digestion of Sludge and Municipal Solid Waste. Computer Aided Chemical Engineering 2017, 40, 853–858. [Google Scholar] [CrossRef]

- Santibañez-Aguilar, J.E.; Martínez-Gómez, J.; Ponce-Ortega, J.M.; Nápoles-Rivera, F.; Serna-González, M.; El-Halwagi, M.M. An Optimal Planning for the Reuse of Municipal Solid Waste Considering Economic, Environmental and Safety Objectives. Computer Aided Chemical Engineering 2014, 33, 1027–1032. [Google Scholar] [CrossRef]

- Pereira, S.S.; Curi, R.C.; Curi, W.F. Uso de Indicadores Na Gestão Dos Resíduos Sólidos Urbanos: Uma Proposta Metodológica de Construção e Análise Para Municípios e Regiões. Engenharia Sanitaria e Ambiental 2018, 23, 471–483. [Google Scholar] [CrossRef]

- UN Sustainable Development Goals Available online:. Available online: https://www.un.org/sustainabledevelopment/ (accessed on 7 July 2024).

- ISWA, (International Solid Waste Association) Waste-to-Energy: State-of-the-Art-Report - Statistics; Copenhagen, 2012.

- Michaels, T.; Krishnan, K. Energy Recovery Council - 2018 Directory of Waste-to-Energy Facilities. 2018. [Google Scholar]

- IRENA Bioenergy & Biofuels Available online:. Available online: https://www.irena.org/Energy-Transition/Technology/Bioenergy-and-biofuels (accessed on 3 July 2024).

- Chi, Y. Waste-to-Energy in China. In Proceedings of the Expert Group Meeting on Sustainable Application of Waste-to-Energy in Asian Region; Busan; 2017. [Google Scholar]

- Schroeder, J. Anaerobic Digestion Facilities Processing Food Waste in the United States (2019): Survey Results; Washington, 2023.

- Pinasseau, A.; Zerger, B.; Roth, J.; Canova, M.; Roudier, S. Best Available Techniques (BAT) Reference Document for Waste Treatment: Industrial Emissions Directive 2010/75/EU (Integrated Pollution Prevention and Control); Joint Research Centre - European Commission’s: Luxembourg, 2018. [Google Scholar]

- Hogg, D.; Favoino, E.; Nielsen, N.; Thompson, J.; Wood, K.; Penschke, A.; Economides, D.; Papageorgiou, S. Economic Analysis of Options for Managing Biodegradable Municipal Waste: Final Report to the European Commission; Bristol, 2002.

- Wang, H.; Wang, L.; Shahbazi, A. Life Cycle Assessment of Fast Pyrolysis of Municipal Solid Waste in North Carolina of USA. J Clean Prod 2015, 87, 511–519. [Google Scholar] [CrossRef]

- Rodrigues, L.F.; Santos, I.F.S. dos; Santos, T.I.S. dos; Barros, R.M.; Tiago Filho, G.L. Energy and Economic Evaluation of MSW Incineration and Gasification in Brazil. Renew Energy 2022, 188, 933–944. [Google Scholar] [CrossRef]

- Paixão, V.P.; Secchi, A.R.; Melo, P.A. Preliminary Design of a Municipal Solid Waste Biorefinery for Environmentally Friendly NH3 Production. Ind Eng Chem Res 2018, 57, 15437–15449. [Google Scholar] [CrossRef]

- Silva, L.J. de V.B. da; Santos, I.F.S. dos; Mensah, J.H.R.; Gonçalves, A.T.T.; Barros, R.M. Incineration of Municipal Solid Waste in Brazil: An Analysis of the Economically Viable Energy Potential. Renew Energy 2020, 149, 1386–1394. [Google Scholar] [CrossRef]

- Klar, D.; Frishammar, J.; Roman, V.; Hallberg, D. A Technology Readiness Level Scale for Iron and Steel Industries. Ironmaking & Steelmaking 2016, 43, 494–499. [Google Scholar] [CrossRef]

- Interlenghi, S.F.; de Almeida Bruno, P.; Araujo, O. de Q.F.; de Medeiros, J.L. Social and Environmental Impacts of Replacing Transesterification Agent in Soybean Biodiesel Production: Multi-Criteria and Principal Component Analyses. J Clean Prod 2017, 168, 149–162. [Google Scholar] [CrossRef]

- Gouveia, N. Resíduos Sólidos Urbanos: Impactos Socioambientais e Perspectiva de Manejo Sustentável Com Inclusão Social. Cien Saude Colet 2012, 17, 1503–1510. [Google Scholar] [CrossRef] [PubMed]

- DATARIO Total Do Lixo Domiciliar Coletado, Por Ano, Segundo Áreas de Planejamento (AP), Regiões de Planejamento (RP) e Regiões Administrativas (RA) No Município Do Rio de Janeiro Entre 1990-2014. Available online: https://www.data.rio/documents/0678f87213aa4c96b31c8ebe2e965a9c/about (accessed on 5 January 2020).

- EPE, (Empresa de Pesquisa Energética) LEN A-5 2022 - Informe de Vencedores; 2022.

- Pragma Anuário Da Reciclagem 2023. 2023.

- Almeida, R. de Aplicação de Cal e Nanofiltração No Tratamento de lixiviado de Aterro Sanitário: Avaliação Tecnológica e Estimativa de Custos. Dissertação de Mestrado, Universidade Federal do Rio de Janeiro: Rio de Janeiro, 2018.

- Seider, W.D.; Seader, J.D.; Lewin, D.R.; Widagdo, S. Product and Process Design Principles: Synthesis, Analysis, and Evaluation; 3rd ed.; John Wiley & Sons, Inc.: Westford, 2009. [Google Scholar]

- Towler, G.; Sinnott, R. Chemical Engineering Design: Principles, Practice and Economics of Plant and Process Design; 2nd ed.; Butterworth-Heinemann: Oxford, 2013. [Google Scholar]

- The Business Council James W. Taylor Jr.: President & CEO, Taylor Biomass Energy, LLC. In Proceedings of the Renewable Energy Conference: A Leadership Forum on Energy Policy; June 2019.

- Taylor Biomass Energy Taylor Biomass Energy. Available online: http://www.taylorbiomassenergy.com/ (accessed on 3 July 2024).

- Rama, A.C.C. de O. Análise Da Viabilidade de Produção de Combustíveis Derivados de Resíduos. Master, Instituto Universitario de Lisboa: Lisboa, 2010.

- Turton, R.; Bailie, R.C.; Whiting, W.B.; Shaeiwitz, J.A.; Bhattacharyya, D. Solutions Manual for Analysis, Synthesis and Design of Chemical Processes; 4th ed.; Prentice Hall: New York, 2012.

- Peters, M.S.; Timmerhaus, K.D.; West, R.E. Plant Design and Economics for Chemical Engineers; 5th ed.; McGraw-Hill Education: New York, 2003.

- European Commission Integrated Pollution Prevention and Control Reference: Document on the Best Available Techniques for Waste Treatments Industries; Brussels. 2006.

- APChemi A Blog by APChemi. Available online: https://www.pyrolysisplant.com/ (accessed on 3 July 2024).

- Saveyn, H.; Eder, P.; Ramsay, M.; Thonier, G.; Warren, K.; Hestin, M. Towards a Better Exploitation of the Technical Potential of Waste-to-Energy, Luxembourg, 2016.

- Enerkem W2C Rotterdam Project Welcomes Shell as Partner. Available online: https://enerkem.com/news-release/w2c-rotterdam-project-welcomes-shell-as-partner/ (accessed on 5 January 2020).

- CEWEP Waste-to-Energy Plants in Europe in 2021. Available online: https://www.cewep.eu/waste-to-energy-plants-in-europe-in-2021/ (accessed on 3 July 2024).

- Rio de Janeiro Plano Estadual de Resíduos Sólidos Do Rio de Janeiro (PERS): Relatório Síntese; Rio de Janeiro. 2013.

- EPE, (Empresa de Pesquisa Energética) 2024 Statistical Yearbook of Electricity: 2023 Baseline Year; Rio de Janeiro. 2024.

- ANA, (Agência Nacional de Águas e Saneamento Básico) Impacto Da Mudança Climática Nos Recursos Hídricos No Brasil; Brasília. 2024.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).