1. Introduction

Hydrogen is a clean energy carrier which can be used to harness heat and power for industrial applications. The use of hydrogen powered fuel cell vehicles (FCV) is increasing by twofold chiefly across the world due to its high efficiency and durability. However, the commercialization of the FCV is limited by high-cost hydrogen production methods such as steam electrolysis, steam and natural gas reforming. The water electrolysis cell shows 70% efficiency, and no green-house gasses are produced in the process. The magnitude of hydrogen produced via electrolysis pathway has increased by twofold since 2010. Thereby, the renewable energy sources (RES) are combined with the water electrolyzer cells to enable energy storage for the microgrids. The electricity obtained from the RES is converted into gas molecules by the cells and stored in the metal hydride wells. This approach can be used as a response management strategy for the smart grids. Although the hydrogen storage systems ensure the stability and security that is needed for the smart grid [

1], it is not yet scaled for the local electricity-gas grid requirements. Furthermore, decomposing water to hydrogen molecule using the electrolyzer is still an expensive and energy intensive process. The degradation rate of its components is high when the gas production rates go up during the peak hour electricity energy demand. Deploying cheaper technologies such as photoelectrochemical cell (PEC) will be an alternate approach to produce hydrogen. The cells or stacks can be connected to the 'Power to Gas' grids where hydrogen is injected into the gas-grids and transported to the energy storage infrastructures.

The components of PEC absorb the photons in the sunlight to produce energy. The cell comprises light sensitive nano-materials such as a n or p type semiconductors to absorb photons.

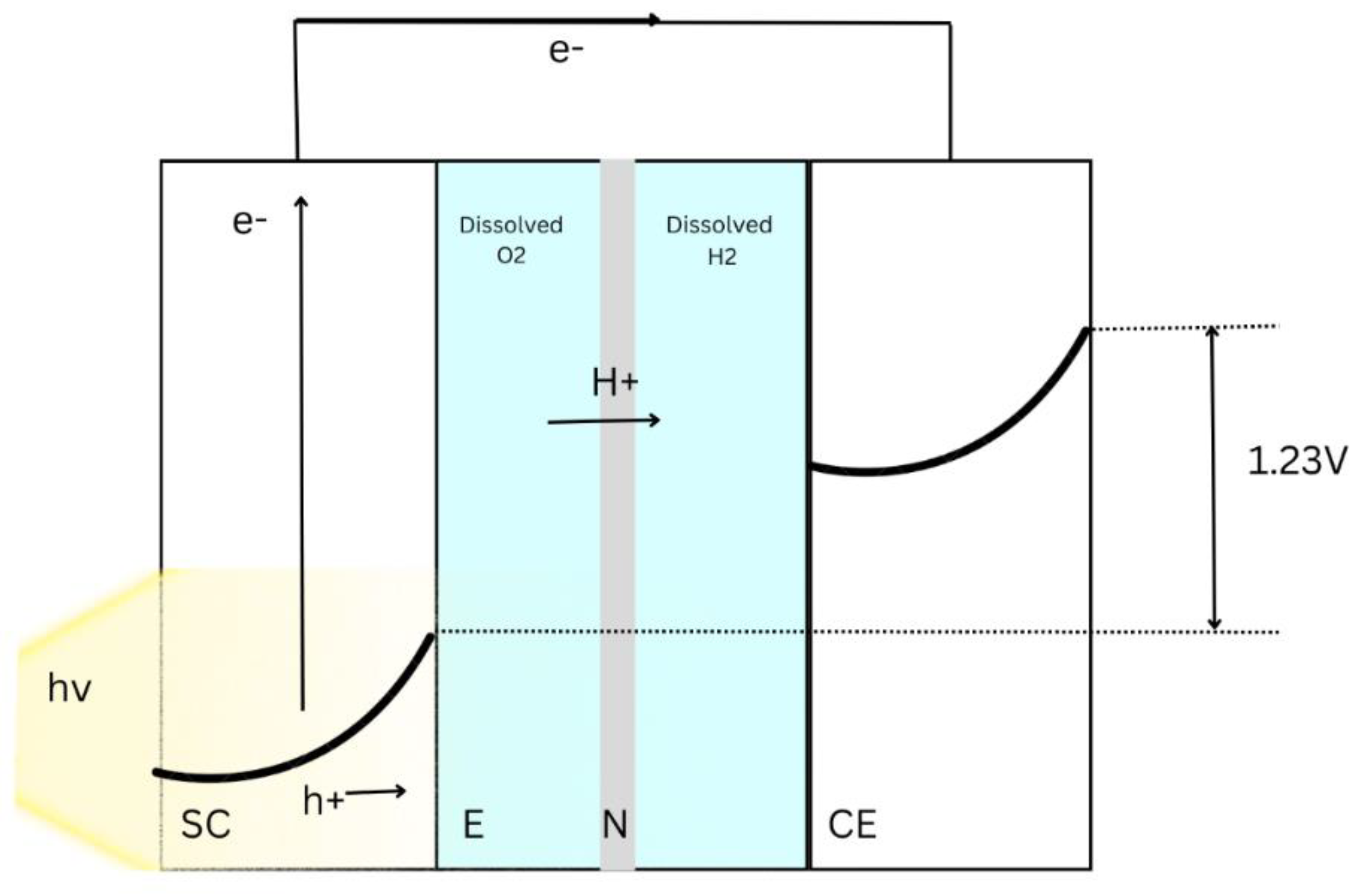

Figure 1 depicts the schematic of the cell. The incident photons irradiate the surface of the cell and forms electron-hole pairs at space charge regions. The holes are separated from the electron by the electric field at the surface of the semiconductor. When the electrons depart towards the external circuit, the holes are pushed into the SEI of the cell [

2]. In an acidic environment, the electrons flow via the external circuit and reach the interface of the counter electrode (CE). These electrons react with H+ ions and form hydrogen gas at the CE. The holes at the SEI of the photo-electrode react with water to form oxygen species. [

2] The reactions steps of the cell are given in Equations 1-2.

In a basic environment, the holes generated at the semiconductor react with the hydroxyl ions form oxygen while the electrons in the CE decompose water into hydrogen and hydroxyl ions.[

2] Equations 3-4 provide the reactions associated with the water splitting.

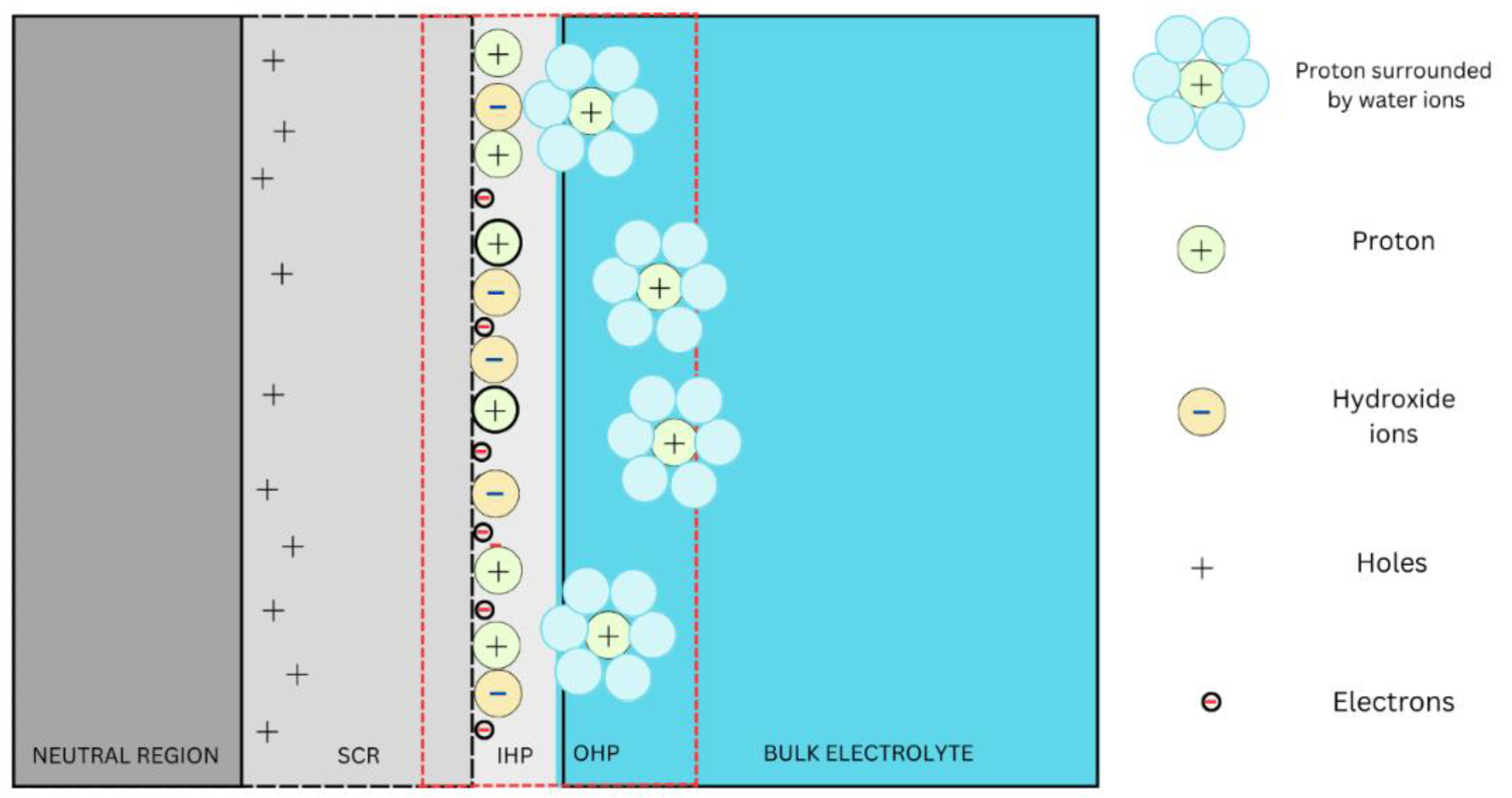

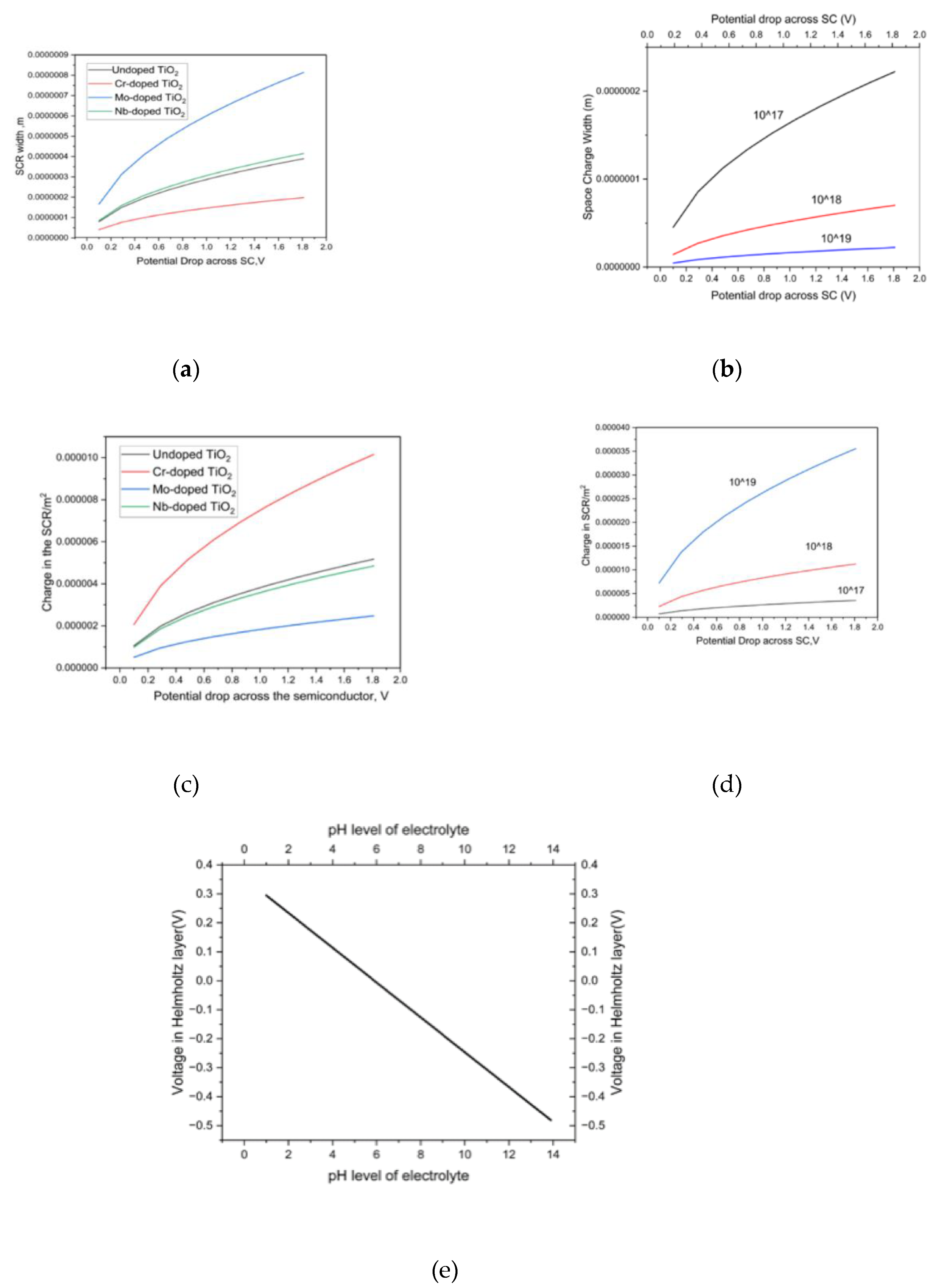

The production rate of the hydrogen from the cell depends on the stability of the Semi-conductor Electrolyte Interface (SEI). It has three regions as illustrated in

Figure 2. They are bulk semiconductor, space charge region (SCR) and the Helmholtz regions. The interfacial interactions, mapping of the photocurrent, and the thickness of the SEI against the cell performance are not well understood. The modeling of the layers involves creating an accurate mathematical formulation of the SEI. The mapping of voltage drop across the SEI shall provide an accurate representation on the transport phenomena of the hole-electron pairs and hydrogen production rate. The parameters such as the surface charge width and the size of the band gap are vital in identifying the processing functions, providing the description of the hole-pair and quantifying the rate at which the electrons migrated from the interface to the external circuit. Developing a predictive transport - voltage loss break down model for the SEI is cumbersome as it requires estimation of transport and physicochemical properties of the cell.

Figure 2 provides the schematic of the SEI and highlights the interaction of electrons, donor ions containing holes and the ions in the electrolyte. Empirical models reported in the literature provide description on the role of reverse current, bias, and the recombination parameters at the SEI [

3,

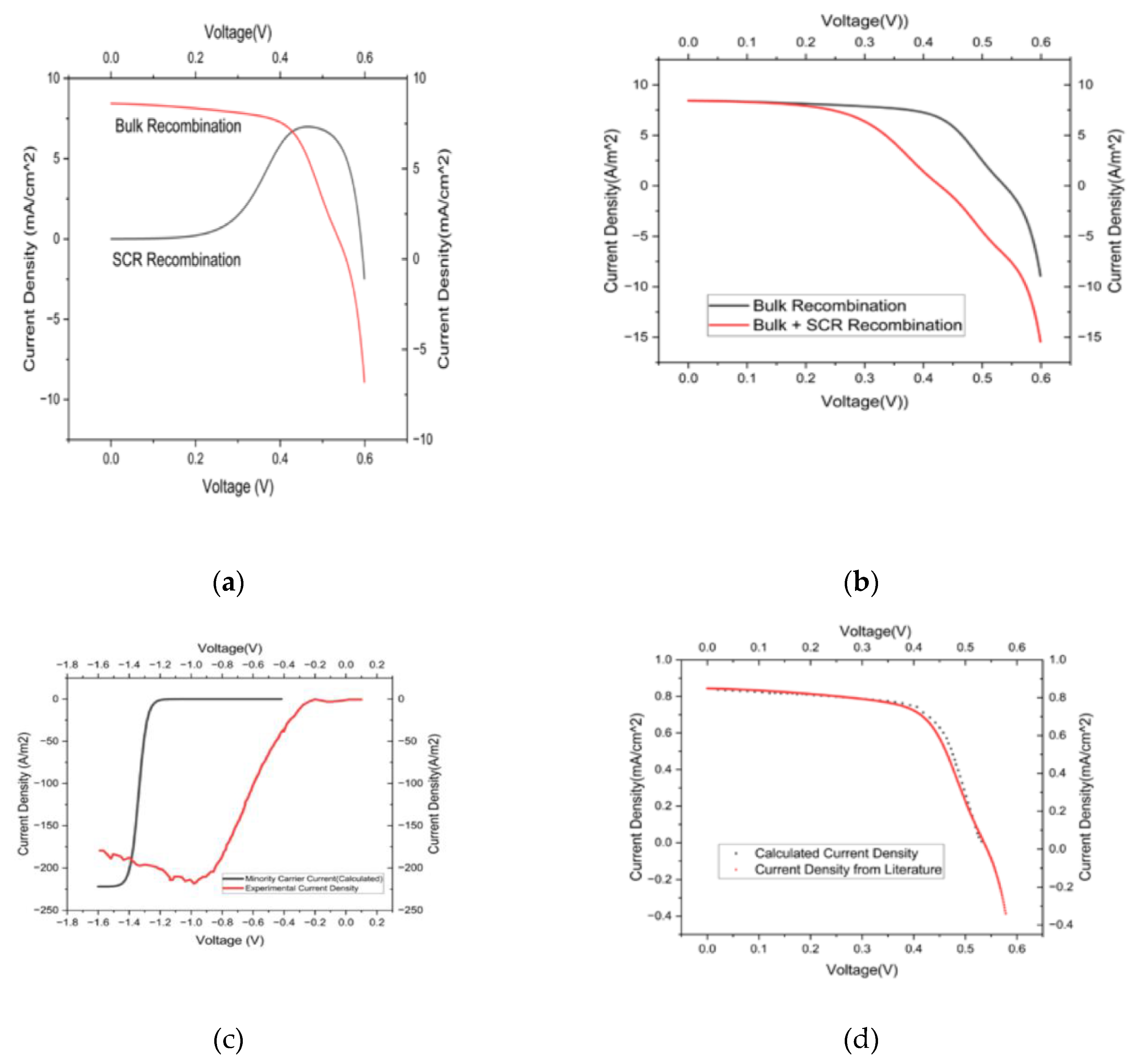

4]. Any attempt to model the voltage loss break down across the SEI depends on the quality of the photo-current and potential data. The use of large quantities of historical data to create interface models has provided a basis for forecasting, control and optimization. However, the spatial accuracy of the model is compromised as the model has lower dimensionality. Furthermore, describing the semiconductor- electrolytic behavior against the potential loss in the cell is not straight forward. Zero-dimensional (0-D) models reported in the literature identifies relationships between cell components and transport barriers at the semiconductor. Gartner proposed series of theoretical equations to compute the photocurrent generated by the photoelectrode under reverse bias [

3]. The performance of the model is limited by the Schottky barrier and the ion transfer across the SEI. The model could not address issues related to the recombination at the SEI. Reichman improved the 0-D model and provided equations to compute the potential drop across the bulk and SCR recombination regions at the SEI [

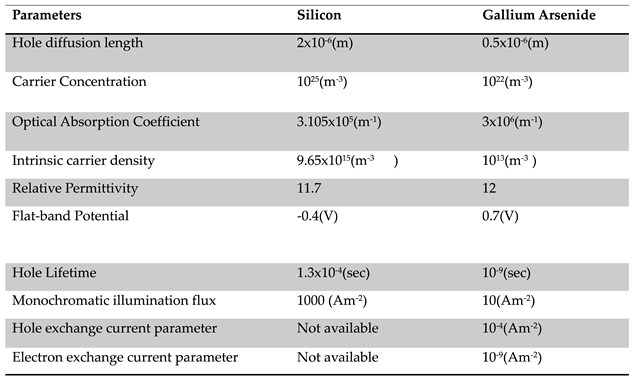

4] Equation 5-7 are used by Reichman to calculate the current due to minority carriers, J

p.

where

is the intrinsic carrier density(m

-3),

is the carrier density (m

-3),

corresponds to Current Density in the Gartner model(A m

-2), q corresponds to elementary charge(C), I

0 is the photon flux,(A-m

-2)

and

are the electron and hole exchange current parameters(A m

-2), W is the space charge width(m),

is the hole diffusion length(m),

is the optical absorption coefficient of the semiconductor(m

-1),

is the saturation current density(A m

-2) and

is the hole lifetime(sec).

Unlike 0-D models, one-dimensional (1-D) models represent the PEC system in a single axis. Wenger et al [

5] report 1-D models for the Dye sensitized cells (DSC) where the optical and electrical equations are coupled [

5]. Their model captures the behavior of the DSC and provide an accurate description on how the excited electrons convert the incident photons to electricity [

6]. In a DSC, the photo-sensitive dye is injected into a wide-bandgap semiconductor to harness the photocurrent. Therefore, the dye absorption rate, an output of the optical model, is trivial to obtain the steady state dye electron injection efficiency and hole diffusion length. [

5]. The balance between complexity and computational efficiency is hard to achieve in both 0-D and 1-D PEC models. Hence, Two-dimensional models are reported by Hernandez et al [

7]. They analyze the oxygen bubbles covering the electrode in the PEC by approximating the inner surface layer as a two-dimensional flat surface. Giacoppo

et al reported three dimensional models to provide an accurate representation of the PEC system but the convergence of their model is limited by computational complexity [

8]. Their model is formulated based on the Gartner’s equations. The simulation of the 3D model shows that the cell attained 10 mA cm

-2 at bias voltages of 1V. But no recombination losses are accounted in their model. Although modelling of DSCs and microscopic interfacial behavior in the PEC have been studied extensively, focused efforts on modelling of the SEI and probing the recombination mechanism for the PEC nano-materials is still not explored well. 0-D models developed by the Reichman (Equations 5-7) show a good approximation of the experimental polarization plots. They report that the recombination in the SCR and charge transfer across the SEI depends on the current exchange parameters. They are determined by (a) the degree of overlap in the semiconductor band, (b) interface states with the redox ions and (c) the transition probabilities for charge transfer [

4]. The values of the exchange current parameters for n or p-type materials are not readily available to scale their model for new photoelectrode nano scale materials. No attempts are made to estimate the current exchange parameters for the photoelectrode nanomaterials.

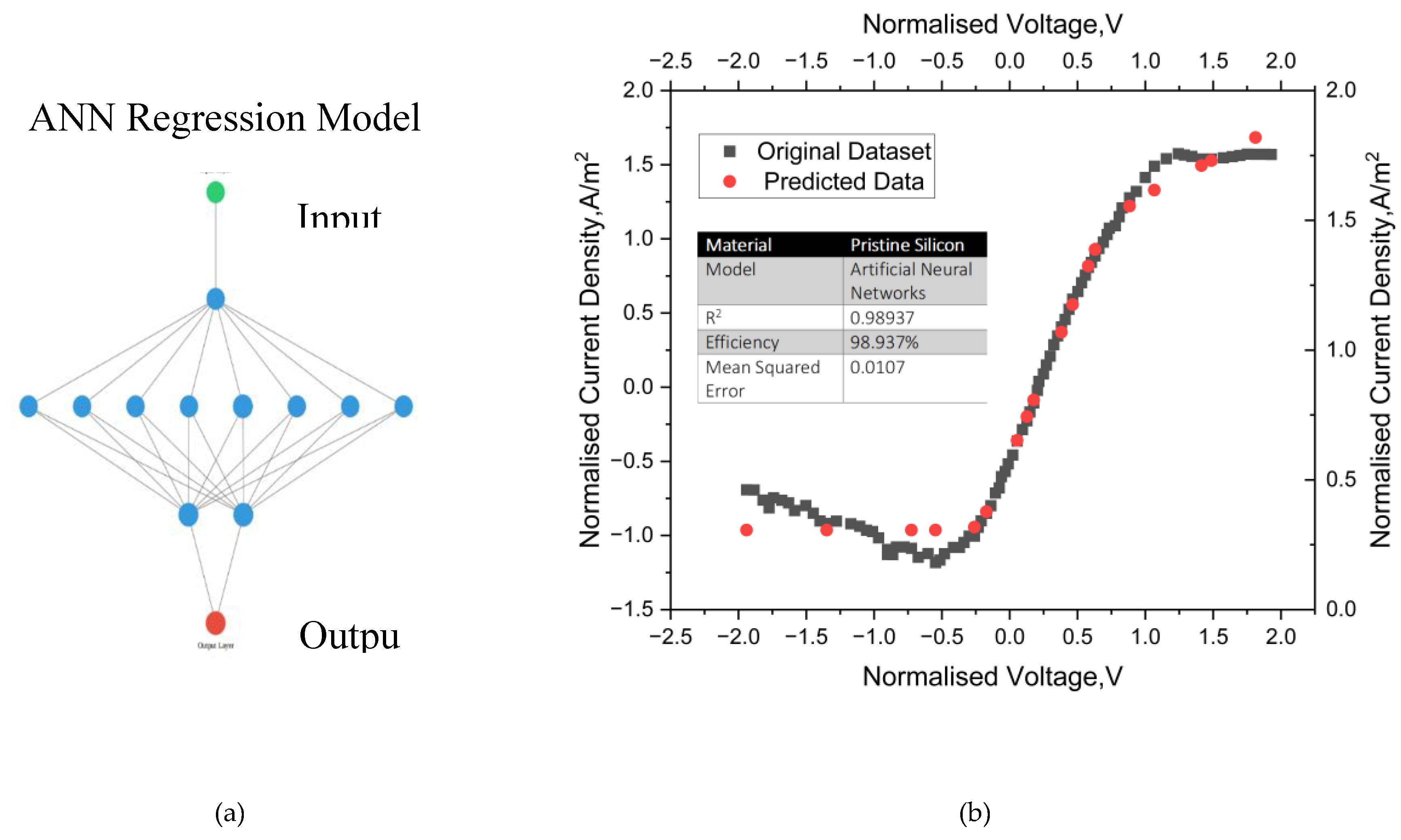

The decisions on the operating strategies of the PEC are attained by combining the physical computations of the theoretical models with experimental data. Simplified Semi empirical models reported in the literature adopts linear regression where corelation amongst variables are achieved. This approach cannot be directly used to diagnose the cause-effect-mechanism of the PEC’s components. Increasing amounts of data generated from the cell are not effectively used to assess the durability, and performance of the cell. A model that can (a) reveal the electrochemical parameters; (b) classify large number of the materials properties to reinforce the learning; (c) perform iterative tasks through repeated interactions with the i-V dataset in a dynamic environment; (d) explore huge i-V data sets to identify the features and pattern in the PEC electrodes would be useful to set the design metrics for the next generation cell. Uncovering the hidden pattern or feature in the i-V dataset will provide new strategies and operating protocols for the PEC. However, no such model is readily available in the literature. Even modern quantum chemistry methods are not accurate to predict the complex characteristics such as diurnal variation of the cell. The machine learning models could resolve the listed research needs. Applying the ML models could address the performance decay related to the diurnal variation. Furthermore, structure – property – performance relationship can be attained for the cell using the ML models. Integrating the experimental data with ML techniques will be useful to uncover the operating and the failure modes of the cell. It could provide a common pattern, specific predicted electrochemical properties, and strategies for the real world testing of the cell.

Predictive maintenance of the PEC depends on the durability and the P

C-V datasets. The machine and deep learning models are needed to understand the non-linearity in the P

C-V data collected from the cell. The architecture of the deep learning models can process wide range of datasets and accurately predict the P

C-V characteristics than the traditional machine learning or 0-D models. It has the ability to ingest and process the given datasets via several iterations and learn the non-linearity in the features. Developing algorithms, reducing the computation power, and creating a database of the PEC parameters could provide enormous growth in applying Deep Learning in Simulation (DLS) for the cell. It can handle noise in the data and make efficient predictions based on the history of the data collection. The complex trends between photocurrent, voltage and important intrinsic parameters in PECs can be captured using the DLS approach for different nano-materials. Wang et al [

9] built a machine learning model to predict the effect of dopants on photoelectrodes.[

9] Oral et al [

10] implemented Random Forest, Decision tree and Association Rule Mining to predict bandgap and photocurrent density. They have used thirty-three features including electrode materials, methods of synthesis, irradiation properties and electrolyte in their model [

10]. Kharade et al reports an Artificial Neural Network (ANN) model that predicts the adsorption efficiency in a DSC using a three-layer approach for a DSC [

11]. The parameters such as Fill factor, short circuit current and open circuit voltage are considered in the model optimization and the efficiency calculations. Despite having ML models for predicting photocurrent using features and voltage datasets, they still need high computational power and time. A model with robust algorithm is required to capture the real time events of the cell and circumvent the numerically intense calculations of 0-D modelling A framework comprising of a 0-dimensional model coupled with the DLS algorithm can be useful to accelerate the new material development for the PECs.

Based on the current state of research, the present work pursues the following objectives; (a) Derive a theoretical model to assess the current density across the SEI for two different PEC components. The model shall; (b) approximate the hole exchange current parameter (Ipo); (c) evaluate the photocurrent across the SEI; (d) demonstrate voltage loss break down against the cell parameters for the gallium arsenide and pristine silicon cells, and (e) develop an ANN model to predict photocurrent for the cell; For the first time, we aim to provide a framework that consists of an analytical model and machine learning model that can provide parameters such as space charge width and the photocurrent.

Author Contributions

Conceptualization, SRD., CRK. and N.S; methodology, N.S; SRD; software, C.R.K; validation, S.R.D; M.F., M.S., and B.W; and D.S.; formal analysis, N.S and C.R.K.; investigation, M.F., S.R.D, D.S;; resources, S.R.D,.; data curation, N.S.; writing—original draft preparation, S.R.D and N S.; writing—review and editing, B.W, S.R.D and M.S.; visualization, S.R.D and N.S.,; supervision, S.R.D.; project administration, M.W; S.R.D, and B.W;.; All authors have read and agreed to the published version of the manuscript.