Submitted:

20 July 2024

Posted:

22 July 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Results

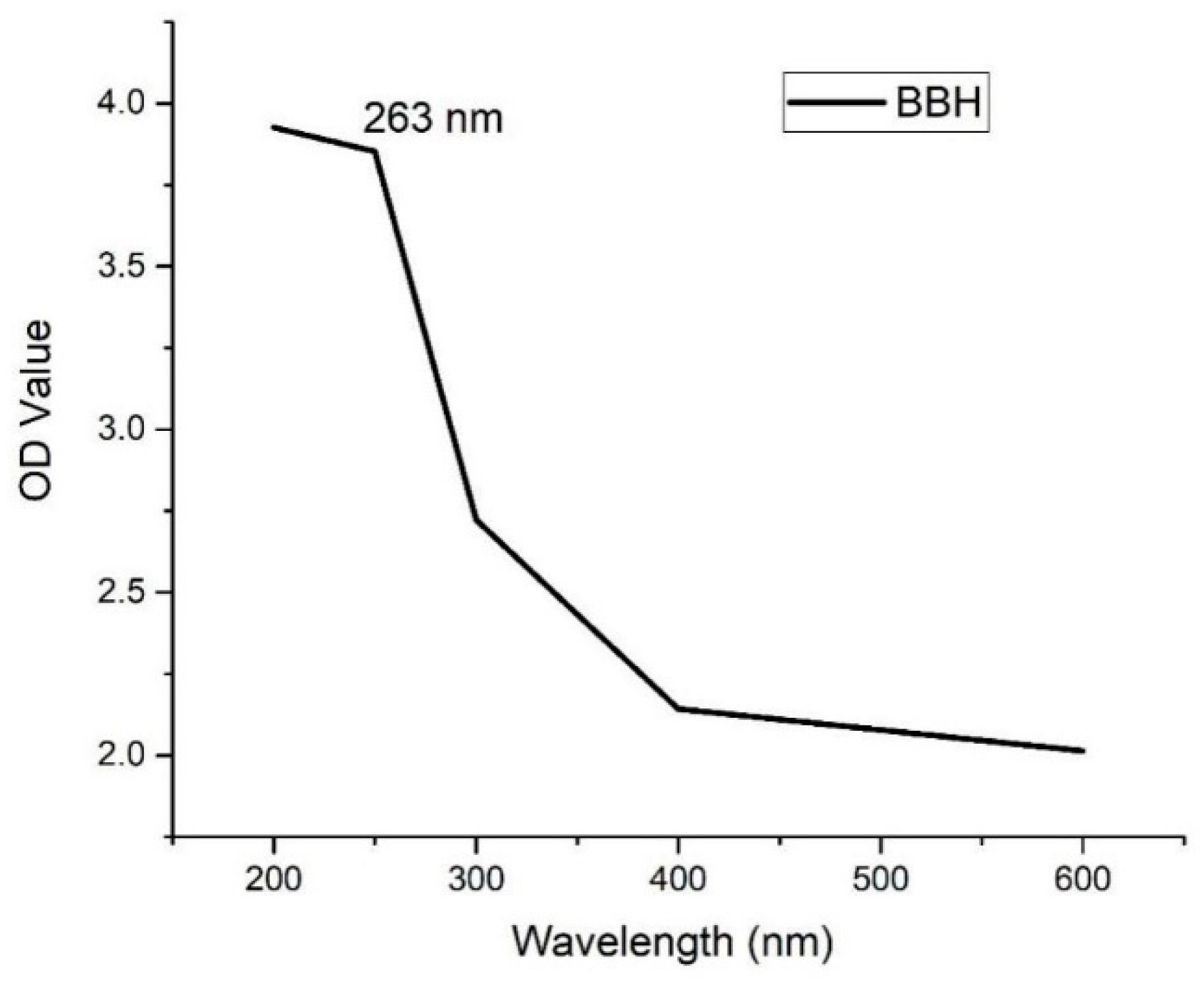

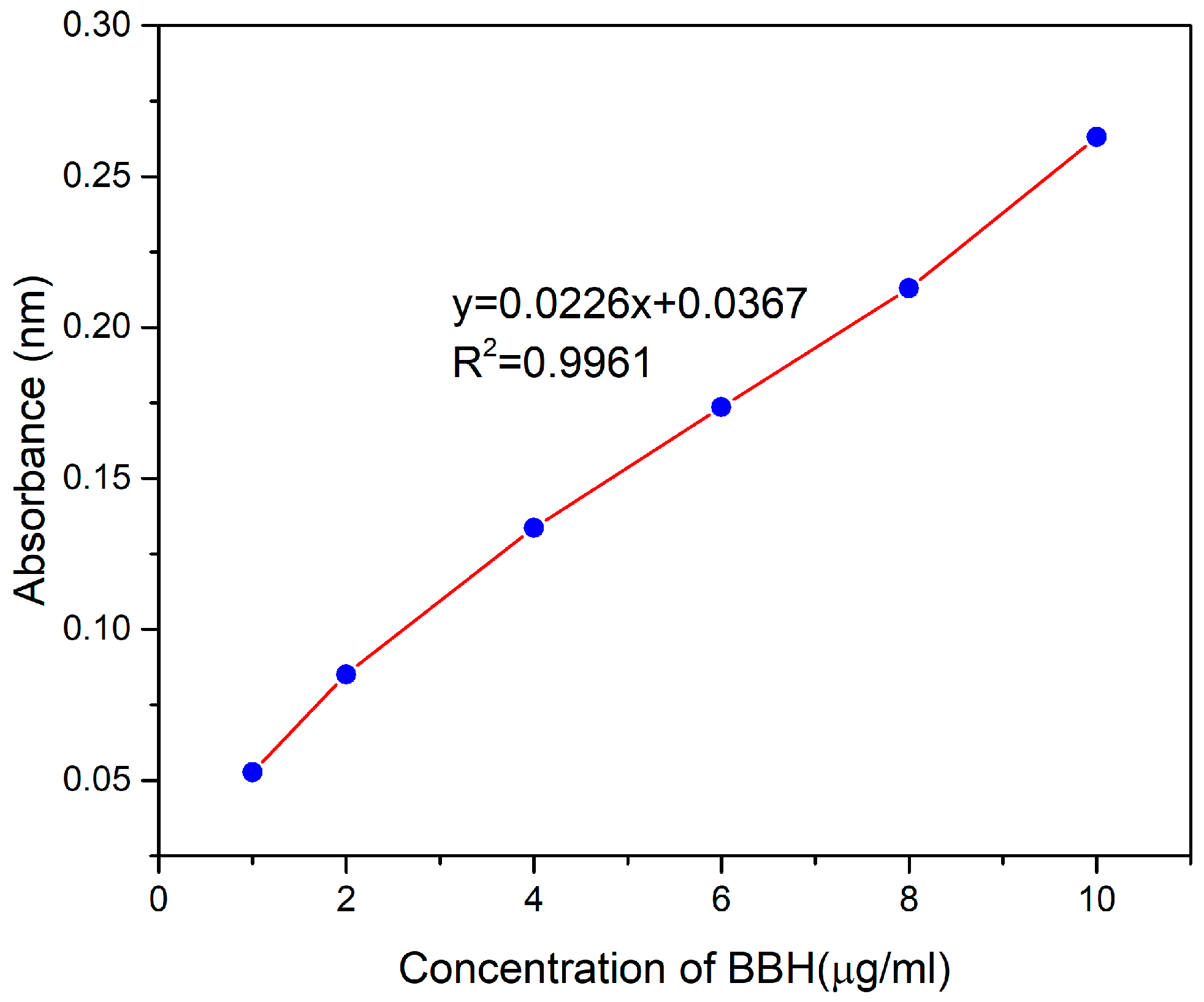

2.1. Wavelength Study and Solubility

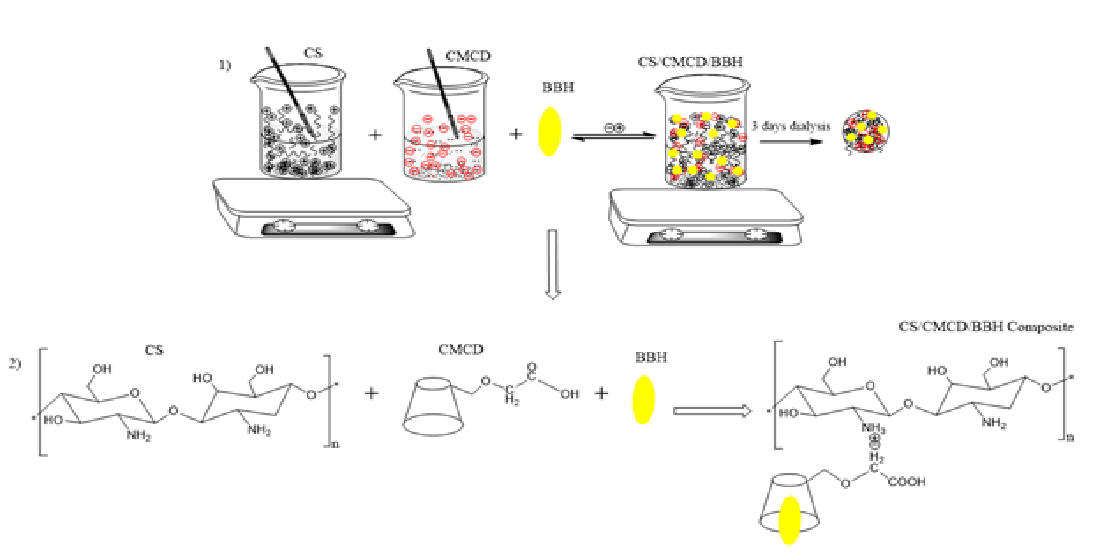

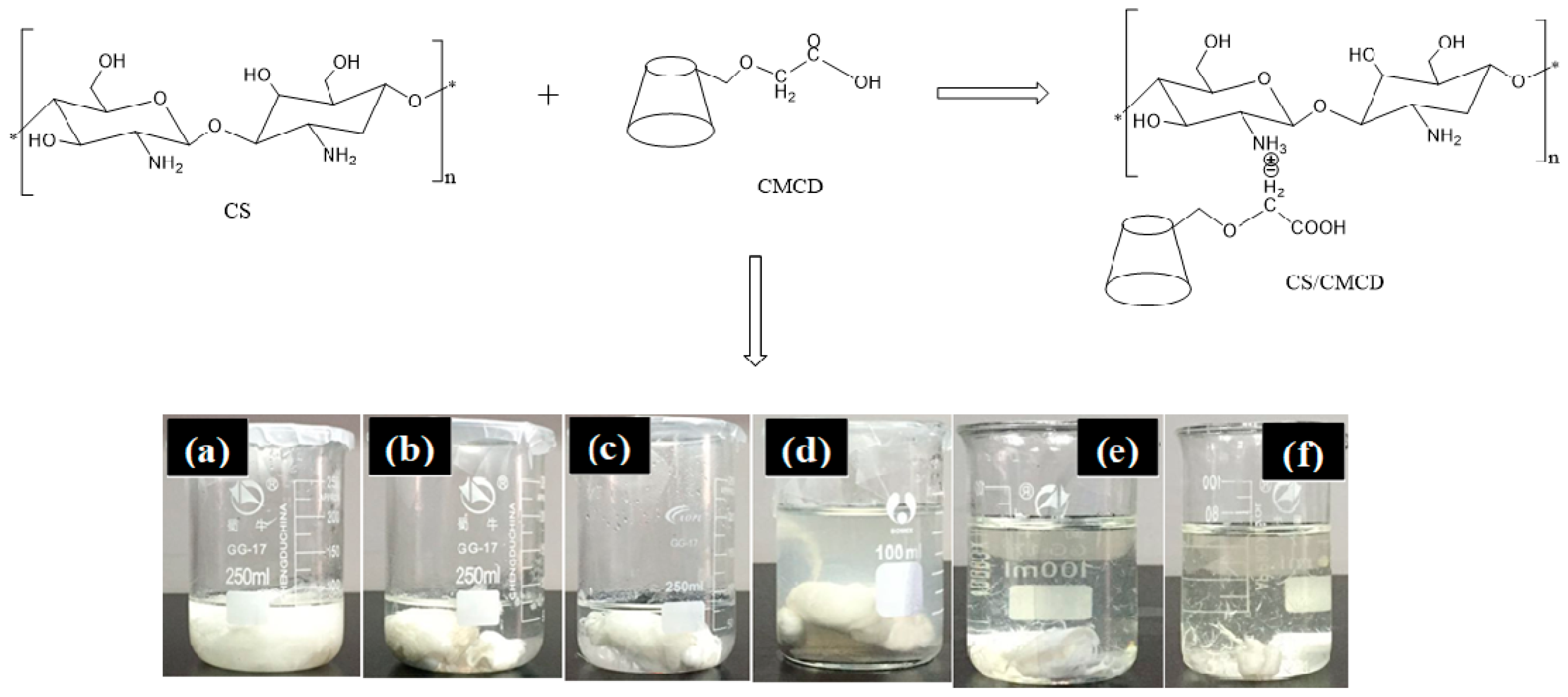

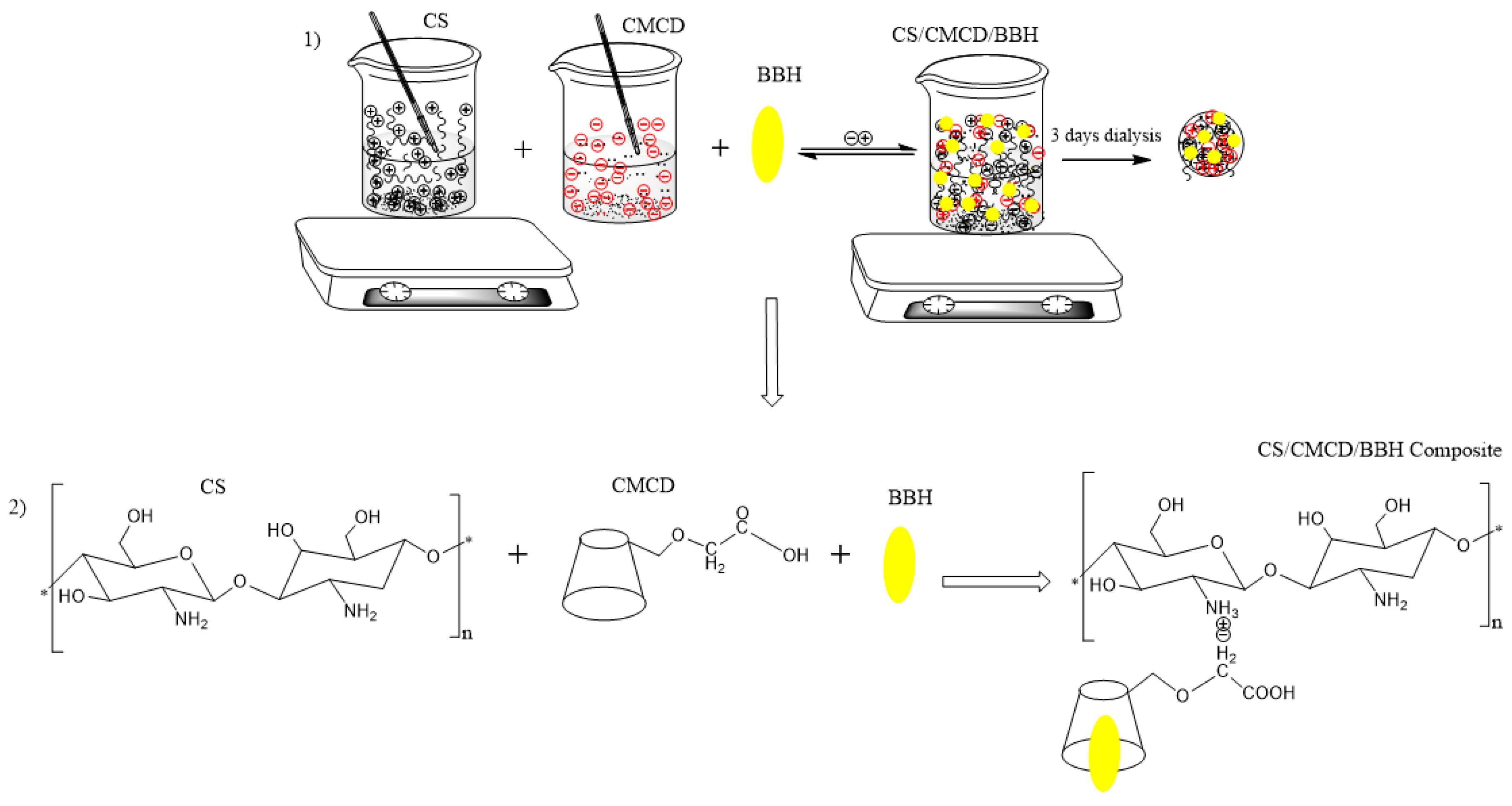

2.2. Synthesis of CS/CMCD and Synthesis of CS/CMCD Loaded BBH Hydrogel

2.3. Characterization of CS/CMCD and CS/CMCD/BBH Hydrogels

2.3.1. Analysis of Water Content

| Sample (g) | First weighing (g) | Second weighing (g) | Water content (g) | WCD (%) |

|---|---|---|---|---|

| CS/CMCD(1:10) | 3.972±0.005 | 1.211±0.005 | 2.760±0.001 | 69.5 |

| CS/CMCD(1:8) | 3.567±0.0005 | 1.198±0.005 | 2.369±0.001 | 66.4 |

| CS/CMCD(1:6) | 3.248±0.005 | 1.192±0.005 | 2.056±0.001 | 63.3 |

| CS/CMCD(1:4) | 2.989±0.005 | 1.172±0.005 | 1.817±0 | 60.1 |

| CS/CMCD(1:2) | 0.937±0.005 | 0.394±0.005 | 0.539±0.001 | 57.5 |

| CS/CMCD(1:1) | 0.195±0.005 | 0.112±0.005 | 0.083±0 | 42.4 |

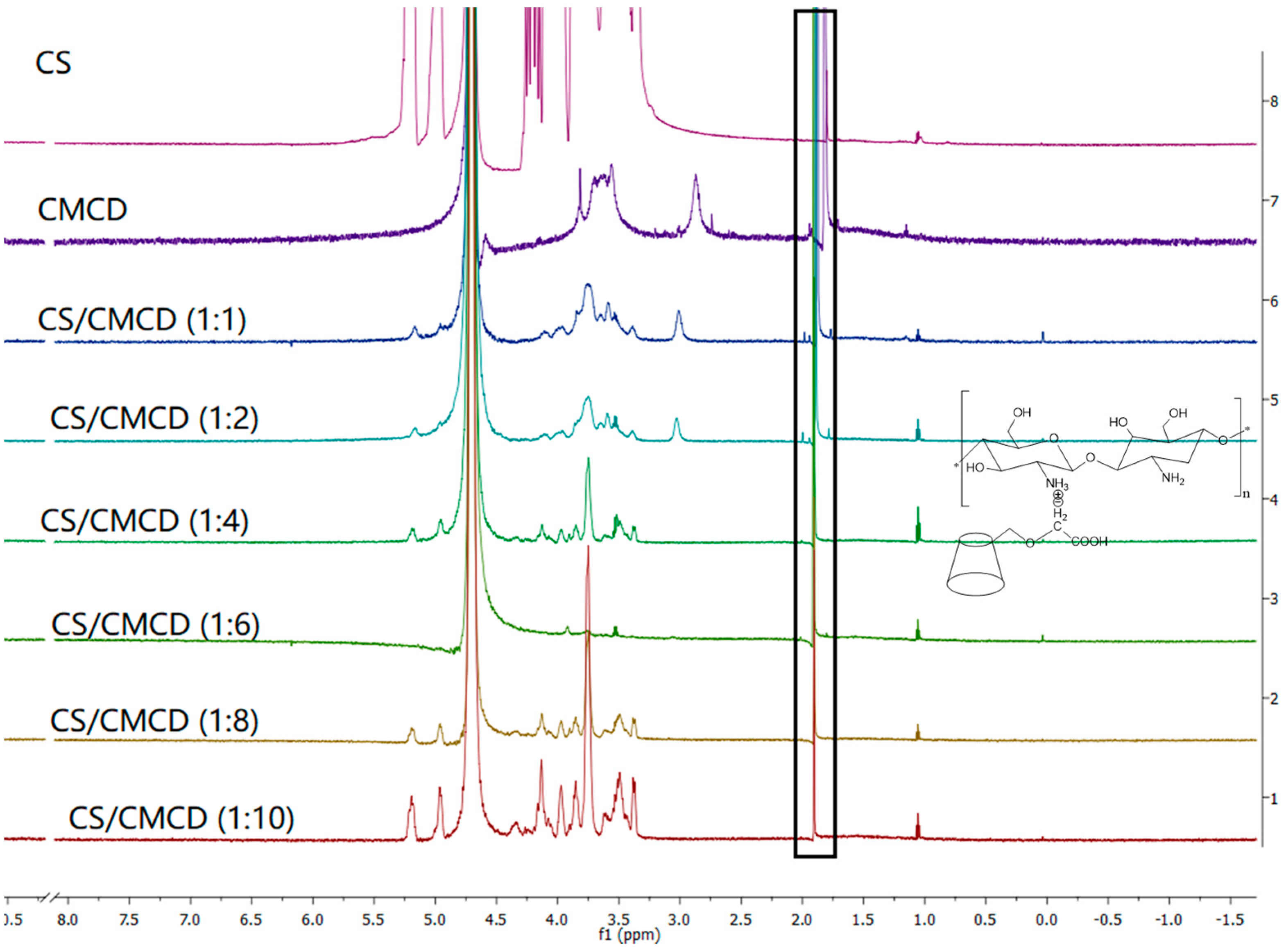

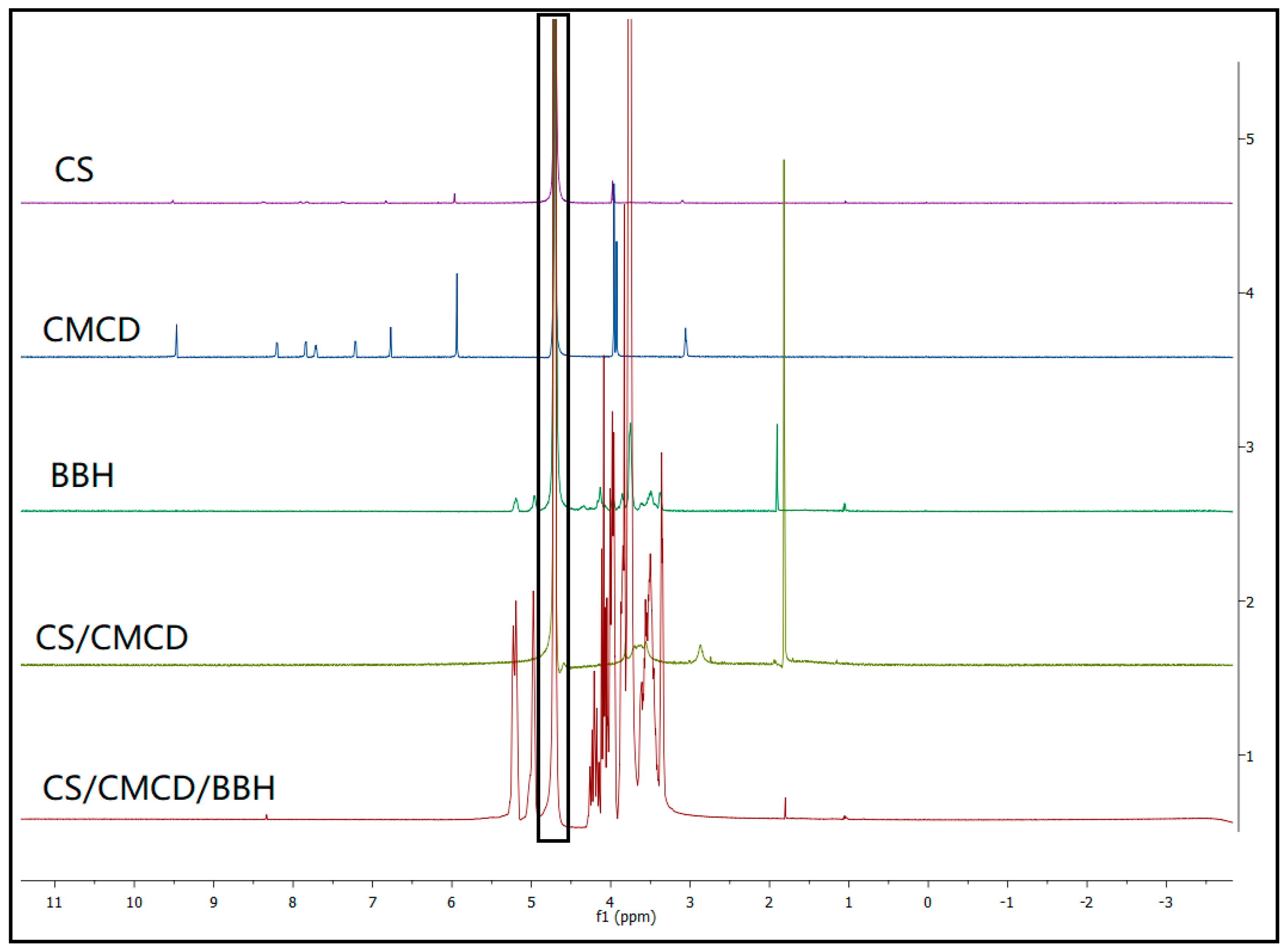

2.3.2. Proton NMR

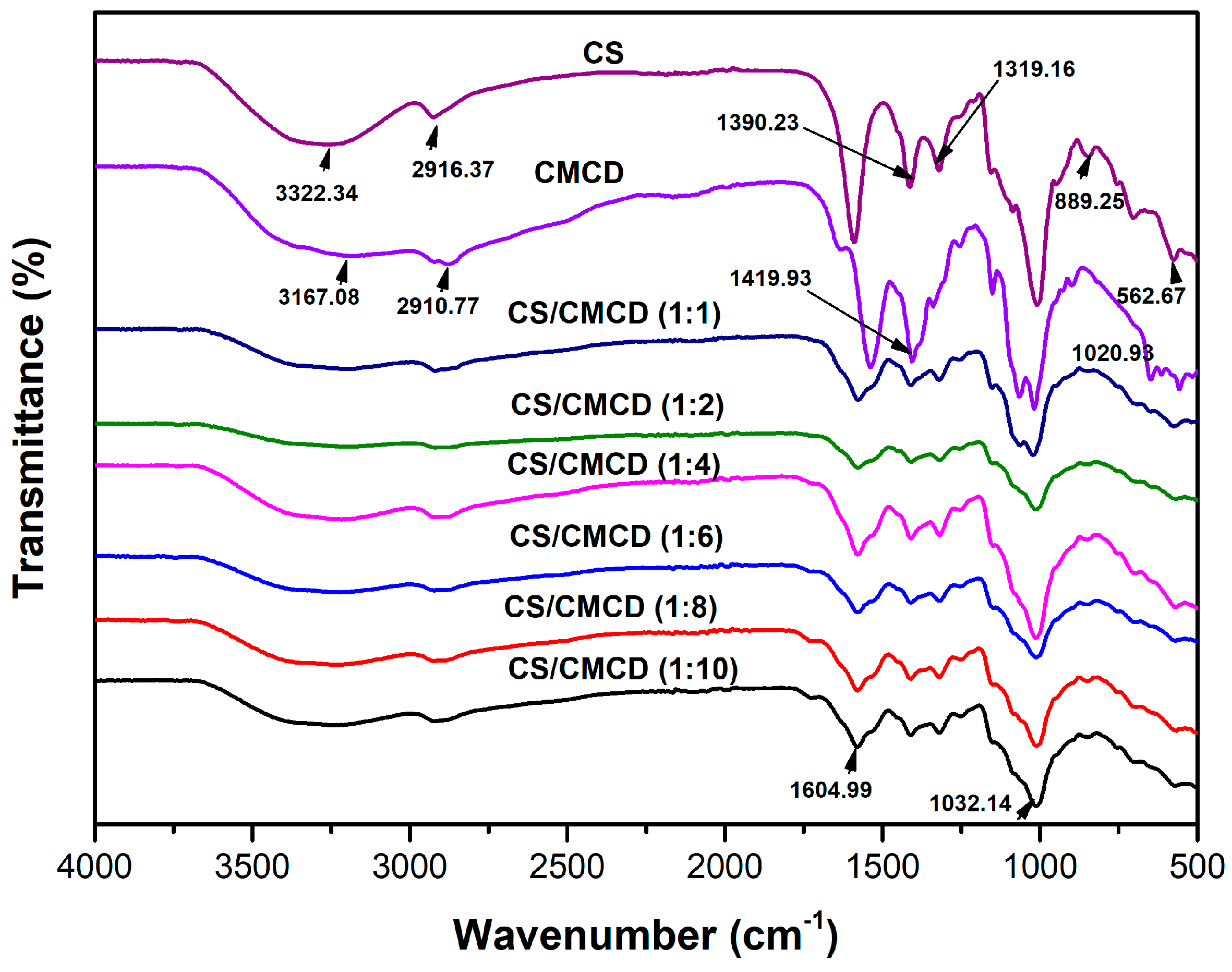

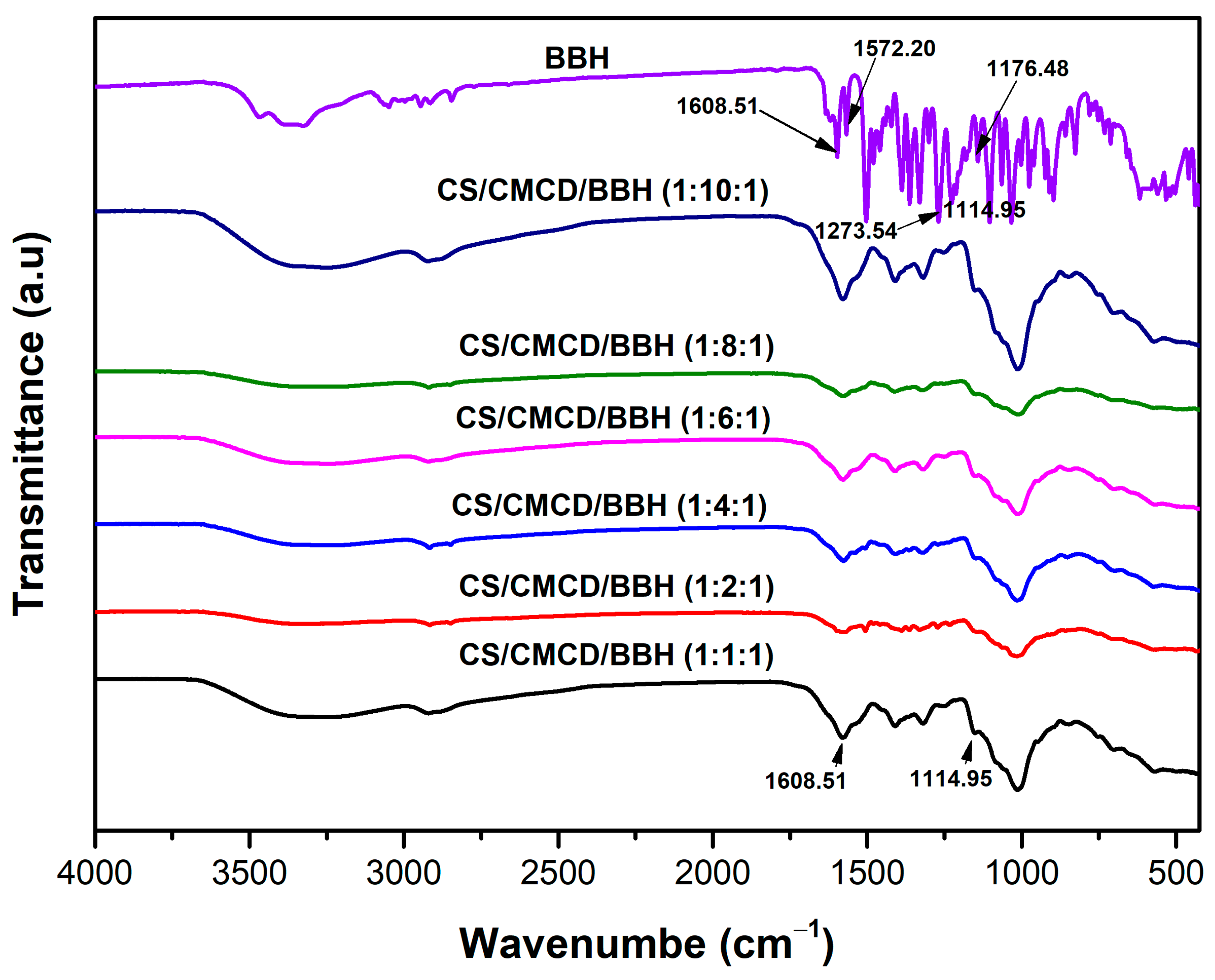

2.3.3. FTIR

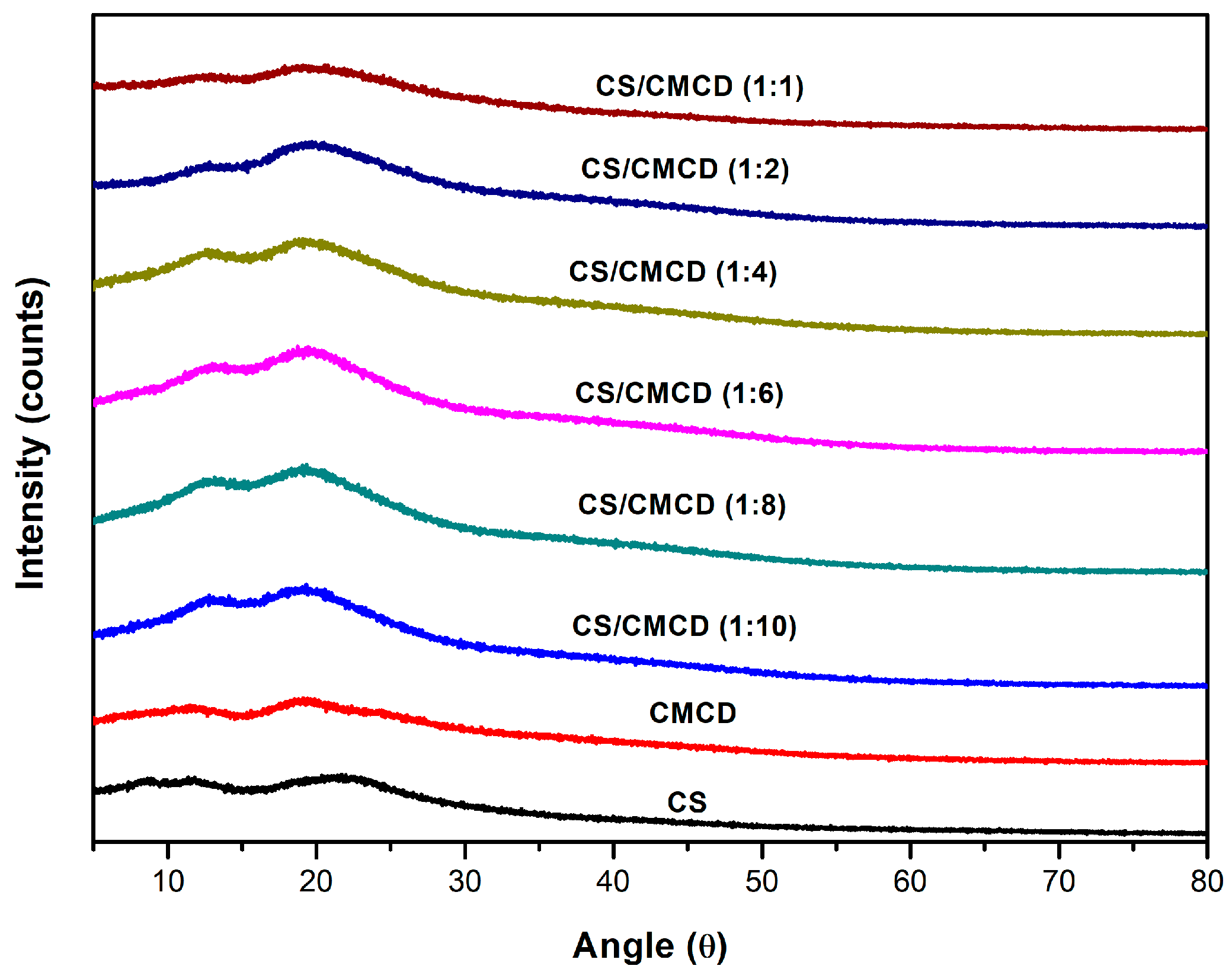

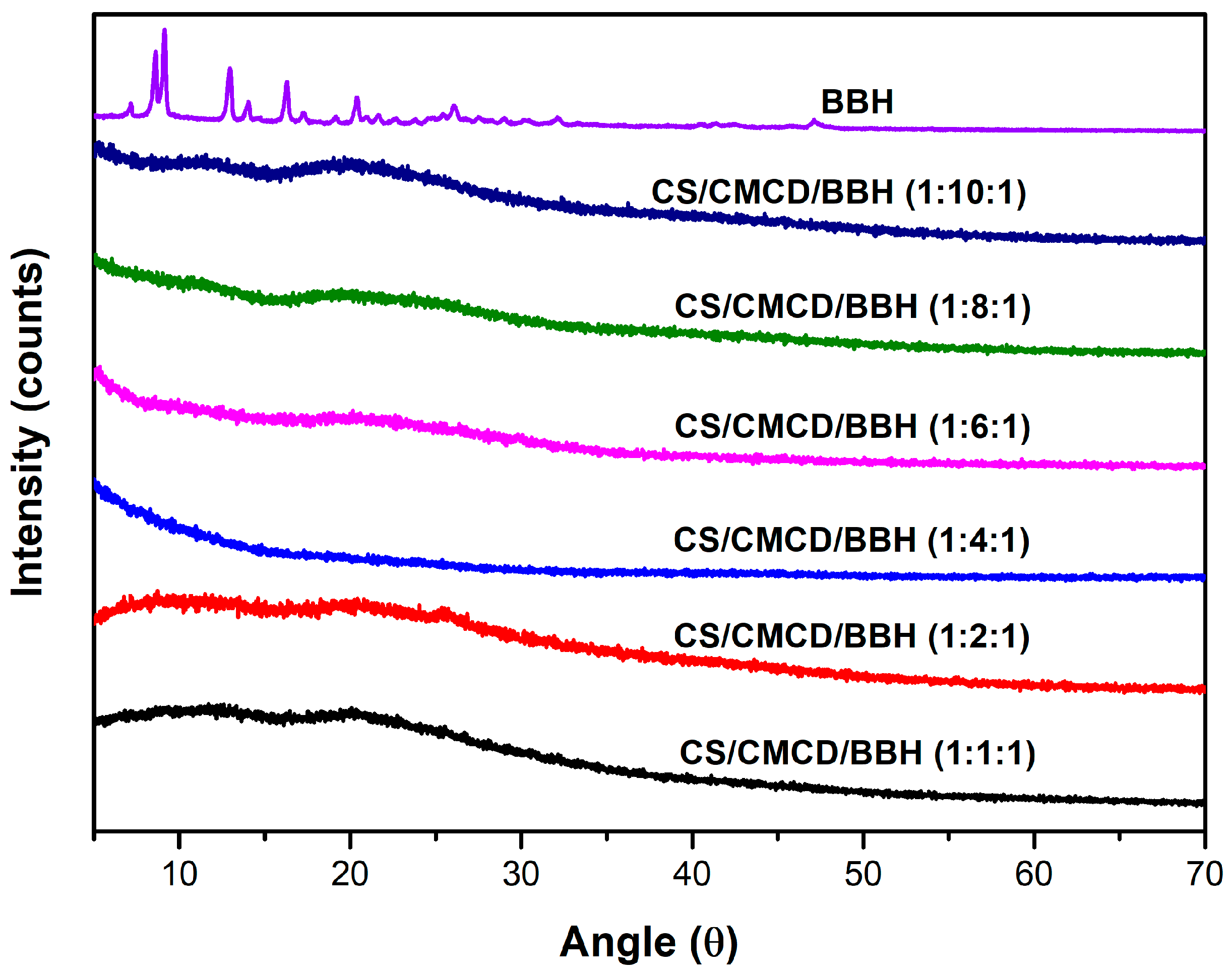

2.3.4. XRD

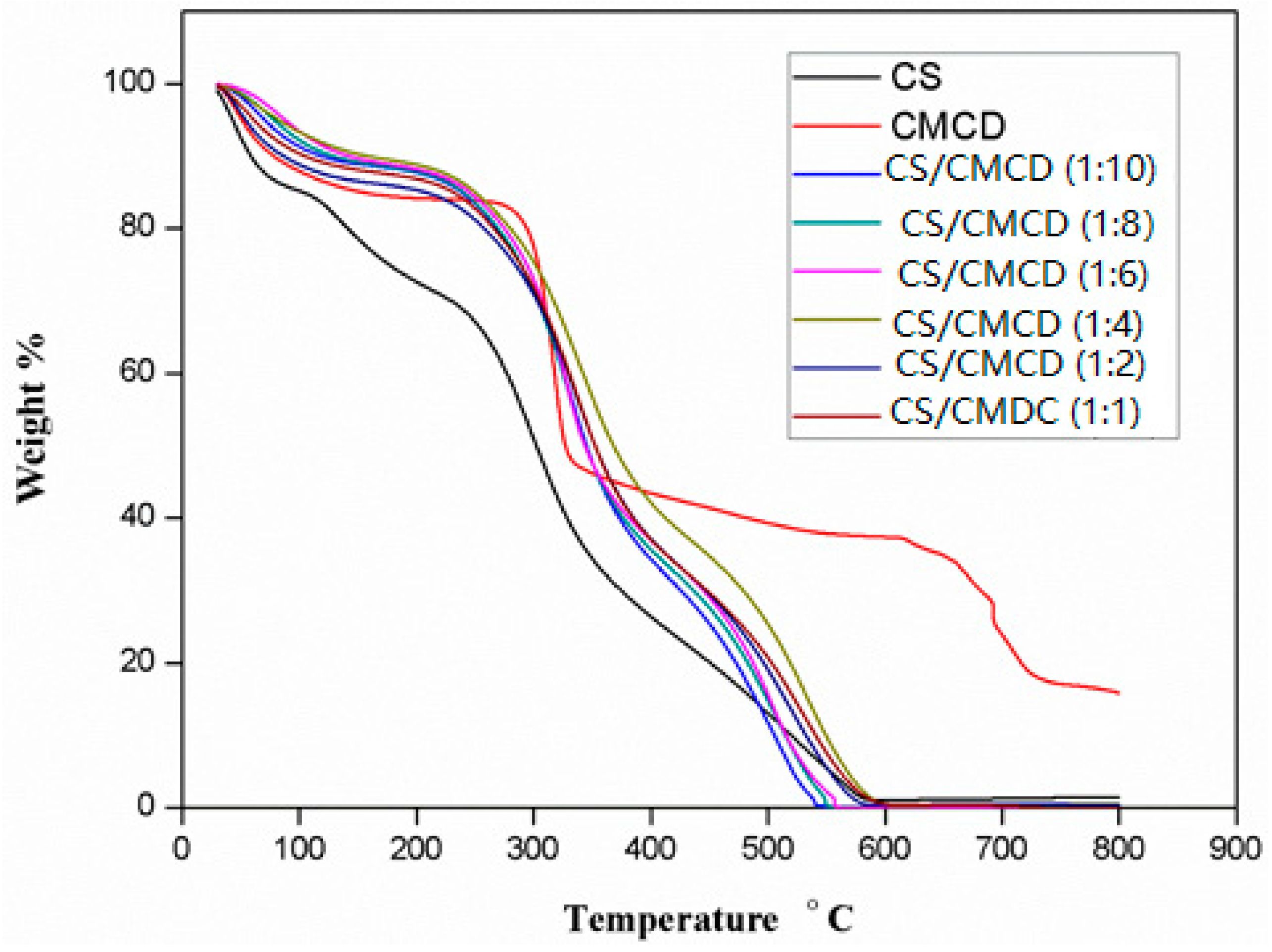

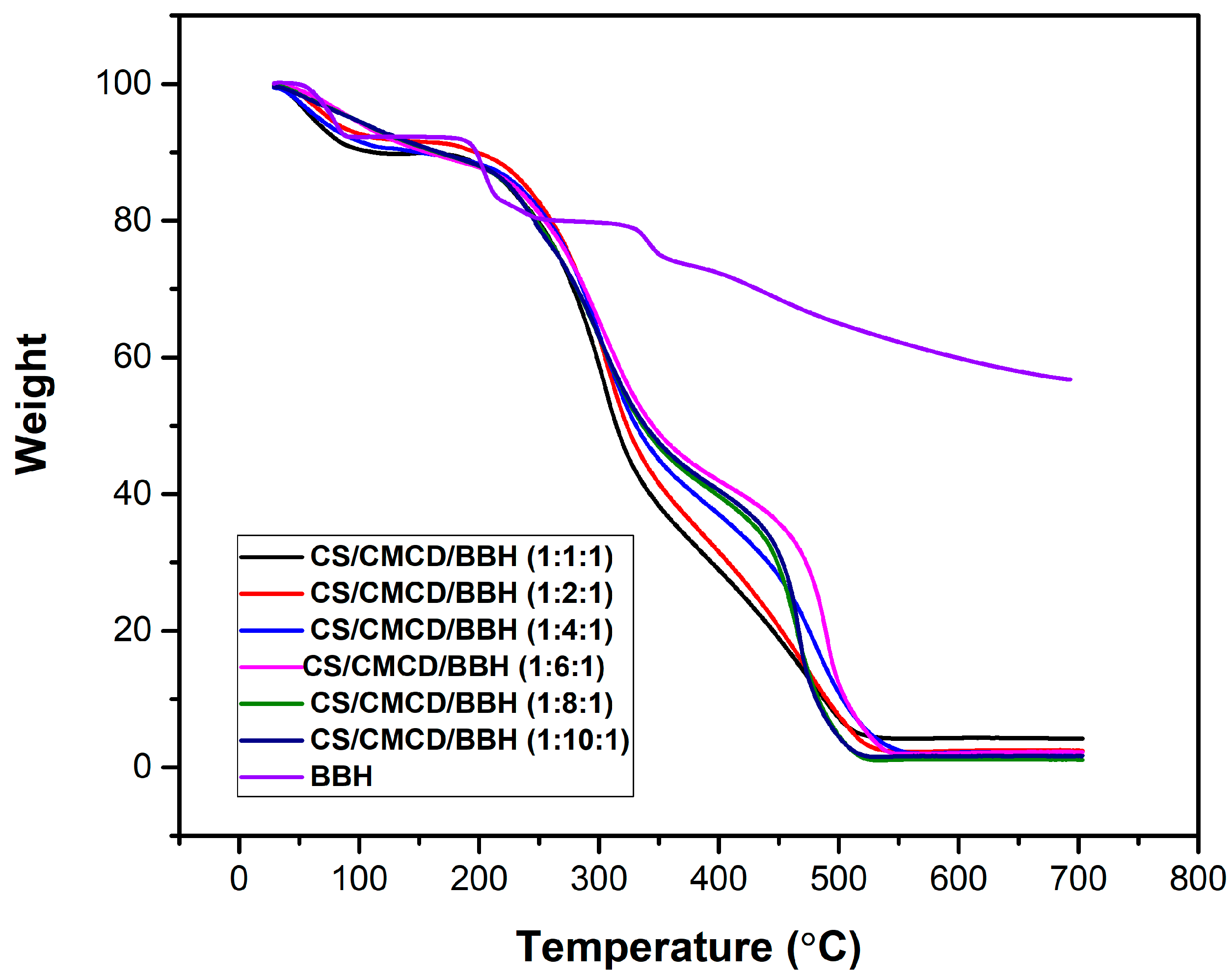

2.3.5. TGA

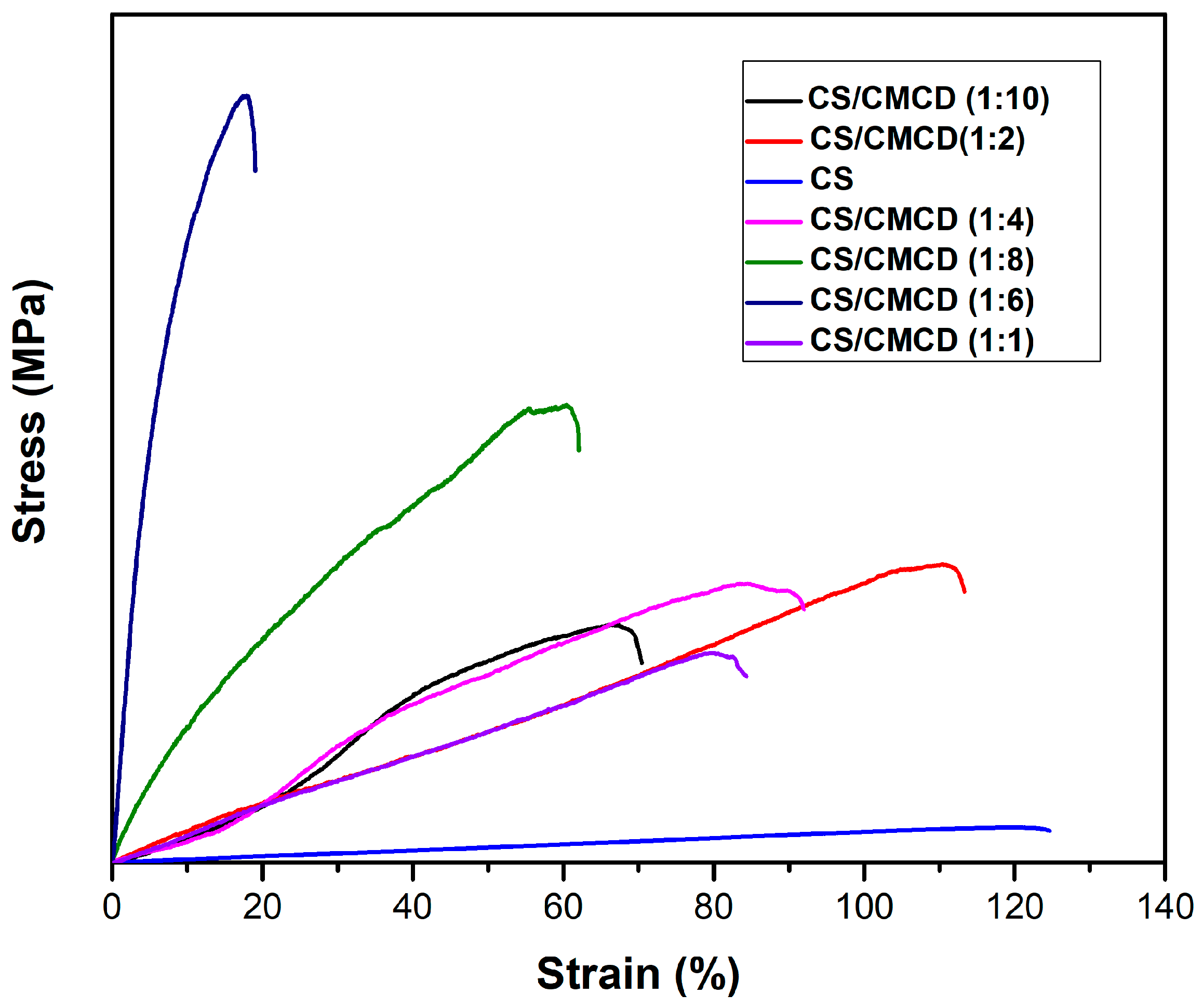

2.3.6. Mechanical Properties

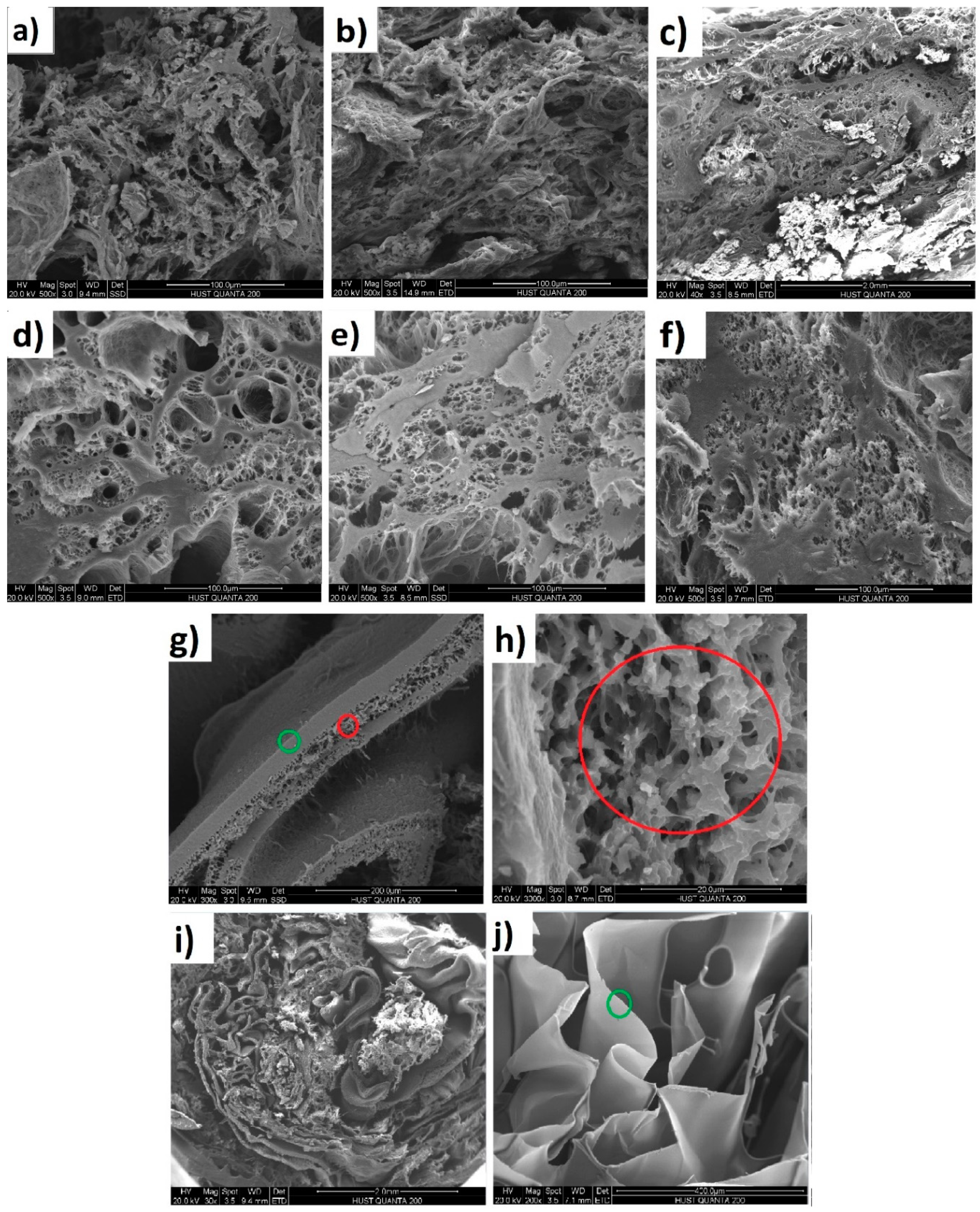

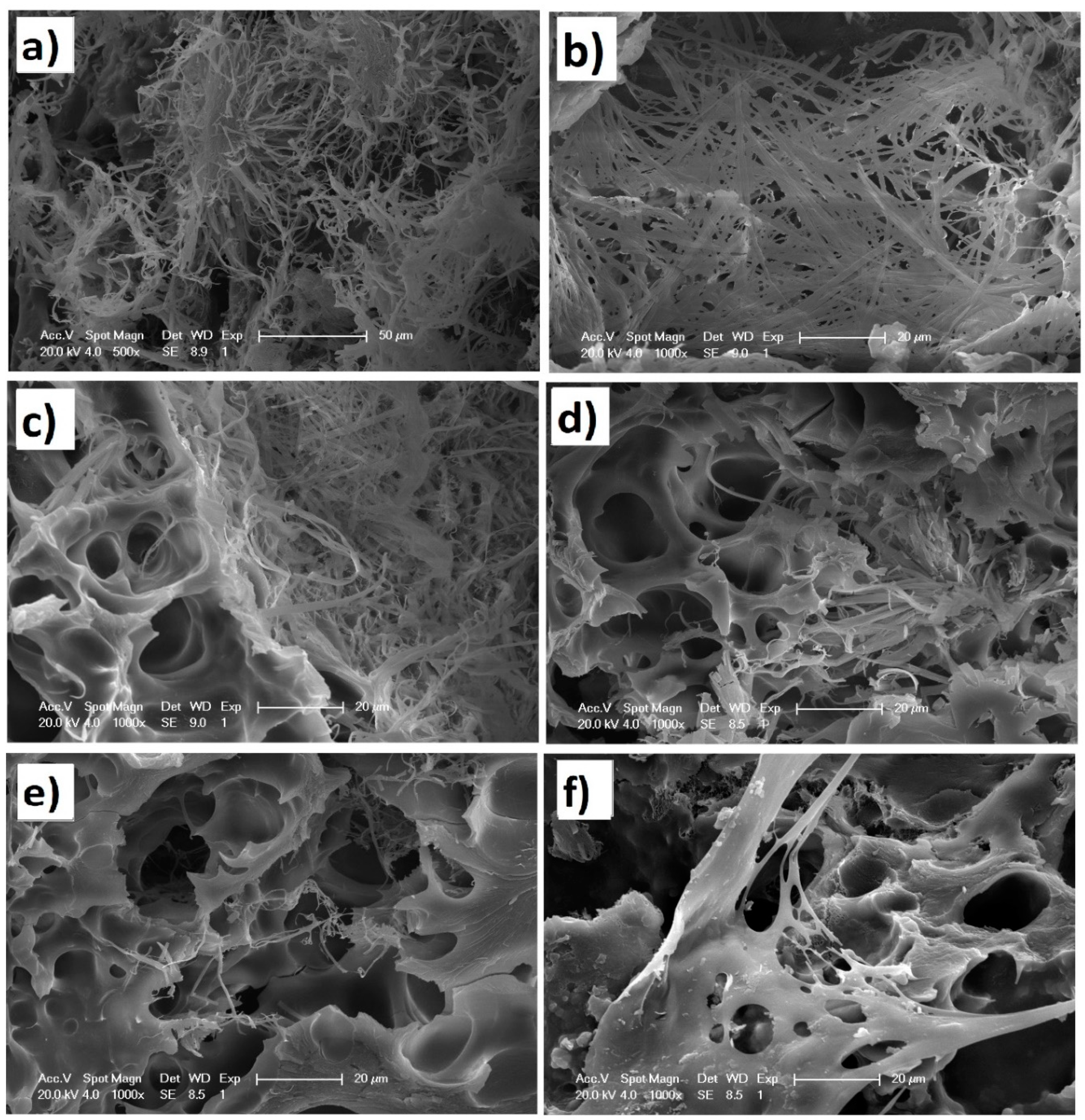

2.3.7. SEM

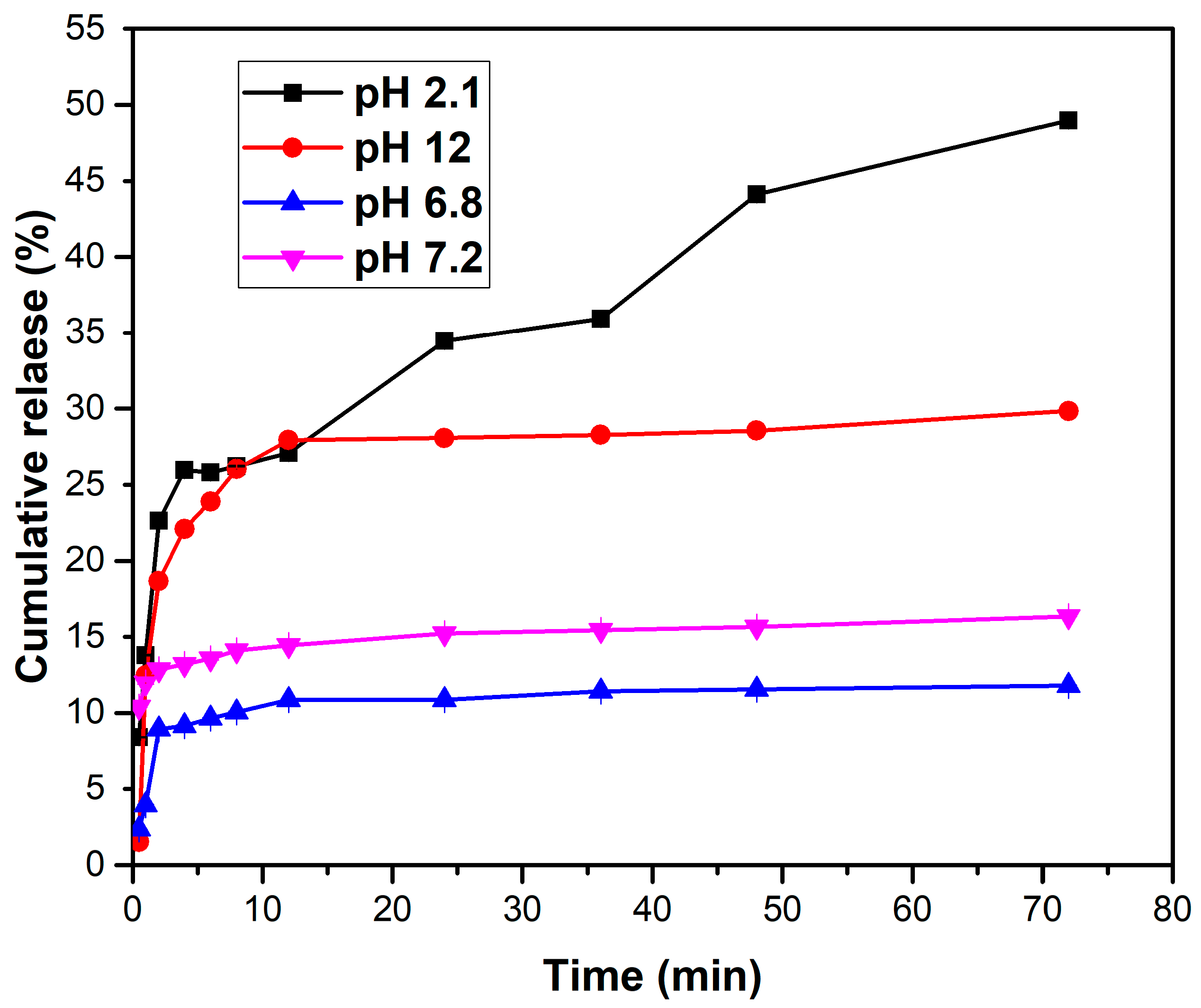

2.4. Drug Release and Loading System

2.4.1. Loading Capacity and Encapsulation Efficiency

2.4.2. Drug Release Profile

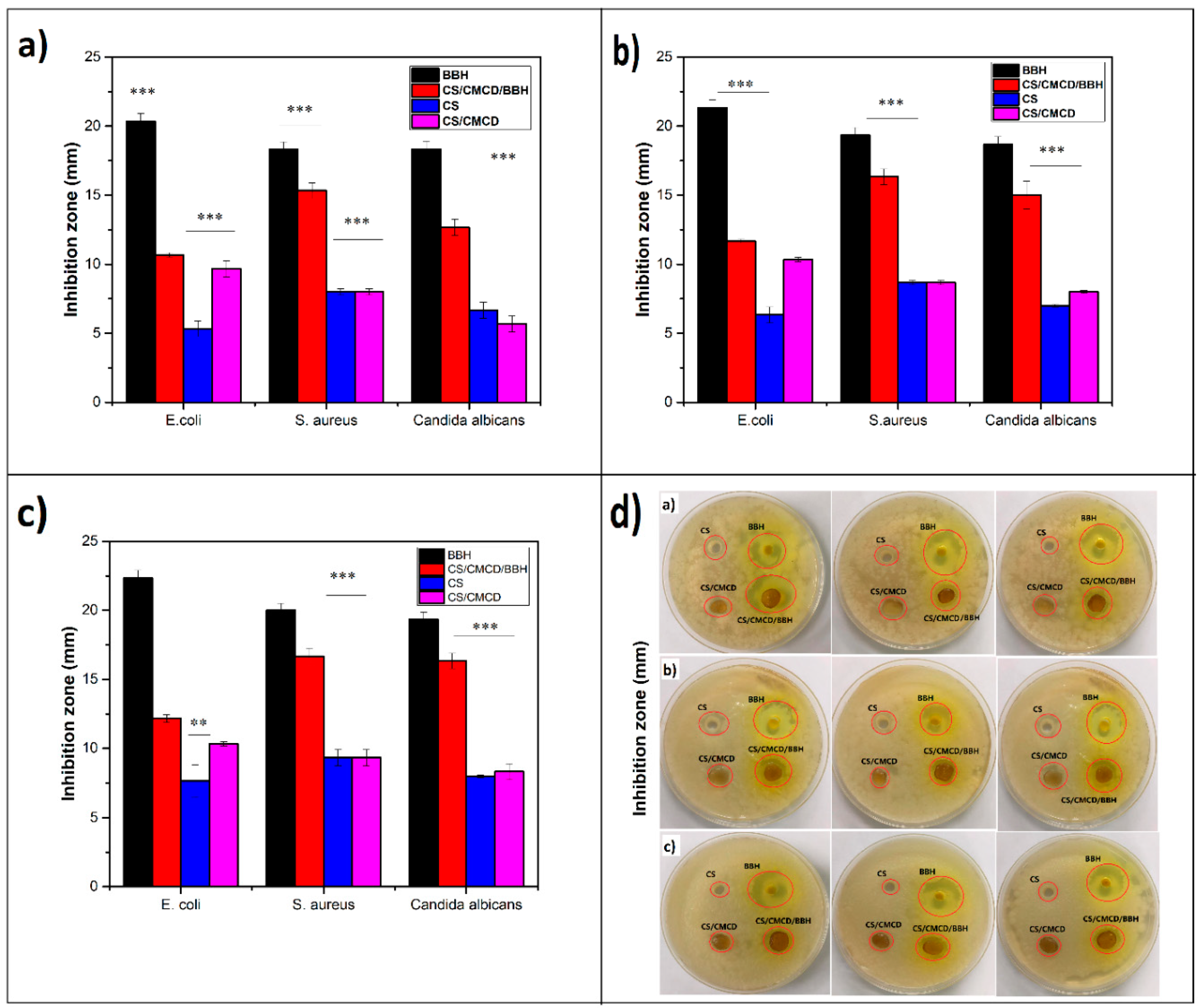

2.5. Anti-Bacterial Effect of CS/CMCD and CS/CMCD/BBH Hydrogels

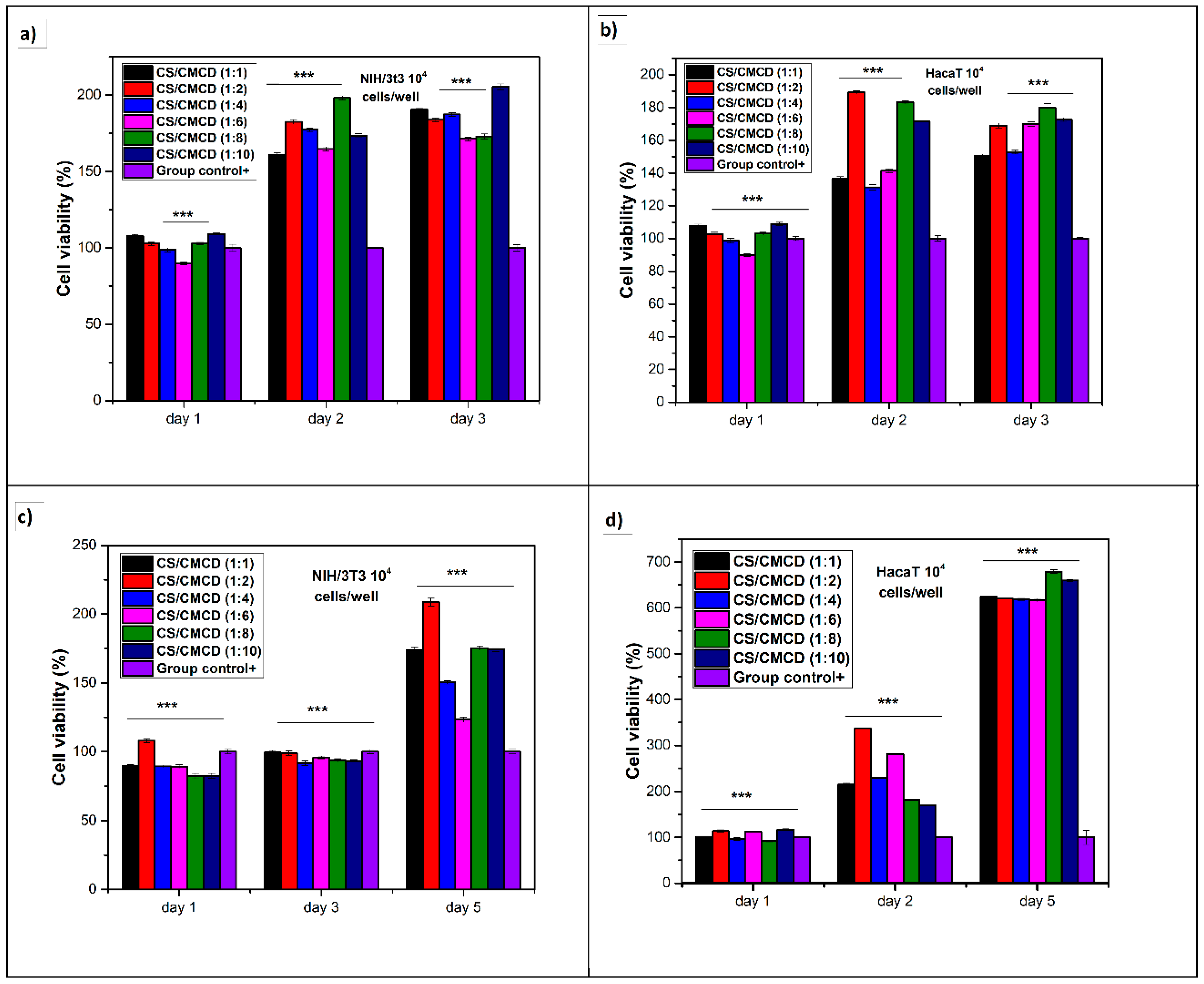

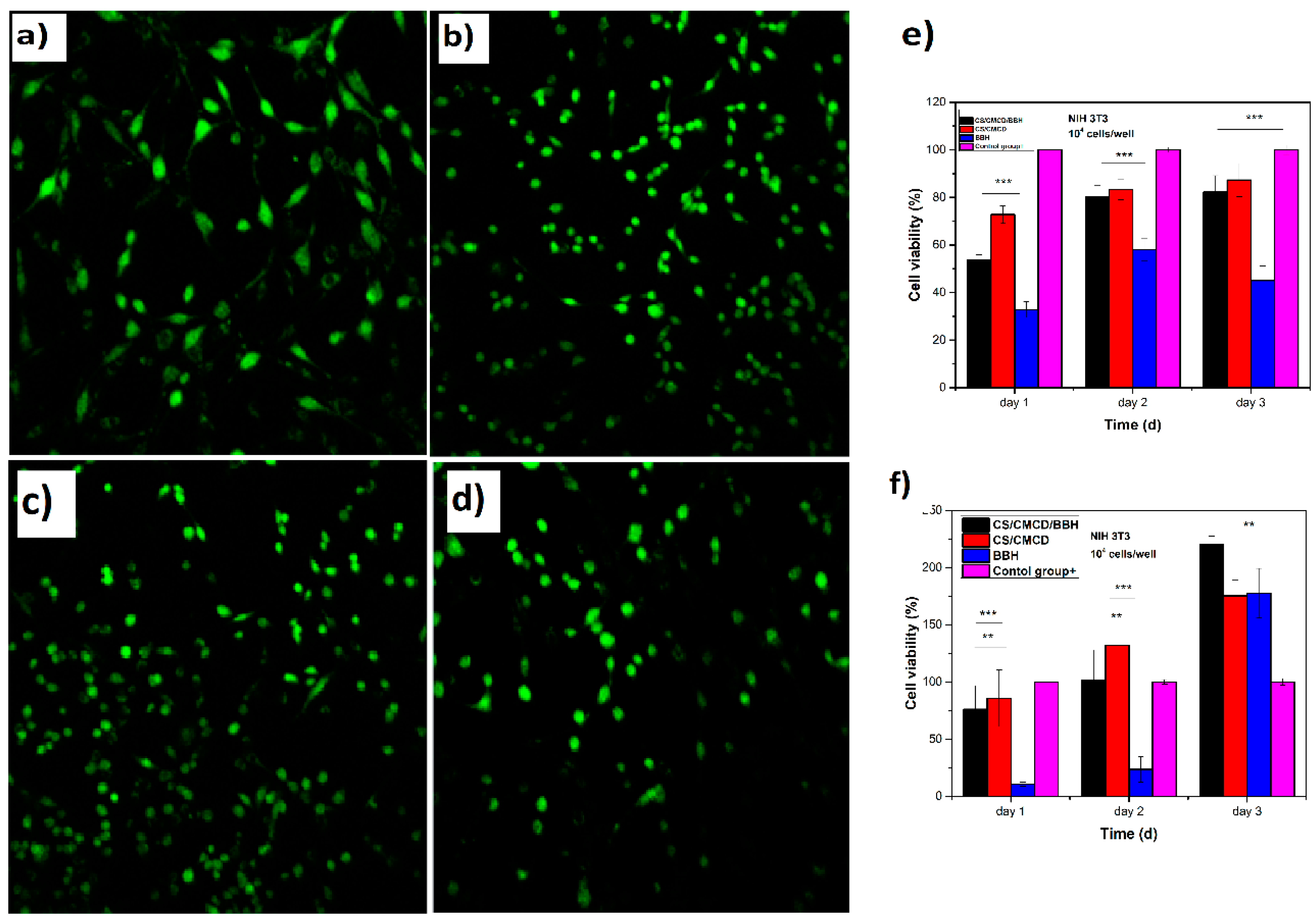

2.6. Cytotoxicity Effect of CS/CMCD and CS/CMCD/BHH Hydrogels

3. Discussion and Conclusion

4. Materials and Methods

4.1. Chemicals, Microbial Strains, and Cell Strains

4.2. Selection of Detection Wavelength

4.2. Determination of the Solubility

4.3. Synthesis of CS/CMCD and Synthesis of BBH-Loaded CS/CMCD

4.4. Characterization of the CS/CMCD and CS/CMCD/BBH Composite Biomaterials

4.5. Drug Loading and Drug Delivery System

4.5.1. Determination of the Loading Capacity and Encapsulation Efficiency

4.5.2. In Vitro Drug Loading and Drug Release

4.6. Antimicrobial Assessment

4.7. Cell Viability Cytotoxicity Assay

4.8. Drug Efficacy Assay

4.9. Confocal or Staining Assay

4.10. Statistical Analysis

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Conc. (mmol/L) | OD value Absorbance value | Absorbance value |

|---|---|---|

| 0.1 | 3.1123 | 0.0537 |

| 0.2 | 3.1581 | 0.0995 |

| 0.4 | 3.2017 | 0.1431 |

| 0.6 | 3.2441 | 0.1735 |

| 0.8 | 3.2725 | 0.2139 |

| 1.0 | 3.3204 | 0.2618 |

| 10 | 6.0000 | 2.9414 |

References

- Almowallad, S.; Al-Massabi, R. Berberine Modulates Cardiovascular Diseases as a Multitarget-Mediated Alkaloid with Insights into Its Downstream Signals Using in Silico Prospective Screening Approaches. Saudi Journal of Biological Sciences 2024, 31, 103977. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.; Yang, K.; Hong, Y.; Gong, Y.; Ni, J.; Yang, N.; Ding, W. A New Perspective on the Antimicrobial Mechanism of Berberine Hydrochloride Against Staphylococcus Aureus Revealed by Untargeted Metabolomic Studies. Front. Microbiol. 2022, 13, 917414. [Google Scholar] [CrossRef] [PubMed]

- Peng, L.; Kang, S.; Yin, Z.; Jia, R.; Song, X.; Li, L.; Li, Z.; Zou, Y.; Liang, X.; Li, L.; et al. Antibacterial Activity and Mechanism of Berberine against Streptococcus Agalactiae. Int J Clin Exp Pathol 2015, 8, 5217–5223. [Google Scholar]

- Bandyopadhyay, S.; Patra, P.H.; Mahanti, A.; Mondal, D.K.; Dandapat, P.; Bandyopadhyay, S.; Samanta, I.; Lodh, C.; Bera, A.K.; Bhattacharyya, D.; et al. Potential Antibacterial Activity of Berberine against Multi Drug Resistant Enterovirulent Escherichia Coli Isolated from Yaks (Poephagus Grunniens) with Haemorrhagic Diarrhoea. Asian Pacific Journal of Tropical Medicine 2013, 6, 315–319. [Google Scholar] [CrossRef] [PubMed]

- Naz, I.; Masoud, M.S.; Chauhdary, Z.; Shah, M.A.; Panichayupakaranant, P. Anti-inflammatory Potential of Berberine-rich Extract via Modulation of Inflammation Biomarkers. Journal of Food Biochemistry 2022, 46. [Google Scholar] [CrossRef] [PubMed]

- Mujtaba, M.A.; Akhter, M.H.; Alam, Md.S.; Ali, M.D.; Hussain, A. An Updated Review on Therapeutic Potential and Recent Advances in Drug Delivery of Berberine: Current Status and Future Prospect. CPB 2022, 23, 60–71. [Google Scholar] [CrossRef] [PubMed]

- Domínguez-Delgado, C.L.; Rodríguez-Cruz, I.M.; Fuentes-Prado, E.; Escobar-Chávez, J.J.; Vidal-Romero, G.; García-González, L.; Puente-Lee, R.I. Drug Carrier Systems Using Chitosan for Non Parenteral Routes. In Pharmacology and Therapeutics; Gowder, S.J.T., Ed.; InTech, 2014 ISBN 978-953-51-1620-2.

- Garg, U.; Chauhan, S.; Nagaich, U.; Jain, N. Current Advances in Chitosan Nanoparticles Based Drug Delivery and Targeting. Adv Pharm Bull 2019, 9, 195–204. [Google Scholar] [CrossRef]

- Parhi, R. Drug Delivery Applications of Chitin and Chitosan: A Review. Environ Chem Lett 2020, 18, 577–594. [Google Scholar] [CrossRef]

- Utami, A.R.; Maksum, I.P.; Deawati, Y. Berberine and Its Study as an Antidiabetic Compound. Biology (Basel) 2023, 12, 973. [Google Scholar] [CrossRef]

- Awasthi, S.; Hasan, N.; Nadeem, M.; Rizvi, M.A.; Alam, K.; Kesharwani, P.; Ahmad, F.J. Optimized Formulation of Berberine Hydrochloride Loaded Nanoemulgel for Management of Skin Cancer. Colloids and Surfaces A: Physicochemical and Engineering Aspects 2024, 687, 133406. [Google Scholar] [CrossRef]

- Majidzadeh, H.; Araj-Khodaei, M.; Ghaffari, M.; Torbati, M.; Ezzati Nazhad Dolatabadi, J.; Hamblin, M.R. Nano-Based Delivery Systems for Berberine: A Modern Anti-Cancer Herbal Medicine. Colloids and Surfaces B: Biointerfaces 2020, 194, 111188. [Google Scholar] [CrossRef]

- Tan, J.; Luo, Y.; Guo, Y.; Zhou, Y.; Liao, X.; Li, D.; Lai, X.; Liu, Y. Development of Alginate-Based Hydrogels: Crosslinking Strategies and Biomedical Applications. International Journal of Biological Macromolecules 2023, 239, 124275. [Google Scholar] [CrossRef]

- Mirhadi, E.; Rezaee, M.; Malaekeh-Nikouei, B. Nano Strategies for Berberine Delivery, a Natural Alkaloid of Berberis. Biomedicine & Pharmacotherapy 2018, 104, 465–473. [Google Scholar] [CrossRef]

- Javed Iqbal, M.; Quispe, C.; Javed, Z.; Sadia, H.; Qadri, Q.R.; Raza, S.; Salehi, B.; Cruz-Martins, N.; Abdulwanis Mohamed, Z.; Sani Jaafaru, M.; et al. Nanotechnology-Based Strategies for Berberine Delivery System in Cancer Treatment: Pulling Strings to Keep Berberine in Power. Front. Mol. Biosci. 2021, 7, 624494. [Google Scholar] [CrossRef] [PubMed]

- Vigata, M.; Meinert, C.; Hutmacher, D.W.; Bock, N. Hydrogels as Drug Delivery Systems: A Review of Current Characterization and Evaluation Techniques. Pharmaceutics 2020, 12, 1188. [Google Scholar] [CrossRef]

- Farooq, T.; Sohail, M.; Shah, S.A.; Mahmood, A.; Mohammad Qalawlus, A.H.; Rehman Kashif, M.U.; Kousar, M. Colloidal Curcumin-Laden pH-Responsive Hydrogels: A Promising Approach to Enhance Solubility, Dissolution, and Permeation of Hydrophobic Drug. Journal of Drug Delivery Science and Technology 2023, 84, 104471. [Google Scholar] [CrossRef]

- Najm, A.; Niculescu, A.-G.; Bolocan, A.; Rădulescu, M.; Grumezescu, A.M.; Beuran, M.; Gaspar, B.S. Chitosan and Cyclodextrins-Versatile Materials Used to Create Drug Delivery Systems for Gastrointestinal Cancers. Pharmaceutics 2023, 16, 43. [Google Scholar] [CrossRef] [PubMed]

- Le-Deygen, I.M.; Skuredina, A.A.; Mamaeva, P.V.; Kolmogorov, I.M.; Kudryashova, E.V. Conjugates of Chitosan with β-Cyclodextrins as Promising Carriers for the Delivery of Levofloxacin: Spectral and Microbiological Studies. Life 2023, 13, 272. [Google Scholar] [CrossRef]

- Jafernik, K.; Ładniak, A.; Blicharska, E.; Czarnek, K.; Ekiert, H.; Wiącek, A.E.; Szopa, A. Chitosan-Based Nanoparticles as Effective Drug Delivery Systems—A Review. Molecules 2023, 28, 1963. [Google Scholar] [CrossRef]

- Xu, P.-W.; Yuan, X.-F.; Li, H.; Zhu, Y.; Zhao, B. Preparation, Characterization, and Physicochemical Property of the Inclusion Complexes of Cannabisin A with β-Cyclodextrin and Hydroxypropyl-β-Cyclodextrin. Journal of Molecular Structure 2023, 1272, 134168. [Google Scholar] [CrossRef]

- Sahu, K.M.; Patra, S.; Swain, S.K. Host-Guest Drug Delivery by β-Cyclodextrin Assisted Polysaccharide Vehicles: A Review. International Journal of Biological Macromolecules 2023, 240, 124338. [Google Scholar] [CrossRef]

- Huang, L.; Chen, X.; Nguyen, T.X.; Tang, H.; Zhang, L.; Yang, G. Nano-Cellulose 3D-Networks as Controlled-Release Drug Carriers. J. Mater. Chem. B 2013, 1, 2976. [Google Scholar] [CrossRef] [PubMed]

- Sarabia-Vallejo, Á.; Caja, M.D.M.; Olives, A.I.; Martín, M.A.; Menéndez, J.C. Cyclodextrin Inclusion Complexes for Improved Drug Bioavailability and Activity: Synthetic and Analytical Aspects. Pharmaceutics 2023, 15, 2345. [Google Scholar] [CrossRef] [PubMed]

- Gao, S.; Zong, L.; Zhang, Y.; Zhang, Y.; Guo, X.; Guo, G.; Zhao, L.; Ye, F.; Fu, Y. Antifungal Pentachloronitrobenzene/Hydroxypropyl-Beta-Cyclodextrin Inclusion Complex Nanofibers by Electrospun with No Polymer: Fabrication and Characterization. Journal of Cleaner Production 2023, 413, 137499. [Google Scholar] [CrossRef]

- Pardeshi, C.V.; Kothawade, R.V.; Markad, A.R.; Pardeshi, S.R.; Kulkarni, A.D.; Chaudhari, P.J.; Longhi, M.R.; Dhas, N.; Naik, J.B.; Surana, S.J.; et al. Sulfobutylether-β-Cyclodextrin: A Functional Biopolymer for Drug Delivery Applications. Carbohydrate Polymers 2023, 301, 120347. [Google Scholar] [CrossRef]

- Lee, S.J.; Nah, H.; Ko, W.-K.; Lee, D.; Moon, H.-J.; Lee, J.S.; Heo, M.; Hwang, Y.-S.; Bang, J.B.; An, S.-H.; et al. Facile Preparation of β-Cyclodextrin-Grafted Chitosan Electrospun Nanofibrous Scaffolds as a Hydrophobic Drug Delivery Vehicle for Tissue Engineering Applications. ACS Omega 2021, 6, 28307–28315. [Google Scholar] [CrossRef]

- Wang, D.; Jia, M.; Wang, L.; Song, S.; Feng, J.; Zhang, X. Chitosan and β-Cyclodextrin-Epichlorohydrin Polymer Composite Film as a Plant Healthcare Material for Carbendazim-Controlled Release to Protect Rape against Sclerotinia Sclerotiorum (Lib.) de Bary. Materials 2017, 10, 343. [Google Scholar] [CrossRef]

- Kwon, M.; Lim, D.Y.; Lee, C.H.; Jeon, J.-H.; Choi, M.-K.; Song, I.-S. Enhanced Intestinal Absorption and Pharmacokinetic Modulation of Berberine and Its Metabolites through the Inhibition of P-Glycoprotein and Intestinal Metabolism in Rats Using a Berberine Mixed Micelle Formulation. Pharmaceutics 2020, 12, 882. [Google Scholar] [CrossRef]

- Tsai, C.-J.; Hsu, L.-R.; Fang, J.-Y.; Lin, H.-H. Chitosan Hydrogel as a Base for Transdermal Delivery of Berberine and Its Evaluation in Rat Skin. Biological & Pharmaceutical Bulletin 1999, 22, 397–401. [Google Scholar] [CrossRef]

- Zhou, H.Y.; Tong, J.N.; Ren, L.J.; Hao, P.Y.; Zheng, H.J.; Guo, X.M.; Chen, Y.W.; Li, J.B.; Park, H.J. Preparation and Performance of Chitosan/Cyclodextrin-g-Glutamic Acid Thermosensitive Hydrogel. Journal of Drug Delivery Science and Technology 2022, 74, 103504. [Google Scholar] [CrossRef]

- Xiao, L.; Poudel, A.J.; Huang, L.; Wang, Y.; Abdalla, A.M.E.; Yang, G. Nanocellulose Hyperfine Network Achieves Sustained Release of Berberine Hydrochloride Solubilized with β-Cyclodextrin for Potential Anti-Infection Oral Administration. International Journal of Biological Macromolecules 2020, 153, 633–640. [Google Scholar] [CrossRef]

- Malik, N.S.; Ahmad, M.; Alqahtani, M.S.; Mahmood, A.; Barkat, K.; Khan, M.T.; Tulain, U.R.; Rashid, A. β-Cyclodextrin Chitosan-Based Hydrogels with Tunable pH-Responsive Properties for Controlled Release of Acyclovir: Design, Characterization, Safety, and Pharmacokinetic Evaluation. Drug Delivery 2021, 28, 1093–1108. [Google Scholar] [CrossRef]

- Johari, N.; Moroni, L.; Samadikuchaksaraei, A. Tuning the Conformation and Mechanical Properties of Silk Fibroin Hydrogels. European Polymer Journal 2020, 134, 109842. [Google Scholar] [CrossRef]

- Tenório, F.S.; Do Amaral Montanheiro, T.L.; Dos Santos, A.M.I.; Dos Santos Silva, M.; Lemes, A.P.; Tada, D.B. Chitosan Hydrogel Covalently Crosslinked by Gold Nanoparticle: Eliminating the Use of Toxic Crosslinkers. J of Applied Polymer Sci 2021, 138, 49819. [Google Scholar] [CrossRef]

- Lin, Y.-C.; Lin, Z.-R.; Tsai, L.-W.; Perevedentseva, E.; Karmenyan, A.; Cheng, C.-L. Spectral Analysis of Nanodiamond-Berberine Complex Interaction with Living Cells for Nanoparticle Mediated Drug Delivery. JBPE 2017, 3, 010305. [Google Scholar] [CrossRef]

- Zhang, X.N.; Wang, Y.J.; Sun, S.; Hou, L.; Wu, P.; Wu, Z.L.; Zheng, Q. A Tough and Stiff Hydrogel with Tunable Water Content and Mechanical Properties Based on the Synergistic Effect of Hydrogen Bonding and Hydrophobic Interaction. Macromolecules 2018, 51, 8136–8146. [Google Scholar] [CrossRef]

- Tripathi, A.N.; Chauhan, L.; Thankachan, P.P.; Barthwal, R. Quantum Chemical and Nuclear Magnetic Resonance Spectral Studies on Molecular Properties and Electronic Structure of Berberine and Berberrubine. Magnetic Reson in Chemistry 2007, 45, 647–655. [Google Scholar] [CrossRef]

- Department of chemistry, North East Frontier Technical University, Arunachal Pradesh, India; Manikyam, H.K.; Ramesh, C.; School of pharmaceutical Management, IIHMR University, Jaipur, Rajasthan India; Poluri, K.M.; Department of Biotechnology, Indian Institute of Technology Roorkee, Roorkee, India; Assad, A.; Department of Mathematics, Indian Institute of Technology Roorkee, Roorkee, India Microwave Assisted Subcritical Water Extraction of Berberine Hydrochloride from the Roots of Berberis Aristata Using Harmony Search Algorithm. JHMR 2017, 1–9. [CrossRef]

- Galante, R.; Rediguieri, C.F.; Kikuchi, I.S.; Vasquez, P.A.S.; Colaço, R.; Serro, A.P.; Pinto, T.J.A. About the Sterilization of Chitosan Hydrogel Nanoparticles. PLoS ONE 2016, 11, e0168862. [Google Scholar] [CrossRef]

- Zhou, H.Y.; Hao, P.Y.; Jiang, S.Q.; Zhang, W.H.; Ren, L.J.; Zheng, H.J.; Chen, Y.W.; Chen, J.L.; Park, H.J. Preparation and Antibacterial Activity of Chitosan Grafted Cyclodextrin Hydrogel Loaded Berberine Hydrochloride Using Dual Gelling Agent. Journal of Molecular Structure 2024, 1295, 136709. [Google Scholar] [CrossRef]

- Koide, T.; Iwata, M.; Maekawa, K.; Saito, H.; Tanimoto, T.; Okada, S. [Berberine Hydrochloride Reference Standard (Control 001) of National Institute of Health Sciences]. Kokuritsu Iyakuhin Shokuhin Eisei Kenkyusho Hokoku 2001, 97–100. [Google Scholar]

- Nagase, Y.; Hirata, M.; Wada, K.; Arima, H.; Hirayama, F.; Irie, T.; Kikuchi, M.; Uekama, K. Improvement of Some Pharmaceutical Properties of DY-9760e by Sulfobutyl Ether β-Cyclodextrin. International Journal of Pharmaceutics 2001, 229, 163–172. [Google Scholar] [CrossRef] [PubMed]

- Anirudhan, T.S.; Divya, P.L.; Nima, J. Synthesis and Characterization of Novel Drug Delivery System Using Modified Chitosan Based Hydrogel Grafted with Cyclodextrin. Chemical Engineering Journal 2016, 284, 1259–1269. [Google Scholar] [CrossRef]

- Yang, Y.; Liu, Y.; Chen, S.; Cheong, K.-L.; Teng, B. Carboxymethyl β-Cyclodextrin Grafted Carboxymethyl Chitosan Hydrogel-Based Microparticles for Oral Insulin Delivery. Carbohydrate Polymers 2020, 246, 116617. [Google Scholar] [CrossRef] [PubMed]

- Sahibzada, M.U.K.; Sadiq, A.; Faidah, H.S.; Khurram, M.; Amin, M.U.; Haseeb, A.; Kakar, M. Berberine Nanoparticles with Enhanced in Vitro Bioavailability: Characterization and Antimicrobial Activity [Retraction]. DDDT 2024, Volume 18, 257–258. [Google Scholar] [CrossRef]

- Mishra, A.K.; Sharma, A.K. Synthesis of γ-Cyclodextrin/Chitosan Composites for the Efficient Removal of Cd(II) from Aqueous Solution. International Journal of Biological Macromolecules 2011, 49, 504–512. [Google Scholar] [CrossRef] [PubMed]

- Mishra, A.K.; Allauddin, S.; Radhika, K.R.; Narayan, R.; Raju, K.V.S.N. Effect of NCO/OH Ratio and Ce-Zr Nanoparticles on the Thermo-mechanical Properties of Hyperbranched Polyurethane Urea Coatings. Polymers for Advanced Techs 2011, 22, 882–890. [Google Scholar] [CrossRef]

- Trotta, F.; Zanetti, M.; Camino, G. Thermal Degradation of Cyclodextrins. Polymer Degradation and Stability 2000, 69, 373–379. [Google Scholar] [CrossRef]

- Gao, J.; Fan, D.; Song, P.; Zhang, S.; Liu, X. Preparation and Application of pH-Responsive Composite Hydrogel Beads as Potential Delivery Carrier Candidates for Controlled Release of Berberine Hydrochloride. R. Soc. open sci. 2020, 7, 200676. [Google Scholar] [CrossRef]

- Sgarminato, V.; Tonda-Turo, C.; Ciardelli, G. Reviewing Recently Developed Technologies to Direct Cell Activity through the Control of Pore Size: From the Macro- to the Nanoscale. J Biomed Mater Res B Appl Biomater 2020, 108, 1176–1185. [Google Scholar] [CrossRef]

- Murphy, C.M.; Haugh, M.G.; O’Brien, F.J. The Effect of Mean Pore Size on Cell Attachment, Proliferation and Migration in Collagen-Glycosaminoglycan Scaffolds for Bone Tissue Engineering. Biomaterials 2010, 31, 461–466. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.; Zhou, Y.; Yu, Y.; Zhou, X.; Du, W.; Wan, M.; Fan, Y.; Zhou, X.; Xu, X.; Zheng, L. Evaluation of Chitosan Hydrogel for Sustained Delivery of VEGF for Odontogenic Differentiation of Dental Pulp Stem Cells. Stem Cells International 2019, 2019, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Assaad, E.; Maire, M.; Lerouge, S. Injectable Thermosensitive Chitosan Hydrogels with Controlled Gelation Kinetics and Enhanced Mechanical Resistance. Carbohydrate Polymers 2015, 130, 87–96. [Google Scholar] [CrossRef] [PubMed]

- Tong, J.; Hou, X.; Cui, D.; Chen, W.; Yao, H.; Xiong, B.; Cai, L.; Zhang, H.; Jiang, L. A Berberine Hydrochloride-Carboxymethyl Chitosan Hydrogel Protects against Staphylococcus Aureus Infection in a Rat Mastitis Model. Carbohydr Polym 2022, 278, 118910. [Google Scholar] [CrossRef] [PubMed]

- Siegel, R.A.; Rathbone, M.J. Overview of Controlled Release Mechanisms. In Fundamentals and Applications of Controlled Release Drug Delivery; Siepmann, J., Siegel, R.A., Rathbone, M.J., Eds.; Springer US: Boston, MA, 2012; pp. 19–43. ISBN 978-1-4614-0880-2. [Google Scholar]

- Controlled Release in Oral Drug Delivery; Wilson, C.G., Crowley, P.J., Eds.; Springer US: Boston, MA, 2011; ISBN 978-1-4614-1003-4. [Google Scholar]

- Arun Rasheed Cyclodextrins as Drug Carrier Molecule: A Review. Sci. Pharm. 2008, 76, 567–598. [CrossRef]

- Chen, T.; Jiang, Y.; Wang, C.; Cai, Z.; Chen, H.; Zhu, J.; Tao, P.; Wu, M. The pH-Triggered Drug Release and Simultaneous Carrier Decomposition of Effervescent SiO 2 –Drug–Na 2 CO 3 Composite Nanoparticles: To Improve the Antitumor Activity of Hydrophobic Drugs. RSC Adv. 2021, 11, 5335–5347. [Google Scholar] [CrossRef]

- Hu, C.; He, S.; Lee, Y.J.; He, Y.; Kong, E.M.; Li, H.; Anastasio, M.A.; Popescu, G. Live-Dead Assay on Unlabeled Cells Using Phase Imaging with Computational Specificity. Nat Commun 2022, 13, 713. [Google Scholar] [CrossRef]

- Huang, L.; Chen, X.; Nguyen, T.X.; Tang, H.; Zhang, L.; Yang, G. Nano-Cellulose 3D-Networks as Controlled-Release Drug Carriers. J. Mater. Chem. B 2013, 1, 2976. [Google Scholar] [CrossRef]

| Hydrogel weight (mg) | Loaded weight (mg) | Drug weight (mg) | LC (%) | EE (%) |

|---|---|---|---|---|

| 18.6±2.57±1.656 | 260.9±4.17 | 242.3±1.656 | 92.3±0.86 | 85.7±5.15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).